Ladle refining air brick with micro argon bubbles formed through bottom blowing

A technology of ladle refining and air-permeable bricks, applied in the field of air-permeable bricks, can solve the problems that core components are easily eroded by molten steel, it is difficult to take into account the long service life, and uniform argon bubbles cannot be obtained, so as to save the cost of argon blowing and improve casting. sex, good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

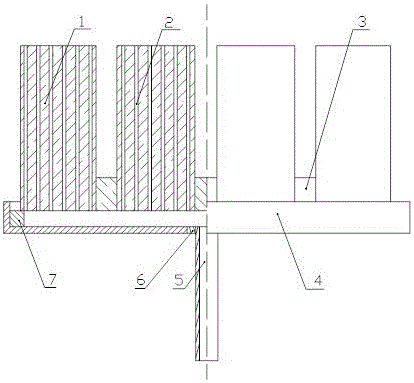

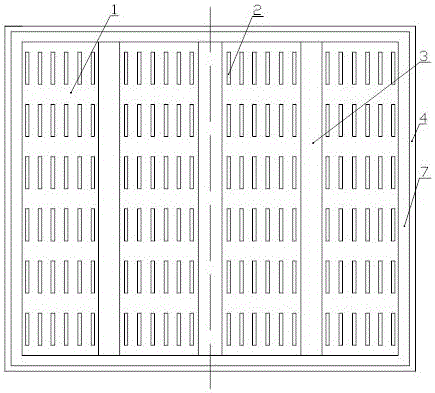

[0027] A gas permeable brick with bottom-blown fine argon bubbles for ladle refining. The breathable bricks are as figure 1 and figure 2 As shown, including refractory brick 1, base 4 and air supply pipe 5. The base 4 is as figure 1 , figure 2 , Figure 4 and Figure 5 As shown, a rectangular frame is fixed on the periphery of the rectangular bottom plate, and a strip-shaped boss 7 is arranged close to the inner wall of the rectangular frame. The strip-shaped boss 7 is located on the upper plane of the rectangular bottom plate, and the height of the strip-shaped boss 7 The height ratio to the rectangular frame is 1: (2~3). Such as figure 1 As shown, there are refractory bricks 1 built on the strip boss 7, and there are 4 refractory bricks 1, and refractory mud 3 is bonded between each refractory brick. Such as figure 2 As shown, each refractory brick 1 is provided with a ventilation slit 2. Such as figure 1 , Figure 4 and Figure 5 As shown, a sleeve 6 is fixe...

Embodiment 2

[0031] A gas permeable brick with bottom-blown fine argon bubbles for ladle refining. The breathable bricks are as figure 1 and figure 2 As shown, including refractory brick 1, base 4 and air supply pipe 5. The base 4 is as figure 1 , figure 2 , Figure 4 and Figure 5 As shown, a rectangular frame is fixed on the periphery of the rectangular bottom plate, and a strip-shaped boss 7 is arranged close to the inner wall of the rectangular frame. The strip-shaped boss 7 is located on the upper plane of the rectangular bottom plate, and the height of the strip-shaped boss 7 The height ratio to the rectangular frame is 1: (2~3). Such as figure 1 As shown, there are refractory bricks 1 built on the strip-shaped boss 7, and the number of refractory bricks 1 is 2 to 3 or 5 to 8, and refractory mud 3 is bonded between each refractory brick. Such as figure 2 As shown, each refractory brick 1 is provided with a ventilation slit 2. Such as figure 1 , Figure 4 and Figure 5...

Embodiment 3

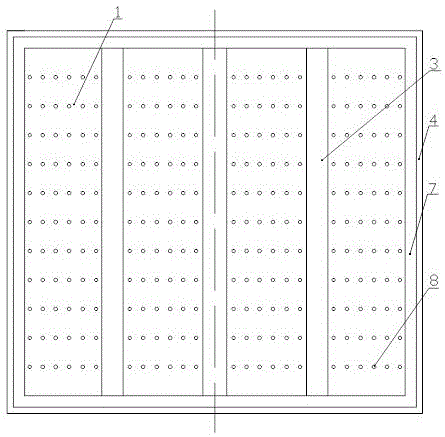

[0035] A gas permeable brick with bottom-blown fine argon bubbles for ladle refining. The breathable bricks are as figure 1 and image 3 As shown, including refractory brick 1, base 4 and air supply pipe 5. The base 4 is as figure 1 , image 3 , Figure 4 and Figure 5 As shown, a rectangular frame is fixed on the periphery of the rectangular bottom plate, and a strip-shaped boss 7 is arranged close to the inner wall of the rectangular frame. The strip-shaped boss 7 is located on the upper plane of the rectangular bottom plate, and the height of the strip-shaped boss 7 The height ratio to the rectangular frame is 1: (2~3). Such as figure 1 As shown, there are refractory bricks 1 built on the strip boss 7, and there are 4 refractory bricks 1, and refractory mud 3 is bonded between each refractory brick. Such as image 3 As shown, each refractory brick 1 is provided with ventilation holes 8 . Such as figure 1 , Figure 4 and Figure 5 As shown, a sleeve 6 is fixed a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com