Functional composite wire based on carbon fiber reinforced nylon and electrothermal drive element made of functional composite wire

A composite wire and electrothermal drive technology, applied in the field of composite materials, can solve the problems that the functionality has not been widely developed and applied, and achieve the effect of easy maintenance and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

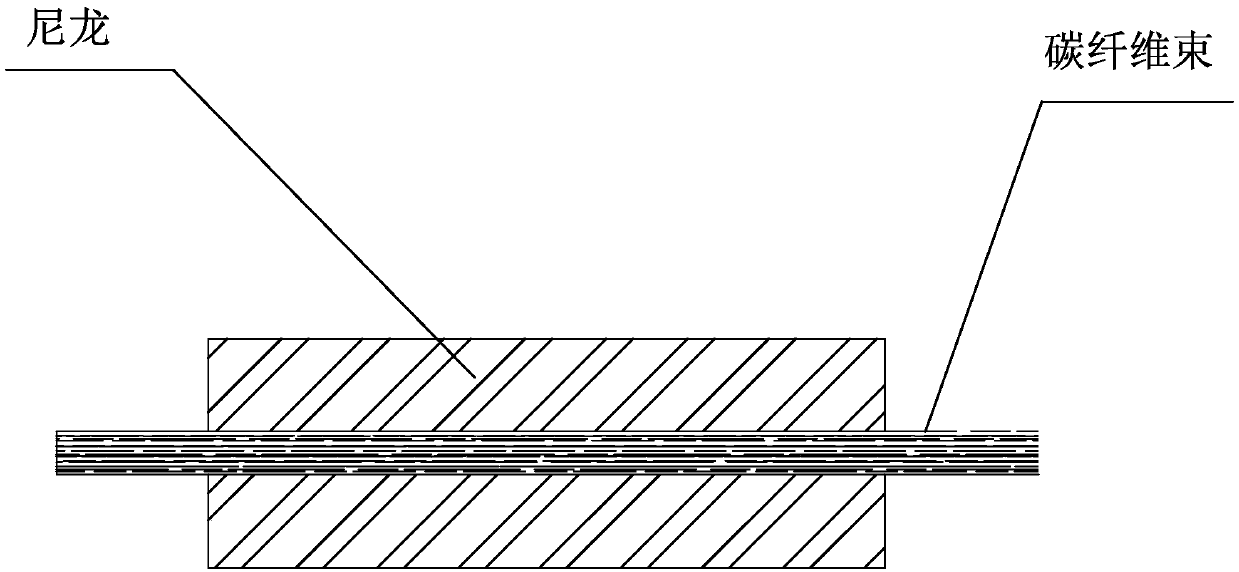

[0016] At 230°C-280°C, it is extruded by an extruder, and 0.5mm thick nylon is wrapped on a 0.1mm diameter carbon fiber bundle, and the carbon fibers are exposed at both ends. The extruded material is rapidly cooled in water or other media to prevent crystallization. Rewind the material for use.

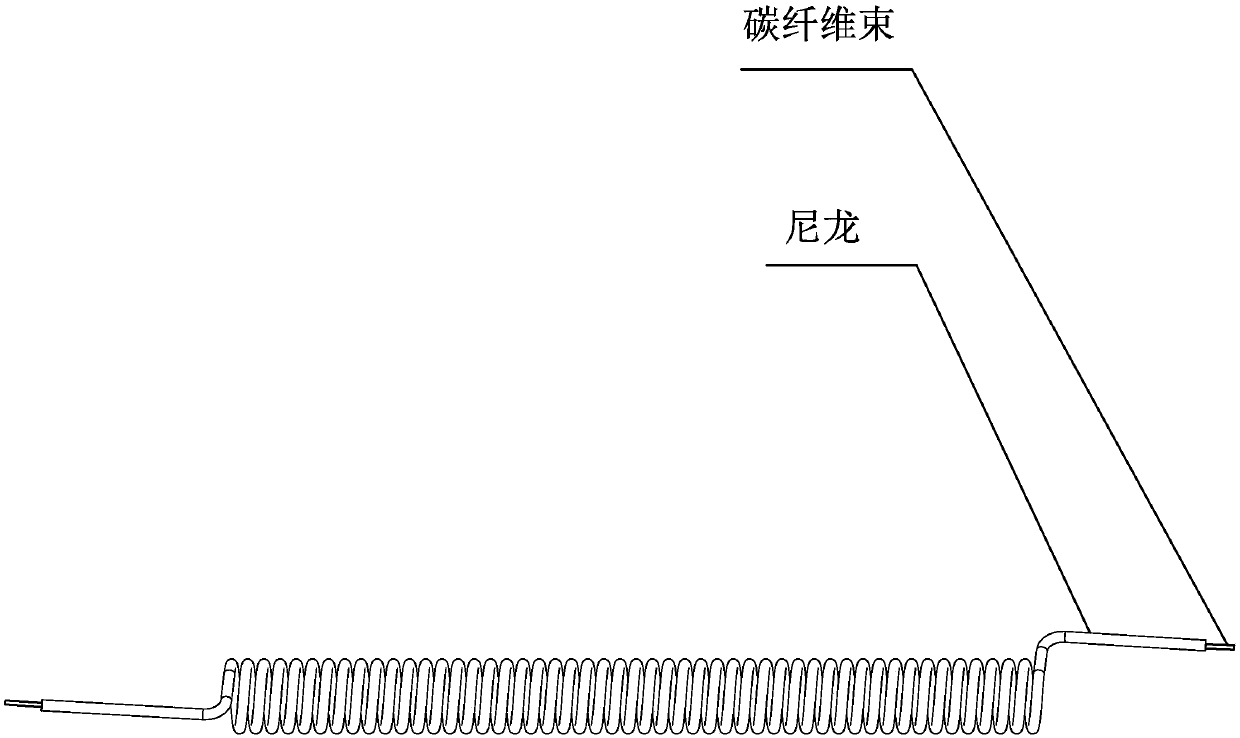

[0017] Then hang one or more ends of the material on the free end of the motor rotor, and add a counterweight of 0.1-3kg to the other end. The free end of the motor rotor faces the ground, and the counterweight can only move up and down, not rotating or moving. Run the motor to drive the material to twist, and with the gradual accumulation of stress, the material is twisted into a spring shape.

[0018] Then the material is heated at 60-200°C to fix the shape.

[0019] Electrothermal driving process: connect the carbon fiber exposed at both ends of the material to the power source, apply a DC voltage of 0.1-30V, and heat the carbon fiber as a heating wire to 60-180°C. When the "spring" i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com