Centralized combustion device applied to internal heating type rotary furnace

A technology of a combustion device and a rotary furnace, which is applied in the field of boilers, can solve problems such as endangering physical and mental health, disease transmission, space pollution, etc., and achieve the effect of widespread use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

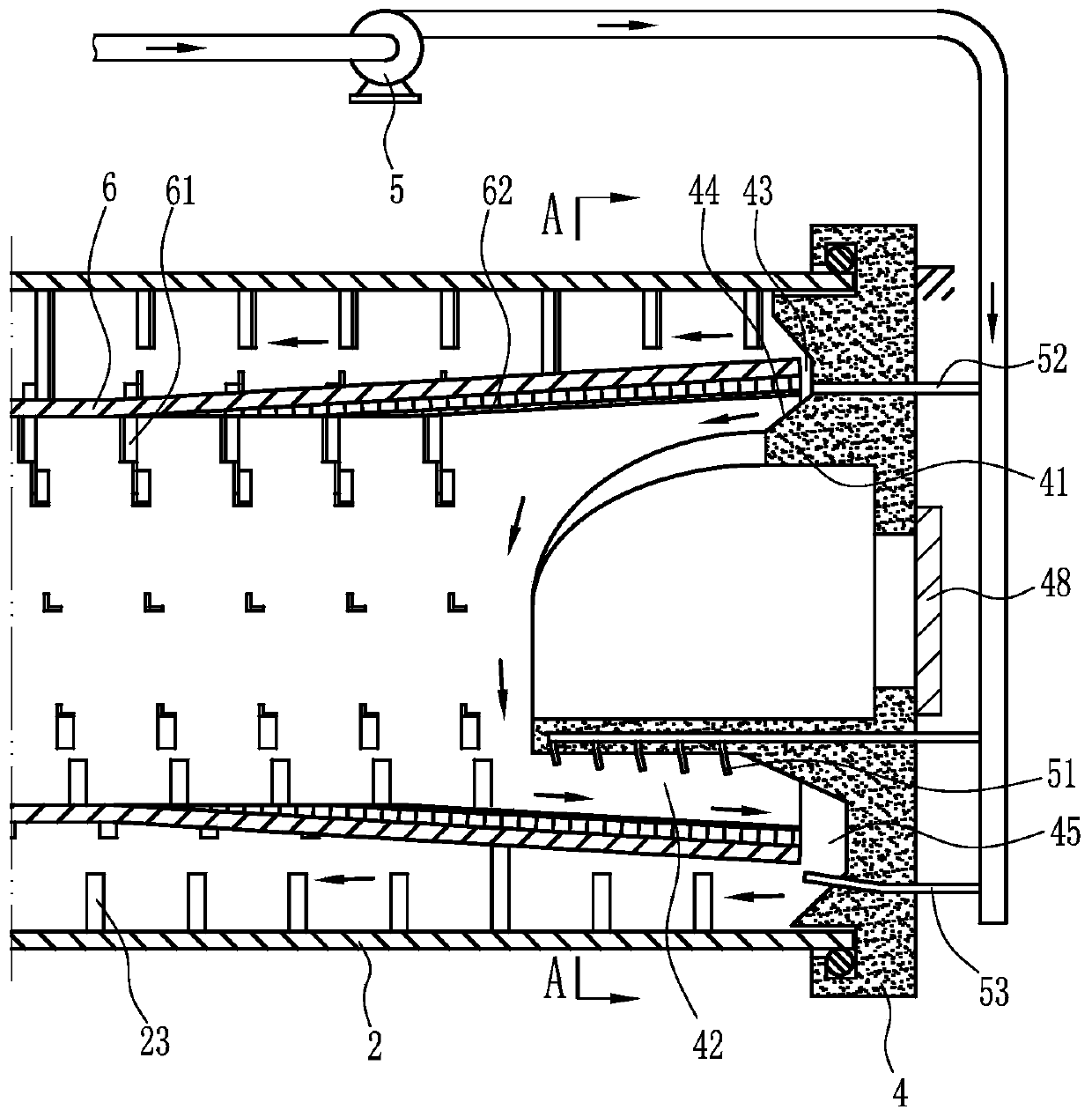

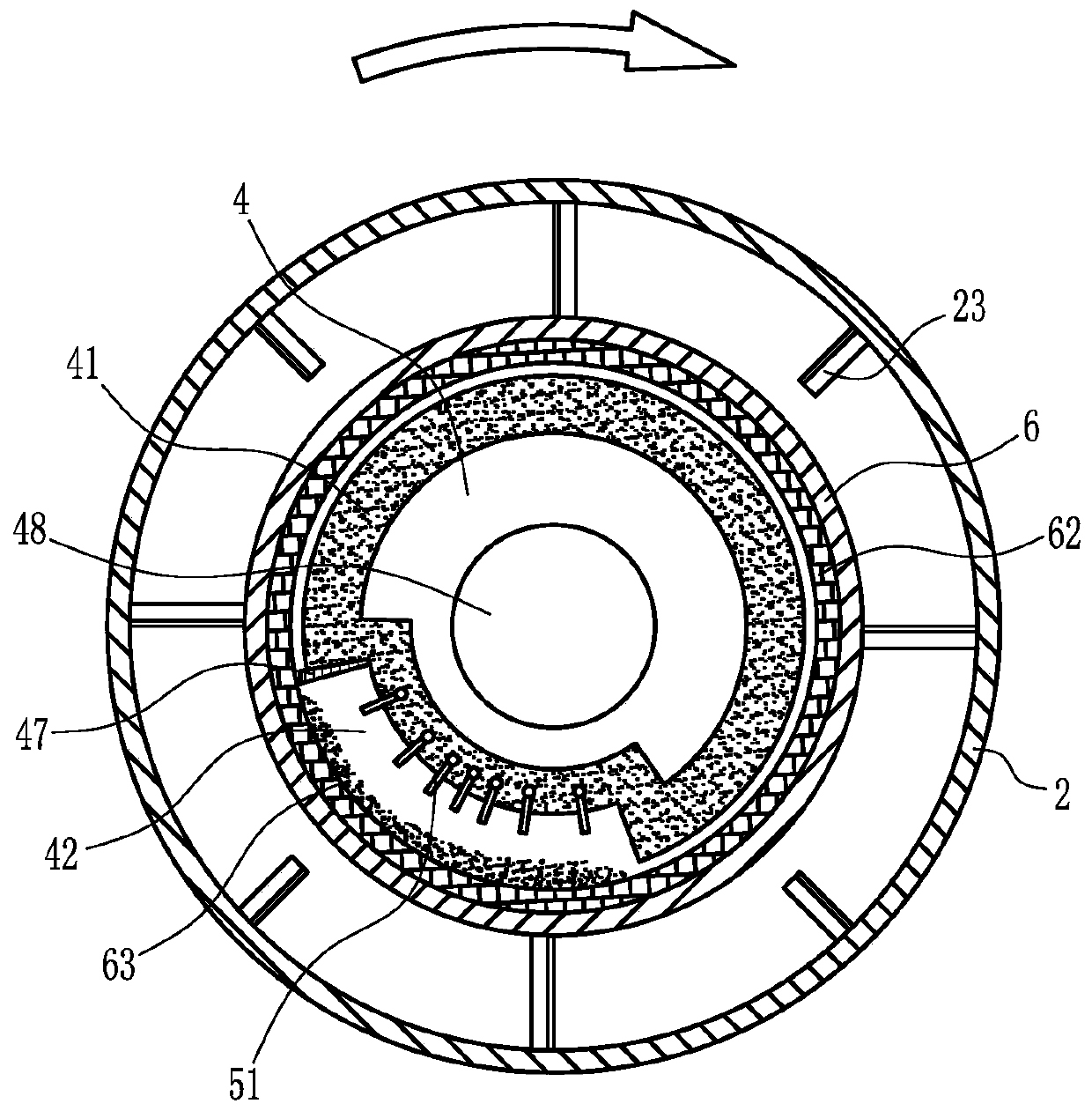

[0024] Embodiment one: if figure 1 and figure 2 As shown, the gathering combustion device for internal heating rotary furnace, this embodiment can burn and utilize raw materials containing mineral components such as lignite and oily soil, and the specific structure and principle of this embodiment will be described with oily soil.

[0025] This embodiment includes a furnace outer cylinder 2 and a furnace inner cylinder 6 which are rotated synchronously and arranged concentrically. The furnace outer cylinder 2 can be rotatably installed by a supporting wheel device and driven to rotate by an outer cylinder driving device. The end of the outer cylinder 2 of the furnace is dynamically sealed and connected with a gathering combustion end seat 4, and the dynamic sealing connection is a known technology, and will not be repeated here. The other end of the furnace outer cylinder 2 and the furnace inner cylinder 6 is also sealed and connected to the smoke exhaust port, slag discharg...

Embodiment 2

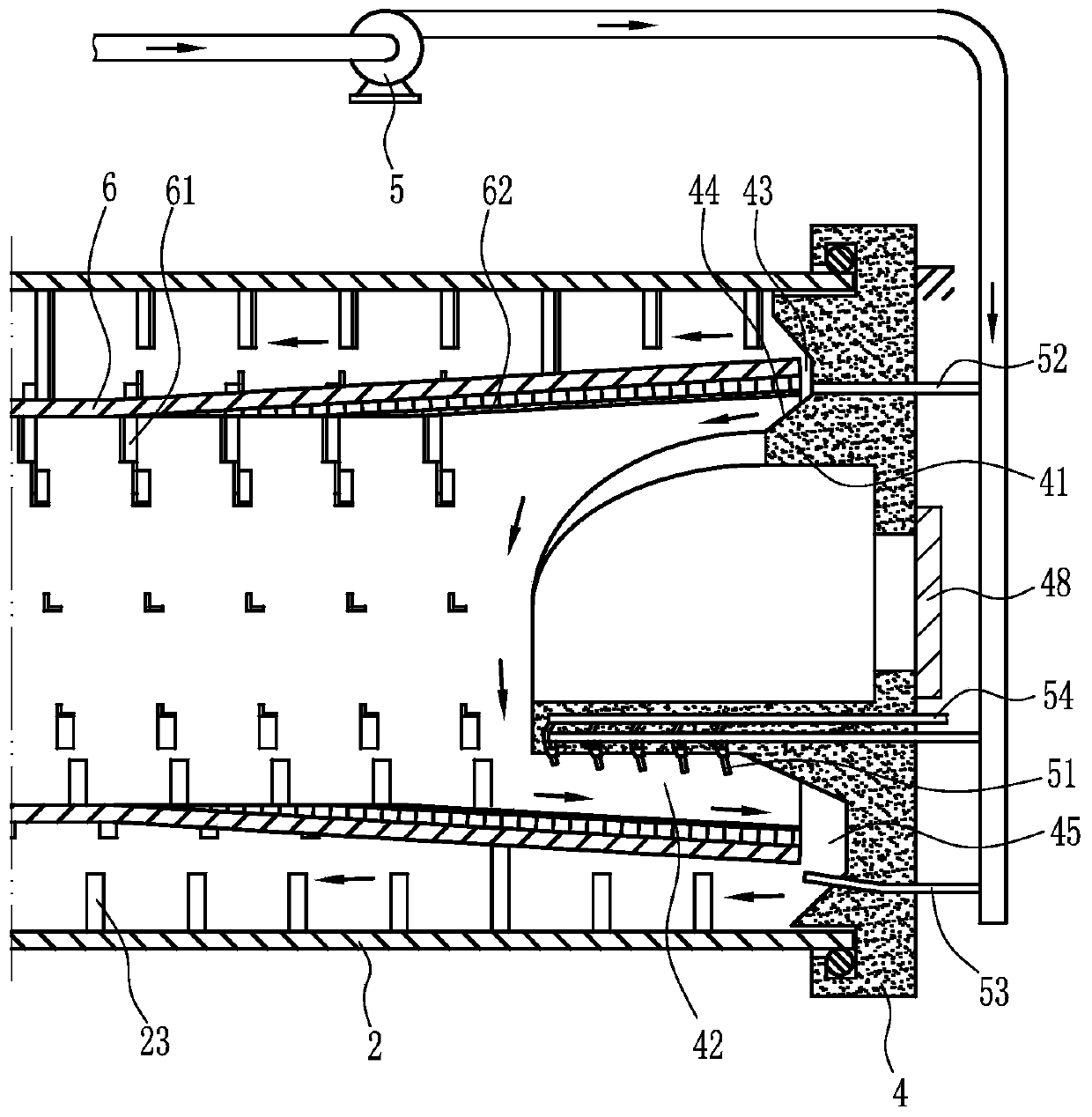

[0036] Embodiment two: if image 3 As shown, this embodiment can be used for industrial tail waste, such as boiler tail dust, organic sludge and other raw materials containing certain combustibles, for combustion and utilization. This embodiment uses the combustion of organic sludge to illustrate the specific structural principles.

[0037] The structure difference between this embodiment and Embodiment 1 is that the combustion-supporting air supply pipe 51 is connected with a natural gas supply device, and the known technology of supplying natural gas by the natural gas supply device will not be repeated here and only shown in the figure Natural gas supply pipe 54. This embodiment shows that the natural gas supply pipe 54 communicates with each of the combustion air supply pipes 51 through the branch pipes corresponding to the combustion air supply pipes 51 one by one, forming a mixed gas near the nozzle of the combustion air supply pipe 51 .

[0038] In this embodiment, th...

Embodiment 3

[0040] Embodiment three: as Figure 4 As shown, this embodiment can be used for the combustion and utilization of medical waste and even domestic waste. The structure of this embodiment when burning medical waste is the same as that of Embodiment 1, but its working principle is: the outer cylinder of the furnace 2 drives the inner cylinder of the furnace The cylinder 6 rotates synchronously, the combustion-supporting air supply pipe 51 continues to supply air, the isolation air pipe 52 keeps the air curtain isolated, and the furnace inner cylinder 6 forms a stable airflow to the furnace outer cylinder 2; medical waste is supplied to the The inner tube 6 of the furnace is gradually conveyed to the gathering and burning end seat 4 under the action of the inner tube pushing device 61. During this process, the medical waste is evenly heated by turning over the material, and part of the organic components can be cracked and gasified , the medical waste finally arrives at the gather...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com