Submerged entry nozzle

a nozzle and submerged technology, applied in the direction of transportation and packaging, manufacturing tools, liquid transfer devices, etc., can solve the problems of surface defects, surface cracks, surface cracks in finished steel, etc., to improve the flow dynamics of molten steel entering the mold, improve the quality of cast steel, and minimize the effect of steel flow turbulen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

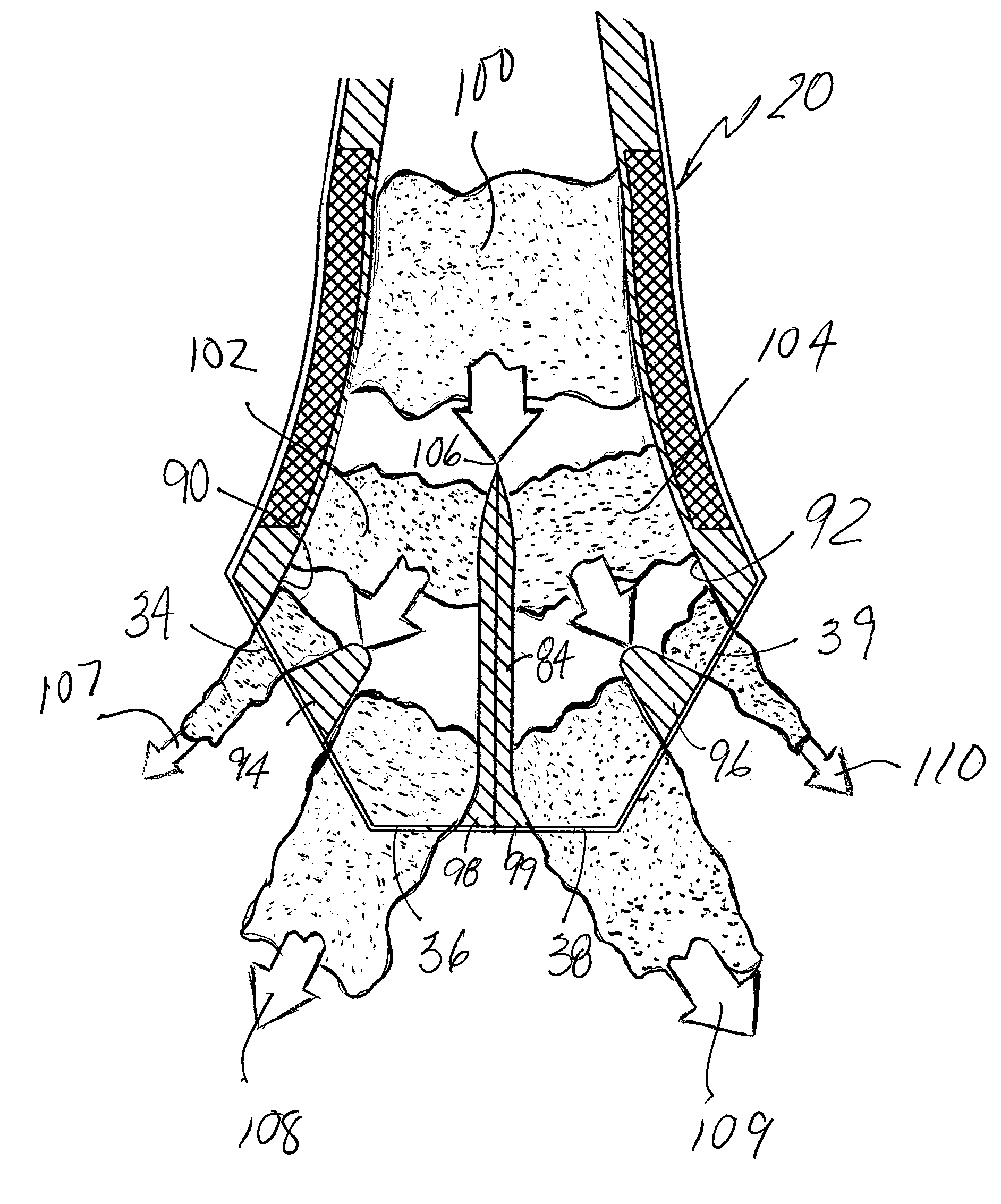

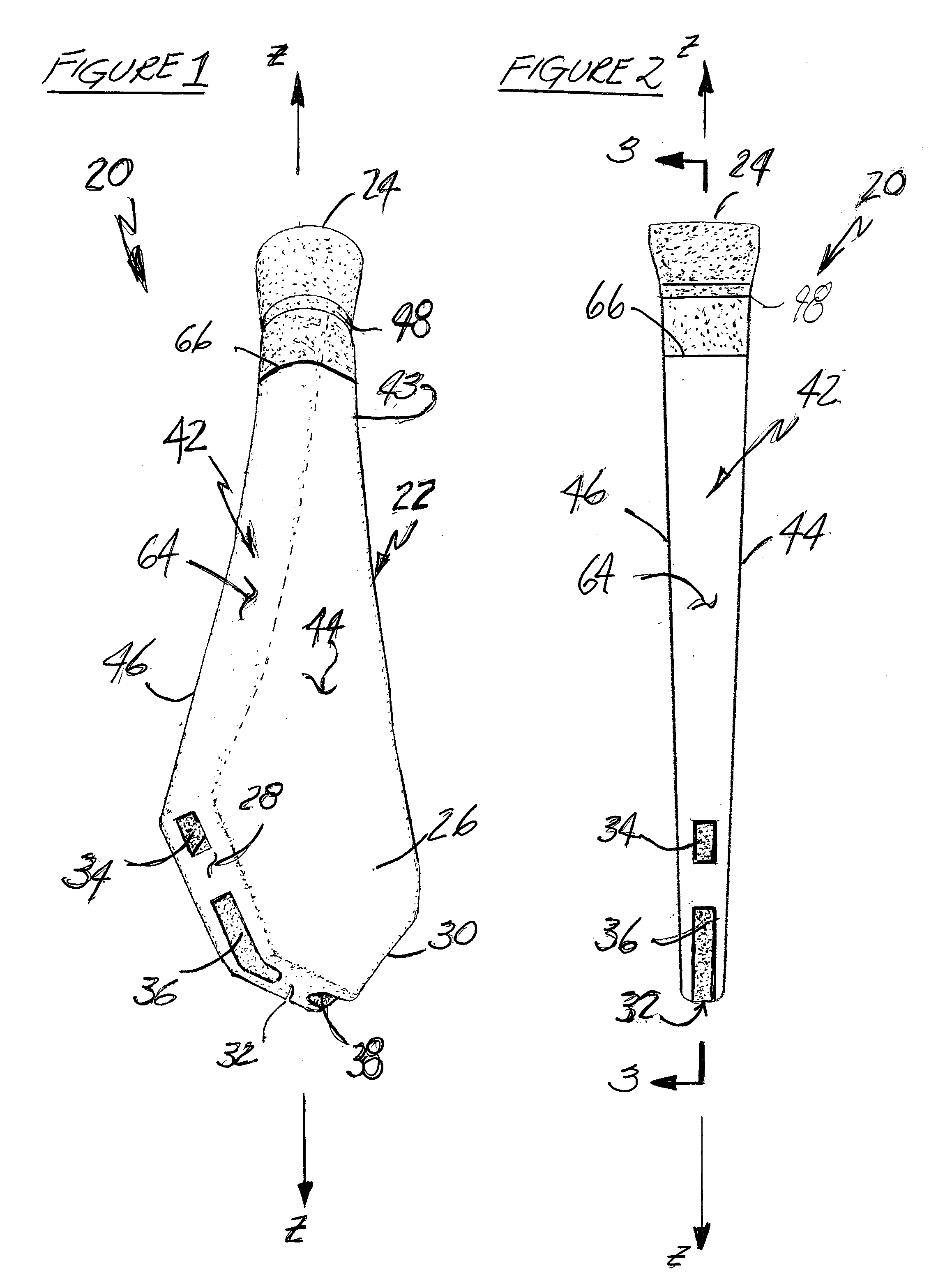

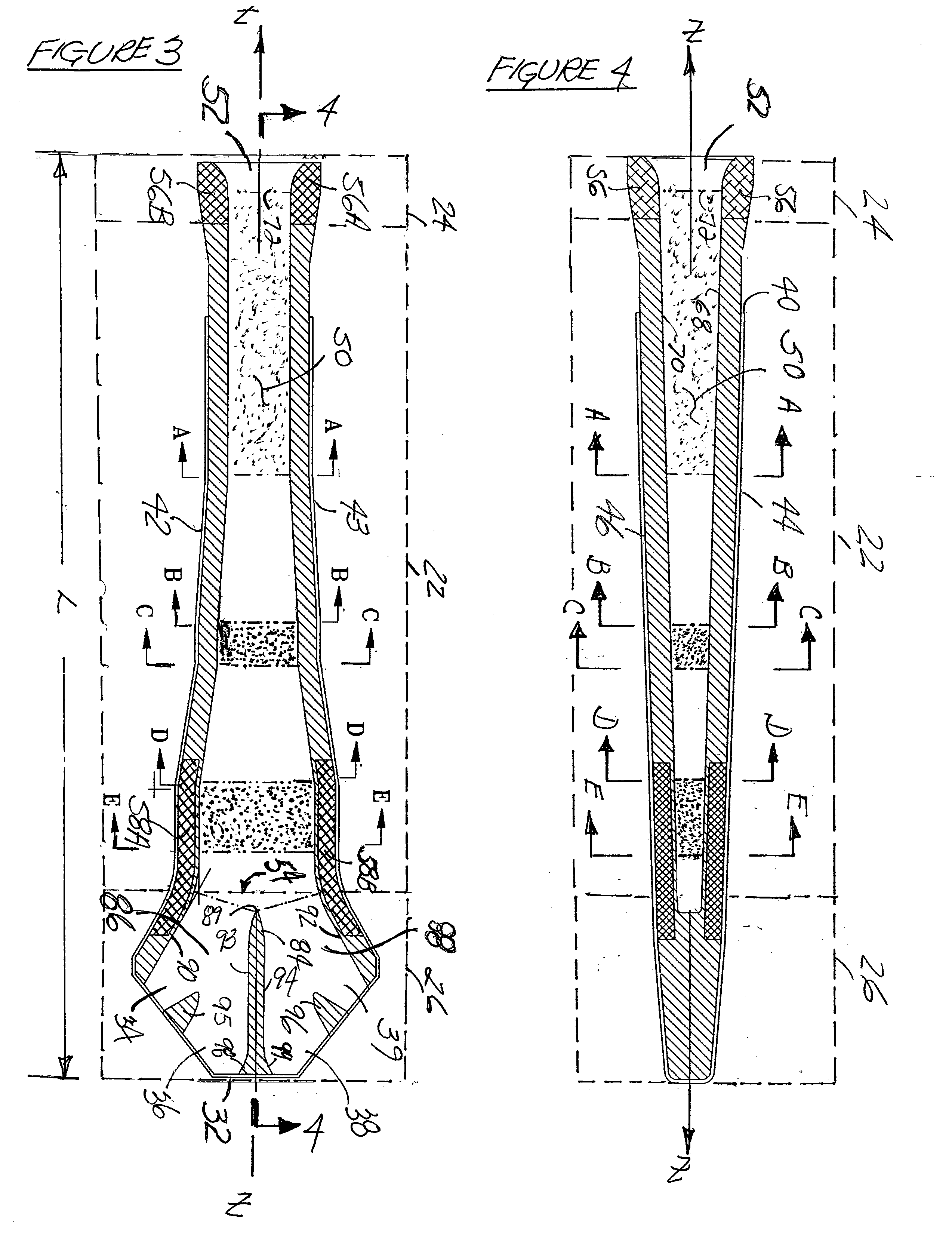

[0032]FIG. 1 is a perspective illustration of the submerged entry nozzle, or “SEN”20 of the present invention, which is shown vertically positioned along its longitudinal axis (Z) as in its operational placement between the casting machine tundish and mold. The SEN 20 has a main body 22, with an inlet 24 at one end for receiving liquid steel from a tundish (not shown), and a distribution zone 26 at the opposite end for delivering the liquid steel to the casting machine mold. The inlet 24 is adapted to mate with the output coupling of the tundish, which is generally a circular coupling at a stated diameter. The liquid steel received at the inlet flows through a central bore in the main body 22 (described hereinafter with respect to FIGS. 3 through 10) to the distribution zone 26. The distribution zone 26 channels the flow though interior lateral passages (also described hereinafter with respect to FIGS. 3 through 10) to outlet ports disposed in opposite side segments, or facets 28, 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com