Steel ladle working lining capable of controlling molten steel slag entrapment

A technology for working lining and ladle, applied in manufacturing tools, metal processing equipment, casting melt containers, etc., can solve the problems of harsh materials and high preparation costs, and achieve the effect of improving steel quality, high practicability, and improving green energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

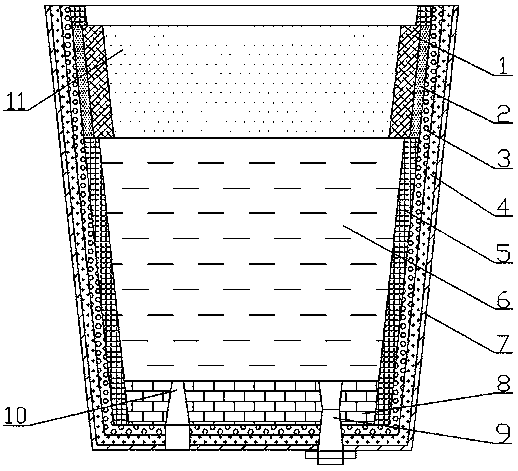

[0023] A ladle working lining for controlling slag entrapment of molten steel. Such as figure 1 As shown, the ladle working lining includes a slag line brick (1), an electromagnetic coil (2), a solid oxide fuel cell layer (3), an insulation layer (4), a wall brick (5), a seat brick layer (8) and Ladle shell (7). The ladle shell (7) is composed of a wall shell and a bottom shell; a thermal insulation layer (4) is built on the inner wall of the ladle shell (7), and a solid state is provided on the inner wall of the thermal insulation layer (4). Oxide fuel cell layer (3).

[0024] Such as figure 1 As shown, an electromagnetic coil (2) is provided on the inner wall of the solid oxide fuel cell layer (3) above the slag line of the clad wall, and a slag line brick (1) is built close to the inner wall of the electromagnetic coil (2). ); The positive and negative electrodes of the solid oxide fuel cell layer (3) are respectively connected to the electromagnetic coil (2) through their...

Embodiment 2

[0034] A ladle working lining for controlling slag entrapment of molten steel. Except for the following technical parameters, the rest are the same as in Example 1:

[0035] The solid oxide fuel cell layer (3) is tubular; the thickness of the solid oxide fuel cell layer (3) is 0.4 to 0.7 times the thickness of the wall brick (5); the solid oxide fuel cell The electrolyte of layer (3) is fluorite structure doped cerium oxide or silicon carbide; the cathode material of the solid oxide fuel cell layer (3) is ferrite-based oxide, porous platinum, and praseodymium oxide doped One of zirconia; the anode material of the solid oxide fuel cell layer (3) is porous platinum.

[0036] The thickness of the electromagnetic coil (2) is 0.3 to 0.4 times the thickness of the wall-clad brick (5); the number of turns of the electromagnetic coil (2) is 2000 to 6000 turns; the thickness of the electromagnetic coil (2) The electromagnetic wire is a fine wire of glass film, and the diameter of the elec...

Embodiment 3

[0042] A ladle working lining for controlling slag entrapment of molten steel. Except for the following technical parameters, the rest are the same as in Example 1:

[0043] The solid oxide fuel cell layer (3) is tubular; the thickness of the solid oxide fuel cell layer (3) is 0.5 to 0.8 times the thickness of the wall brick (5); the solid oxide fuel cell The electrolyte of layer (3) is LaGaO doped with perovskite structure 3 The cathode material of the solid oxide fuel cell layer (3) is a cobaltate-based oxide; the anode material of the solid oxide fuel cell layer (3) is porous platinum.

[0044] The thickness of the electromagnetic coil (2) is 0.4 to 0.5 times the thickness of the wall-clad brick (5); the number of turns of the electromagnetic coil (2) is 4000 to 8000; the thickness of the electromagnetic coil (2) The electromagnetic wire is a high-temperature insulated wire or a carbon fiber heating wire, and the diameter of the electromagnetic wire is 2.0 to 3.2 mm.

[0045] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number of turns | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Number of turns | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com