Hot area structure of MW-level solid oxide fuel cell power generation system and operation method of hot area structure

A solid oxide and fuel cell technology, applied in the direction of fuel cell heat exchange, fuel cells, fuel cell additives, etc., can solve the problems of small fuel processing capacity in hot areas, insufficiently compact functional components, and low thermal efficiency, and achieve improved fuel efficiency. Utilization rate, small space in the hot zone, and the effect of improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

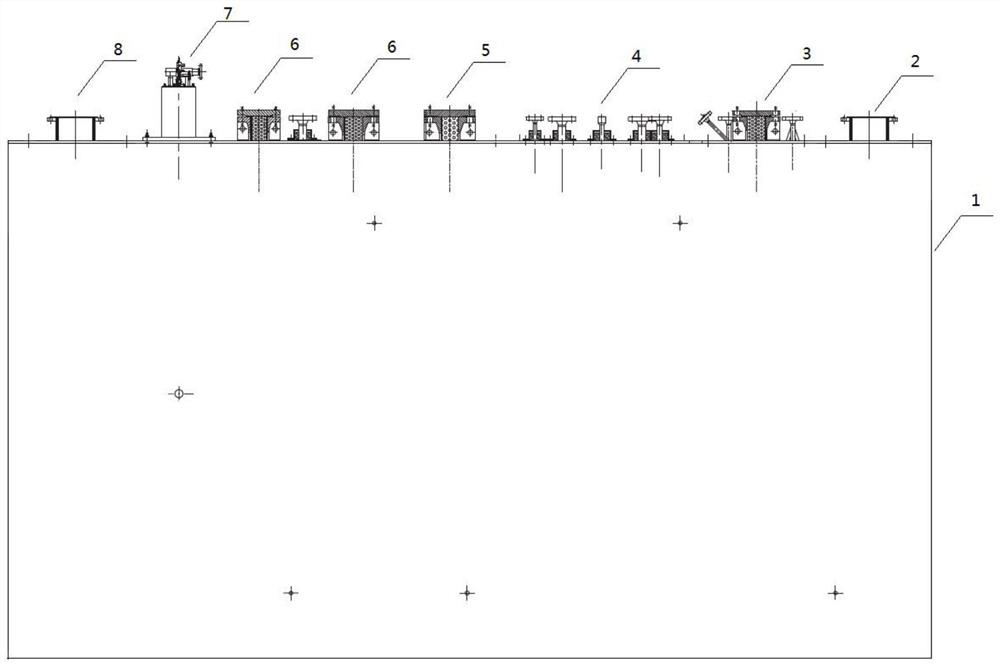

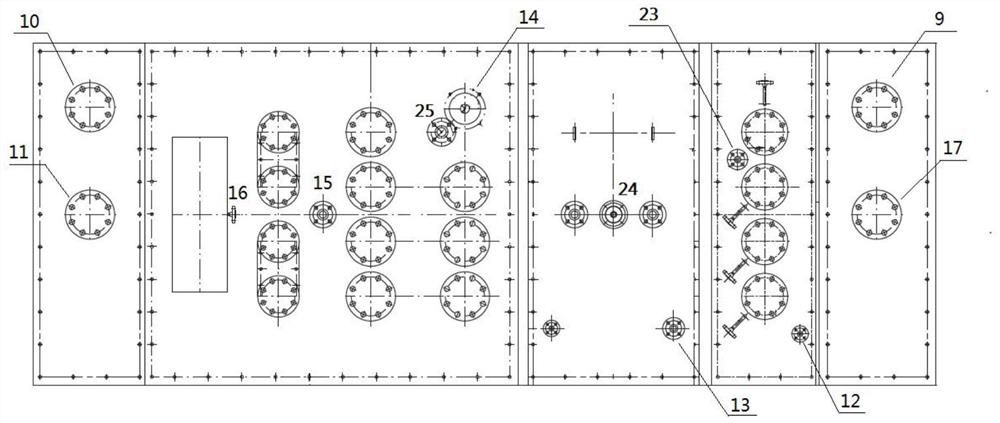

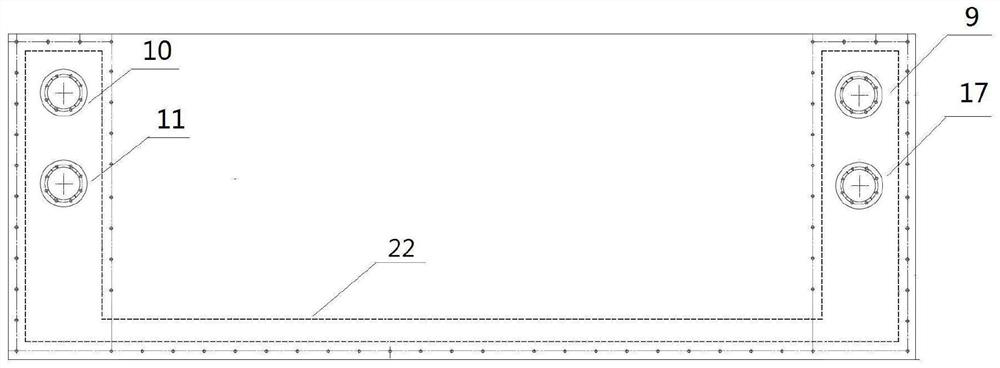

[0038] Such as Figure 1-12 As shown, the hot zone structure of a MW-level solid oxide fuel cell power generation system includes a closed heat-insulating shell 1, a two-stage air preheater, a burner 7, a reformer 6, a pre-reformer 5, The steam generator 4 and the desulfurizer 3, the two-stage air preheater includes the high temperature section 8 of the air preheater and the low temperature section 2 of the air preheater communicated through the air channel 22; the interior of the heat insulation shell 1 is from left to right The high-temperature section 8 of the air preheater, the burner 7, the reformer 6, the pre-reformer 5, the steam generator 4, the desulfurizer 3, the low-temperature section 2 of the air preheater and the corresponding pipelines are arranged in sequence; the heat insulation shell 1 There are air inlet 9, fuel inlet 12, desulfurization fuel outlet 23, deionized water inlet 13, water vapor outlet 24, mixed gas inlet 25, anode tail gas circulation gas inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com