Guide plate for charge and discharge system and preparation method of guide plate

A deflector, charging and discharging technology, applied in the field of deflectors, can solve the problems of increased production cost, troublesome handling, environmental pollution, etc., and achieves the effects of reduced environmental impact, convenient production and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below with reference to the accompanying drawings and in conjunction with the embodiments.

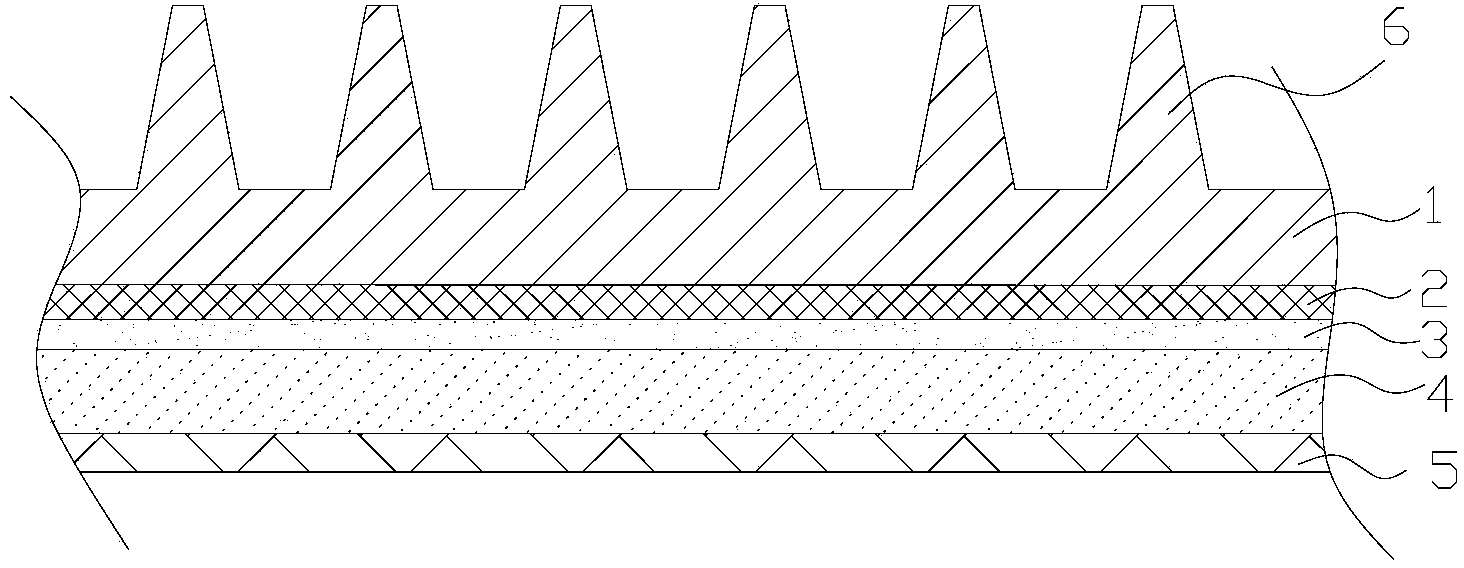

[0014] Such as figure 1 As shown, the deflector of the present invention is mainly composed of a substrate 1 , an aluminum alloy layer 2 , a zinc alloy layer 3 , a high-phosphorus nickel-phosphorus alloy coating 4 and a low-phosphorus nickel-phosphorus alloy coating 5 . The deflector is a flat plate structure as a whole, and the shape can be selected according to needs during use.

[0015] The base material 1 is formed by die-casting silicon carbide powder, and the aluminum alloy layer 2, the zinc alloy layer 3, the high-phosphorus nickel-phosphorus alloy coating 4 and the low-phosphorus nickel-phosphorus alloy coating 5 are all arranged on the base material 1 in sequence, in order to obtain For a better flow guiding effect, the bottom surface of the substrate 1 can be further uniformly and densely covered with protrusions 6 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com