In-situ composite high-strength thick steel plate and manufacturing method thereof

A manufacturing method and high-strength technology, which are applied in the field of self-generating composite high-strength thick steel plates and their manufacturing fields, can solve the problems of difficult realization of large-size products, complicated production processes, and difficult rolling, so as to ensure the Z-direction performance and improve the structure. Uniformity, the effect of ensuring the binding ability

Inactive Publication Date: 2010-08-25

BAOSHAN IRON & STEEL CO LTD

View PDF1 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Commonly used clad steel slabs are made of at least one layer of basic steel and more than one layer of other steel alternately and closely stacked. This method can produce clad steel plates of different materials, but the rolling is difficult and the production process is complicated.

Chinese patent application number 200410018300.9 discloses the preparation of regular fibrous oriented γ-(Fe, Mn) by high-speed directional solidification with ultra-high temperature gradient 3 C eutectic self-generated composite material, its research method provides a new idea for the preparation of eutectic composite material, but this method requires ultra-high temperature gradient and high-speed directional solidification conditions, and it is difficult to realize it in large-scale products

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

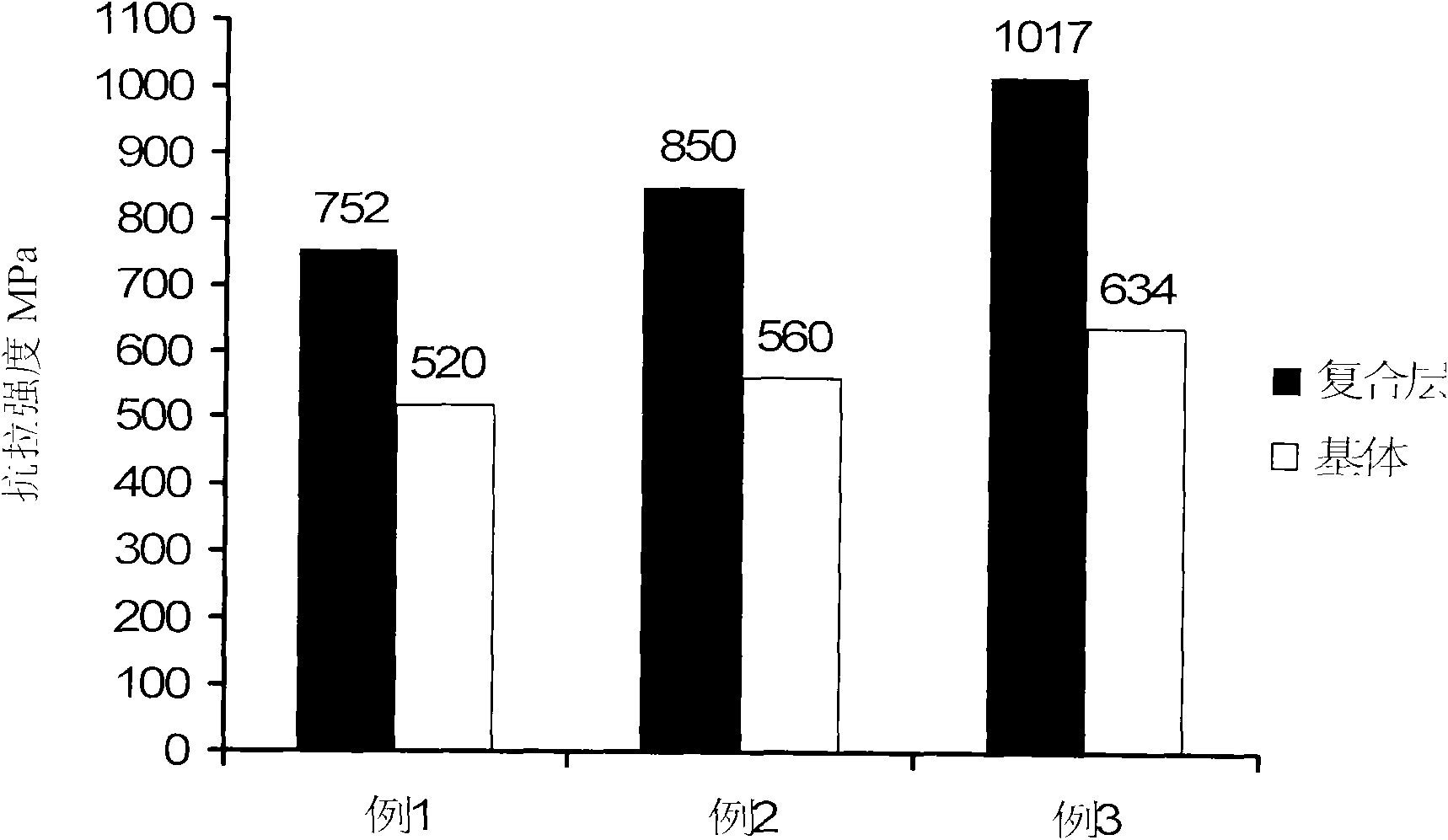

example 1 example 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

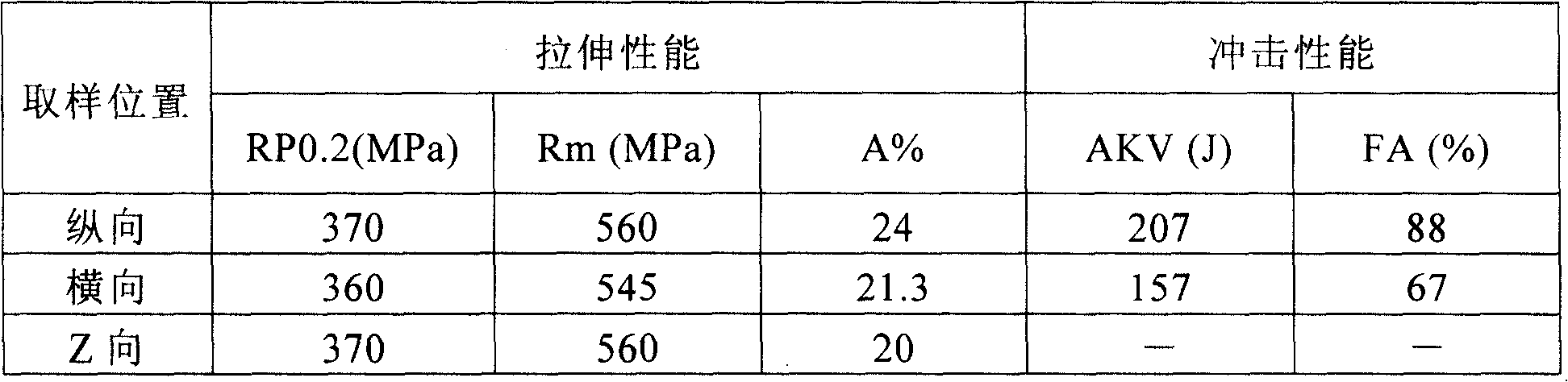

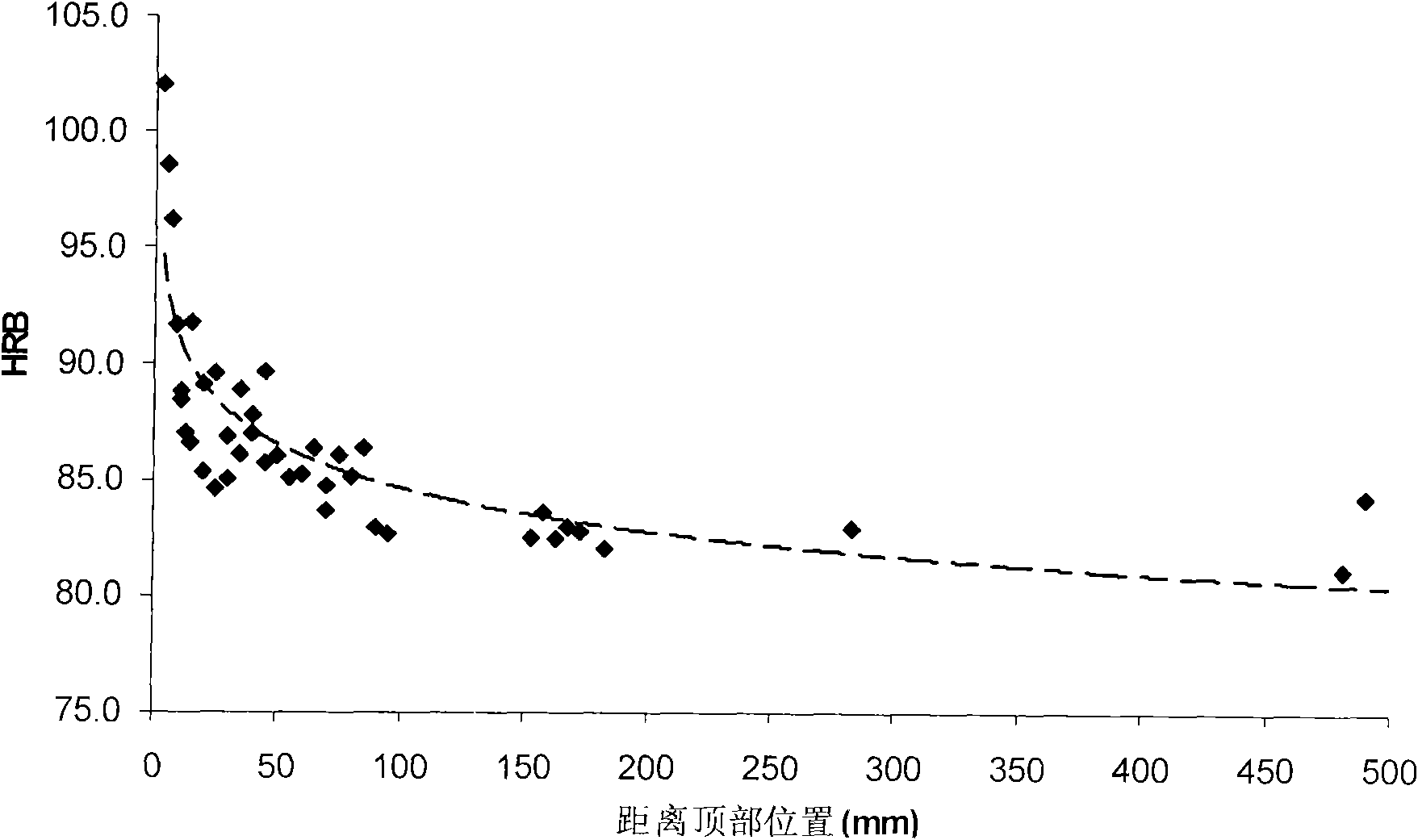

The invention discloses an in-situ composite high-strength thick steel plate and a manufacturing method thereof. The in-site composite high-strength thick steel plate comprises the following components in mass percentage: 0.1 to 0.2 percent of C, 1.2 to 1.8 percent of Mn, 0.2 to 0.3 percent of Si, less than or equal to 0.015 percent of P, less than or equal to 0.002 percent of S, 0.15 to 0.2 percent of Cu, 0.2 to 0.25 percent of Ni, 0.02 to 0.03 percent of Nb, 0.01 to 0.015 percent of Ti, less than or equal to 0.04 percent of Al, less than or equal to ppm of N, less than or equal to 20 ppm of O and the balance of Fe and inevitable impurities, wherein the carbon equivalent Ceq which is the ratio of C+(Mn+Si) to 6+(Ni+Cu) to 15+(Cr+Mo+V) is 0.36 to 0.58; and the steel plate thickness is 50 to 400 millimeters. In the invention, the bottom of the produced steel ingot has no negative segregation, the section concentration is almost equal to the molten steel concentration, and the positive segregation is formed on the upper part of the steel ingot; and the tensile strength and the yield strength of the steel can be greatly improved by solute elements such as C and Mn in the steel and by solution strengthening. The upper strength of billets is improved by one-way solidification manufacturing technology starting from the bottom by the segregations of the elements such as C and Mn at the end of the solidification.

Description

technical field The invention relates to a composite steel plate and a manufacturing method thereof, in particular to a self-generated composite high-strength thick steel plate and a manufacturing method thereof. Background technique With the development of modern industry, the demand for composite materials is increasing day by day, and the research and application of composite materials have also developed rapidly. Commonly used clad steel slabs are made of at least one layer of basic steel and more than one layer of other steel alternately and closely stacked. This method can produce clad steel plates of different materials, but the rolling is difficult and the production process is complicated. Chinese patent application number 200410018300.9 discloses the preparation of regular fibrous oriented γ-(Fe, Mn) by high-speed directional solidification with ultra-high temperature gradient 3 The research method of C eutectic self-generated composite materials provides a new i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C38/16C22C33/04B22D27/00C21D8/04

Inventor 龚羽焦四海裴云毅沈建国

Owner BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com