Rare earth microalloyed high-strength construction steel bar and production method thereof

A technology of microalloying and building steel bars, which is applied in the field of steel for building structures, can solve the problems of high cost, achieve the effects of ensuring production, improving the utilization rate of rare earths, and preventing performance deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

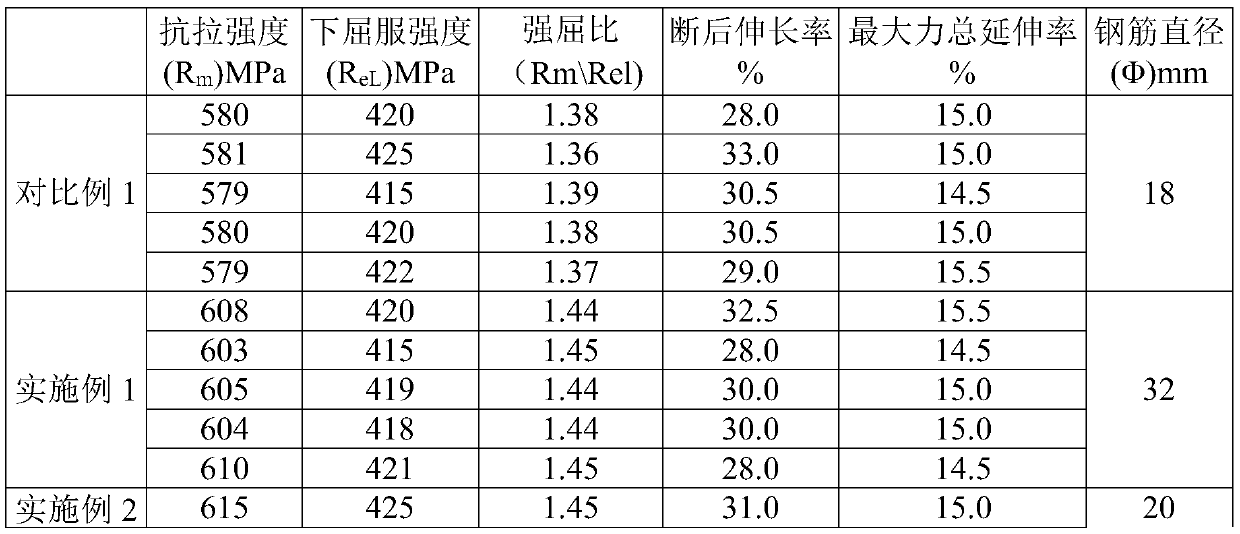

[0027] A rare earth microalloyed high-strength building steel bar and its production method will be further described in detail below in conjunction with specific examples. These examples are only for the purpose of comparison and explanation, and the present invention is not limited to these examples.

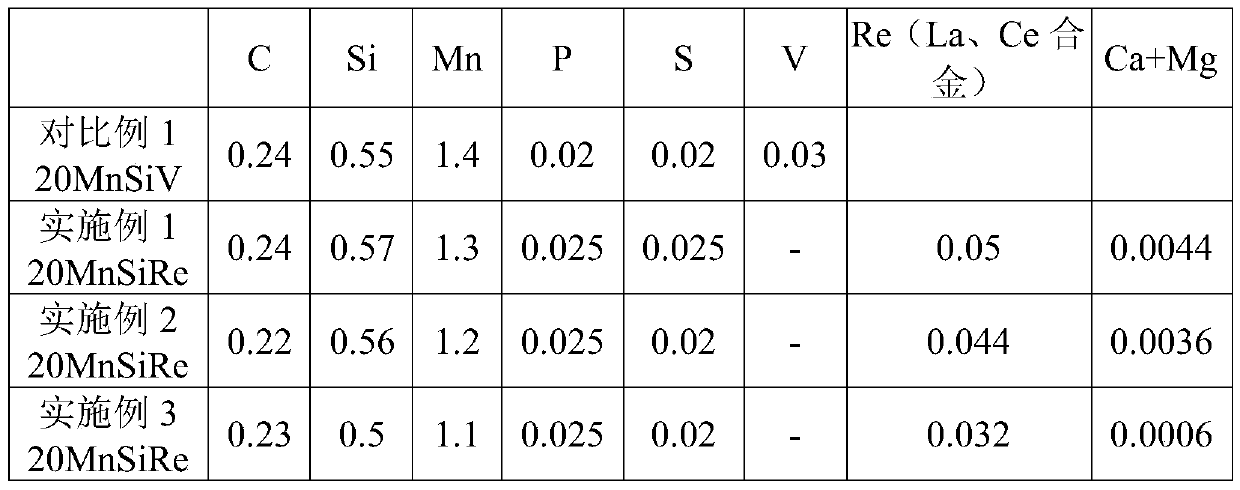

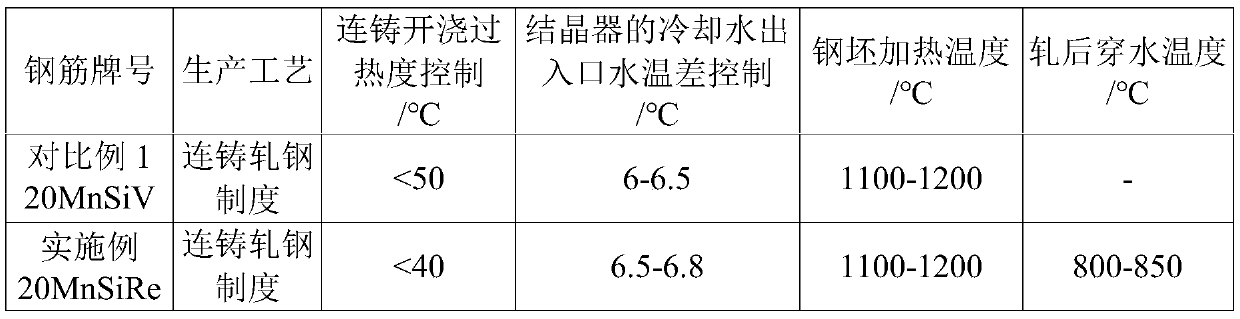

[0028] A rare earth microalloyed high-strength building steel bar, the chemical composition of which is calculated by weight percentage: C: 0.20%-0.25%, Si: 0.40%-0.80%, Mn: 1.1%-1.60%, Re>0.025%, P: <0.045%, S: <0.045%, the mass percentage of O, Ca+Mg meets: O / S<0.2, Re / (Ca+Mg) is controlled between 10-100; the rest is Fe and unavoidable impurities.

[0029] The effect and proportioning basis of each element of the present invention are as follows:

[0030]Carbon: It can directly affect the mechanical properties of steel such as strength and toughness. It has a significant solid solution strengthening effect and improves the hardenability of steel. However, when the content...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com