Patents

Literature

113results about How to "Guaranteed desulfurization effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

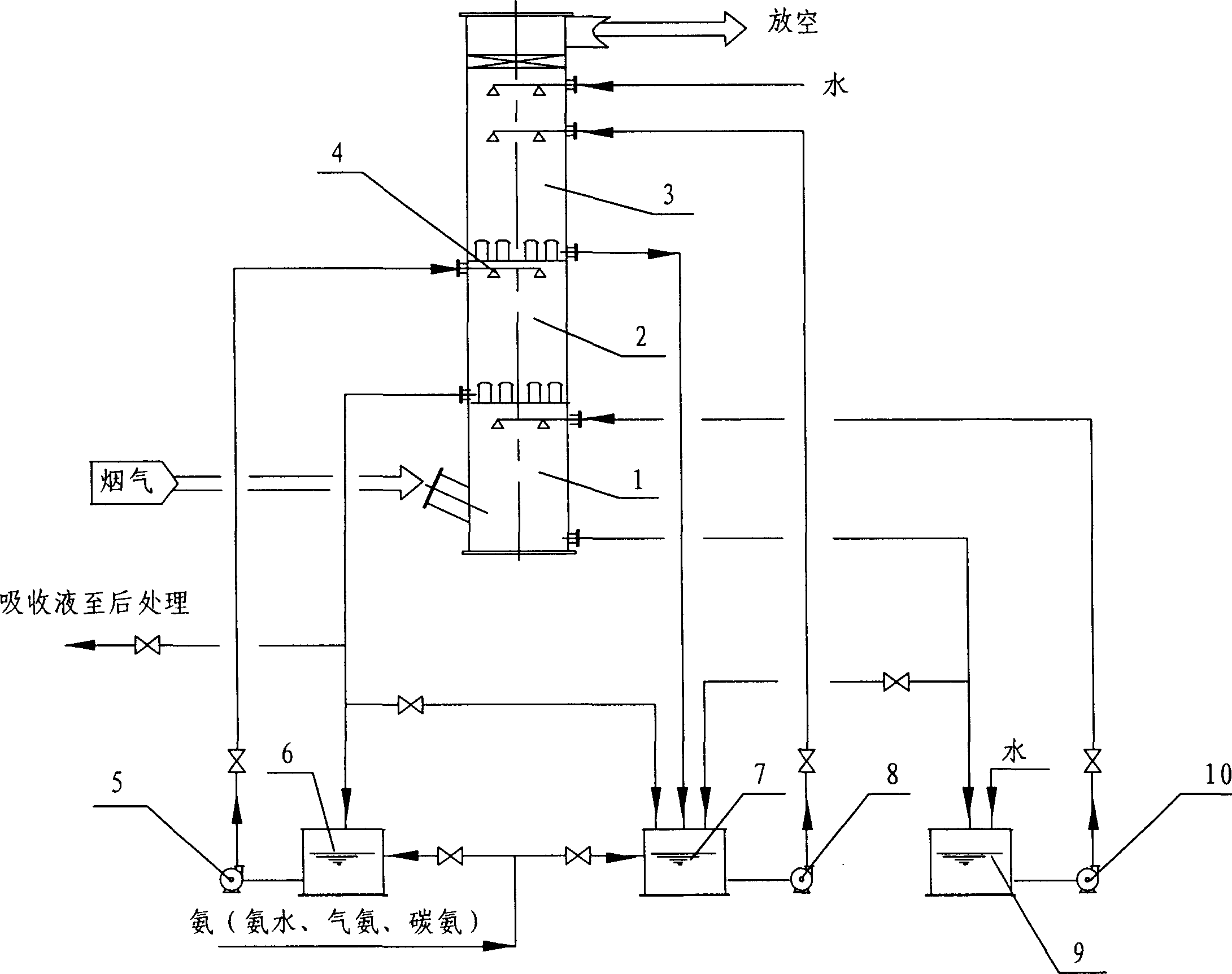

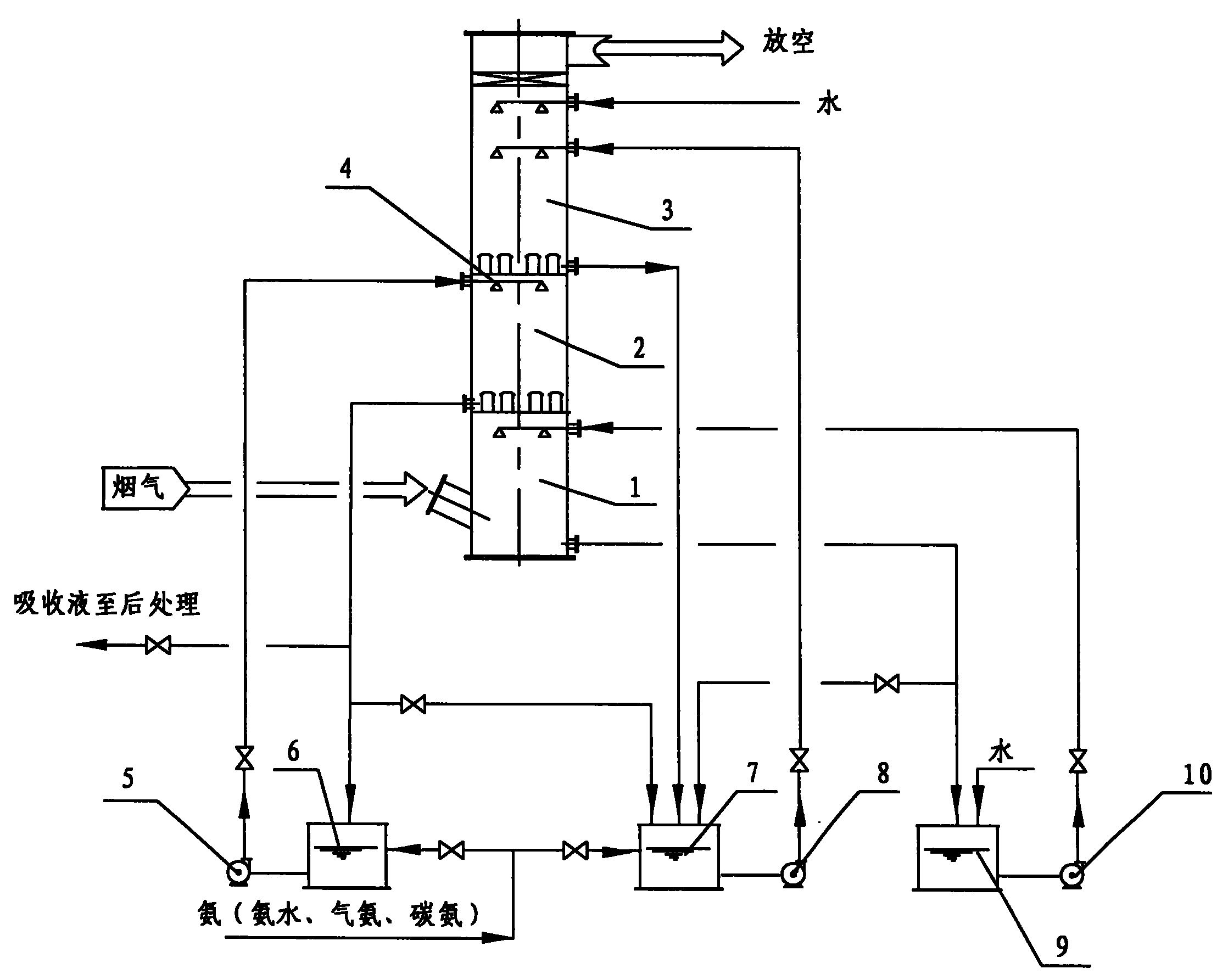

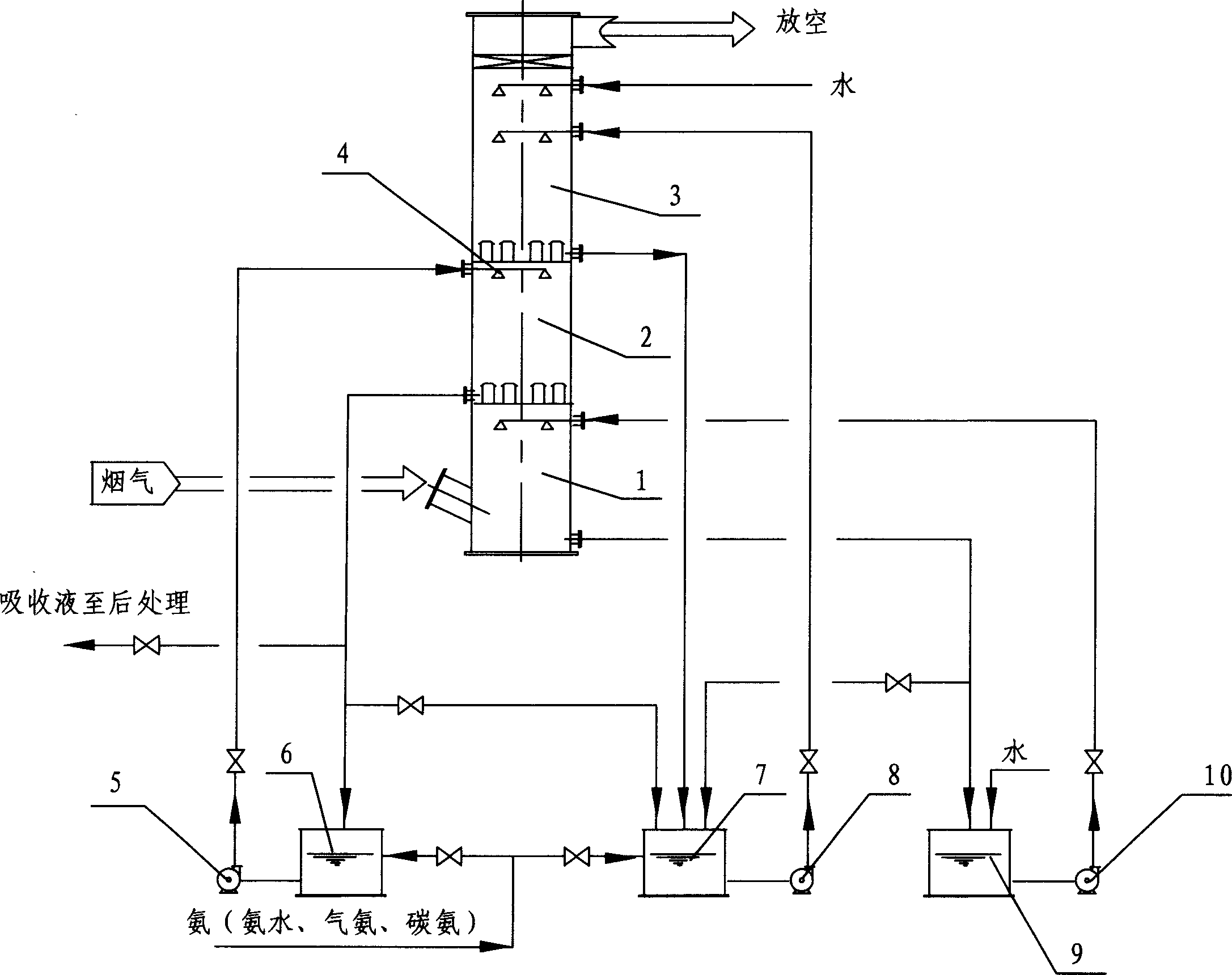

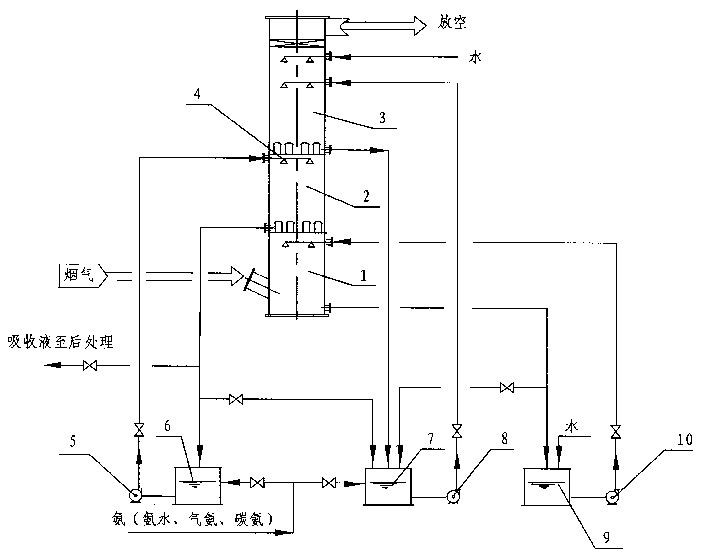

Fuel coal smoke low oxidation rate desulfur method

InactiveCN1283346CGuaranteed desulfurization effectGuaranteed total desulfurization efficiencyDispersed particle separationFlue gasTower

The invention belongs to the environmental protection technology, and relates to a method for recycling sulfur dioxide in flue gas of a coal-fired boiler, in particular to a method for desulfurization of coal-fired flue gas with a low oxidation rate. Its treatment process and parameters in the desulfurization tower are: a. Cool down and remove dust, spray and wash the flue gas entering the tower with water first, so that the temperature of the flue gas will drop to 40-50°C within 2-3 seconds; b. For the first level of absorption, use the ammonium salt absorption solution with a concentration of 500-650g / l and a pH value of 5.2-6.2 for spray absorption; c. For the second-level absorption, use a concentration of 300-500g / l and a pH value of 5.4 ~6.5% ammonium salt absorption liquid is sprayed and absorbed; d. Washing and defogging the flue gas after absorption treatment, eluting the absorption liquid entrained in the flue gas and emptying it. The invention can reduce the oxidation rate in the ammonia desulfurization process and improve the utilization value of by-products.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

Fuel coal smoke low oxidation rate desulfur method

InactiveCN1597061AGuaranteed desulfurization effectGuaranteed total desulfurization efficiencyDispersed particle separationEngineeringAmmonia

A low-oxidization method for desulfurizing the fume generated by burning coal includes such steps as spraying water for cooling and dusting the fume, stage-one absorption by spraying the absorbing liquid A, stage-two absorption by spraying the absorbing liquid B, spraying water for defrosting, and exhausting.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

Liquefied gas desulfurizing and refining method

InactiveCN1775924AGood regeneration performanceNo emissionsGaseous fuelsCatalytic oxidationEnvironmental engineering

The invention relates to a method of liquefied gas refining desulfurization that includes the following steps: putting the liquefied gas need to refining into pre-desulfurization tower to take desulfurization reaction; filtering in the sand tower after separating in separating tower; adding desulfurization agent into oxidizing regeneration tower to take oxidizing regeneration and could periodic duty after being separated. If the liquefied gas does not meet the request, it could take further oxidation sweetening mellow with sulfonation lush coblt activator, alkaline liquor and air, then separating, filtering to gain refined product. The invention has good desulfurization effect, low cost, simple device and has no secondary pollution.

Owner:BEIJING BIOTECHINA ENVIRONMENT CORP

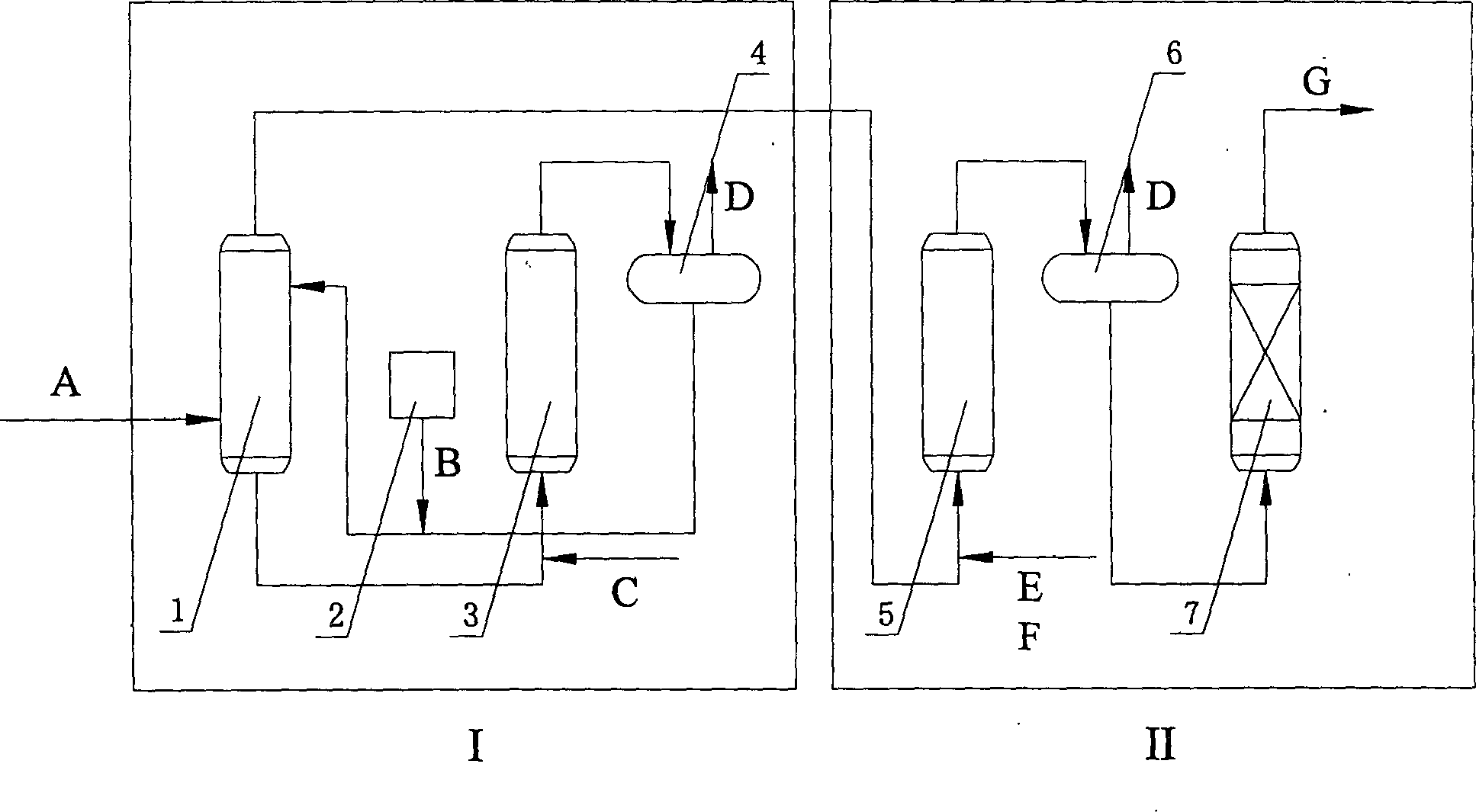

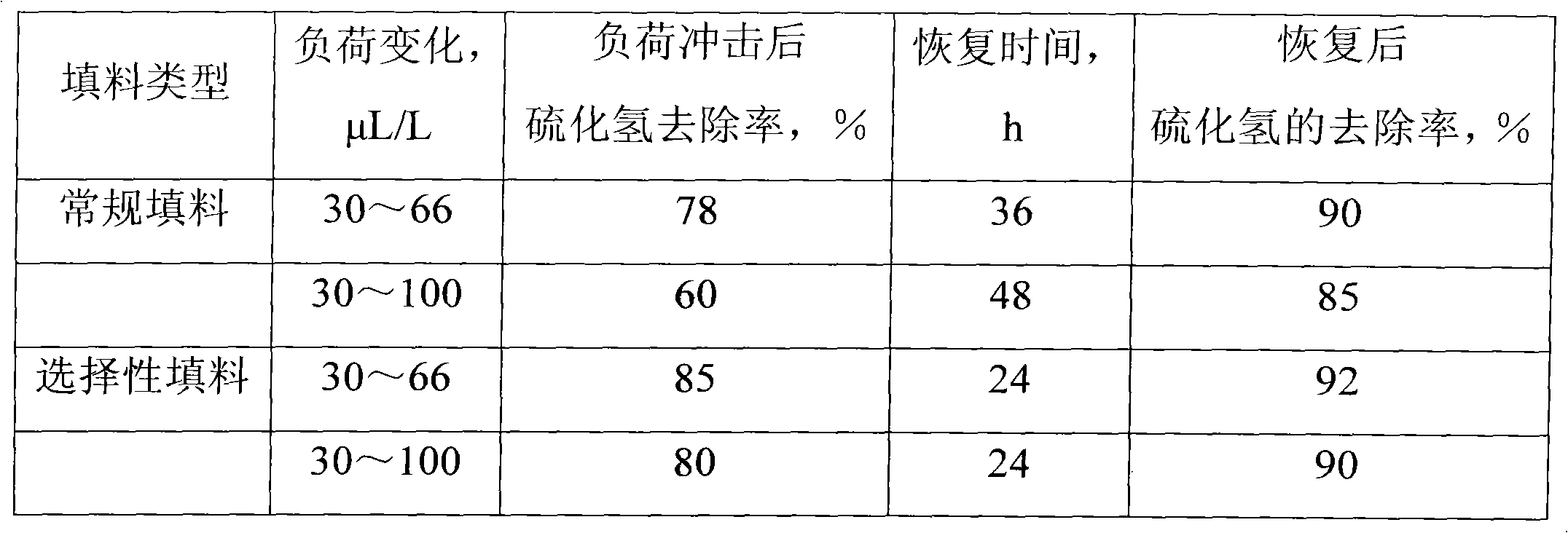

Method for preparing selective microbial packing

InactiveCN102050516ASuitable for growthImprove impact resistanceDispersed particle separationAir quality improvementFiberActivated sludge

The invention relates to a method for preparing selective microbial packing. A plant organic fiber or a mixture of the plant organic fiber and activated carbon is used as basic packing, and the method comprises the following steps of: screening, separating and purifying activated sludge to obtain specific desulfurization bacteria; massively propagating and culturing the bacteria in nutrient solution to prepare desulfurization bacterium mother solution; and performing nutrient solution soaking, spraying and mother solution biofilm formation on the basic packing to prepare the selective microbial packing. The biological packing is used for microbial purification in waste gas treatment, and is particularly used for removing stinky pollutants produced in petrochemical plants, sewage treatment plants, urban sewage treatment plants, animal husbandry farms and the like. By the method, class I pollutants in exhaust gases of a refinery are treated specially, the treatment load and efficiency of the pollutants are improved, and impact resistance during change of working conditions is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

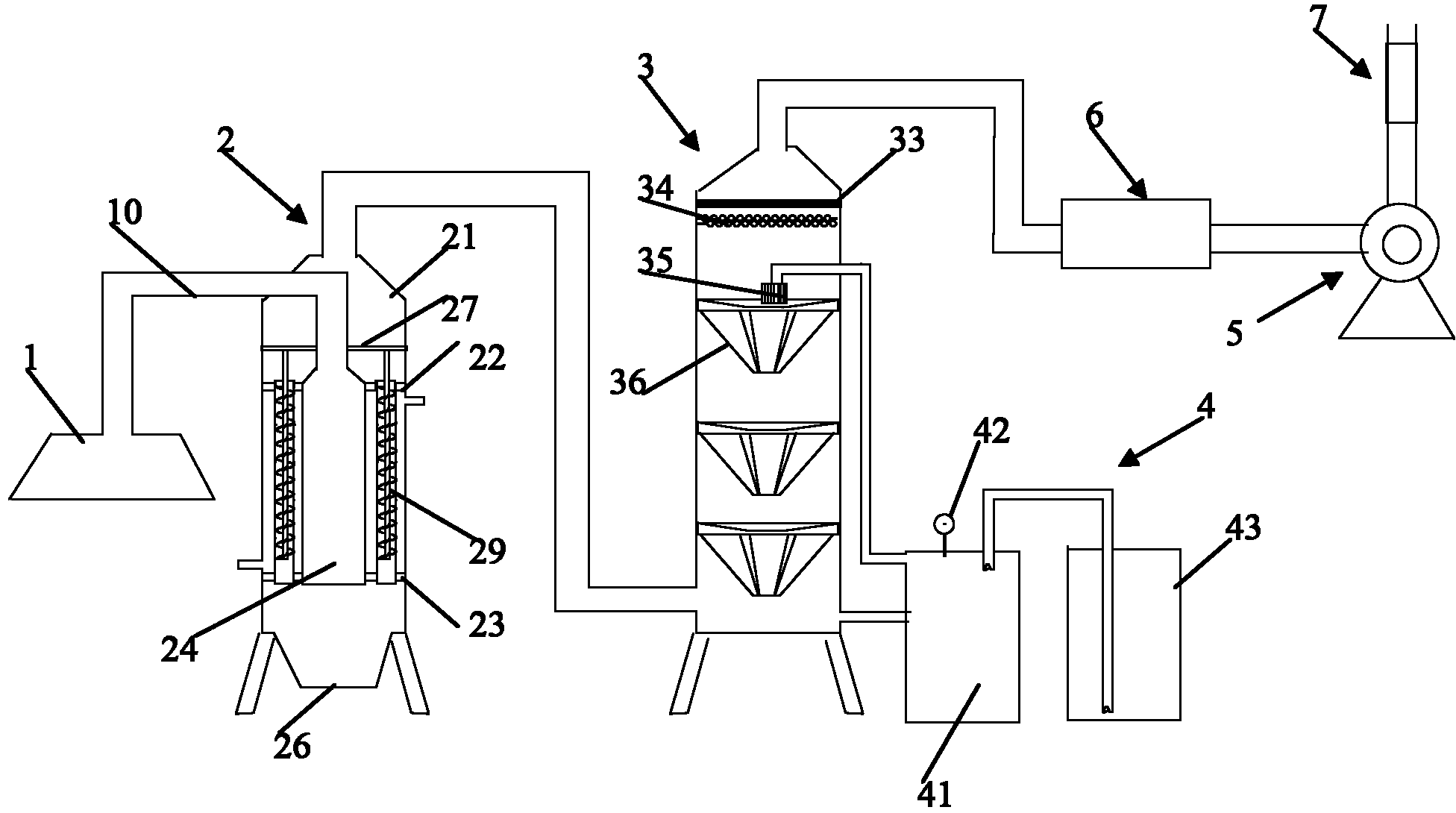

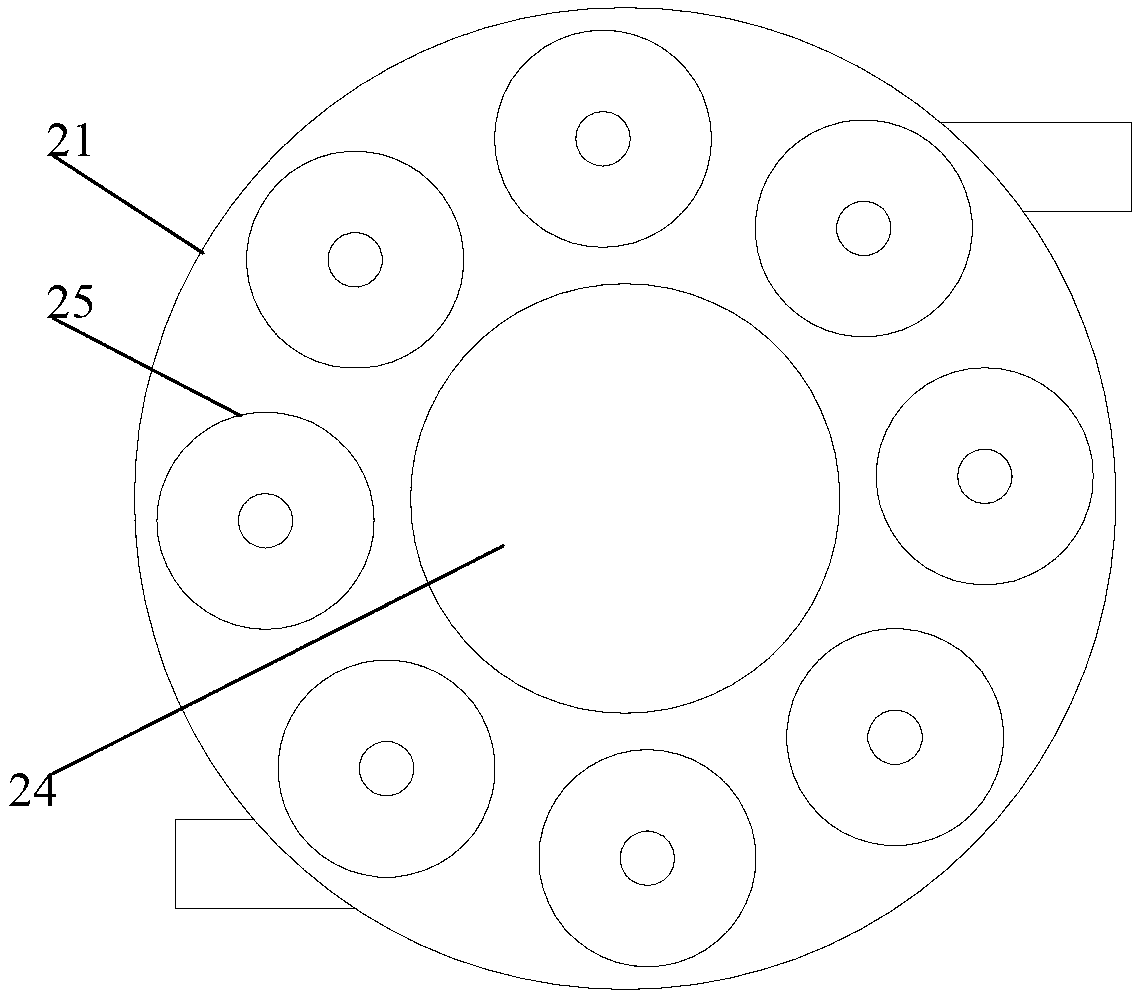

Waste gas purification system in rubber processing field

InactiveCN103230729ALow costReduce difficultyCombination devicesActivated carbon filtrationCatalytic oxidation

The invention discloses a waste gas purification system in the rubber processing field. The waste gas purification system comprises a plurality of wind collecting covers, an assistant recovery tower, a desulfurization purification tower, a draught fan, an activated carbon filtration tower or ultraviolet catalytic oxidation waste gas purification apparatus, an oxyhydrogen flame combustor and a treating liquid circulating device, wherein the wind collecting covers are respectively arranged above each working station; the assistant recovery tower is communicated with the wind collecting covers through gas inlet pipes; the desulfurization purification tower is communicated with a gas outlet of the assistant recovery tower; the draught fan is communicated with a gas outlet of the desulfurization purification tower and is used for forcing air into the wind collecting covers and finally discharging to the outside; the activated carbon filtration tower or ultraviolet catalytic oxidation waste gas purification apparatus is connected in series between the desulfurization purification tower and the draught fan; the oxyhydrogen flame combustor is arranged at a wind outlet of the draught fan; and the treating liquid circulating device is used for supplying treating liquid to the desulfurization purification tower. According to the invention, the waste gas purification system in the rubber processing field cools and depressurizes high-temperature waste gas to gradually separate particles and liquid drops included in the waste gas from the waste gas and collect in the collecting covers; and the assistant recovery rate can be up to 70%.

Owner:TIANJIN DONGZHEN RUBBER

Ultra-low aluminum steel and smelting method thereof

The invention belongs to the technical field of ferrous metallurgy and particularly relates to ultra-low aluminum steel and a smelting method thereof. The smelting method provided by the invention adopts a production route with the steps of deep removal of S and P by molten iron pretreatment, decarbonization by a converter, deoxidization and alloying of silicon manganese during tapping, deslagging by argon blowing, deep removal of O, S and P by ladle refining, micro-alloying of Ti, Ni, Mo, V and other elements, RH (Ruhstahl-Hausen) vacuum circulation degassing, soft argon blowing and full-protection casting; the prepared ultra-low aluminum steel has low content of harmful elements, particularly has low content of O and Al, can prevent the inclusion of brittle aluminum oxide and realize high impact-resistant and fatigue-resistant performances of the steel, and is suitable for application fields with relatively high requirements for fatigue and impact performances, such as high-speed track traffic and the like.

Owner:JIANGSU UNIV

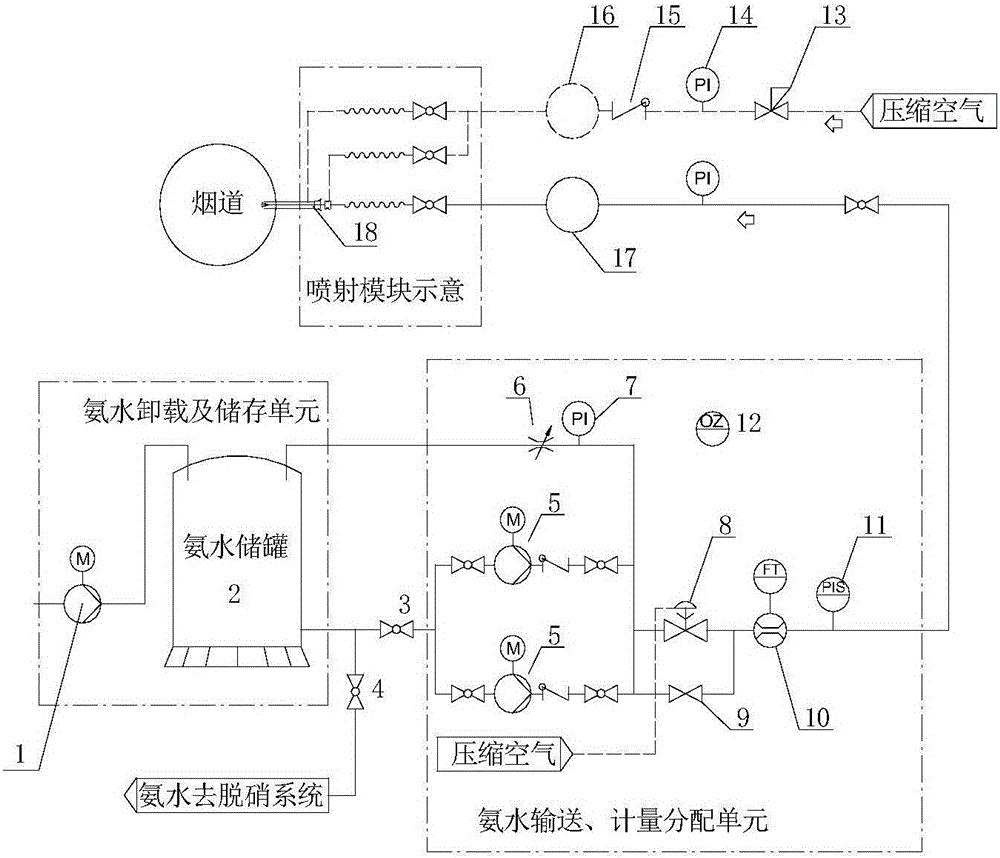

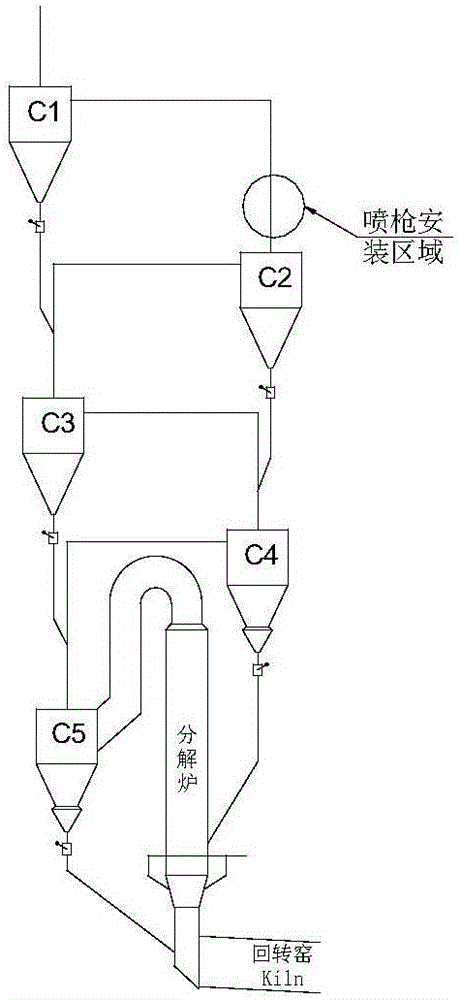

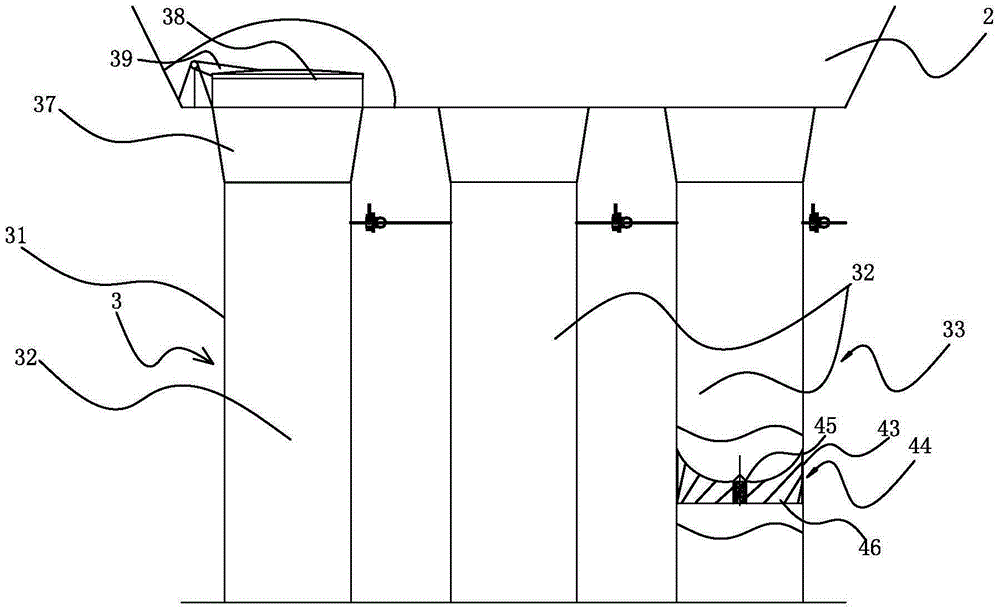

Desulfurization system and method for flue gas of cement kiln furnace

ActiveCN106166437ALess investmentReduce the investment cost onceGas treatmentDispersed particle separationFlue gasSulfur

The invention relates to a desulfurization system and method for flue gas of a cement kiln furnace. The desulfurization system comprises an ammonia water storing tank, conveying pumps, spraying guns, a cement decomposing furnace, a cement kiln pre-decomposing system and an automatic control system, wherein the cement kiln pre-decomposing system comprises a multi-stage pre-heater; the ammonia water storing tank communicates with the spraying guns through the conveying pumps; and spraying points of the spraying guns are located at an outlet of a cyclone barrel of a second-stage pre-heater. The desulfurization method comprises the following steps of I, preparing a 15-25% ammonia water; II, performing real-time detection on the concentration of SO2, and according to the concentration of the SO2 in flue gas, calculating and adjusting the spraying amount of the ammonia water through the automatic control system; and III, according to the spraying amount of the ammonia water, which is obtained through calculation in the step II, injecting the ammonia water which is pressurized through the conveying pumps to the spraying guns, and spraying the ammonia water into the cement kiln pre-decomposing system, wherein the spraying points of the spraying guns are located at the outlet of the cyclone barrel of the second-stage pre-heater. According to the desulfurization system and method disclosed by the invention, the desulfurization efficiency can reach 95% or above, the desulfurization efficiency is high, the ammonia-sulfur ratio is 2-2.5, and the operating cost is low.

Owner:NANJING C HOPE ENVIRONMENTAL SCI & TECH

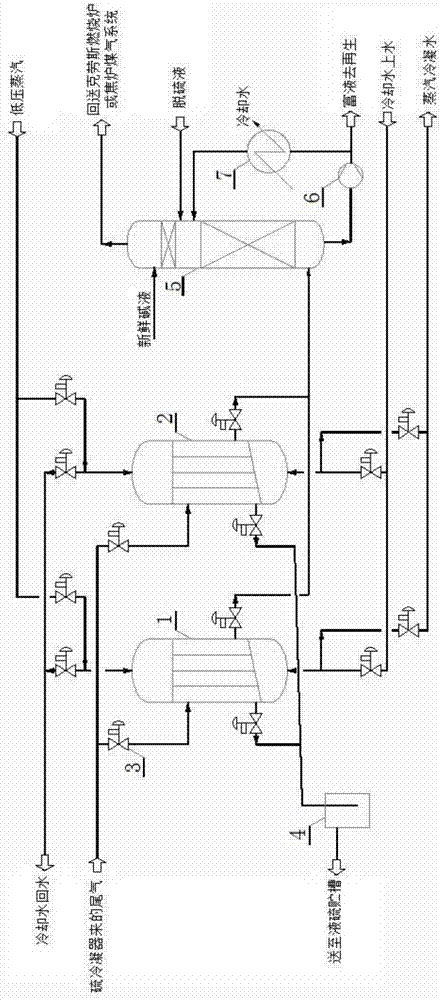

Claus tail gas condensing treatment process

The invention relates to a Claus tail gas condensing treatment process, which comprises the steps that Claus tail gas coming from a Claus process sulfur condenser enters a heat exchanger I, gaseous sulfur is condensed and removed; the gaseous sulfur-removed Claus tail gas is sent to a desulfurizing absorption tower and is sprayed by adopting a doctor solution coming from a gas purification device, rich liquor is returned to the gas purification device for regeneration, and regenerated acid gas is used as a raw material for a Claus process; the upper part of the desulfurizing absorption tower is provided with an alkali washing section, and alkali liquor is a replenishing solution coming from a desulfurizing unit of the gas purification device; after the removal of H2S, the Claus tail gas is sent to a coke oven gas system or is returned to a returned gas system; the heat exchanger I and a heat exchanger II work in a cyclic alternating pattern, and the continuous condensing of the gaseous sulfur in the Claus tail gas is realized. The Claus tail gas condensing treatment process has the remarkable advantages of small investment, low operating cost, energy conservation, greenness, environmental protection and the like.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

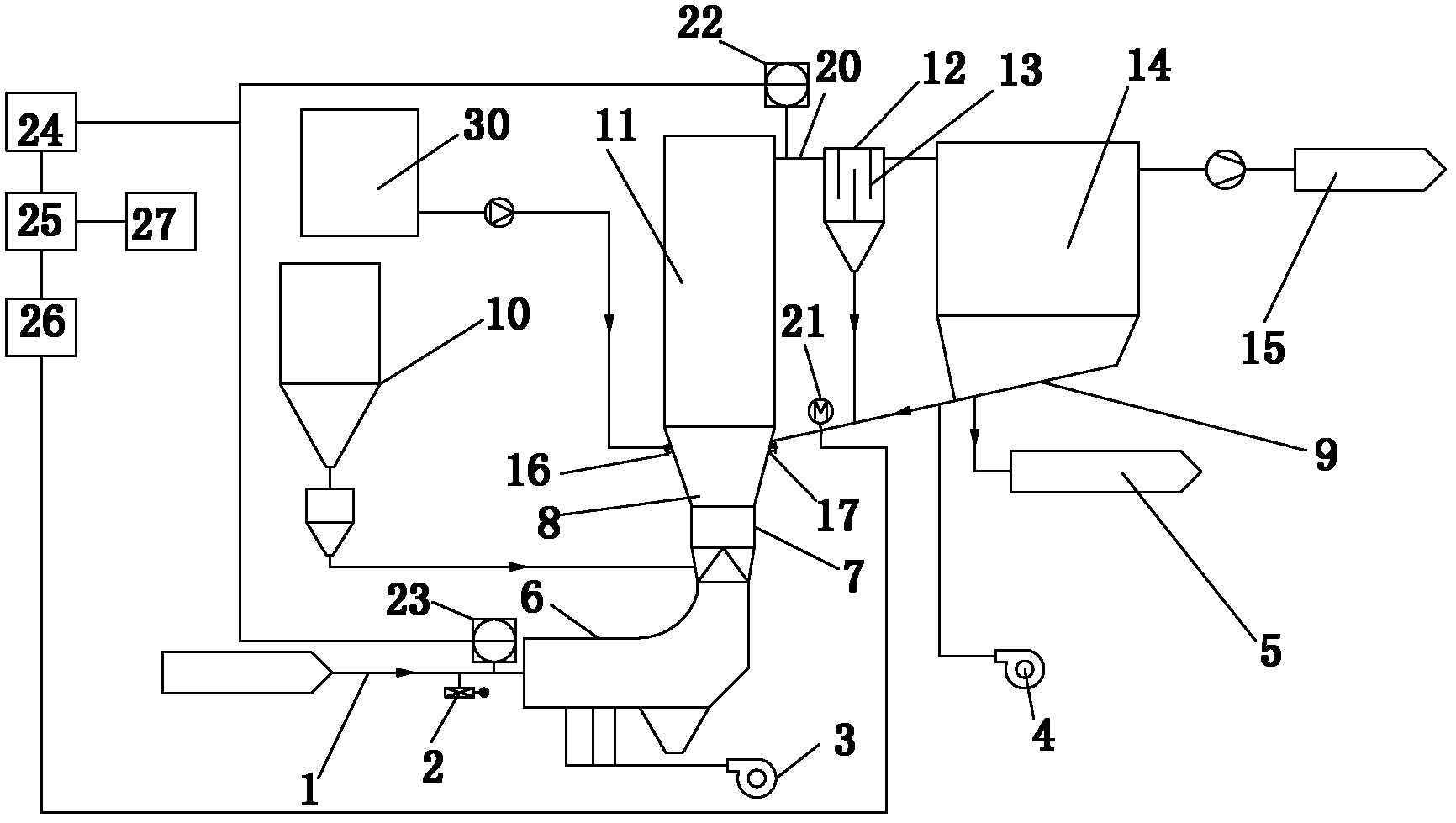

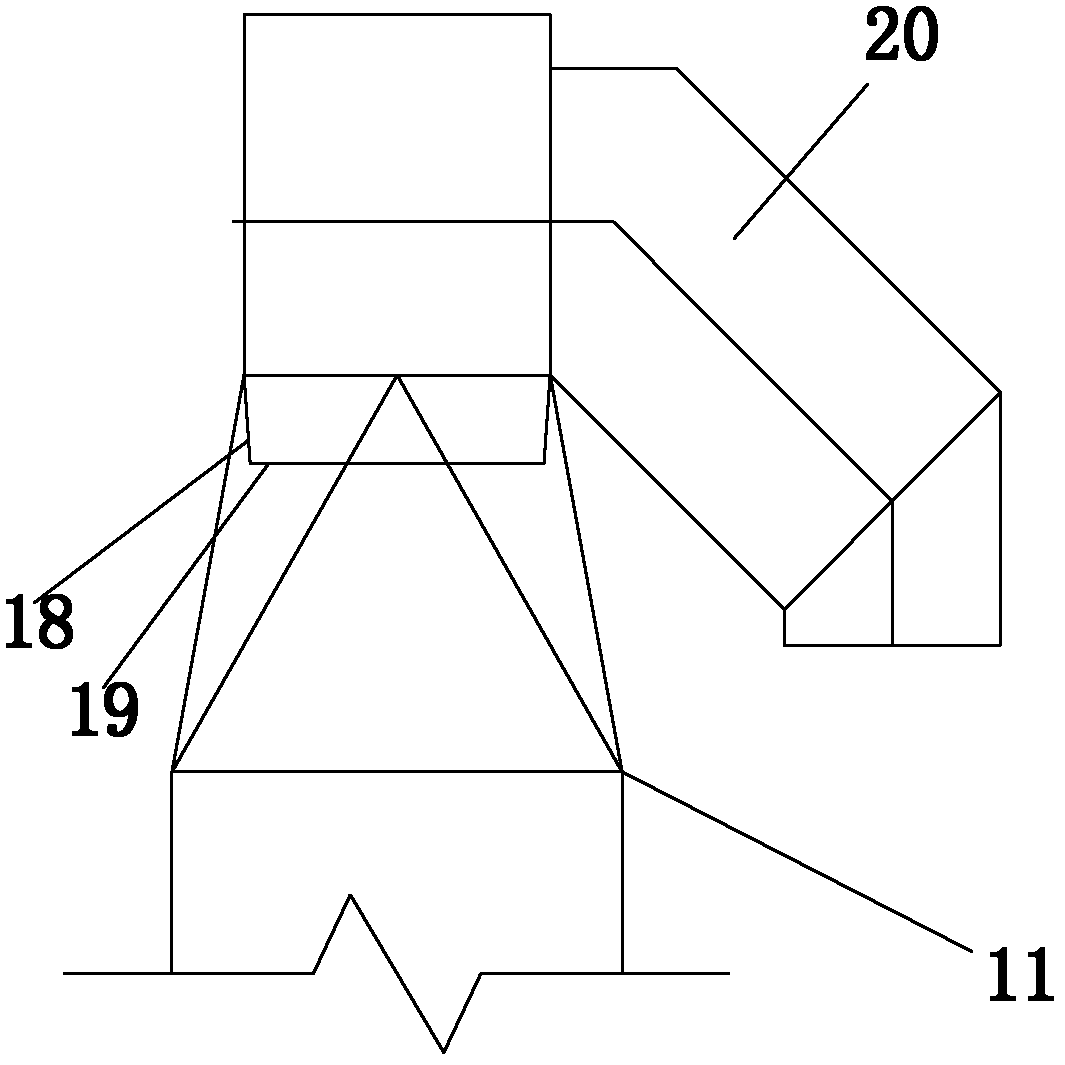

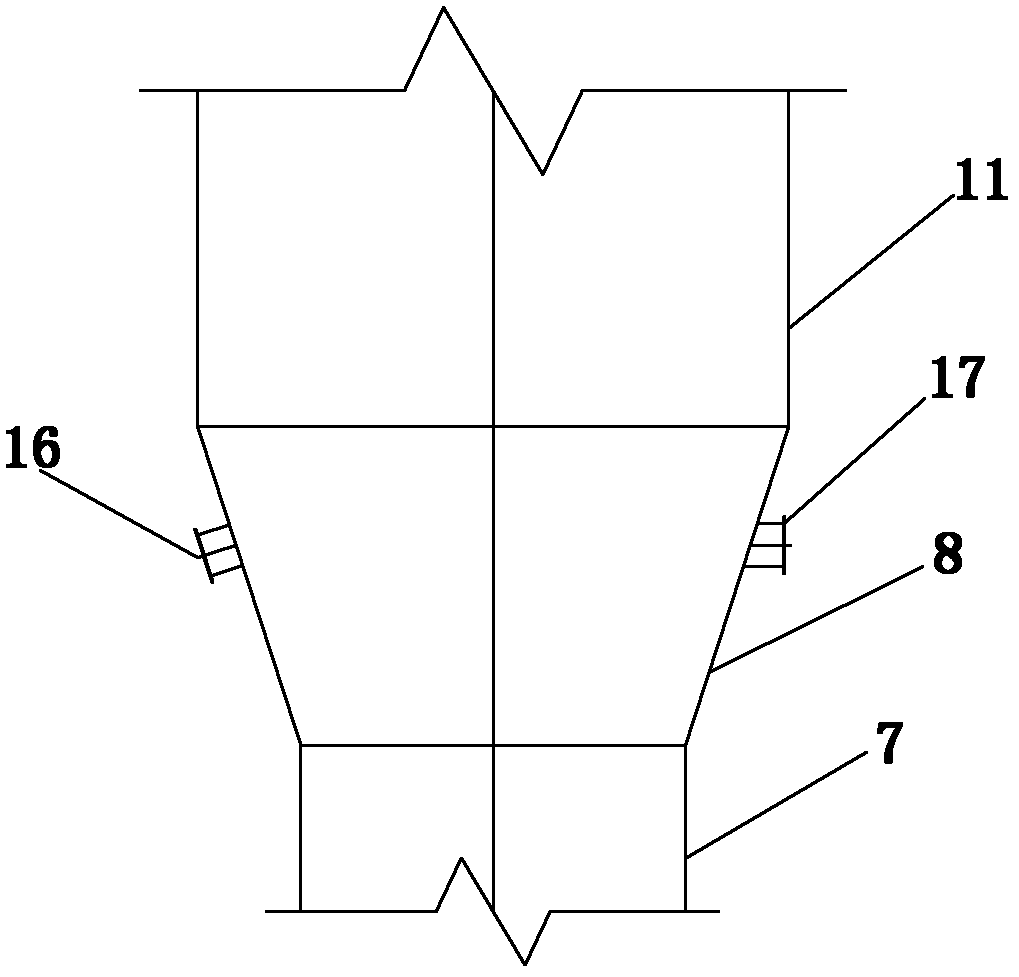

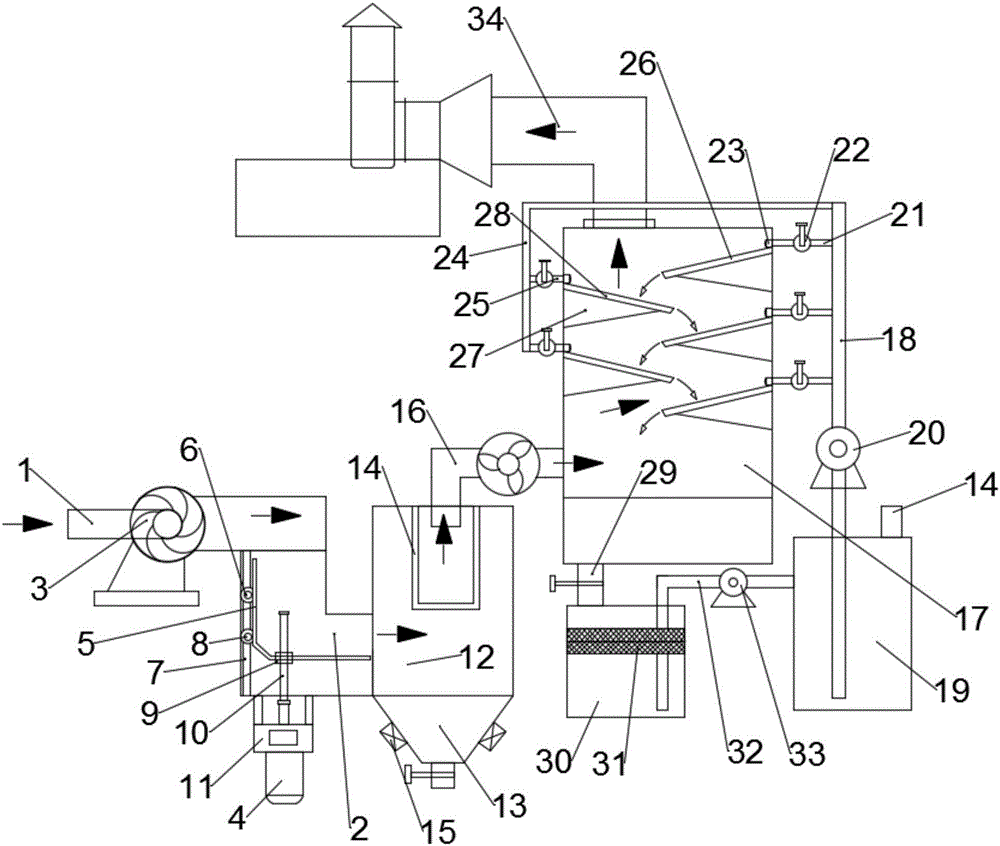

Flue gas cleaning device and method for circulating fluidized bed through semi-dry method

The invention discloses a flue gas cleaning device and a method for a circulating fluidized bed through a semi-dry method. The method comprises the following steps of: sequentially desulfurizing flue gas come from a boiler room, pre-dedusting the flue gas through a pre-dedusting device, and dedusting the flue gas through a bag-type deduster, and then discharging the flue gas into a chimney; and respectively returning the collected desulfurized ash after being subjected to pre-dedusting and dedusting to a desulfurizing tower through an air chute so as to be desulfurized, and discharging the ash out of an ash silo. According to the device and the method, the desulfuration reaction can be accelerated, the desulfuration effect is improved, the flue gas capacity in the desulfurizing tower can be controlled in real time, the normal fluidization in the desulfurizing tower is maintained, and the service life of the flue gas cleaning device is prolonged.

Owner:LAN TIAN ENVIRONMENTAL ENGINEERING CO LTD

Water curtain check-type super-purification smoke exhaust dedusting and desulfurization system

InactiveCN106693650AAffect the effect of dust removalAffect the purification effectCombination devicesGas treatmentExhaust fumesEngineering

The invention discloses a water curtain check-type super-purification smoke exhaust dedusting and desulfurization system, which comprises a smoke exhaust inlet tube, wherein the end part of the smoke exhaust inlet tube is connected to a flow rate control tube; the left side wall of a tube body of the flow rate control tube is provided with a guide rail; the internal thread of a lifting nut is adaptively provided with a rotating screw rod; two side walls of a conical extrusion cavity are respectively provided with one vibrating motor; the left side wall of the upper side of an inner cavity in a case body of an ultra-clean desulfuration case is provided with first diversion water curtain boards; the two first diversion water curtain boards and three second diversion water curtain boards are staggered; the bottom end of a tube body of a drainage through tube is communicated with a circulating filter box pump. The system is capable of solving the problem of weakened desulfuration effect caused by uncontrollable smoke feeding velocity in a traditional process, ensuring that sulfides in the smoke are fully absorbed and removed and the treated solvent also can be recycled, and further saving the solvent resource.

Owner:合肥图腾龙企业管理事务所(有限合伙)

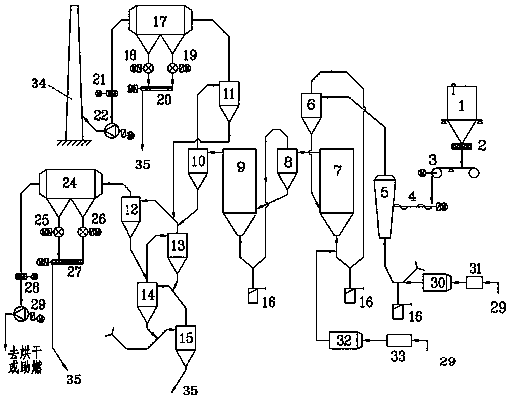

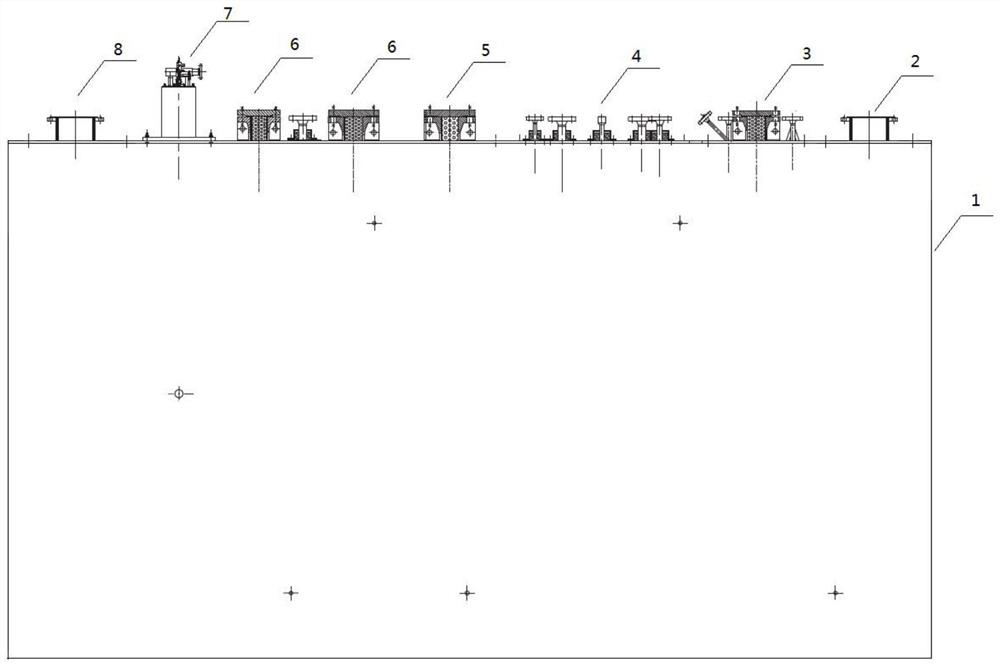

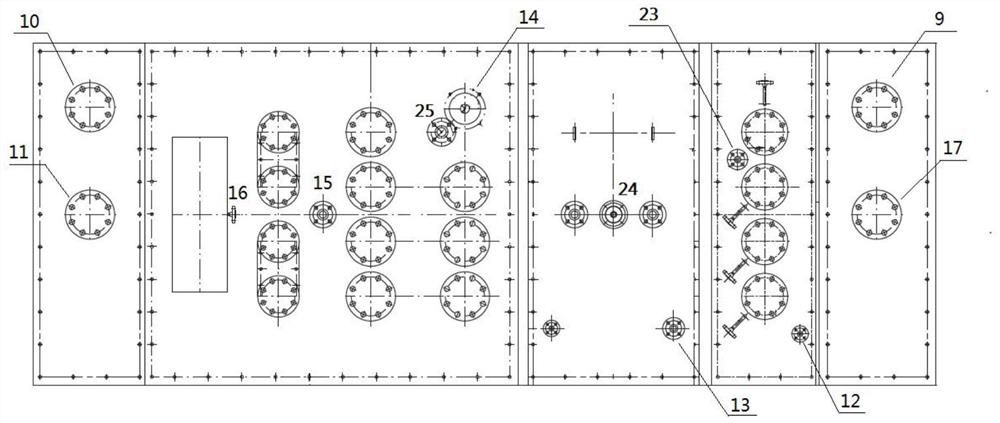

Concurrent high-sulfur bauxite desulfurization roasting process and device

PendingCN111170346AIncrease contact timeGuaranteed dynamic propertiesAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationFlue gasProcess engineering

The invention discloses a concurrent high-sulfur bauxite desulfurization roasting process and device. The process comprises the steps of grinding, weighing and feeding, drying, primary suspension desulfurization roasting, secondary suspension desulfurization roasting, desulfurization roasting dust collection, cyclone cooling, cooling and dust removal and the like. According to the invention, a flue gas and material concurrent manner is adopted in the desulfurization roasting section, the contact time of the material and high-temperature flue gas in a proper reaction temperature interval rangeis prolonged, the dynamic characteristic of the high-sulfur bauxite desulfurization reaction is ensured, no return material is generated in the technological process, and the method has the characteristics of good desulfurization effect, low production cost, stable product quality and high production efficiency.

Owner:贵州正道实业有限公司

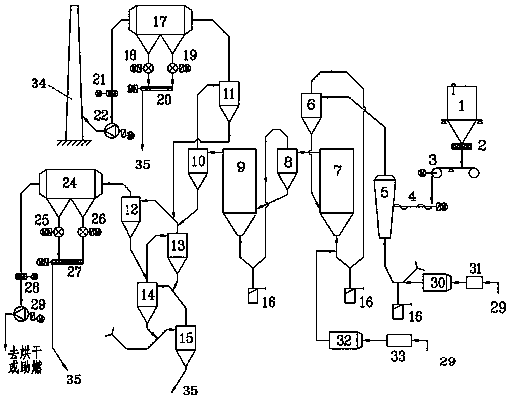

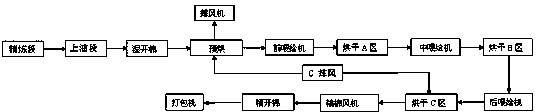

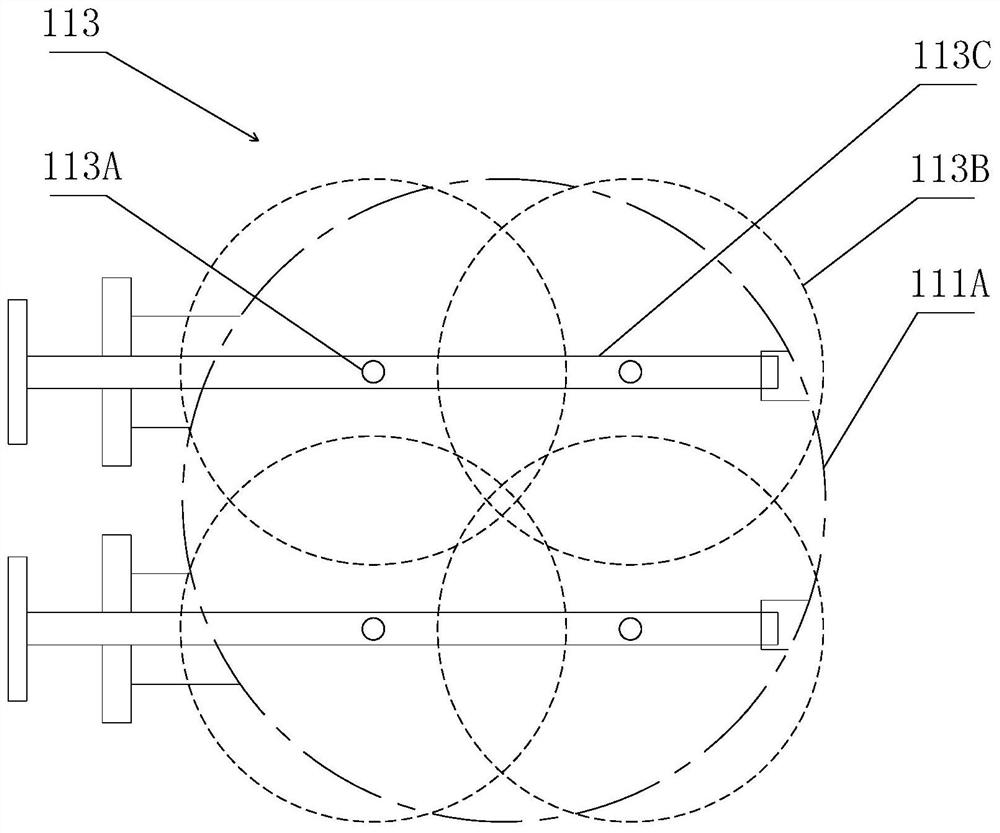

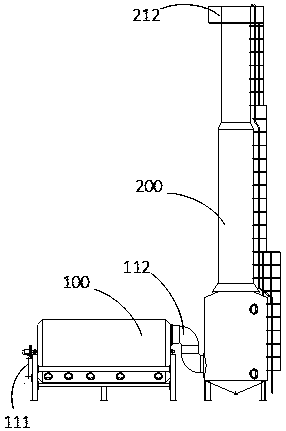

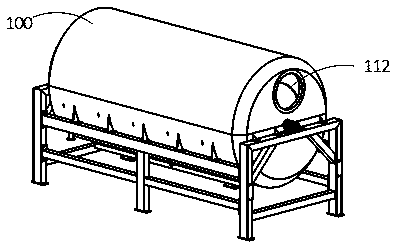

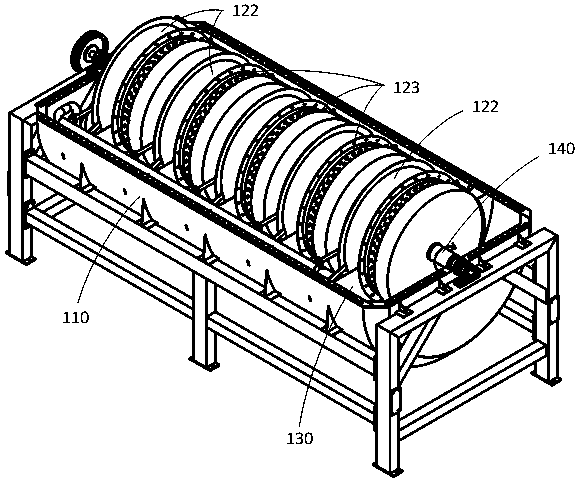

High-capacity viscose staple fiber post-treatment production line

InactiveCN103422290AIncrease washing timeWash Time GuaranteeSucessive textile treatmentsLiquid/gas/vapor removalProduction lineSingle process

The invention aims at providing a high-capacity viscose staple fiber post-treatment production line in order to reach the annual yield of 100 thousand tons. The production line comprises a refining system and a drying system. A refiner in the refining system comprises a refining section and an oiling section. The high-capacity viscose staple fiber post-treatment production line is characterized in that the breadth of the refiner of the refining system is 4000mm, the refining section is divided into 13-18 process areas, the oiling section is divided into 2 process areas and the length of a single process area is 2500mm. The viscose staple fiber post-treatment production line comprises the refining system and the drying system, and has the advantages that the production capacity is strong, the operation stability is high, the automation level is high and the product quality is guaranteed.

Owner:YIBIN GRACE +2

Lime production desulfurization and dust removal equipment and process

The invention discloses desulfurization and dust removal equipment and process for lime production. The equipment comprises a desulfurization and dust removal tower and a wastewater concentration tank, a water discharging pipe is arranged on one side of a lower end of the desulfurization and dust removal tower, an inclined guide plate is connected into the lower end of the desulfurization and dustremoval tower, a smoke inlet pipe is connected to one side of the desulfurization and dust removal tower, an overflow port is formed in a side, away from the smoke inlet pipe, of the desulfurizationand dust removal tower, and a partition plate is movably connected into the overflow port through a rotating shaft. The invention provides the lime production desulfurization and dust removal equipment and the desulfurization and dust removal process. The desulfurization and dust removal tower is connected with the wastewater concentration tank; flue gas is guided into the desulfurization and dustremoval tower through an induced draft fan and is spirally guided into an upper end of the desulfurization and dust removal tower through a corrosion-resistant spiral plate, meanwhile, a rotary drumand an arc-shaped plate are arranged, the contact time of the gas and desulfurization liquid is prolonged, the desulfurization effect of the equipment is improved, multiple layers of spraying pipes are vertically arranged in the desulfurization and dust removal tower, and space and energy are saved.

Owner:郭春林

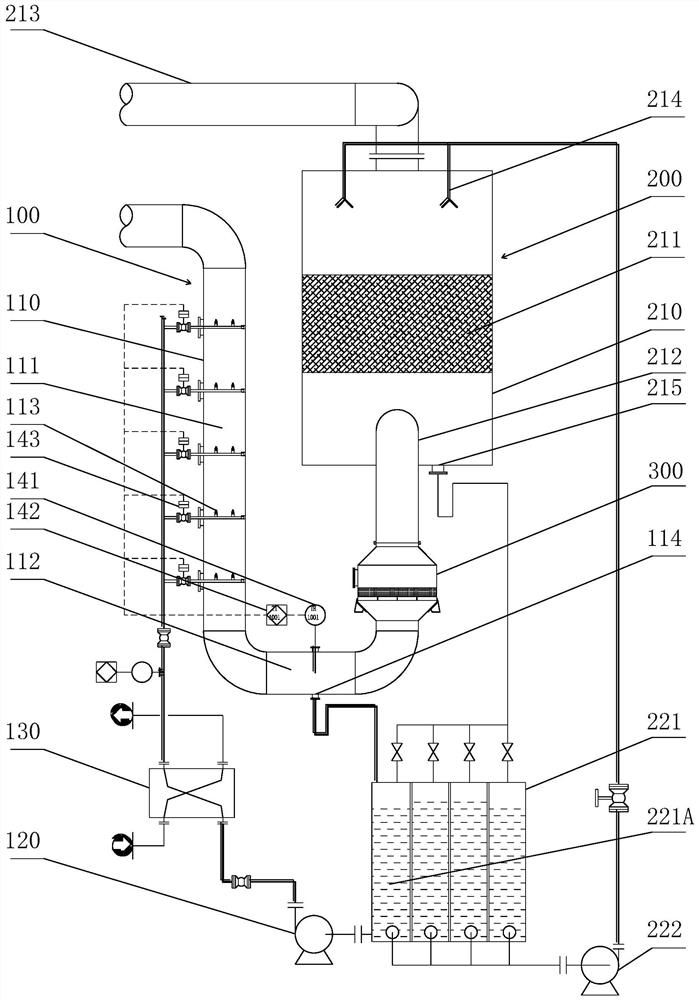

Flue gas desulfurization method and flue gas desulfurization equipment

ActiveCN112657331AIncrease humidityReduce consumptionLighting and heating apparatusDispersed particle separationThermodynamicsPtru catalyst

The invention discloses a flue gas desulfurization method and flue gas desulfurization equipment, and aims to solve the technical problem of helping to improve the flue gas purification effect of catalytic flue gas desulfurization. The flue gas desulfurization method comprises the following steps: introducing target flue gas into a cooling system, so that the target flue gas is cooled by spraying liquid; introducing the cooled target flue gas into a desulfurization system, so that the target flue gas is desulfurized through a catalyst, and sulfur dioxide removed in the desulfurization system forms sulfuric acid on the catalyst and enters regeneration liquid for washing and regenerating the catalyst along with washing and regeneration of the catalyst, wherein the spraying liquid is from the regeneration liquid. The target flue gas is cooled through the spraying liquid, so that the dust content in the target flue gas can be reduced, and the target flue gas can reach a catalytic activity temperature interval required by the catalyst conveniently; as the spraying liquid comes from the regeneration liquid, the concentration of the spraying liquid can be increased, and subsequent utilization of the spraying liquid is facilitated.

Owner:成都达奇环境科技有限公司 +1

Desulfurization and defogging equipment

PendingCN108722126AMeet the need for protectionRealize desulfurization and purificationDispersed particle filtrationTransportation and packagingWater flowHigh pressure water

The invention provides desulfurization and defogging equipment, which comprises a waste gas desulfurization structure and a waste gas defogging structure, wherein the waste gas desulfurization structure comprises a desulfurization shell; at least one desulfurization component is arranged in the desulfurization shell; the desulfurization component comprises a high-pressure water pipe and a screen cloth component arranged by facing the high-pressure water pipe; the high-pressure water pipe injects current to knock the screen cloth component to generate a water curtain and sprays; the waste gas defogging structure comprises a defogging shell and at least one defogging component arranged in the defogging shell; the front side of the defogging component is arranged by facing a waste gas airflowdirection; the waste gas is desulfurized and purified by the waste gas desulfurization structure to enter the defogging shell, and the temperature and the water mist of the waste gas are absorbed bythe defogging component to realize the cooling and the defogging of the waste gas. The invention provides the desulfurization and defogging equipment, and a traditional spray type waste gas processingstructure is optimized to improve the desulfurization and defogging effect of the waste gas processing structure.

Owner:盐城全鼎晟科技有限公司

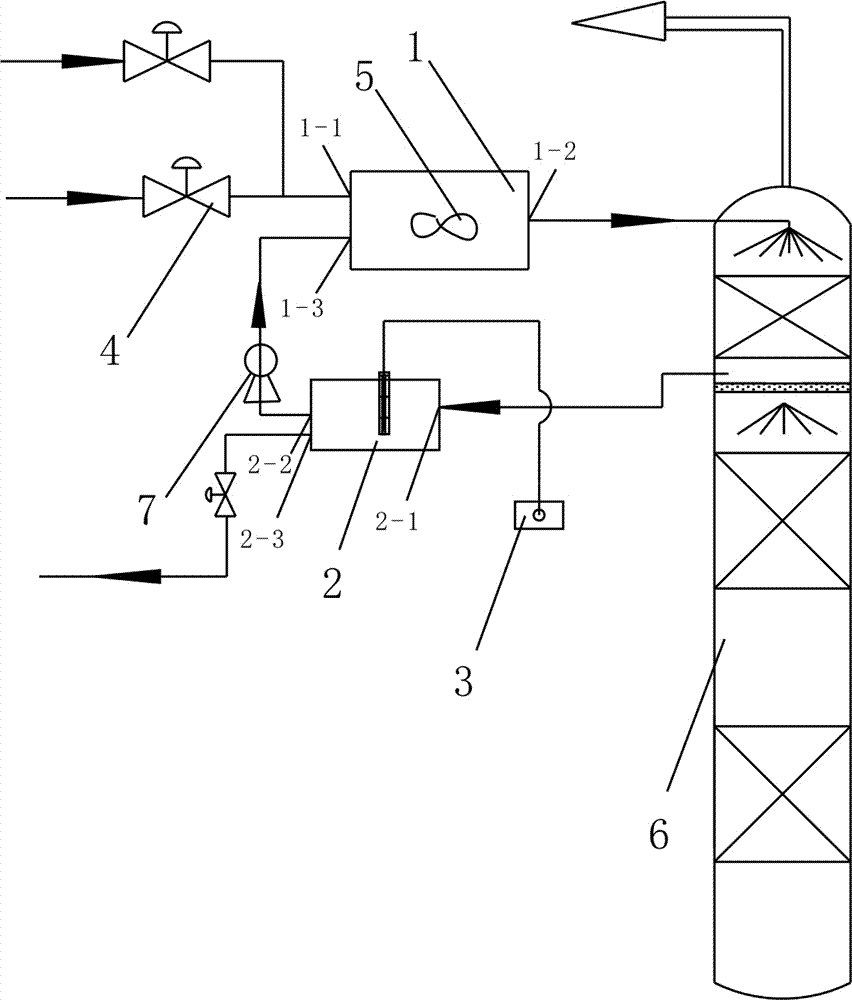

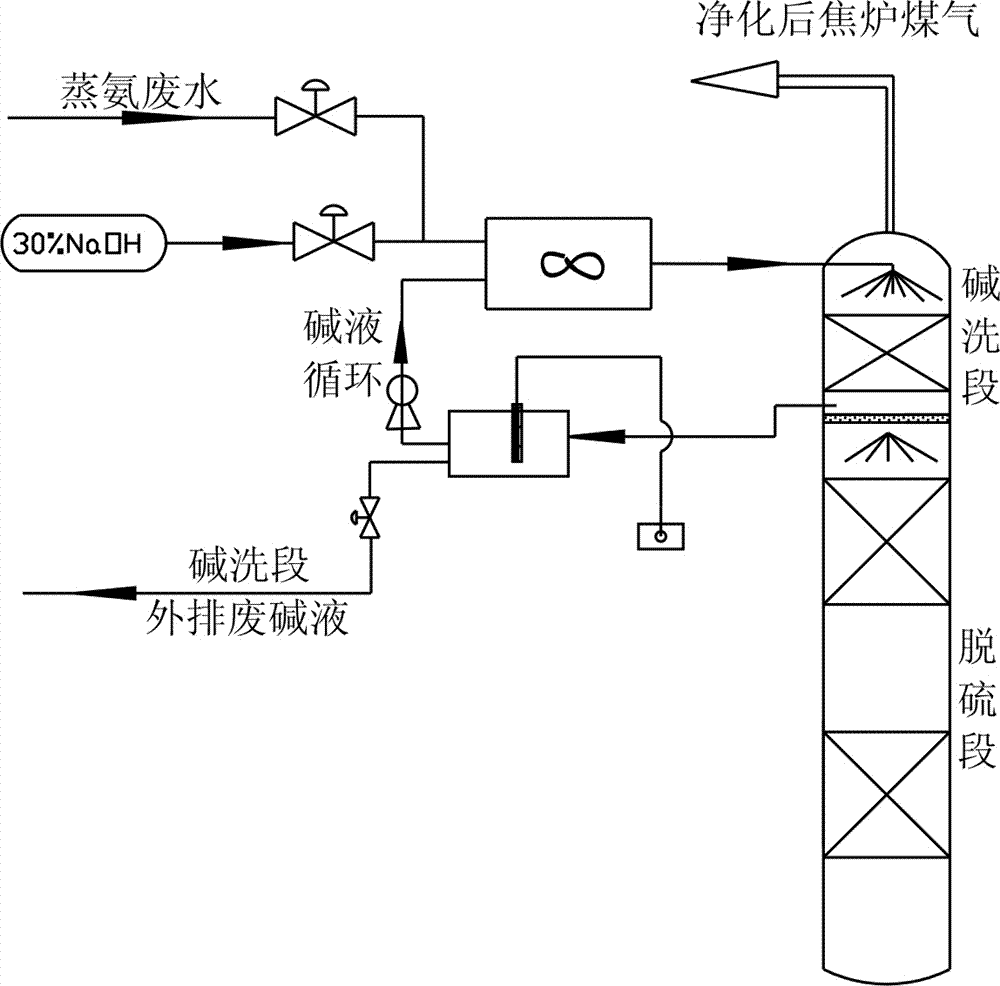

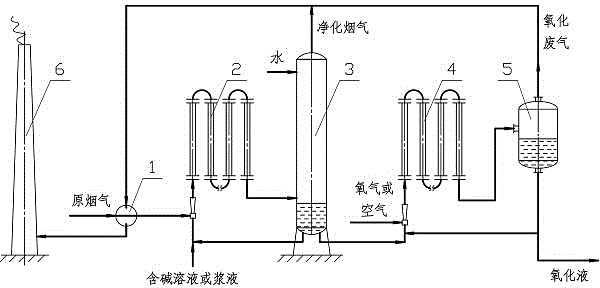

Method and device for improving utilization rate of alkali liquor at alkaline cleaning section of vacuum potassium carbonate desulfurization technique

ActiveCN103691276AImprove efficiencyGuaranteed desulfurization effectDispersed particle separationProcess engineeringEnvironmental engineering

The invention relates to method and device for improving utilization rate of alkali liquor at an alkaline cleaning section of vacuum potassium carbonate desulfurization technique. The method comprises the following steps: diluting NaOH solution by replacing industrial new water with ammonia still waste water in a chemical workshop, and storing the diluted NaOH solution in a NaOH alkali liquor tank; conveying NaOH alkali liquor in the NaOH alkali liquor tank to the NaOH alkaline cleaning section at the upper part of a desulfurizing tower for carrying out alkaline cleaning, enabling the alkaline cleaning water to flow back into a waste alkaline tank, then evenly mixing the alkaline cleaning water in the waste alkaline tank with NaOH alkali liquor in the NaOH alkali liquor tank, conveying back to the alkaline cleaning section at the upper part of the desulfurizing tower for recycling, and stopping recycling until the pH value of waste liquor in the waste alkaline tank is lower than 10; conveying the waste liquor in the waste alkaline tank into an ammonia still tower to be used as alkaline instead of NaOH. According to the method and the device, the alkaline liquor at the alkaline cleaning section can be recycled, and the usage efficiency of the alkali liquor can be improved on the premise of guaranteeing the desulfurization effect of the desulfurizing tower.

Owner:武汉钢铁有限公司

Method for treating ash deposition and scaling of GGH (gas-gas heater)

InactiveCN104880123AReduce cloggingGuaranteed uptimeFlush cleaningHigh pressureFlue-gas desulfurization

The invention discloses a method for treating ash deposition and scaling of a GGH (gas-gas heater). The method for treating ash deposition and scaling of the GGH has the advantages that the steps of blowing ash online by compressed air, flushing online by high-pressure water, flushing by low-pressure water before halting and performing high-pressure flushing by chemical cleaners after halting are adopted, so that the problems of severe ash deposition and scaling of a heated surface of the GGH due to ash deposition, acid coagulation, liquid drop adhesion and the like are solved, blockage resulting from ash deposition and scaling of the GGH is slowed down substantially, normal operation and flue gas desulfurization effect of a desulfurization system are guaranteed, halting times of the desulfurization system are decreased, and safety operation and safety economy of a unit are guaranteed under a rated condition.

Owner:DATANG HUAIBEI POWER PLANT

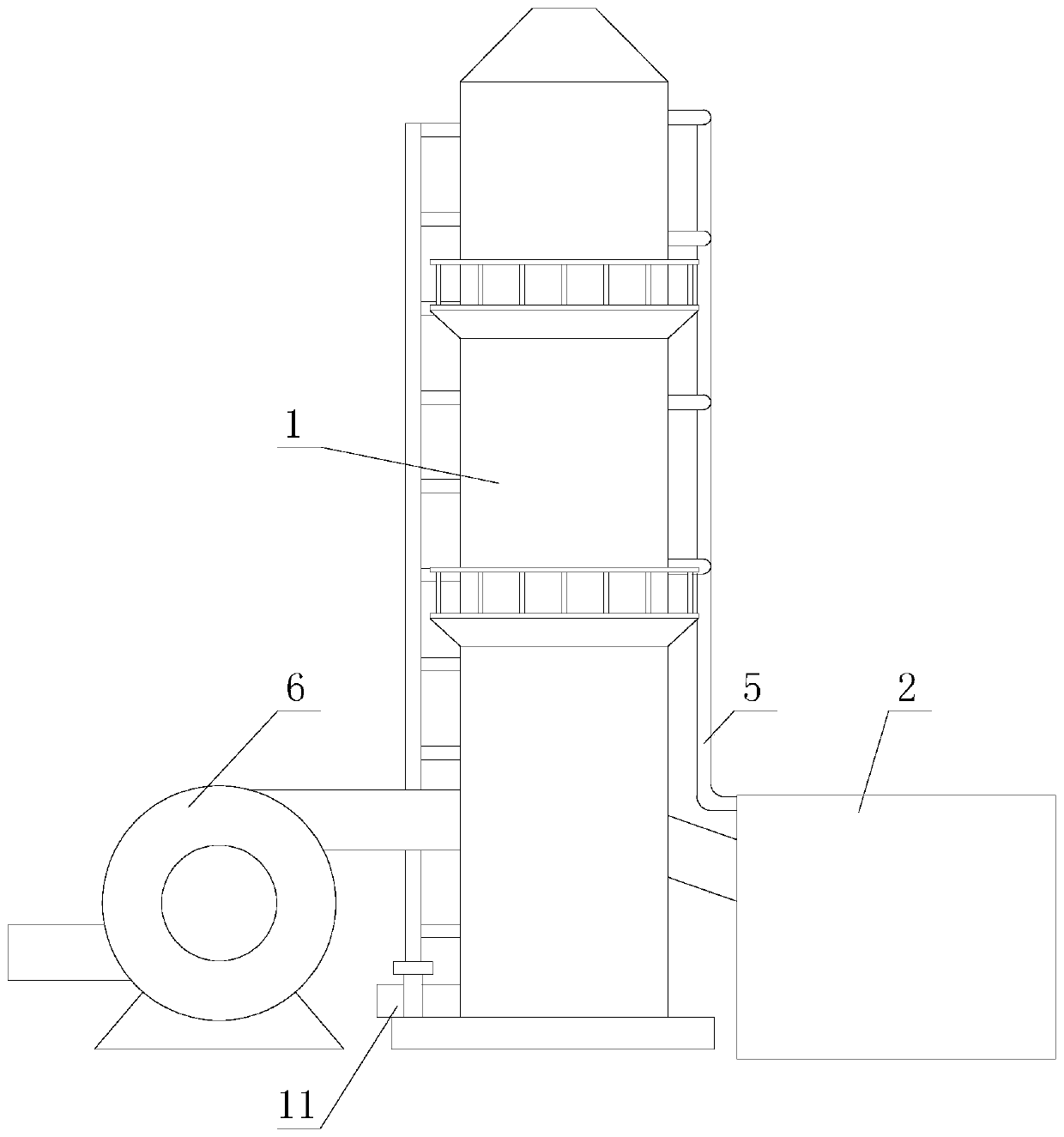

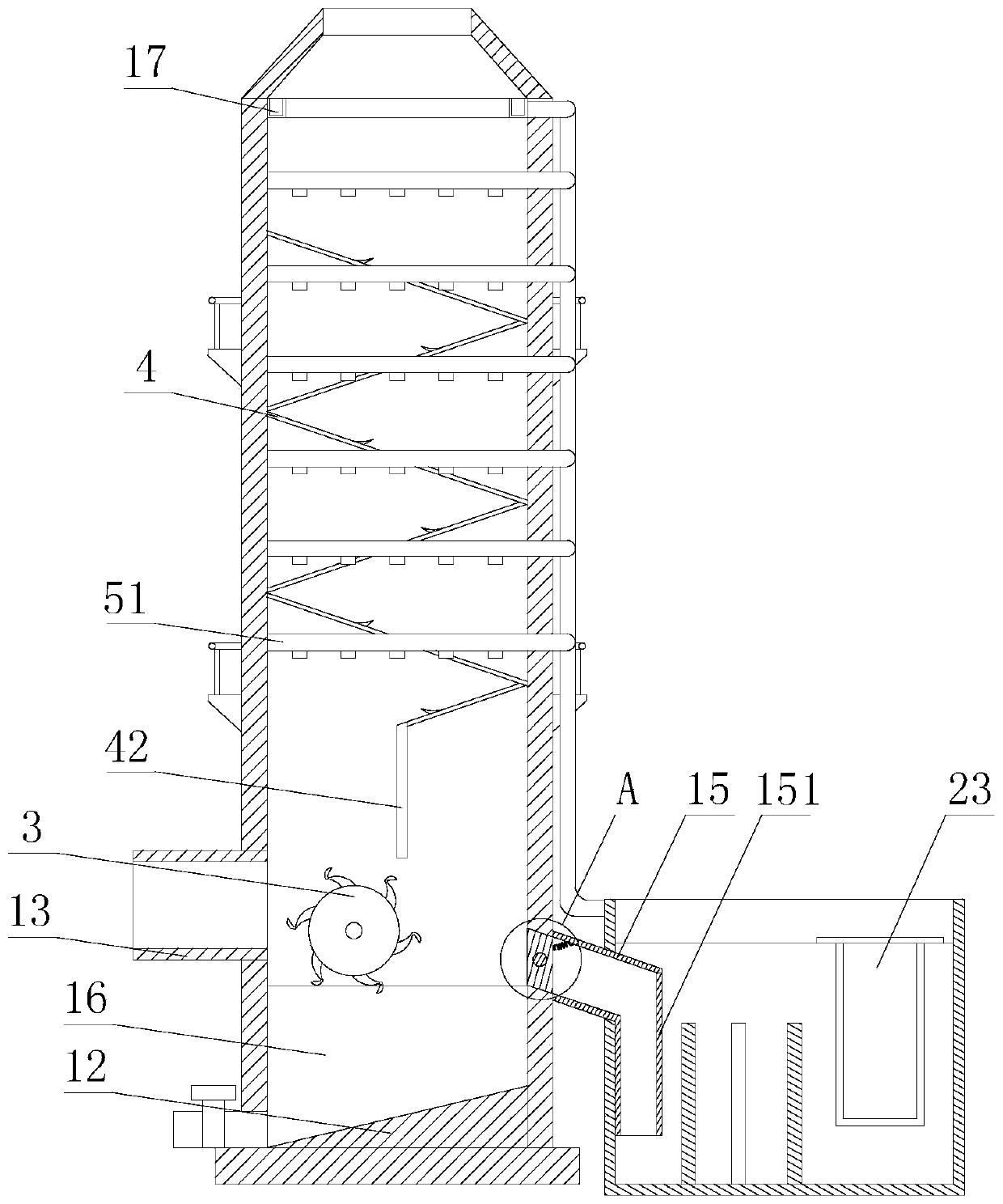

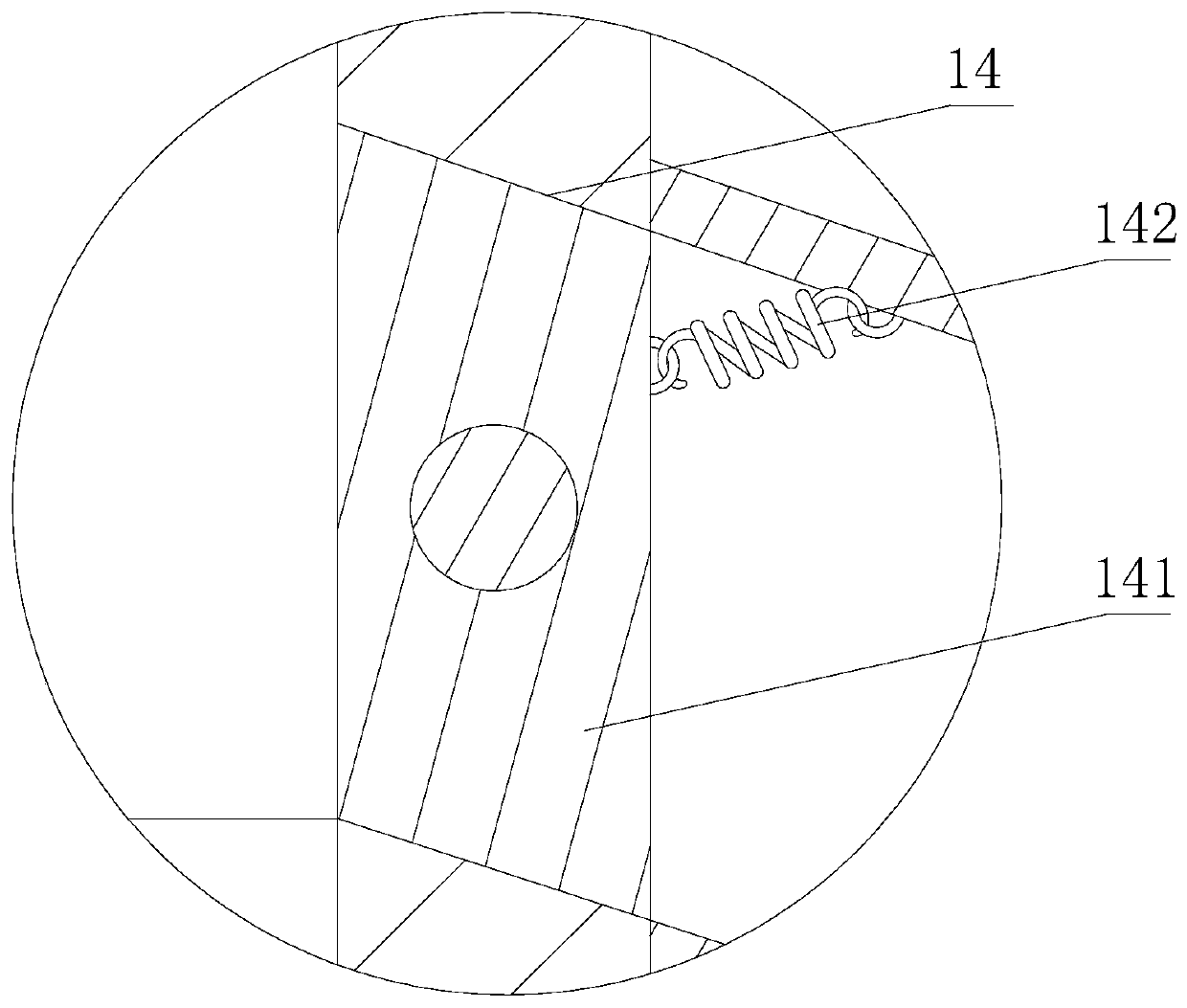

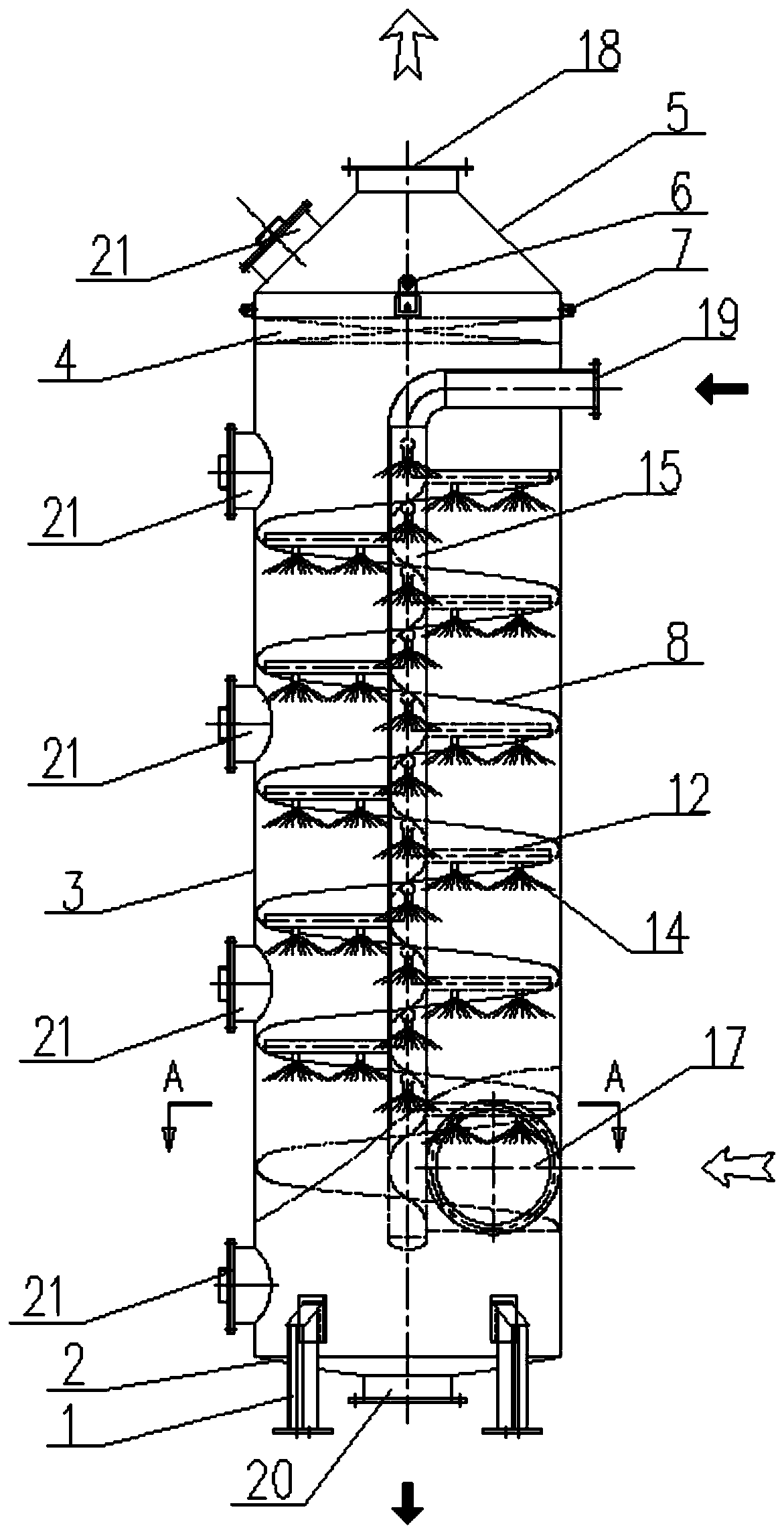

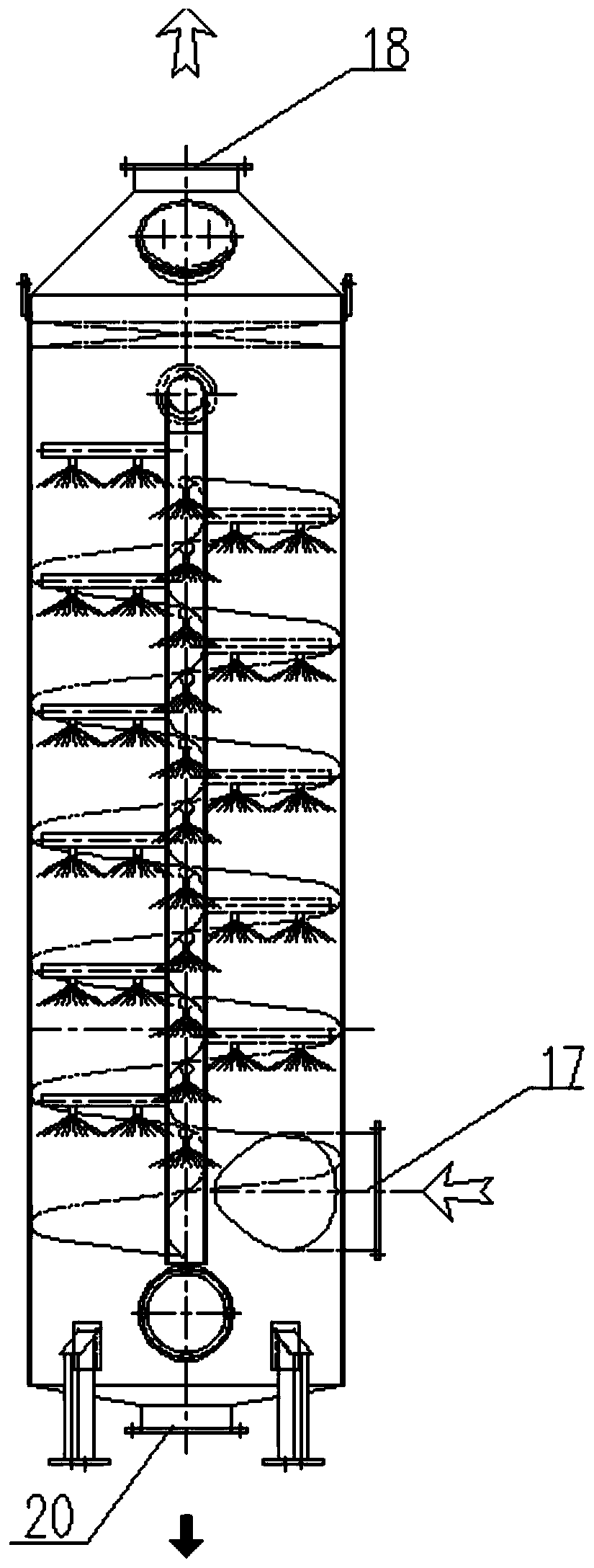

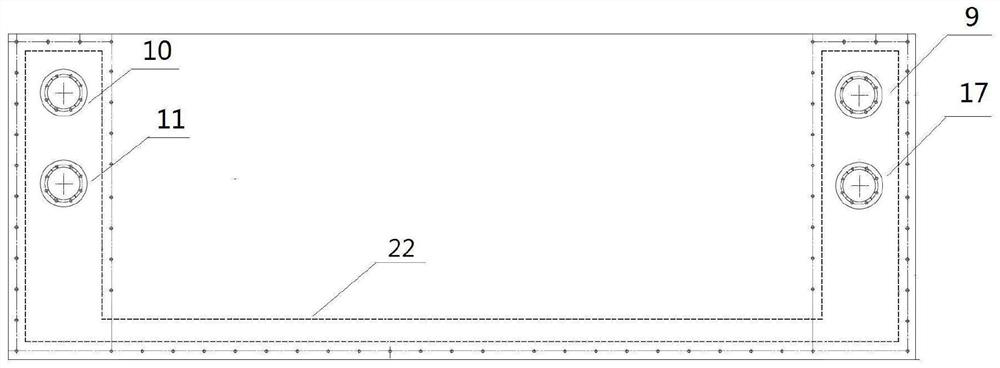

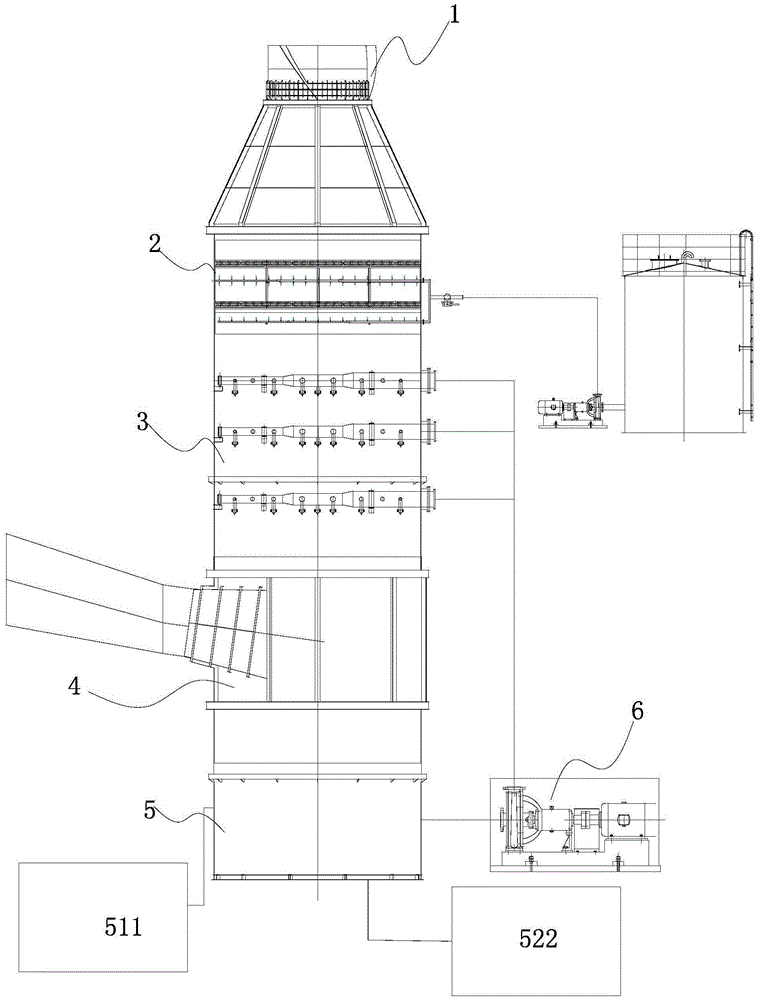

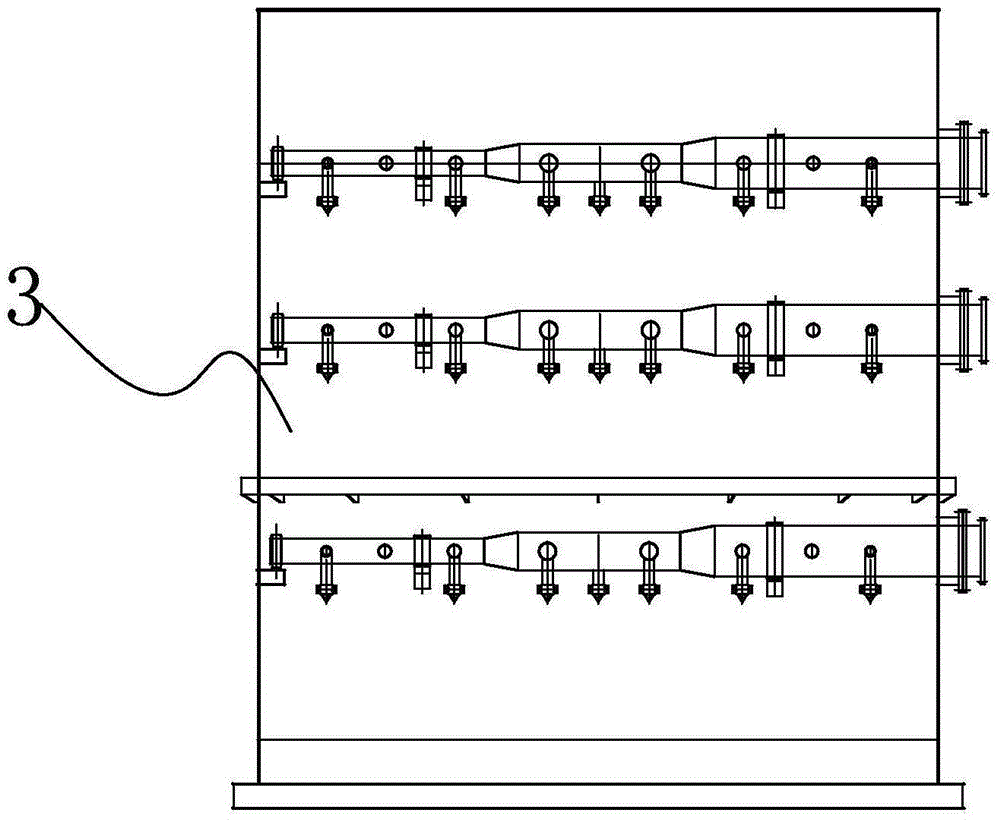

Washing tower for ship tail gas treatment

PendingCN111013389AReduce tower spaceReduce device sizeDispersed particle separationExhaust gasFlue gas

Owner:ZHEJIANG TUNA ENVIRONMENTAL SCI & TECH

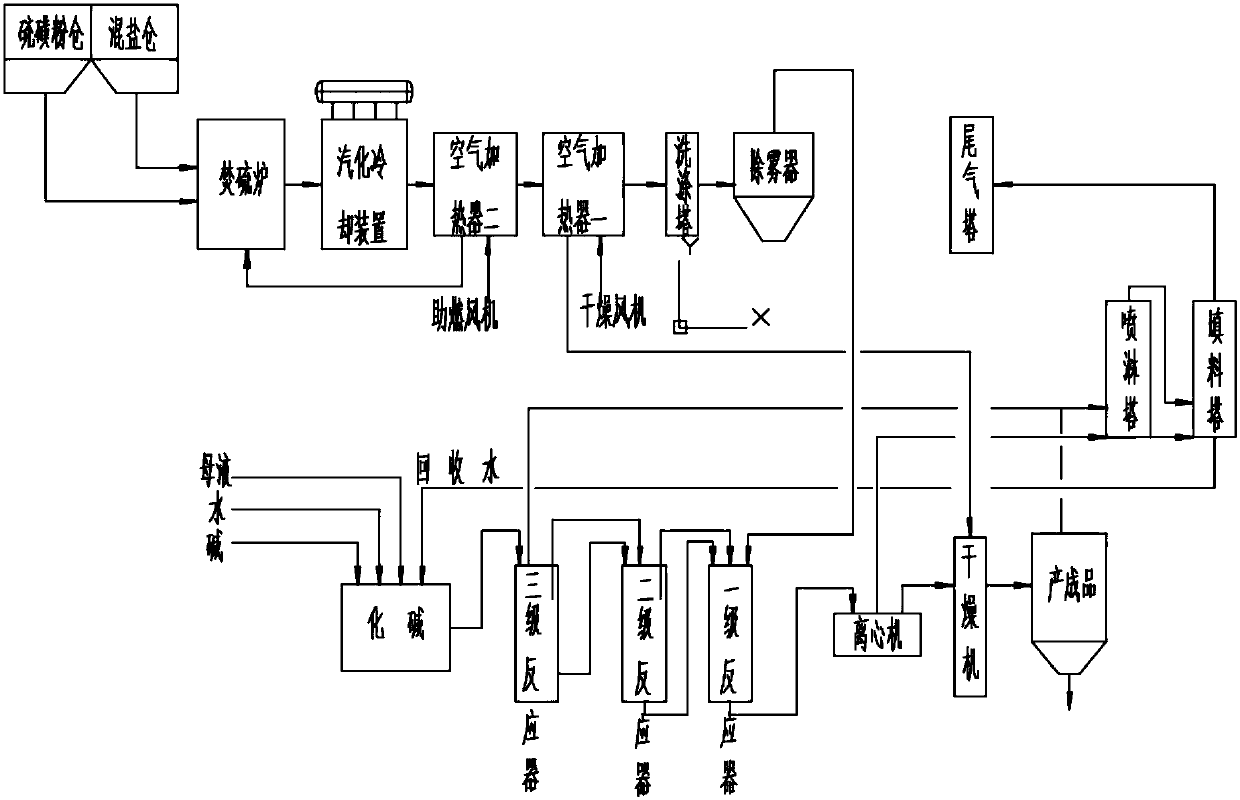

Method for preparing sodium pyrosulfite from coking desulfurization waste liquid and crude sulfur

InactiveCN109607575ASolve the whereabouts problemReduce restrictionsAlkali metal sulfite preparationSulfurDirect combustion

The invention discloses a method for preparing sodium pyrosulfite from coking desulfurization waste liquid and crude sulfur, which comprises a raw material pretreatment step, a sulfur burning step, afurnace gas purification step and a finished product step. The invention adopts the technology of a sulfur melting kettle to prepare sulfur, and the desulfurization waste liquid is subjected to concentrated crystallization to directly prepare mixed salt, and then the mixed salt is respectively sent to an incinerator for direct combustion, thereby not only innocuously treating the desulfurization waste liquid, but also comprehensively utilizing the sulfur resources; the low pressure saturated steam from coking plant is used to produce massive sulfur by using the technology of the sulfur meltingkettle, and the desulfurization waste liquid is also concentrated and crystallized by using the low pressure saturated steam to produce mixed salt, the method has features of low investment, low energy consumption which is only 30%-40% of that of direct hot air drying and no exhaust emission.

Owner:朱华东

Alkali-water desulphurization dust removal technology

InactiveCN105983307AFully contactedIncrease mass transfer driving forceUsing liquid separation agentSulfateSpray nozzle

The invention relates to an alkali-water desulphurization dust removal technology, and relates to a wet-method environment-friendly treatment technology for sulfur-containing smoke. The alkali-water desulphurization dust removal technology comprises the following steps: performing primary desulphurization dust removal by taking a sulfur-containing solution as a first desulphurization agent, performing the secondary desulphurization dust removal by adopting the water as a second desulphurization agent, performing the primary desulphurization dust removal in a tubular reaction device, and performing the secondary desulphurization dust removal in a tower-type device; and enabling the desulphurized dust-removed sulphite-containing mixed solution to enter an independent tubular oxidation reactor, and performing the oxidation reaction to obtain a sulfate mixed solution. By adopting the alkali-water desulphurization dust removal technology, the technical defects of the traditional wet-method desulphurization technology that a spray nozzle is blocked by scales formed on the inner wall and components in the desulphurization tower can be overcome, and the long-term operation of the device can be guaranteed; the equipment investment is low, the operation expense is low, the operation flexibility is high, the absorption, neutralization and oxidation are thoroughly carried out, and the desulphurization efficiency is high.

Owner:吴剑华

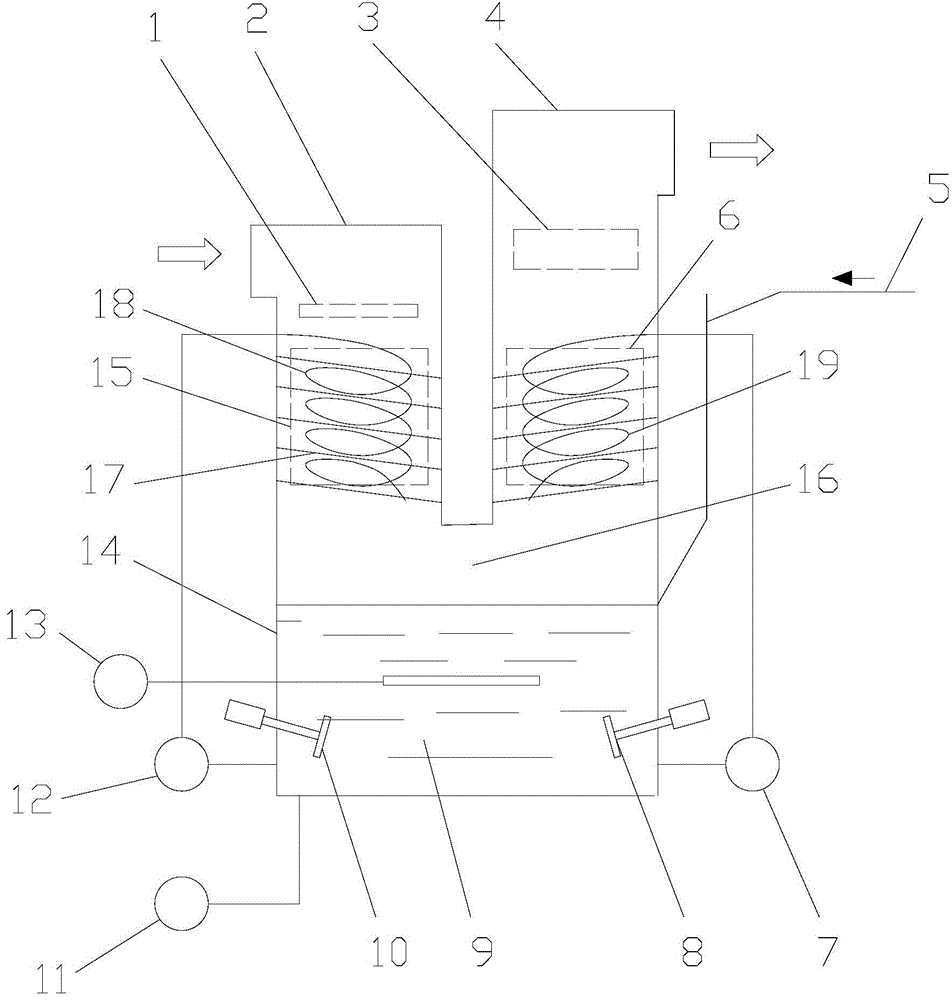

Desulfurizing tower

InactiveCN104874283AWell mixedGuaranteed desulfurization effectDispersed particle separationEngineeringCirculating pump

The invention discloses a desulfurizing tower which comprises a desulfurizing tower body. The upper portion of the desulfurizing tower body includes a down-flow tower and an adverse-flow tower, a smoke inlet is formed in the down-flow tower, a smoke outlet is formed in the adverse-flow tower, and the lower portion of the desulfurizing tower body is a slurry pool. A front circulating desulfurizing zone is arranged in the down-flow tower, a rear circulating desulfurizing zone is arranged in the adverse-flow tower, vertical spiral guide vanes are arranged on the inner wall corresponding to the front circulating desulfurizing zone of the down-flow tower and on the inner wall corresponding to the rear circulating desulfurizing zone of the adverse-flow tower, an outlet of a front circulating pump is communicated to the front circulating desulfurizing zone through a front circulating pipe, an outlet of a rear circulating pump is communicated to the rear circulating desulfurizing zone through a rear circulating pipe, and spiral channels formed by a front circulating pipe and a rear circulating pipe along the corresponding vertical spiral guide vanes spirally extend into the front circulating desulfurizing zone and the rear circulating desulfurizing zone. The front circulating pipe and the rear circulating pipe extend into the spiral channels and can spray slurry in the spiral channels to enable smoke and slurry to be mixed fully, and desulfurizing effect is ensured.

Owner:CHONGQING RADIO & TV UNIV +1

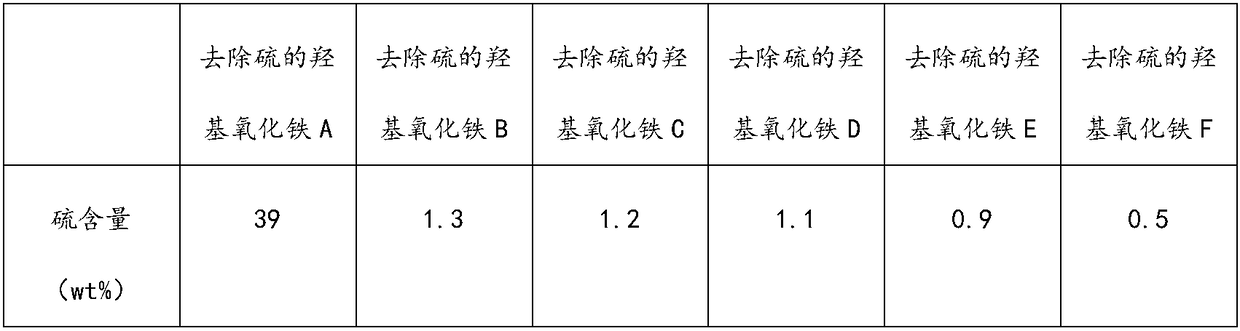

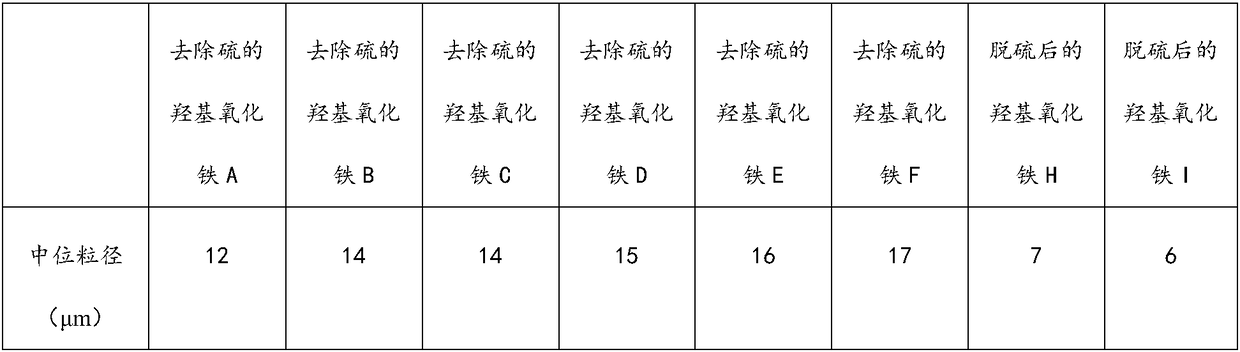

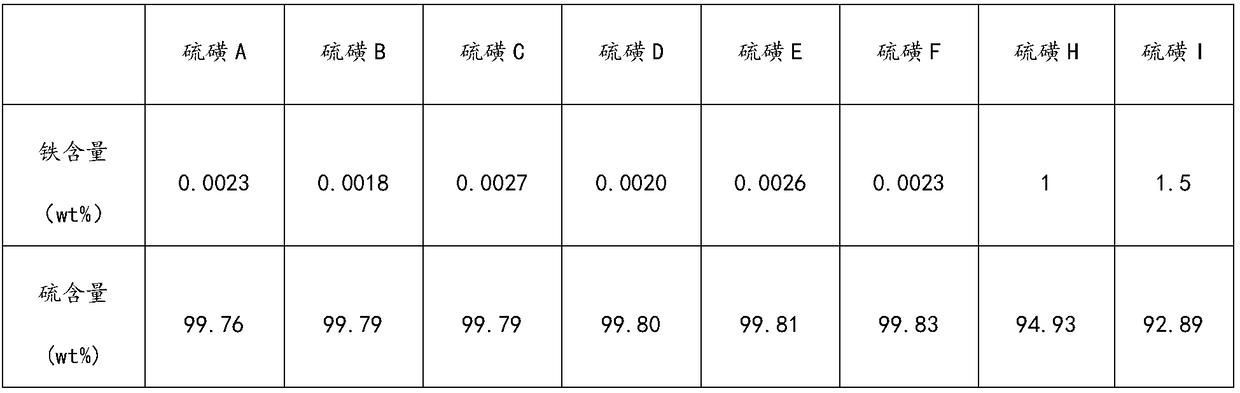

Method for removing sulfur on hydroxyl oxidize iron and application of sulfur-removed hydroxyl oxidize iron

ActiveCN108298592AEnsure desulfurization abilityGuaranteed purityIron compounds preparationIron oxides/hydroxidesOrganic solventSulfur containing

The invention provides a method for removing sulfur on hydroxyl oxidize iron. By strictly controlling the water content of sulfur-containing hydroxyl oxidize iron, the desulfuration capability of hydroxyl oxidize iron and the purity of recycled sulfur are effectively ensured on the premise of efficiently separating sulfur from hydroxyl oxidize iron, which is because when the water content of hydroxyl oxidize iron is too high, the water is dispersed into fine particles in an organic solvent, which not only reduces the desulfurization capability of hydroxyl oxidize iron, but also causes the recycled sulfur to contain a large number of iron.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

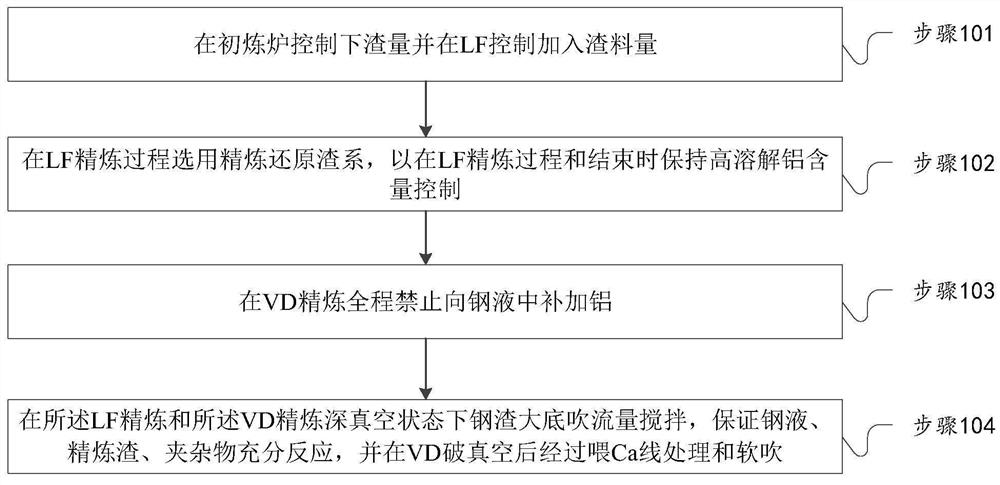

Aluminum content control method

ActiveCN112094985AReduce in quantitySimple control methodProcess efficiency improvementSlagAluminium

The invention discloses an aluminum content control method. The aluminum content control method is used for reducing the quantity of inclusions in ultra-low sulfur steel and controlling the aluminum content in the steel, and comprises the following steps that the slag amount is controlled in a primary smelting furnace and the slag adding amount is controlled in an LF; a refining reducing slag system is selected in the LF refining process so as to keep high dissolved aluminum content control in the LF refining process and at the end of the LF refining process; in the whole VD refining process,aluminum is forbidden to be supplemented into molten steel; under the LF refining and VD refining deep vacuum state, steel slag large bottom blowing flow stirring is carried out, it is guaranteed thatmolten steel, refining slag and inclusions react sufficiently, and after VD vacuum breaking, Ca line feeding treatment and soft blowing are carried out; and after the molten steel is rolled, the maximum inclusions are less than 20 microns, and the distribution density of various inclusions of 5-20 microns is 0.2-0.8 / mm < 2 >.

Owner:SHOUGANG CORPORATION

Smoke desulfurization device and method

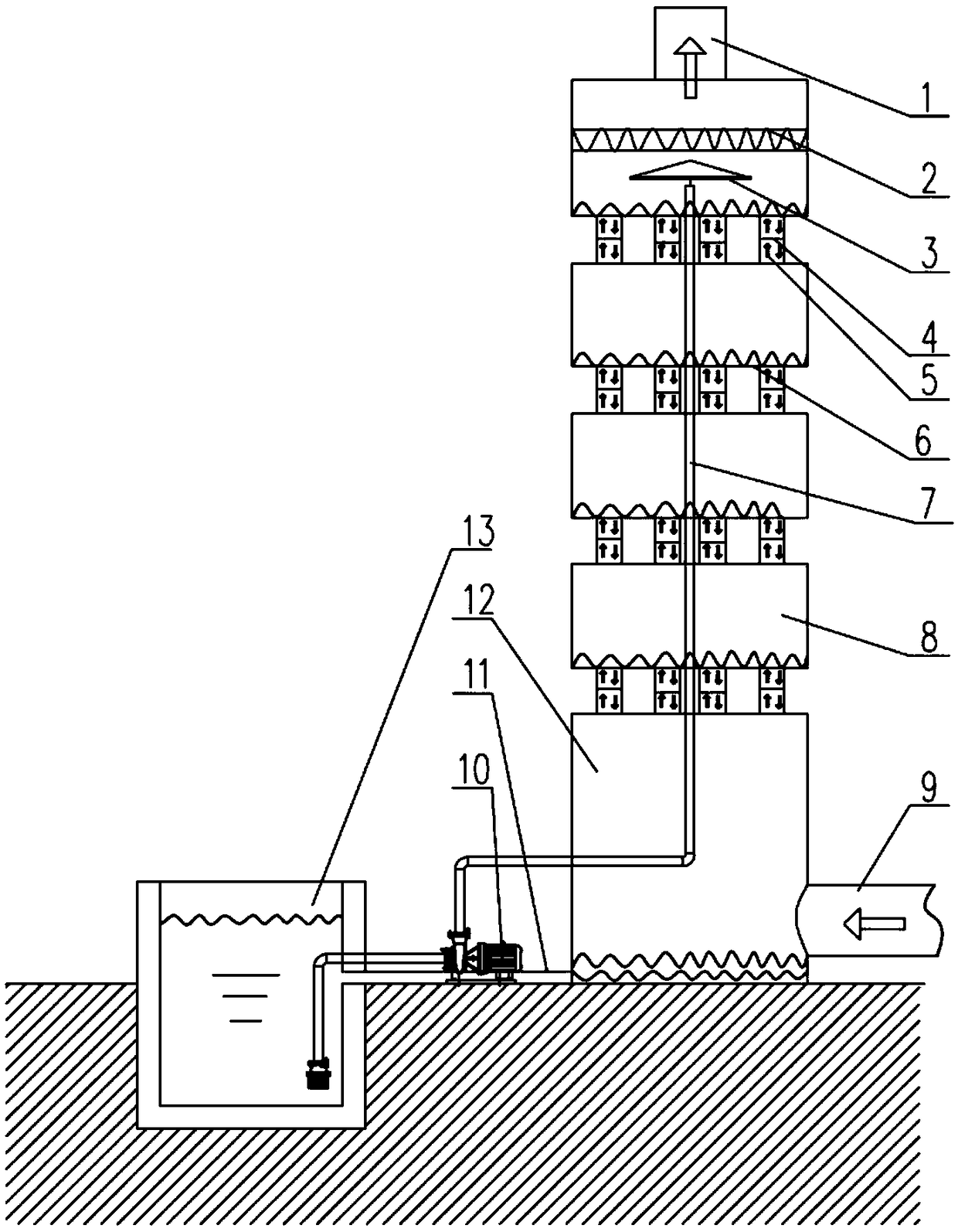

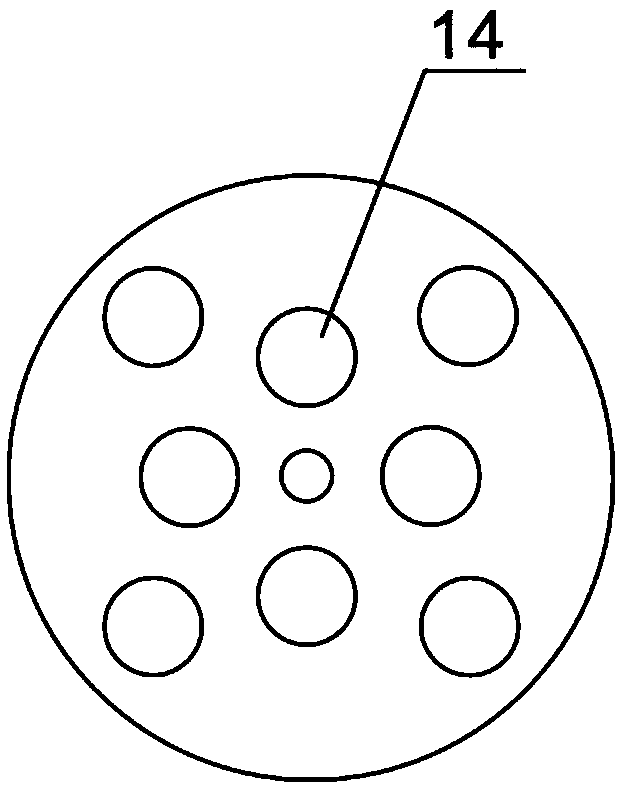

The invention relates to a smoke desulfurization device and method, belongs to the technical field of environmental protection equipment and solves the problems of poor desulfurization effect and highoperation cost due to short contact time and small contact area of smoke with a desulfurized liquid in the prior art. The smoke desulfurization device comprises a plurality of desulfurization barrelsand a liquid feeding pipe, wherein the adjacent desulfurization barrels are vertically communicated through a desulfurization channel, and a desulfurized liquid level is formed on a bottom plate of each desulfurization barrel; the liquid feeding pipe penetrates through centers of the desulfurization barrels, and a liquid outlet of the liquid feeding pipe is located in the top desulfurization barrel. By means of the desulfurization method of the smoke desulfurization device, the height of the desulfurized liquid level is can be adjusted, and the adjustability of the desulfurized liquid level is realized. The provided smoke desulfurization device and method can be widely used for smoke desulfurization in industrial production such as power generation, brick making, tile burning, incineration and the like.

Owner:CHINA UNIV OF MINING & TECH

Hot area structure of MW-level solid oxide fuel cell power generation system and operation method of hot area structure

ActiveCN113903949ALarge amount of processingIncrease profitFuel cell heat exchangeAir preheaterElectric efficiency

The invention relates to a hot area structure of an MW-level solid oxide fuel cell power generation system. The hot area structure comprises a heat insulation shell, a two-section air preheater, a desulfurizer, a steam generator, a pre-converter, a reformer, a combustor and corresponding gas pipelines. The hot area structure is large in fuel handling capacity, small in hot area space and compact in internal device arrangement, meanwhile, achieves fuel treatment, air preheating, tail gas treatment and waste heat utilization and meets the requirements of the MW-level solid oxide fuel cell power generation system adopting natural gas, methane, marsh gas and the like as fuel; an anode tail gas recycling process is adopted, so that the fuel utilization rate is improved, the water-carbon ratio is reduced, and the electric efficiency and the thermal efficiency of the SOFC power generation system are favorably improved; and the two-section air preheater is adopted, the air preheater high-temperature section and the air preheater low-temperature section of smoke are fully utilized, the smoke exhaust temperature is effectively reduced, and it is guaranteed that air at the cathode inlet of an SOFC cell stack reaches the proper temperature.

Owner:广东佛燃科技有限公司

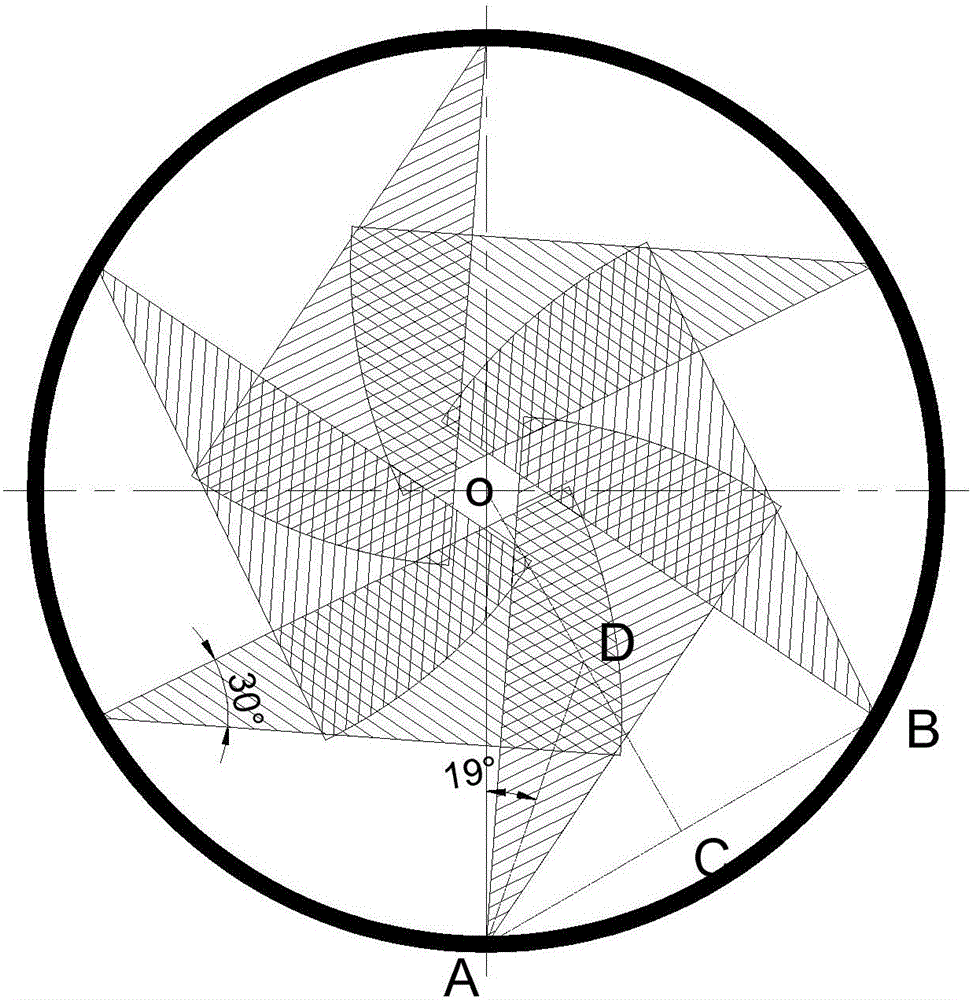

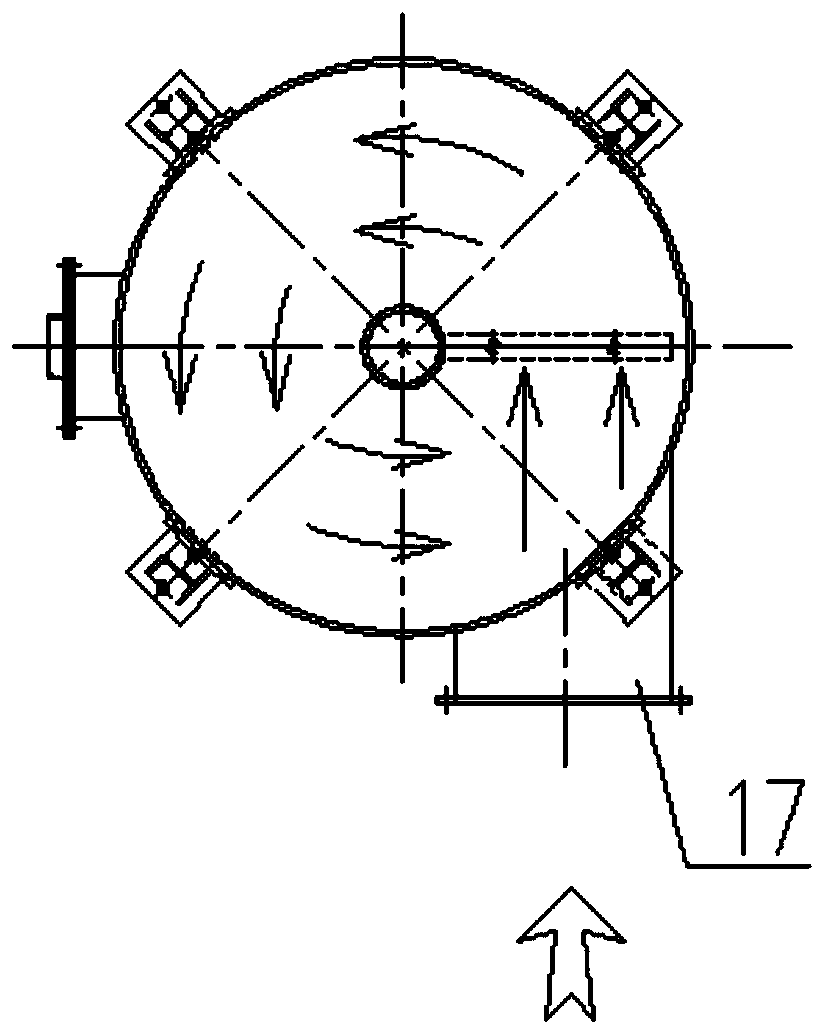

Rotational flow reaction device and flue gas desulfurization device

ActiveCN105169925AIncrease concentrationImprove desulfurization efficiencyDispersed particle separationImpellerFlue gas

The invention discloses a rotational flow reaction device and a flue gas desulfurization device. The rotational flow reaction device comprises a rotational flow shell and at least two rotational flow chambers, wherein each rotational flow chamber is provided with at least one swirler, a circular reaction slurry inlet is formed in the upper portion of each rotational flow chamber, and the lower side of each rotational flow chamber is communicated with a gas uniformizing chamber. Each swirler is a swirl impeller comprising an impeller shell, an impeller center shaft and at least five swirl vanes surrounding the impeller center shaft, wherein the impeller shell is fixed in the corresponding rotational flow chamber, the inner edge of each swirl vane is fixed to the impeller center shaft, and the outer edge of each swirl vane is fixed to the impeller shell. A flue gas flow regulating device is arranged on the top of each rotational flow chamber, can open and close the rotational flow chamber, and is connected with the top of the rotational flow chamber. The rotational flow reaction device is simple in structure, the number of the rotational flow chambers involved in reaction can be selected, the velocity of flue gas can be effectively controlled, flue gas desulfurization effect and degree can be guaranteed, energy can be saved, and environment pollution can be avoided.

Owner:龙创信恒(北京)科技有限公司

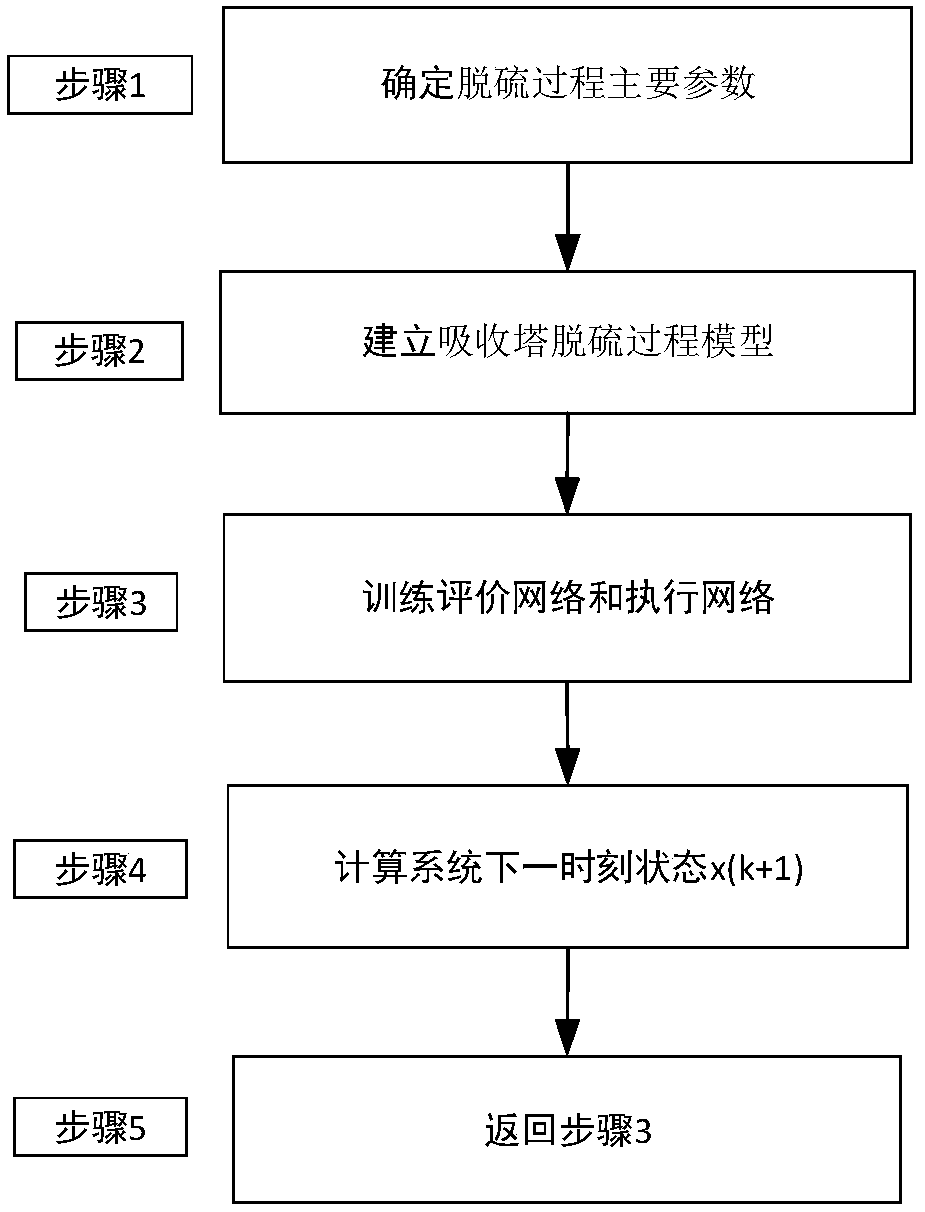

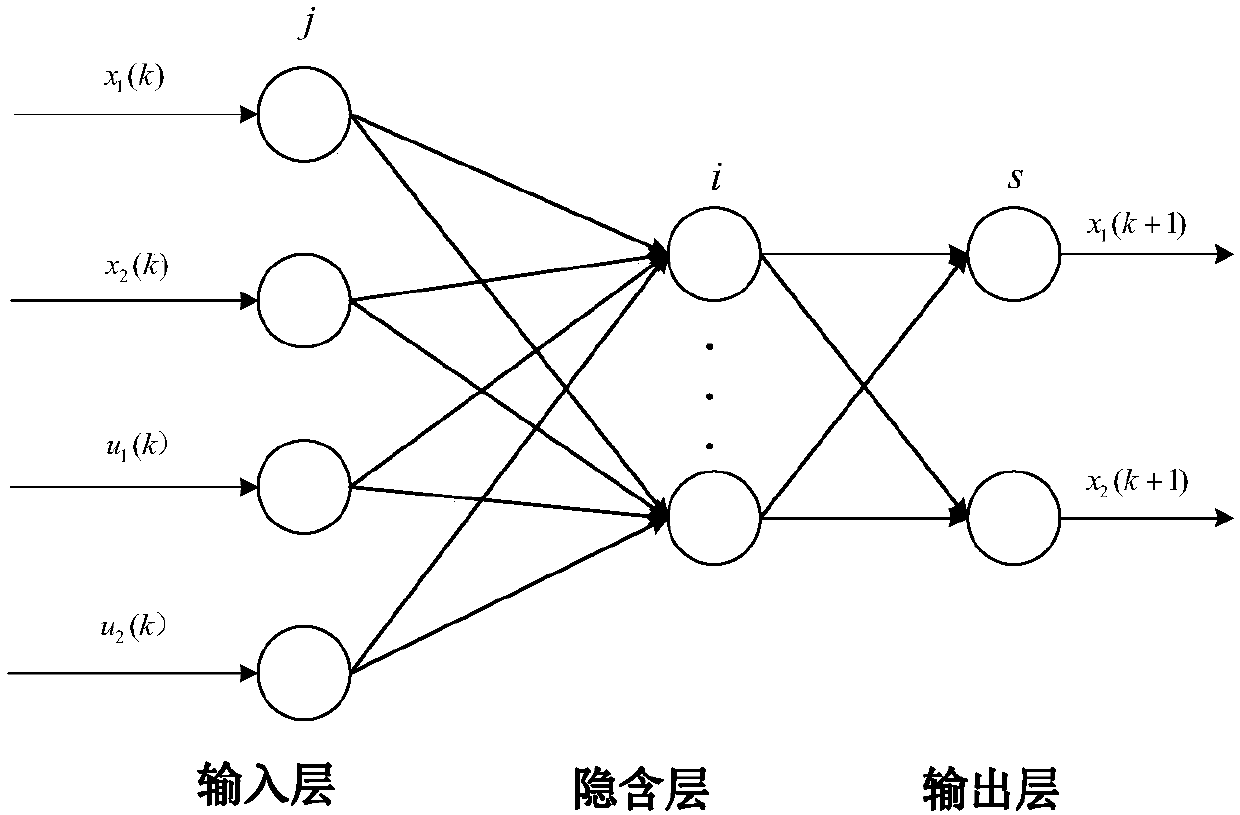

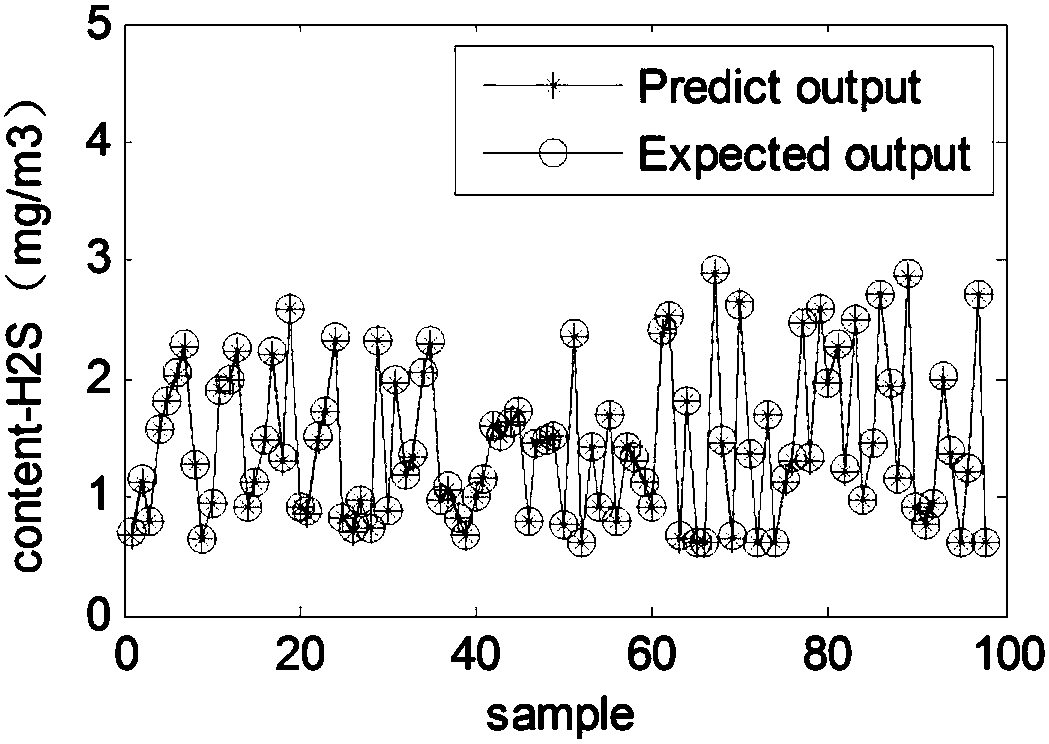

Natural gas absorption tower desulfuration process control method based on RBF and GDHP

The invention provides a natural gas absorption tower desulfuration process control method based on RBF and GDHP. The method comprises the steps: carrying out the modeling of a desulfuration process of an absorption tower through a BP neural network, taking a model as a controlled object to carrying out a control simulation experiment of the desulfuration process of the absorption tower, continuously updating an optimization weight according to a control error and a performance index function, and obtaining a new control signal till achieving the optimal control of the desulfuration process. The desulfuration process of the absorption tower is complex, and is uncertain, nonlinear, strong in coupling performance and dynamic, so a precise mathematic model is difficult to build, and the control difficulty is larger. Aiming at the problems that a conventional absorption tower desulfuration process control method is low in control precision, is large in time lag and is not stable, the invention proposes the method, and the method guarantees the stability and control precision of a control system, also reduces the response time, and truly achieves the real-time control of the desulfuration process of the absorption tower.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

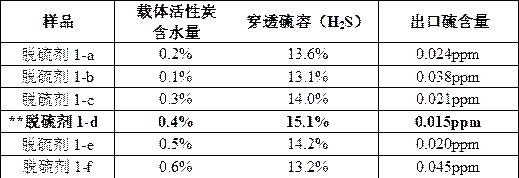

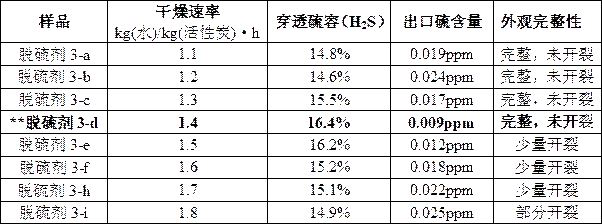

Preparation method of zinc-iron composite oxide loaded activated carbon desulfurizer

ActiveCN112354518AImprove load uniformityHigh sulfur capacityGas treatmentOther chemical processesActivated carbonPhysical chemistry

The invention relates to a preparation method of a zinc-iron composite oxide loaded activated carbon desulfurizer, which comprises the following steps: impregnating activated carbon with the water content of 0.1-0.5 wt% in a zinc-iron mixed solution at 60-80 DEG C, and controlling the impregnation time according to the bulk density of the activated carbon; drying the impregnated activated carbon,and controlling the drying rate according to the adsorption saturation of the activated carbon during the period; and roasting the dried activated carbon at 500-700 DEG C for 2-4 hours to obtain the finished product of the zinc-iron composite oxide loaded activated carbon desulfurizer. By improving and innovating the preparation process, the loading uniformity and dispersity of the active components on the carrier are greatly improved, and the sulfur capacity and desulfurization precision of the loaded activated carbon desulfurizer are effectively improved, so that hydrogen sulfide in the chemical production process is efficiently and stably removed, equipment corrosion is prevented, and the environment is protected.

Owner:HUNAN HUANDA ENVIRONMENTAL PROTECTION

Hydrogen peroxide desulfurization recovery device

PendingCN109589772AStrong desulfurization activityIncrease reaction rateSulfur compoundsDispersed particle separationReaction rateProcess engineering

The invention relates to a hydrogen peroxide desulfurization recovery device. The hydrogen peroxide desulfurization recovery device comprises a desulfurization tower; a tail gas cooling device, a hydrogen peroxide conveying device and a circulation device are connected to the desulfurization tower through a gas transmission pipeline; the interior of the desulfurization tower is provided with a spraying subassembly, a mist discharge layer, a filler layer and a circulation groove; the circulation groove is disposed at the bottom of the desulfurization tower; one end of the circulation device isconnected with the circulation groove, and the other end of the circulation device is connected with the spraying subassembly. The desulfurization tower, the tail gas cooling device, the hydrogen peroxide conveying device and the circulation device are designed so that the desulfurization efficiency is efficient; the desulfurization device is efficient and convenient; the hydrogen peroxide tail gas desulfurization activity is strong; and the reaction rate is fast.

Owner:湖北蔚天环保科技有限公司

Removal method for impurity ions in organic amine desulfurized solution

InactiveCN107930399AEfficient removalImprove cleanlinessDispersed particle separationChemical industryImpurity ions

The invention belongs to the field of chemical industry, and specifically relates to a removal method for impurity ions in an organic amine desulfurized solution. The invention is to solve a technicalproblem of providing the removal method for the impurity ions in the organic amine desulfurized solution. The removal method comprises the following steps: allowing an organic amine desulfurized richliquor to pass through a cation resin exchange column of chelated resin so as to adsorb Fe3+ and Cu2+ ions, allowing the obtained organic amine desulfurized rich liquor to enter a regeneration tower,carrying out SO2 regeneration so as to obtain a poor liquor, allowing the poor liquor to pass through an anionic resin exchange column of macroporous weakly basic resin so as to remove Cl-, and allowing the obtained poor liquor to enter a freezing crystallization system so as to remove SO4<2->. The method provided by the invention can purify a used organic amine desulfurizer, reduces poisoning ofthe desulfurizer, stabilizes the effect of desulfurization, reduces the operation cost of desulfurization, and guarantees normal and stable operation of a desulfurization system.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com