Patents

Literature

35results about How to "Burning violently" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

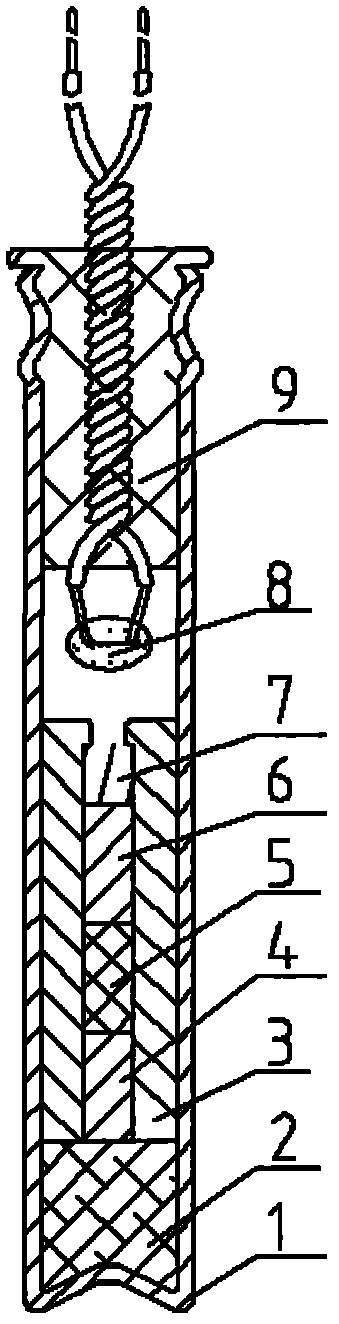

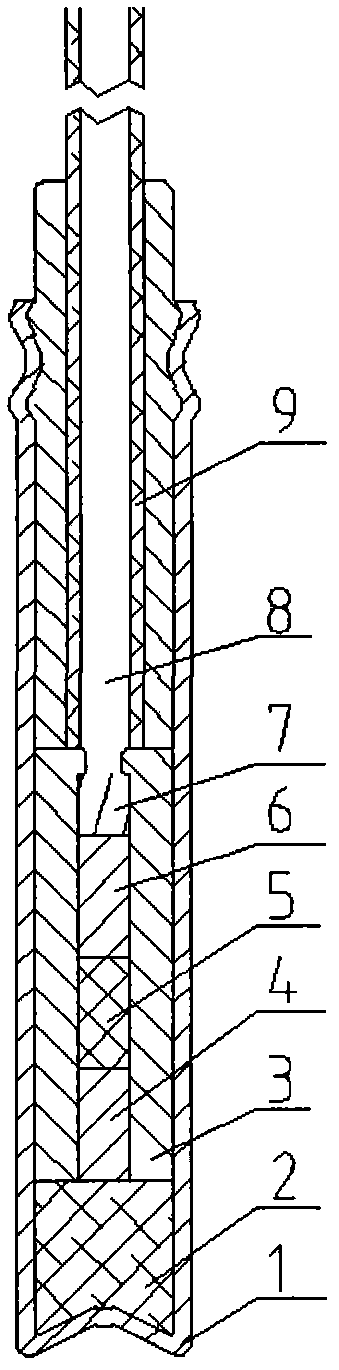

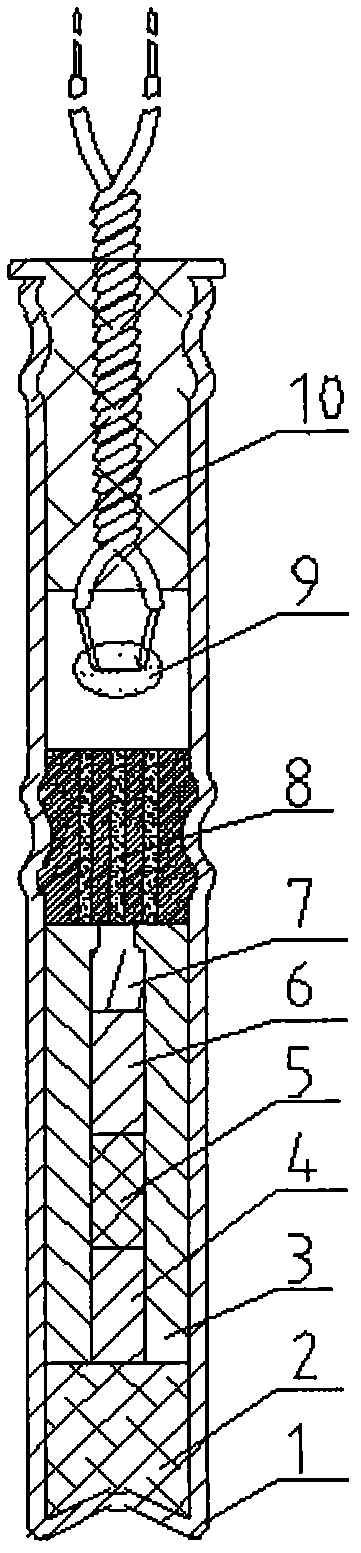

A non-priming charge detonator

The invention relates to the structure, charge and production process of a non-priming charge detonator. The invented non-priming charge detonator includes two types of instant detonators, electric igniter tip and non-electric plastic nonel, and a millisecond delay detonator with a lead core delay body. It stimulates the combustion of gunpowder in the steel pipe to generate high-pressure gas, which acts on the high explosive to make it burn in the steel pipe and develop into a high-speed detonation at the bottom of the steel pipe, thereby making a non-priming detonator. The design is optimized for reliable operation and simple fabrication.

Owner:ANHUI UNIV OF SCI & TECH

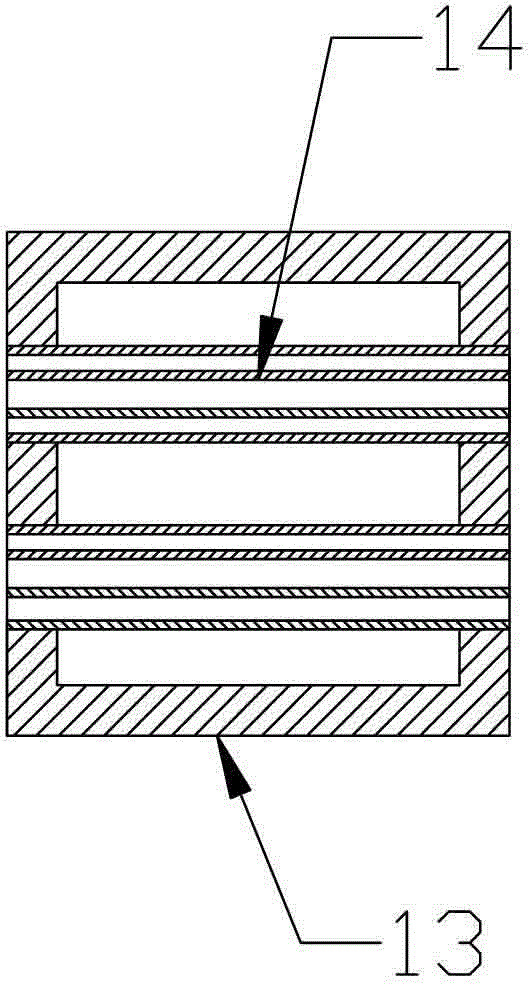

Lithium ion battery and its preparing method

ActiveCN1988241AImprove high temperature stabilityImprove securityFinal product manufactureCell component detailsLithium-ion batteryCeramic membrane

This invention relates to Li ioninc cells including a pole set and non-solution electrolyte sealed in a shell, and the pole includes a positive, a negative pole and ceramic membranes, which is stable under high temperature and safe.

Owner:江苏永茂普隆汽车配件制造有限公司

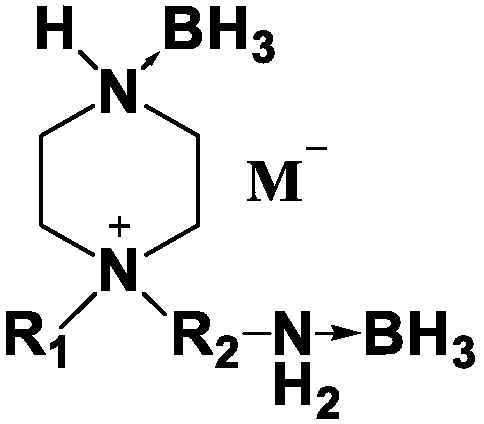

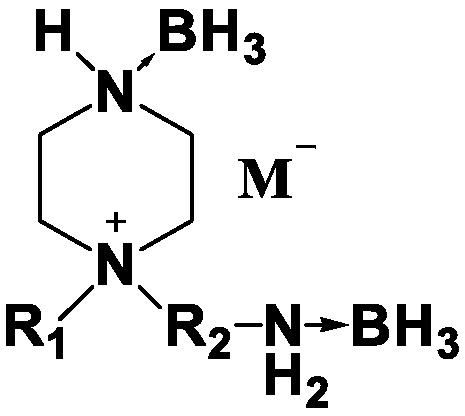

Piperazine cation-base ionic liquid containing ammonia and boron groups and preparation method thereof

ActiveCN108774181ARaise the intensityImprove burn durationGroup 3/13 element organic compoundsPiperazineCombustion

Te invention discloses piperazine cation-base ionic liquid containing ammonia and boron groups and a preparation method thereof. The preparation method comprises the steps of introducing the ammonia and boron groups into piperazine cation-base ionic liquid, and generating replacement reaction by virtue of a piperazine onium-salt borane complex and sodium salt or silver salt of anions, so as to obtain the piperazine cation-base ionic liquid containing the ammonia and boron groups. The product has very high combustion gas discharging amount and has potential application values in the field of natural liquid propellants; and the preparation method is simple, mild and easy to implement.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

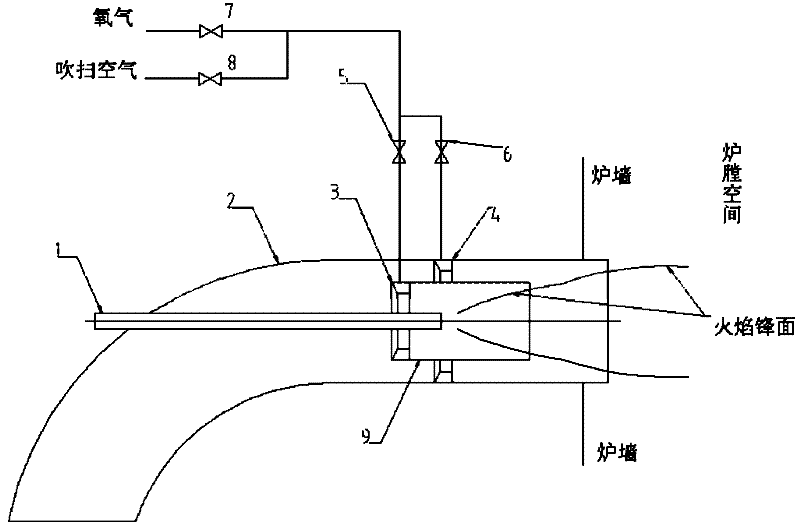

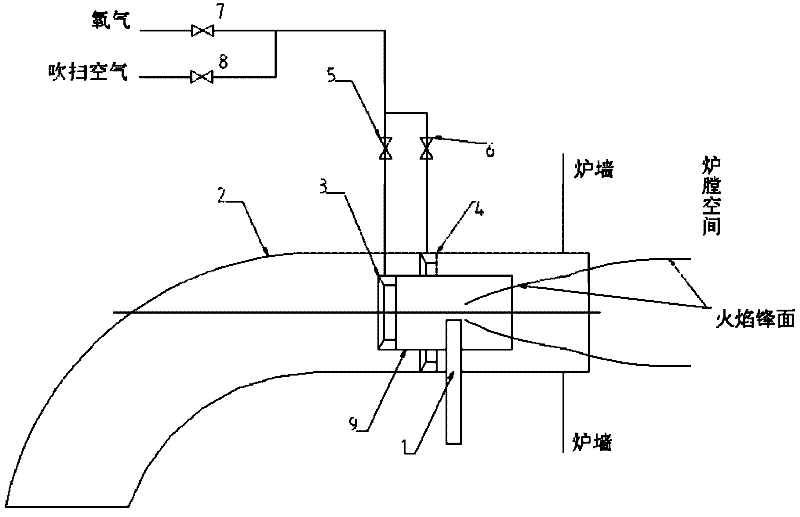

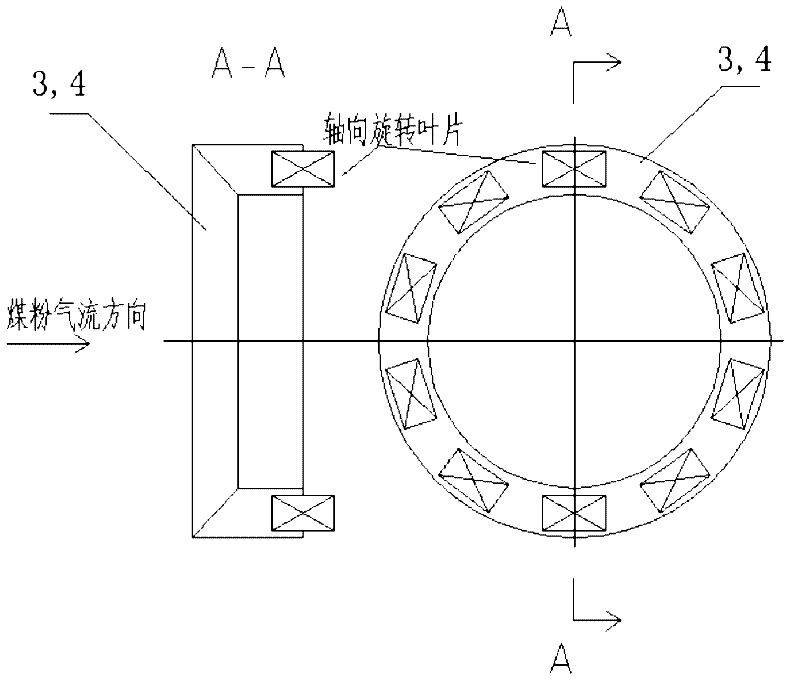

Micro-oil ignition burner

ActiveCN102444890AAdapt to wideImprove burnout ratePulverulent fuel combustion burnersIndirect carbon-dioxide mitigationCombustorEngineering

The invention discloses a micro-oil ignition burner, comprising a small micro-oil-gasification oil gun and a burner, wherein the burner internally comprises at least one coaxial or non-coaxial sleeve, two oxygen guiding pipes are installed in the burner, one oxygen guiding pipe is installed on the inner wall of the sleeve facing the direction of air flow of pulverized coal, the other oxygen guiding pipe is installed on the inner wall of the burner, oxygen can enter the burner and the annular space of the sleeve through the oxygen guiding pipes, and oxygen-rich zones are formed in the burner and the flowing space of the air flow of the pulverized coal in the boiler so as to enhance the burning of the air flow of the pulverized coal.

Owner:SHANGHAI BOILER WORKS

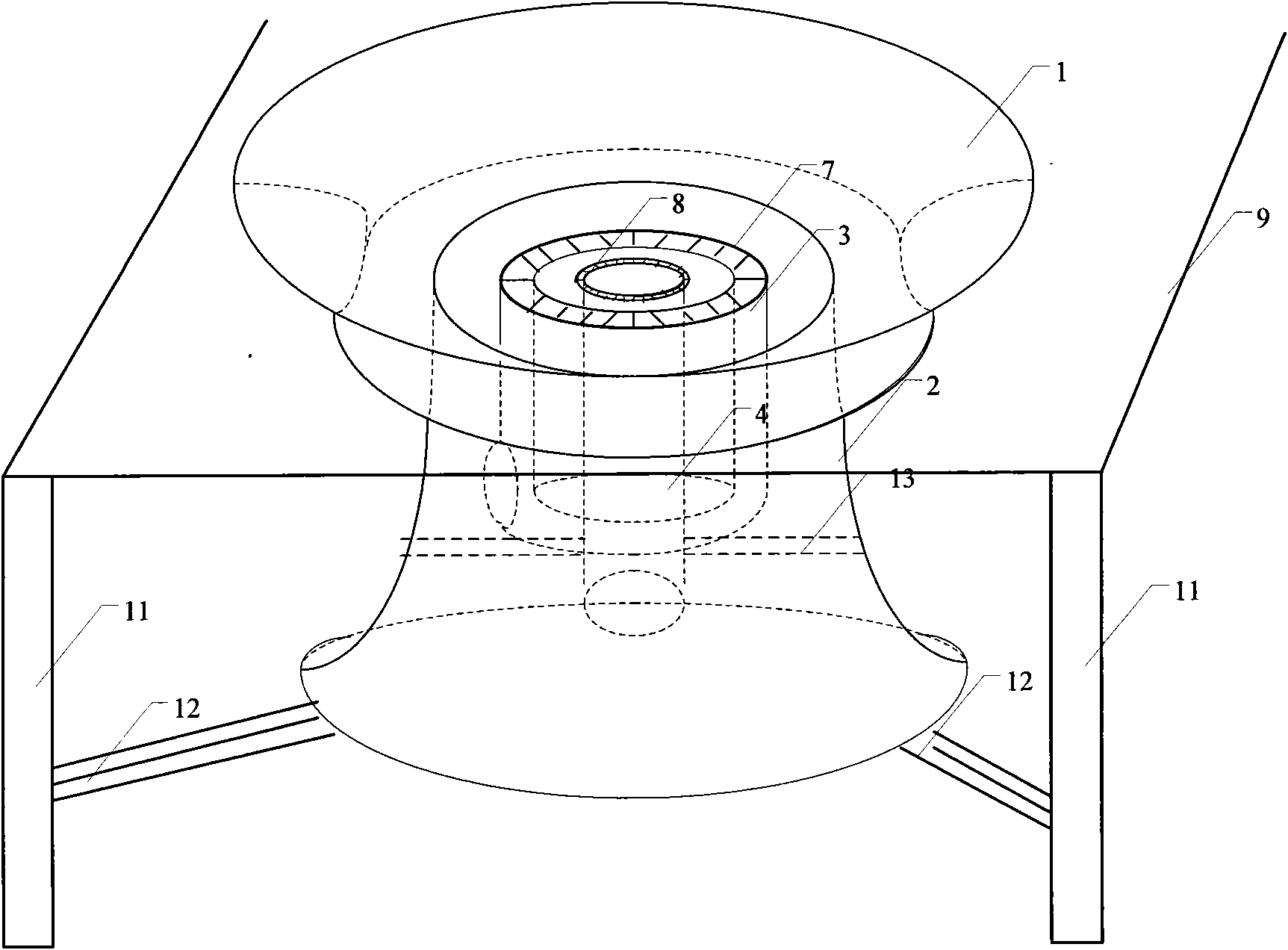

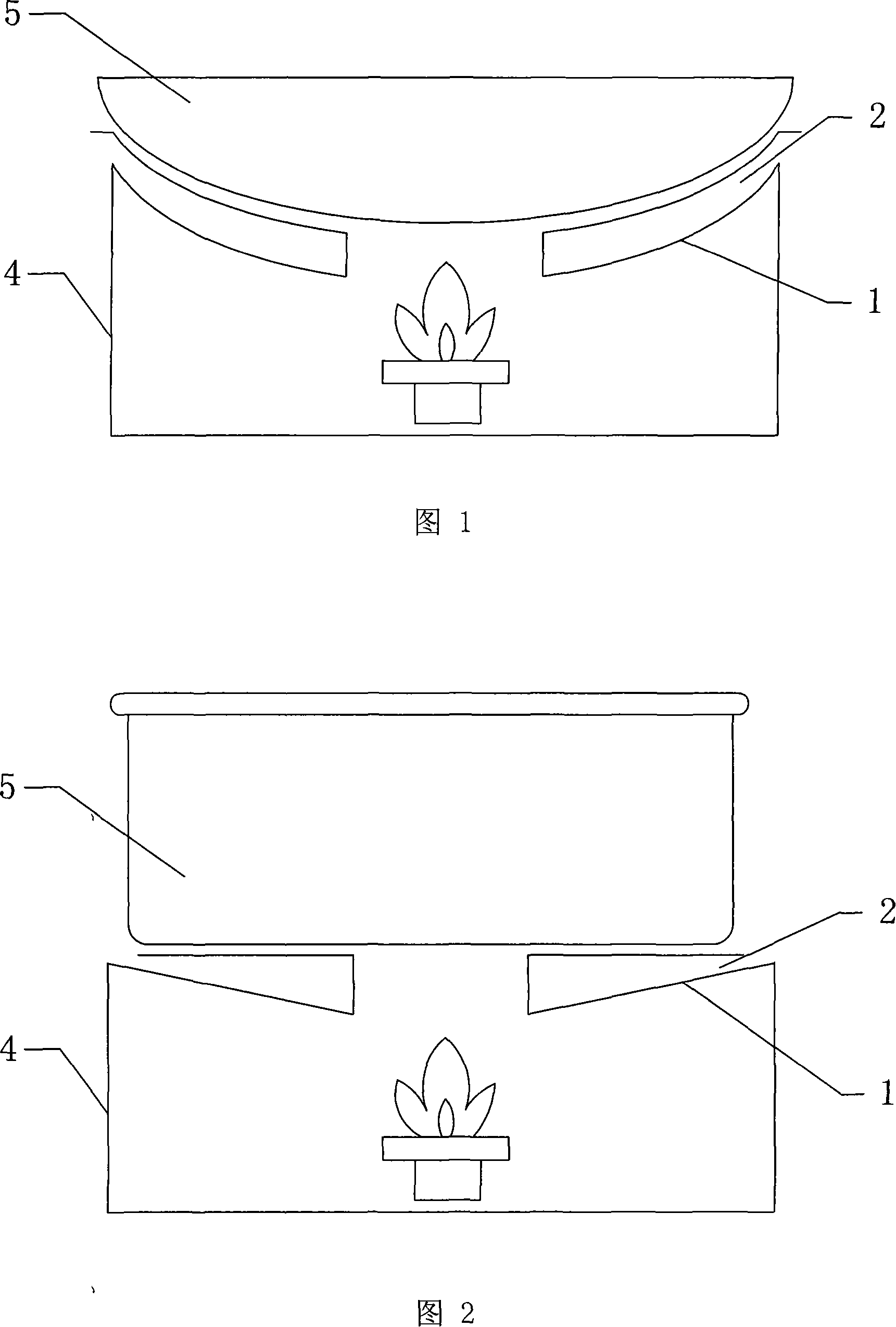

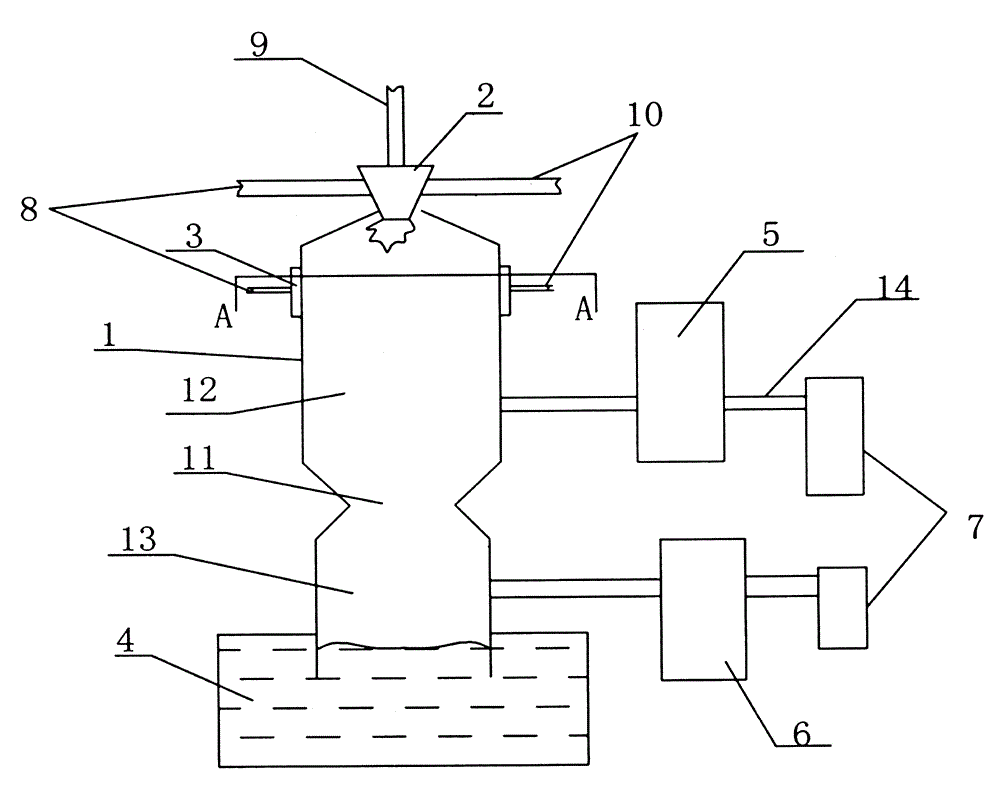

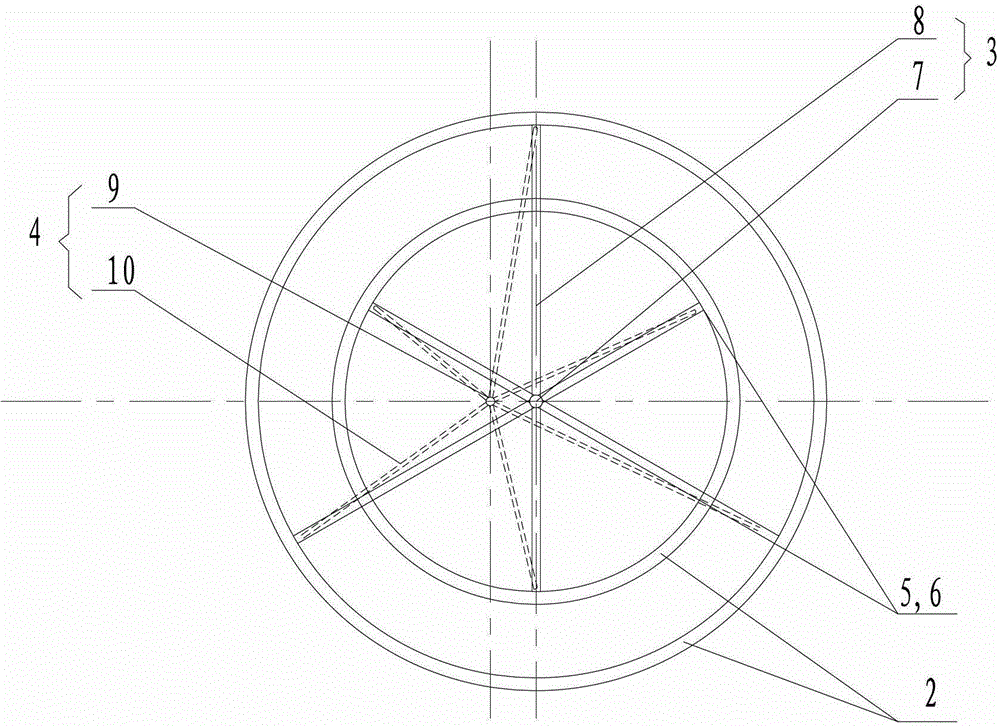

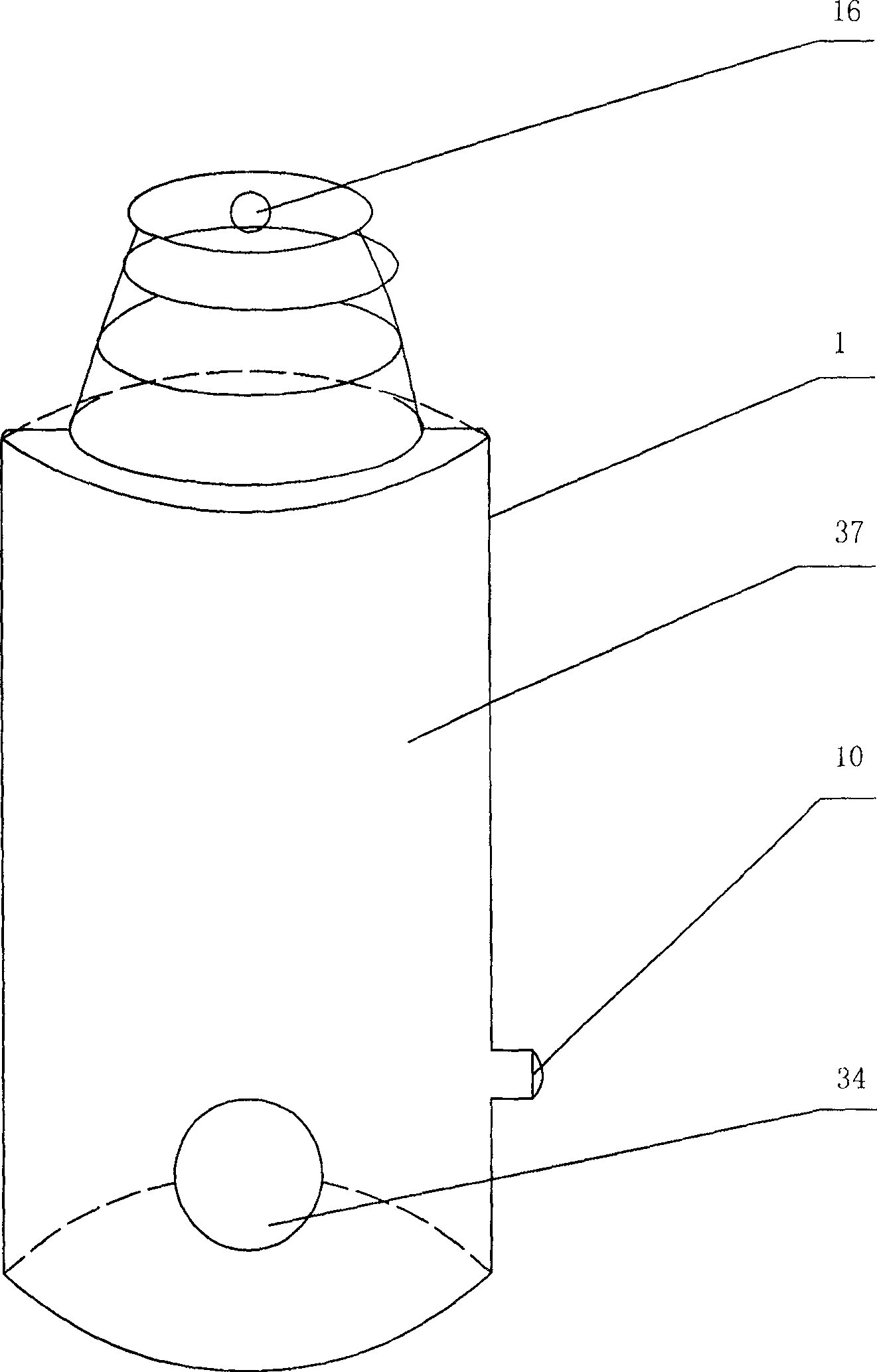

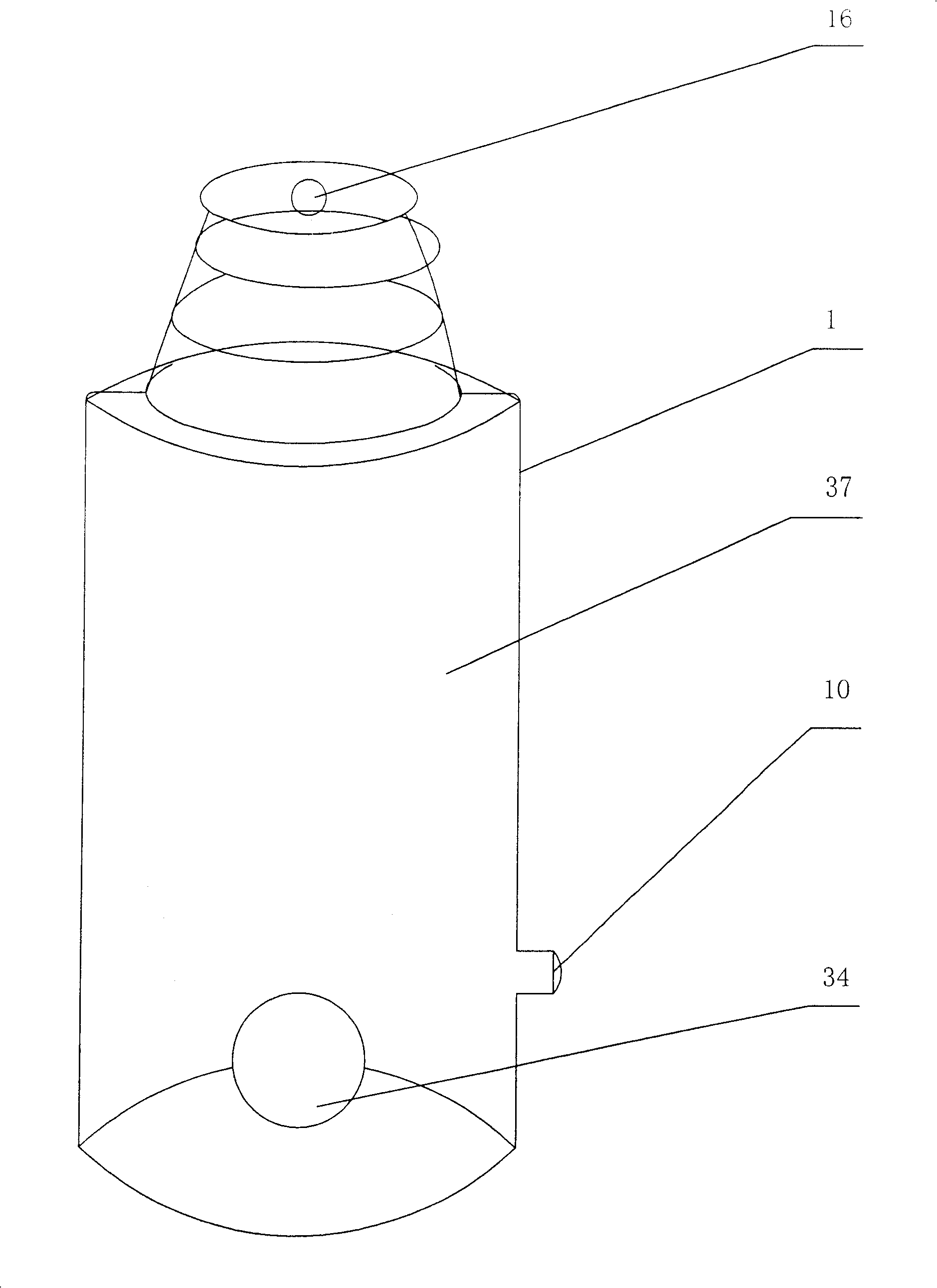

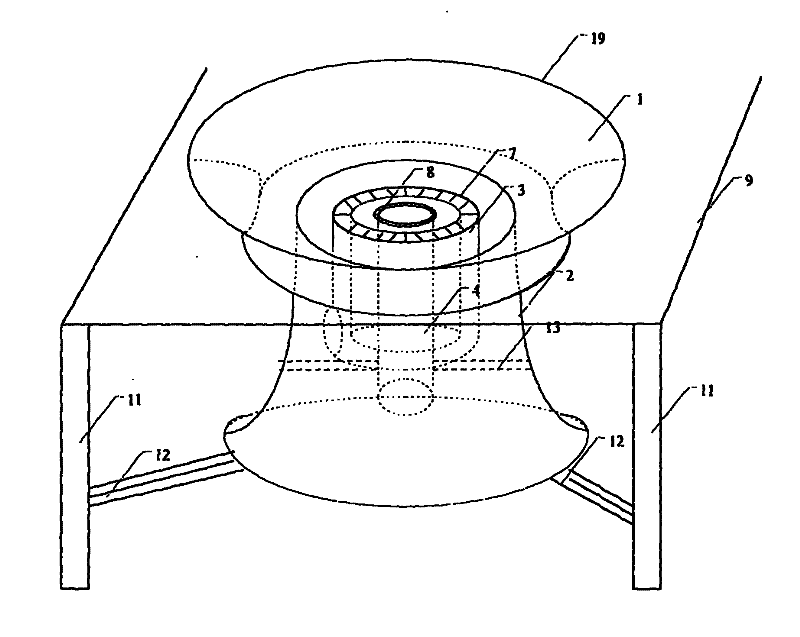

Ventilation tower-type lower air-inlet gas cooker

InactiveCN101556058ALarge heat transfer temperature differenceReduce lossesDomestic stoves or rangesStoves/ranges topsCookerProduct gas

The invention provides a ventilation tower-type lower air-inlet gas cooker belonging to the field of gas cooker. The technical proposal different from the prior art comprises a hyperbolic guide flow cylinder (1); the lower end port of the hyperbolic guide flow cylinder is provided with a hearth (2) with a ventilation tower-type structure; and the hearth is internally provided with a burner. When the gas combusts in the hearth, the temperature of the fire in the hearth is much higher than the temperature of the air outside the hearth; a chimney effect is generated under the effect of hot pressure; the secondary air is sucked in from the lower end port of the hearth, is then combusted and exhausted out from the upper end port of the hearth; the hearth has a function of gathering fire and drawing fire; an external mixing chamber (3) and an internal mixing chamber (4) of the burner are structures of small cross-section and long cylinder body, and generate small resistance to the secondary air flowing from bottom to top; simultaneously, the mixed gas is heated for a long time by the hot mixing chamber cylinder and the temperature thereof is increased quickly so that the combustion is more sufficient and fierce. The gas cooker can reinforce the combustion and improve the heat gathering effect without increasing the external power.

Owner:陈洪巨

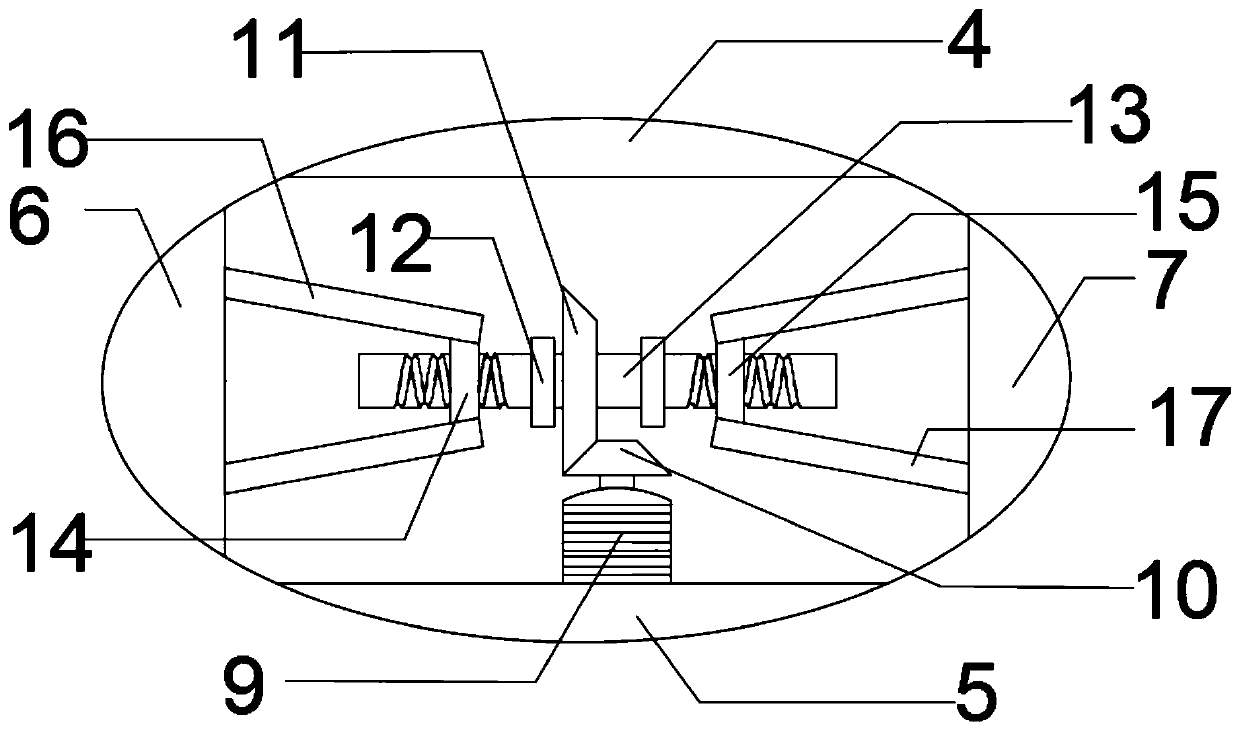

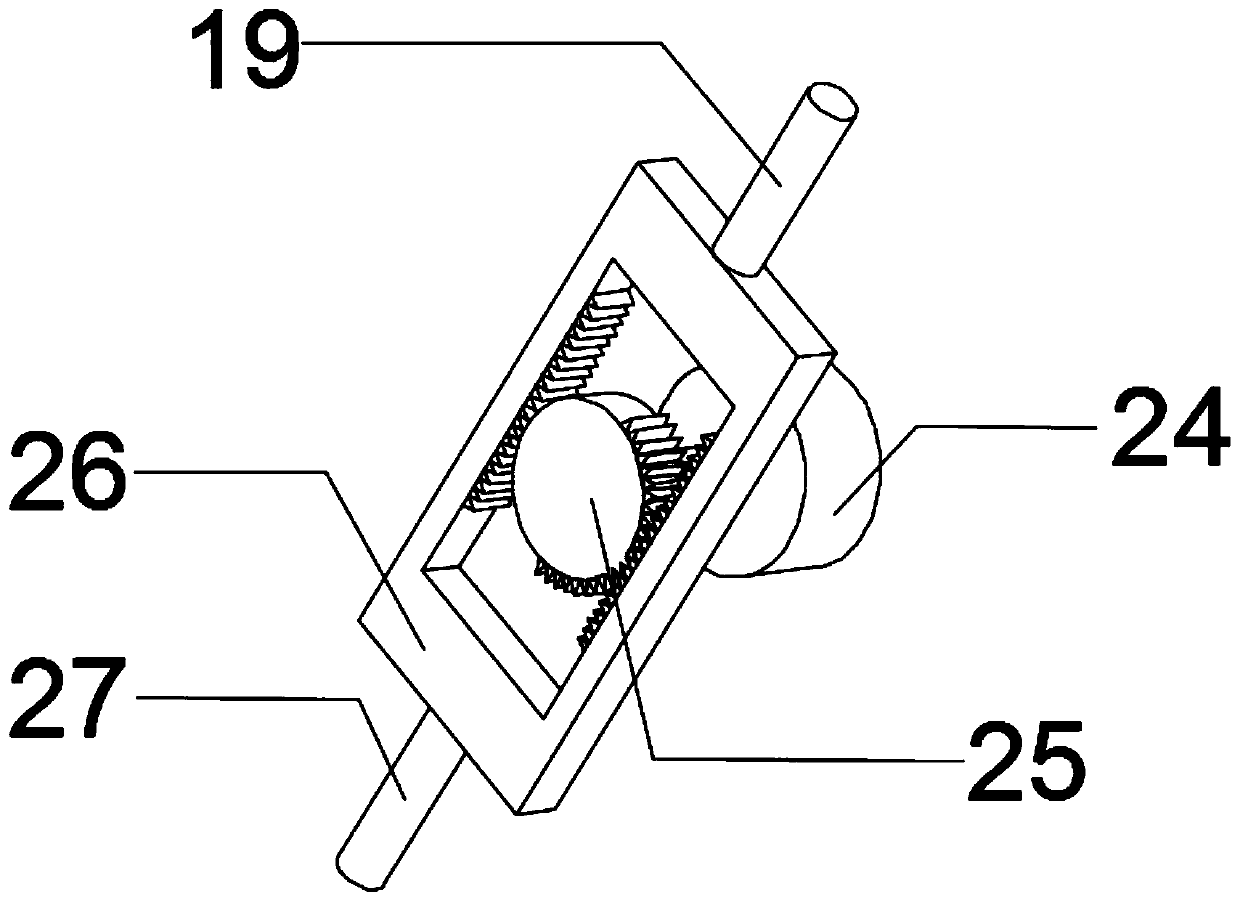

Coal briquette grinding device for boiler combustion

InactiveCN111036380ASatisfy combustion needsBurning violentlyGrain treatmentsCoal briquetteThermodynamics

The invention discloses a coal briquette grinding device for boiler combustion. The device comprises a device shell, a feeding port, a discharging port and a crushing mechanism, wherein the feeding port and the discharging port are formed at an upper end and a lower end of the device shell correspondingly, the crushing mechanism is arranged in the device shell, and the crushing mechanism comprisesan upper fixing plate, a lower fixing plate, a left crushing sliding block, a right crushing sliding block and a crushing driving mechanism. The device has the advantages that through the crushing mechanism, coal briquettes can be further crushed, and thereby the combustion requirement is met; by arranging a powder grinding mechanism, the coal briquettes can be thoroughly crushed and ground intopowder, and thereby combustion of the coal briquettes is more violent.

Owner:高红

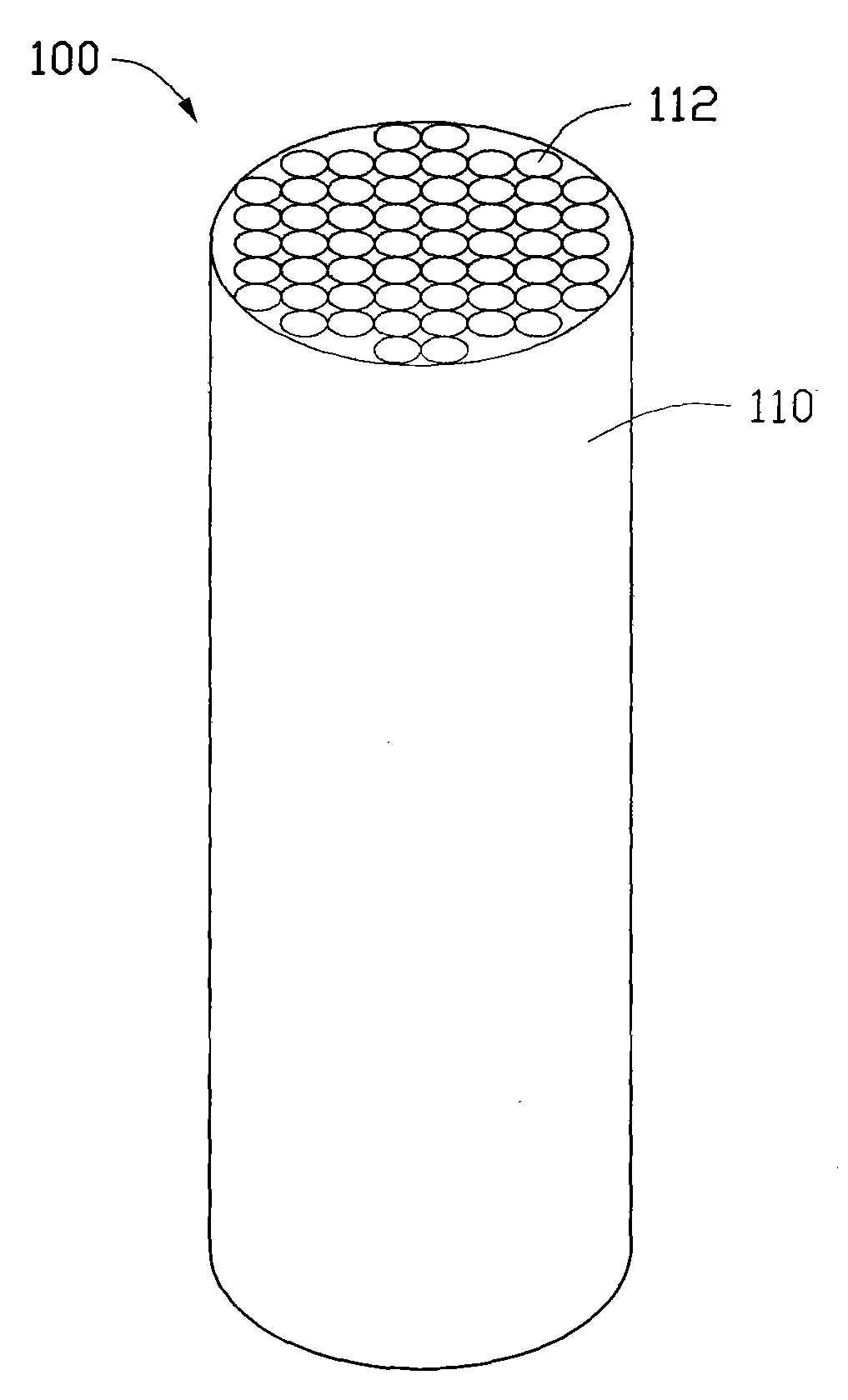

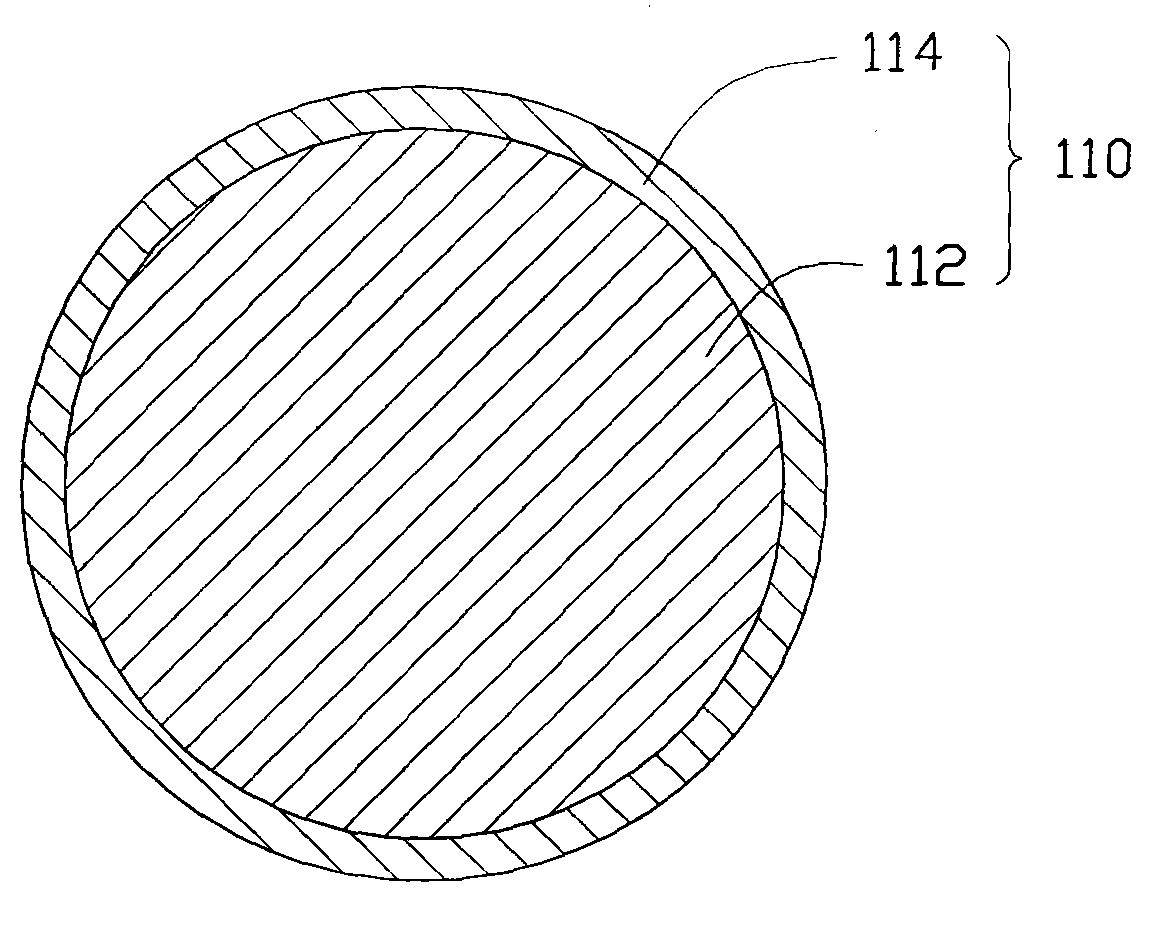

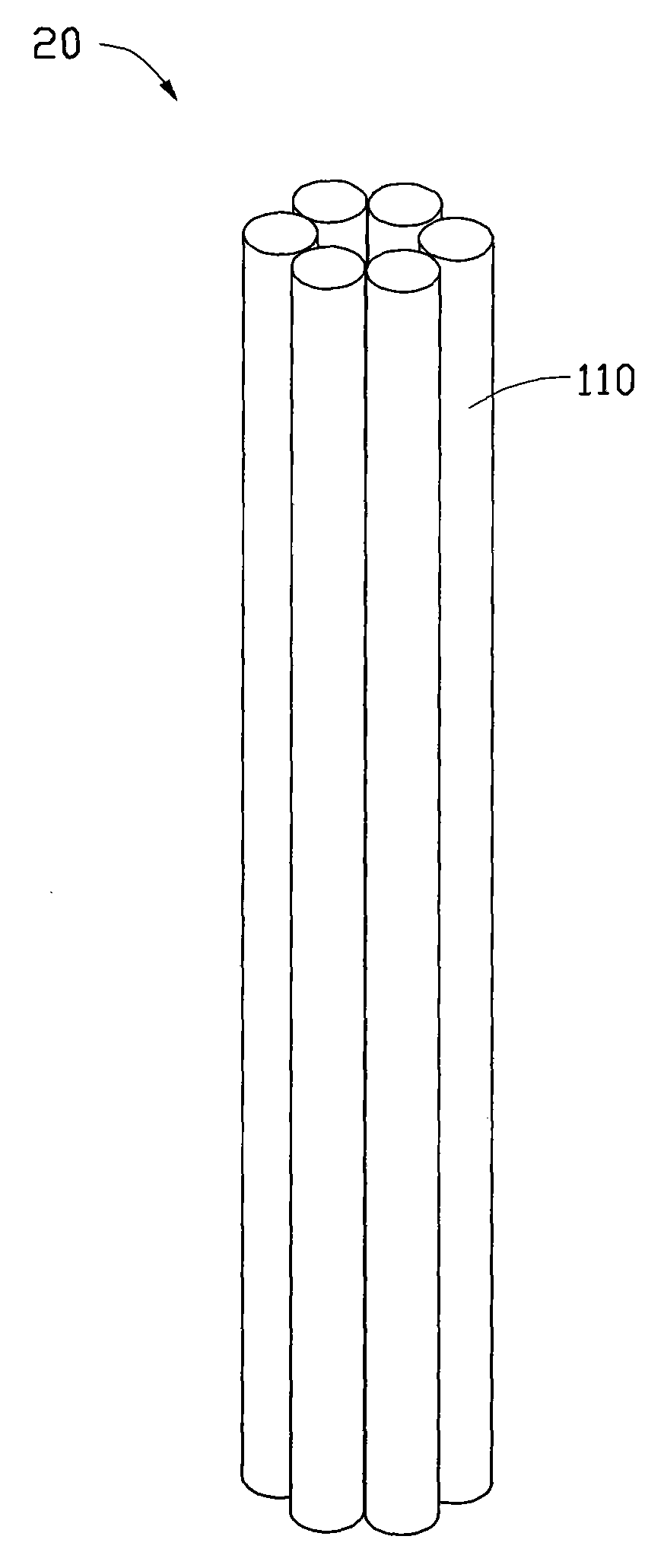

Lithium ion battery and its preparing method

ActiveCN100505407CImprove high temperature stabilityImprove securityFinal product manufactureCell component detailsEngineeringLithium-ion battery

A lithium ion battery, the battery includes an electrode group and a non-aqueous electrolyte, the electrode group and the non-aqueous electrolyte are sealed in a battery case, the electrode group includes a positive electrode, a negative electrode and a diaphragm, wherein the diaphragm is a ceramic diaphragm. The lithium ion battery provided by the invention has good high temperature stability and safety performance.

Owner:江苏永茂普隆汽车配件制造有限公司

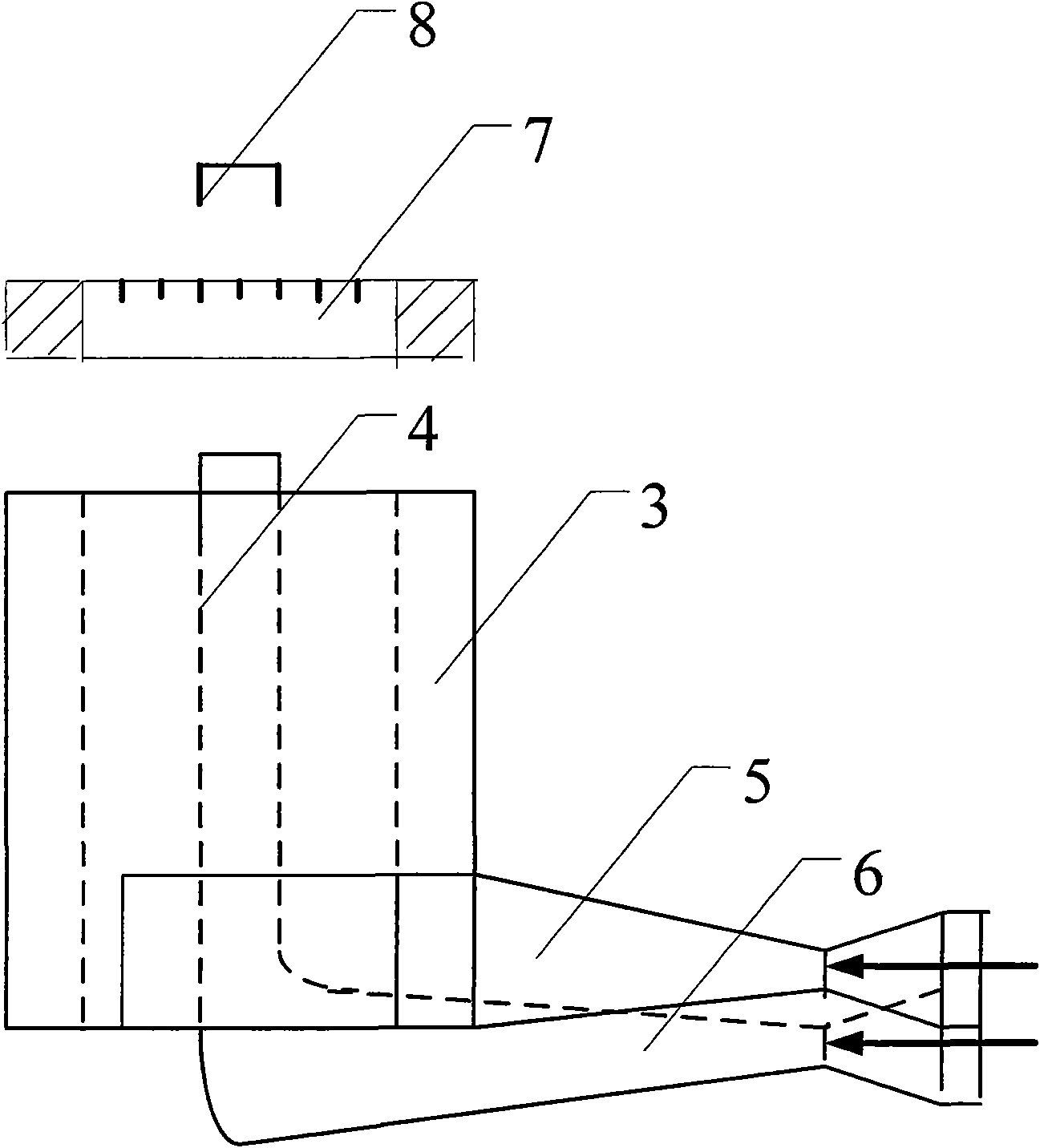

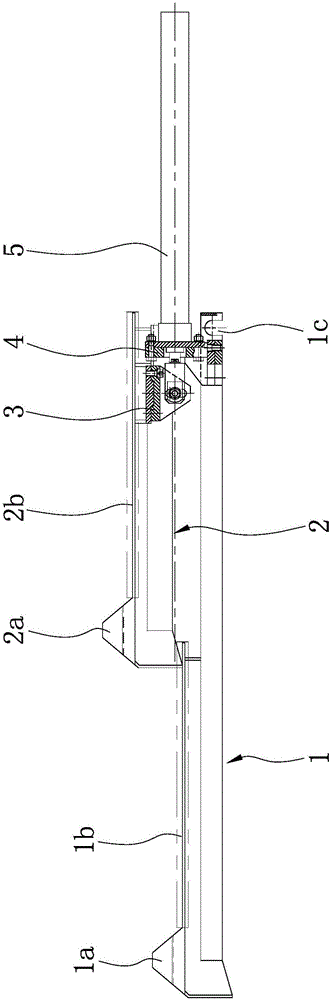

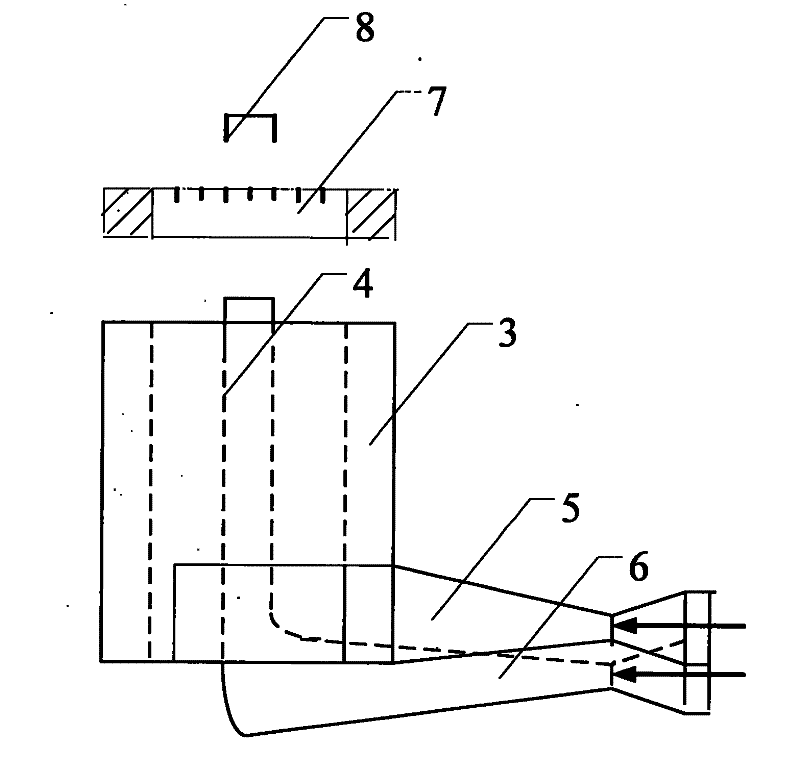

Grate set for garbage incinerator

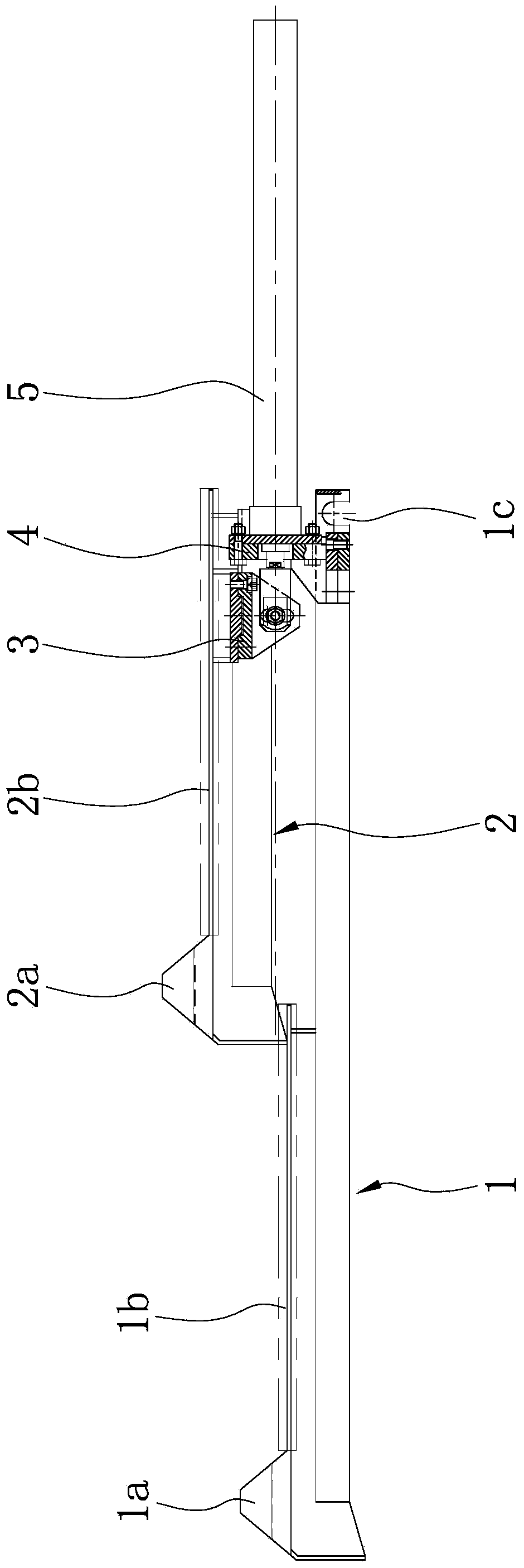

The invention discloses a grate set for a garbage incinerator. The upper end of the front of a fixed grate segment (1) is provided with a first back movement plane (1b), the front end of the first back movement plane (1b) protrudes upwards to form a first head boss (1a), the upper end of a movable grate segment (2) is provided with a second back movement plane (2b), the top of the front end of the second back movement plane (2b) protrudes upwards to form a second head boss (2a), a driving support (3) is fixed at the bottom of the rear end of the movable grate segment (2), a positioning seat (4) in the rear of the driving support (3) is fixed at the rear end of the fixed grate segment (1), a driving device (5) is mounted on the positioning seat (4), and the front end of the driving device (5) is connected with the driving support (3). The grate set has the advantages that since the fixed grate segment and the movable grate segment are modularized, on one hand, assembly process is simplified, and assembly difficulty is lowered; on the other hand, labor intensity of workers is reduced, and assembly efficiency is improved greatly.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP

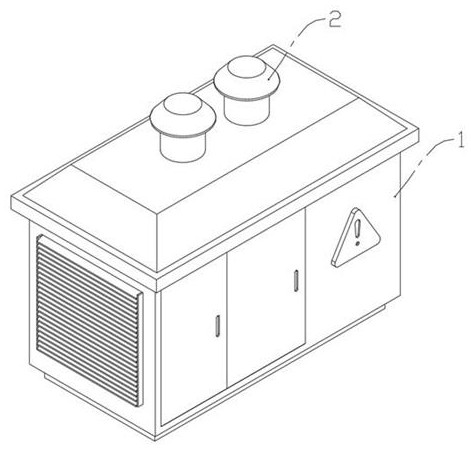

Fireproof European style box-type substation

ActiveCN114361960ABurning violentlyInnovative designClimate change adaptationSubstation/switching arrangement cooling/ventilationTransformerEngineering

The invention relates to a fireproof European-style box-type transformer substation which comprises two air outlets symmetrically formed in the upper end of a box-type transformer substation body, detachable moisture-proof covers are arranged on the air outlets, fans and plugging plates are rotationally arranged in the air outlets, the number of the plugging plates is two, and the plugging plates and the air outlets are coaxially arranged; the plugging plate is arranged in the box-type transformer body and connected with a trigger mechanism arranged in the box-type transformer body, the trigger mechanism drives the plugging plate to plug the air outlet when a fire occurs in the box-type transformer body, and the nozzle is movably arranged in the box-type transformer body and connected with a storage tank fixed on the side wall of the box-type transformer body through a corrugated pipe. The nozzle is further connected with a reciprocating driving mechanism arranged in the box-type transformer substation body, the reciprocating driving mechanism is used for driving the nozzle to move in the box-type transformer substation body and enabling the nozzle to rotate in the moving process through a meshing structure arranged between the nozzle and the box-type transformer substation body, an abutting rod is arranged on the triggering mechanism and matched with a reciprocating assembly mechanism, and the reciprocating assembly mechanism is used for driving the nozzle to move in the box-type transformer substation body. And rapid fire extinguishing is realized.

Owner:徐州鑫贝克电力设备股份有限公司

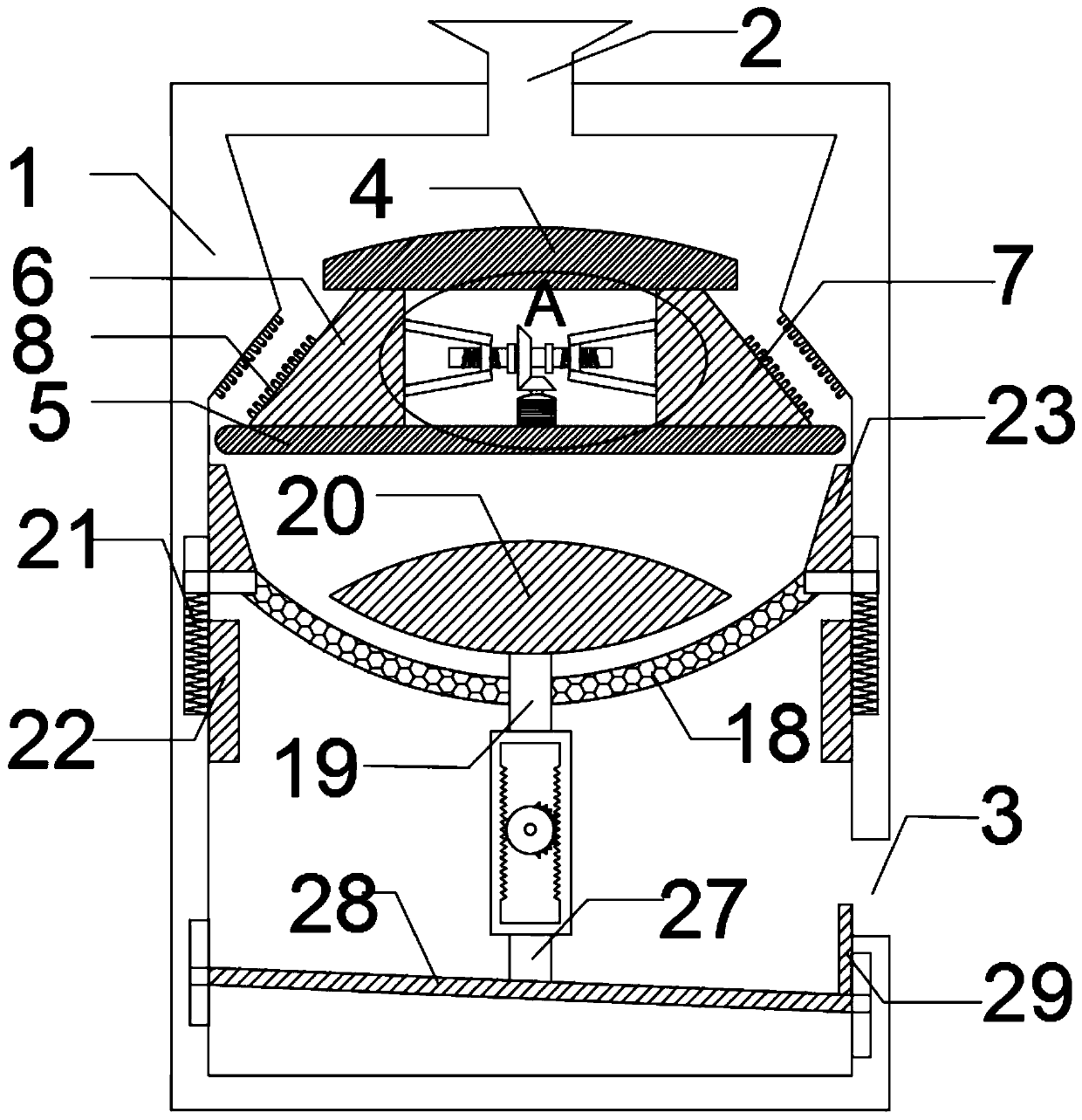

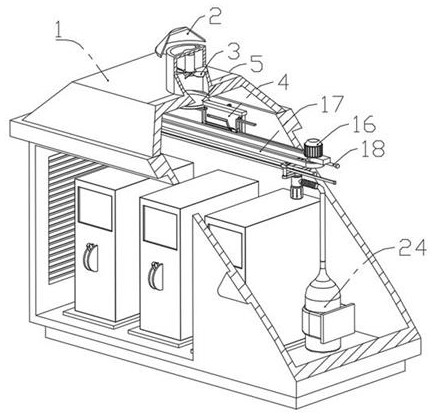

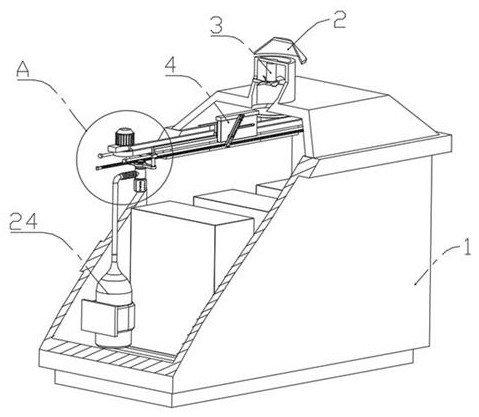

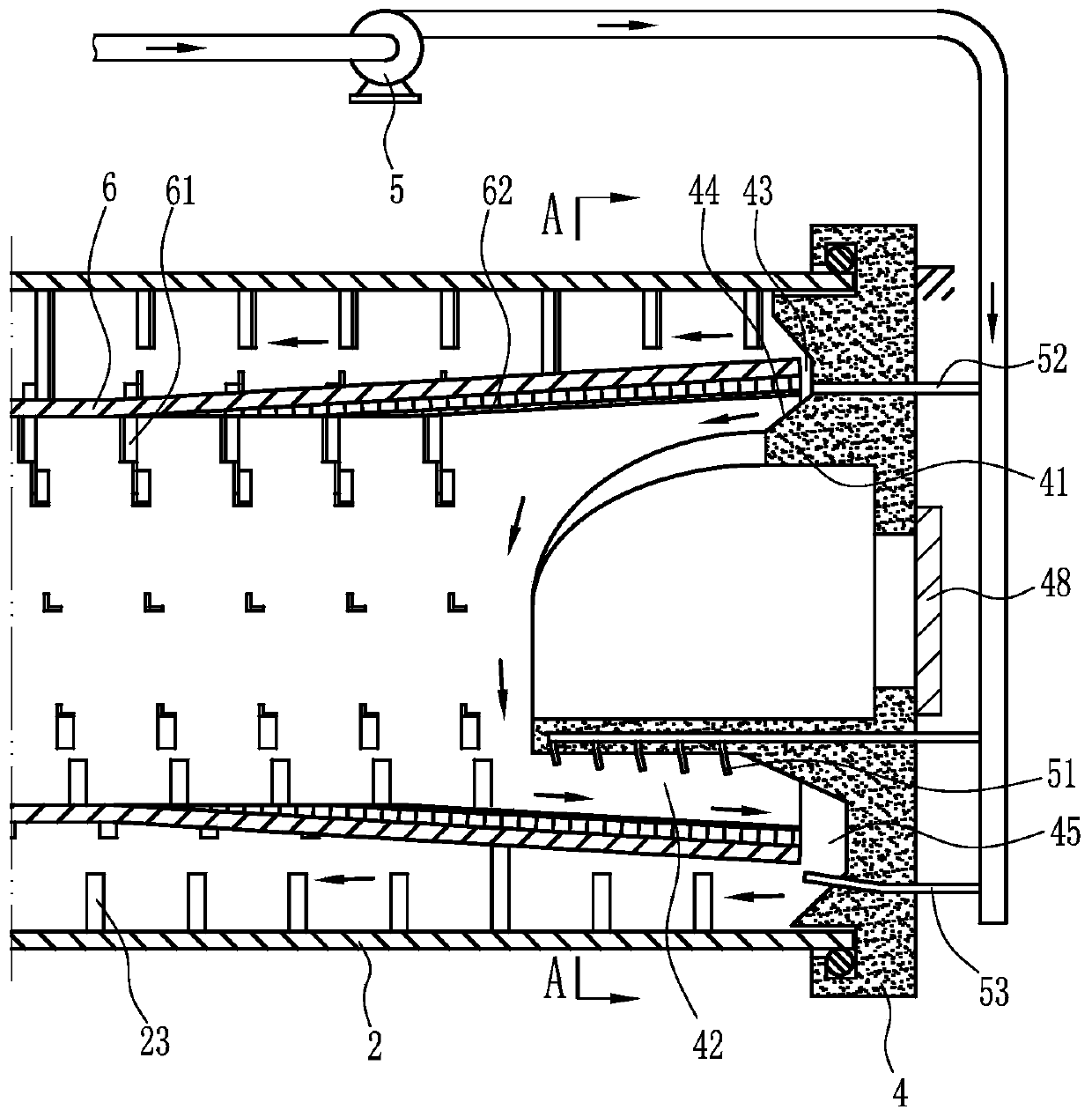

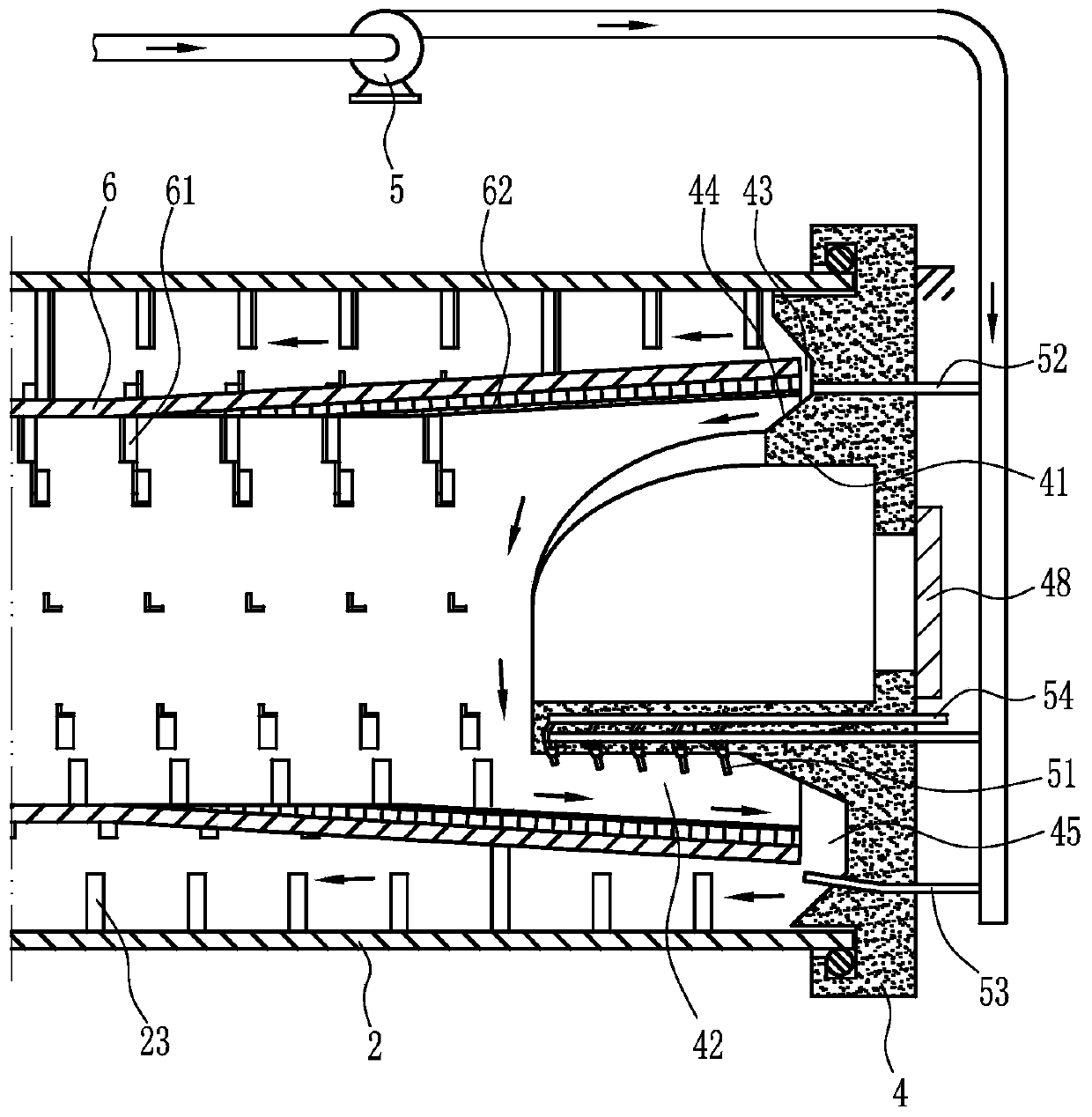

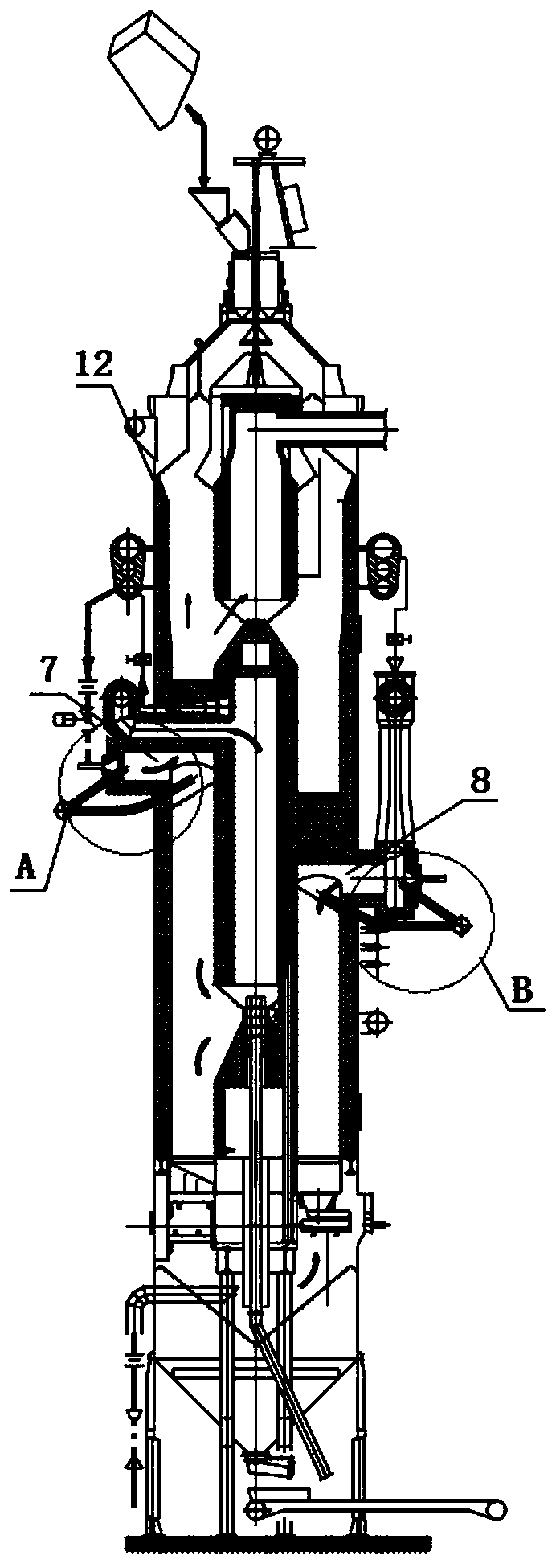

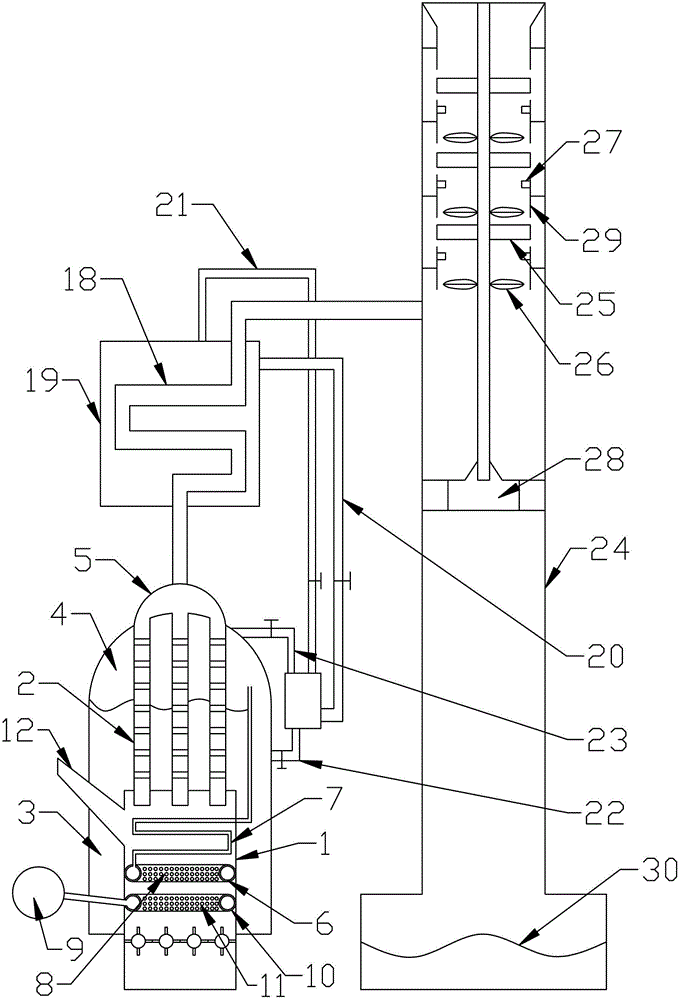

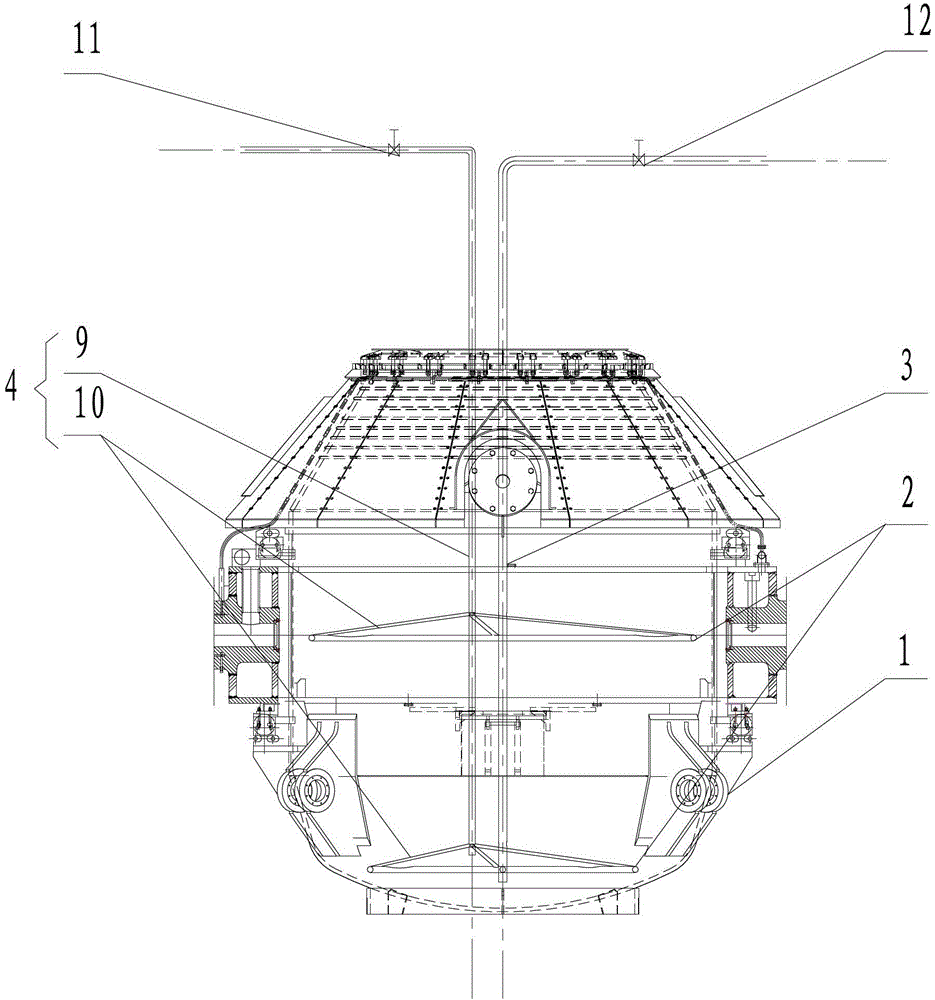

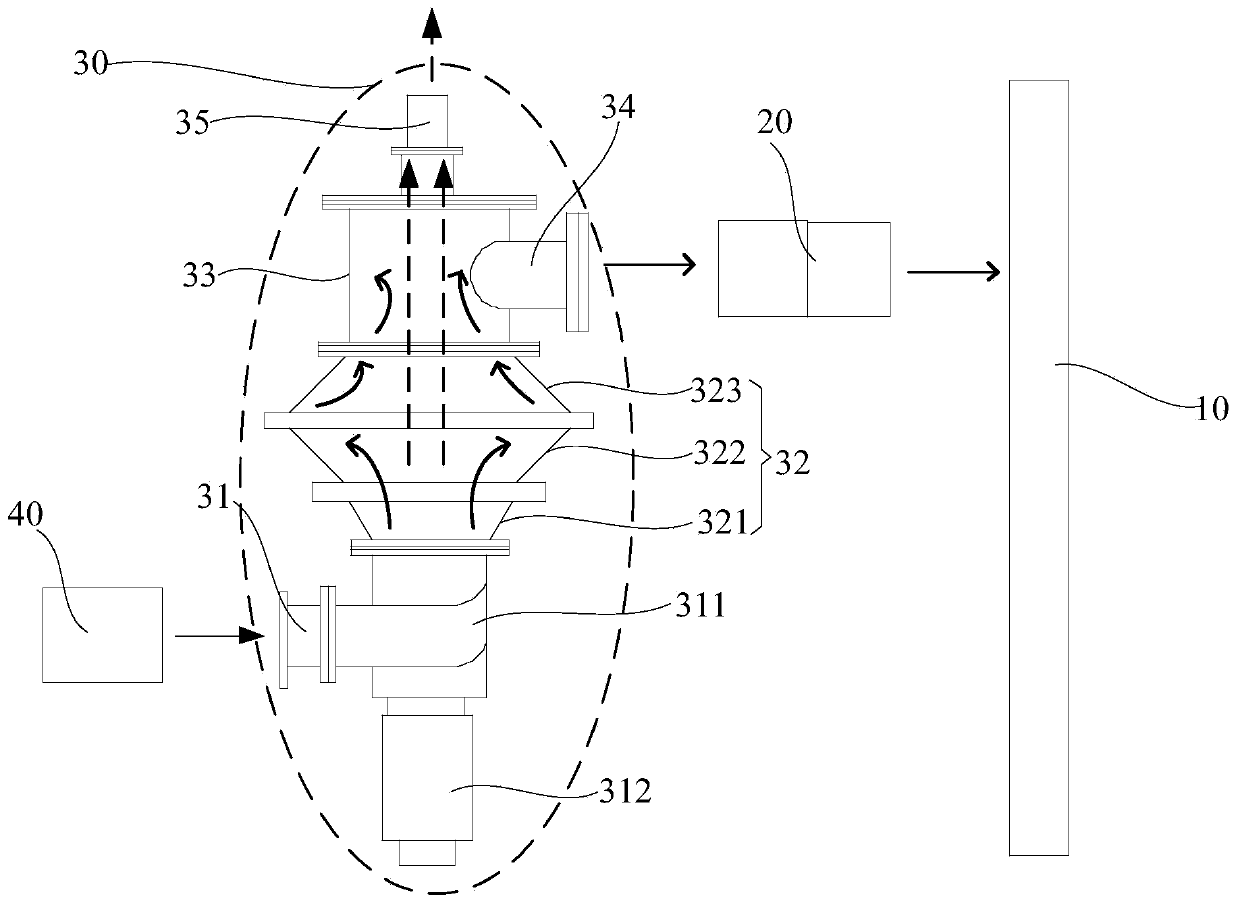

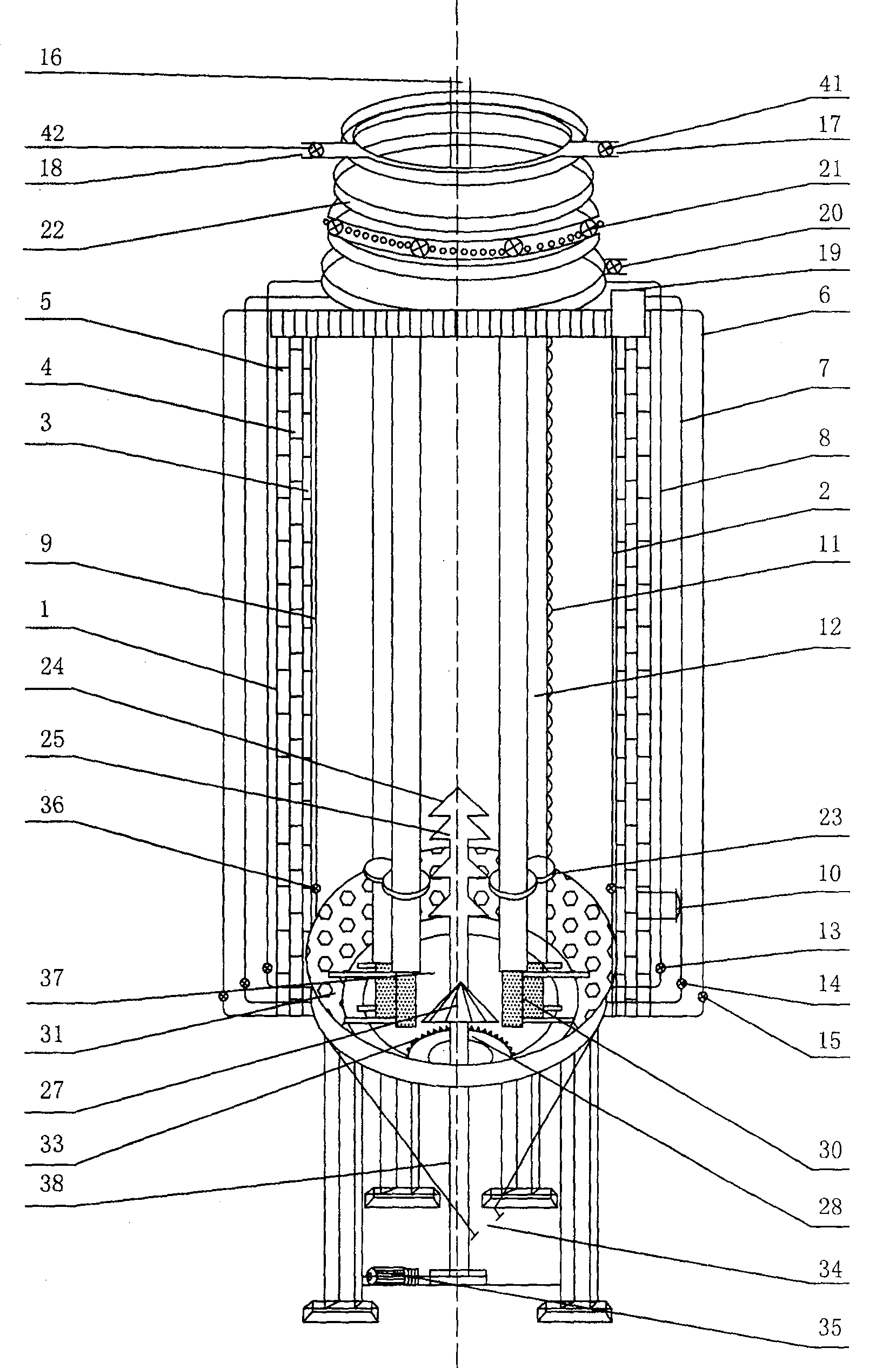

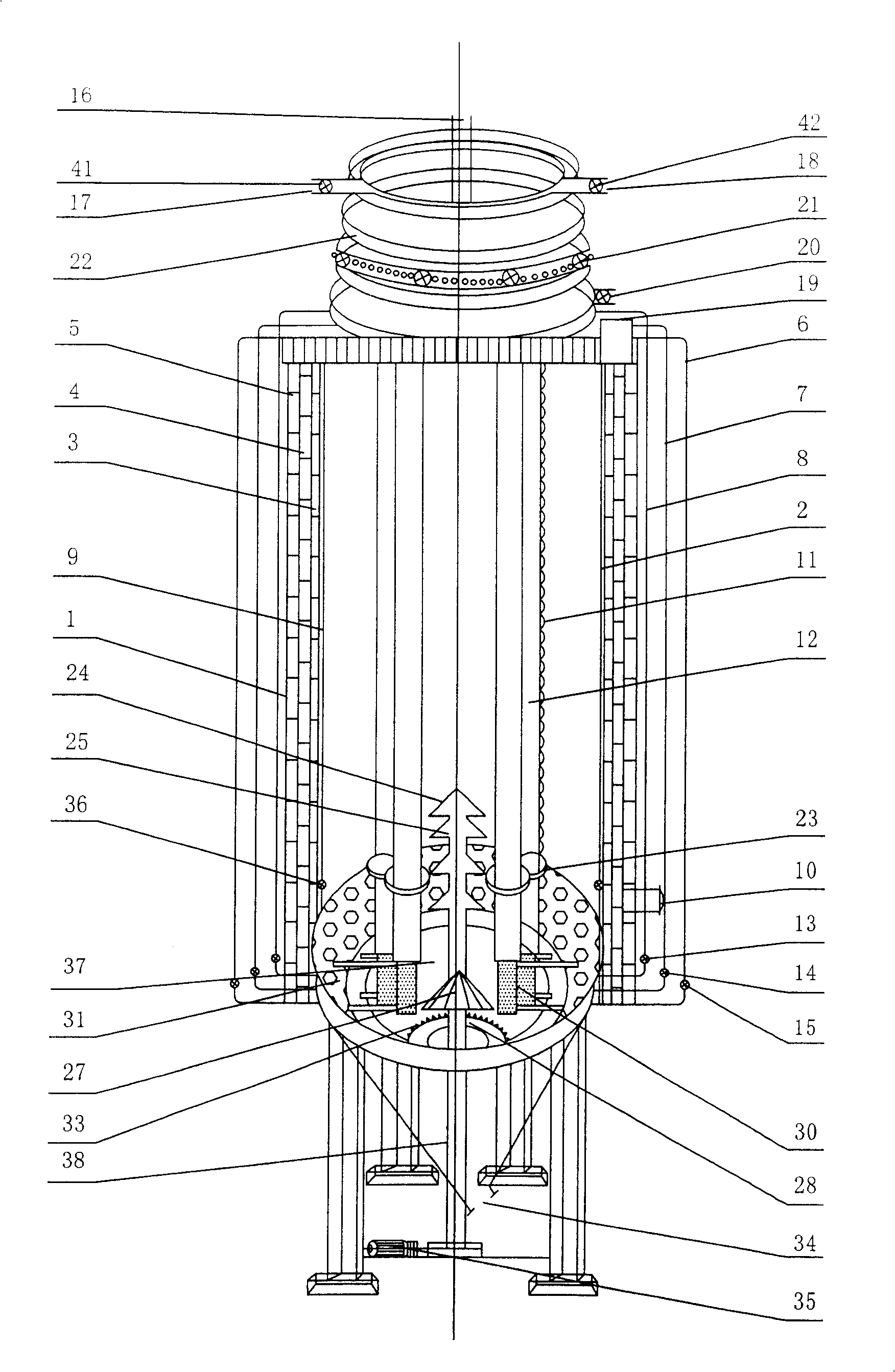

Centralized combustion device applied to internal heating type rotary furnace

PendingCN109855101APlay a heating roleViolent decomposition and combustionIncinerator apparatusCombustionHazardous substance

The invention discloses a centralized combustion device applied to an internal heating type rotary furnace. The centralized combustion device comprises a furnace outer cylinder and a furnace inner cylinder; an inner cylinder push device is arranged inside the furnace inner cylinder; an outer cylinder returning device is arranged inside the furnace outer cylinder; the end part of the furnace outercylinder is in dynamic tight coupling with a centralized combustion end base; the centralized combustion end base is provided with a combustion isolator which extends into the furnace inner cylinder;the combustion isolator is provided with a centralized combustion channel; a slag falling opening is arranged between the centralized combustion end base and the furnace inner cylinder; the centralized combustion channel is provided with a plurality of combustion-supporting air supply pipelines; an annular flame retardant coating is arranged inside the furnace inner cylinder; an air stop device isarranged between the centralized combustion end base and the furnace inner cylinder which is arranged outside a material collection region; and the furnace inner cylinder is connected with an air replenishing device. According to the centralized combustion device disclosed by the invention, a raw material can be preheated by adopting the combustion heat; organic components can be separated out, pyrolyzed and vaporized; by virtue of the air flow, gaseous combustible substances can reach the centralized combustion channel and are centralized so that centralized and violent combustion can be easily formed, thus sufficient combustion of residual combustible substances in the raw material can be promoted, and harmful substances contained in tail gases can also be obviously reduced.

Owner:山东金成环保科技有限公司

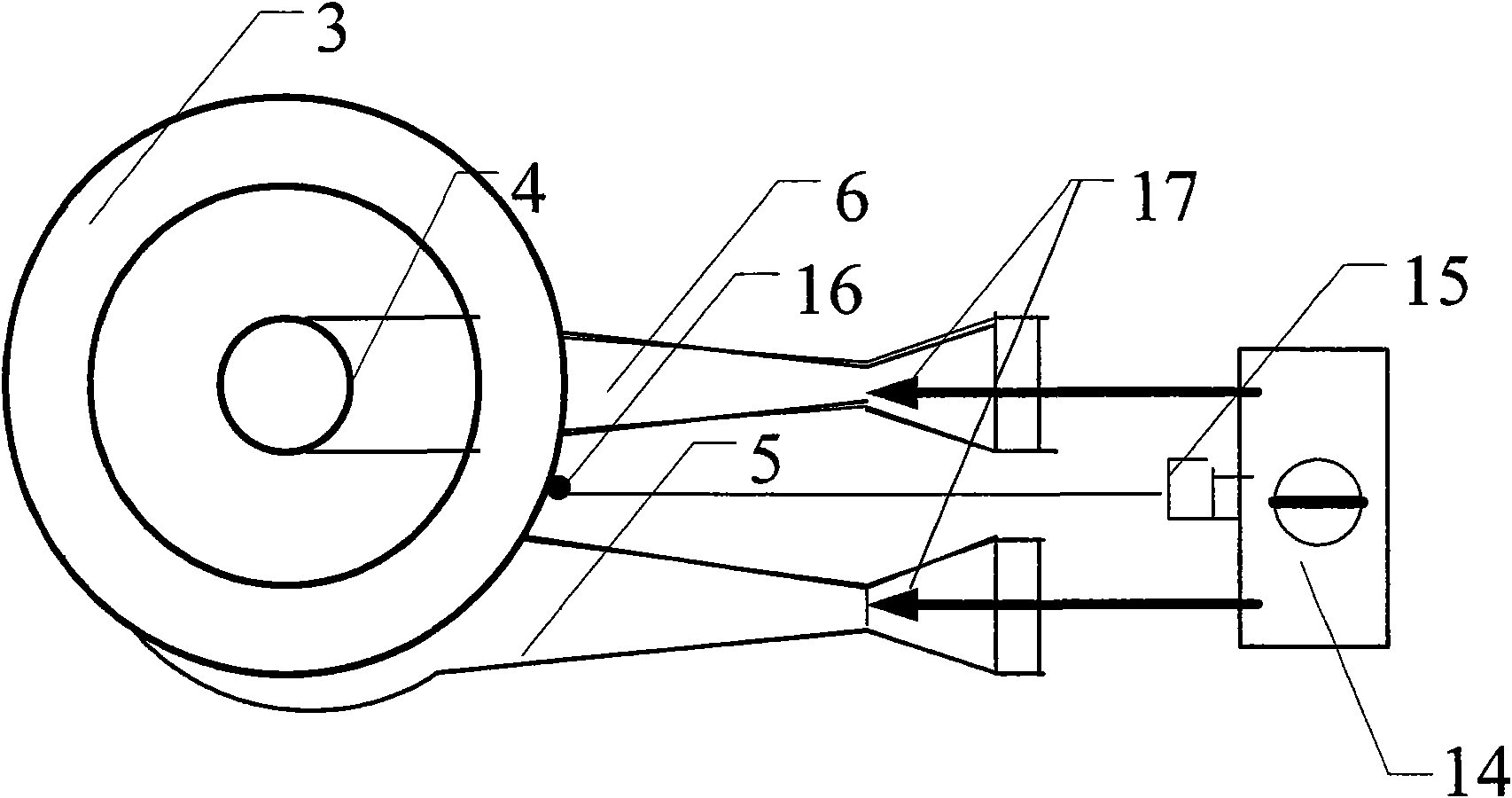

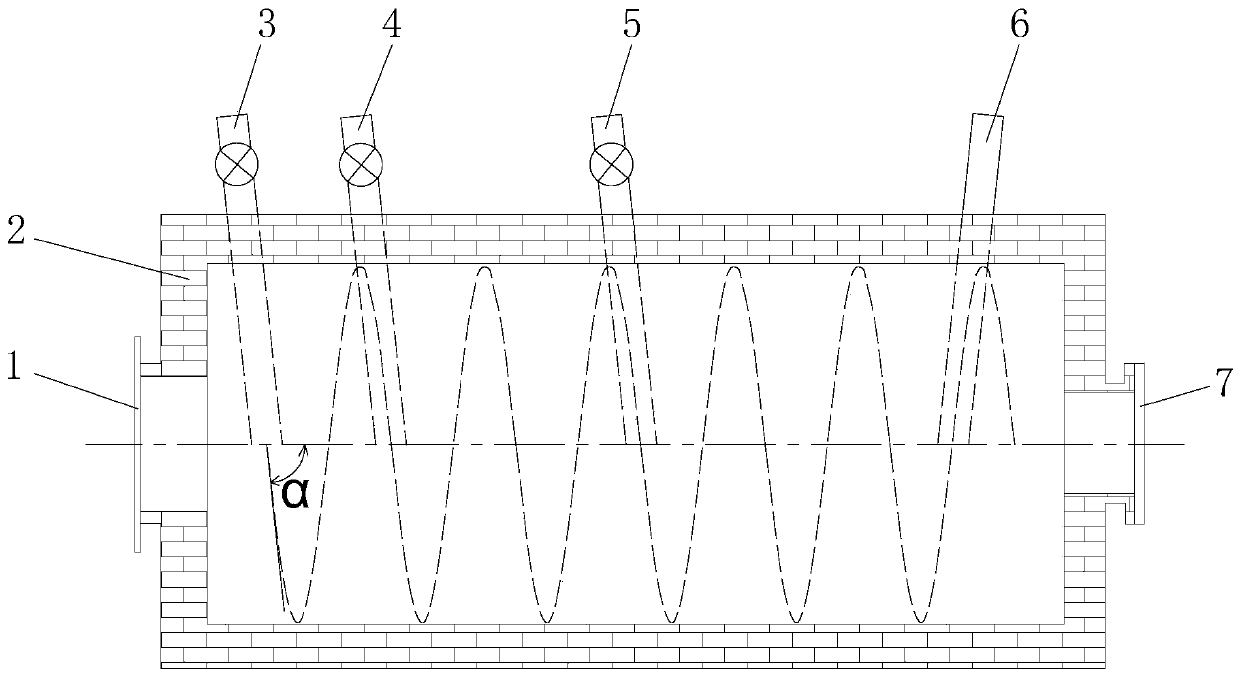

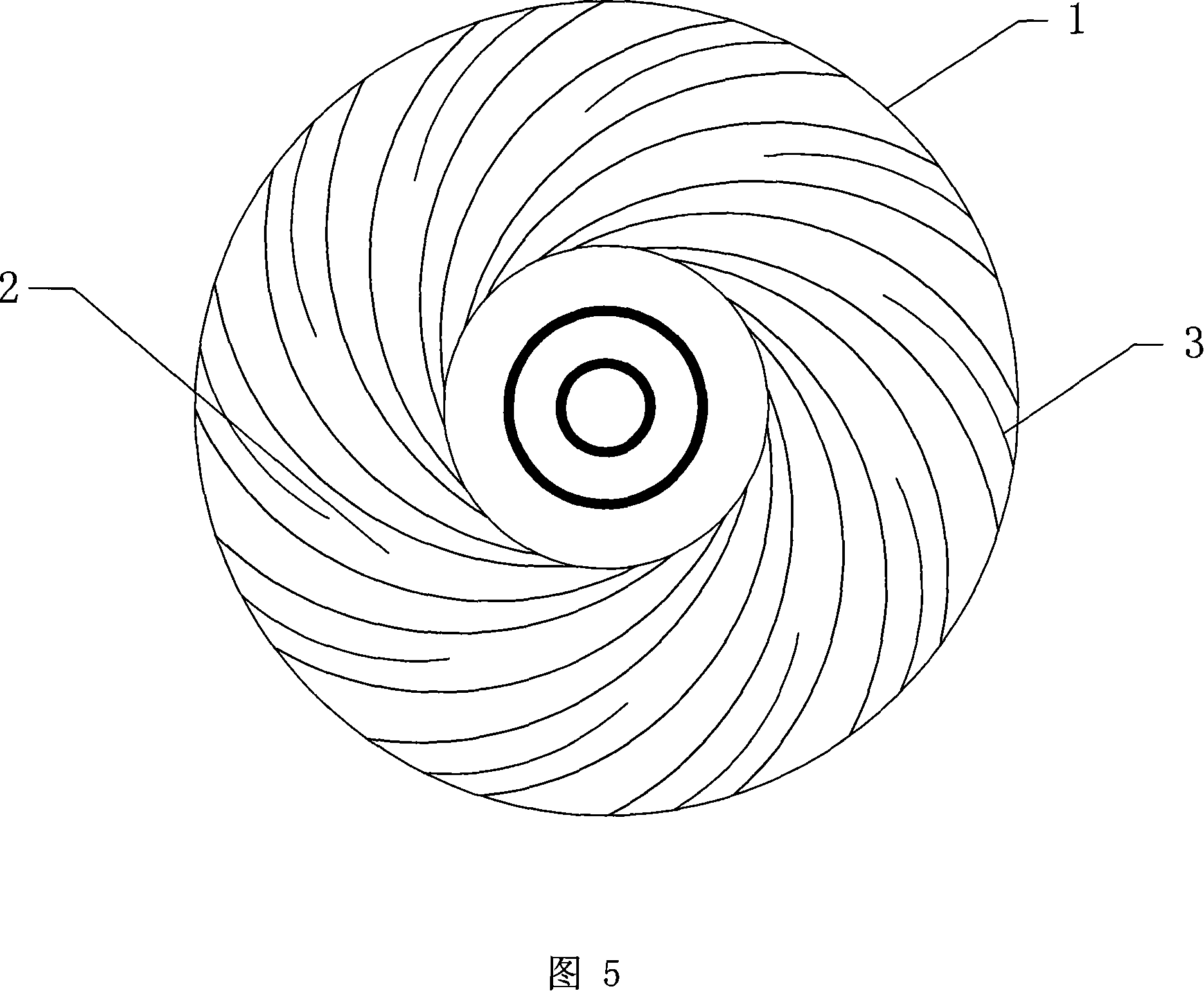

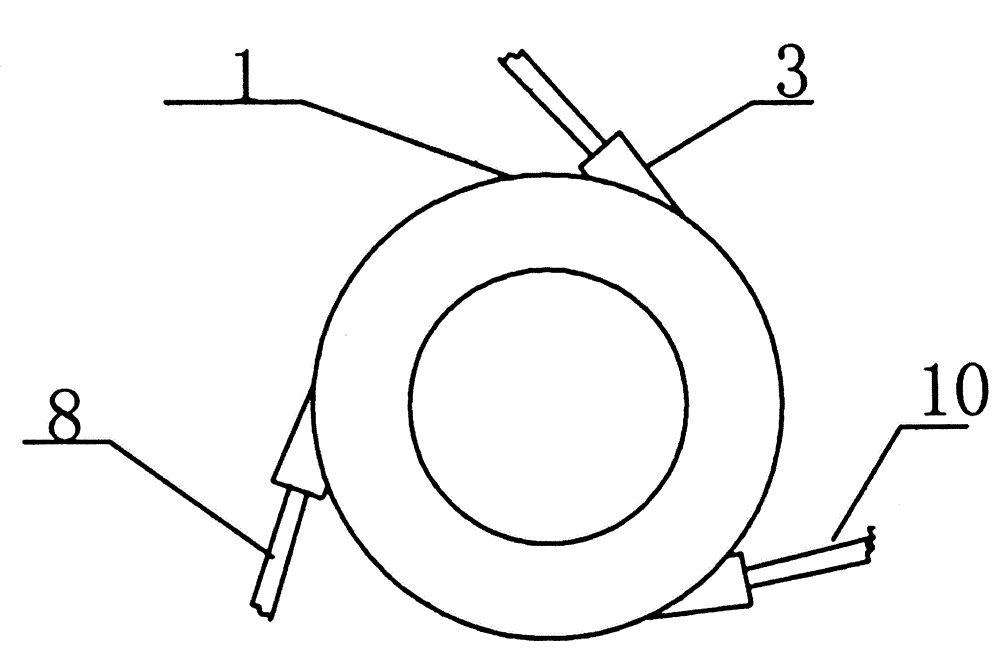

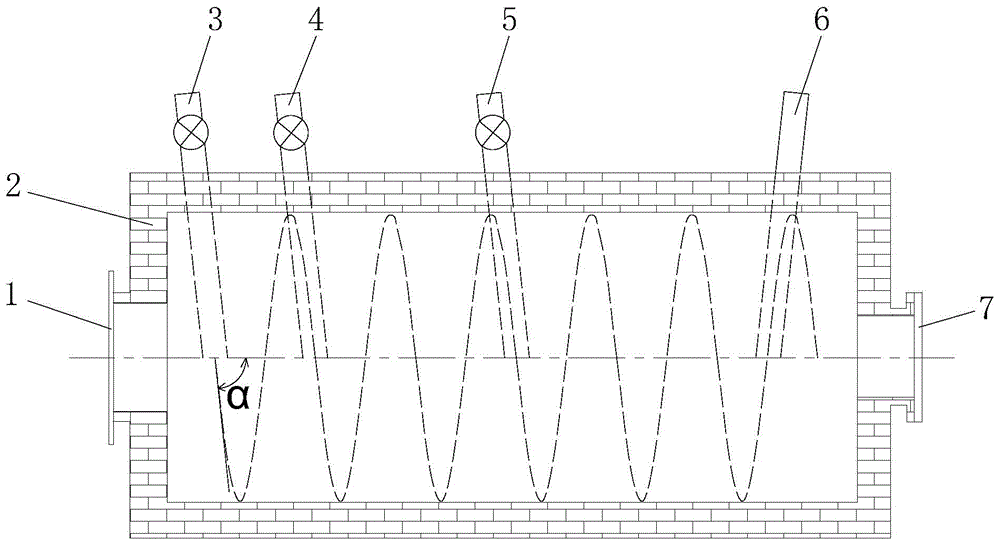

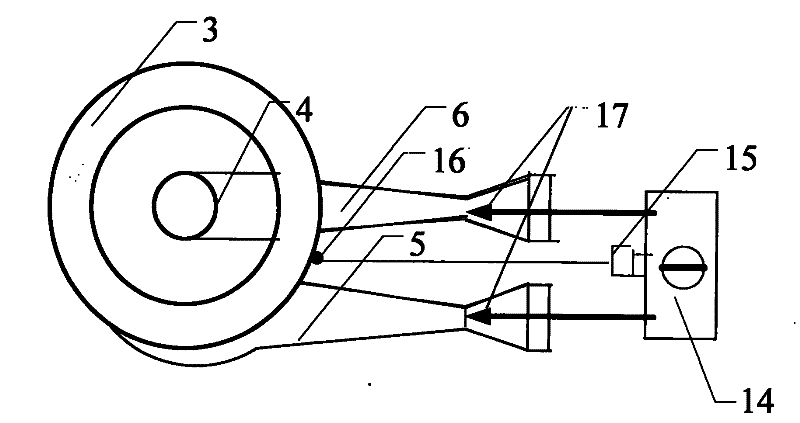

A spiral gas burner

The invention relates to a spiral gas combustor. The spiral gas combustor comprises a cylinder, a gas pipe, a primary air distribution pipe and a secondary air distribution pipe, wherein the gas pipe and the primary air distribution pipe are respectively connected with the low-temperature end of the cylinder and are communicated with a combustion chamber in the outer circumferential direction of the circular cross section of the combustion chamber; a spiral angle alpha is formed between the axis of each of the gas pipe and the primary air distribution pipe and the axis of the cylinder; a flame jet nozzle is arranged at the high-temperature end of the cylinder; the secondary air distribution pipe is connected with the cylinder between the gas pipe and the flame jet nozzle at the same spiral angle alpha. According to the spiral gas combustor, the combustion path of a gas is designed into a spiral shape, and a secondary air distribution technology is used, so that the combustion stroke of the gas is greatly prolonged under the condition of fixed volume of the cylinder; the gas is combusted more uniformly; various pollutants caused by incomplete combustion are avoided; the travelling speed of a fuel is improved, so that the combustion is more drastic.

Owner:叶利顺

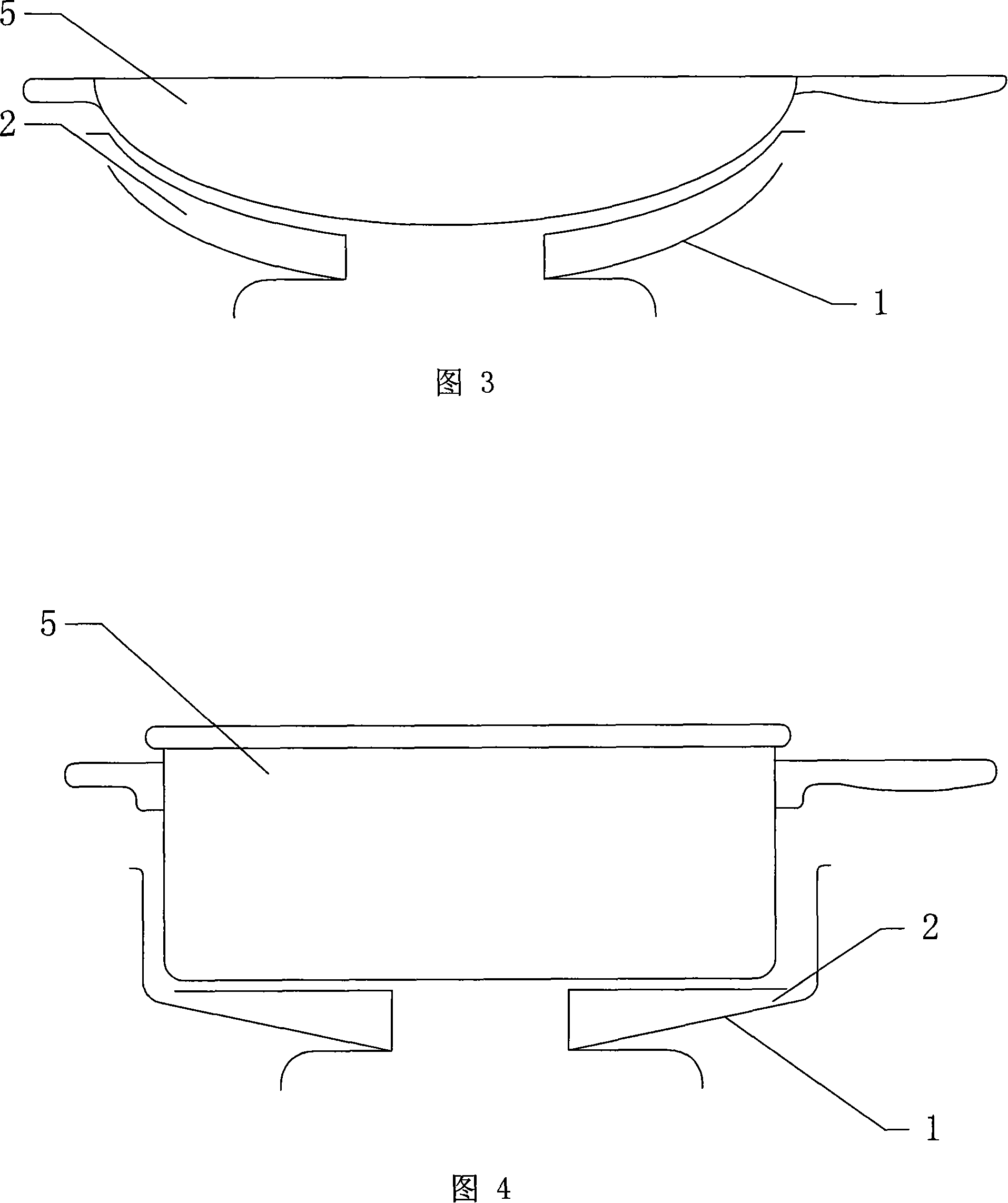

Energy-saving type range tray

The invention discloses a household single-pipe infrared furnace end, a single pipe enters from the lower side of the furnace end and is communicated with a combustion chamber; the bottom of the single pipe, a primary inclined plane faced by the single pipe and two inclined planes at both sides form an inlet cavity. The invention is characterized in that a half-round gas diversion post is arranged on the primary inclined plane of the inlet cavity, the function of the gas diversion post is to reduce the gas pressure and at the same time most of the gas is evenly divided into two parts before entering the combustion chamber; in this way, the gas is evenly mixed with the air and filled in the whole combustion chamber, and the purpose of high-temperature combustion and uniform combustion on a ceramic combustion board arranged at the top of the furnace end can be realized. The invention of the single-pipe infrared furnace end is additionally provided with a standard-sized locating clip, and can be matched and used with a standard furnace.

Owner:韩久和 +1

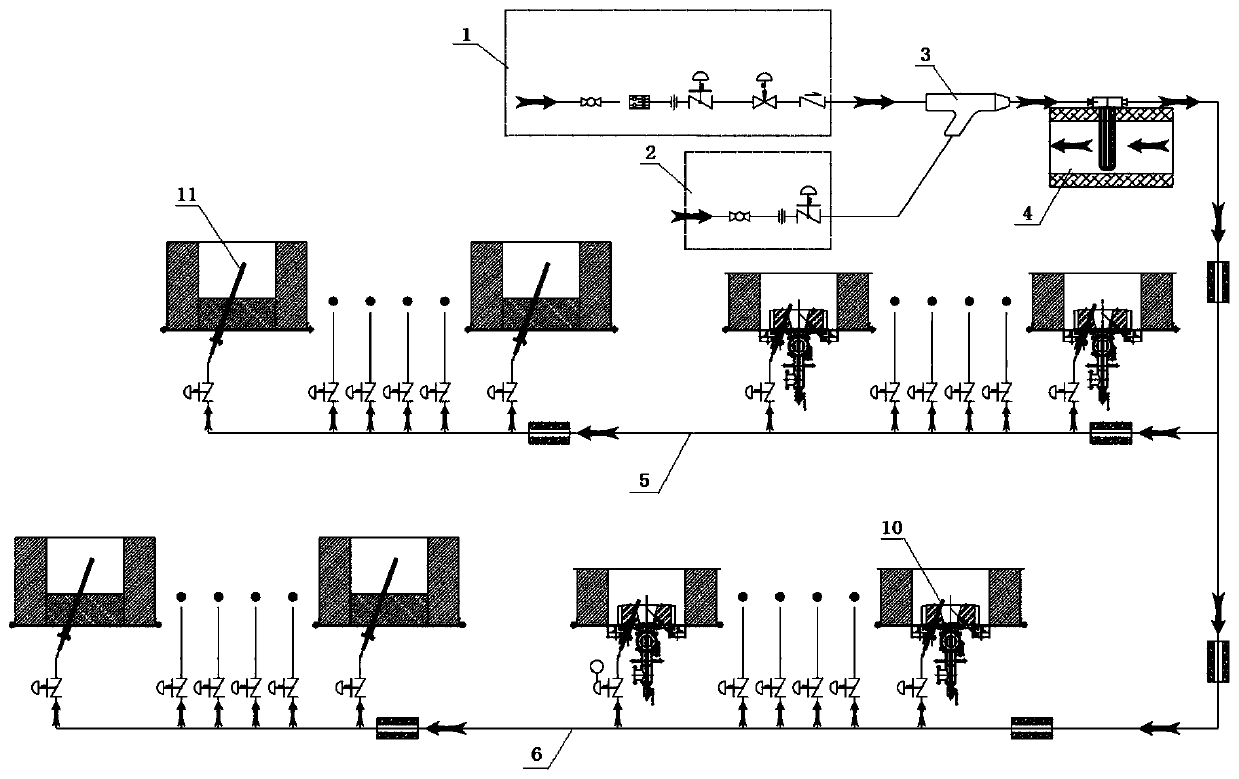

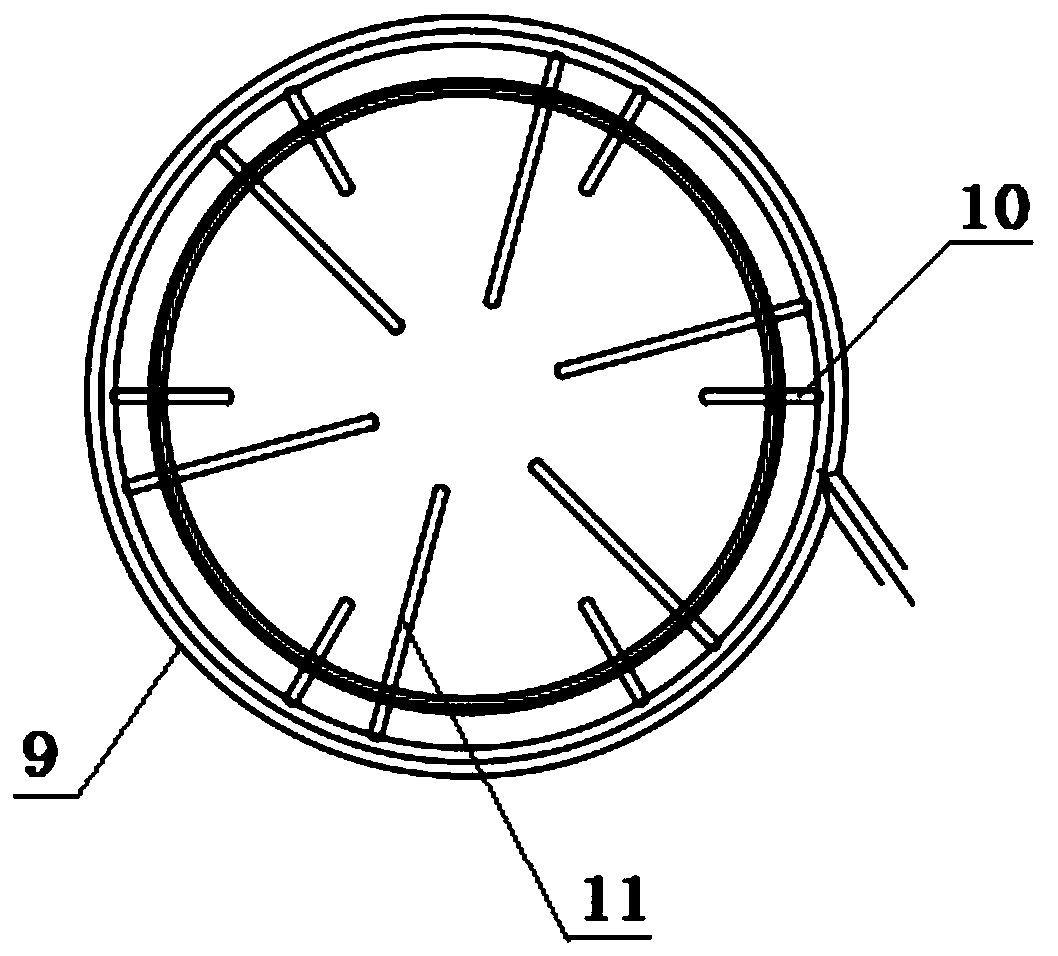

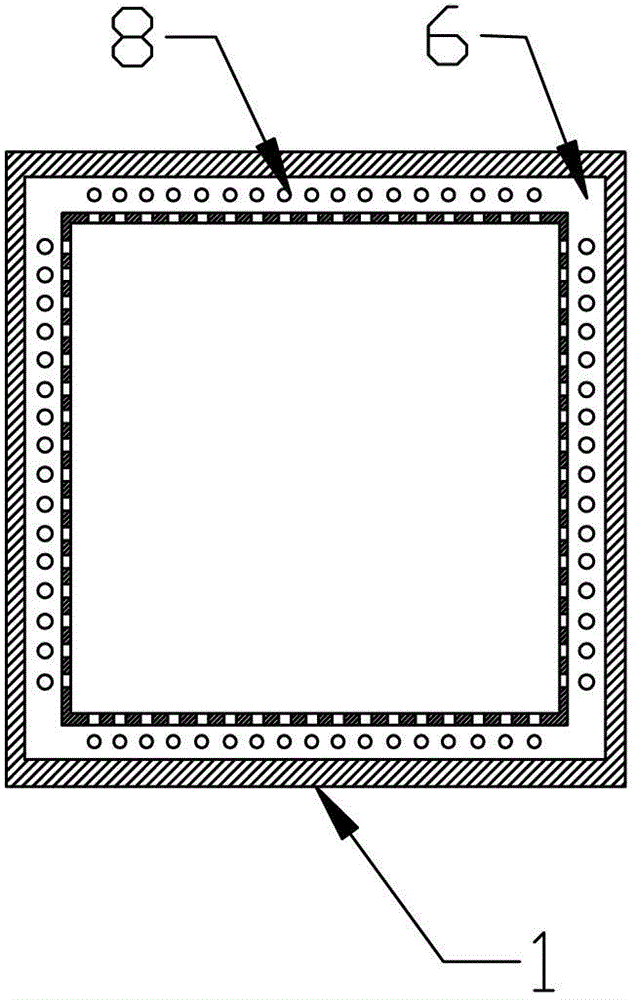

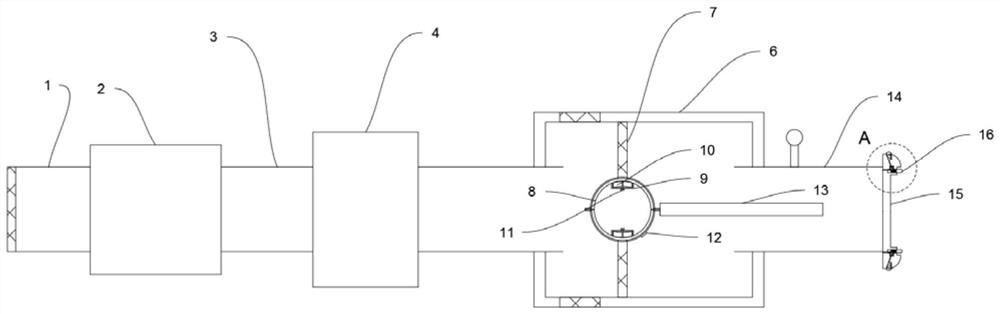

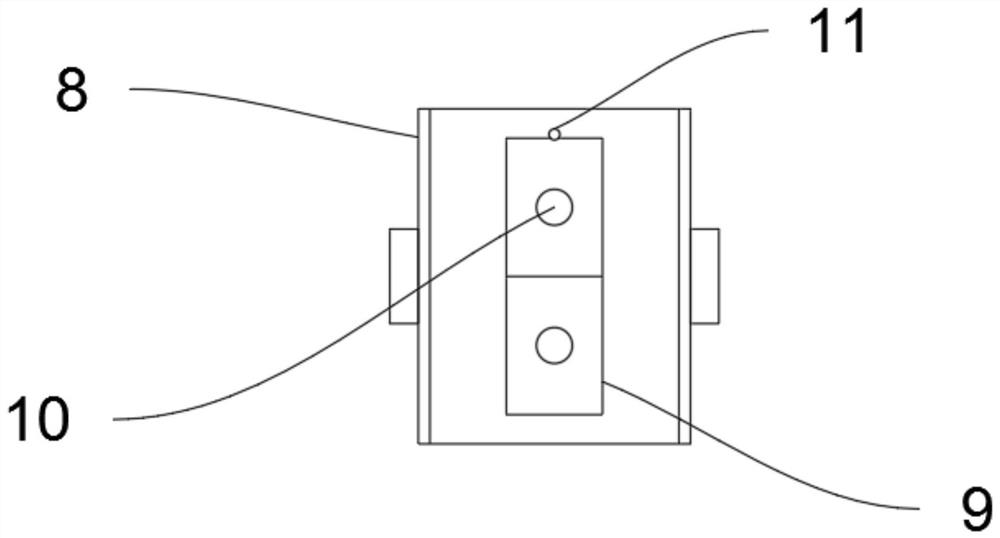

Sleeve kiln local oxygenation system

PendingCN111442649AReduce usageImprove combustion efficiencyMaintainance of heating chambersWaste heat treatmentCombustion chamberOxygen enhanced

The invention discloses a sleeve kiln local oxygenation system. The sleeve kiln local oxygenation system comprises an oxygen generation unit, an ejection unit, a heat exchange unit and an oxygenationunit, wherein the oxygen generation unit is used for producing pure oxygen, the inlet end of the ejection unit is connected with the oxygen generation unit, the inlet end of the heat exchange unit isconnected with the outlet end of the ejection unit, the heat exchange unit is arranged on a hot gas pipeline from an upper inner sleeve outlet flue of the sleeve kiln to the heat exchanger, the inletend of the oxygenation unit is connected with the outlet end of the heat exchange unit, the oxygenation unit is arranged outside a combustion chamber, the oxygenation unit comprises an oxygenation annular pipe, a plurality of oxygenation spray guns and a plurality of oxygenation spray pipes are arranged on the oxygenation annular pipe in the circumferential direction, the oxygenation spray guns are arranged on a combustion chamber panel, and the oxygenation spray pipes are arranged below an arch bridge. According to the sleeve kiln local oxygenation system, after local oxygen-enriched combustion, the combustion efficiency is improved, the combustion-supporting air volume and the use amount of fuel can be properly reduced, a better energy-saving effect can be achieved, the ignition temperature of the fuel in an oxygen-enriched state can be reduced, the combustion speed is increased, the combustion process is violent, the combustion reaction is sufficient and complete, and a better heatexchange effect is achieved.

Owner:JIANGSU ZHONGSHENGYUAN TECH CO LTD

Cyclone Pulverized Coal Gasifier

ActiveCN103820158BBurning violentlyPromote gasification reactionEnergy inputGranular/pulverulent flues gasificationCycloneManufacturing cost reduction

The invention discloses a cyclonic pulverized coal gasifier. The cyclonic pulverized coal gasifier comprises a gasifier body, a top nozzle, gasifier wall nozzles, a slag cooling tank, a waste heat boiler, an auxiliary waste heat boiler and a gas storage device, and the gasifier sprays a gas (steam) to the internal of the gasifier through the nozzles, so the gasification intensity of pulverized coal is good, and the reaction is full. Cyclonic current is generated in the gasifier to make slag, impurities and the pulverized coal adhered to the gasifier wall, so the retention time of coal in the gasifier is prolonged, and the reaction of the coal is promoted. The pulverized coal pure oxygen nozzle arranged at the top of the gasifier can substantially improve the reaction temperature in the gasifier, and a tangential gas (steam) blow nozzle arranged at the upper portion of the gasifier body can form strong cyclone to promote the reaction and forms steam curtain to avoid the high temperature ablation of the gasifier wall. Compared with other high temperature gasifiers, the cyclonic pulverized coal gasifier has the advantages of making cost reduction, raw material coal consumption cost reduction, high gasification efficiency and strong practicality.

Owner:李晓林

Heating and steam dual-purpose boiler

InactiveCN102748851BHigh thermal efficiencyImprove burnout rateSteam generation heating methodsWater heatersSlagEngineering

Owner:高宏亮

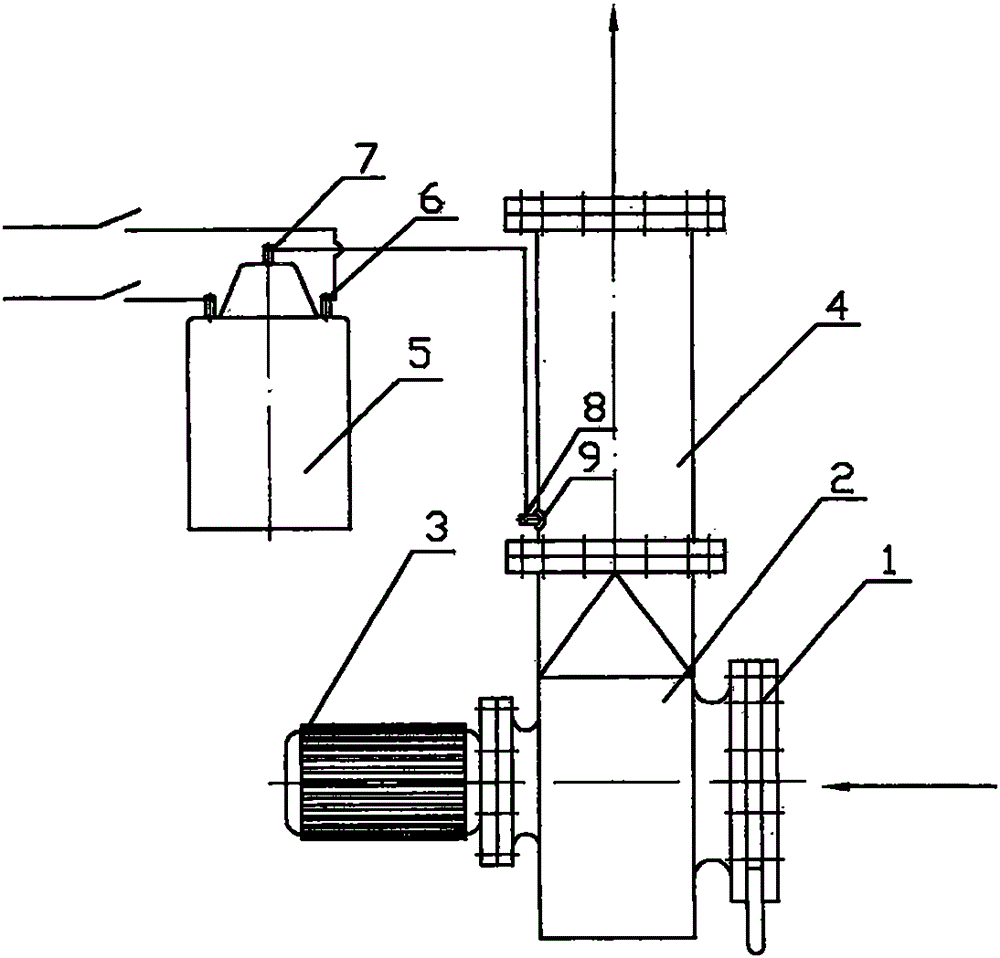

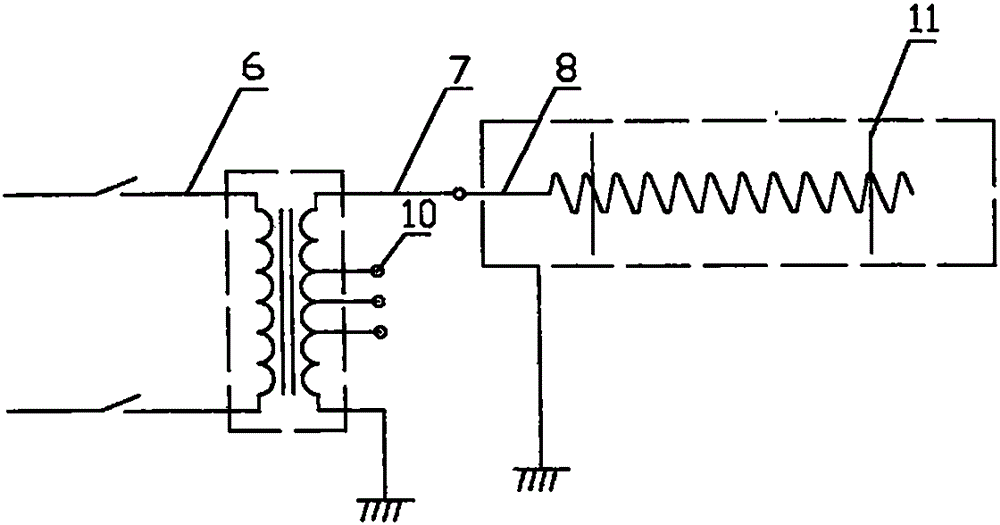

Method for pretreating air or fuel gas through high-voltage electrostatic field

The invention discloses a method for pretreating air or fuel gas through a high-voltage electrostatic field. The ionized combustion-supporting air or fuel gas is provided for a boiler through a high-voltage electrostatic device, a combustion reaction can be more intense and sufficient, and the purposes of improving thermal efficiency of the boiler, lowering energy consumption and reducing soot emission are achieved. The high-voltage electrostatic device is formed by mechanically connecting an air door, a forced draught blower, an electromotor and a metal ionization tube in sequence. A primary winding binding post, a secondary winding binding post and a high-voltage spiral electrode binding post of a voltage booster are electrically connected. The combustion-supporting air or fuel gas enters the metal ionization tube through the forced draught blower, is ionized through the high-voltage electrostatic field and then is sent into the boiler for supporting combustion or being combusted.

Owner:上饶市江心锅炉有限公司

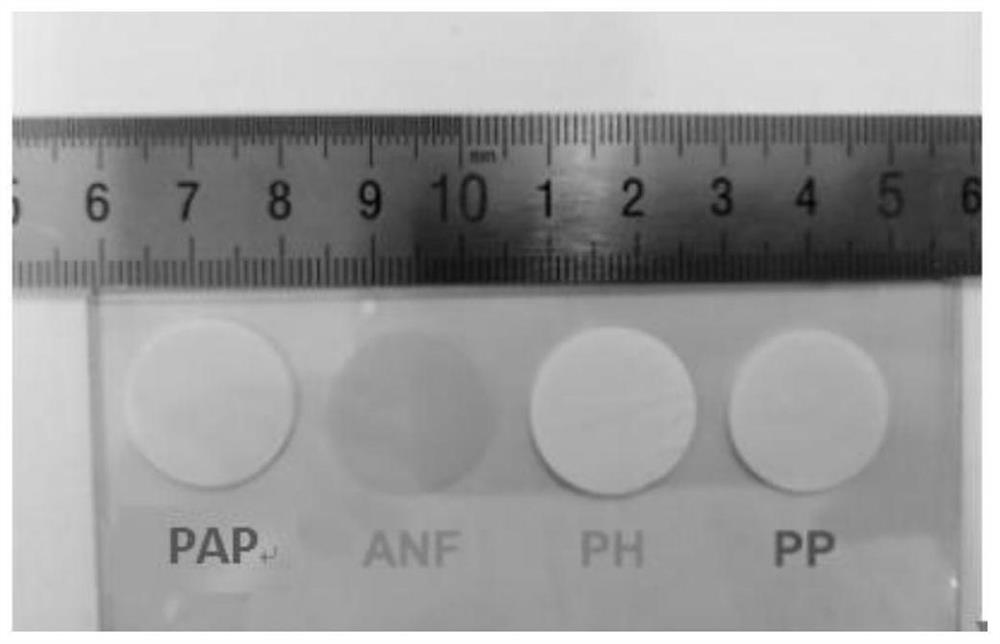

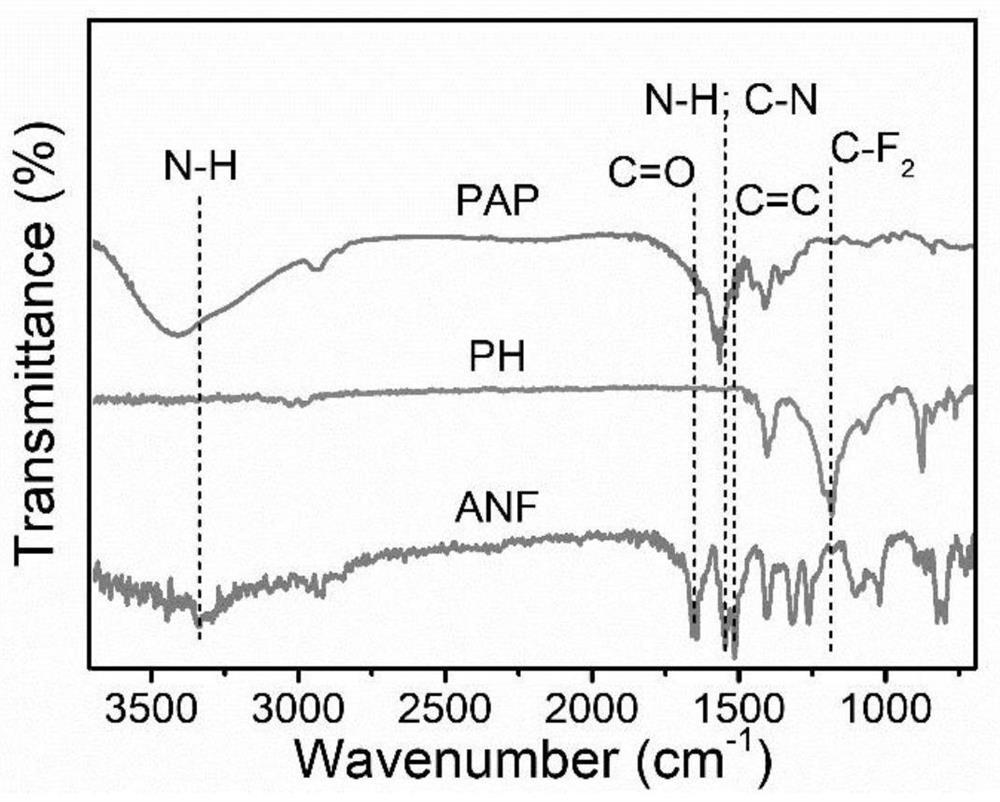

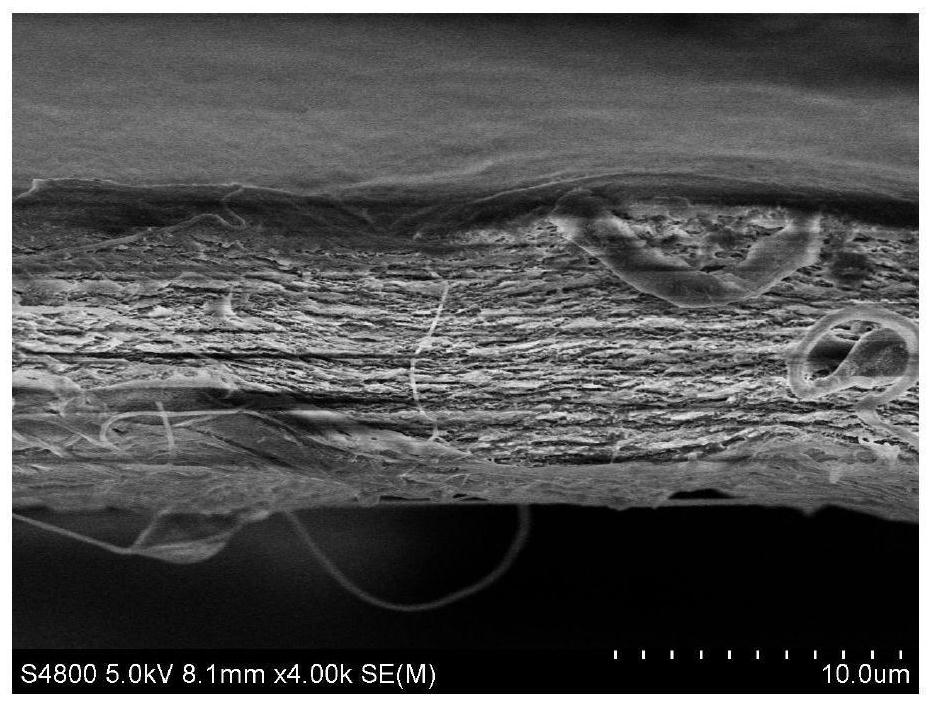

Lithium ion battery composite gel diaphragm as well as preparation method and application thereof

InactiveCN113036308AImprove securityAvoid burnsCell seperators/membranes/diaphragms/spacersSecondary cellsHexafluoropropyleneLithium-ion battery

The invention belongs to the field of battery diaphragms, and particularly relates to a lithium ion battery composite gel diaphragm as well as a preparation method and application thereof. The lithium ion battery composite gel diaphragm provided by the invention is of a three-layer composite structure, the middle layer is an aramid nanofiber diaphragm, and the two sides are polyvinylidene fluoride-hexafluoropropylene gel diaphragms. The composite gel diaphragm provided by the invention has the characteristics of high liquid absorption rate, high modulus and high strength, also has excellent performance of high-temperature hole closing, and is an ideal polymer gel diaphragm. The composite gel diaphragm provided by the invention has the liquid absorption rate of 320%, the tensile strength of 177.6 MPa and the Young modulus of 4.58 GPa. Moreover, a half battery assembled by the gel diaphragm provided by the invention shows excellent electrochemical performance, the reversible capacity can still be stabilized at 145.2 mAh.g <-1 > after 300 cycles, and the capacity retention rate is 92.01%.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

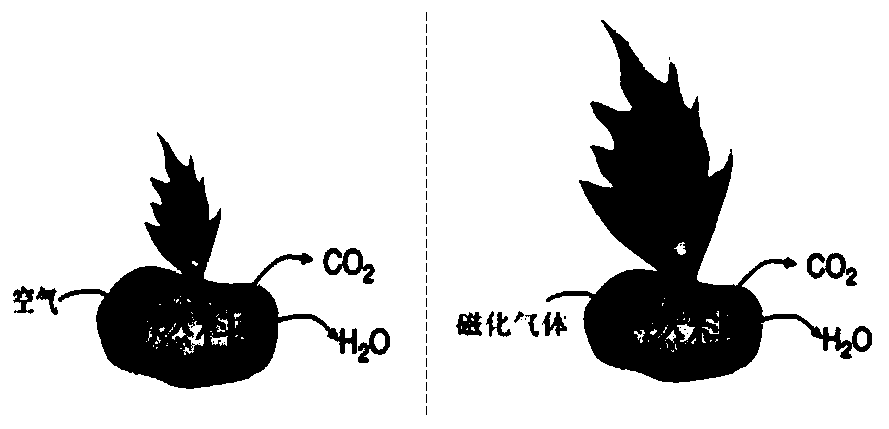

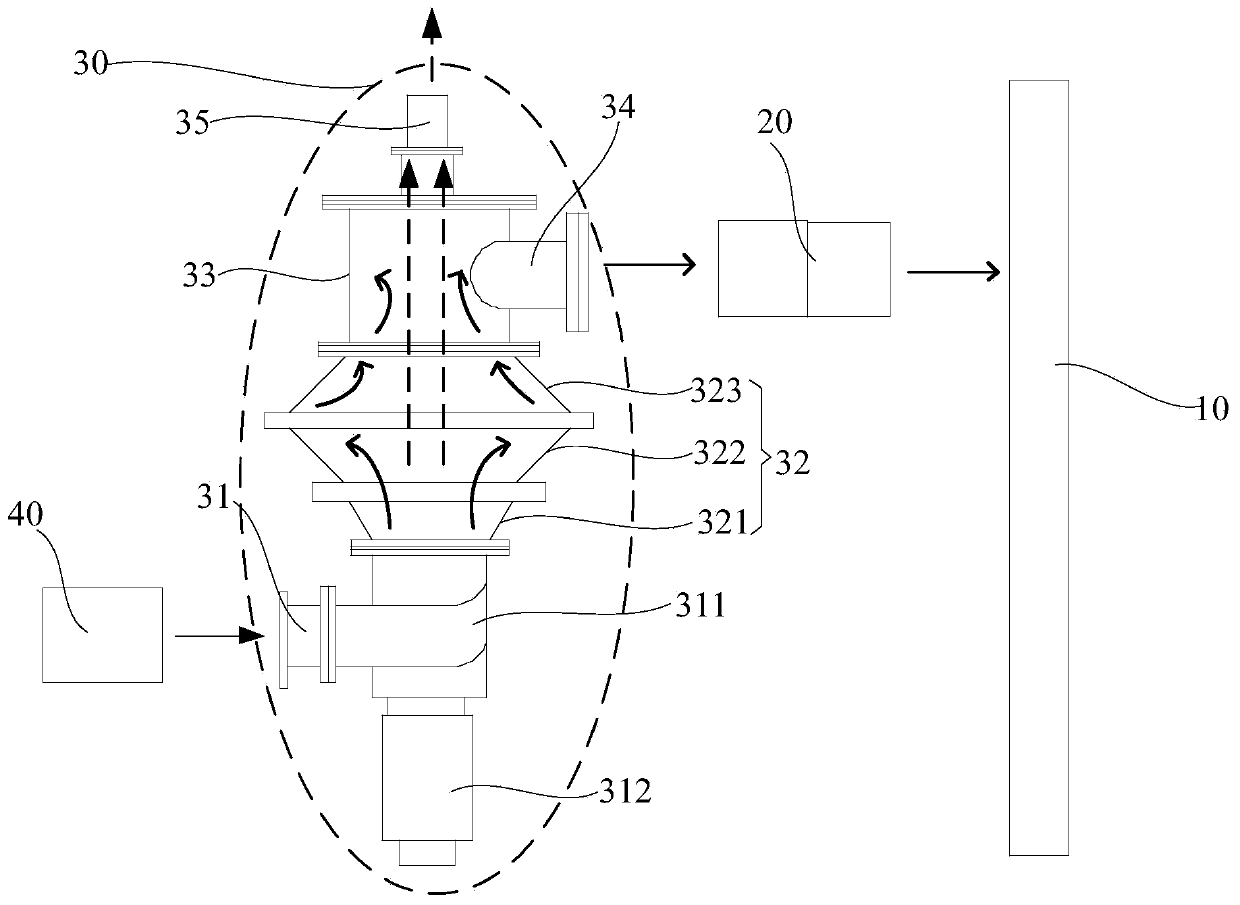

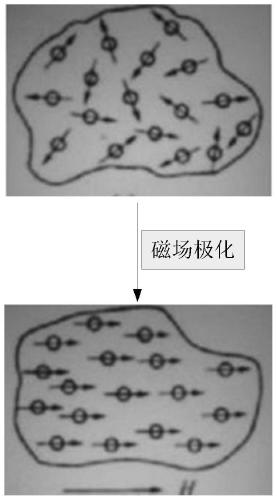

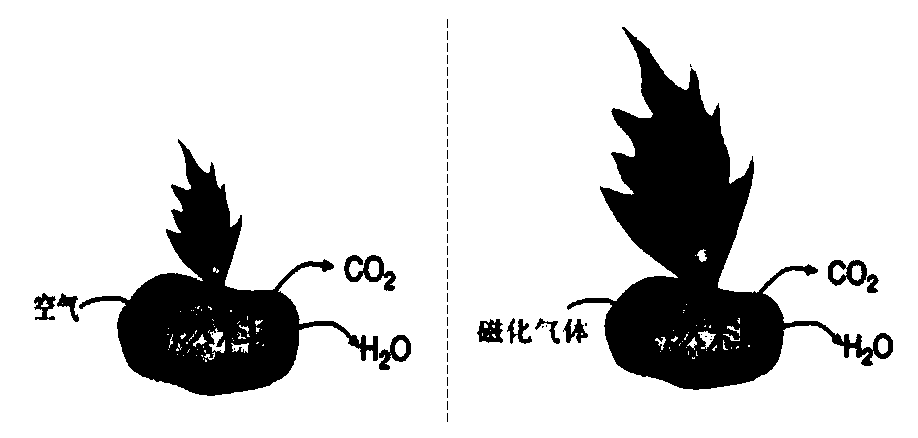

Oxygen gathering device surrounded by magnetic field, kiln combustion system and oxygen gathering combustion method surrounded by magnetic field

ActiveCN110015641BIncrease oxygen contentImprove combustion efficiencyFurnace componentsGaseous fuel burnerEngineeringCarbon dioxide content

The invention relates to a magnetic field-surrounding oxygen-collecting device, a furnace kiln combustion system containing the magnetic field-surrounding oxygen-collecting device and a magnetic field-surrounding oxygen-collecting combustion method. The magnetic field-surrounding oxygen-collecting device comprises a gas inlet pipe section, a vortex pipe section, an oxygen collecting pipe section,a nitrogen-oxide separation pipe section and an oxygen discharge pipe section which are connected in sequence; and the oxygen collecting pipe section is composed of a shell, cylindrical magnets and amagnetic conductive metal blanket, a plurality of cylindrical magnets are arranged at intervals around the inner wall of the shell to form a magnetic field ring, and the magnetic conductive metal blanket is arranged on the side of the magnetic field ring to form magnetic field surrounding. The magnetic field-surrounding oxygen-collecting device and the magnetic field-surrounding oxygen-collectingcombustion method provided by the invention can improve an oxygen content of a combustion-supporting gas flow, have low energy consumption, and can improve combustion efficiency, save fuel, reduce carbon dioxide content and significantly improve thermal efficiency, thereby facilitating promotion.

Owner:WUHAN FUSHIDA ENERGY TECH CO LTD

Magnetic-method combustion-supporting device for fan and connecting structure of magnetic combustion-supporting device

PendingCN113617178ATurn up the guessImprove liquidityGas treatmentDispersed particle filtrationCombustionOxygen enhanced

The invention discloses a magnetic-method combustion-supporting device for a fan and a connecting structure of the magnetic-method combustion-supporting device, relates to the technical field of magnetic-method oxygenation devices and connecting modes, and aims to solve the problem that in general, an existing fan directly extracts gas in air and provides the gas to a flame, but in the method, all the gas in the air is directly extracted for use, the main components of the air are oxygen and nitrogen, and the nitrogen is an inert gas and has no help for combustion supporting of the flame. paramagnetic oxygen molecules and diamagnetic nitrogen molecules in the air are separated through the mutual cooperation of a filter screen, a shell, a mounting piece, a magnet, a bolt, a fastener and a magnetic plate in the ion separating bin, and the oxygen content in the air is purified, so that in the subsequent use process, the combustion of flames is more violent, and the residual comburent is completely combusted; and through the components on a connecting piece, the connecting piece can be conveniently and rapidly connected with the air inlet of the fan, time and labor are saved, and the installation efficiency is improved.

Owner:沈建忠

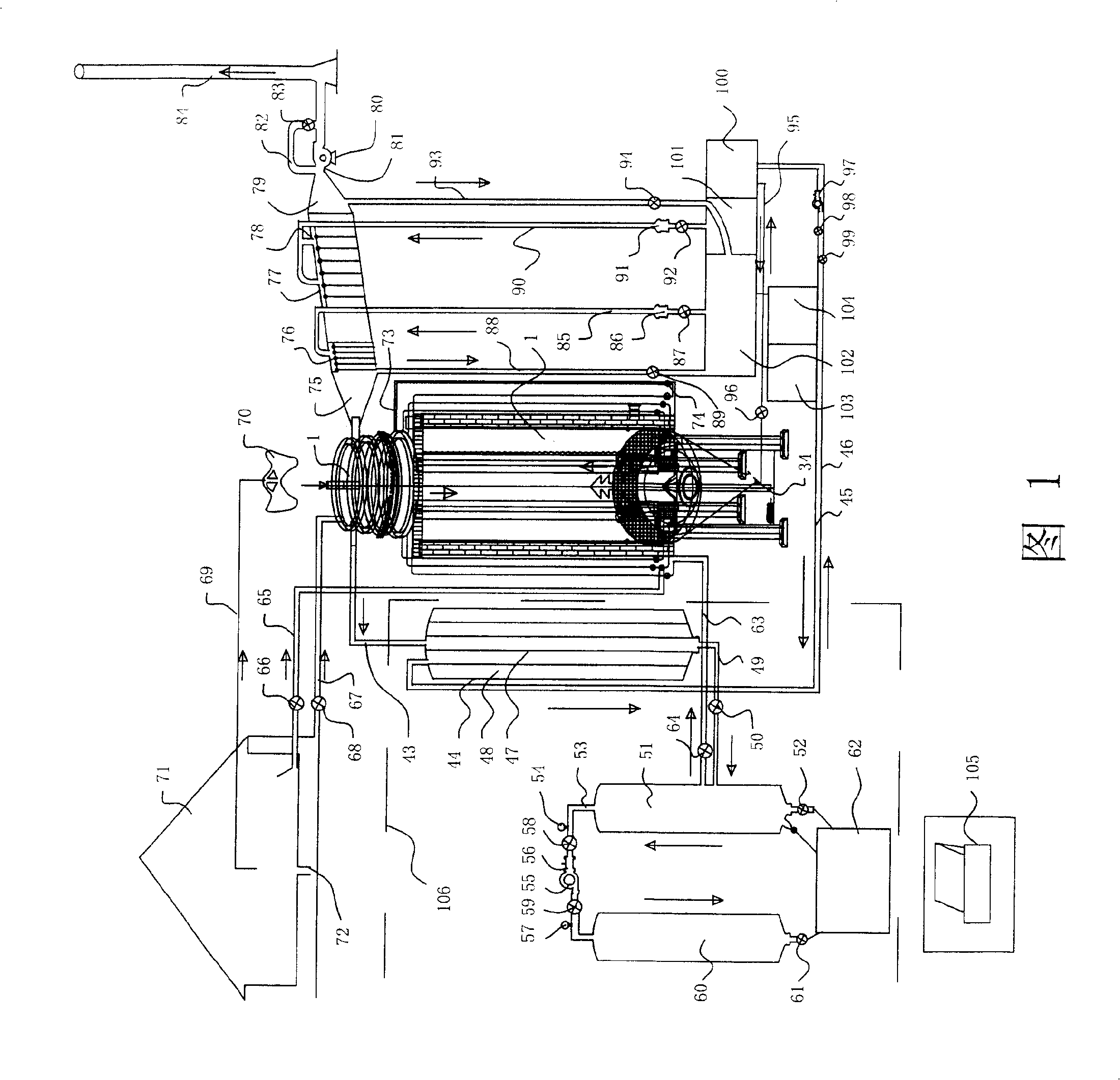

System and method for producing hydrogen fuel gas by low-energy nuclear reaction

InactiveCN108910823ASecurity scale is smallFast gas productionNuclear energy generationEnergy inputCirculator pumpEngineering

The invention discloses a system and method for producing hydrogen fuel gas by low-energy nuclear reaction. The technical scheme is characterized in that the system comprises a desalting tank, a reaction feeding pump, a water preheater, a low-energy nuclear reactor, a buffer tank, a filter, a gas storage tank, a hydrogen internal combustion generator set, a waste heat-recovery heat exchanger and alow-deuterium water condenser, wherein a bottom by-product discharge port of the low-energy nuclear reactor is connected with a sedimentation tank, the sedimentation tank is connected with a screw conveyor, and a reaction circulation pump is disposed between a cold water outlet of the water preheater and a top circulating water inlet of the low-energy nuclear reactor; and the method includes a step of low-energy nuclear reaction, a step of hydrogen fuel gas purification, and a step of hydrogen storage and utilization. The technical scheme has the advantage that a huge amount of energy can begenerated without producing greenhouse gases or polluting the environment.

Owner:任海峰

Spiral gas combustor

The invention relates to a spiral gas combustor. The spiral gas combustor comprises a cylinder, a gas pipe, a primary air distribution pipe and a secondary air distribution pipe, wherein the gas pipe and the primary air distribution pipe are respectively connected with the low-temperature end of the cylinder and are communicated with a combustion chamber in the outer circumferential direction of the circular cross section of the combustion chamber; a spiral angle alpha is formed between the axis of each of the gas pipe and the primary air distribution pipe and the axis of the cylinder; a flame jet nozzle is arranged at the high-temperature end of the cylinder; the secondary air distribution pipe is connected with the cylinder between the gas pipe and the flame jet nozzle at the same spiral angle alpha. According to the spiral gas combustor, the combustion path of a gas is designed into a spiral shape, and a secondary air distribution technology is used, so that the combustion stroke of the gas is greatly prolonged under the condition of fixed volume of the cylinder; the gas is combusted more uniformly; various pollutants caused by incomplete combustion are avoided; the travelling speed of a fuel is improved, so that the combustion is more drastic.

Owner:叶利顺

Grate Group for Garbage Incinerator

ActiveCN103742926BSimple structureCompact structureIncinerator apparatusUltimate tensile strengthMechanical engineering

The invention discloses a grate set for a garbage incinerator. The upper end of the front of a fixed grate segment (1) is provided with a first back movement plane (1b), the front end of the first back movement plane (1b) protrudes upwards to form a first head boss (1a), the upper end of a movable grate segment (2) is provided with a second back movement plane (2b), the top of the front end of the second back movement plane (2b) protrudes upwards to form a second head boss (2a), a driving support (3) is fixed at the bottom of the rear end of the movable grate segment (2), a positioning seat (4) in the rear of the driving support (3) is fixed at the rear end of the fixed grate segment (1), a driving device (5) is mounted on the positioning seat (4), and the front end of the driving device (5) is connected with the driving support (3). The grate set has the advantages that since the fixed grate segment and the movable grate segment are modularized, on one hand, assembly process is simplified, and assembly difficulty is lowered; on the other hand, labor intensity of workers is reduced, and assembly efficiency is improved greatly.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP

Gas heating device and integral annealing method for converter shell

InactiveCN103667623BIncrease pressureIntense heatingManufacturing convertersFurnace typesRoom temperatureFree cooling

The invention relates to a gas heating device of a converter shell. The gas heating device comprises a heating pipe as well as a gas pipe and a compressed air pipe communicated with the heating pipe, wherein a plurality of outward heating holes are formed in the circumference of the heating pipe. The invention further relates to an integral annealing method of the converter shell. The method using the gas heating device of the converter shell to heat the converter shell comprises the following steps: heating the converter shell to 630-650 DEG C, wherein the heating speed is 40-60 DEG C / h at temperature above 300 DEG C; preserving the heat of the converter shell for 3-3.5h at 630-650 DEG C; cooling the converter shell to 300-280 DEG C at a cooling speed of 40-60 DEG C / h; and then, naturally cooling the converter shell to normal temperature. The converter shell heated by the gas heating device is quick to warm, and the operating time and cost can be saved by using the gas heating device to integral annealing of the converter shell.

Owner:PANGANG GRP ENG TECH

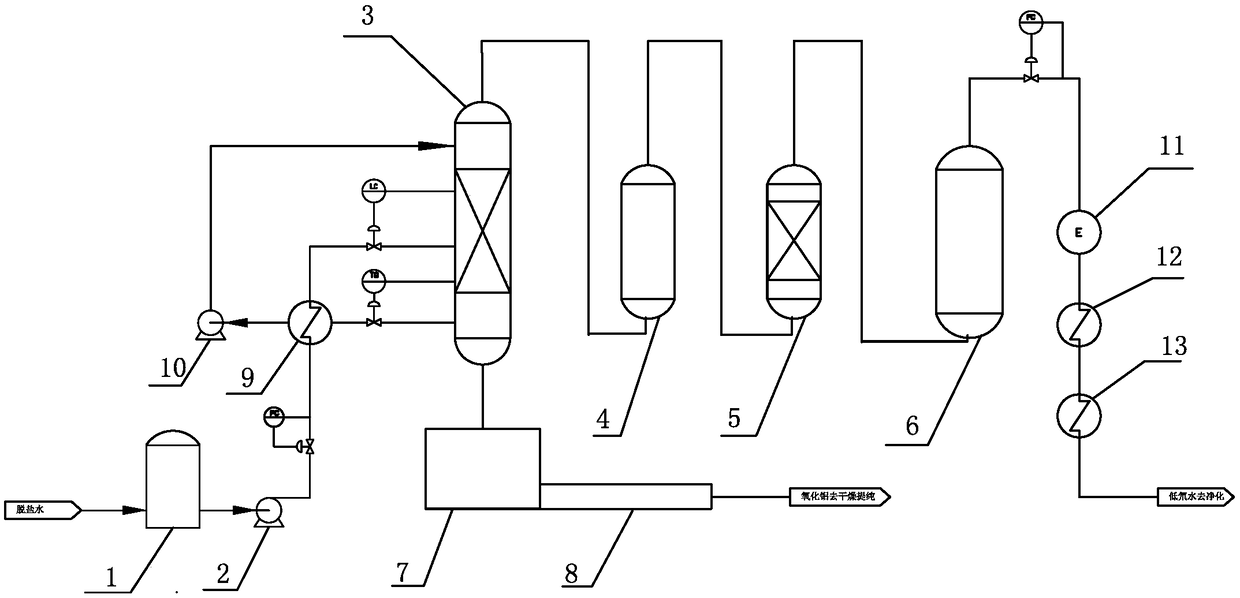

Environment-friendly biogas power generation biogas pretreatment method

InactiveCN111849577AReduce moisture contentReduce gas contentGaseous fuelsWaste based fuelBiogasProcess engineering

The invention provides an environment-friendly biogas pretreatment method for biogas power generation, and relates to the technical field of biogas pretreatment. The environment-friendly biogas pretreatment method for biogas power generation comprises the following step of: S1, wet desulphurization: conveying mixed gas generated by anaerobic fermentation in a biogas digester into a desulphurization tower for desulphurization treatment. According to the environment-friendly biogas power generation biogas pretreatment method, sulfide components in the biogas can be fully removed through wet desulphurization, so that excessive toxic and environment-polluting gas generated by the biogas during actual combustion is effectively reduced; meanwhile, the sulfide solution can be effectively prevented from severely corroding biogas conveying equipment; through dehydration treatment, the moisture content of the biogas can be effectively reduced; meanwhile, large solid particles in the biogas can be conveniently filtered; through filtration of solid impurities, the situation that in the actual conveying process of the biogas, the interior of conveying equipment is not prone to being blocked canbe avoided, and the biogas can be normally conveyed.

Owner:东营市延旭环保科技有限公司

Magnetic field-surrounding oxygen-collecting device, furnace kiln combustion system and magnetic field-surrounding oxygen-collecting combustion method

ActiveCN110015641AIncrease oxygen contentReduce energy consumptionFurnace componentsGaseous fuel burnerMagnetEngineering

The invention relates to a magnetic field-surrounding oxygen-collecting device, a furnace kiln combustion system containing the magnetic field-surrounding oxygen-collecting device and a magnetic field-surrounding oxygen-collecting combustion method. The magnetic field-surrounding oxygen-collecting device comprises a gas inlet pipe section, a vortex pipe section, an oxygen collecting pipe section,a nitrogen-oxide separation pipe section and an oxygen discharge pipe section which are connected in sequence; and the oxygen collecting pipe section is composed of a shell, cylindrical magnets and amagnetic conductive metal blanket, a plurality of cylindrical magnets are arranged at intervals around the inner wall of the shell to form a magnetic field ring, and the magnetic conductive metal blanket is arranged on the side of the magnetic field ring to form magnetic field surrounding. The magnetic field-surrounding oxygen-collecting device and the magnetic field-surrounding oxygen-collectingcombustion method provided by the invention can improve an oxygen content of a combustion-supporting gas flow, have low energy consumption, and can improve combustion efficiency, save fuel, reduce carbon dioxide content and significantly improve thermal efficiency, thereby facilitating promotion.

Owner:WUHAN FUSHIDA ENERGY TECH CO LTD

An energy saving biomass gasifying furnace

The energy saving biomass gasifying furnace has simple structure, convenient operation and less environmental pollution, and is used to treat various kinds of garbage and waste into fuel oil, fuel gas or other energy source material. Technologically, the energy saving biomass gasifying furnace includes a furnace body with material feeding port, furnace hearth, slag hole and furnace door; spiral smoke box on the furnace body; electrically driven material distributor, steam pipe, secondary burning pipe and air intake pipe inside the furnace hearth; electric valves, exhauster, and other parts.

Owner:SHENZHEN JUNENG BIOMASS GASIFICATION TECH

Environmental protection, energy sources recovery type garbage treatment equipment

A garbage processing device of energy recovery type consists of furnace; fuel has recovering unit and smoke purification unit. It is featured as forming fuel gas recovering unit by condenser, oil-gas separator, air cabinet, oil storage pool; connecting condenser to fuel gas port and oil-gas separator; setting spray quencher and sprayer in smoke purification unit, arranging smoke buffer box at tail end of smoke purification unit and connecting said box to chimney through draught fan.

Owner:SHENZHEN JUNENG BIOMASS GASIFICATION TECH

Fuse and exploder adopting same

ActiveCN102030599ABurning violentlyEasy to controlBlastingFuse detonationCarbon nanotubeOrganic chemistry

The invention relates to a fuse. The fuse comprises at least one carbon nanotube linear structure, the carbon nanotube linear structure comprises a plurality of carbon nanotubes, the fuse further comprises a material, which is easy to oxidize, coated on the surface of the carbon nanotube linear structure, when one end of the fuse is ignited, the material which is easy to oxide can continuously carry out oxidation along the axial direction of the carbon nanotube linear structure. The invention further provides the exploder adopting the fuse.

Owner:TSINGHUA UNIV +1

Ventilation tower-type lower air-inlet gas cooker

InactiveCN101556058BReduce resistanceSufficient oxygen supplyDomestic stoves or rangesStoves/ranges topsCombustorEngineering

Owner:陈洪巨

Blast furnace pulverized coal combustion improver as well as preparation method and application thereof

PendingCN113845955APromote combustionImprove combustion efficiencySolid fuelsAmmonium metavanadateSiderite

The invention discloses a blast furnace pulverized coal combustion improver as well as a preparation method and application thereof. The combustion improver is prepared from the following raw materials in percentage by weight: 30-40% of modified siderite, 30-40% of iron oxide red, 5-15% of manganese dioxide, 5-15% of dust remover, 5-15% of ammonium metavanadate and 1-4% of aluminum powder. The selected raw materials are common and wide in source, combustion of the pulverized coal can be promoted from different stages through reasonable matching, the comprehensive combustion efficiency of the pulverized coal is improved, the ignition point of the pulverized coal can be reduced by 50-60 DEG C, the combustion-supporting efficiency value reaches up to about 17%, and the application prospect is wide.

Owner:云南科兴环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com