Continuous casting nozzle

a technology of continuous casting and nozzle, which is applied in the direction of casting apparatus, melt-holding vessels, manufacturing tools, etc., can solve the problems of insufficient exertion of inclusion adhesion reducing performance, degrading the quality of steel slab, and narrowing of inner holes and subsequent blockages, so as to improve the quality of steel and improve the thermal spalling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

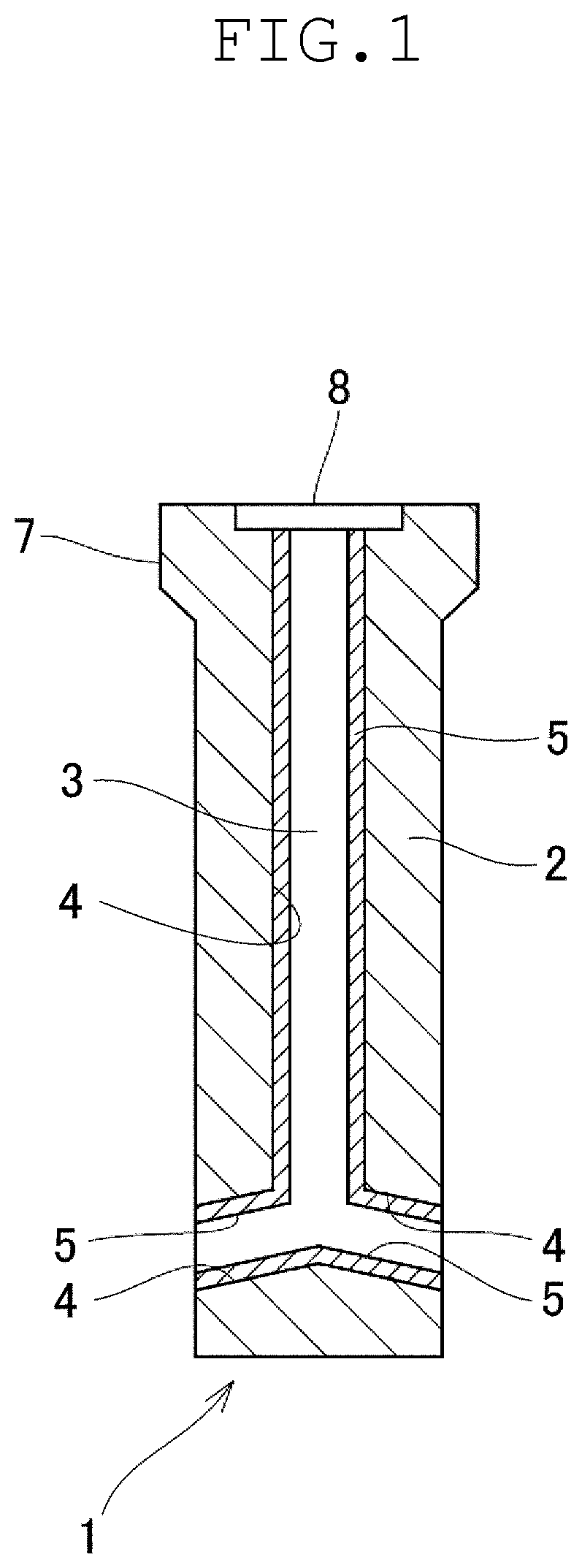

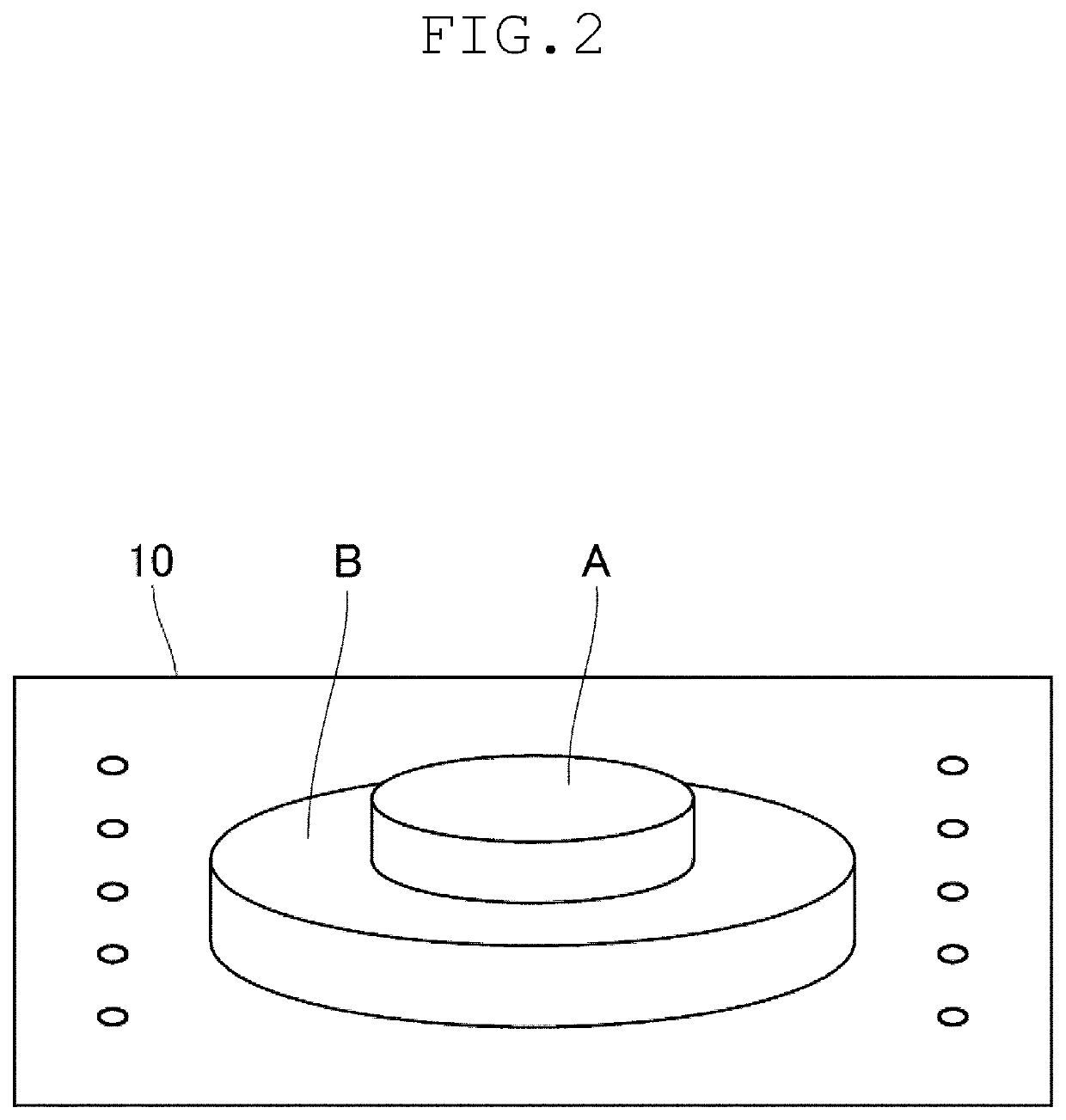

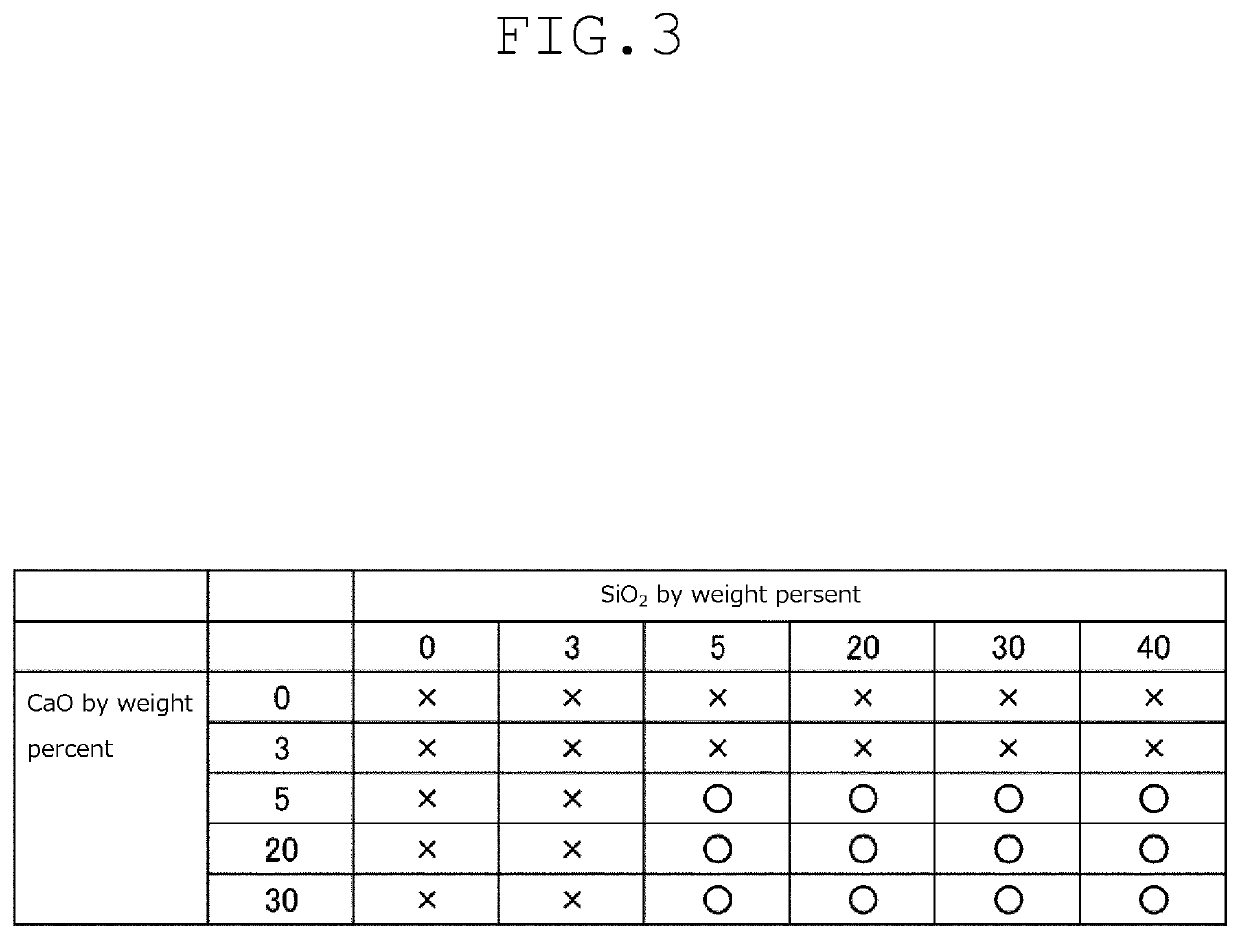

[0019]The continuous-casting nozzle in accordance with the present invention will be described with reference to an embodiment shown in the drawings. As shown in FIG. 11, a continuous casting nozzle 1 of this embodiment has a nozzle main body 2 and a nozzle hole 3 formed through the nozzle main body 2 for flowing molten steel. The nozzle hole 3 has an inner surface 4 on which an alumina-hardly-adherable refractory 5 containing components of MgO, CaO and SiO2 is disposed. The configuration of each component of the continuous casting nozzle 1 will be described in detail below.

[0020]The continuous casting nozzle 1 is an immersion nozzle which is disposed between a tundish and a mold and used when molten steel is poured from the tundish into the mold. The nozzle hole 3 through which the molten steel flows has a surface layer portion formed by the alumina-hardly-adherable refractory 5, whereas the nozzle main body 2 is made of a conventional alumina-black lead refractory.

[0021]The nozzle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com