A special water inlet and exhaust device for cylinder hydrostatic test

A hydraulic test and exhaust device technology, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, can solve the problem of not solving the problem of cylinder hydraulic test, such as one hole with multiple functions, and achieves simple structure, simple working principle, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

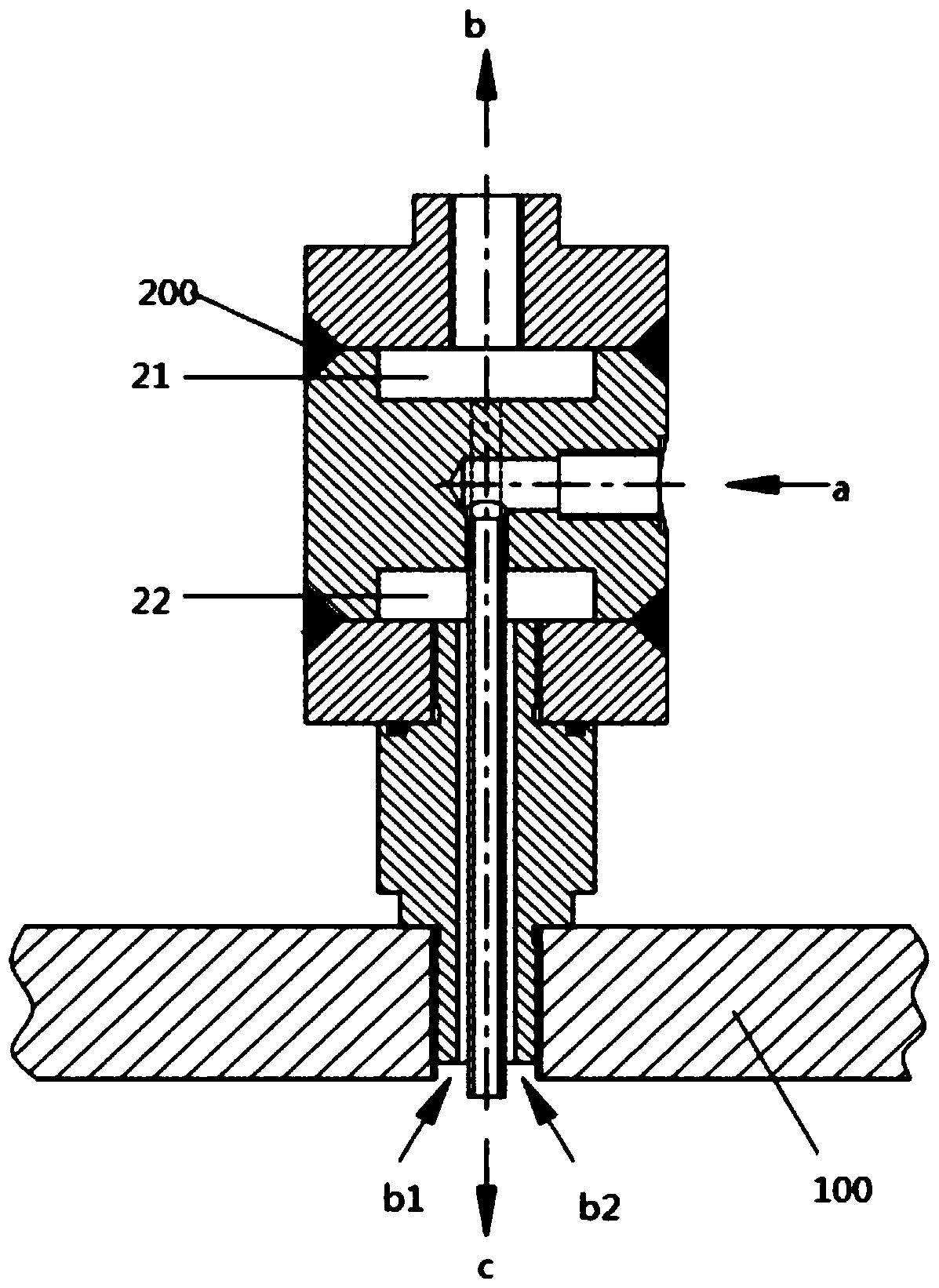

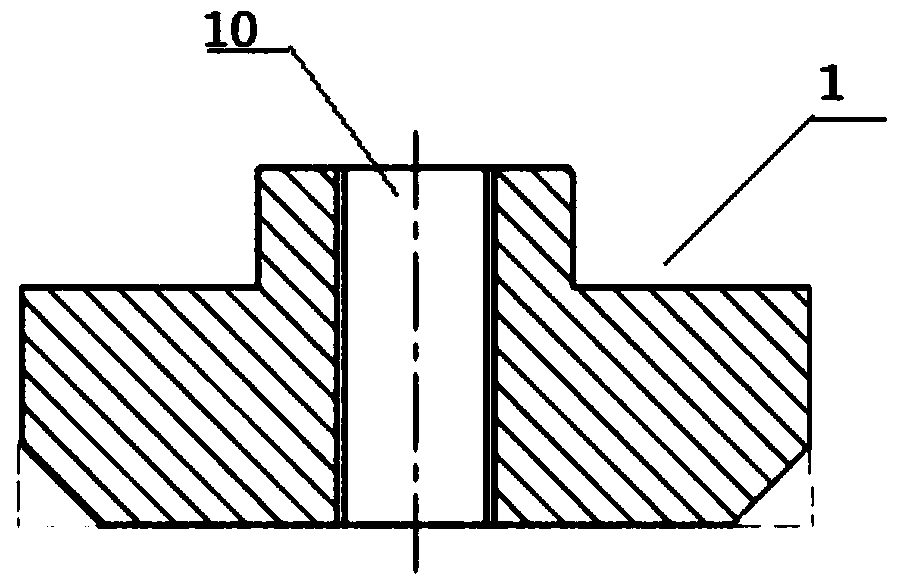

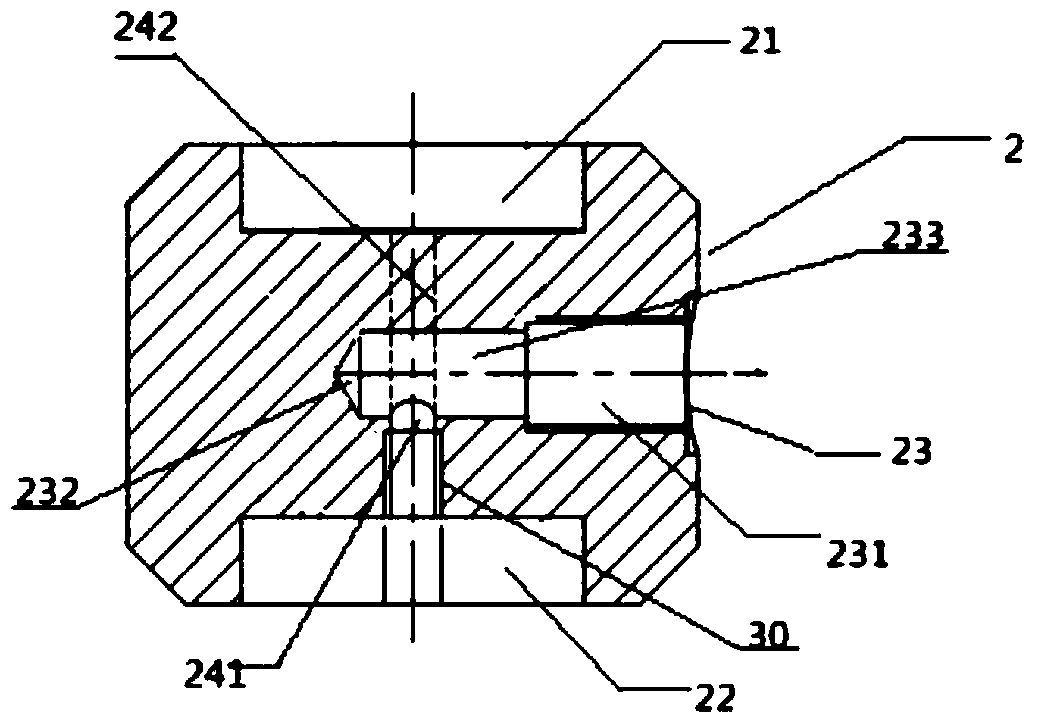

[0029] Such as Figure 1~6A specific embodiment of the present invention shown is as follows: a special water inlet and exhaust device for cylinder hydraulic test, including an upper cover plate 1 with a first exhaust cavity 10 in the middle, a screw cavity in the middle 30 lower cover plate 3, water inlet and exhaust assembly 2 with air cavity and water inlet hole 23, connecting screw 4 with second exhaust cavity 40 in the middle, and water outlet pipe with water outlet cavity 50 in the middle 5. The water intake and exhaust assembly 2 is installed between the upper cover plate 1 and the lower cover plate 3, and connected by welding 200; the water intake and exhaust assembly 2 is also provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com