Patents

Literature

32results about How to "Improve steel quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

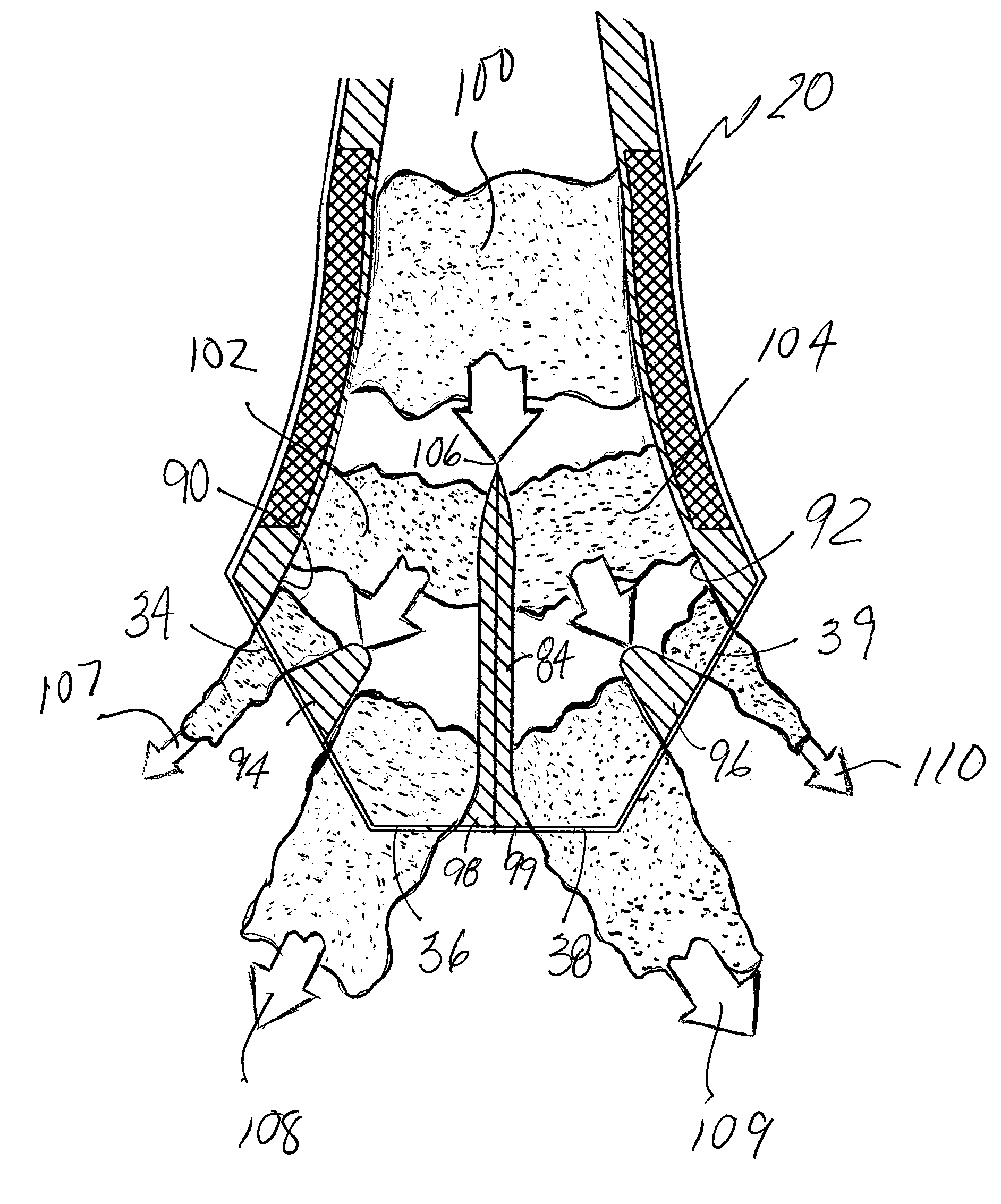

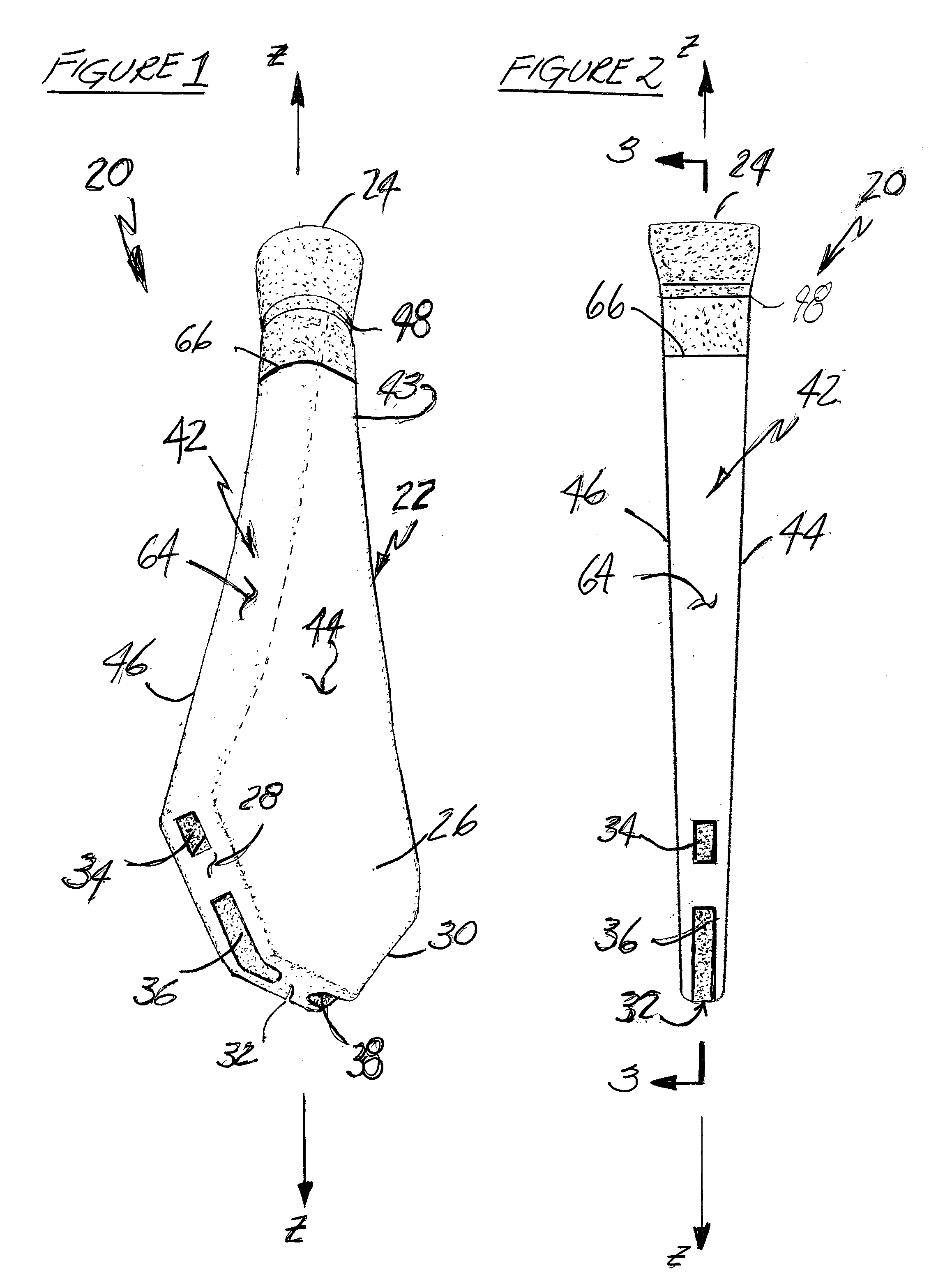

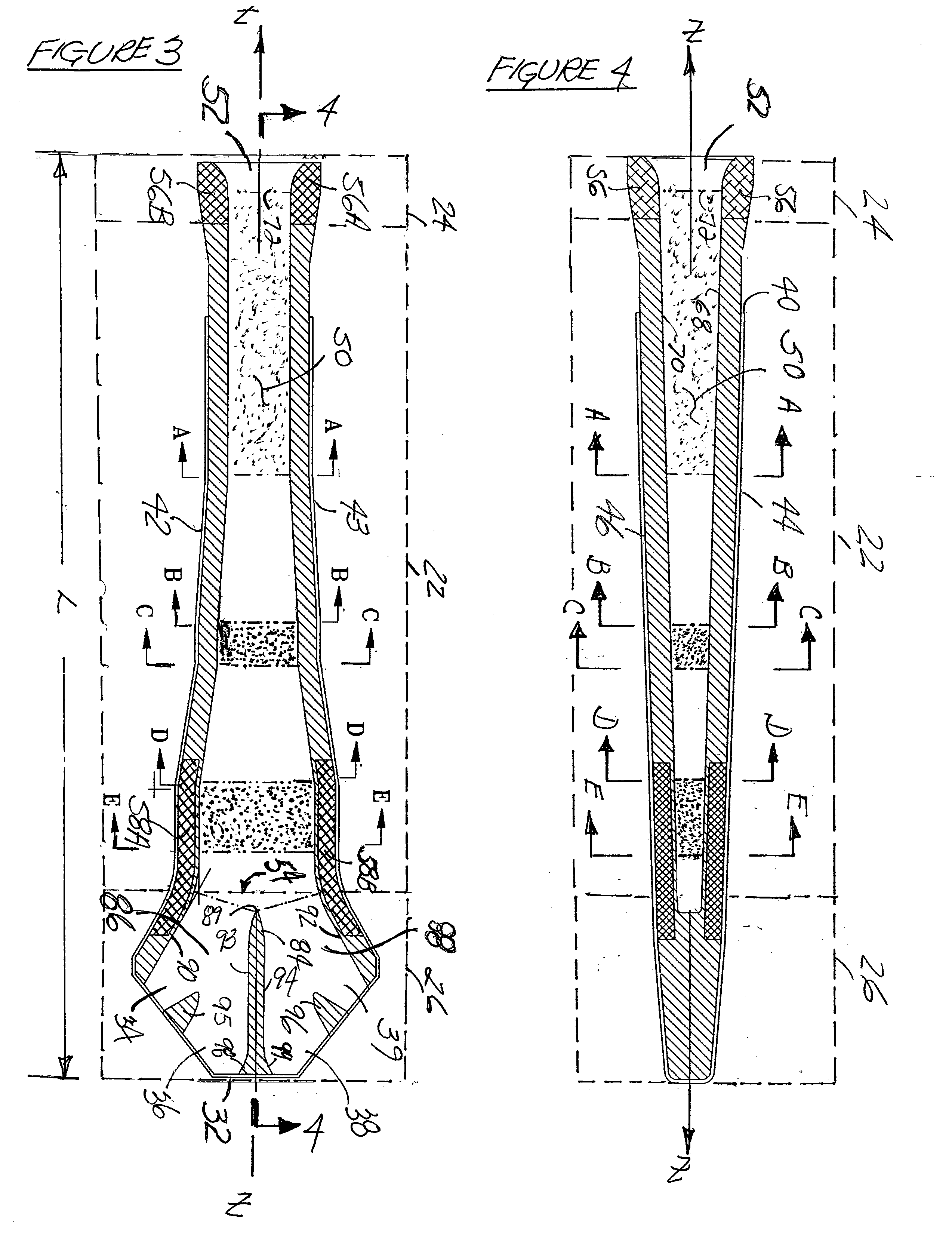

Submerged entry nozzle

InactiveUS20060243760A1Increase flow dynamicsMinimizing steel flow turbulenceMelt-holding vesselsMolten metal pouring equipmentsMetallurgyThin slab

A nozzle for transferring molten steel in a thin slab continuous casting machine from the tundish to the mold which provides at least two areas of stream compression below the major changes in section required to transition from the entry diameter to the rectangular submerged portion of the nozzle.

Owner:NUCOR CORP

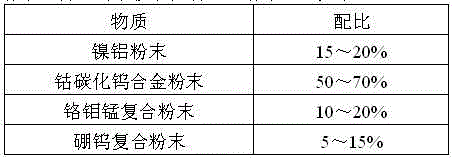

Alloy ultrasonic-spraying strengthening method for roll pass surface of finishing roll of section steel and spraying material

ActiveCN104611664ASimple and efficient operationEasy to operateMolten spray coatingTungstenAluminium

The invention discloses an alloy ultrasonic-spraying strengthening method for a roll pass surface of a finishing roll of section steel and a spraying material, and belongs to the technical field of material surface strengthening. Nano-scaled carbide alloy powder is selected and used in the method and includes 15-20% of nickel-aluminum powder, 50-70% of cobalt-tungsten carbide alloy powder, 10-20% of chrome-molybdenum-manganese composite powder and 5-15% of boron-tungsten composite powder. The method comprises the following steps: firstly, priming on the finishing roll of the section steel with the nickel-aluminum powder by 0.02 mm; secondly, fusing the cobalt-tungsten carbide alloy powder, the chrome-molybdenum-manganese composite powder and the boron-tungsten composite powder, and uniformly spraying a fused material to the surface of the roll, wherein the thickness of a spraying layer is 0.15-0.20 mm, a distance between a spray gun and a sprayed surface is 160-180 mm, and an included angle between the spray gun and the sprayed surface is not more than 90 degrees. The method adopts an alloy ultrasonic-spraying strengthening mode, so that the high-temperature resistance and the wear resistance of the roll pass surface are improved, the online time of the roll is prolonged, the total amount of steel is increased by more than one time, and the service life of the roll is prolonged by more than two times.

Owner:ANHUI HENGYI HARD FACE ENG CO LTD

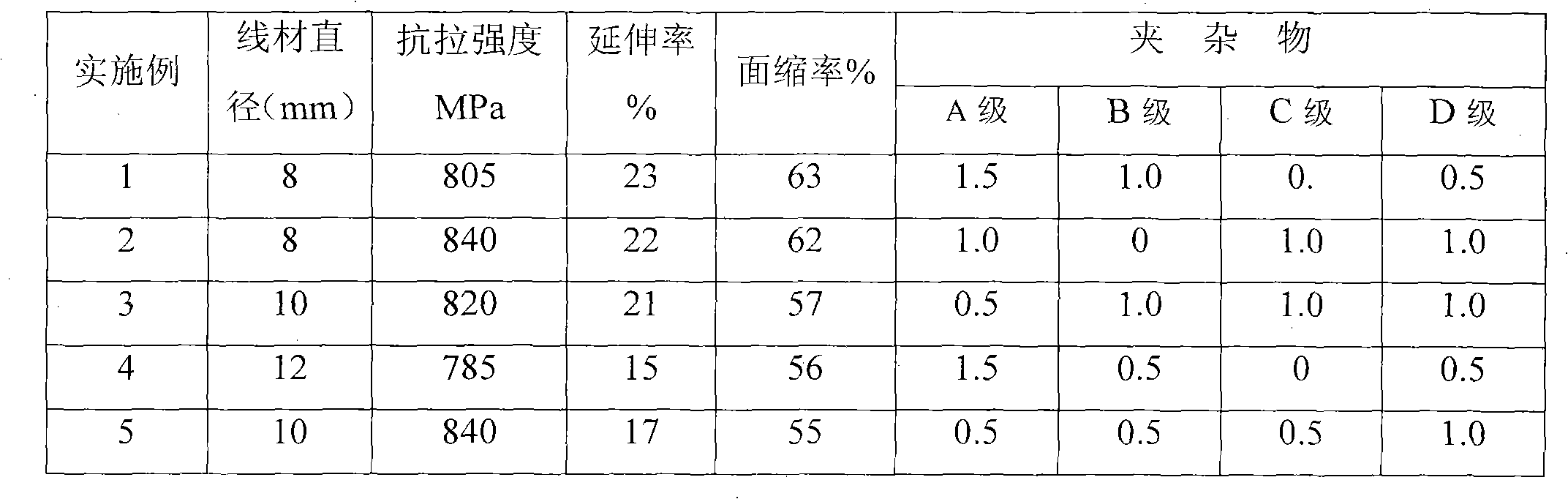

Drahtstahl for high strength fastening piece and production method thereof

InactiveCN101787491AWith energy savingReduce manufacturing costMetal rolling arrangementsWire rodHigh intensity

The invention relates to a drahtstahl for a fastening piece and a production method thereof, and the drahtstahl comprises the following components by weight percent: 0.39-0.48 % of C, 0.15-0.35% of Si, 0.30-0.90% of Mn, 0.60-1.20% of Cr, 0.010-0.07% of Als, less than or equal to 0.035% of P, less than or equal to 0.035% of S and the balance Fe and unavoidable impurity; and the production method comprises the following steps: smelting with a clean steel process and casting into a blank, and adding Si-Ca line in the refining; heating the continuous casting to 980-1,080 DEG C; rough rolling: controlling the deflection to be 70-80%; intermediate rolling: controlling the deflection to be 80-90%; pre-precision rolling: controlling the deflection to be 65-75%; water-cooling until the temperature is cooled to be 1,000-1,020 DEG C; precision rolling: controlling the deflection to be 60-90%; water-cooling for the second time until the temperature is cooled to be 800-900 DEG C; spinning; cooling to phase change initial temperature, namely the range from Ar3 to 50 DEG C higher than Ar3 by adopting an aerial fog mixed method; and continually cooling until the temperature is cooled to be 400-500 DEG C and naturally cooling to environment temperature. The invention can be drawn directly, has good cold deformation and is not easy to crack.

Owner:武钢集团有限公司

Method for smelting phosphorus-containing ultra-low carbon steel

The invention provides a method for smelting phosphorus-containing ultra-low carbon steel. The method comprises the first step of pretreating molten iron, specifically, blowing desulphurizing powder into the molten iron to enable the S content to be less than or equal to 0.003wt%, the second step of conducting deoxygenation and decarburization in a converter, blowing oxygen for 15-18 min, adding slag making materials, conducting slag-stopping and steel tapping when the content of C in the molten steel is less than or equal to 0.06%, the content of O reaches 0.05-0.09%, and the temperature of the molten steel in the converter reaches 1680-1720 DEG C, and adding 2-5 kg / t lime through an argon station, the third step of carrying out ladle furnace (LF) refining, specifically, adding slag former into a steel ladle, carrying out bottom argon blowing and stirring, transferring the molten steel to carry out RH vacuum refining, decarburization and denitrification when the temperature of the molten steel reaches 1630-1650 DEG C, carrying out alloying in batches when the content of C in the steel is less than or equal to 0.0050wt%, carrying out still standing for 15-25 min and then continuous casting when the content of compositions and temperature reach the target content and temperature, blowing argon into spaces between plates at a long nozzle, a stopper rod, an upper nozzle and a submerged nozzle when pouring is conducted on a tundish, and adding carbon-free covering agents to protect pouring. By means of the method, the purity degree of the molten steel and the castability of the steel can be improved, nozzle clogging is effectively controlled, the smelting production efficiency and the steel quality are improved, consumption of spare parts is reduced, and the cost of per ton of steel is lowered.

Owner:ANGANG STEEL CO LTD

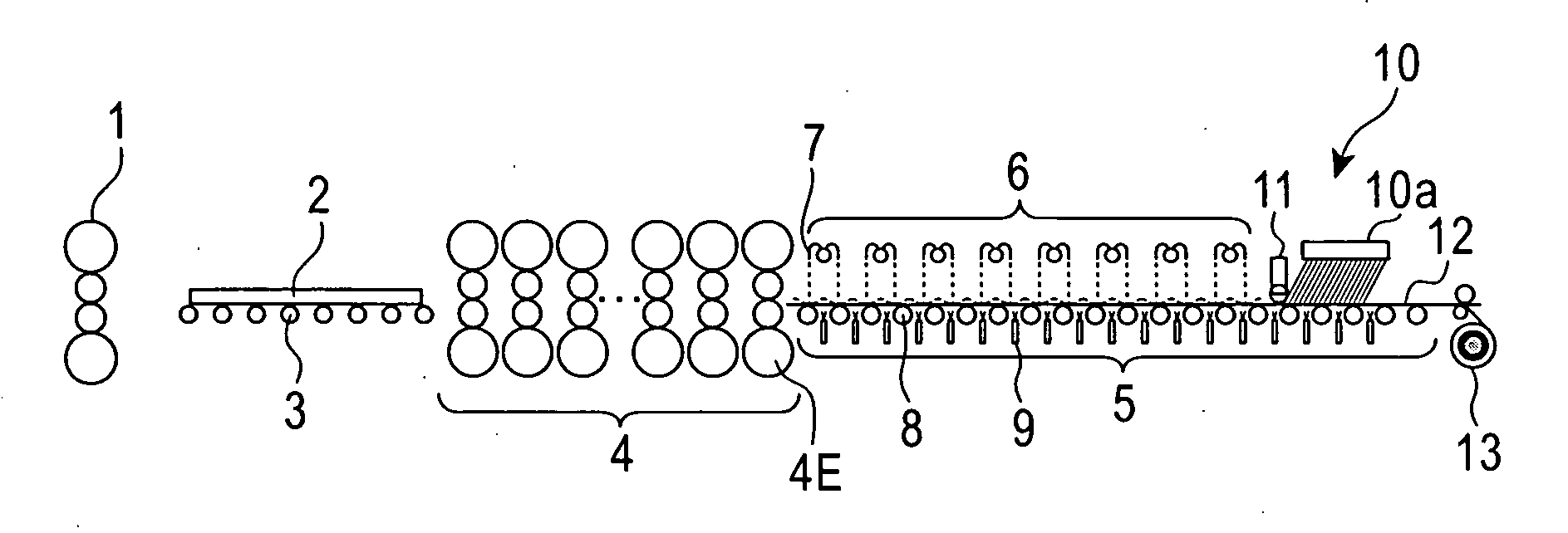

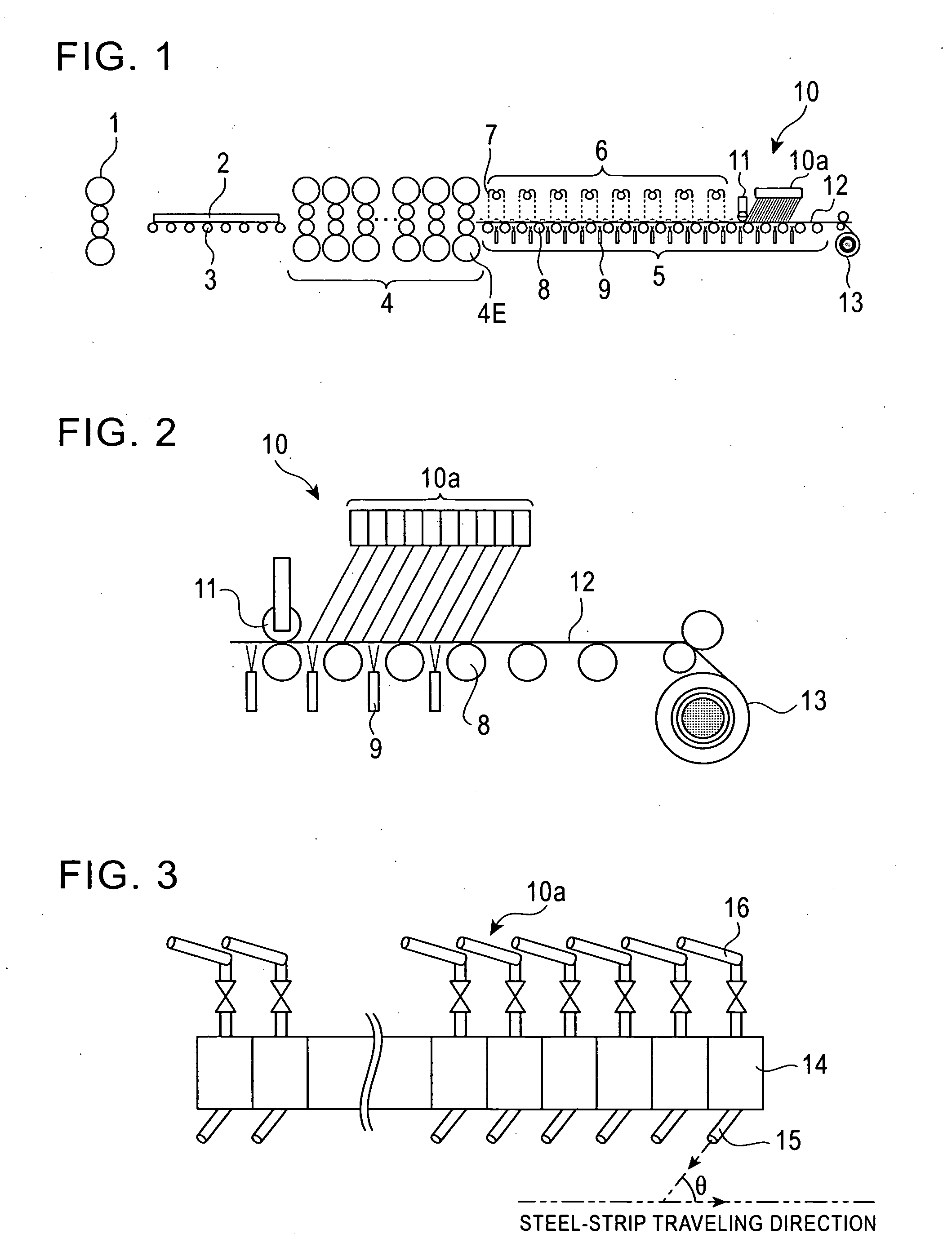

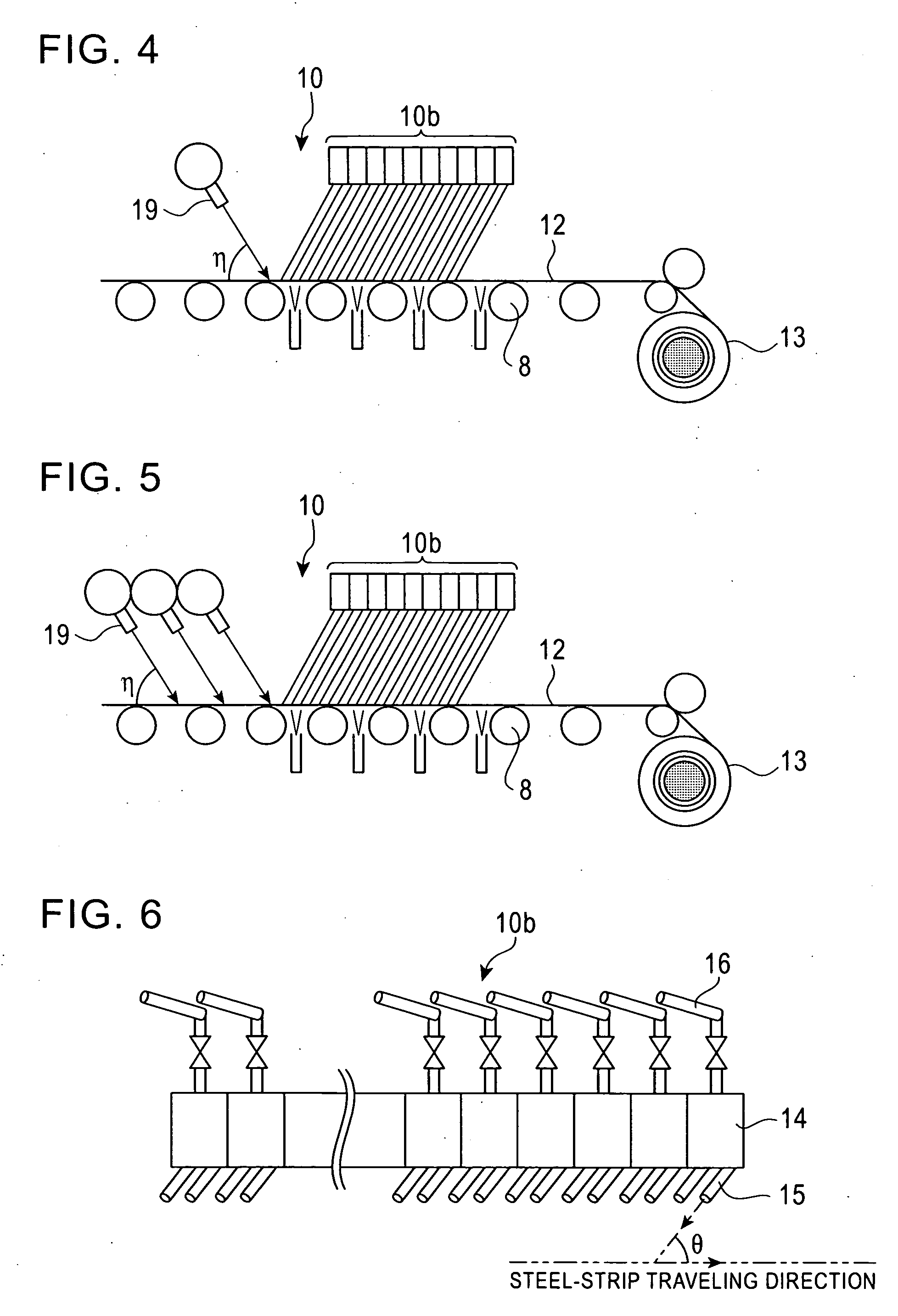

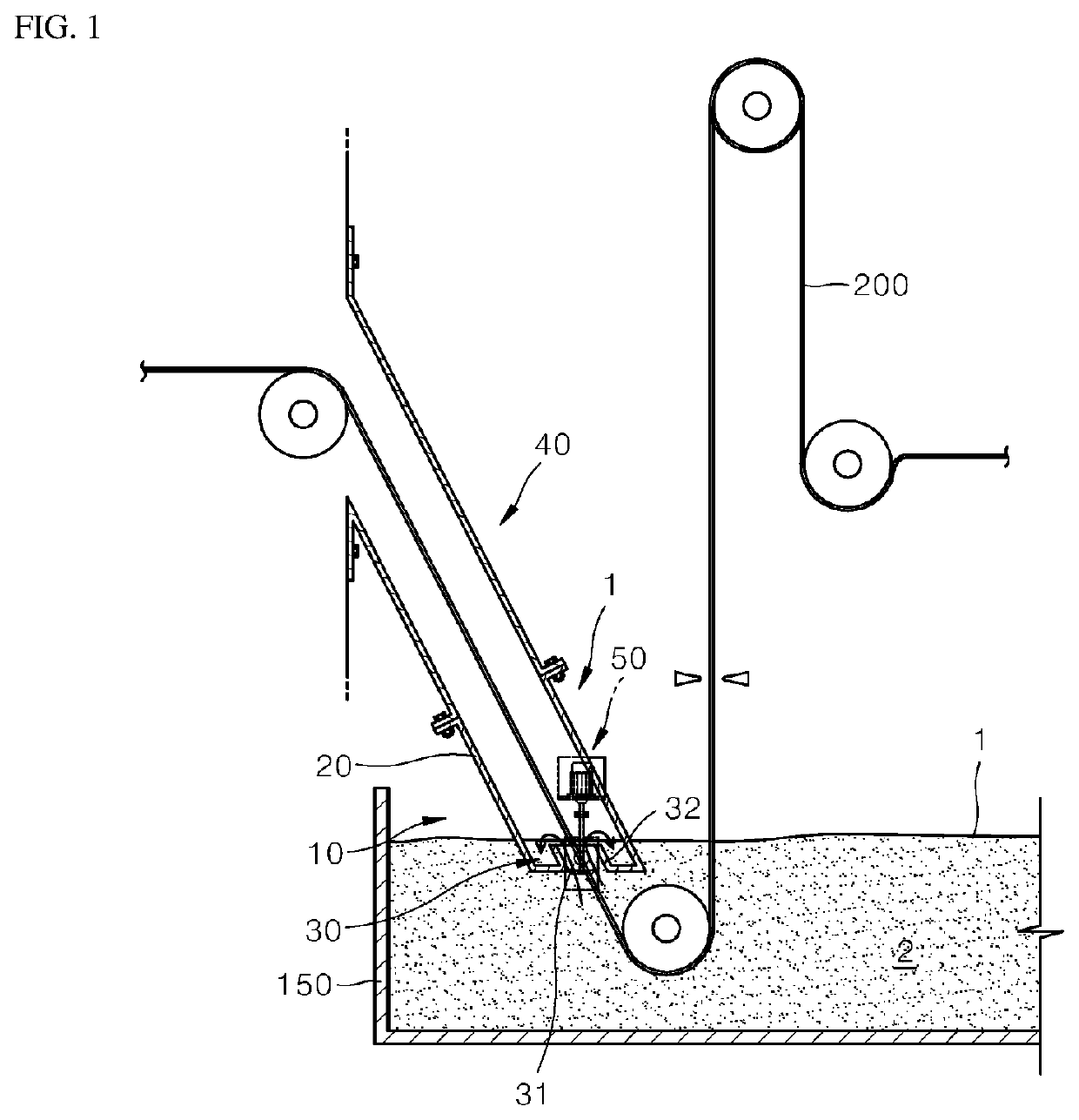

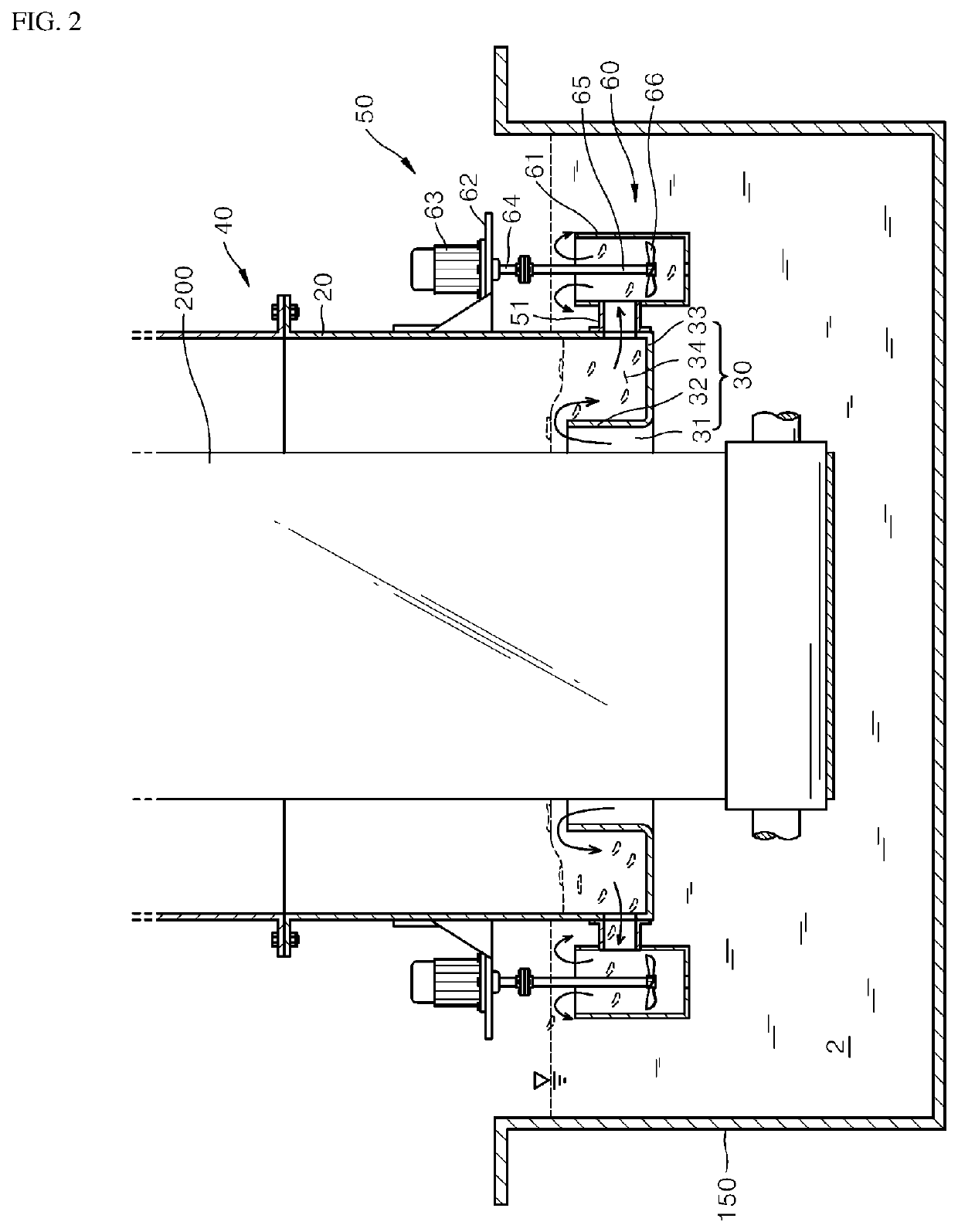

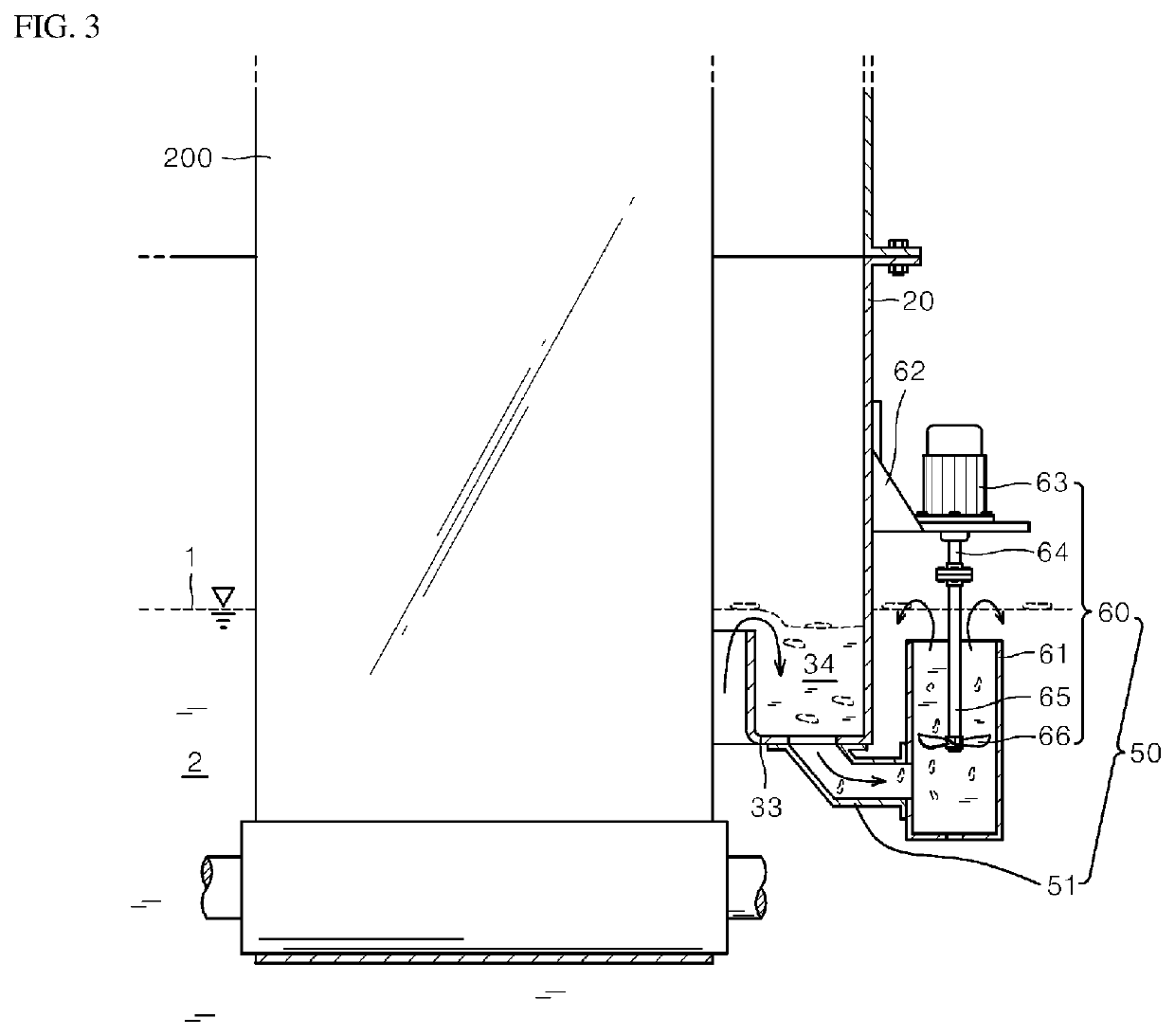

Hot-Strip Cooling Device and Cooling Method

ActiveUS20090019907A1Improve steel qualityHigh yieldBlast furnace detailsCooling devicesEngineeringSteel belt

A hot-strip cooling device and a cooling method are provided wherein uniform cooling of a hot-rolled steel strip using coolant is possible from the leading end to the trailing end of the steel strip. A cooling device (10) includes a plurality of round nozzles (15) disposed obliquely in such a manner as to eject rod-like flows of coolant at an ejection angle θ toward the upstream side in a direction in which a steel strip (12) travels, and a pinch roll (11) disposed on the upstream side with respect to the round nozzles (15) and configured to pinch the steel strip (12) in combination with a roller table (8).

Owner:JFE STEEL CORP

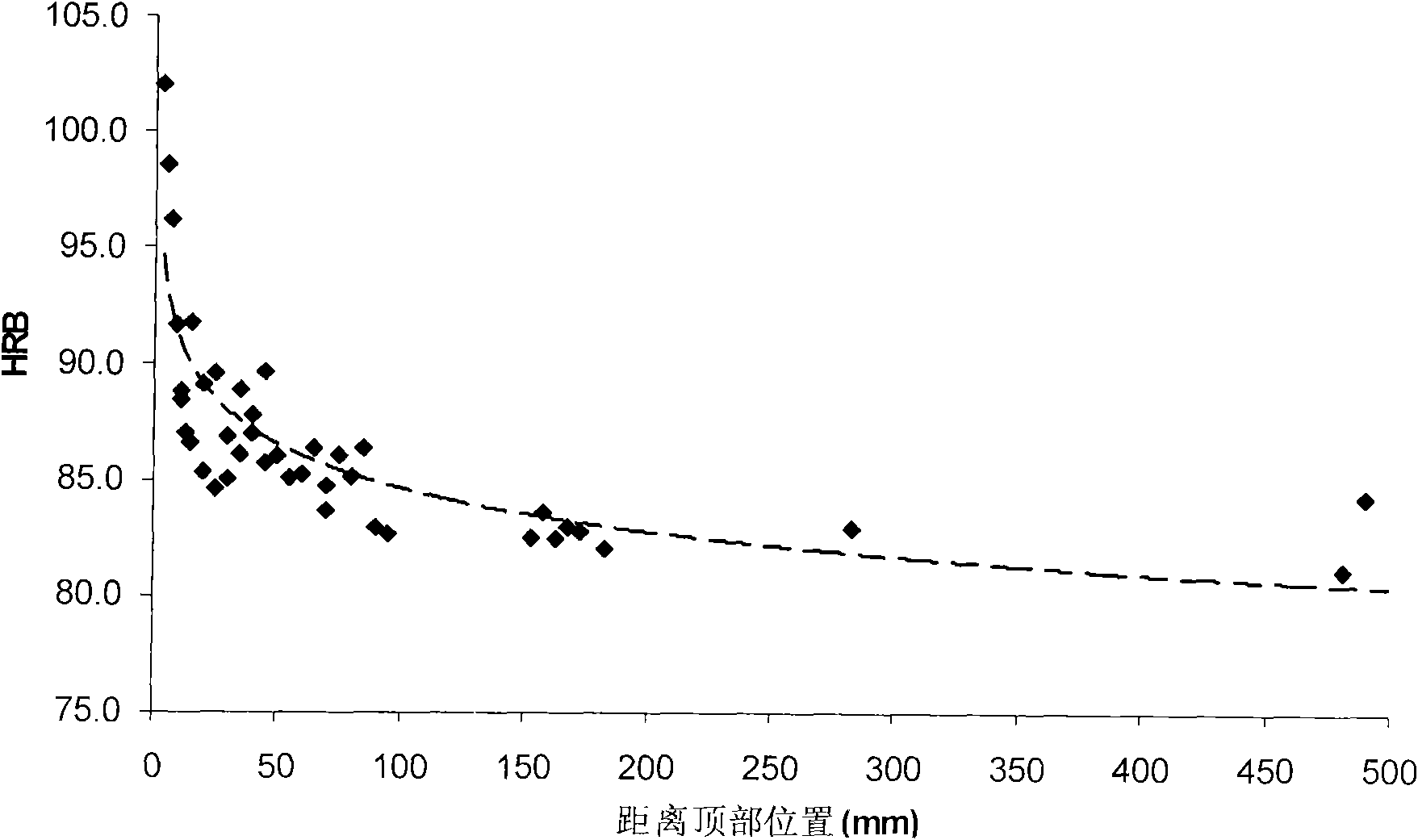

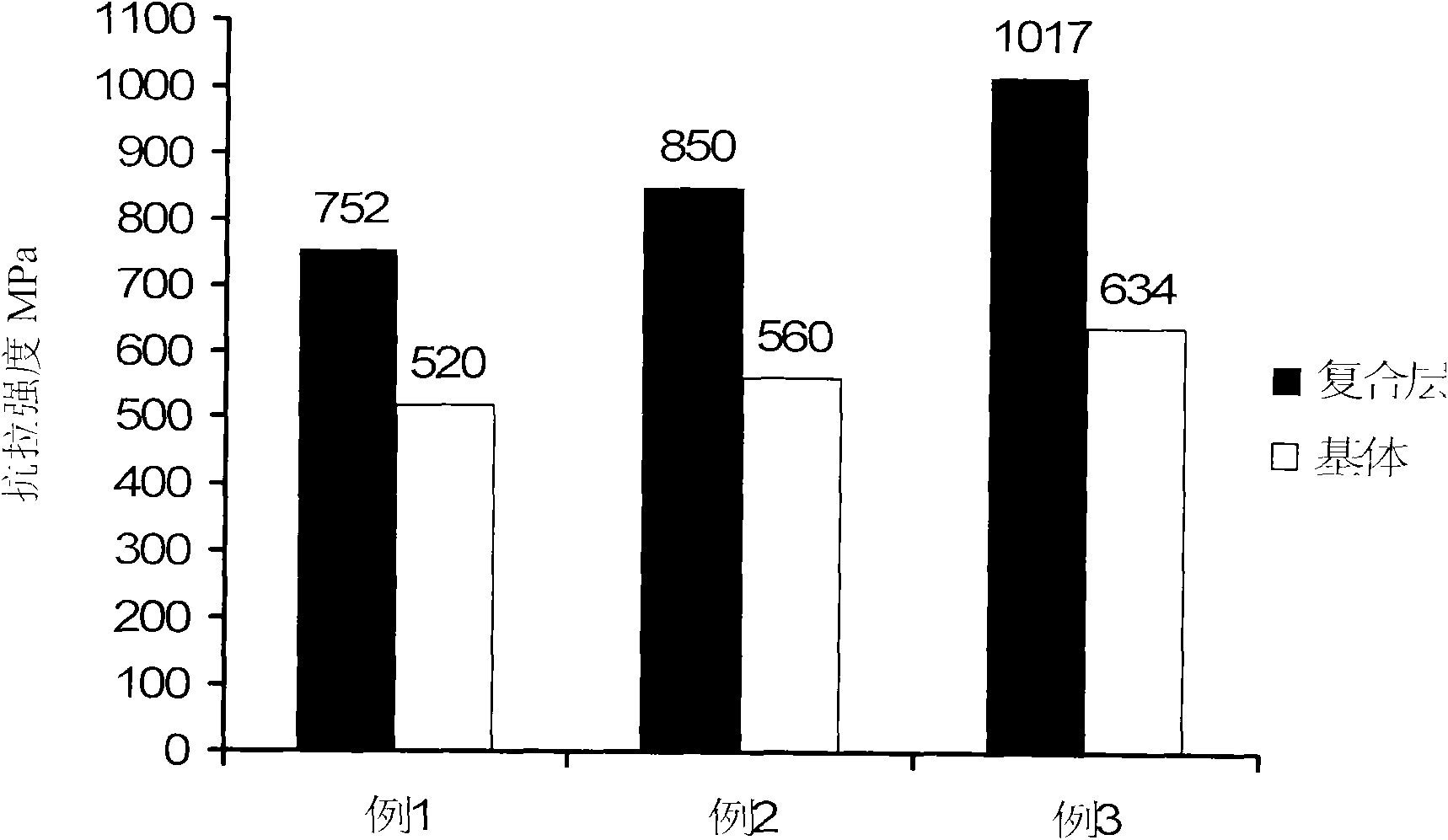

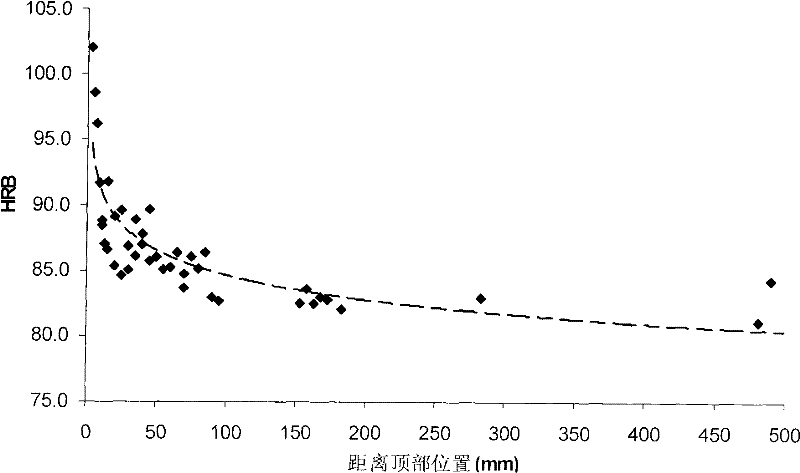

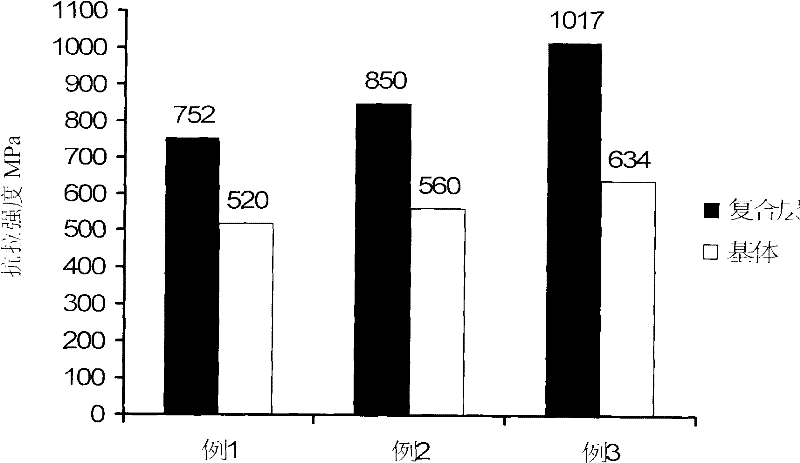

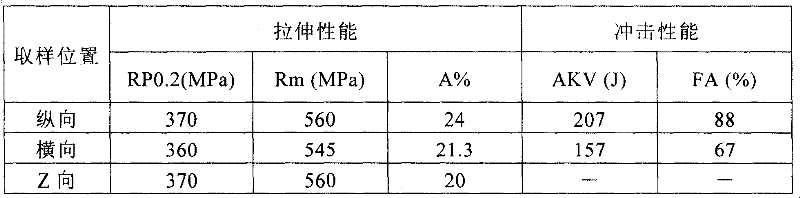

In-situ composite high-strength thick steel plate and manufacturing method thereof

InactiveCN101812640AMeet the requirements of welding performanceGuaranteed one-way solidification conditionsSheet steelManufacturing technology

The invention discloses an in-situ composite high-strength thick steel plate and a manufacturing method thereof. The in-site composite high-strength thick steel plate comprises the following components in mass percentage: 0.1 to 0.2 percent of C, 1.2 to 1.8 percent of Mn, 0.2 to 0.3 percent of Si, less than or equal to 0.015 percent of P, less than or equal to 0.002 percent of S, 0.15 to 0.2 percent of Cu, 0.2 to 0.25 percent of Ni, 0.02 to 0.03 percent of Nb, 0.01 to 0.015 percent of Ti, less than or equal to 0.04 percent of Al, less than or equal to ppm of N, less than or equal to 20 ppm of O and the balance of Fe and inevitable impurities, wherein the carbon equivalent Ceq which is the ratio of C+(Mn+Si) to 6+(Ni+Cu) to 15+(Cr+Mo+V) is 0.36 to 0.58; and the steel plate thickness is 50 to 400 millimeters. In the invention, the bottom of the produced steel ingot has no negative segregation, the section concentration is almost equal to the molten steel concentration, and the positive segregation is formed on the upper part of the steel ingot; and the tensile strength and the yield strength of the steel can be greatly improved by solute elements such as C and Mn in the steel and by solution strengthening. The upper strength of billets is improved by one-way solidification manufacturing technology starting from the bottom by the segregations of the elements such as C and Mn at the end of the solidification.

Owner:BAOSHAN IRON & STEEL CO LTD

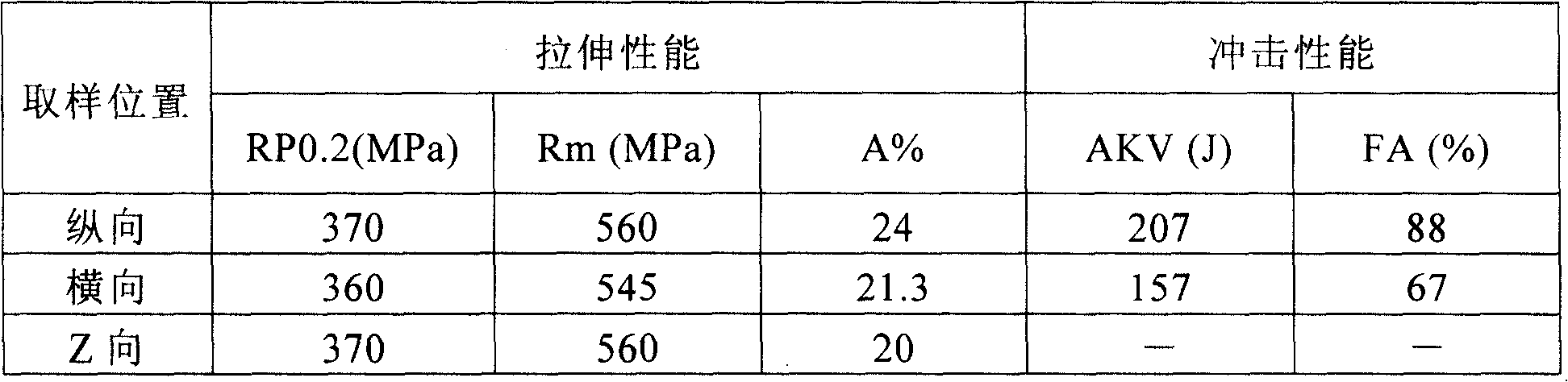

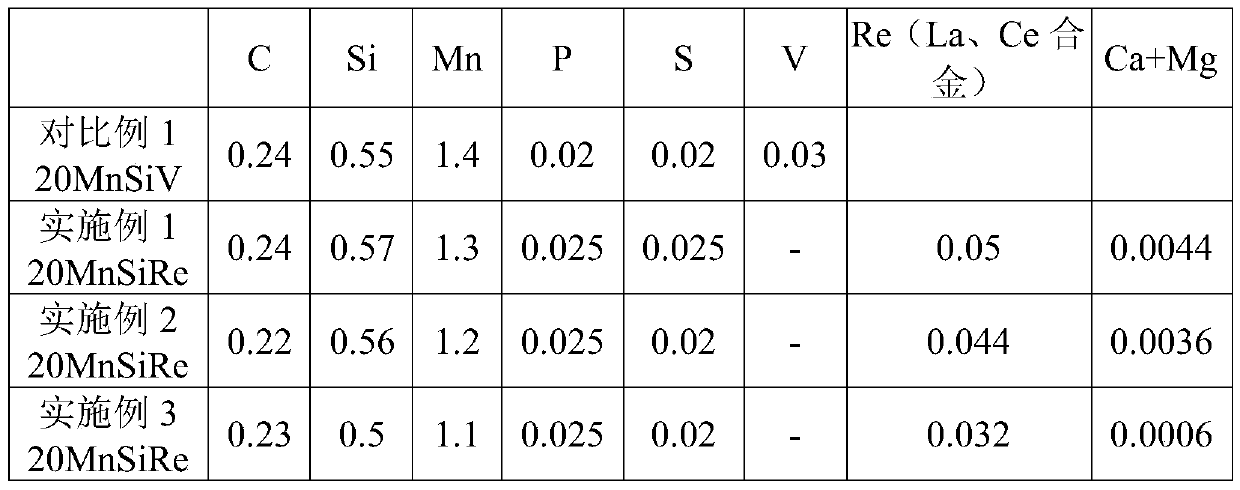

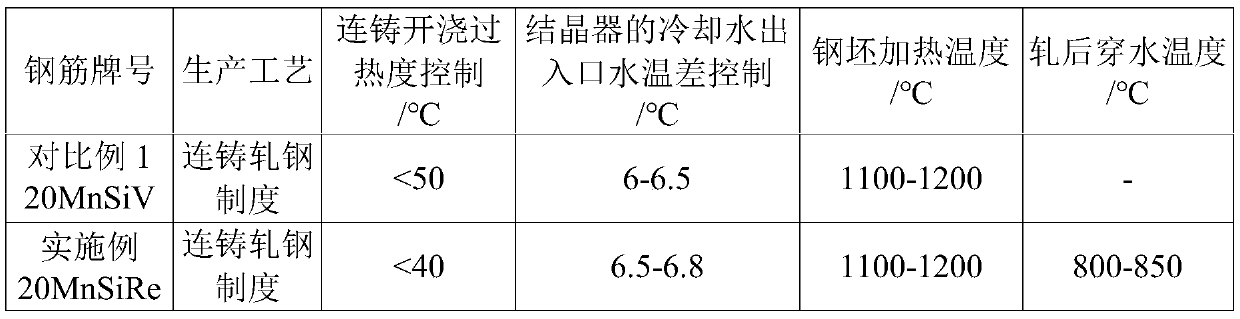

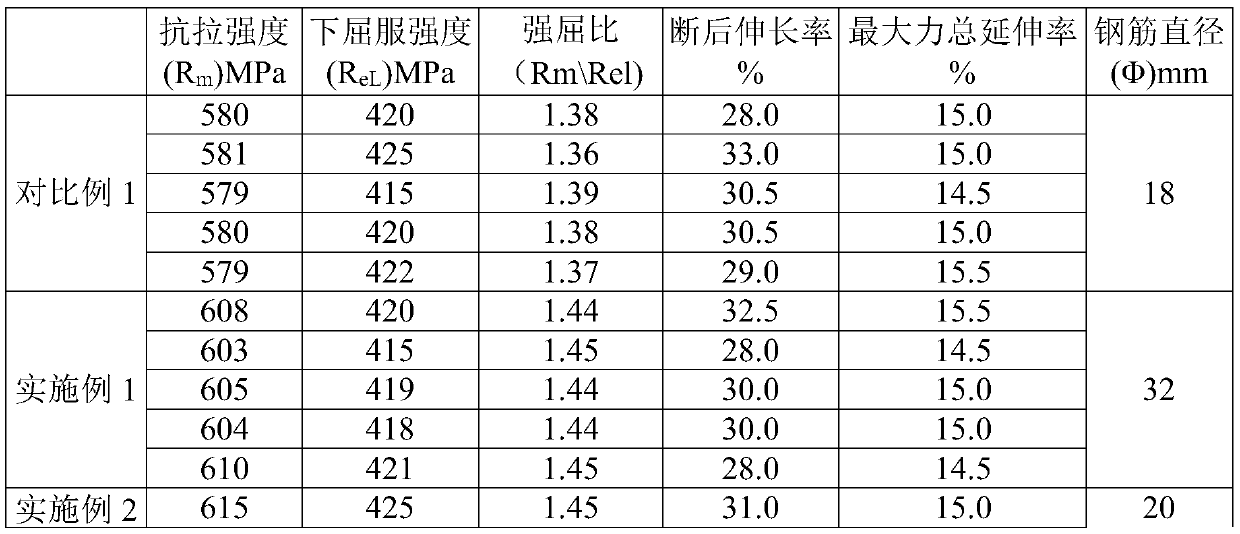

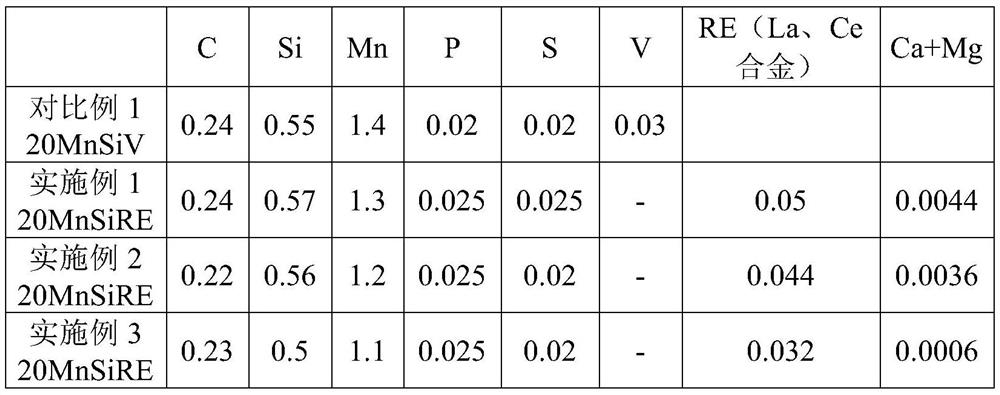

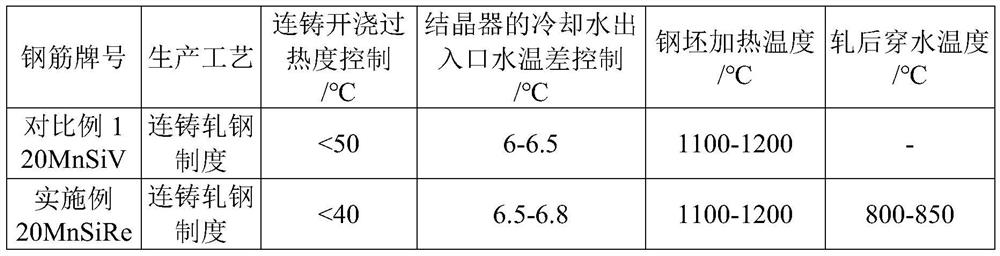

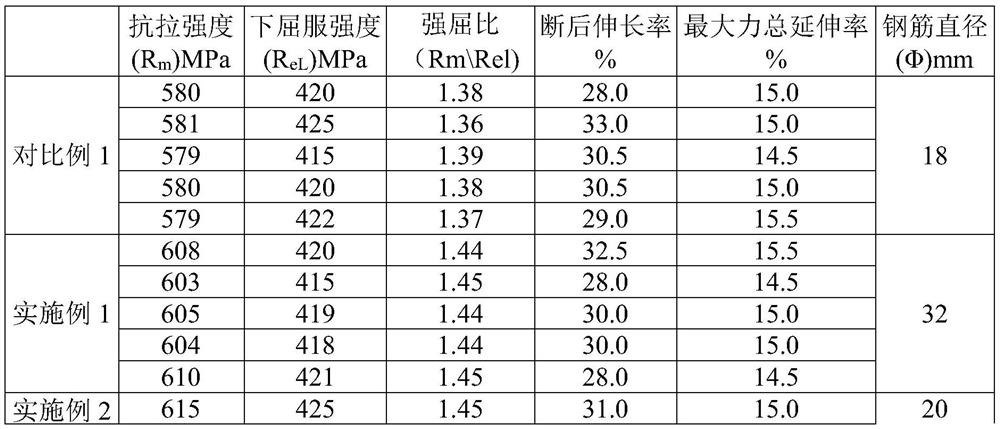

Rare earth microalloyed high-strength construction steel bar and production method thereof

The invention discloses a rare earth microalloyed high-strength construction steel bar and a production method thereof, and belongs to the technical field of steel for construction structures. The novel high-strength construction steel bar is provided, rare earth alloy cored wires are developed according to the variety of the rare earth microalloyed high-strength steel bar, qualified steel bars meeting the national standard requirements are obtained in high-strength steel bar production, and the problem that in the prior art, expensive elements such as V are often used, and consequently the cost is high is solved. The construction steel bar is prepared from the chemical compositions in percentage by weight: 0.20%-0.25% of C, 0.40%-0.80% of Si, 1.1%-1.60% of Mn, greater than 0.025% of Re, less than 0.045% of P, less than 0.045% of S, and the balance of Fe and inevitable impurities, wherein the mass percentage of O, Ca and Mg meets the formula of O / S<0 2, and Re / (Ca+Mg) is controlled between 10-100. The cost is lowered while the construction steel bar meets the national standard requirements.

Owner:CENT IRON & STEEL RES INST +2

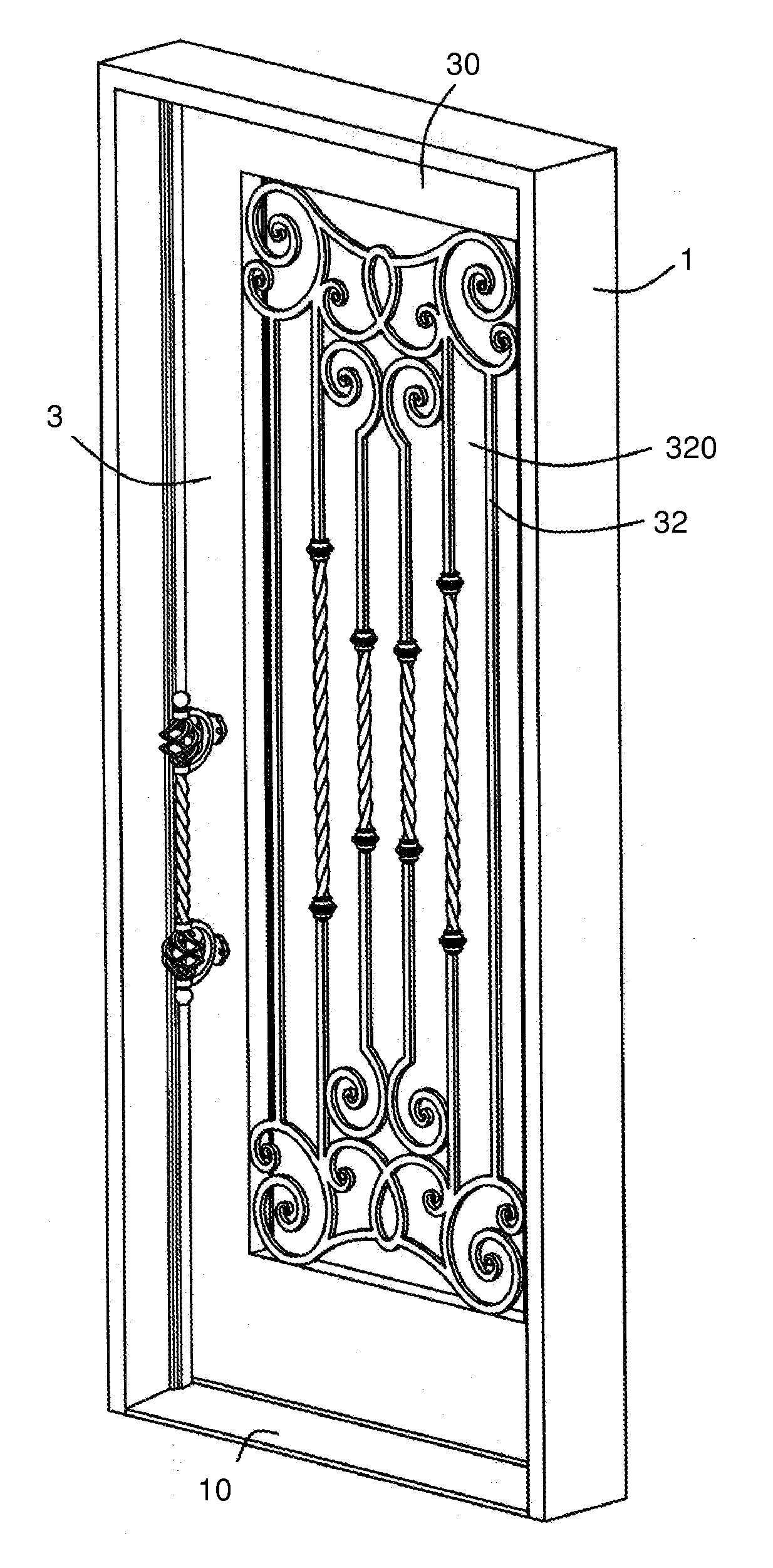

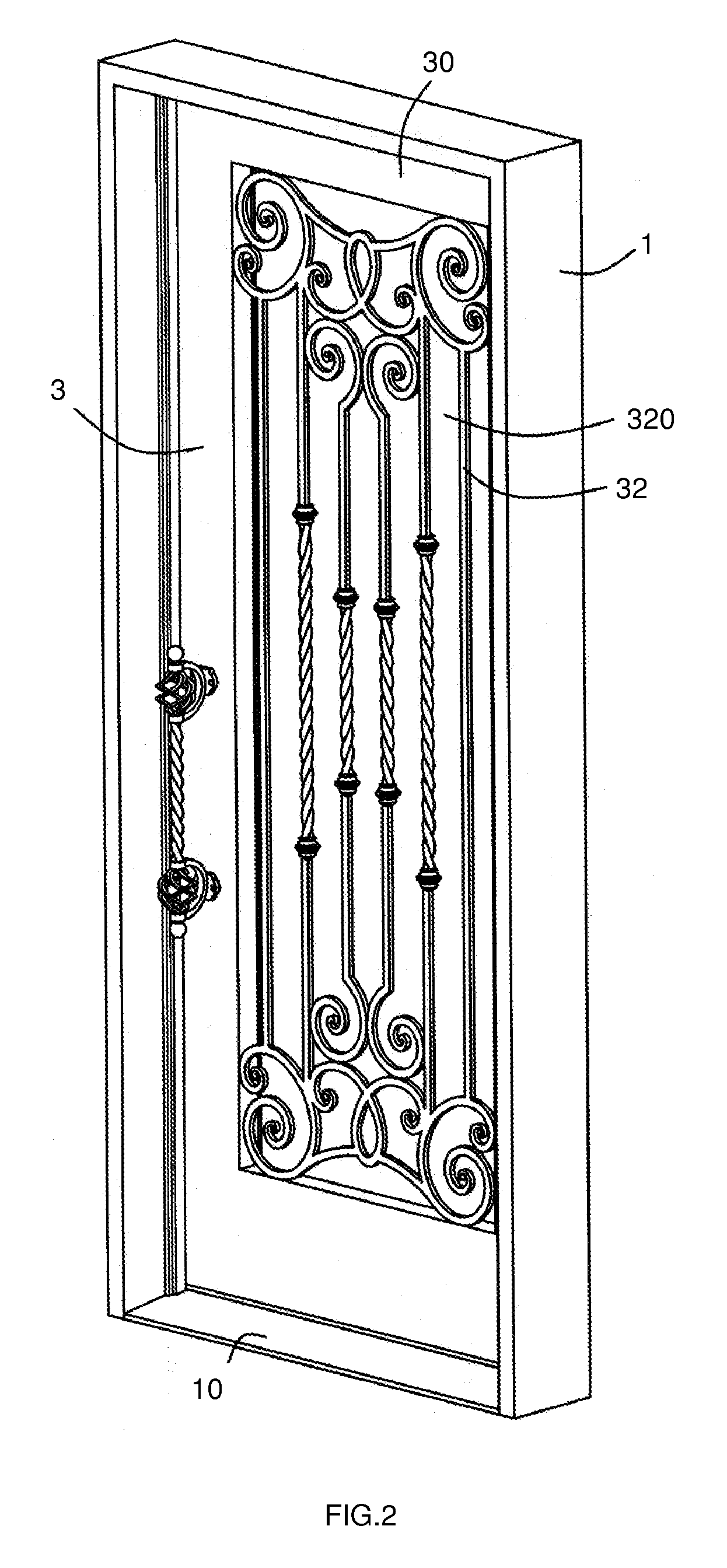

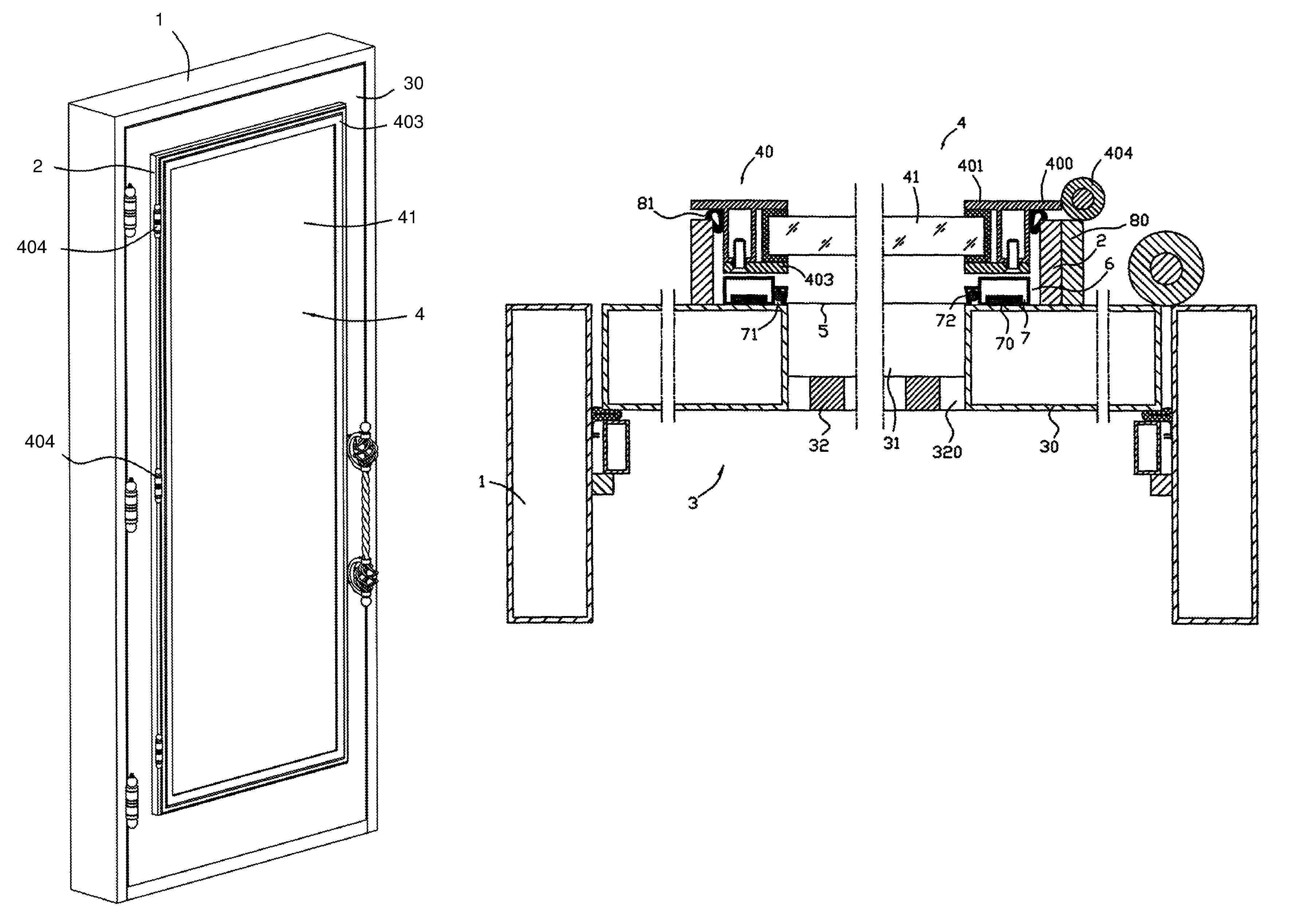

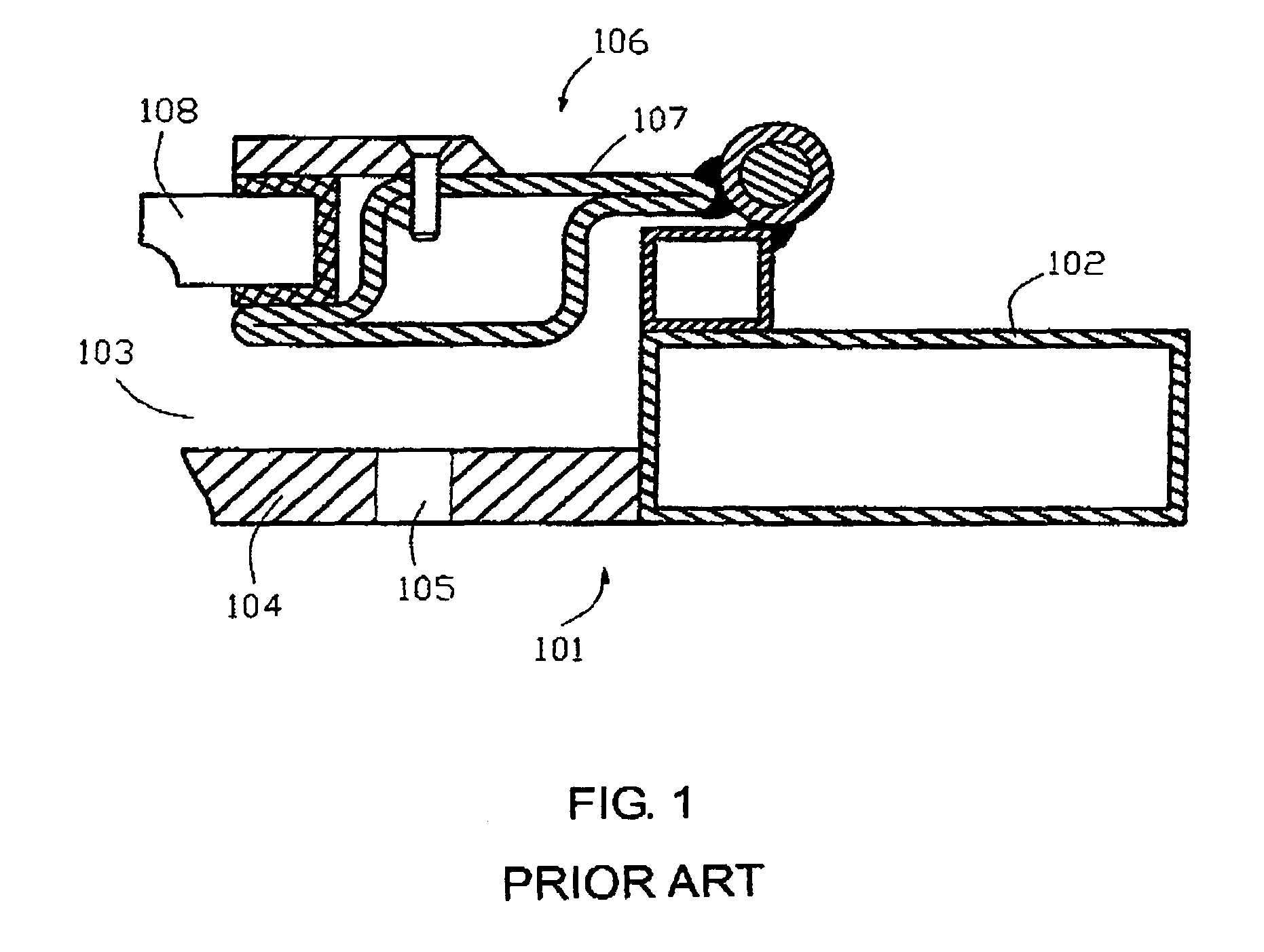

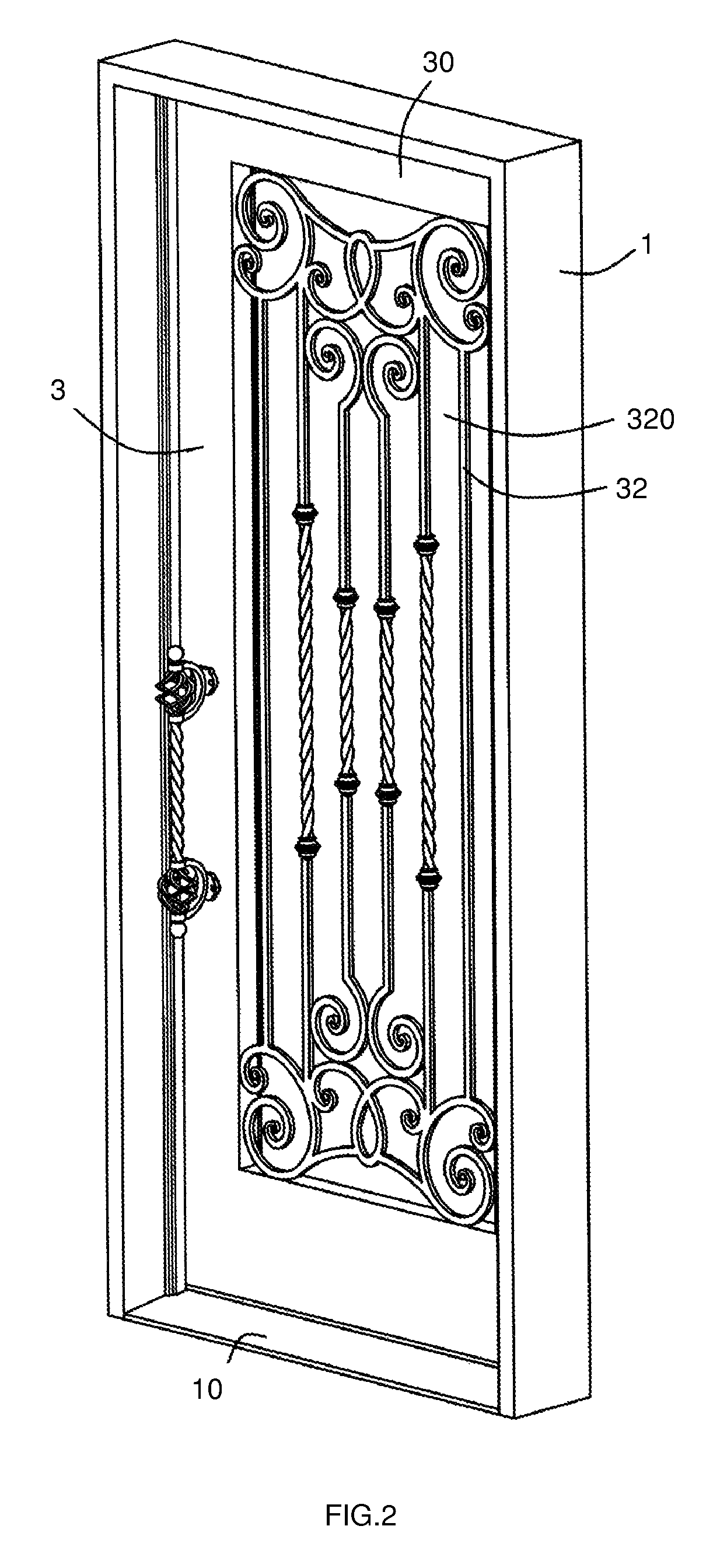

Structure for steel door

InactiveUS20100043340A1Improve visual effectsEnhancing artisticCovering/liningsBurglary protectionBack doorElectrical and Electronics engineering

The present invention relates to an improved structure for a steel door which comprises a steel door frame and a steel door panel which is hinged on one side of the steel door frame, wherein the steel door panel comprises a steel-made door panel frame and a door opening defined by the door panel frame, the door opening has an interior portion which is disposed with a plurality of steel guarding members forming graphics, portions other than the guarding members in the door opening form hollowed units; a rear side of the door panel frame is disposed with a glass door panel which corresponds with the door opening, the glass door panel comprises a steel-made glass door panel frame which surrounds a peripheral body of the door opening and is formed on the rear side of the door panel frame, and a glass which is embedded in the glass door panel frame, one side of the glass door panel frame is hinged on one side of the door panel frame, the glass door panel frame is completely hidden behind the rear side of the door panel frame. The structure enables the entire content of the graphics formed by the plurality of members viewable from either the front side or the rear side of the steel door, thereby bringing about better visual effect on the graphical presentation and enhancing the artistic and ornamental quality of the steel door.

Owner:YAN XIAOJUN

Deoxidization of calcium-silicon barium for smelting 82B steel

InactiveCN1778974AParticipate fully in the deoxygenation reactionImprove dynamic conditionsSlagAlloy

A deoxidizating technique by Si-Ba-Ca alloy in 82B steel-making which includes adding deoxidizing agent such as Al in tapping process. Its characters are as followsú‘adding Si-Ba-Ca alloy as deoxidizing agent to molten steel when tapping from converterú¿weight percentage of each component is Si 52-65ú¼ Ca í¦14ú¼Baí¦14ú¼Alíœ2ú¼Síœ0.15ú¼Píœ0.05 ú”granularity 10-50mmú”specific density 3.2g / cm3ú®. The deoxidizing agent is suggested to add into ladle with other alloy when the tapping percentage is in between 1 / 4 and 1 / 3. There are no Ba inclusion in finished steel and content of large-grained inclusion in finished steel decreased evidently because Baí»s great atomic radius made itself easier oxidated so that almost all the Ba were turned into slag. This technique could control the content of AlT íœ 0.002úÑin finished steel so as to prevent reoxidation of molten steel in continuous pouring process effectively and improve cleanliness of molten steel and increase numbers of pouring convertors. Ití»s highly suitable for pouring light section continuous casting billet and 82B steel for steel strand that requires superheat degree of molten steel more strictly.

Owner:SHOUGANG CORPORATION

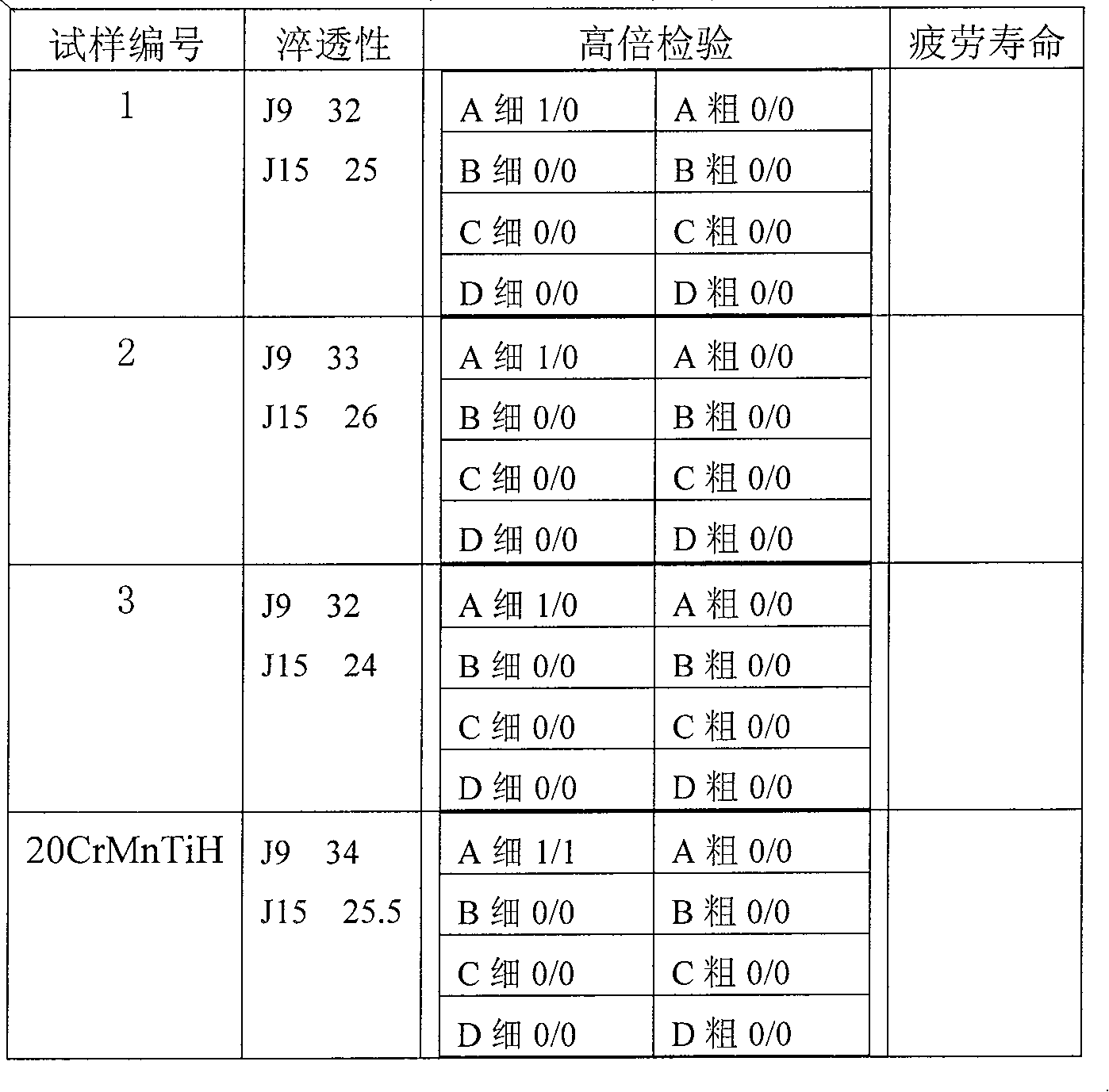

Preparation of Cr-Mn-Ti gear steel

InactiveCN100569983CImprove fatigue lifeGrains do not growTemperature control deviceElectrical steelSlag

The invention provides a production method of Cr-Mn-Ti gear steel, which is characterized in that it adopts the production process of primary smelting in electric furnace or converter—LF refining—vacuum furnace for refining molten steel—full protection continuous casting—rolling into lumber ; The primary smelting furnace melts the primary molten steel, taps steel in the range of 1620°C to 1670°C and adds synthetic slag; carries out refining of molten steel in the ladle refining furnace, controls the temperature at 1520°C to 1630°C, and smelting time at 30 ~50min to tap the steel; then carry out vacuum treatment on the refined molten steel on the vacuum furnace, and blow argon gas into the bottom of the ladle; finally carry out continuous casting under the full protection state. From the perspective of ensuring the strength and fatigue limit of the CrMnTi gear steel, the present invention controls the Ti content in the CrMnTi gear steel to 0.01% to 0.038%, so as to control the grain growth of the CrMnTi gear steel at the carburizing temperature. , Reduce inclusions, improve the purpose of steel, and at the same time help to improve the fatigue life of gears.

Owner:SHANDONG IRON & STEEL CO LTD

Structure for steel door

InactiveUS8136326B2Artistic and ornamental qualitySimple structureCovering/liningsBurglary protectionElectrical and Electronics engineering

The present invention relates to an improved structure for a steel door which comprises a steel door frame and a steel door panel which is hinged on one side of the steel door frame, wherein the steel door panel comprises a steel-made door panel frame and a door opening defined by the door panel frame, the door opening has an interior portion which is disposed with a plurality of steel guarding members forming graphics, portions other than the guarding members in the door opening form hollowed units; a rear side of the door panel frame is disposed with a glass door panel which corresponds with the door opening, the glass door panel comprises a steel-made glass door panel frame which surrounds a peripheral body of the door opening and is formed on the rear side of the door panel frame, and a glass which is embedded in the glass door panel frame, one side of the glass door panel frame is hinged on one side of the door panel frame, the glass door panel frame is completely hidden behind the rear side of the door panel frame. The structure enables the entire content of the graphics formed by the plurality of members viewable from either the front side or the rear side of the steel door, thereby bringing about better visual effect on the graphical presentation and enhancing the artistic and ornamental quality of the steel door.

Owner:YAN XIAOJUN

Smelting method of hot rolling round steel for 40 Cr alloy structure

InactiveCN104962696AReduce sulfur contentReduce refining timeMelt-holding vesselsBlast furnace smeltingAlloy

A smelting method of hot rolling round steel for a 40 Cr alloy structure comprises the steps that KR desulfuration is conducted after blast furnace smelting is conducted; common converter smelting is conducted; refining is conducted in an LF furnace; continuous casting is conducted, wherein Cr drainage sand is used for conducting draining in a cast-on furnace, and Si drainage sand is used for conducting draining in a continuous-casting furnace; common hot rolling is conducted until requirements are met. The sulphur content in the steel is reduced to 40 PPm or lower from the original 200 PPm; on the premise that it is guaranteed that the quality of the hot rolling round steel for the 40 Cr alloy structure is improved, the refining time of the LF furnace is shortened to 0.53 hour or less from the original 0.67 hour, and the energy consumption can be reduced by 15 percent or more.

Owner:武钢集团有限公司

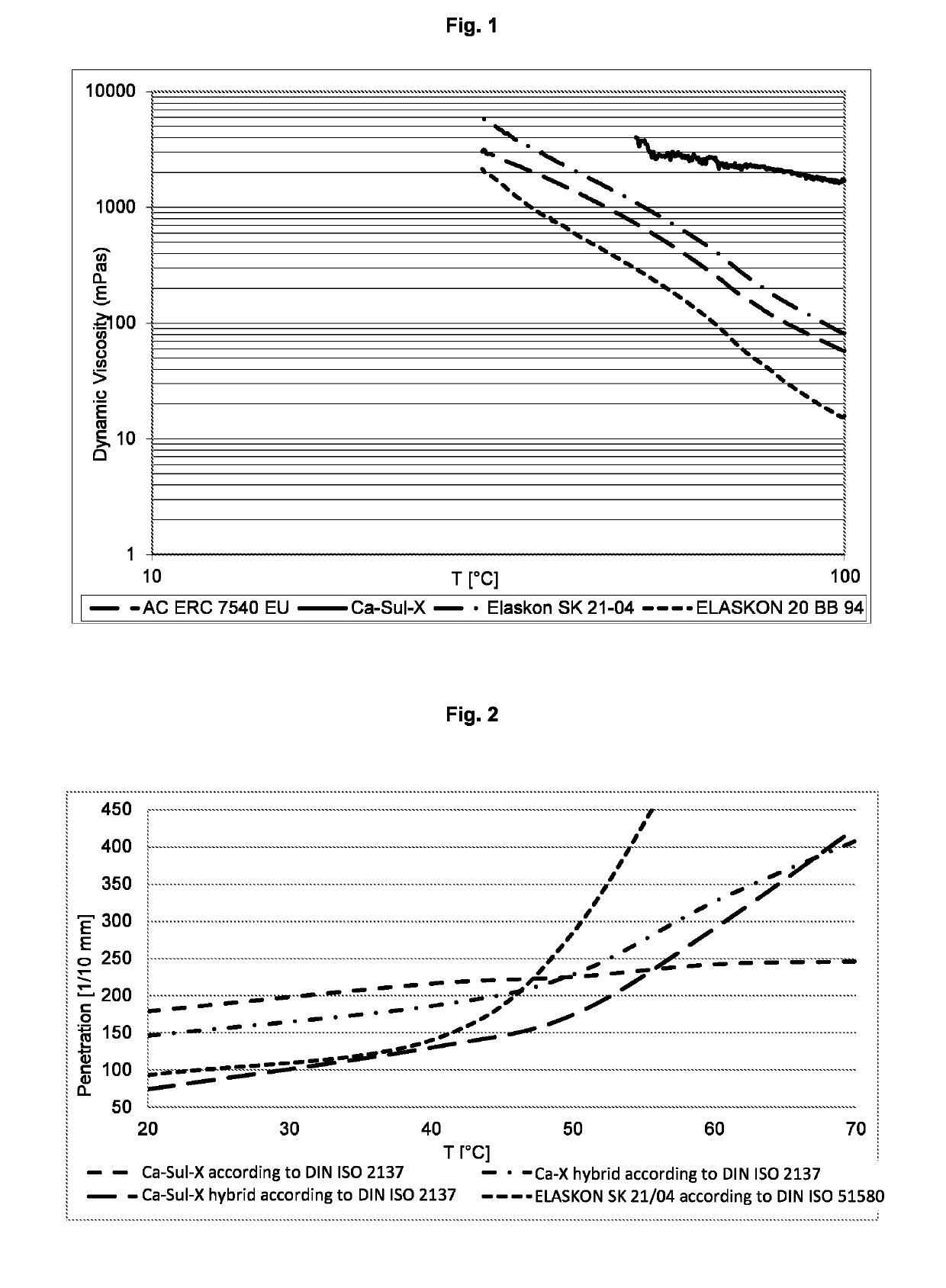

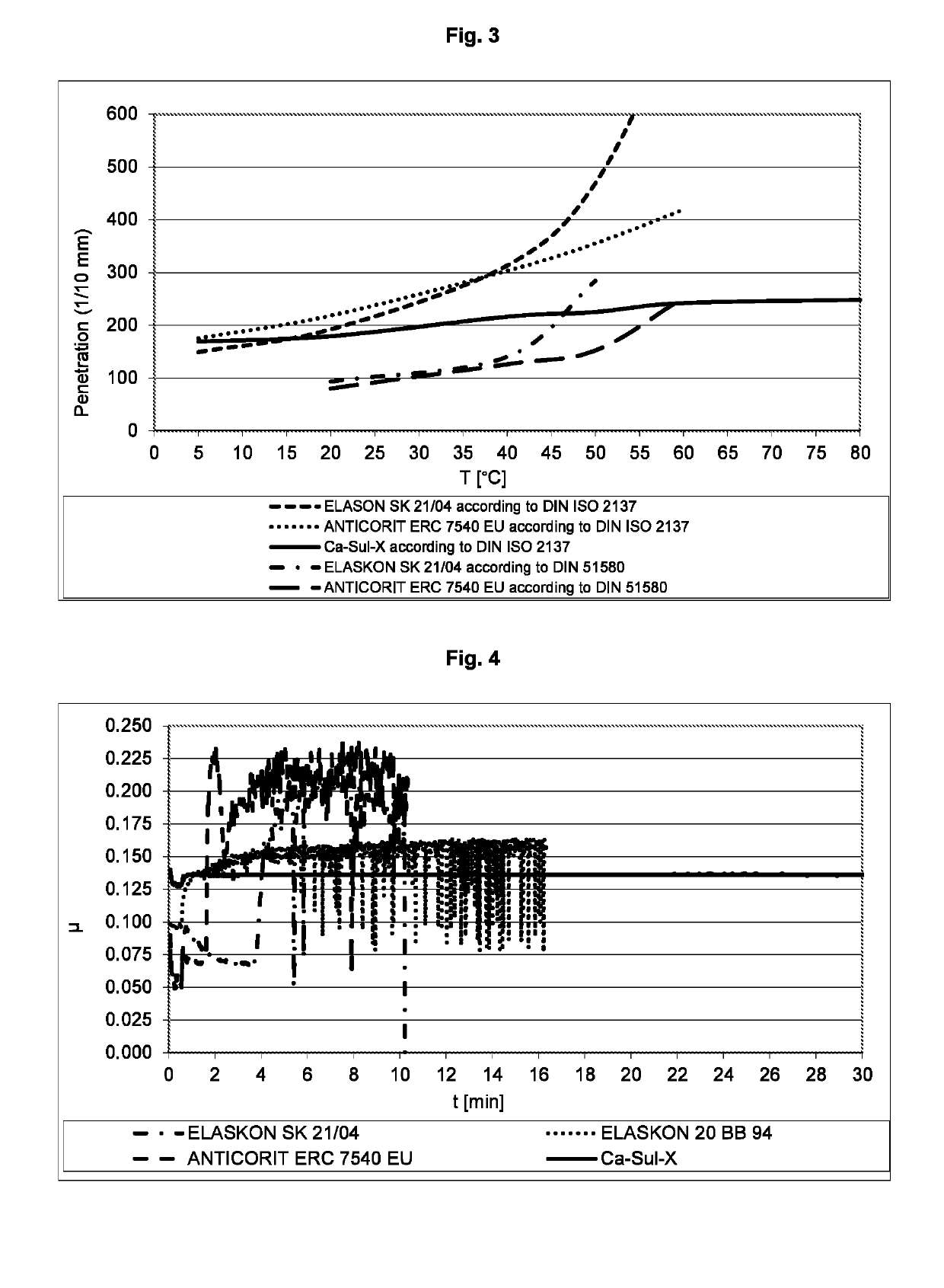

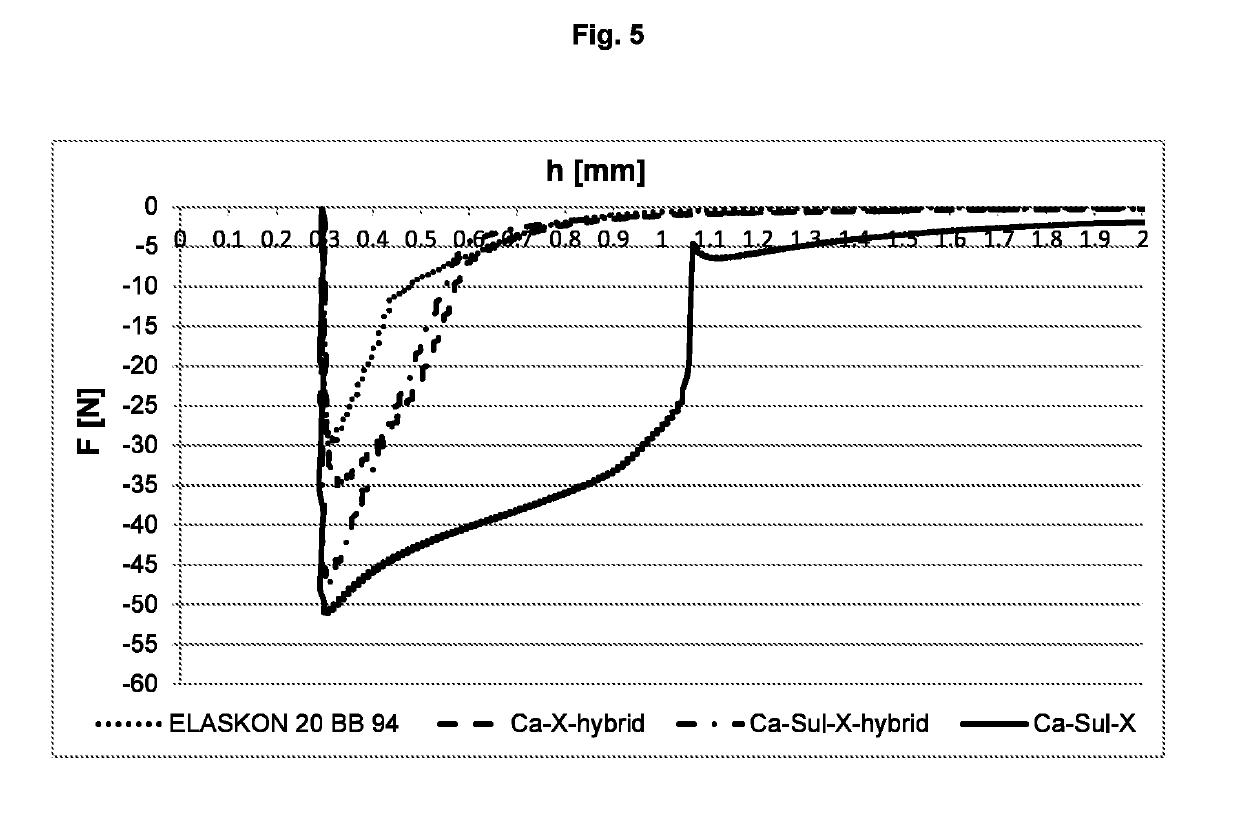

Use of Calcium Complex Lubricating Greases and Calcium Sulfonate Complex Lubricating Greases for the Lubrication of Wire Ropes

Owner:FUCHS PETROLUB SE

Al-Fe alloy with low H, N and O element contents and preparation method thereof

The invention relates to Al-Fe alloy with low H, N and O element contents, which comprises 36 to 65 weight percent of Al and 33 to 62 weight percent of Fe, wherein the weight percent of H in the Al-Fe alloy is lower than or equal to 2PPm, the weight percent of N is lower than or equal to 80PPm, and the weight percent of O is lower than or equal to 20PPm. The invention provides the Al-Fe alloy with low H, N and O element contents and a preparation method thereof. A process with the specific limited conditions is added on the basis of the existing Al-Fe alloy metallurgy process for removing theH, N and O elements in Al-Fe alloy liquid, in addition, the Al-Fe alloy with the ultra-low H, N and O element contents is obtained through precisely controlling relevant parameters in the process, the mechanical property of steel materials is greatly improved, and in addition, the whole process is simple and is easy to implement, so the Al-Fe alloy has very high market prospects.

Owner:江苏江南铁合金有限公司

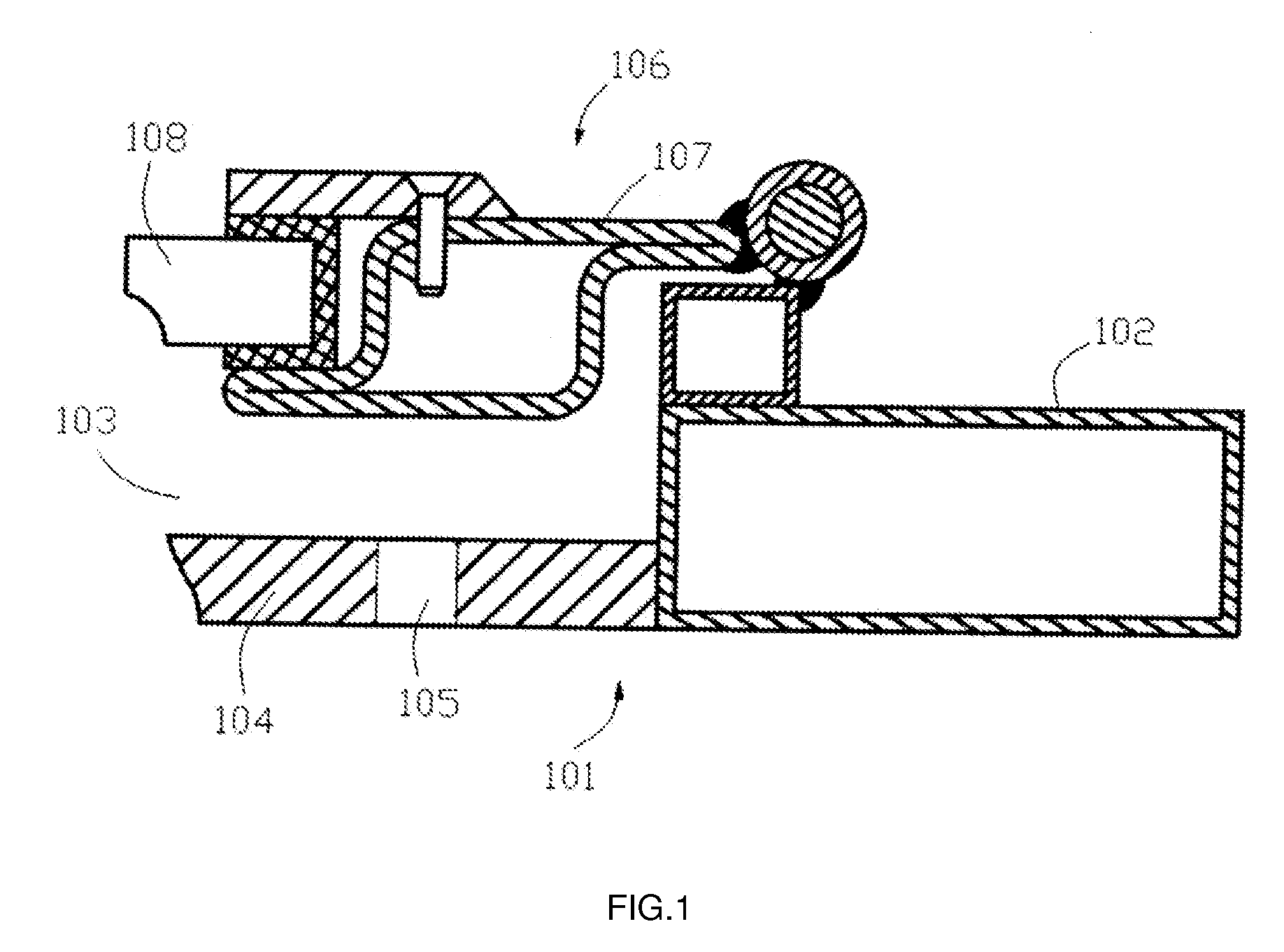

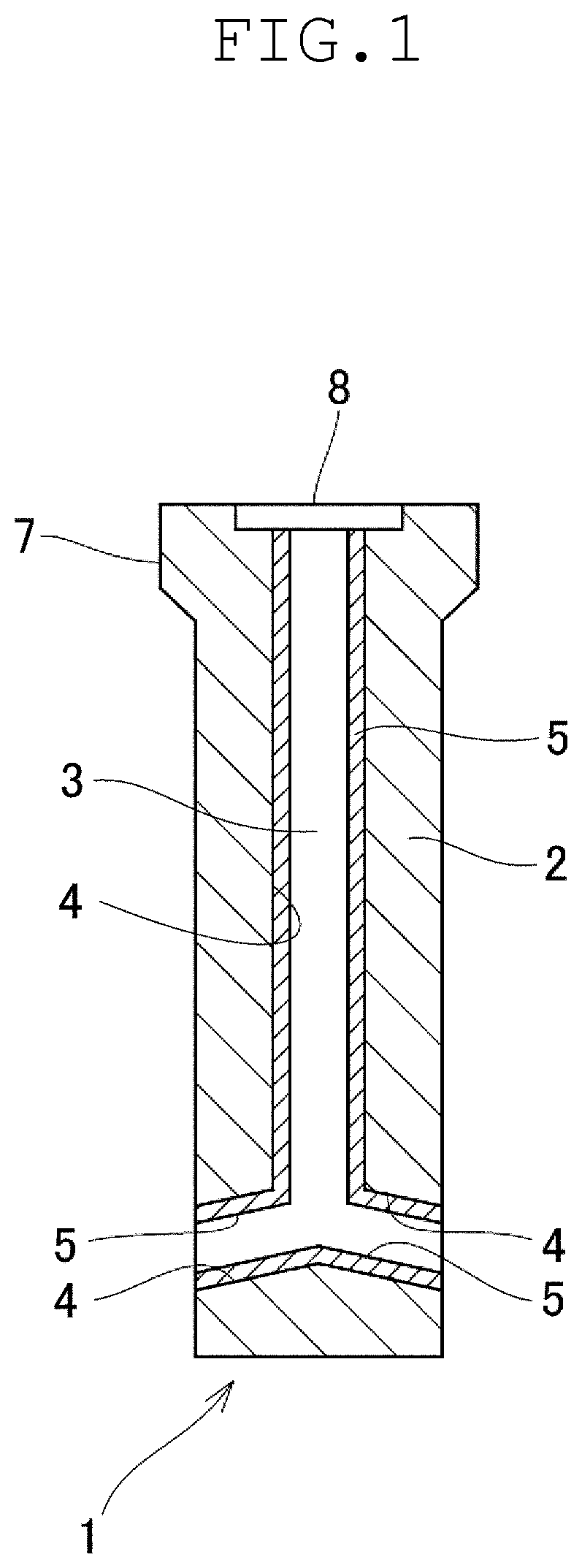

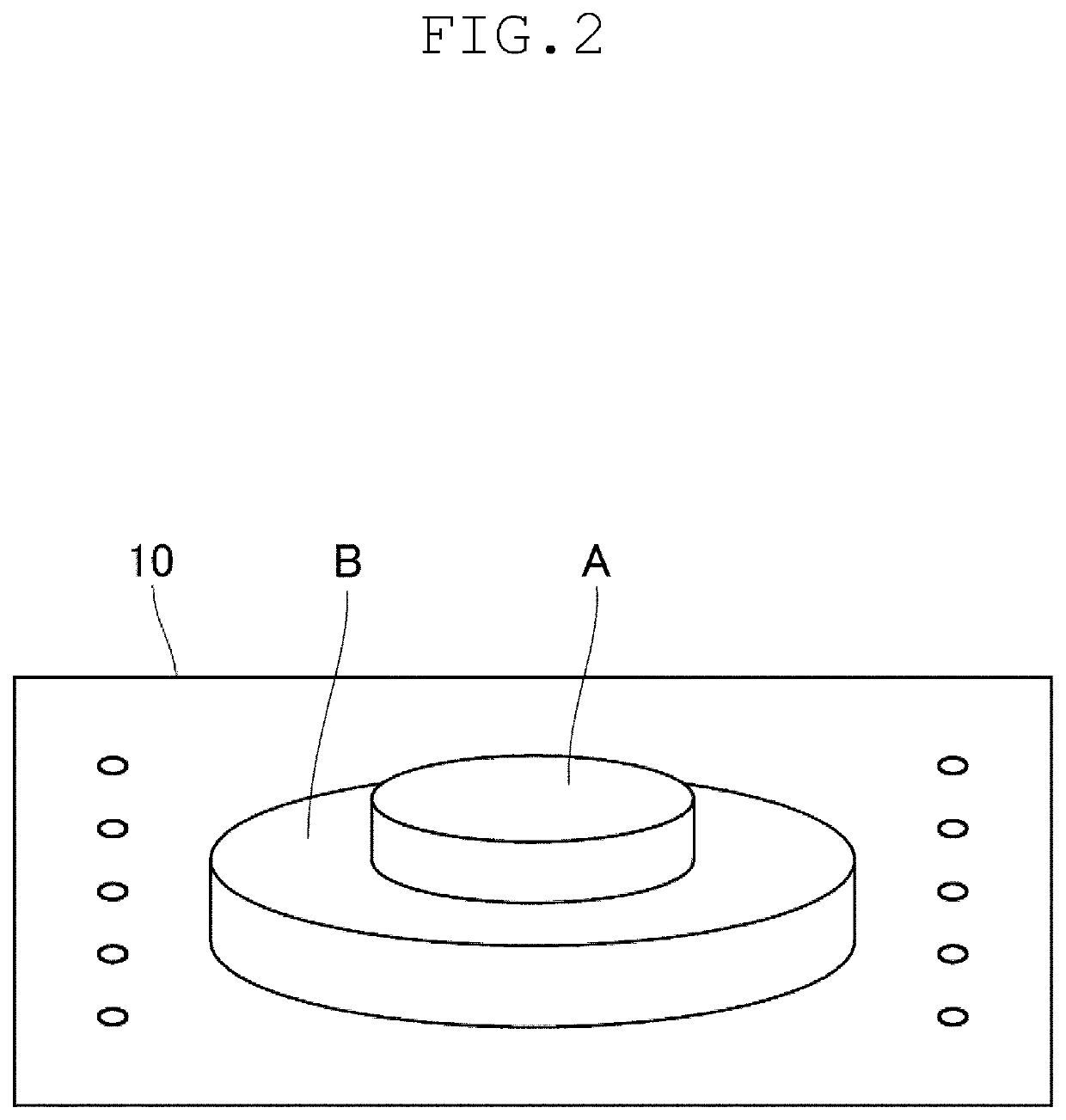

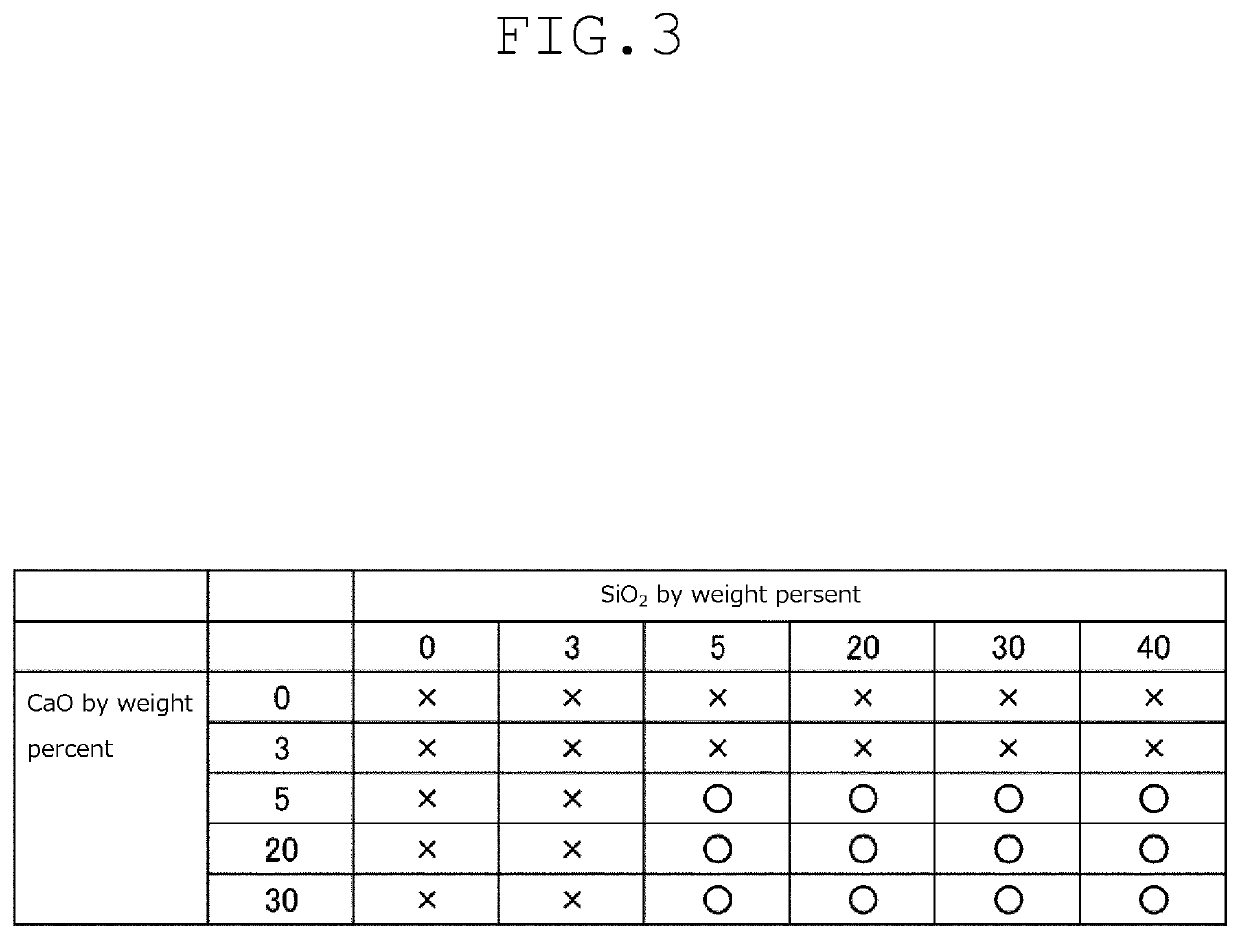

Continuous casting nozzle

InactiveUS20200282457A1Improve steel qualityReduce adhesionMelt-holding vesselsMolten steelMaterials science

A continuous casting nozzle 1 includes a nozzle main body 2 and a nozzle hole 3 formed to extend through the nozzle main body so that molten steel flows therethrough, and an alumina-hardly-adherable refractory 5 containing components of MgO, CaO and SiO2 is disposed on an inner surface defining the nozzle hole. Consequently, even when a temperature of the nozzle is low, adhesion of inclusions in molten steel to a portion in contact with the molten steel can be reduced, with the result that the nozzle hole can be prevented from being blocked and the continuous casting nozzle can contribute to an improvement in the steel quality.

Owner:AKECHI CERAMICS

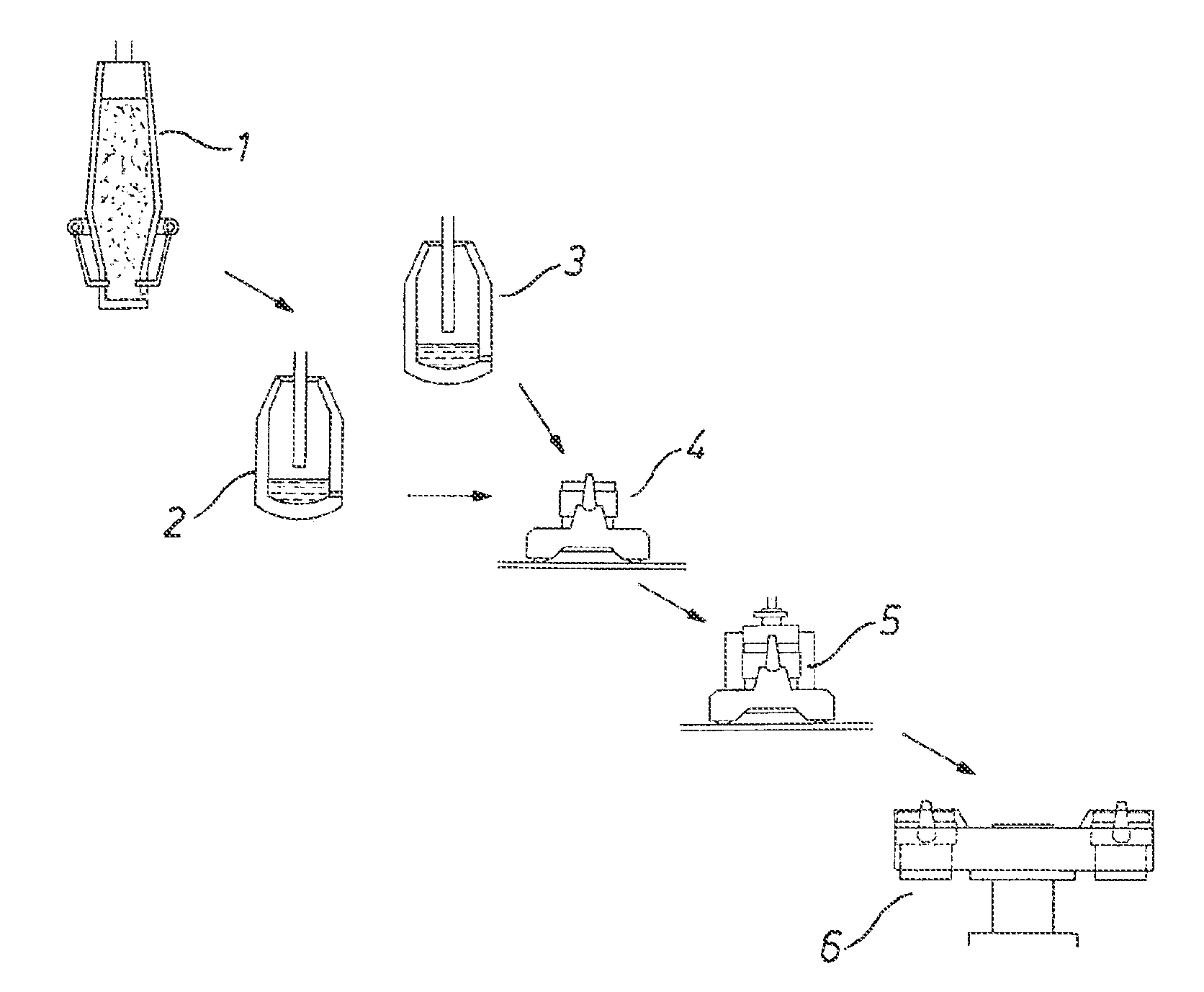

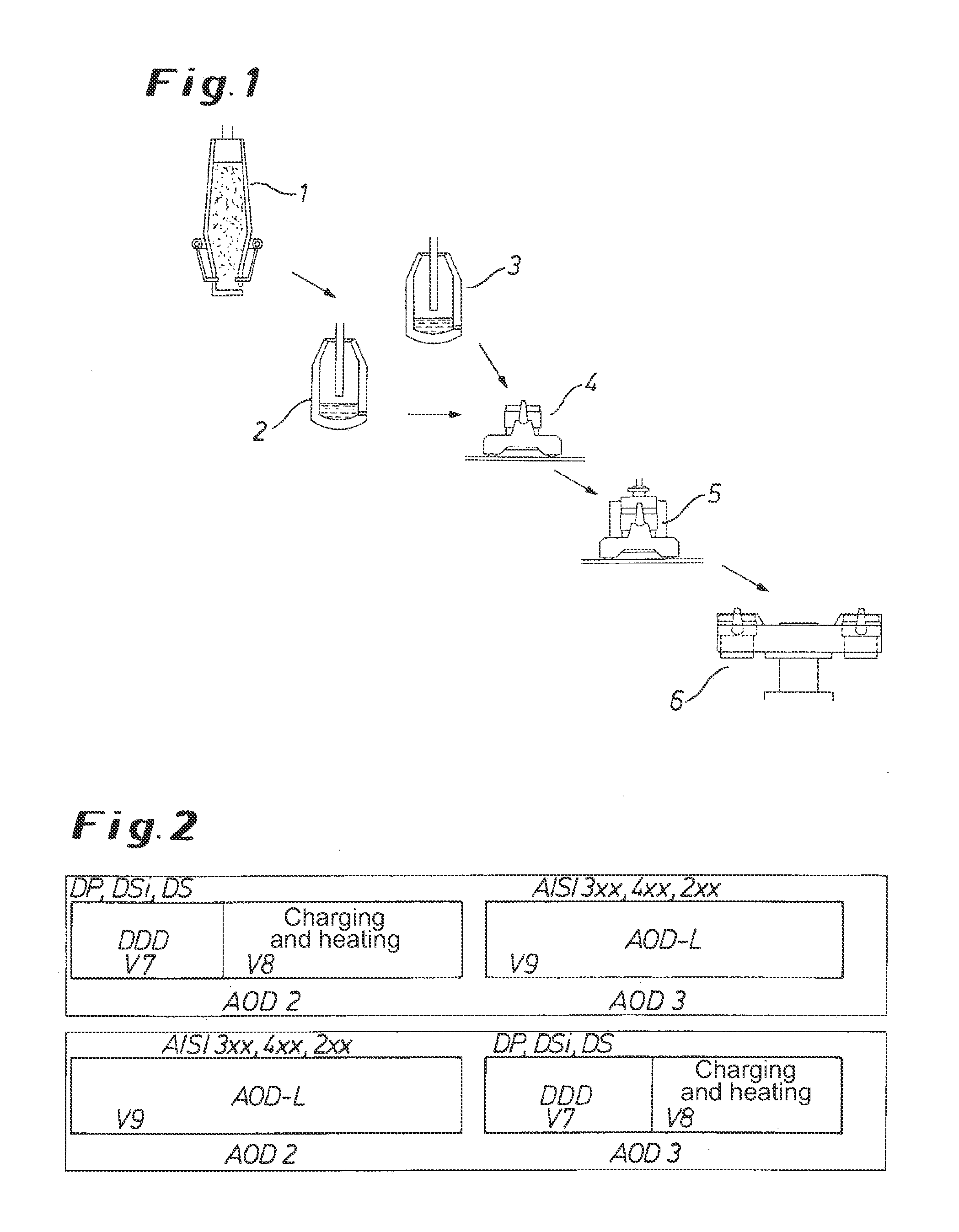

Method and device for producing pig-iron based stainless steel without using a supply of electrical energy

ActiveUS20120175828A1Reduce processing costsLower investment costsSteel manufacturing process aspectsDecarburizationChemical process

The aim of the invention is to produce stainless steel for all stainless steel products both in the austenitic and the ferritic range, based on liquid pig-iron and FeCr solids, without using a supply of electrical energy. According to the invention, the liquid pig-iron, after being pre-treated in a blast furnace, is subjected to a DDD treatment (dephosphorisation, desiliconisation and desulphuration), is heated, finished or alloyed and deoxidated. The quantity of slag-free liquid pig-iron that has been pre-treated in the blast furnace is separated and introduced into two classic “twin” AOD-L converters, where the required chemical process steps (of the DDD treatment and of the heating, decarburization and alloying stages) take place in parallel contrary processes using autogenous chemical energy, the DDD treatment being carried out first in the first twin AOD-L converter and the decarburization being carried out first in the second twin AOD-L converter.

Owner:SMS DEMAG AG

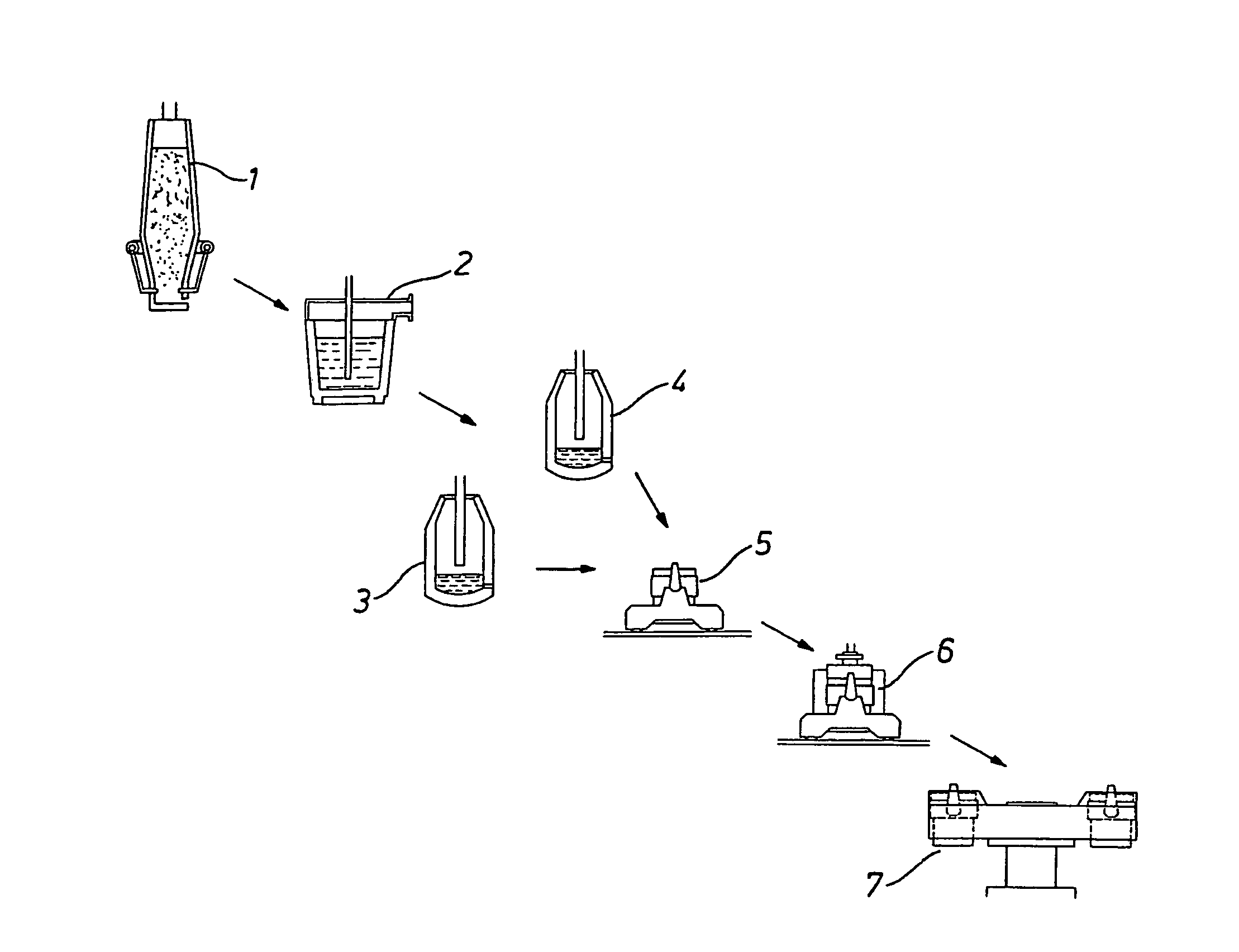

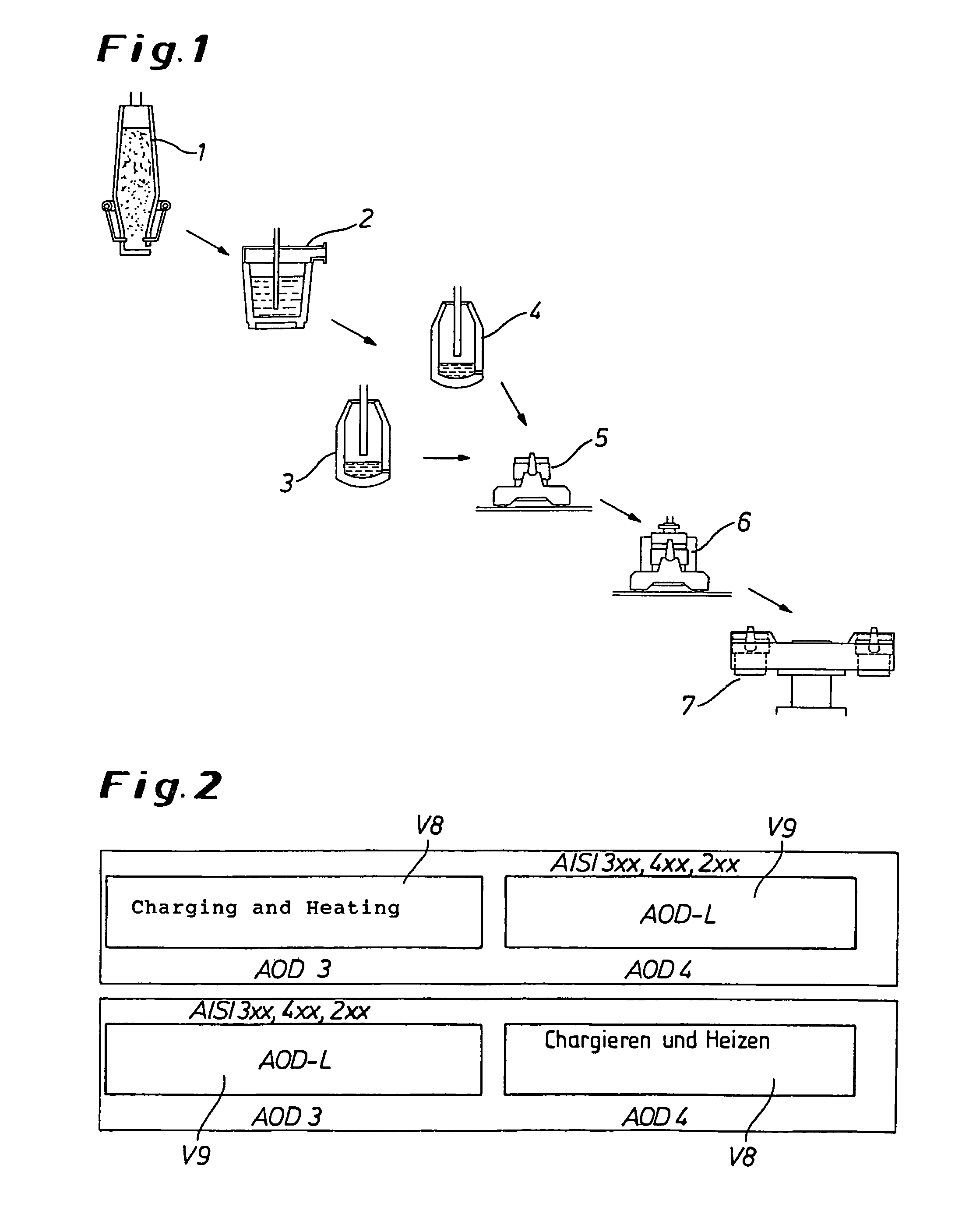

Method and device for producing stainless steel without using a supply of electrical energy, based on pig-iron that has been pre-treated in a DDD installation

ActiveUS8048196B2Improve efficiencyImprove steel qualitySteel manufacturing process aspectsTuyeresSlagPre treatment

The aim of the invention is to produce stainless steel for all stainless steel products both in the austenitic and the ferritic range, based on liquid pig-iron and FeCr solids, without using a supply of electrical energy. According to the invention, the liquid pig-iron, after being pre-treated in a blast furnace (1), is subjected to a DDD treatment (dephosphorization, desiliconization and desulphuration), is heated, finished or alloyed and deoxidated. The quantity of slag-free liquid pig-iron that has been pre-treated in the blast furnace (1) and a DDD device (2) is separated and introduced into two classic “twin” AOD-L converters (3, 4), where the required chemical process steps (of the heating, decarburization and alloying stages) take place in parallel contrary processes using autogenous chemical energy, the heating stage being carried out first in the first twin AOD-L converter (3) and the decarburization being carried out first in the second twin AOD-L converter (4).

Owner:SMS DEMAG AG

Alkaline earth metal oxide composite molten steel refining agent and preparing method thereof

The invention discloses an alkaline earth metal oxide composite molten steel refining agent and a preparing method thereof, and belongs to the technical field of molten steel furnace external refining. The composite refining agent is formed in the manner that alkaline earth metal oxide powder, alkaline earth metal carbonate powder and a self-reduction reducing agent serve as main raw materials, and after the alkaline earth metal oxide powder, the alkaline earth metal carbonate powder and the self-reduction reducing agent are mixed according to a certain proportion, a proper number of bonding agents are added, and the mixture is pressed into balls. After the composite molten steel refining agent is added into a steel ladle at an LF or RH or VD refining station, in the refining, vacuum and reducing atmosphere with the molten steel temperature larger than 1,500 DEG C, alkaline earth metal oxide in the refining agent is partly reduced through the self-reduction reducing agent, oxygen in top slag of the steel ladle can be effectively removed through Ca, Mg and Ba obtained through reduction, a dynamic condition is provided for following desulfuration, and the function of deep removing of [O] and [S] is achieved for the molten steel while Al does not need to be additionally added to carry out oxygen removing on the top slag of the steel ladle; and therefore the production technology is obviously simplified, operation is easy, and the production cost is greatly reduced.

Owner:MAANSHAN XINGDA METALLURGICAL NEW MATERIAL

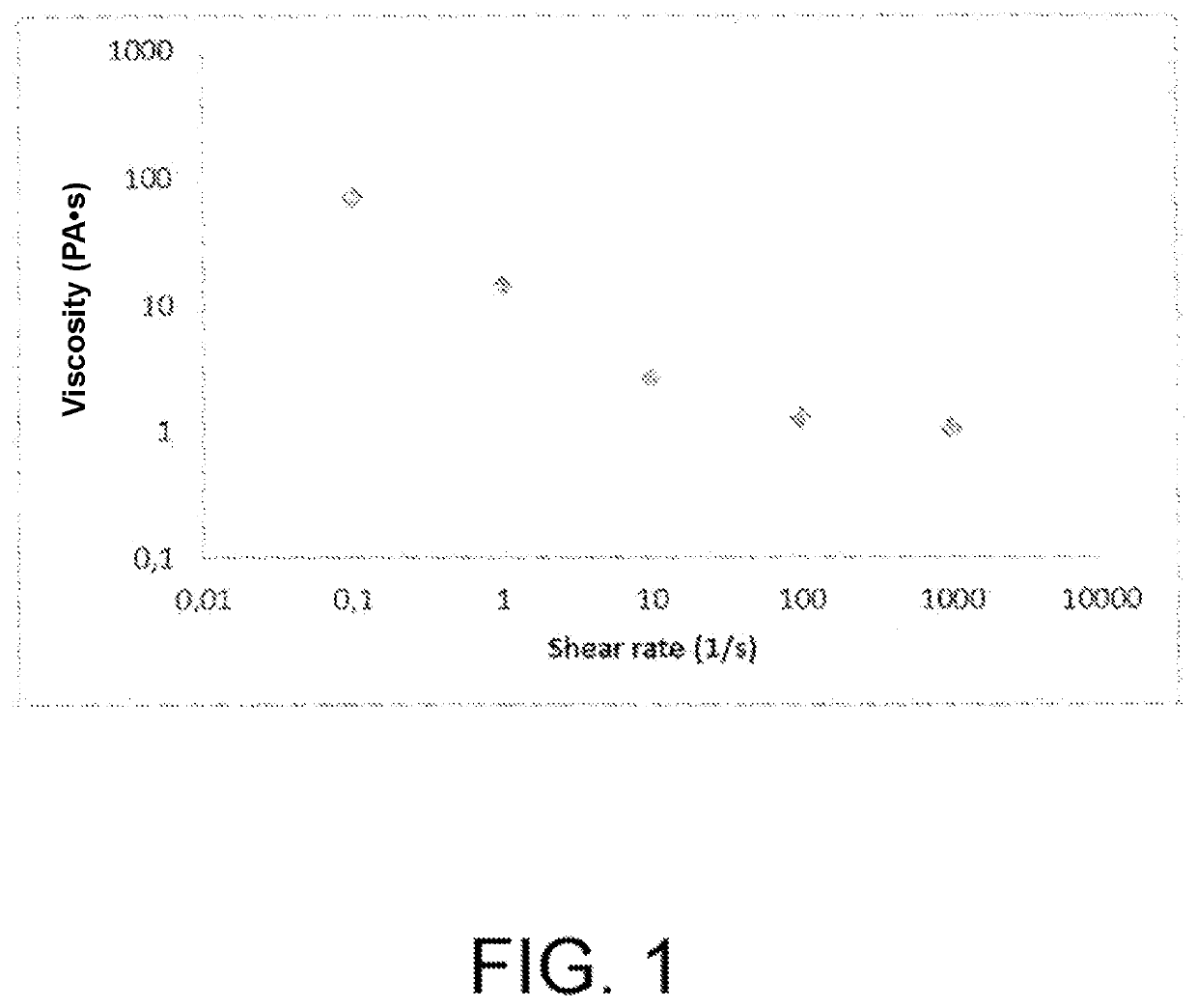

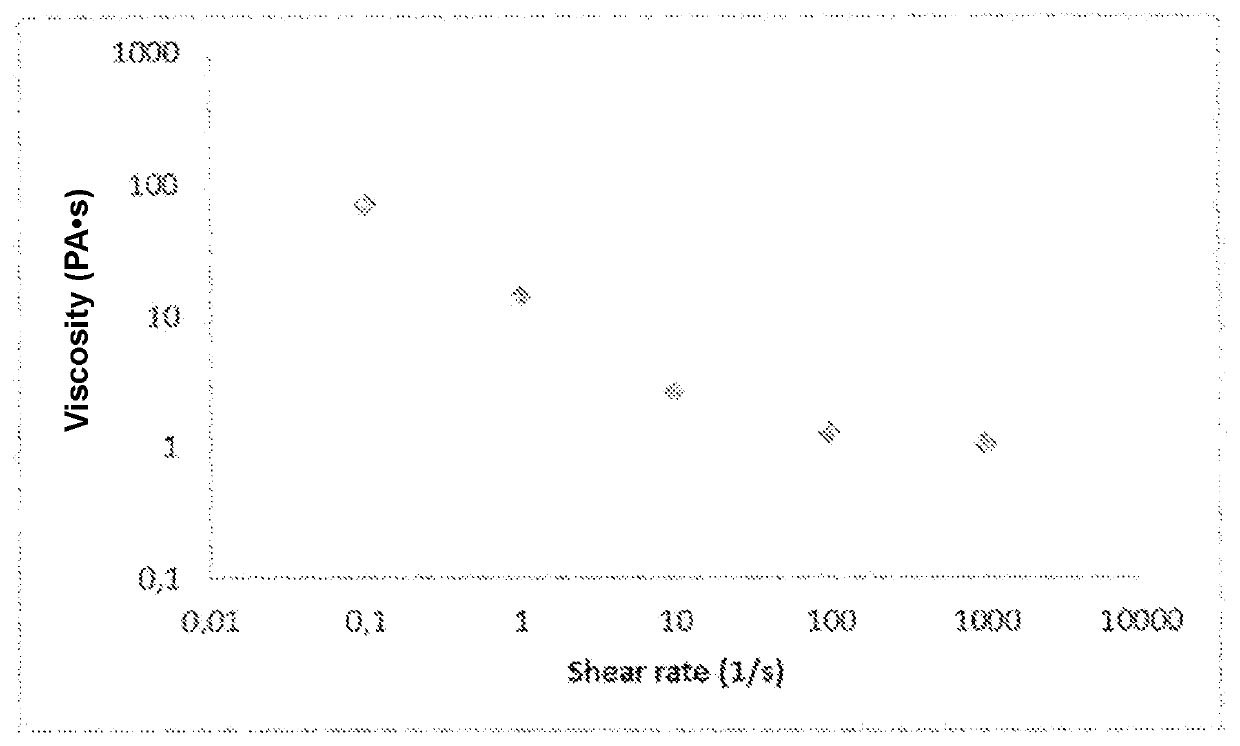

A stabilized lubricant composition for continuous casting processes

ActiveUS20210261880A1Notable manageabilityEnhanced rheological stabilityAdditivesBase-materialsMetallurgyIngot

Described herein is a stabilized lubricant composition for use in steel casting, in particular in continuous casting processes. In particular, the lubricant composition for processes for producing steel by continuous casting includes a dispersion of a lubricant powder, for an ingot mold, in continuous casting, in an oily liquid means, and a stabilization additive, characterized in that it has the following shear thinning index values:RVT0.1 / 11 / 1010 / 100100 / 1000STI3.0-7.52.0-6.51.0-3.00.5-2.0wherein RVT is the ratio between two different shear speeds and STI is the shear thinning index corresponding to the RVT values.

Owner:PROSIMET

Al-Fe alloy with low H, N and O element contents and preparation method thereof

The invention relates to Al-Fe alloy with low H, N and O element contents, which comprises 36 to 65 weight percent of Al and 33 to 62 weight percent of Fe, wherein the weight percent of H in the Al-Fe alloy is lower than or equal to 2PPm, the weight percent of N is lower than or equal to 80PPm, and the weight percent of O is lower than or equal to 20PPm. The invention provides the Al-Fe alloy with low H, N and O element contents and a preparation method thereof. A process with the specific limited conditions is added on the basis of the existing Al-Fe alloy metallurgy process for removing theH, N and O elements in Al-Fe alloy liquid, in addition, the Al-Fe alloy with the ultra-low H, N and O element contents is obtained through precisely controlling relevant parameters in the process, the mechanical property of steel materials is greatly improved, and in addition, the whole process is simple and is easy to implement, so the Al-Fe alloy has very high market prospects.

Owner:江苏江南铁合金有限公司

Steel strip stabilization device

ActiveUS9487853B2Easy to shapeIncrease vibrationHot-dipping/immersion processesLiquid surface applicatorsMetallurgyMagnetic field

Owner:POHANG IRON & STEEL CO LTD

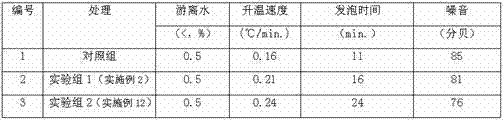

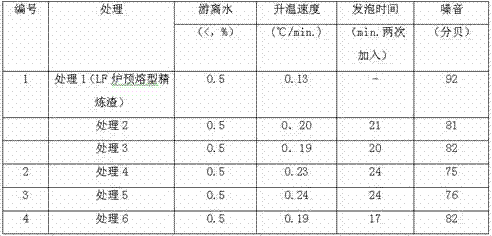

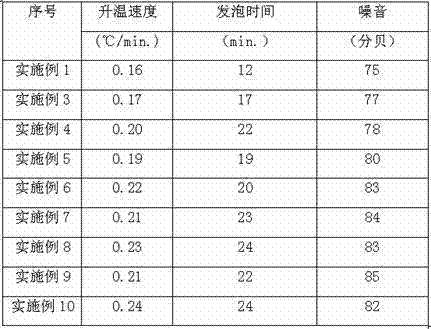

A kind of environment-friendly submerged arc heat storage agent and preparation method thereof

InactiveCN105463158BReduce extreme noiseRealize environmentally friendly steelmakingSteelmakingMetallic aluminum

The invention relates to an auxiliary steelmaking material, in particular to an environment-friendly material and a preparing method thereof. The environment-friendly material is characterized in that a submerged arc heat accumulation agent comprises, by weight, 63-71 parts of limestone, 8-16 parts of magnesite, 7-9 parts of light calcined magnesia, 1-5 parts of barium carbonate, 1-5 parts of metallic aluminum, 1-3 parts of silicon carbide, 0.5-1.5 parts of metallic silicon and 3.5-4.5 parts of water. Material decomposition is achieved at the high temperature, gas is continuously generated under the condition that 0.7-1.0 Kg / ton of steel is added, slag liquid is foamed, the slag liquid is emulsified in the gas-slag mixing state, the slag liquid level rises, and electrode arc light is continuously and more effectively embedded. In the steel refining process, the purposes that the extremely high noise generated by electrode arcing in an LF furnace is lowered, the noise in an operation room of the LF furnace is reduced to 74-85 decibels from 87-97 decibels, and the environment-friendly steel making is achieved are achieved.

Owner:鞍山天祥冶金材料有限公司 +1

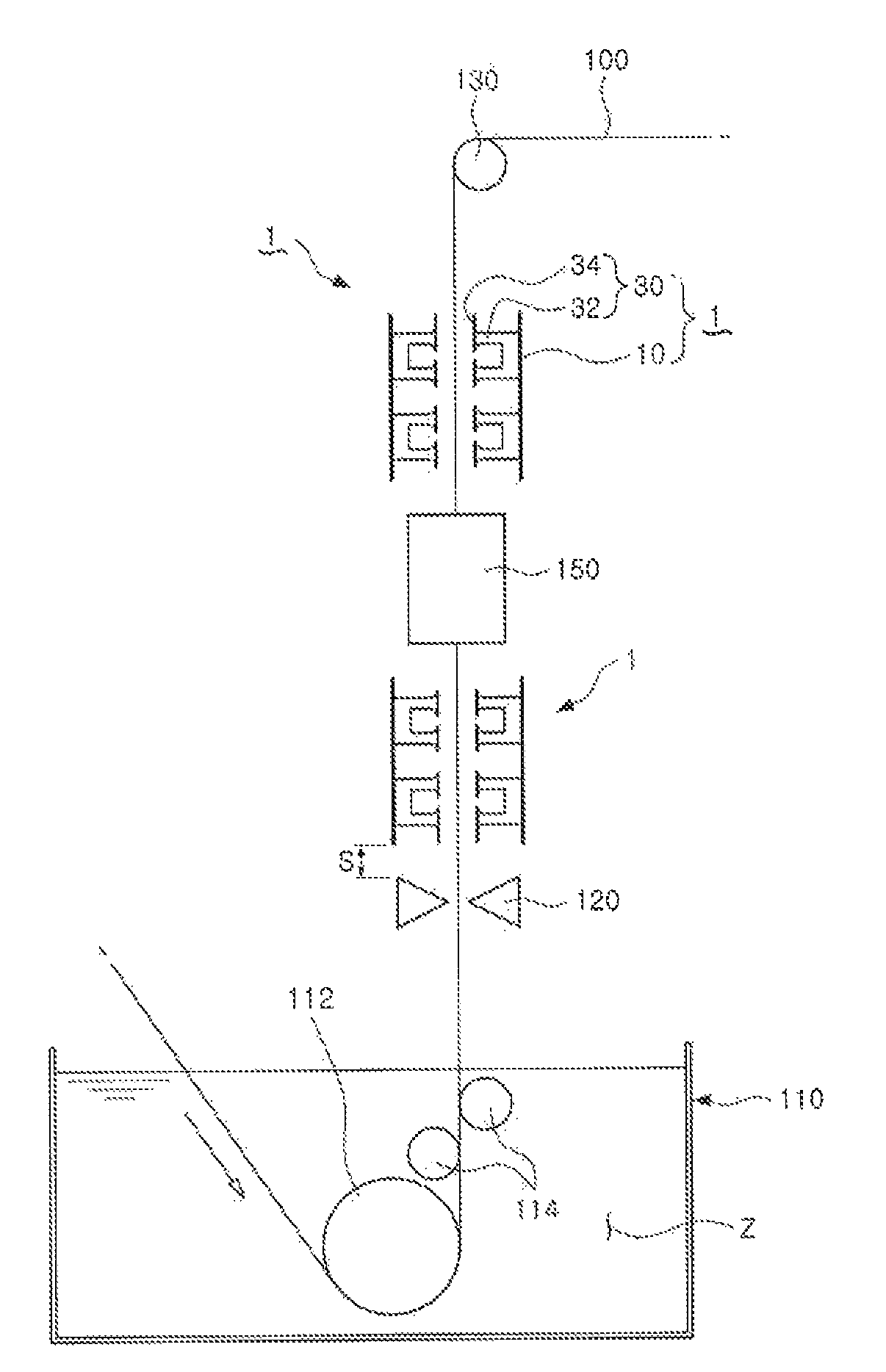

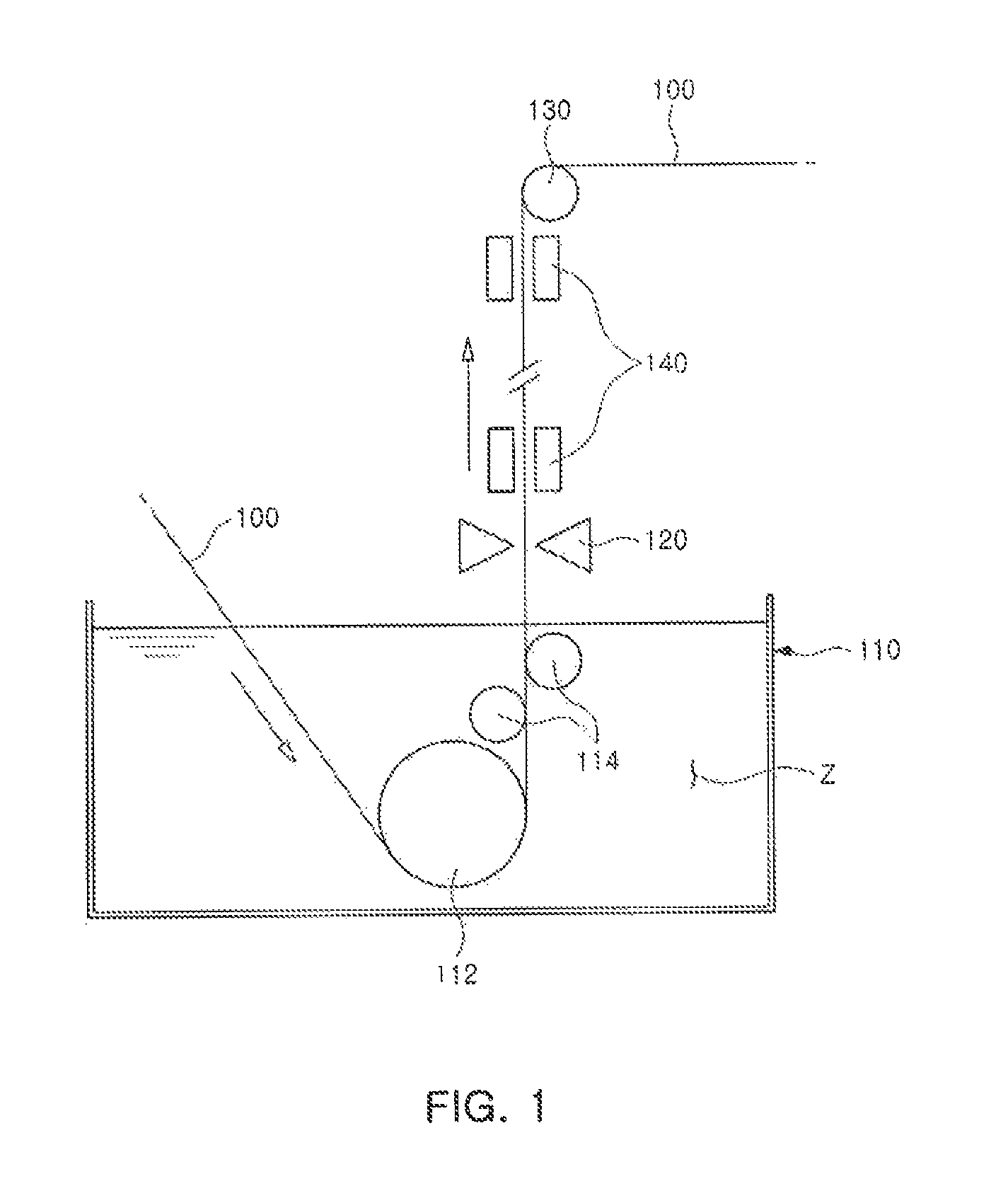

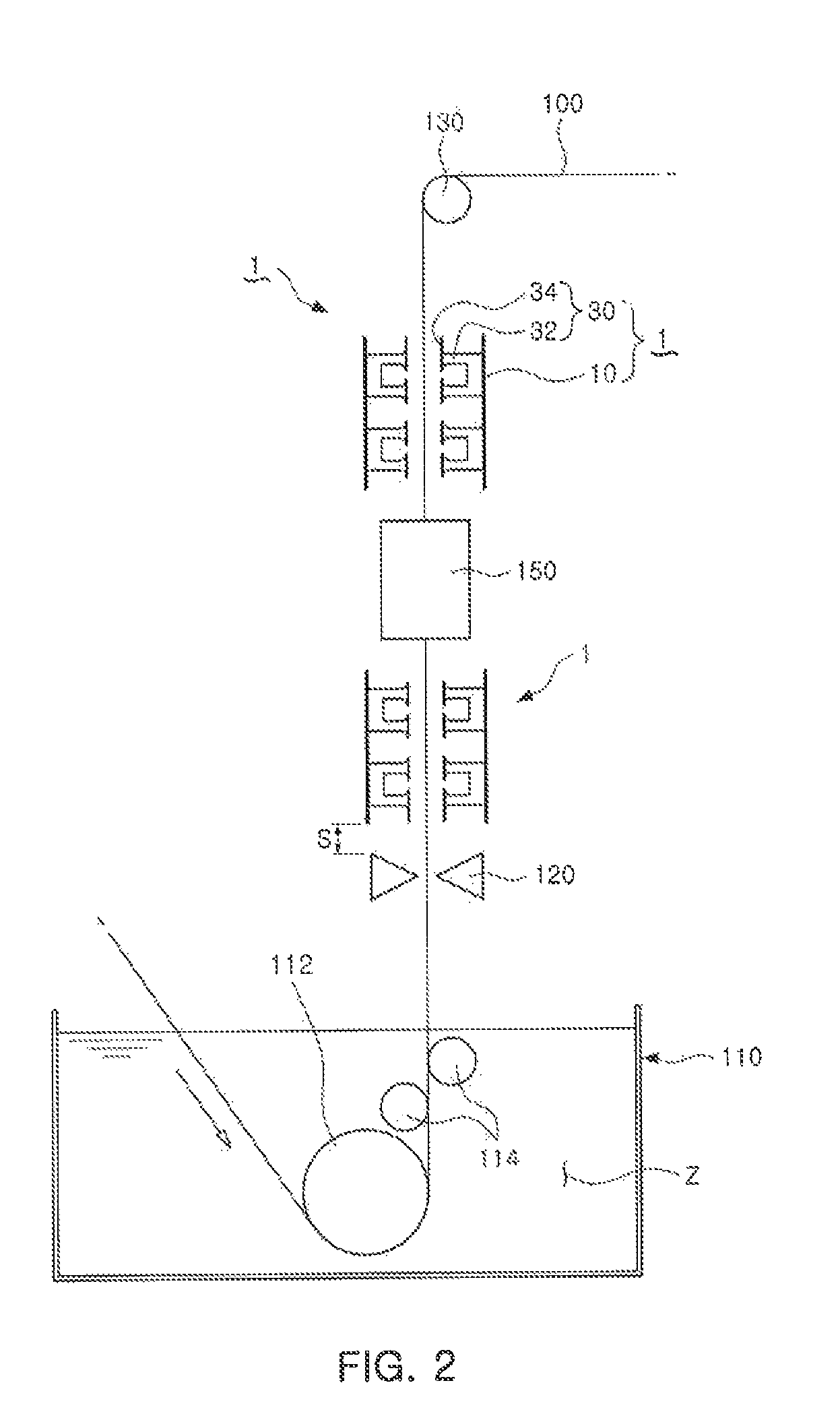

Device for removing foreign material from molten metal surface in steel sheet hot-dip galvanizing process

PendingUS20220106674A1Improve steel qualityReduce driving loadHot-dipping/immersion processesFatty/oily/floating substances removal devicesForeign matterMaterials science

A device for removing foreign material from a molten metal surface in a steel sheet hot-dip galvanizing process, of the present invention, comprises: a snorkel part of which the end portion is submerged under the molten metal surface of a hot-dip galvanizing bath so as to encompass a steel sheet inserted into the hot-dip galvanizing bath, in order to prevent the oxidization thereof; a snout including a dam unit having a dam forming part which encompasses the steel sheet from the end portion of the snorkel part so as to be spaced a predetermined gap from same, and which allows a molten galvanizing solution inside the hot-dip galvanizing bath to flow over toward the inner peripheral surface of the snorkel part so as to prevent the foreign material that falls onto the molten metal surface inside the snorkel part from attaching to the steel sheet; and a molten zinc discharge unit which is provided inside the snorkel part so as to pump, toward the molten metal surface inside the hot-dip galvanizing bath, the molten galvanizing solution having flowed over the dam forming part of the damp unit, thereby preventing the foreign material included in the molten galvanizing solution, having flowed over the dam forming part, from mixing into the molten galvanizing solution inside the hot-dip galvanizing bath and re-polluting the molten galvanizing solution or flowing into the snorkel part again.

Owner:STEPENG

In-situ composite high-strength thick steel plate and manufacturing method thereof

InactiveCN101812640BMeet the requirements of welding performanceGuaranteed one-way solidification conditionsSheet steelManufacturing technology

The invention discloses an in-situ composite high-strength thick steel plate and a manufacturing method thereof. The in-site composite high-strength thick steel plate comprises the following components in mass percentage: 0.1 to 0.2 percent of C, 1.2 to 1.8 percent of Mn, 0.2 to 0.3 percent of Si, less than or equal to 0.015 percent of P, less than or equal to 0.002 percent of S, 0.15 to 0.2 percent of Cu, 0.2 to 0.25 percent of Ni, 0.02 to 0.03 percent of Nb, 0.01 to 0.015 percent of Ti, less than or equal to 0.04 percent of Al, less than or equal to ppm of N, less than or equal to 20 ppm ofO and the balance of Fe and inevitable impurities, wherein the carbon equivalent Ceq which is the ratio of C+(Mn+Si) to 6+(Ni+Cu) to 15+(Cr+Mo+V) is 0.36 to 0.58; and the steel plate thickness is 50 to 400 millimeters. In the invention, the bottom of the produced steel ingot has no negative segregation, the section concentration is almost equal to the molten steel concentration, and the positive segregation is formed on the upper part of the steel ingot; and the tensile strength and the yield strength of the steel can be greatly improved by solute elements such as C and Mn in the steel and by solution strengthening. The upper strength of billets is improved by one-way solidification manufacturing technology starting from the bottom by the segregations of the elements such as C and Mn at the end of the solidification.

Owner:BAOSHAN IRON & STEEL CO LTD

Surface Alloy Supersonic Spraying Strengthening Method and Spraying Material of Finished Steel Roll Pass

ActiveCN104611664BExtend online timeReduce wearMolten spray coatingMaterials scienceSupersonic speed

The invention discloses a surface alloy supersonic spraying strengthening method and a spraying material of a profile steel finish roll pass, belonging to the technical field of material surface strengthening. The method selects nano-scale carbide alloy powder, of which: 15-20% of nickel-aluminum powder, 50-70% of cobalt-tungsten carbide alloy powder, 10-20% of chromium-molybdenum-manganese composite powder, and 5-15% of boron-tungsten composite powder. Use nickel-aluminum powder to make a base of 0.02mm on the profile steel finish roll, and then melt cobalt-tungsten carbide powder, chromium-molybdenum-manganese composite powder and boron-tungsten composite powder and spray evenly on the surface of the roll. The thickness of the sprayed layer is 0.15-0.20mm. The distance between the spray gun and the sprayed surface is 160-180mm, and the angle between the spray gun and the sprayed surface is ≤90°. The method adopts alloy supersonic spraying to strengthen, the surface of the roll pass can resist high temperature and wear resistance, the online time of the roll is prolonged, the amount of passing steel is increased by more than 1 times, and the life of the roll is extended by more than 2 times.

Owner:ANHUI HENGYI HARD FACE ENG CO LTD

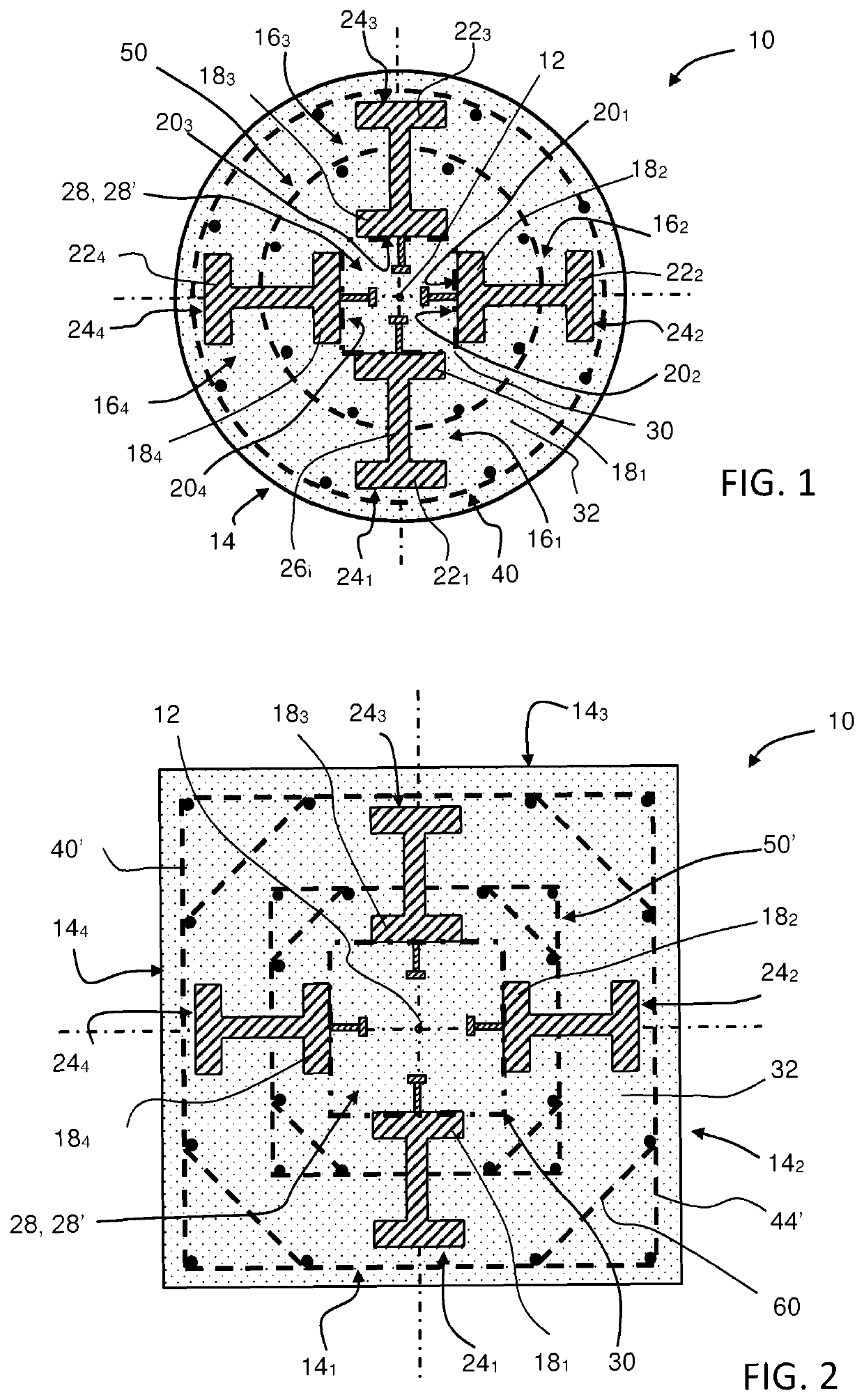

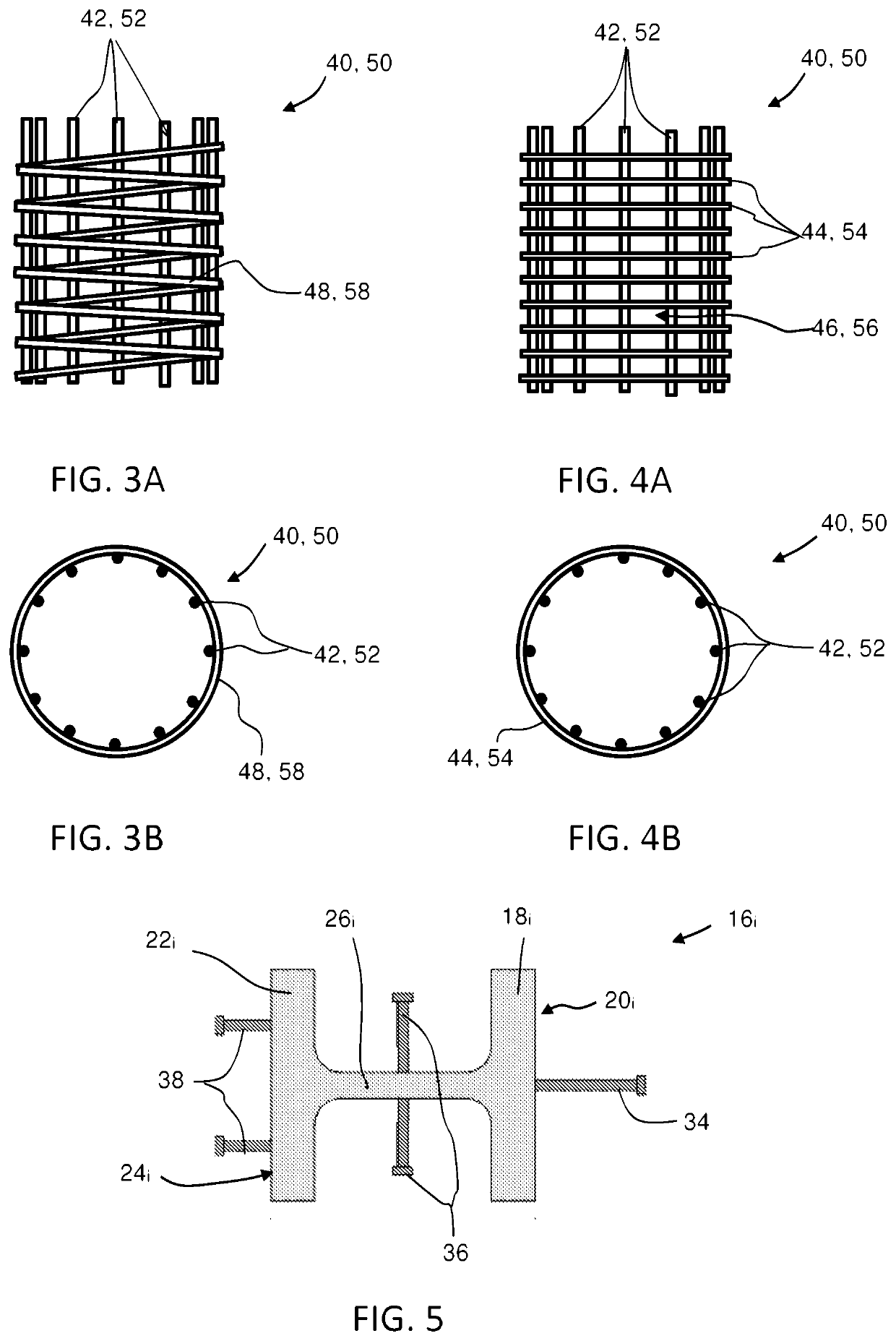

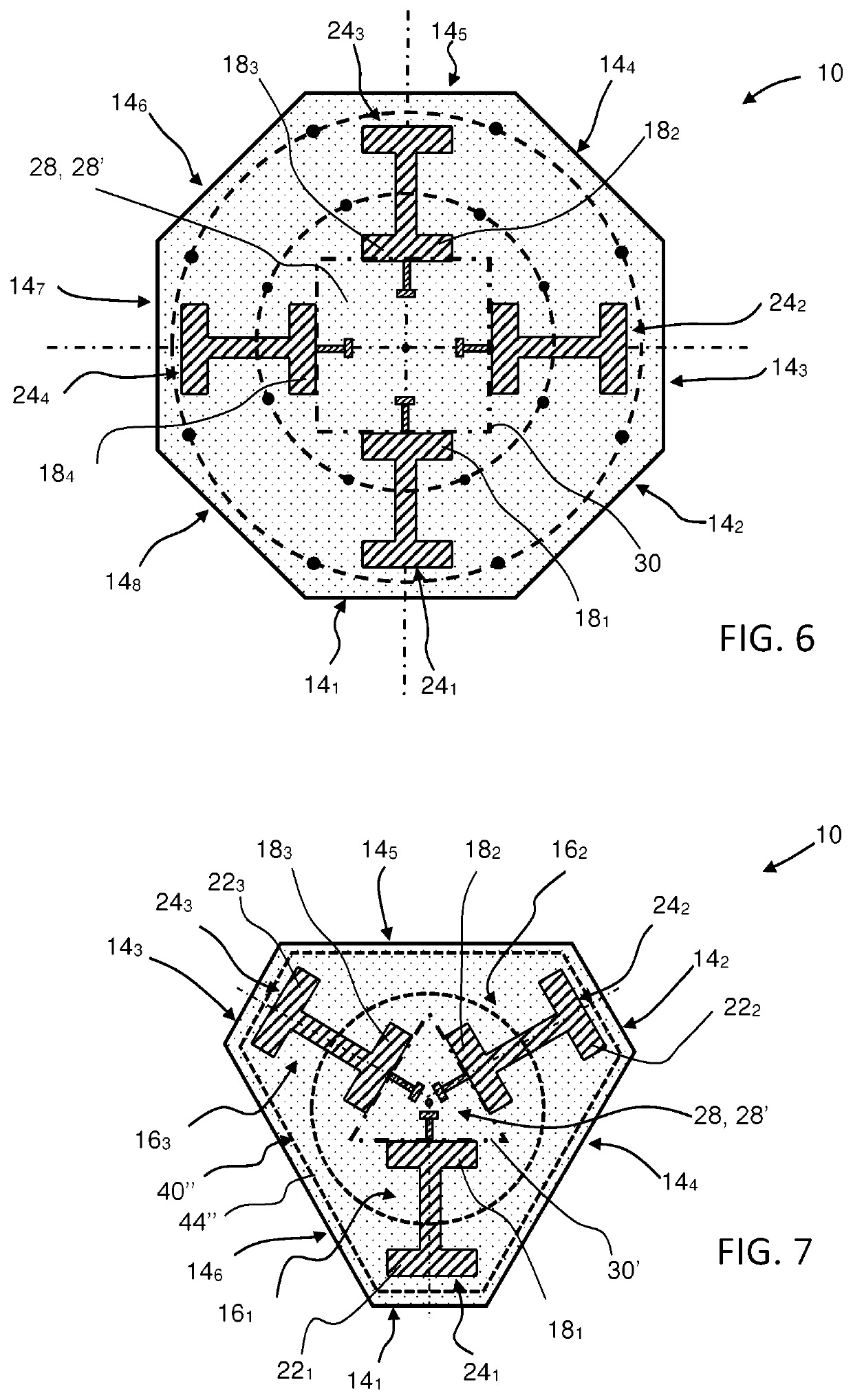

Steel reinforced concrete column

ActiveUS20210230859A1Quality improvementEasy to buildStrutsBuilding reinforcementsReinforced concrete columnArchitectural engineering

A steel reinforced concrete column for a high rise building comprises a plurality of hot-rolled steel sections extending longitudinally through the concrete column. Each of these steel sections has an outward flange with an outer surface turned outwards in the concrete column, an opposite inward flange with an outer surface turned inwards in the concrete column, and a web connecting the outward flange to the inward flange. The steel sections are arranged in the concrete column so that the outer surfaces of their inward flanges at least partially delimit therein a central concrete core with n lateral sides and a transversal cross-section that forms an n-sided polygon, n being at least equal to three, and each of then lateral sides of the central concrete core being coplanar with the outer surface of the inward flange of at least one steel section.

Owner:ARCELORMITTAL INVESTIGACION Y DESARROLLO SL

A rare earth microalloyed high-strength building steel bar and its production method

The invention discloses a rare earth microalloyed high-strength construction steel bar and a production method thereof, and belongs to the technical field of steel for construction structures. The novel high-strength construction steel bar is provided, rare earth alloy cored wires are developed according to the variety of the rare earth microalloyed high-strength steel bar, qualified steel bars meeting the national standard requirements are obtained in high-strength steel bar production, and the problem that in the prior art, expensive elements such as V are often used, and consequently the cost is high is solved. The construction steel bar is prepared from the chemical compositions in percentage by weight: 0.20%-0.25% of C, 0.40%-0.80% of Si, 1.1%-1.60% of Mn, greater than 0.025% of Re, less than 0.045% of P, less than 0.045% of S, and the balance of Fe and inevitable impurities, wherein the mass percentage of O, Ca and Mg meets the formula of O / S<0 2, and Re / (Ca+Mg) is controlled between 10-100. The cost is lowered while the construction steel bar meets the national standard requirements.

Owner:CENT IRON & STEEL RES INST +2

Stabilized lubricant composition for continuous casting processes

Described herein is a stabilized lubricant composition for use in steel casting, in particular in continuous casting processes. In particular, the lubricant composition for processes for producing steel by continuous casting includes a dispersion of a lubricant powder, for an ingot mold, in continuous casting, in an oily liquid means, and a stabilization additive, characterized in that it has the following shear thinning index values:RVT0.1 / 11 / 1010 / 100100 / 1000STI3.0-7.52.0-6.51.0-3.00.5-2.0wherein RVT is the ratio between two different shear speeds and STI is the shear thinning index corresponding to the RVT values.

Owner:PROSIMET

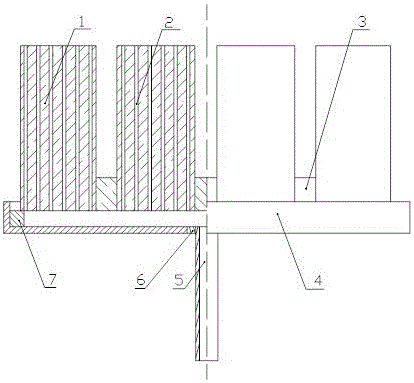

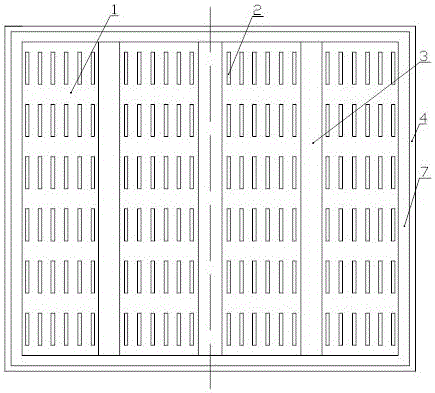

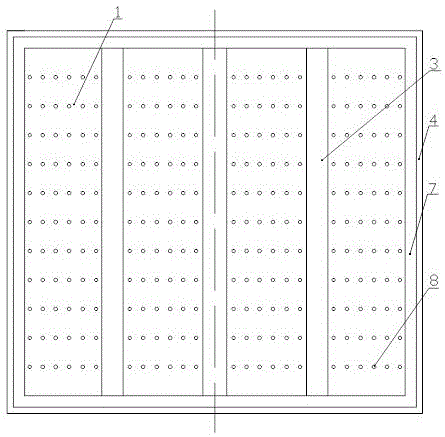

Ladle refining air brick with micro argon bubbles formed through bottom blowing

The invention relates to a ladle refining air brick with micro argon bubbles formed through bottom blowing. According to the technical scheme, a strip-shaped boss (7) is fixed to the inner wall of a rectangular framework in a closely attached mode, 2-8 refractory bricks (1) are built on the strip-shaped boss (7), the refractory bricks (1) are bonded with refractory mortar (3), and the refractory bricks (1) are provided with air slits (2) or air holes (8) serving as independence channels; an air supply pipe (5) is concentrically fixed in a sleeve (6) fixed to the center of a base (4); for the air slits (2), the width is 0.15-0.20 mm, the length is 2-100 times the width, the center distance is 25-50 mm, and the area ratio of the slit area to the upper surfaces of the refractory bricks (1) is 1:(125-300); for the air holes (8), the diameter is 0.15-0.20 mm, the center distance is 25-50 mm, and the area ratio of the hole area to the upper surfaces of the refractory bricks (1) is 1:(200-500). The ladle refining air brick with micro argon bubbles formed through bottom blowing has the advantages of being convenient to install and maintain, good in use effect and long in service life.

Owner:WUHAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com