Patents

Literature

61results about How to "Proper cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

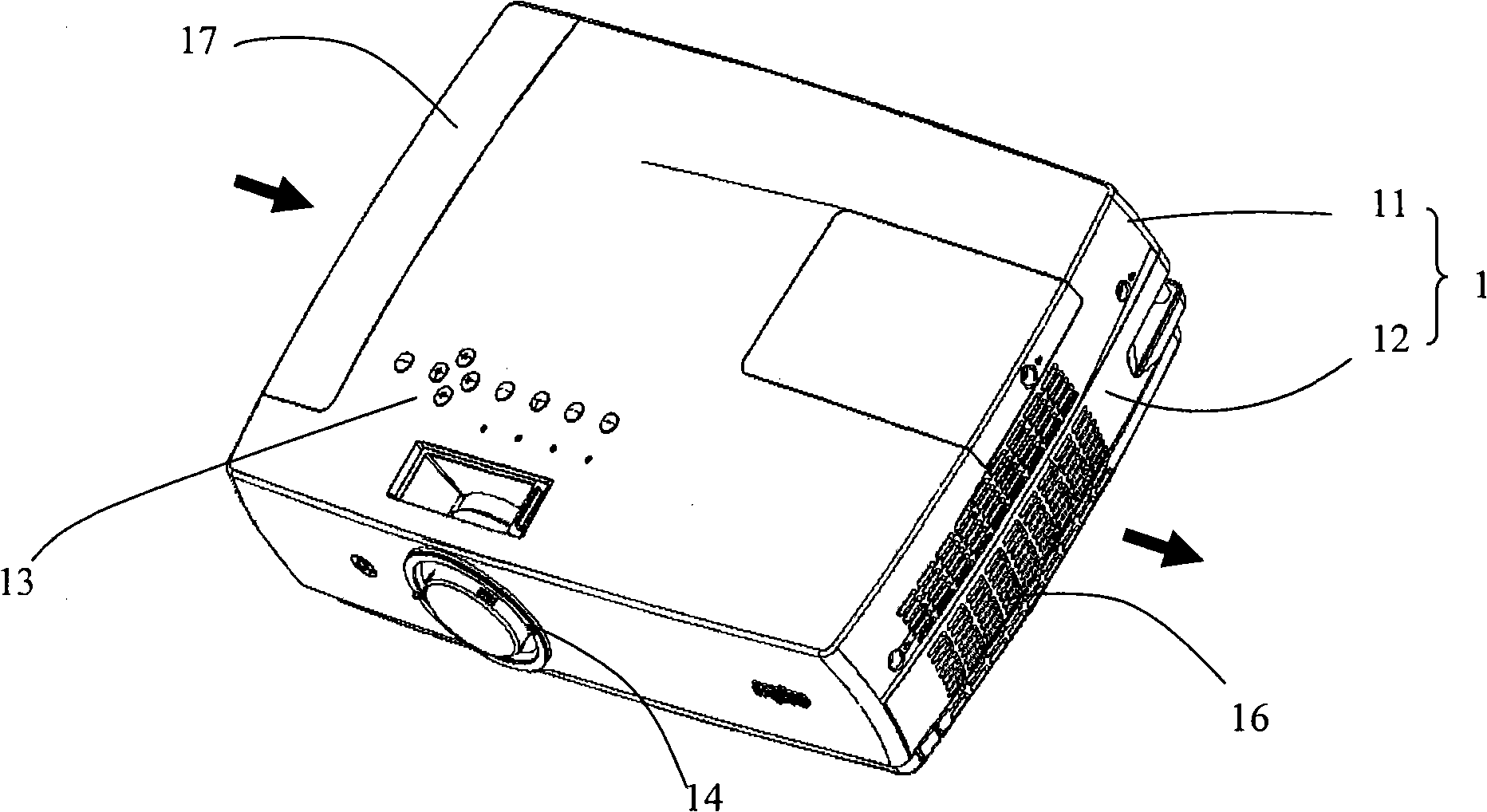

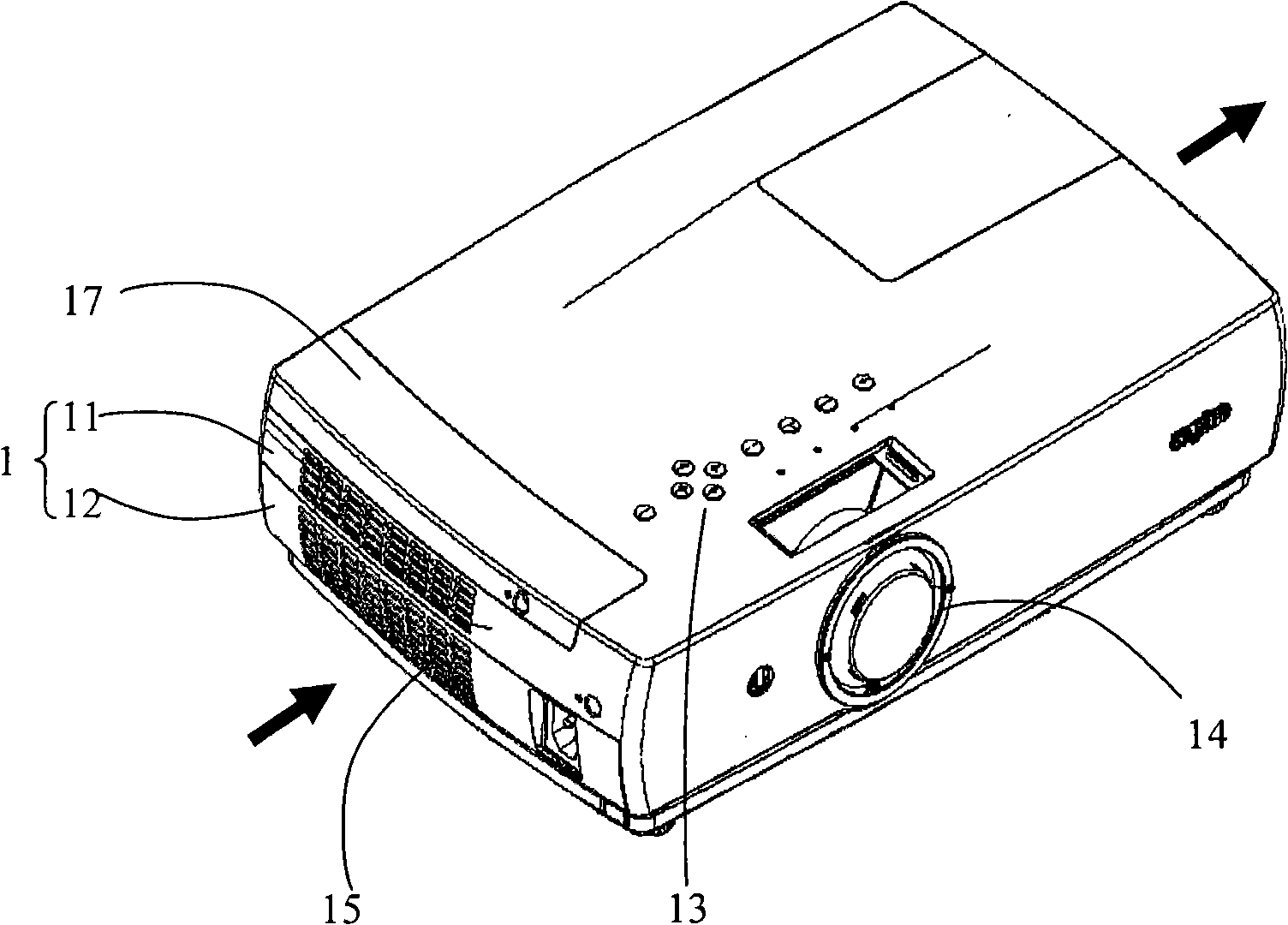

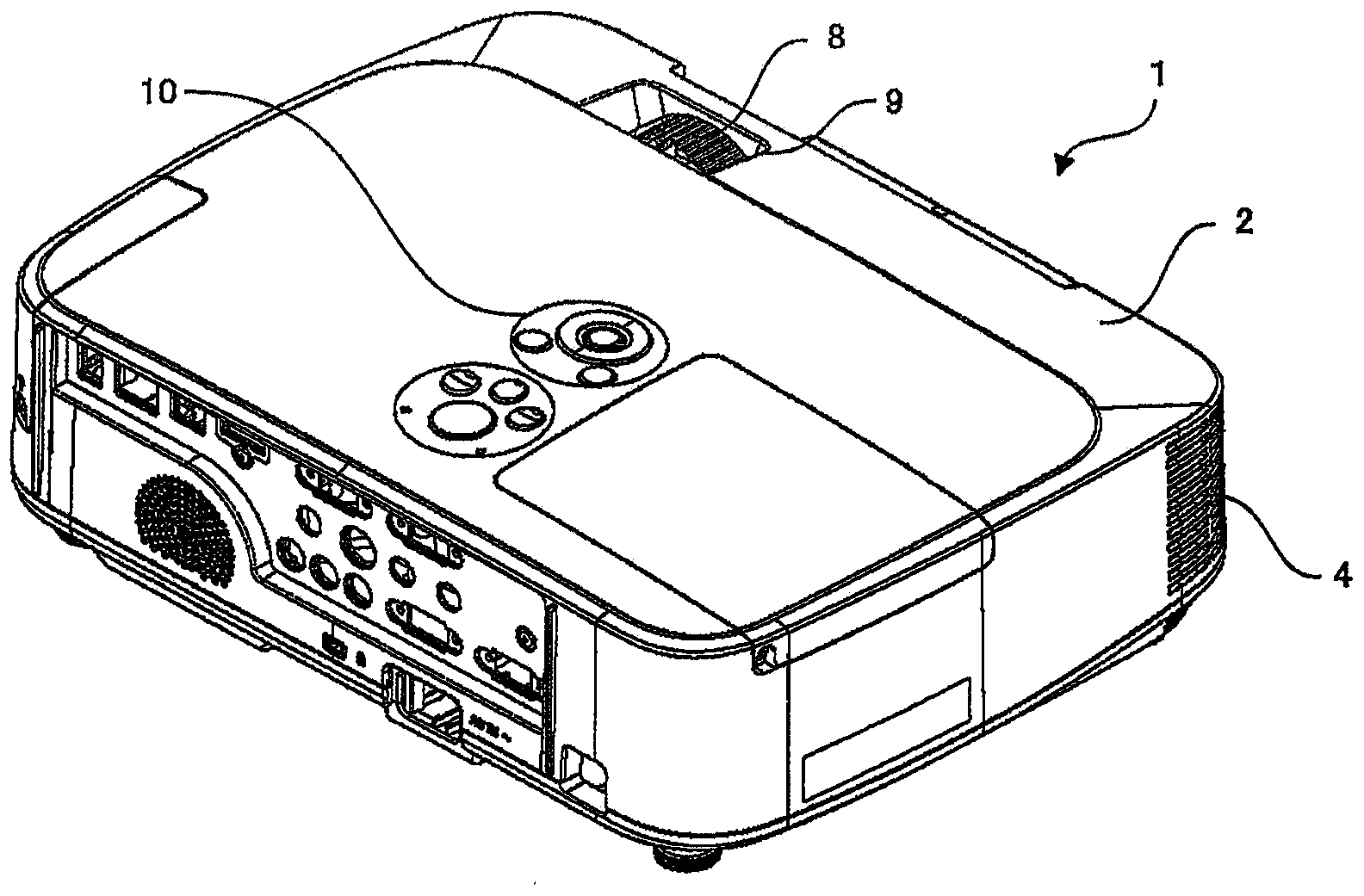

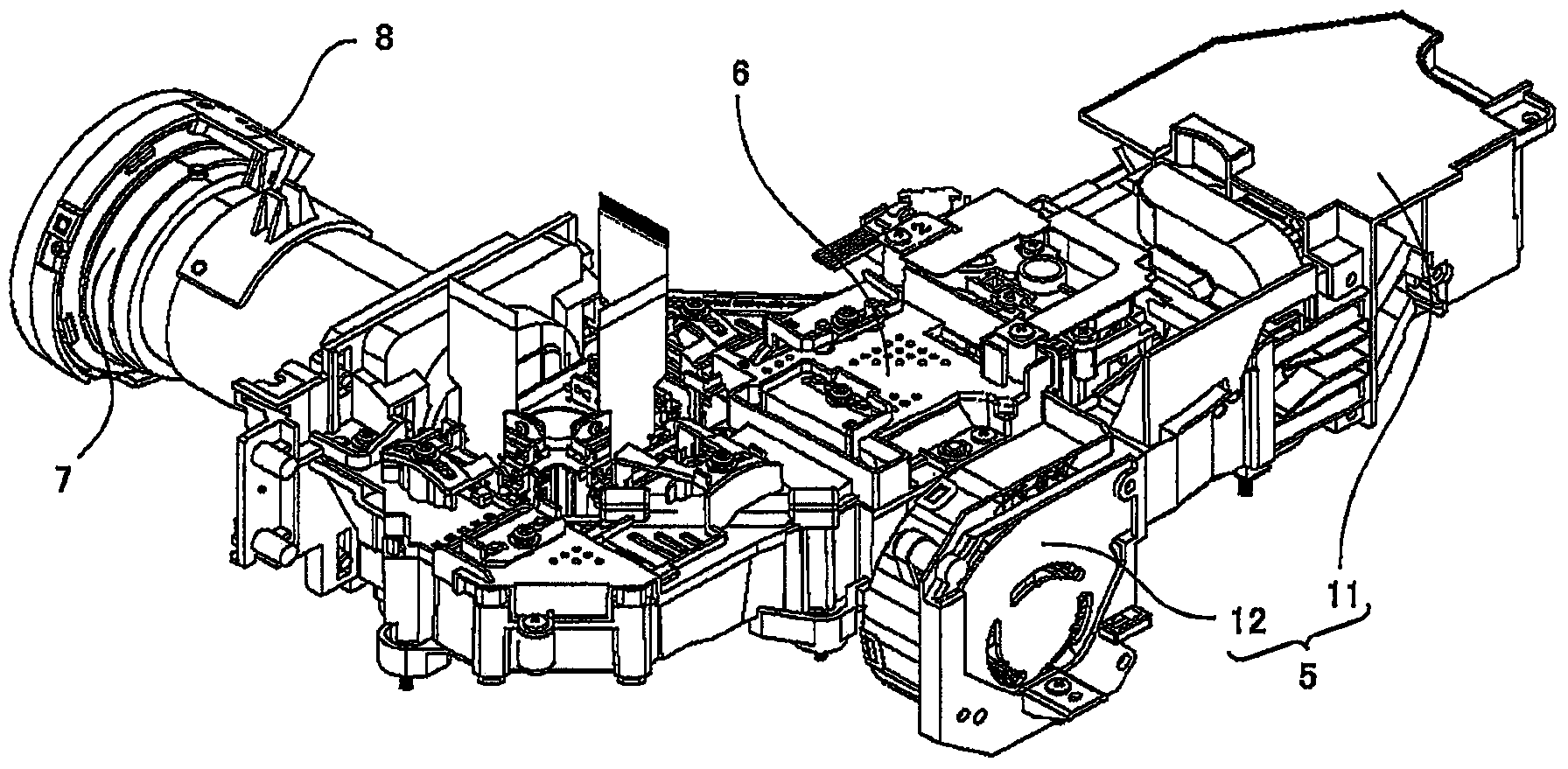

Cooling system and projecting apparatus adopting same

ActiveCN101576706AAvoid enteringImprove dust resistanceProjectorsCooling/ventilation/heating modificationsWaste managementAir channel

The invention provides a cooling system and a projecting apparatus adopting the same. The projecting apparatus comprises a shell and also comprises optical components, a lamp bulb assembly and a power supply component which are arranged in the shell. The cooling system comprises an air inlet, an air outlet, a dust preventing component, a cooling air channel, a lamp bulb component air-cooling unit, a power supply air-cooling unit and an exhauster; the air inlet and the air outlet are respectively arranged at two opposite narrower sides of the shell; the dust preventing component is arranged in the shell and clings to the air inlet; the cooling air channel clings to the dust preventing component and is internally provided with a plurality of fans and air guiding pipes which correspond to the fans, wherein the air guiding pipes lead to all the optical components; the lamp bulb component air-cooling unit and the power supply air-cooling unit collect the air-cooled exhausted air at the air outlet; and the exhauster is arranged in the shell and near to the air outlet and discharges the collected exhausted air out of the shell. When the dust is prevented, heating components in the projecting device are fully cooled, and local hot air accumulation is avoided.

Owner:SANYO TECH CENT SHENZHEN +1

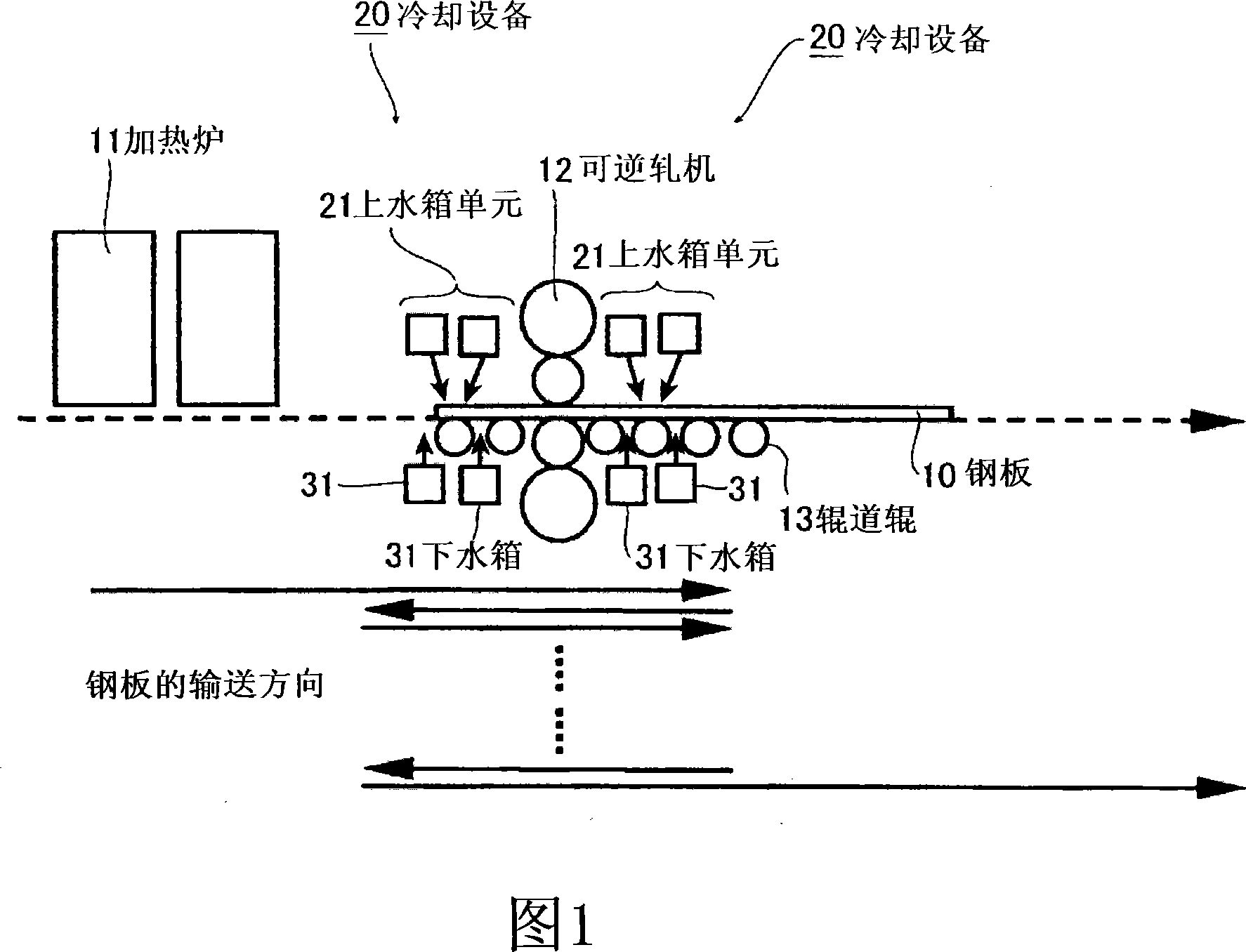

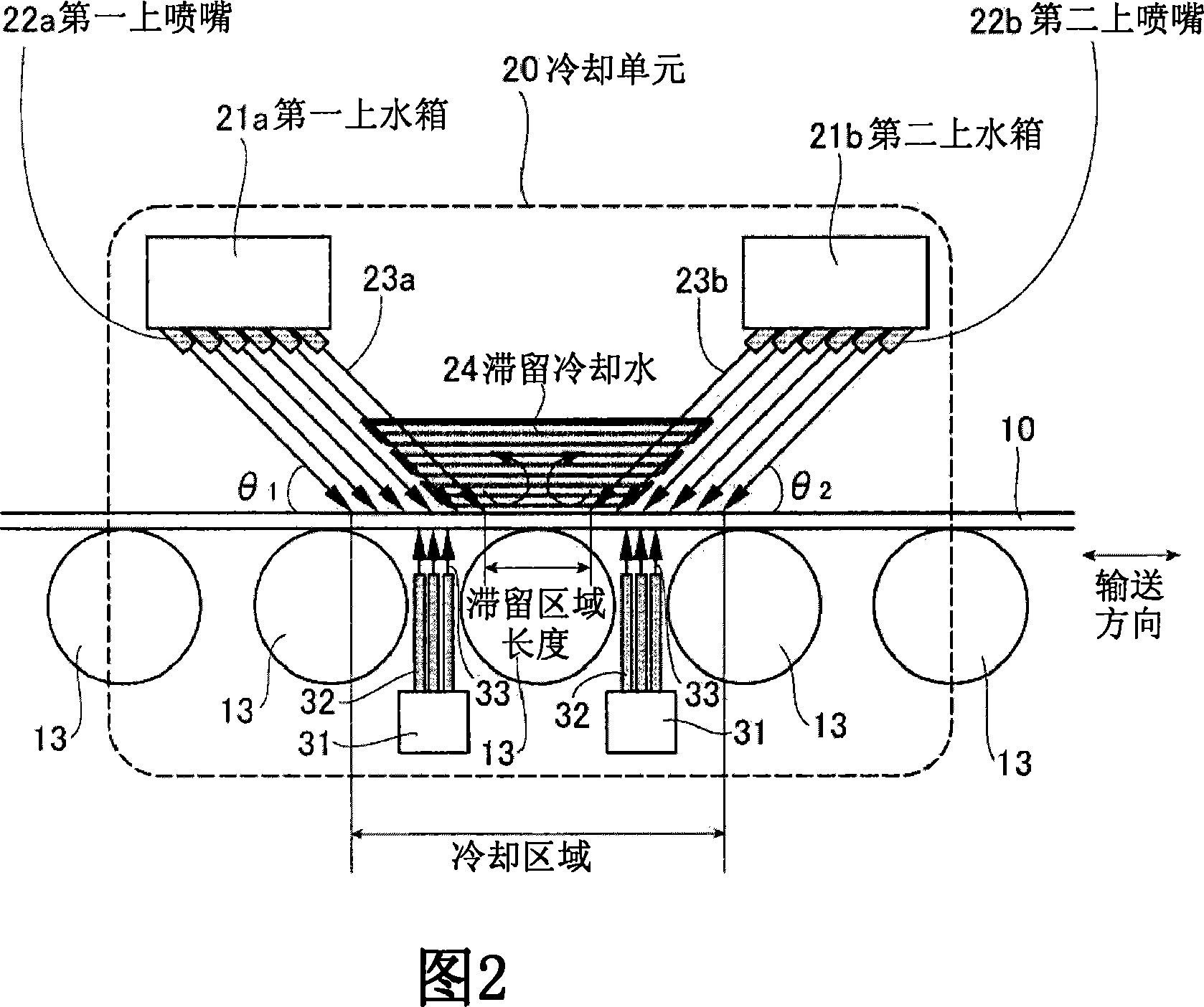

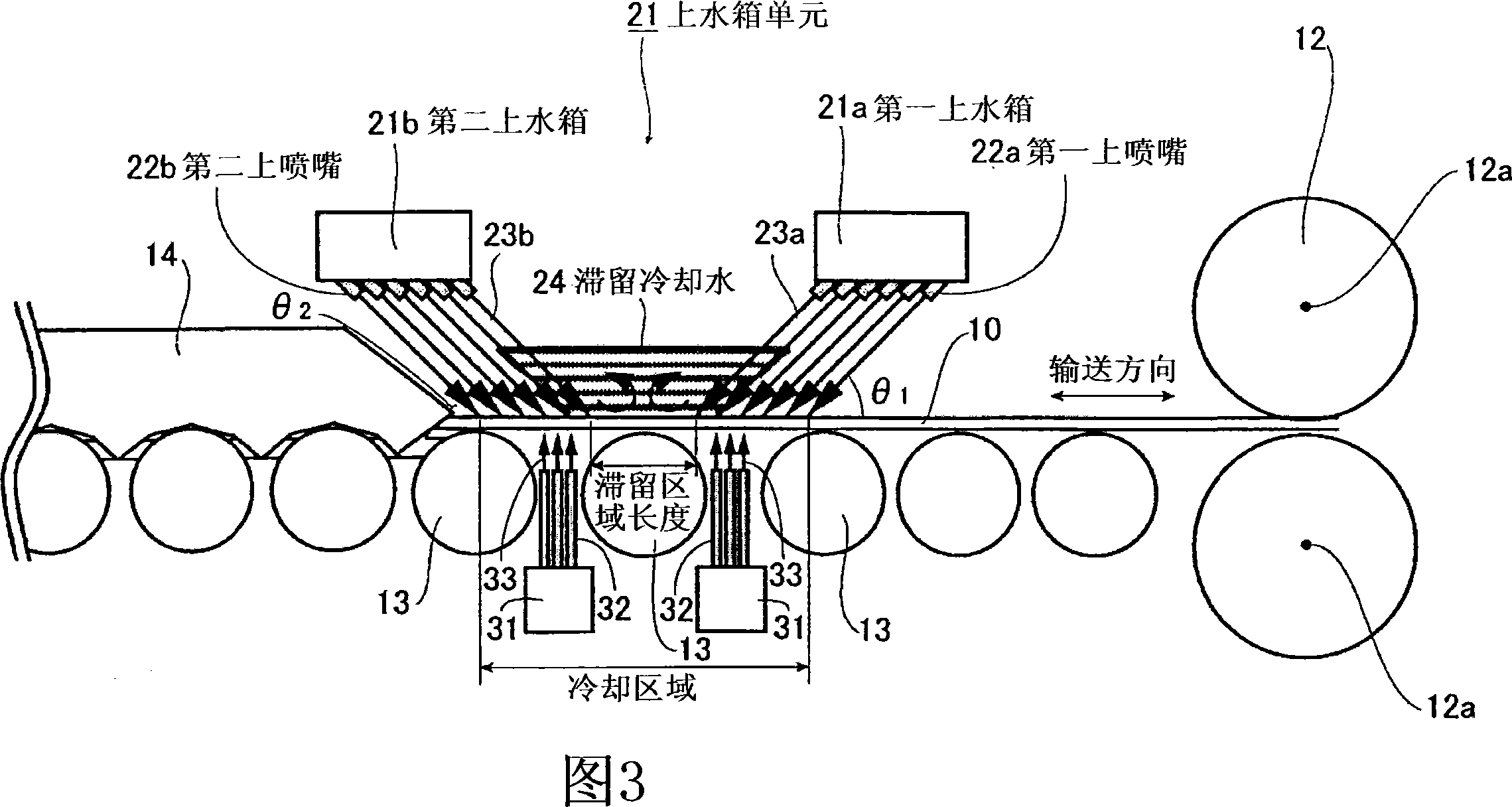

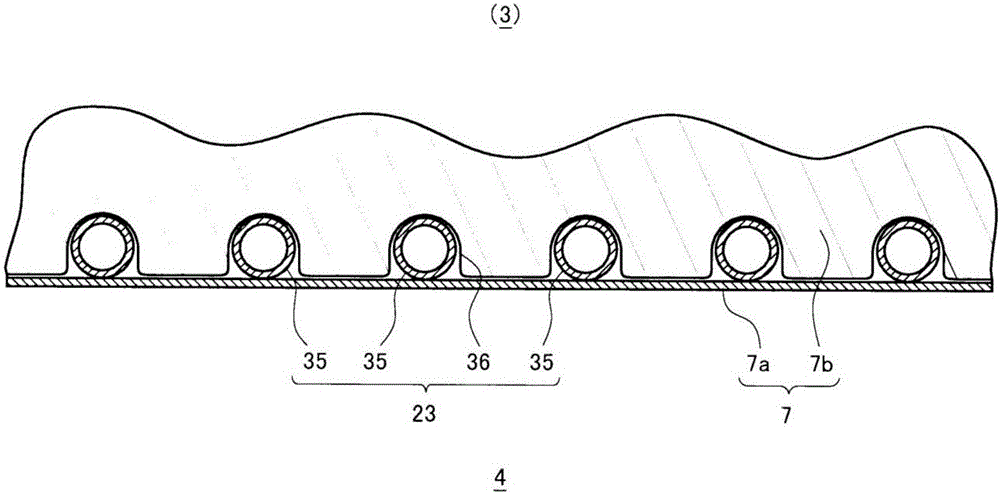

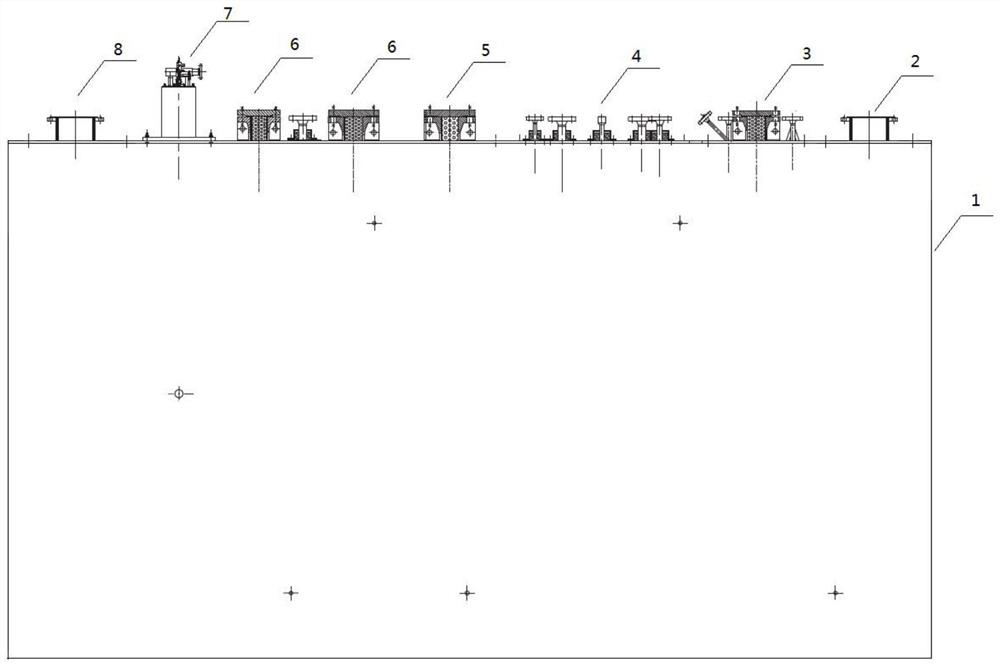

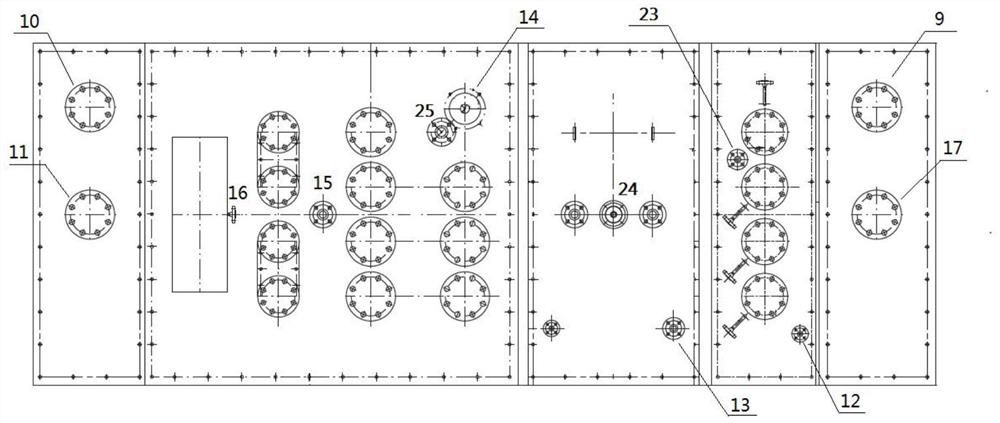

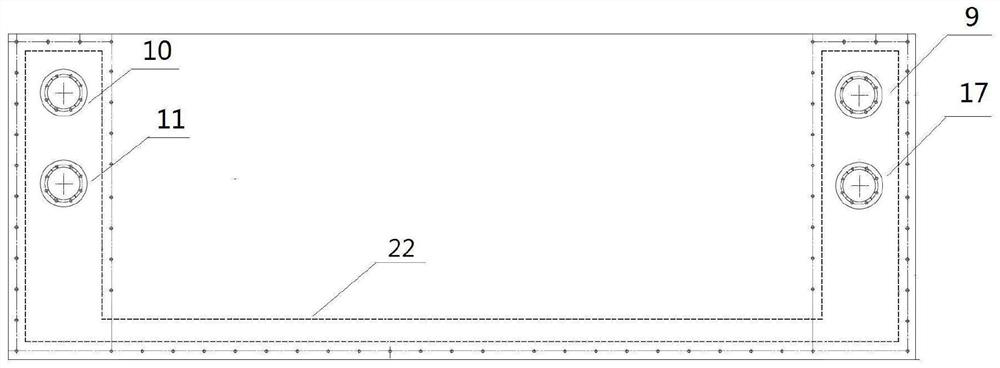

Cooling facility and cooling method of steel plate

ActiveCN101253009AProper coolingShorten the lengthWork cooling devicesMetal rolling arrangementsWater volumeSheet steel

Cooling facility and method of a steel plate for cooling the steel plate properly on a hot rolling line by a compact structure when controlled rolling of the steel plate is performed. The cooling facility of a steel plate, which is a cooling facility for supplying cooling water to the upper and lower surfaces of the steel plate (10) while passing the steel plate (10) when it is hot rolled, has nozzles (22a, 22b) for supplying cooling water obliquely toward the upper surface of the steel plate (10) from above, wherein the nozzles (22a, 22b) are arranged such that ejections of cooling water on the steel plate (10) oppose each other in the carrying direction of the steel plate (10). More concretely, it is a passing type cooling facility (20) having a large water volume density of 4 m<3> / m<2>min or above.

Owner:JFE STEEL CORP

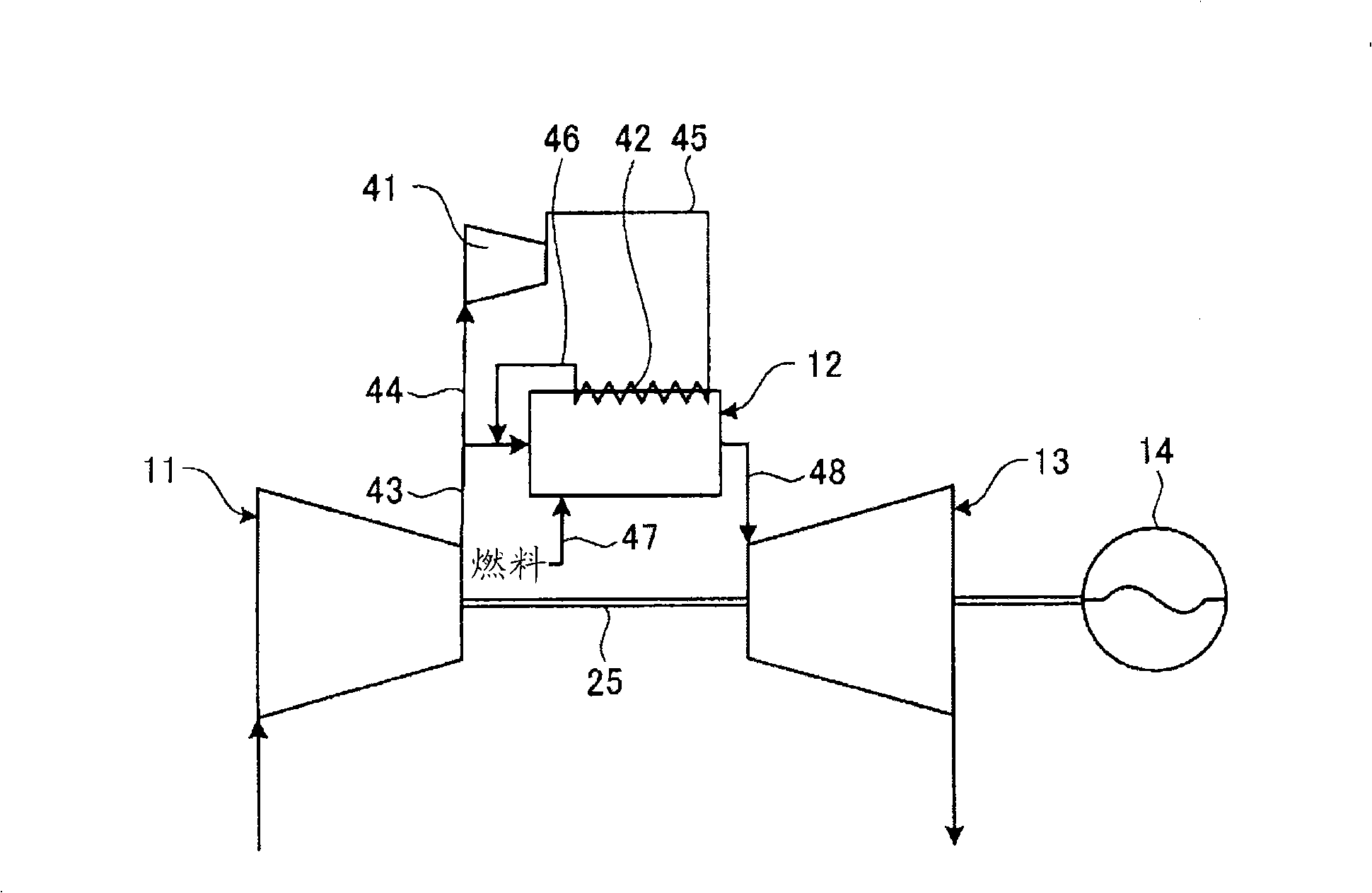

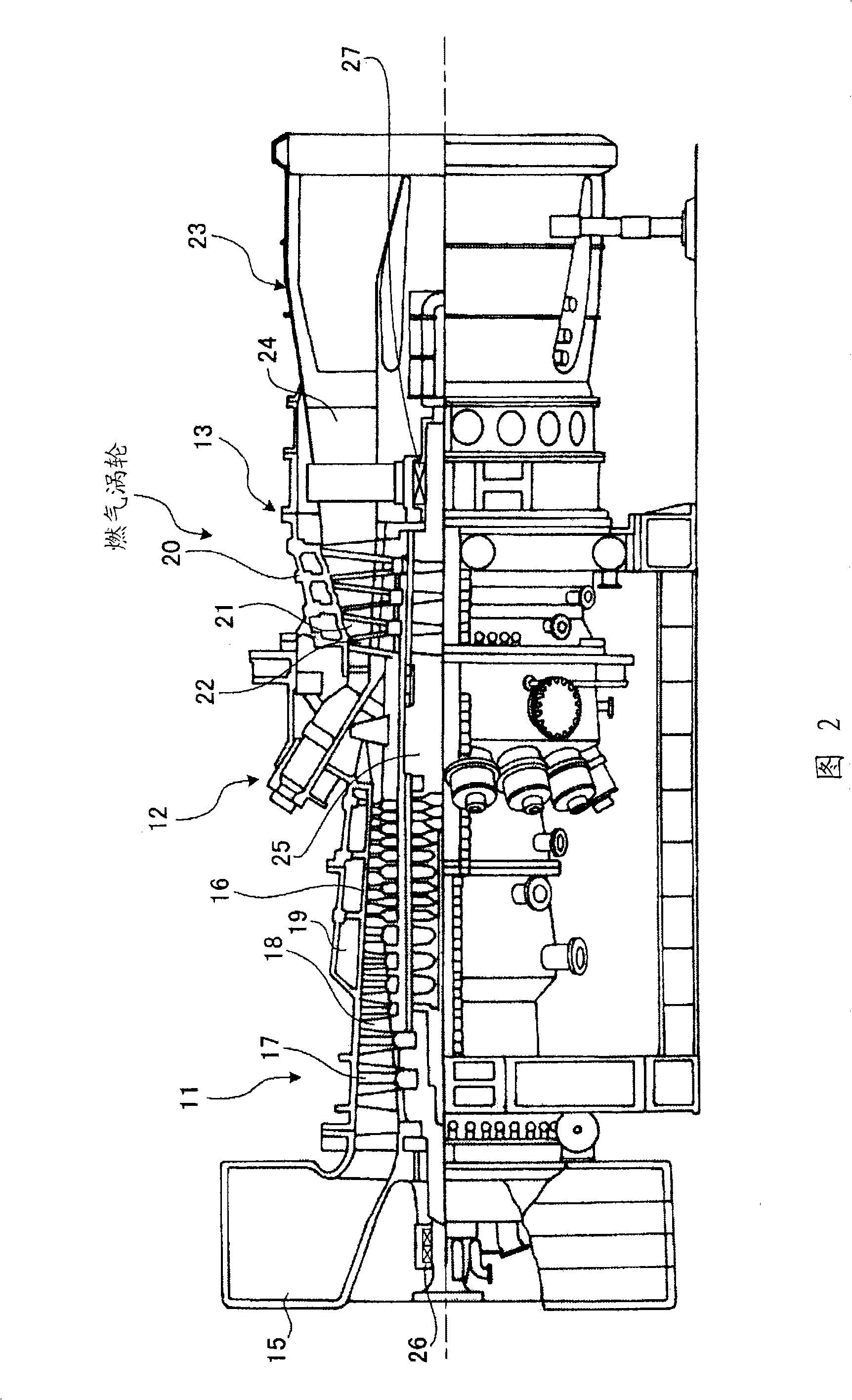

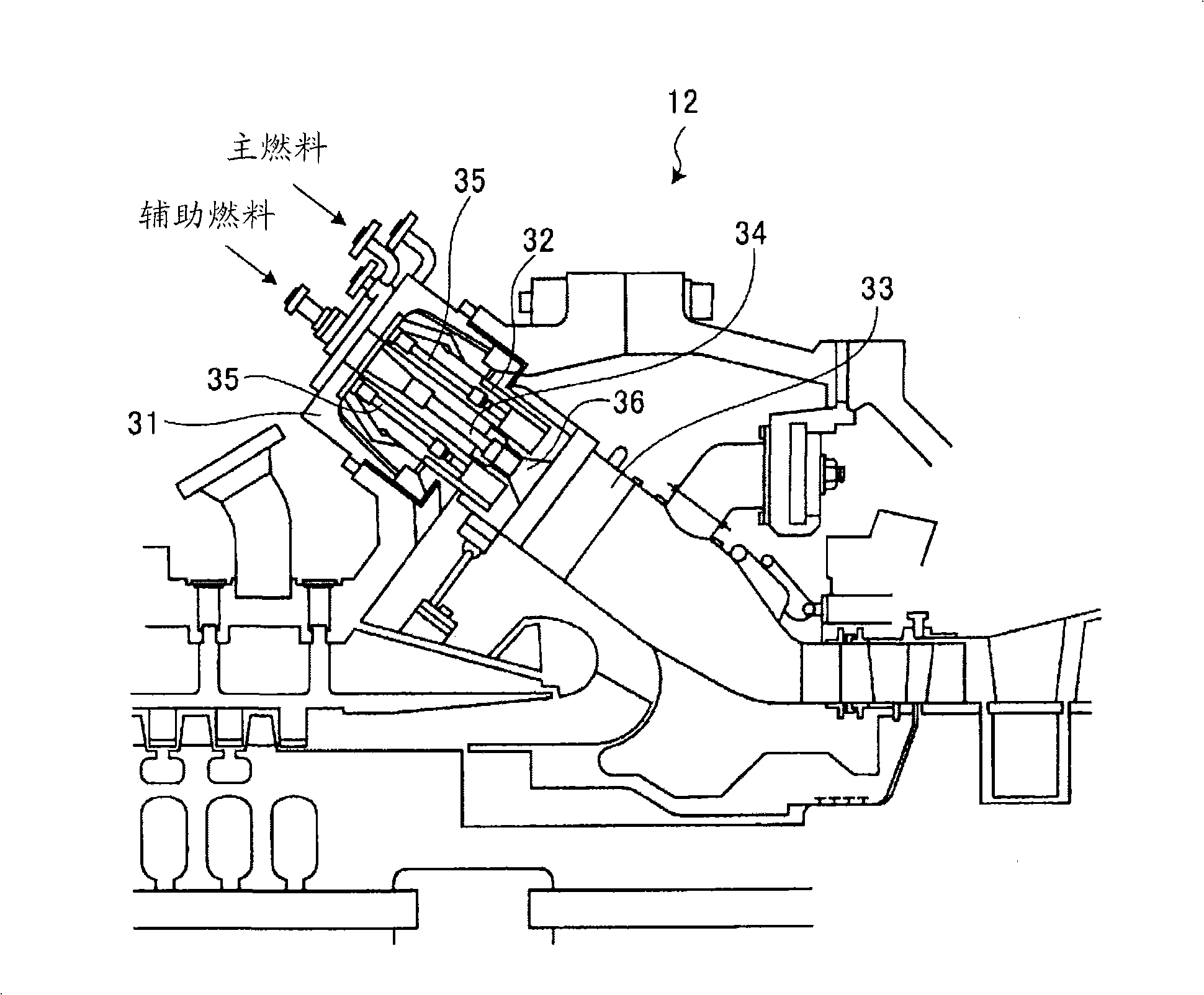

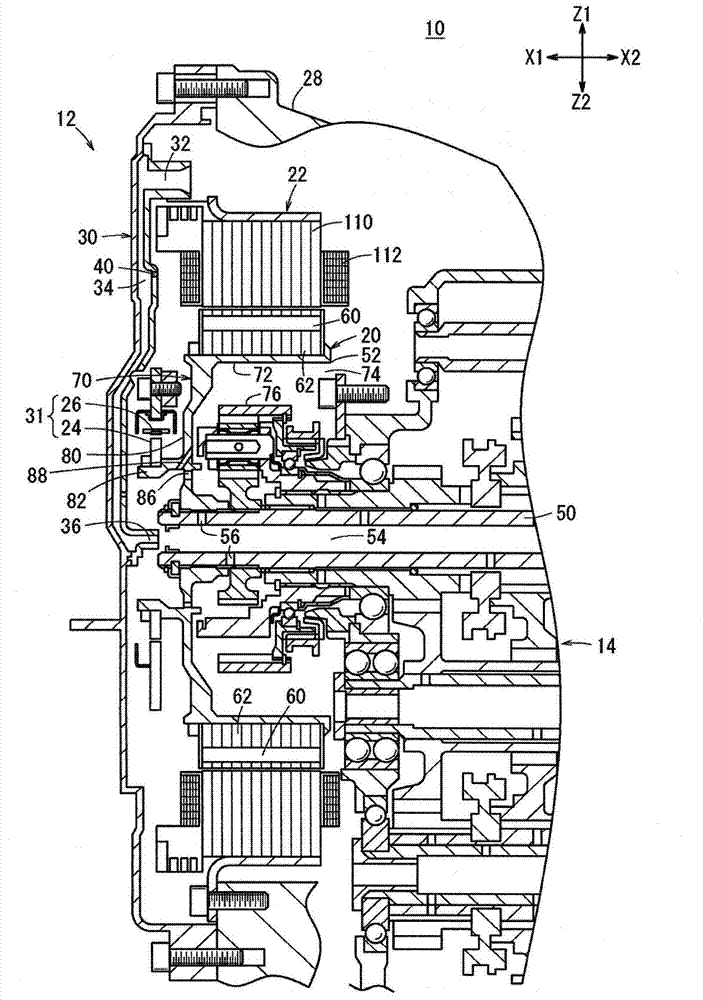

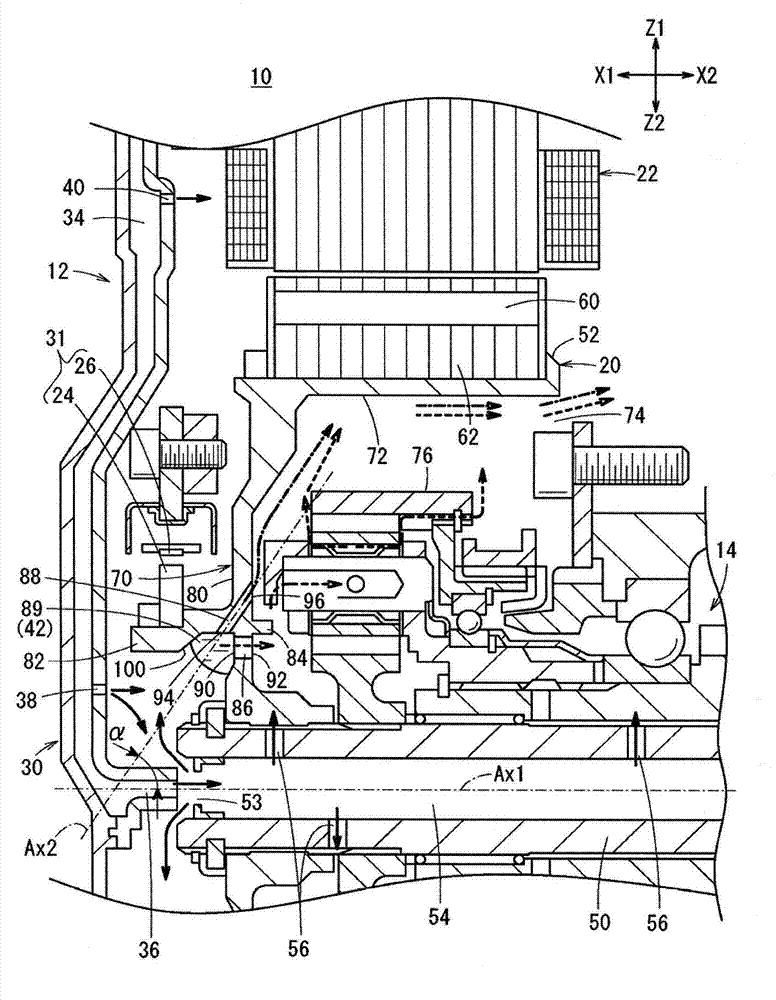

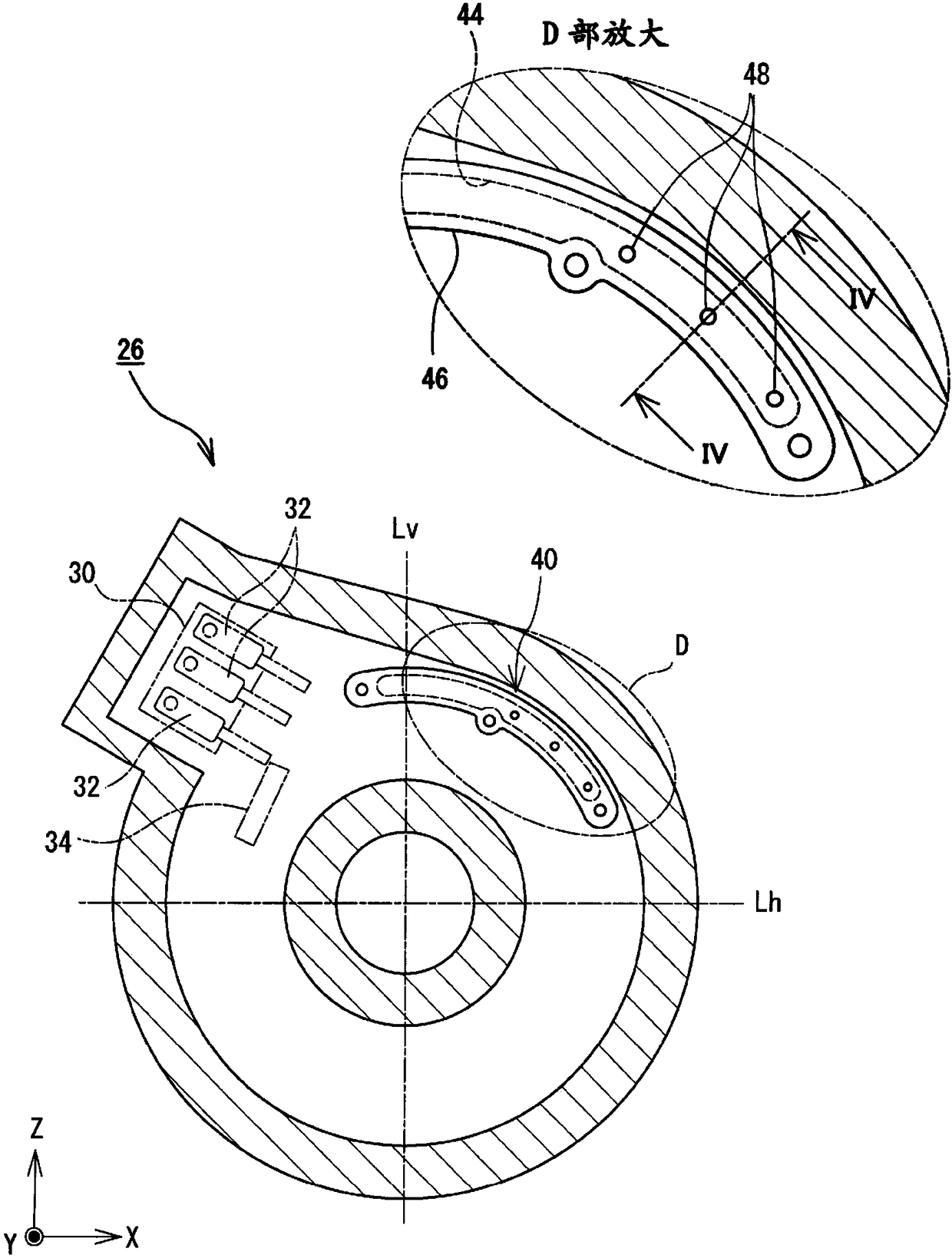

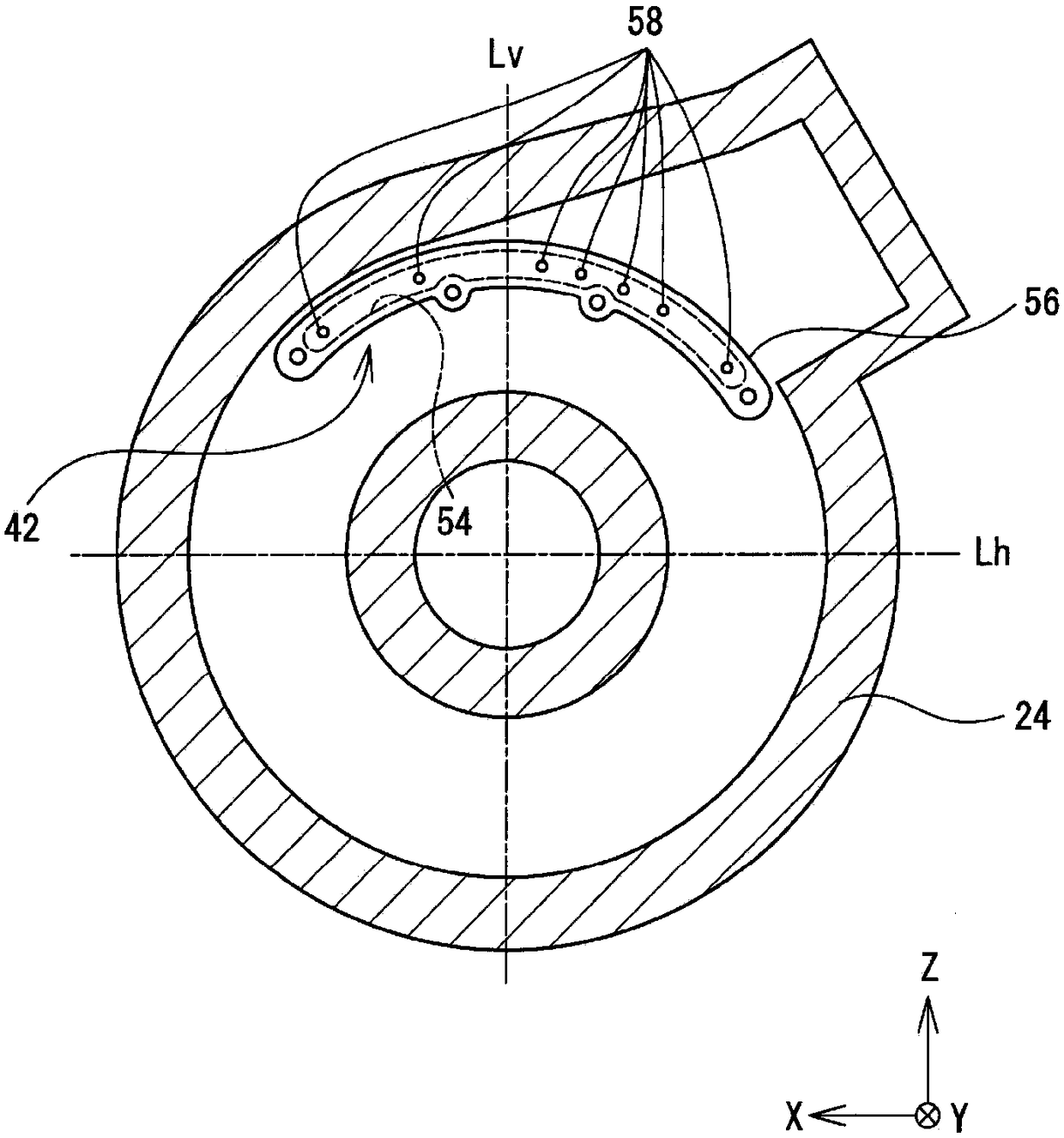

Gas turbine

InactiveCN101517213ASuppress pressure lossEasy dischargeTurbine/propulsion engine coolingEngine fuctionsAir cycleCombustor

The invention provides a gas turbine, in which compressed air that is compressed by a compressor (11) is mixed with fuel in a combustor (12), the mixture is burned to produce combustion gas, and the combustion gas is provided to a turbine (13) to produce rotative power, includes: a pressurizing unit (41) that pressurizes some of the compressed air that is compressed by the compressor (11); a combustor cooling unit (42) that cools the combustor (12) with the compressed air that is pressurized by the pressurizing unit (41); and a compressed air circulation line (46) that provides the compressed air to the casing of the combustor (12). In the gas turbine, the combustor can be cooled by minimizing pressure loss of the compressed air, and degradation of the power efficiency can be prevented.

Owner:MITSUBISHI HEAVY IND LTD

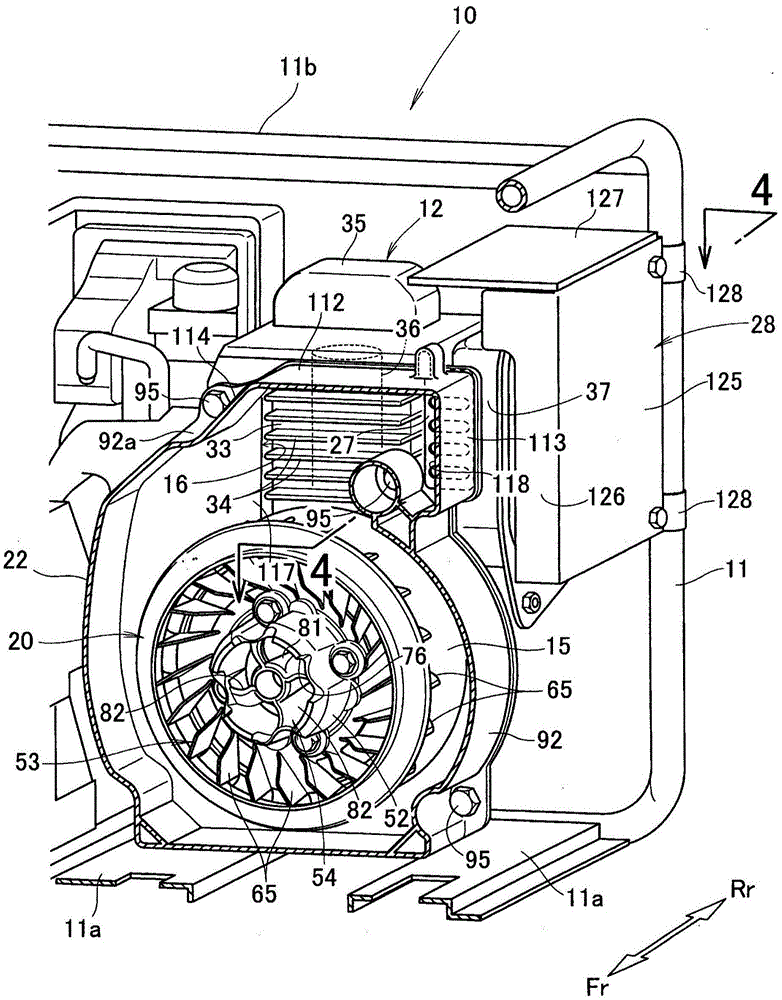

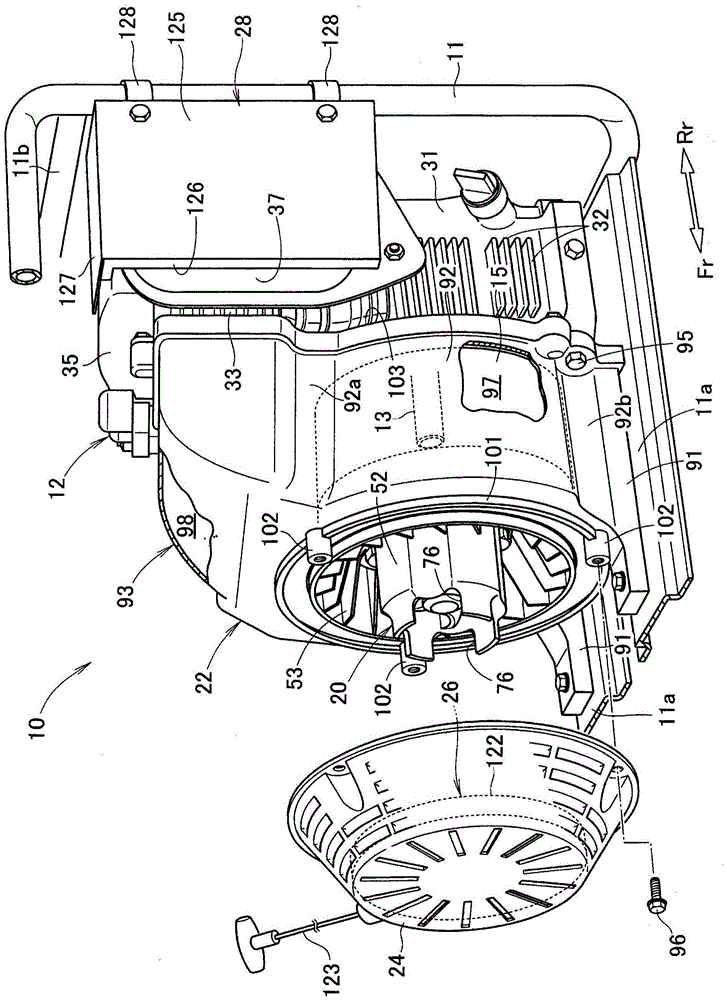

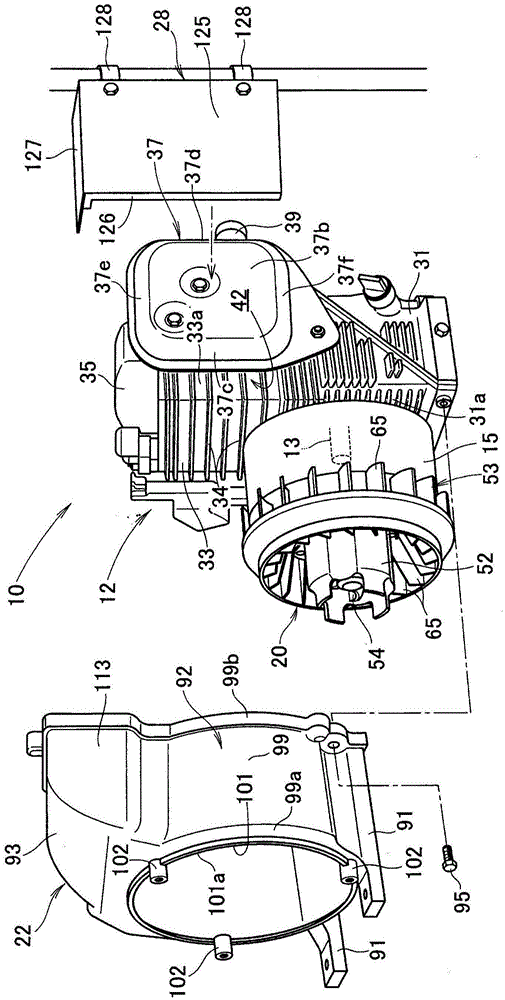

Engine-driven generator

ActiveCN106014587AAchieve compactnessOpening Area AdjustmentCoolant flow controlAir coolingCylinder blockMuffler

The invention provides an engine-driven generator which is capable of achieving down-sizing of the engine-driven generator while securing proper cooling of a cylinder block and an exhaust muffler. The engine-driven generator (10) includes an exhaust muffler (37) disposed adjacent to a lateral side (33a) of a cylinder block (33), a fan cover (22) having an air outlet (116) arranged to face the exhaust muffler (37) and the cylinder block (33), the fan cover (22) being configured to guide cooling air from a cooling fan (20) directly to the air outlet (116), and an opening area-adjustment member (27) provided on a muffler blow-off port (118) of the air outlet (116) for adjusting an opening area of the muffler blow-off port (118).

Owner:HONDA MOTOR CO LTD

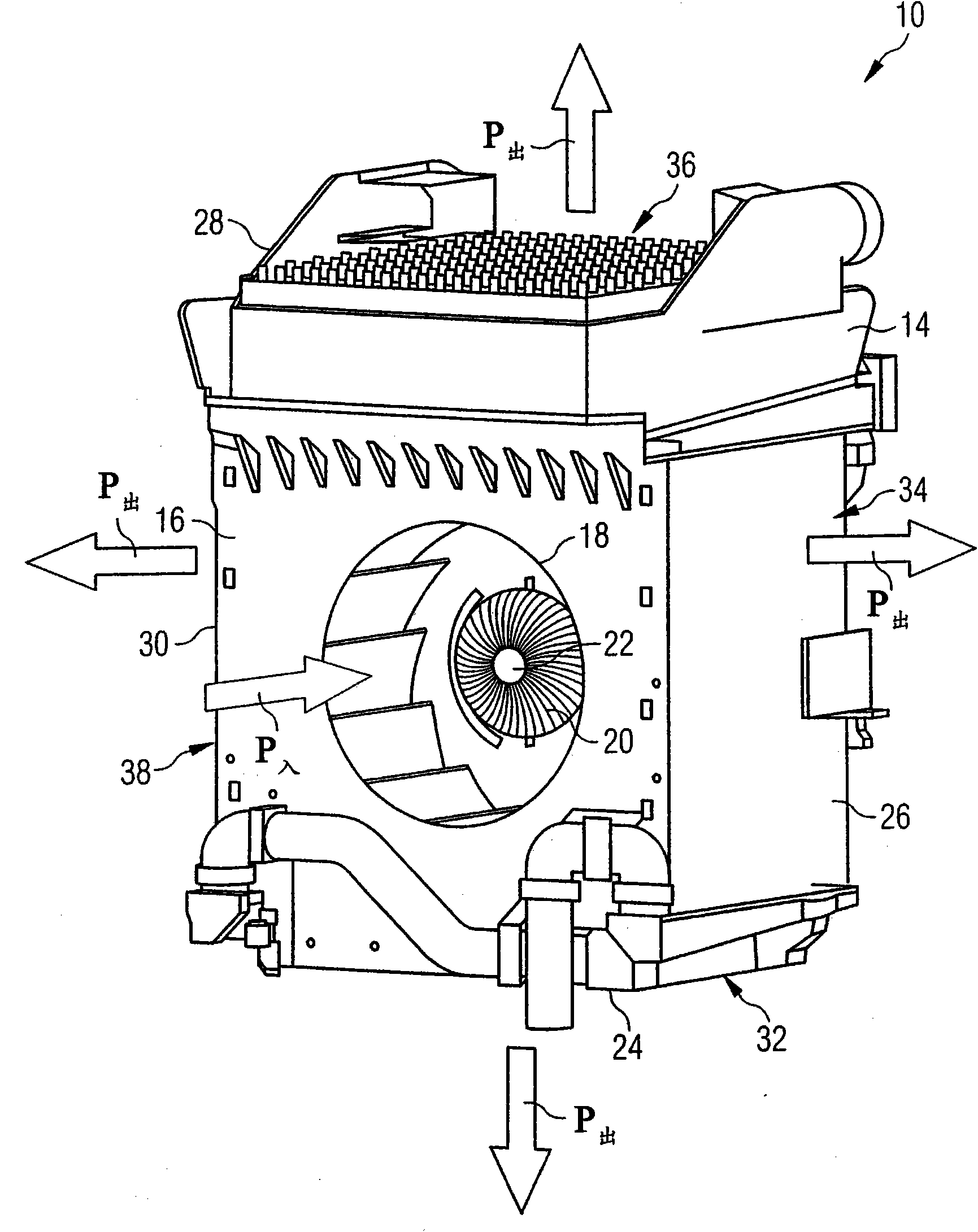

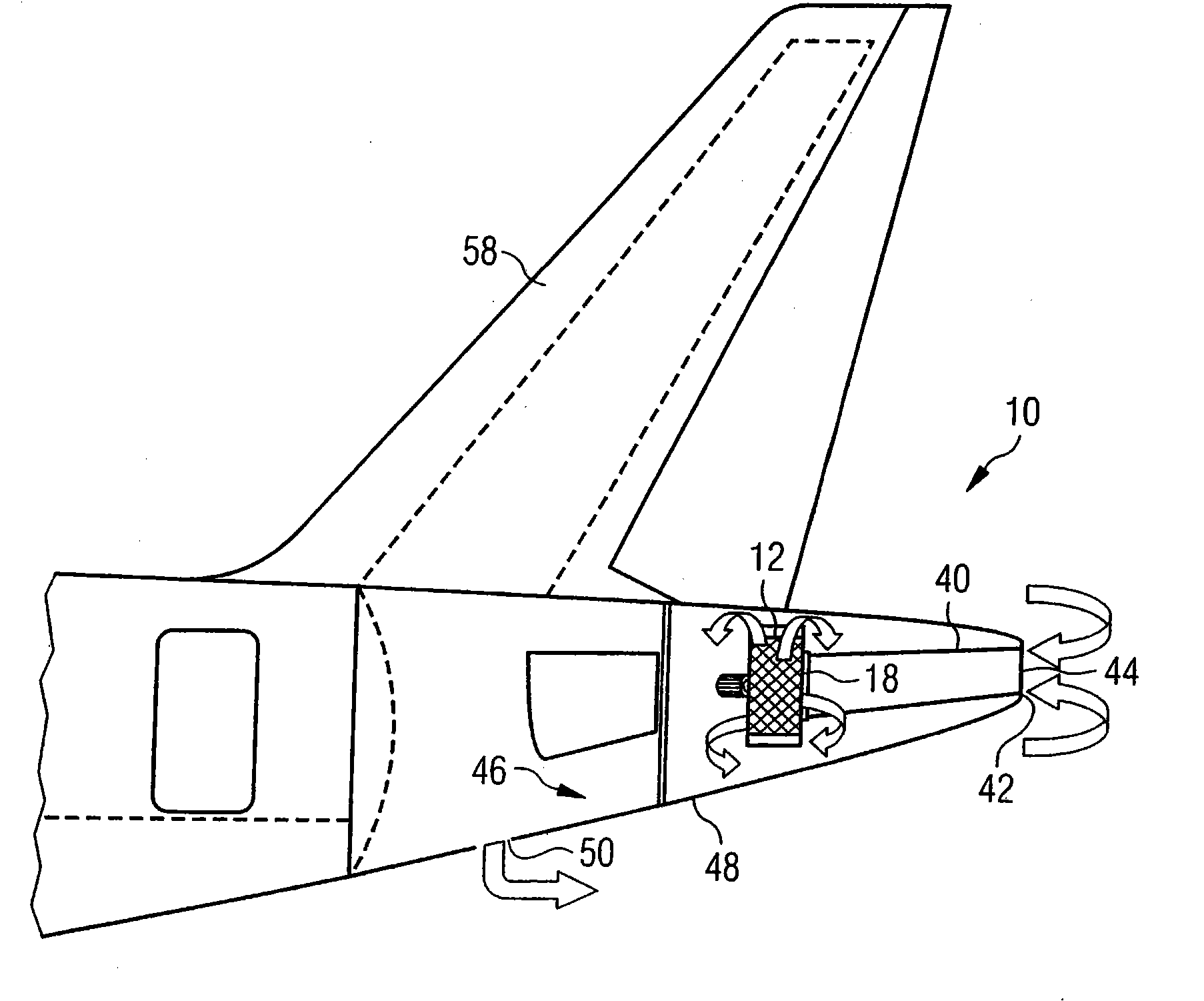

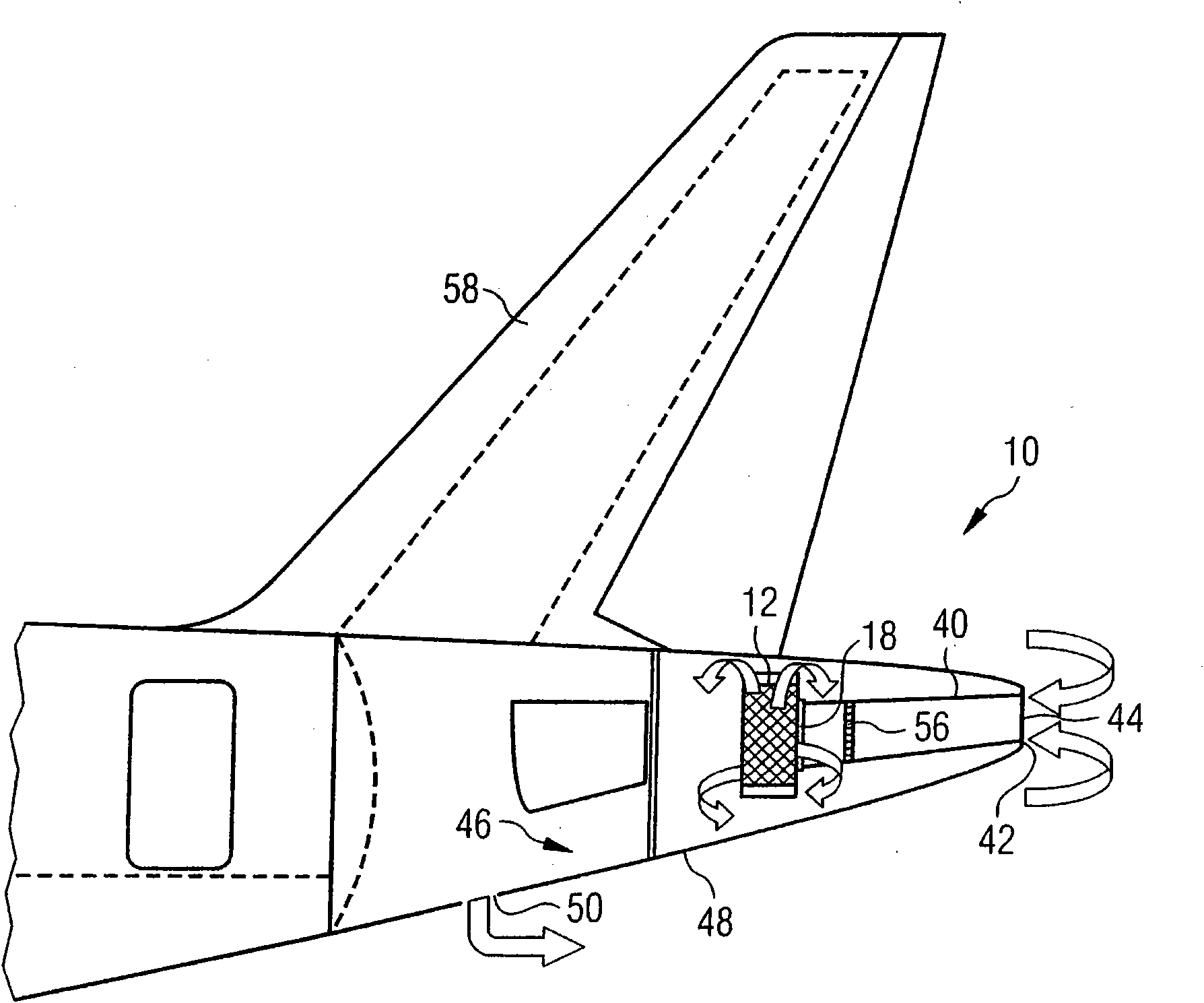

Aircraft cooling system

ActiveCN101903245AIncrease the heat exchange areaStrong cooling capacityPower plant cooling arrangmentsAir-treatment apparatus arrangementsPlate heat exchangerAirplane

The invention relates to an aircraft cooling system (10) comprising a cooling element (12) that comprises a housing (14), a cooling air inlet (18) that is embodied in the housing (14) and a plurality of heat exchangers (32, 34, 36, 38) that are arranged on the lateral surfaces (24, 26, 28, 30) of the housing (14) and through which cooling air supplied to the cooling air inlet (18) flows. A cooling air supply channel (40, 40') joins a cooling air supply opening (44, 44') embodied in a tail section of the aircraft to the cooling air inlet (18) of the cooling element (12). A cooling air outlet channel (46) joins the heat exchanger (32, 34, 36, 38) of the cooling element (12) to a cooling air discharge opening (50).

Owner:AIRBUS OPERATIONS GMBH

Film pipe internal circulation water cooling device of film blowing machine

The invention discloses a film pipe internal circulation water cooling device of a film blowing machine. Previous film pipe water cooling device is arranged outside a film pipe, the cooling speed is slow and water resource is wasted. An internal circulation water cooling device is arranged inside a film pipe and the internal circulation water cooling device composed of a cooling core model, a vacuum chamber inner container, various cooling inlet and outlet pipes which are sleeved coaxially and mutually, a multifolded bent water flow channel and a water absorption ring. Water in the water flow channel goes out and directly flows into the outer core walls of the cooling core model along the film pipe, a water film is formed and the inner wall of the film pipe is subjected to water cooling directly and effectively. The water stained on the inner wall of the film pipe is rapidly sucked dry in a vacuum suction way by the water absorption ring connected with the vacuum chamber inner container, thus the film pipe after cooling can go into the next production process rapidly. The whole device is simple in structure, has rapid cooling speed, raises the production benefits and saves energy. The water cooling device is widely suitable for film pipes or molding pipes of various film blowing machines, blow molding machines and the like.

Owner:SHANTOU CHENGYE MACHINERY

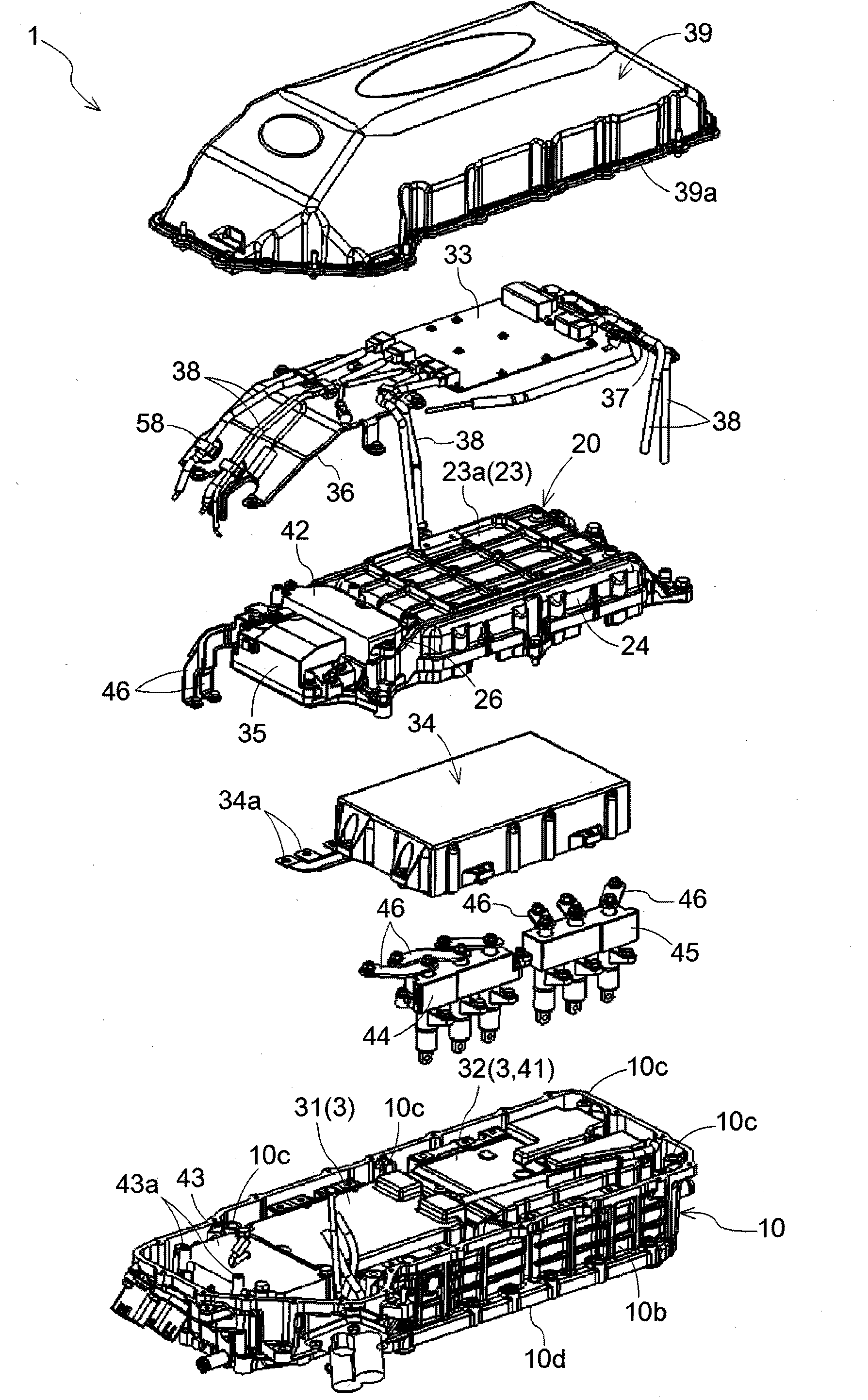

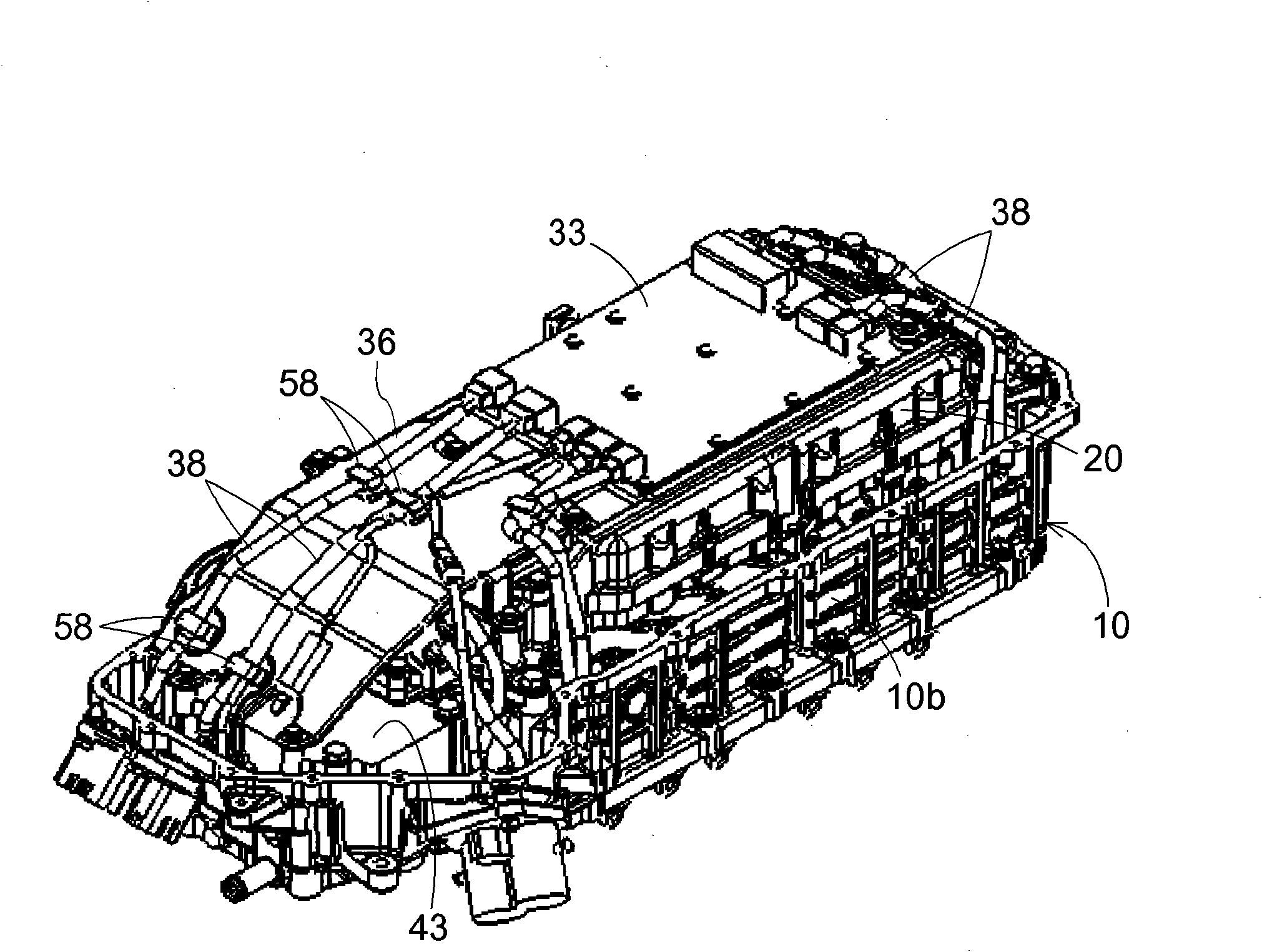

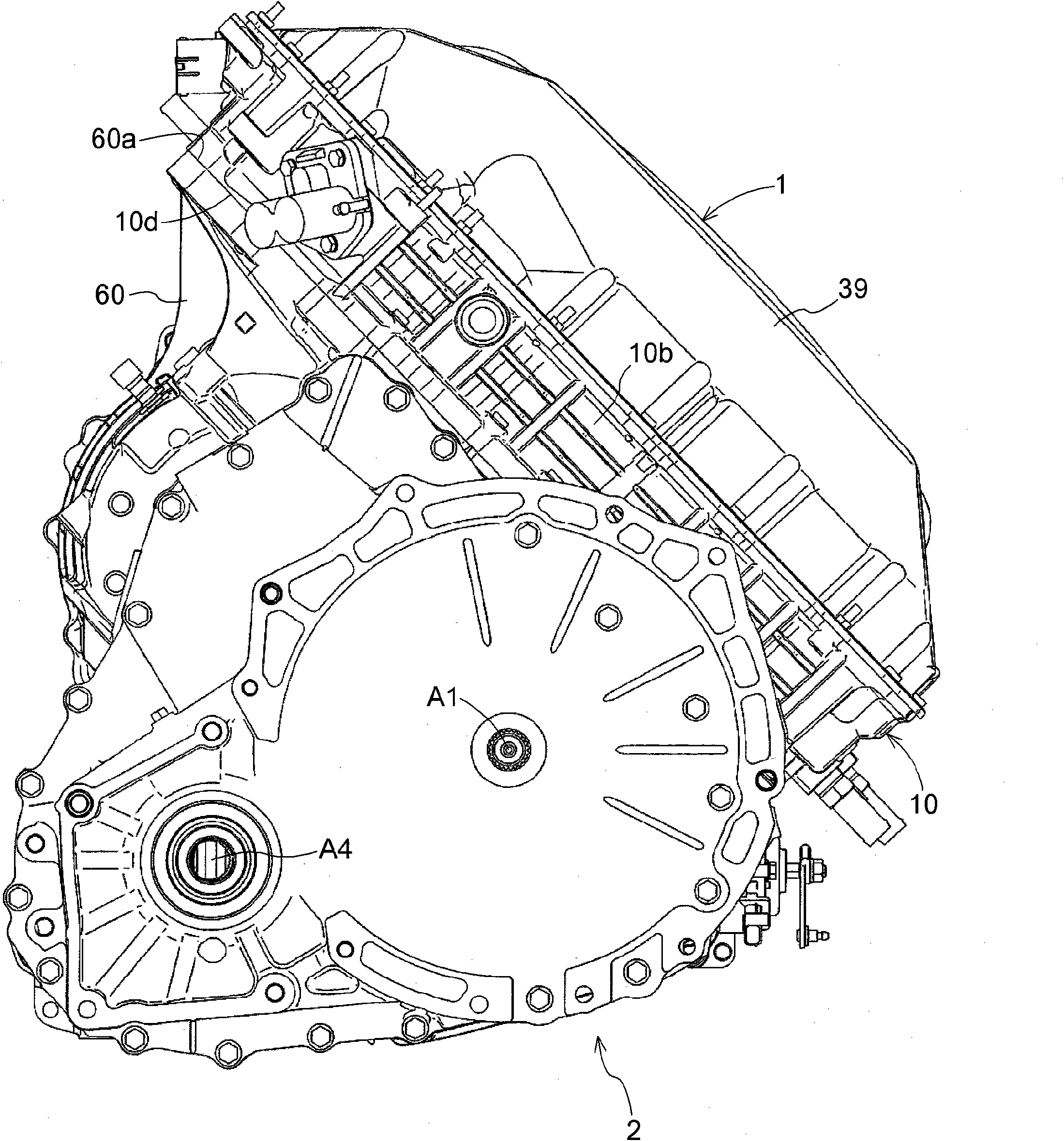

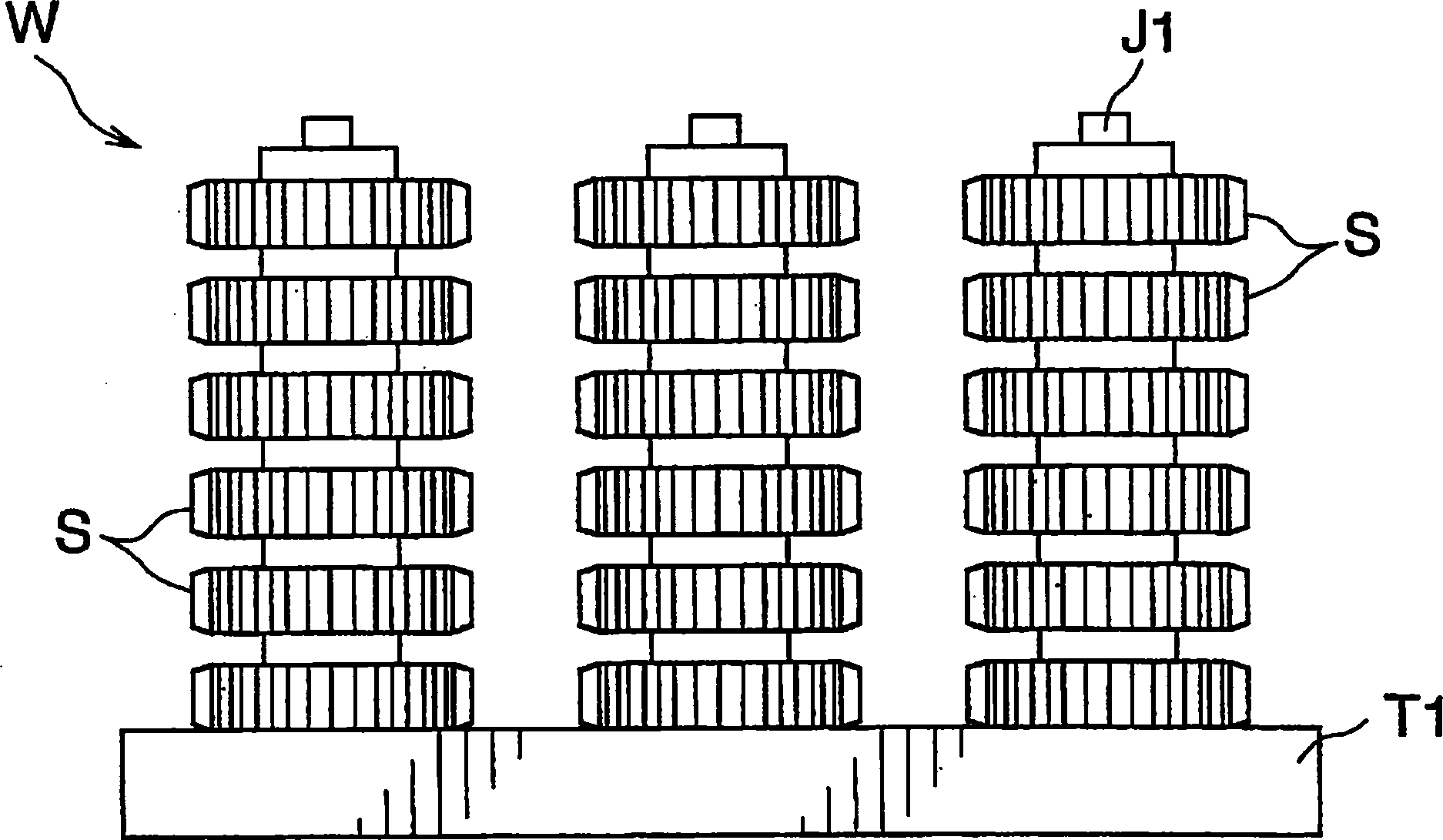

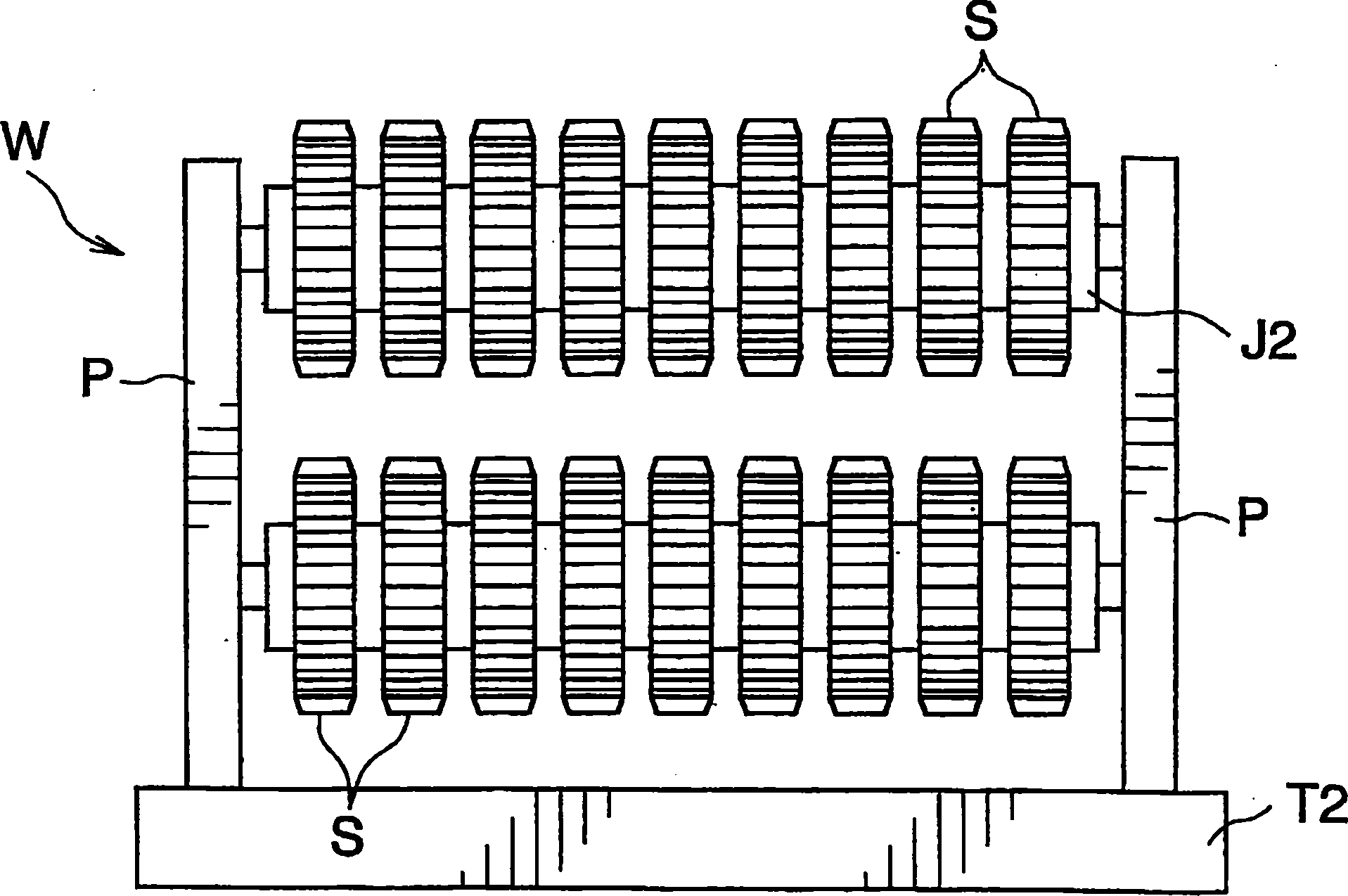

Inverter unit

ActiveCN101842973AProper coolingHybrid vehiclesElectric propulsion mountingEngineeringPower supply voltage

An inverter unit capable of nearly evenly cooling the entire reactor constituting a boost circuit for boosting power supply voltage and properly cooling switching elements constituting the boost circuit and an inverter circuit. The inverter unit comprises a reactor (43) and a boosting switching element (8) constituting a boost circuit (4), inverter switching elements (6, 7) constituting an inverter circuit (3) to which power supply voltage boosted by the boost circuit (4) is supplied, and a cooler (10) provided with a refrigerant flow path (16) through which a refrigerant flows along a cooling surface (12) which the reactor (43) and the switching elements (6, 7, 8) touch. In the refrigerant flow path (16), a reactor cooling section (71) for cooling a region of the cooling surface (12) which the reactor (43) touches is disposed upstream from a switching element cooling section (81) for cooling regions thereof which the switching elements (6, 7, 8) touch.

Owner:AISIN AW CO LTD

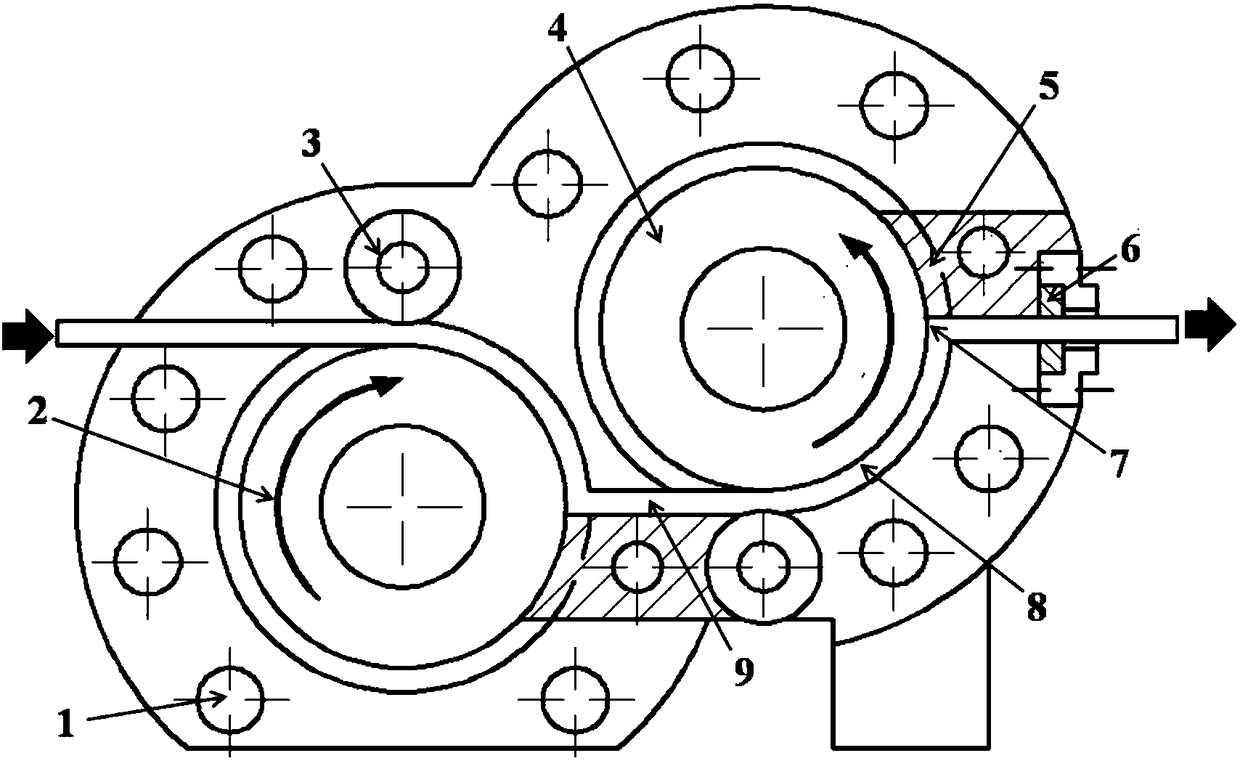

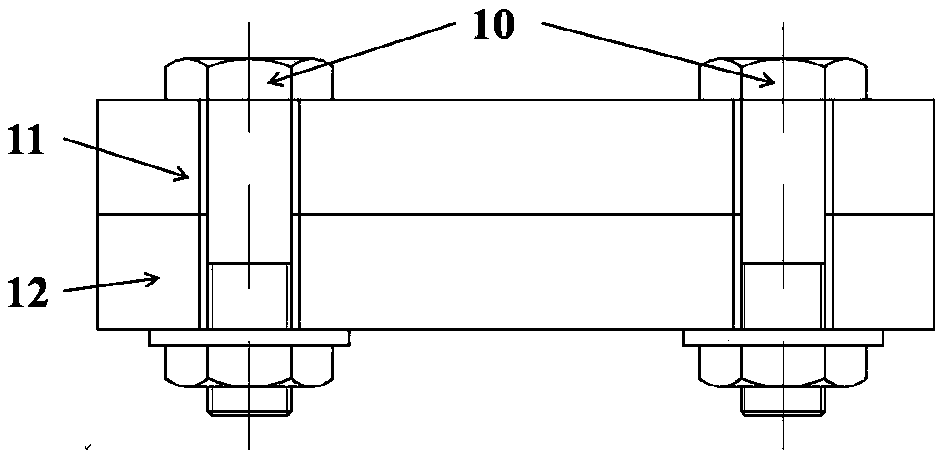

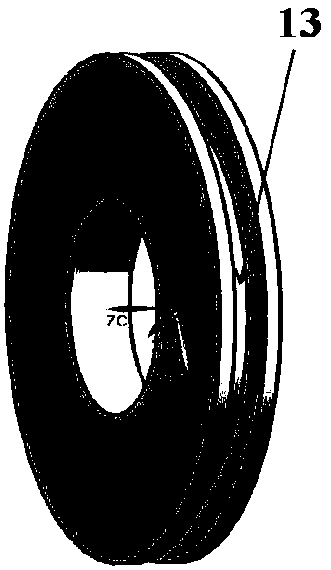

Parallel double-channel ECAP-Conform method and device

The invention belongs to the technical field of material extrusion, and discloses a parallel double-channel ECAP-Conform method and device. The device comprises bolts, extrusion wheels with rectangular grooves at the edge, compaction wheels, upper dies, lower dies, material blocking blocks, an extrusion die and the like; a strip material or a rod material with a certain length is used as a prefabricated blank material; the under the action of three-surface active friction force generated by the blank material making contact with the rectangular grooves at the edges of the extrusion wheel I andthe extrusion wheel II, the blank material rotates clockwise or anticlockwise through the quarter circle along with the wheel; a material blocking block which protrudes into the rectangular grooves at the edges of the extrusion wheels is used for blocking the blank material; and the blank in the rectangular cavity is forced to rotate through the channel cross angles of the two ECAP under the shearing action, so that the two shearing deformations are completed. According to the method and device, two shearing deformations are completed in a continuous equal-channel cross angle extrusion process, the two shearing deformations mainly act on the two surfaces of the blank correspondingy, the ECAP deformation of the path C is equivalent to the two shearing deformations, the production efficiency is high, and the structure performance of the extruded material is more uniform.

Owner:CHONGQING UNIV

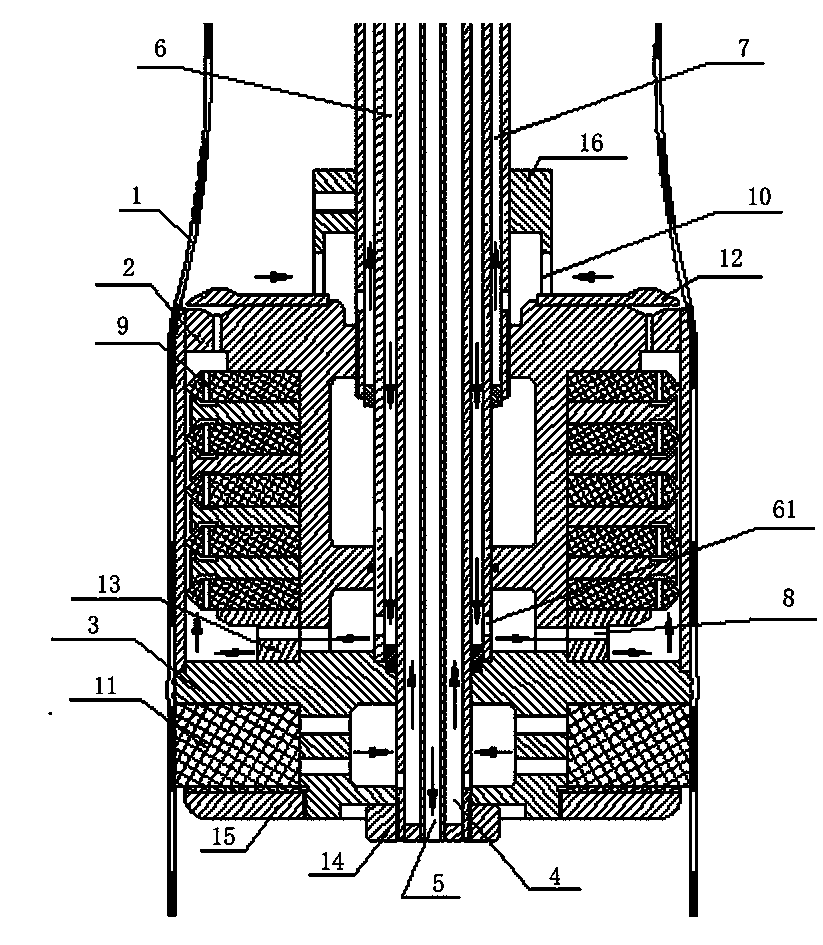

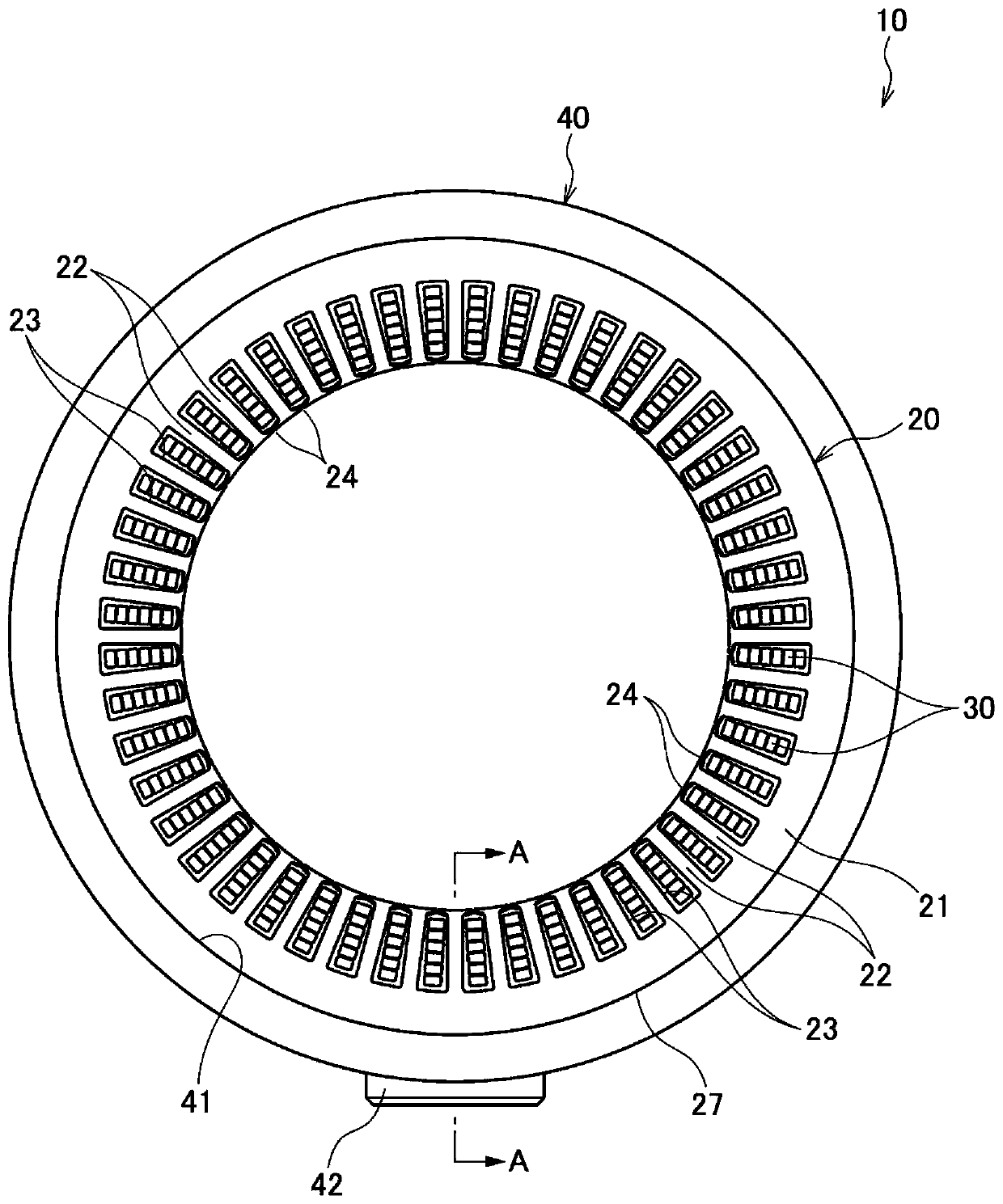

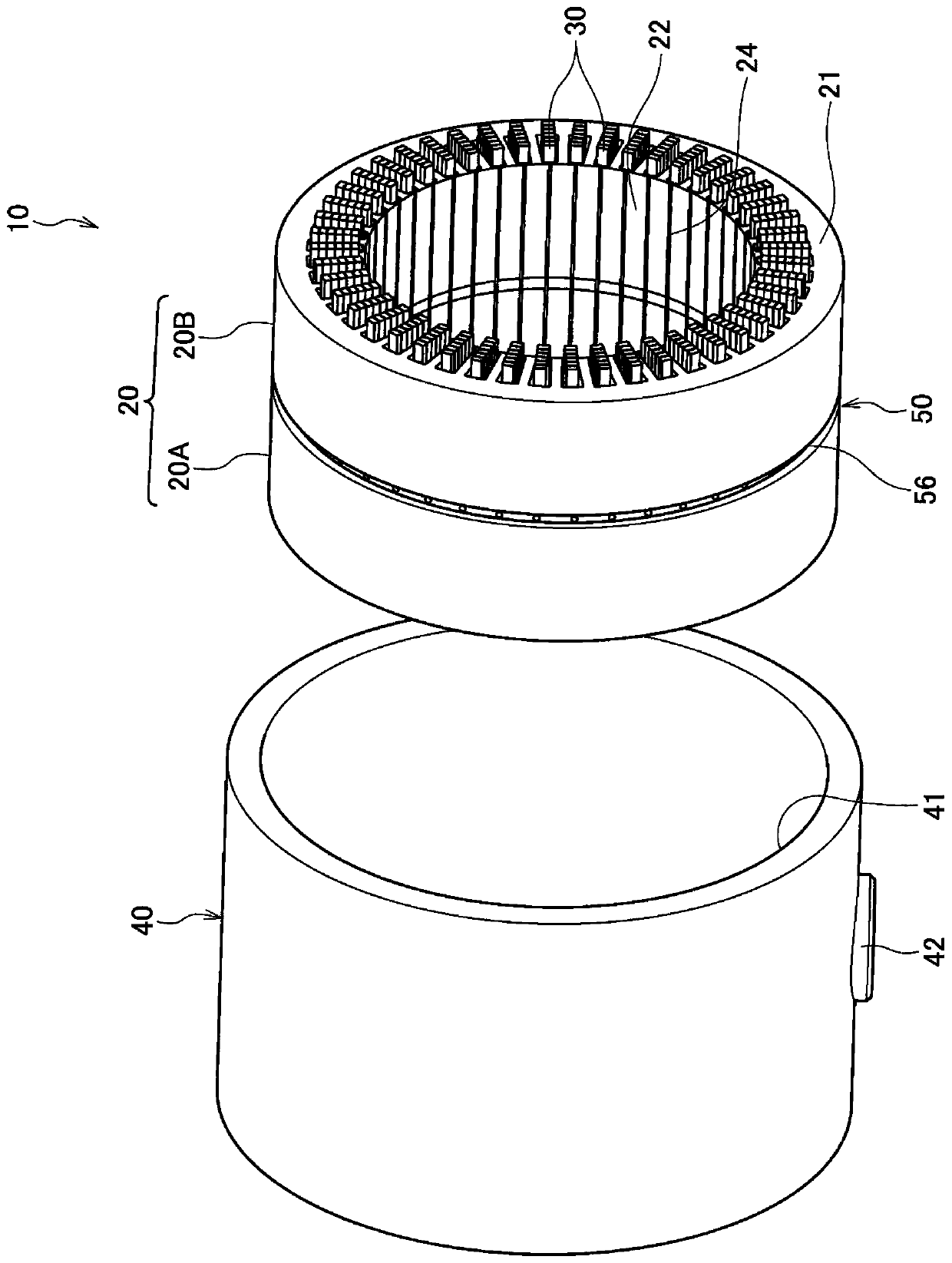

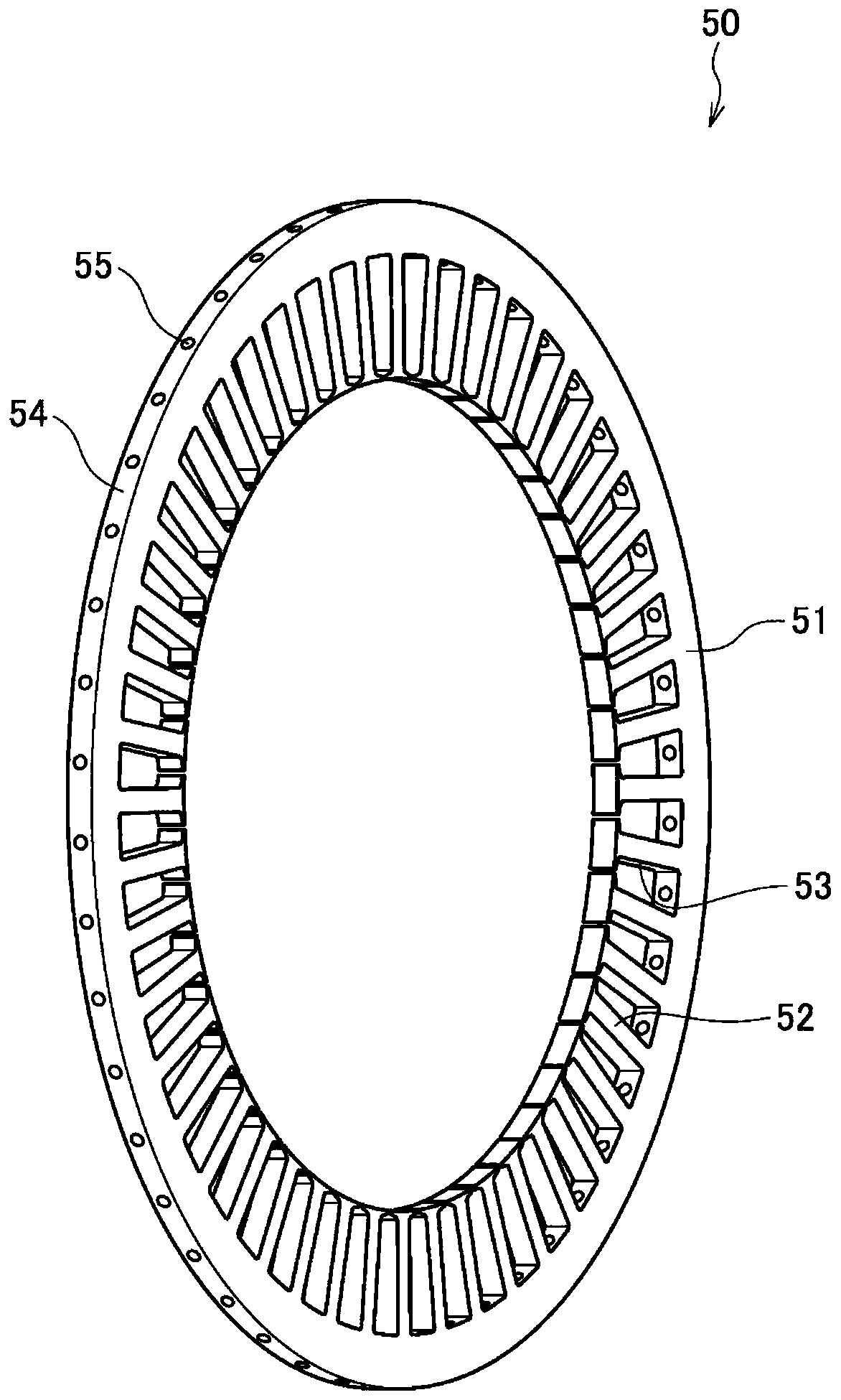

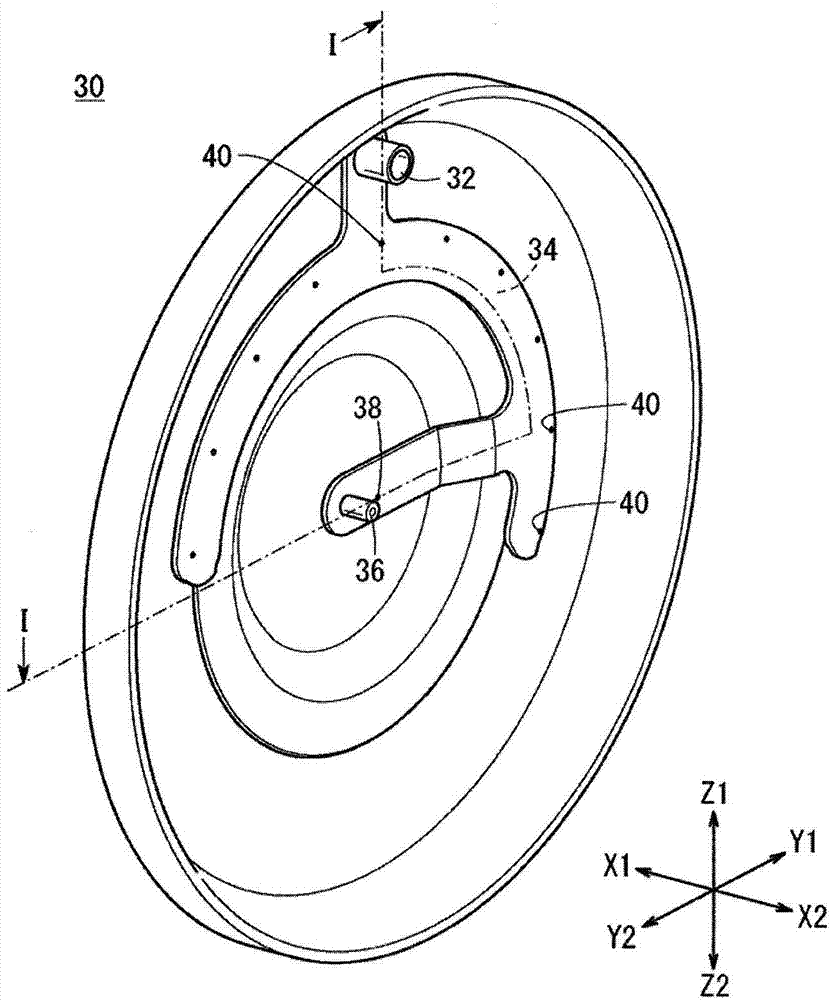

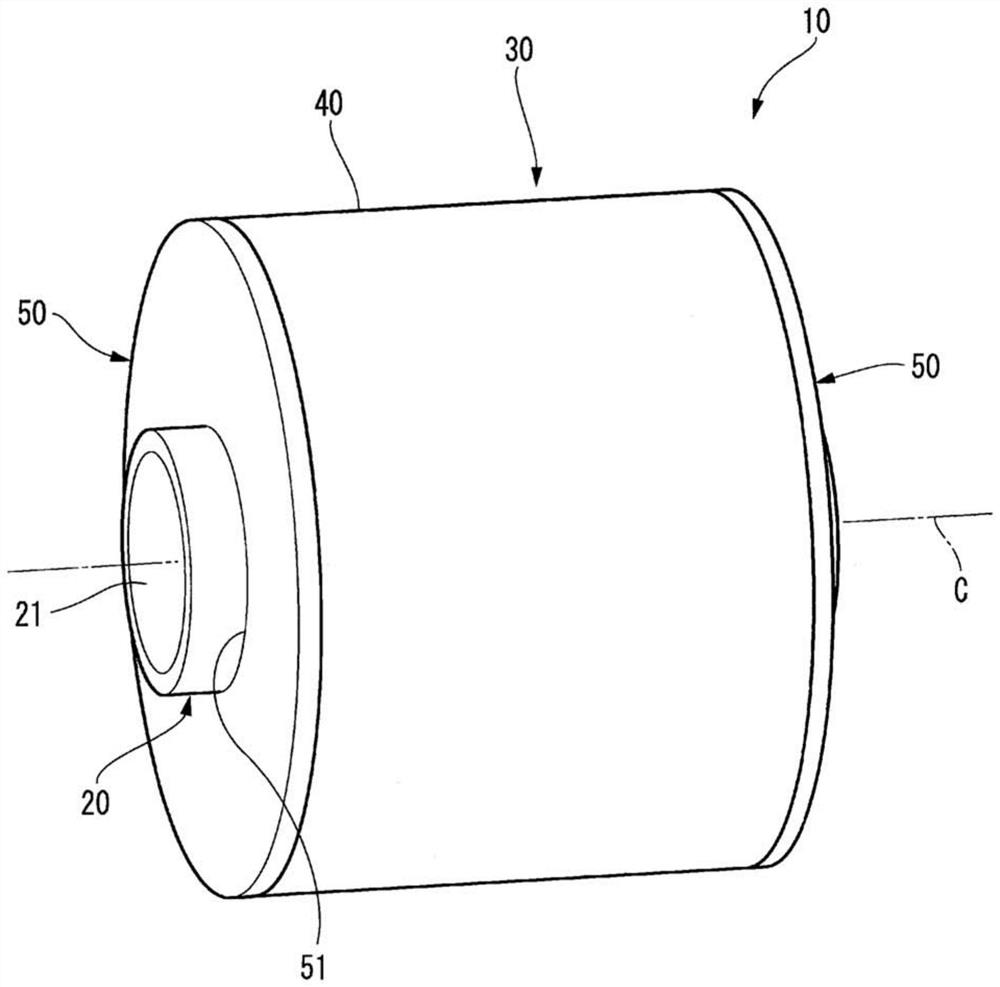

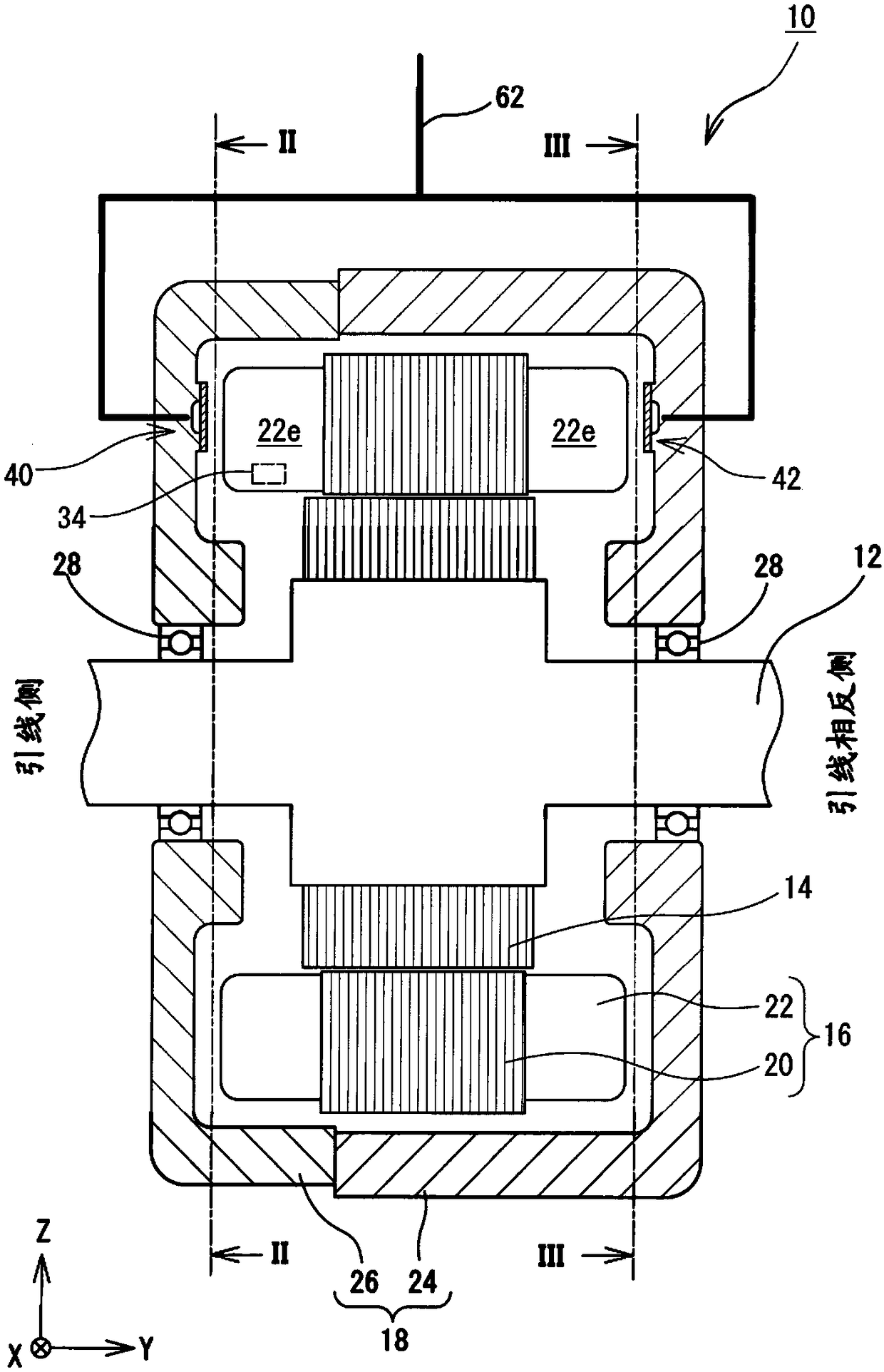

Stator for rotary electric machine

ActiveCN110247485AProper coolingMagnetic circuit stationary partsCooling/ventillation arrangementRefrigerant distributionElectric machine

The invention provides a stator of a rotary electric machine. Coilers arranged in a groove can be properly cooled. The stator (10) comprises a stator core (20) including an annular stator yoke (21), a plurality of teeth (22) protruding from the stator yoke (21) to an inside in a radial direction, and a plurality of slots (23) formed between adjacent teeth (22); and a plurality of coils (30) arranged in each of the slots (23). In the stator core (20), a coolant distributing plate (50) having an annular shape to surround the plurality of coils (30) from an outer circumferential side is interposed, and the coolant distributing plate (500) is provided with coolant supply portions (55) discharging a coolant toward the plurality of coils (30).

Owner:HONDA MOTOR CO LTD

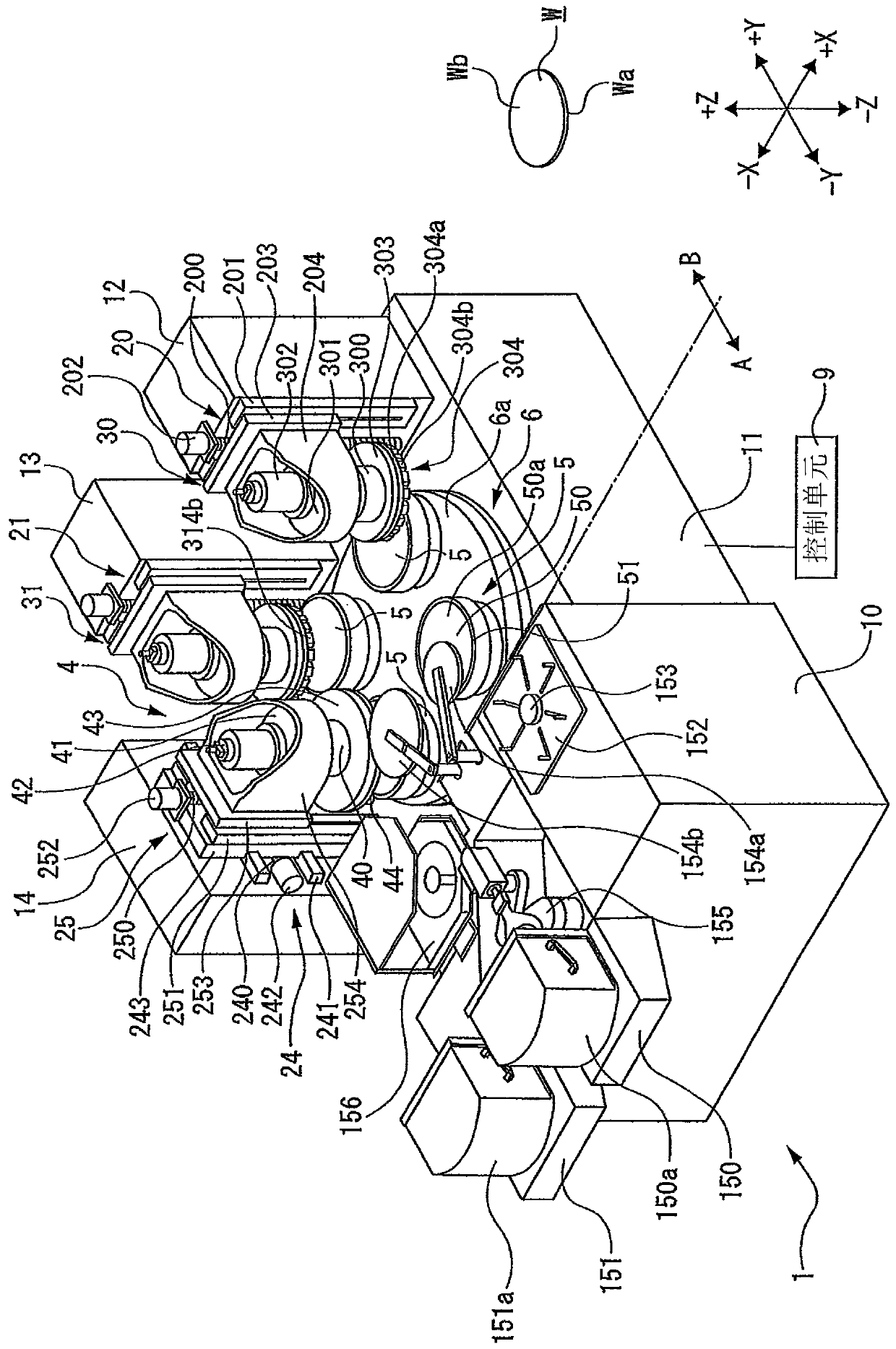

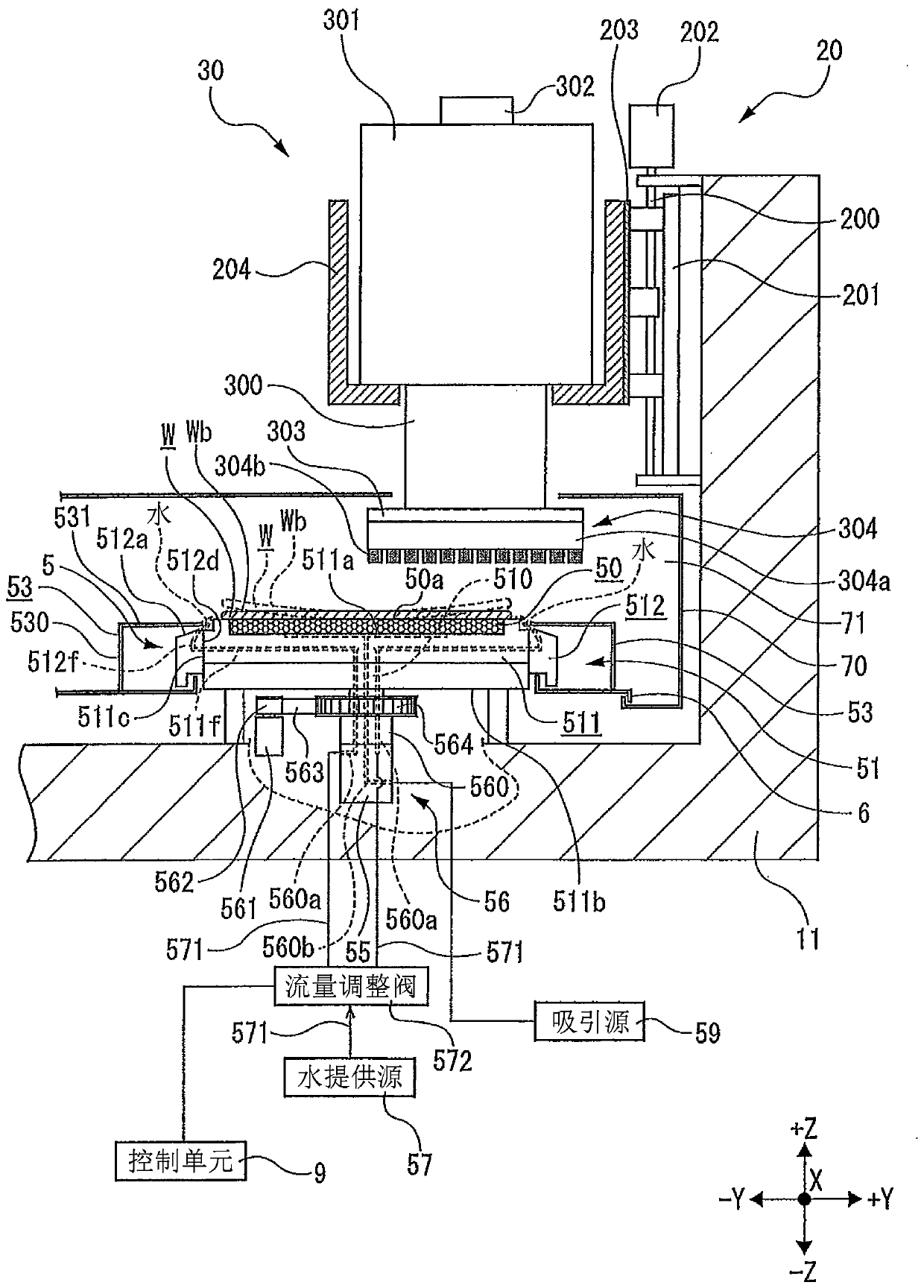

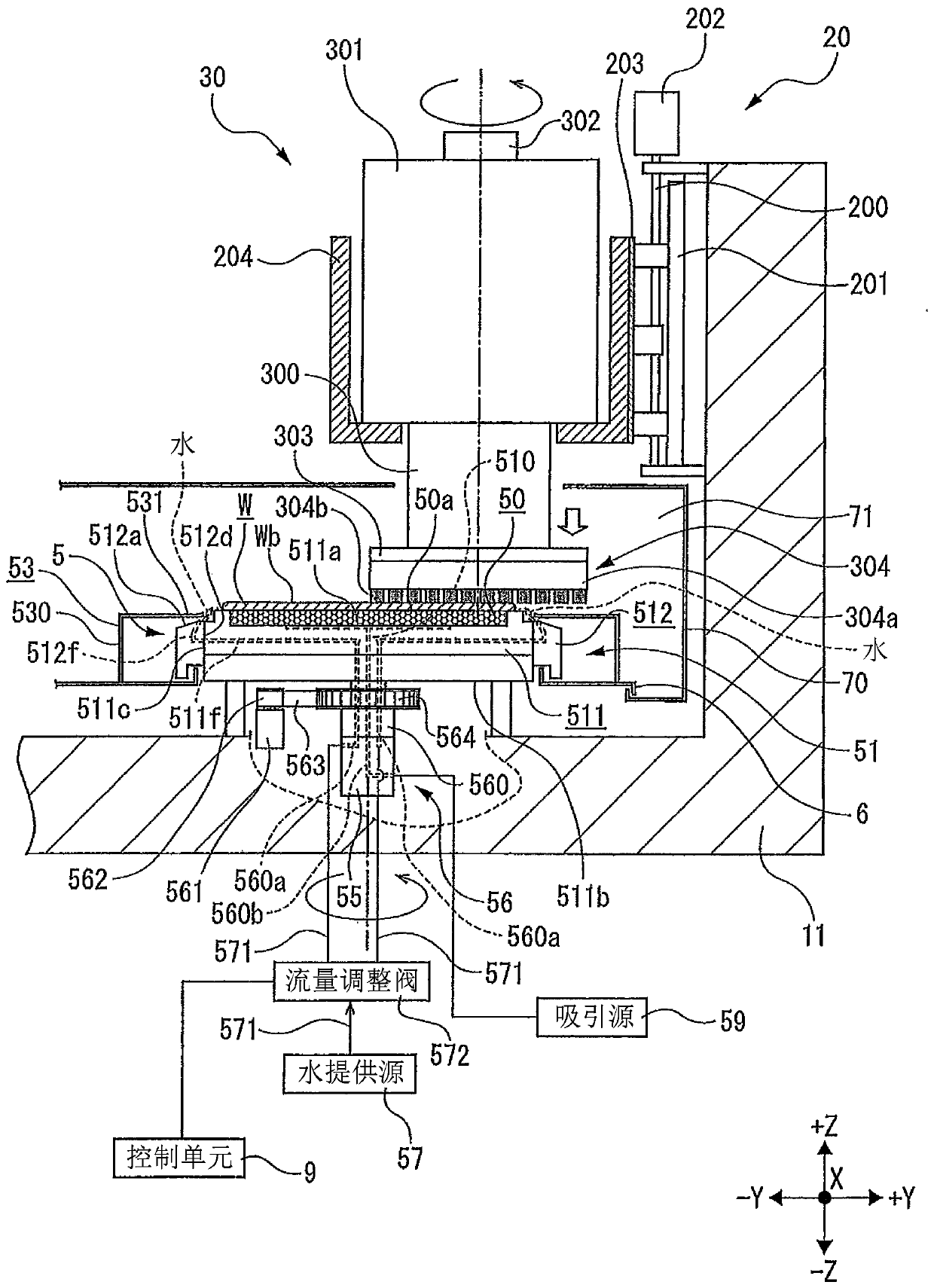

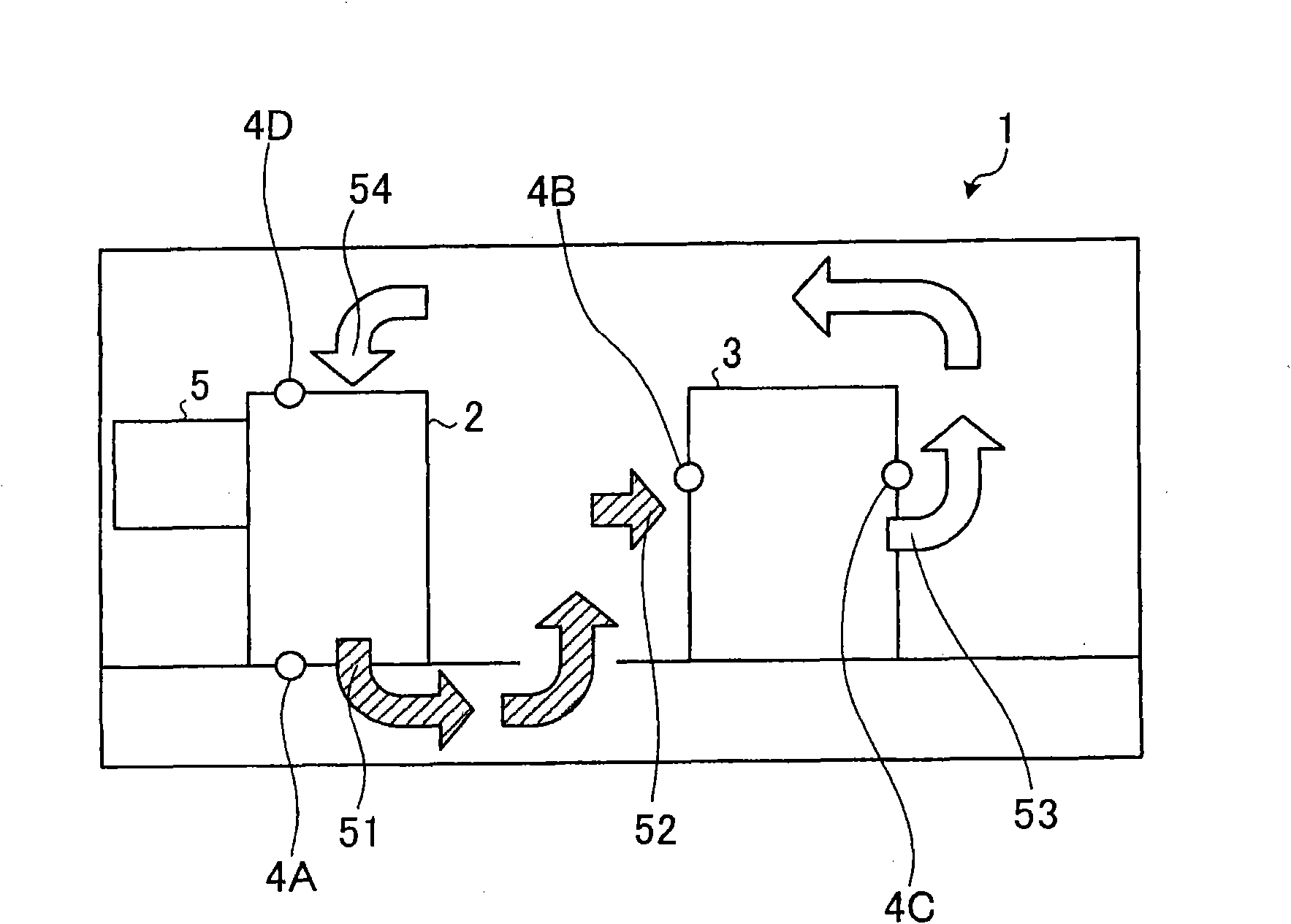

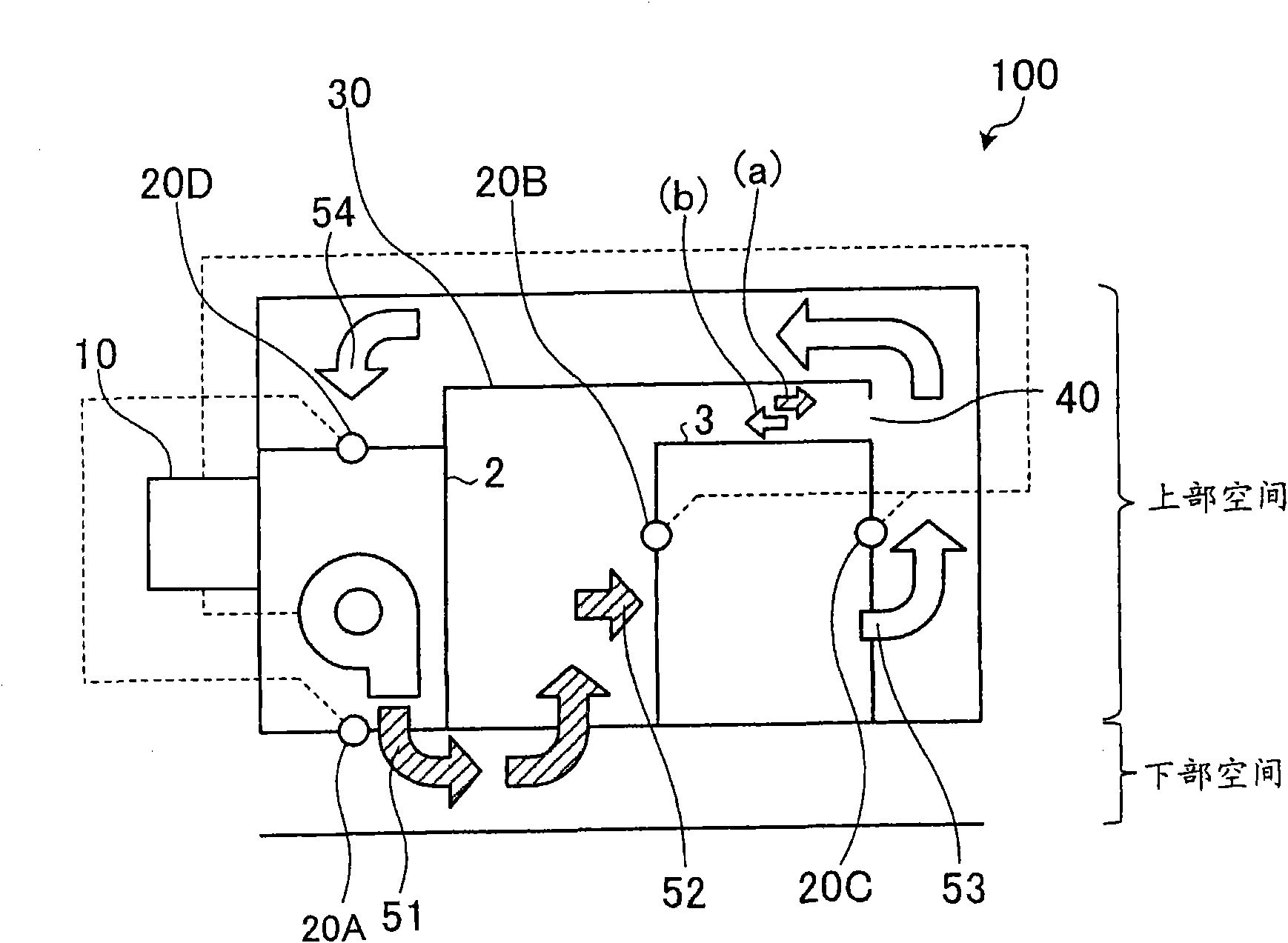

Grinding and polishing apparatus and grinding and polishing method

ActiveCN110103131AProper coolingSemiconductor/solid-state device manufacturingLapping machinesWaferingPolishing

A grinding and polishing apparatus and a grinding and polishing method are provided to eliminate the problem of a large and complex structure of a grinding and polishing apparatus resulting from the formation of a water seal by different mechanisms and the cooling of a table. The grinding and polishing device (1) comprises a holding unit (5), grinding units (30, 31) and a polishing unit (4). The holding unit comprises a porous plate (50) having a wafer holding surface and a frame (51) having a recess (511a) for exposing the holding surface and accommodating the porous plate, wherein the framehas a suction path (510) for communicating a lower surface (511b) of the frame with a bottom surface of the recess and connecting a lower surface side with a suction source (59); and a communicating path which communicates the lower surface with the upper surface on the outside of the recess, and a water supply source (57) is connected to the lower surface side. The grinding and polishing apparatus has a unit (9) that controls the amount of water in a case where a water seal is formed between a wafer and the holding surface by spraying water from a discharge port obtained by opening the communicating path on the upper surface, and the amount of water in a case where the holding unit is cooled.

Owner:DISCO CORP

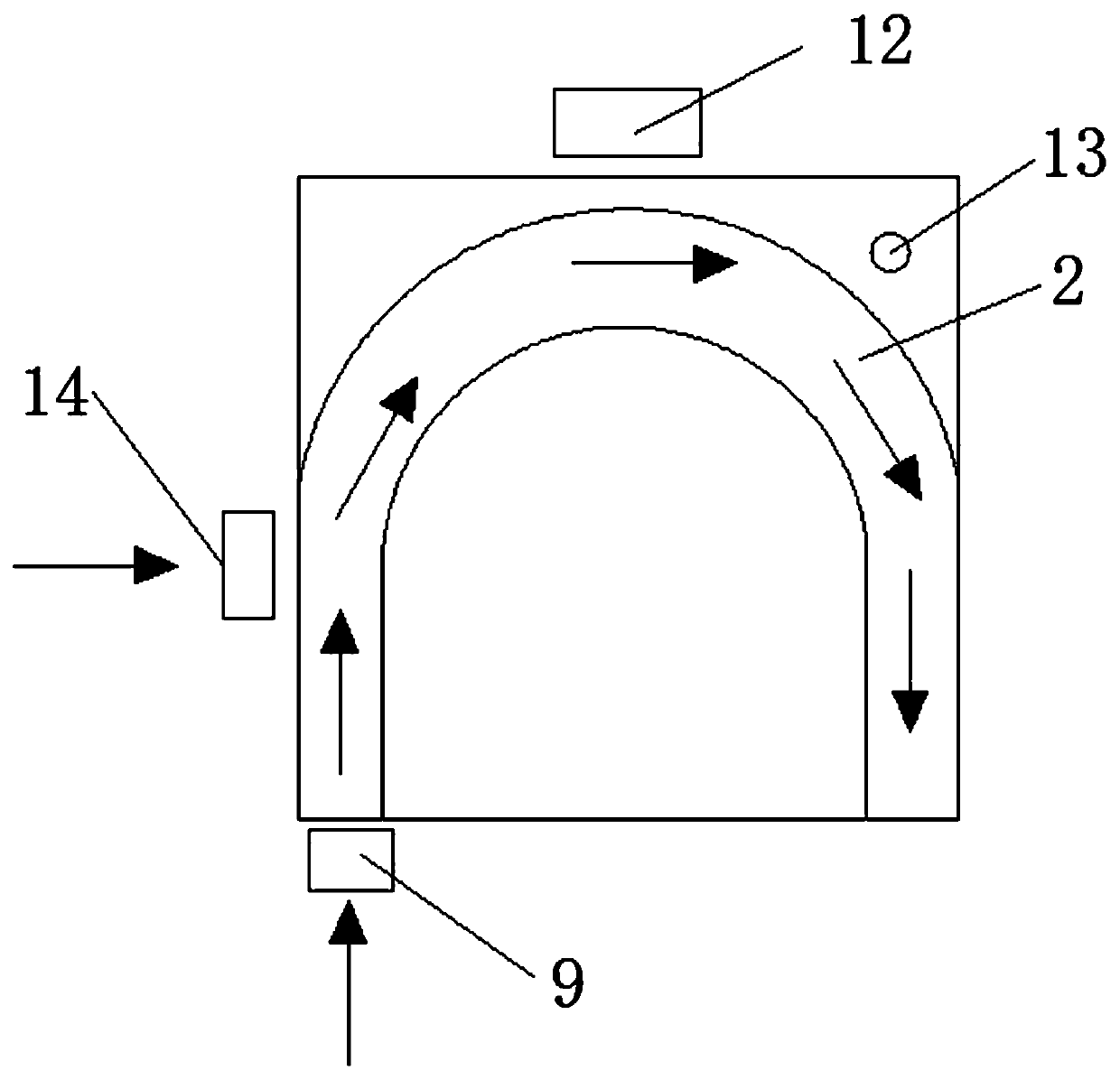

Air conditioning installation and control method

InactiveCN101936591AImprove cooling effectProper coolingMechanical apparatusSpace heating and ventilation safety systemsEngineeringAir conditioning

The invention relates to an air conditioning installation and the control method. An installation for cooling an electronic device includes an air conditioner having an air outlet for blowing cooling air to a room; a first detector adjacent to the air outlet of the air conditioner, for detecting a temperature of the cooling air; a rack accommodating the electronic device, the rack having an air inlet for receiving the cooling air from the air conditioner and an air outlet for exhausting air to the room; a second detector adjacent to the air inlet of the rack, for detecting a temperature of air received through the air inlet of the rack; and a controller for acquiring the temperatures detected by the first and the second detectors, and controlling a quantity of the cooling air blown from the air outlet of the air conditioner so as to decrease a difference between the temperatures detected by the first and the second detectors.

Owner:FUJITSU LTD

Circulating water cooling device in film tube of film blowing machine

The invention discloses a film pipe internal circulation water cooling device of a film blowing machine. Previous film pipe water cooling device is arranged outside a film pipe, the cooling speed is slow and water resource is wasted. An internal circulation water cooling device is arranged inside a film pipe and the internal circulation water cooling device composed of a cooling core model, a vacuum chamber inner container, various cooling inlet and outlet pipes which are sleeved coaxially and mutually, a multifolded bent water flow channel and a water absorption ring. Water in the water flow channel goes out and directly flows into the outer core walls of the cooling core model along the film pipe, a water film is formed and the inner wall of the film pipe is subjected to water cooling directly and effectively. The water stained on the inner wall of the film pipe is rapidly sucked dry in a vacuum suction way by the water absorption ring connected with the vacuum chamber inner container, thus the film pipe after cooling can go into the next production process rapidly. The whole device is simple in structure, has rapid cooling speed, raises the production benefits and saves energy. The water cooling device is widely suitable for film pipes or molding pipes of various film blowing machines, blow molding machines and the like.

Owner:SHANTOU CHENGYE MACHINERY

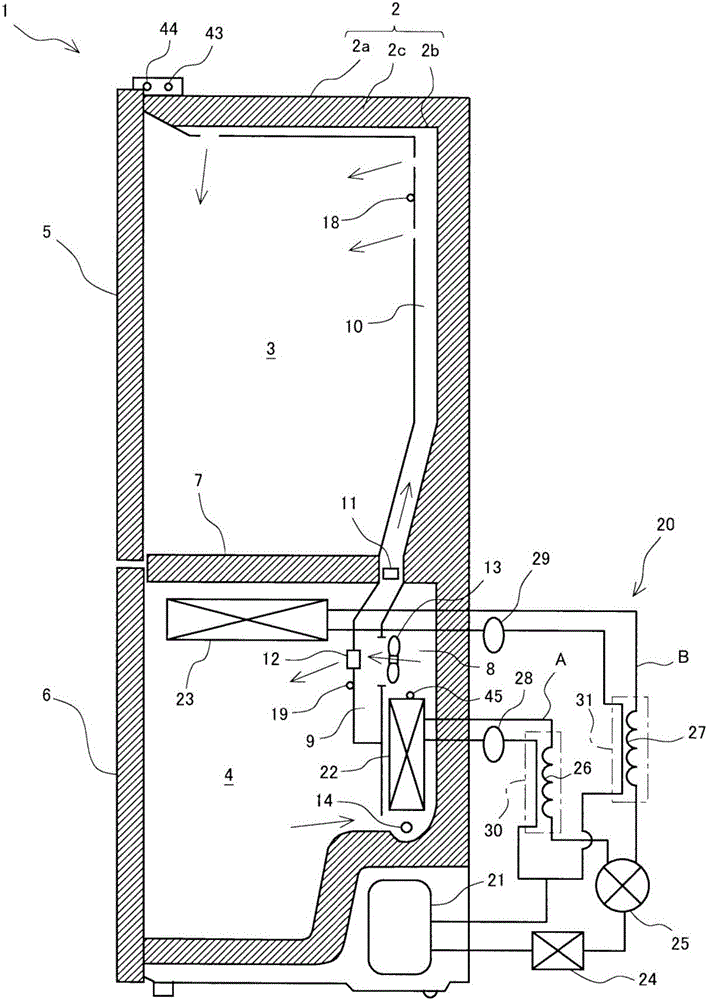

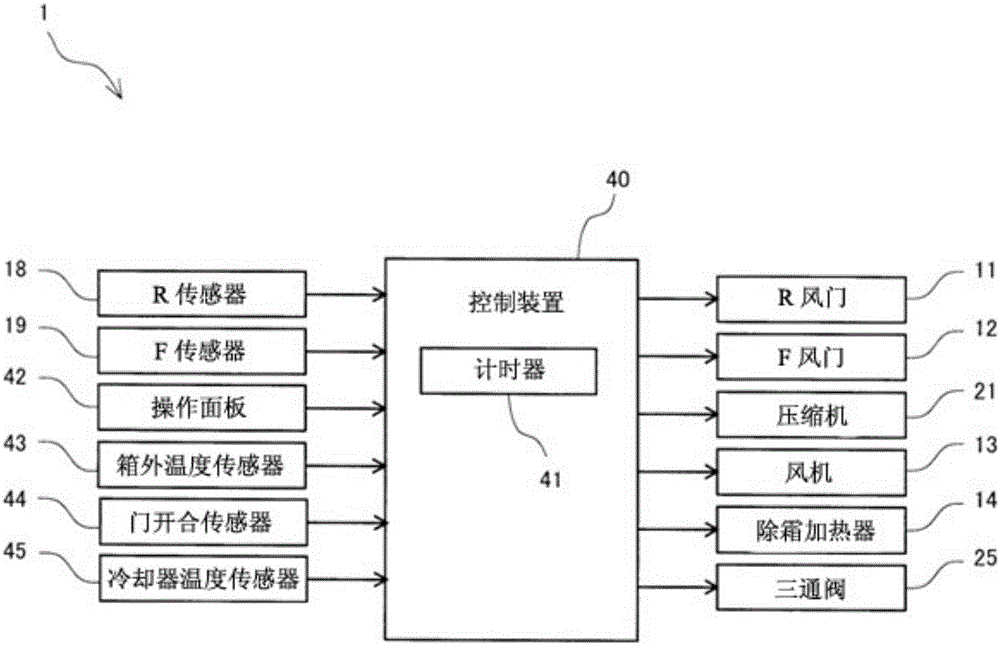

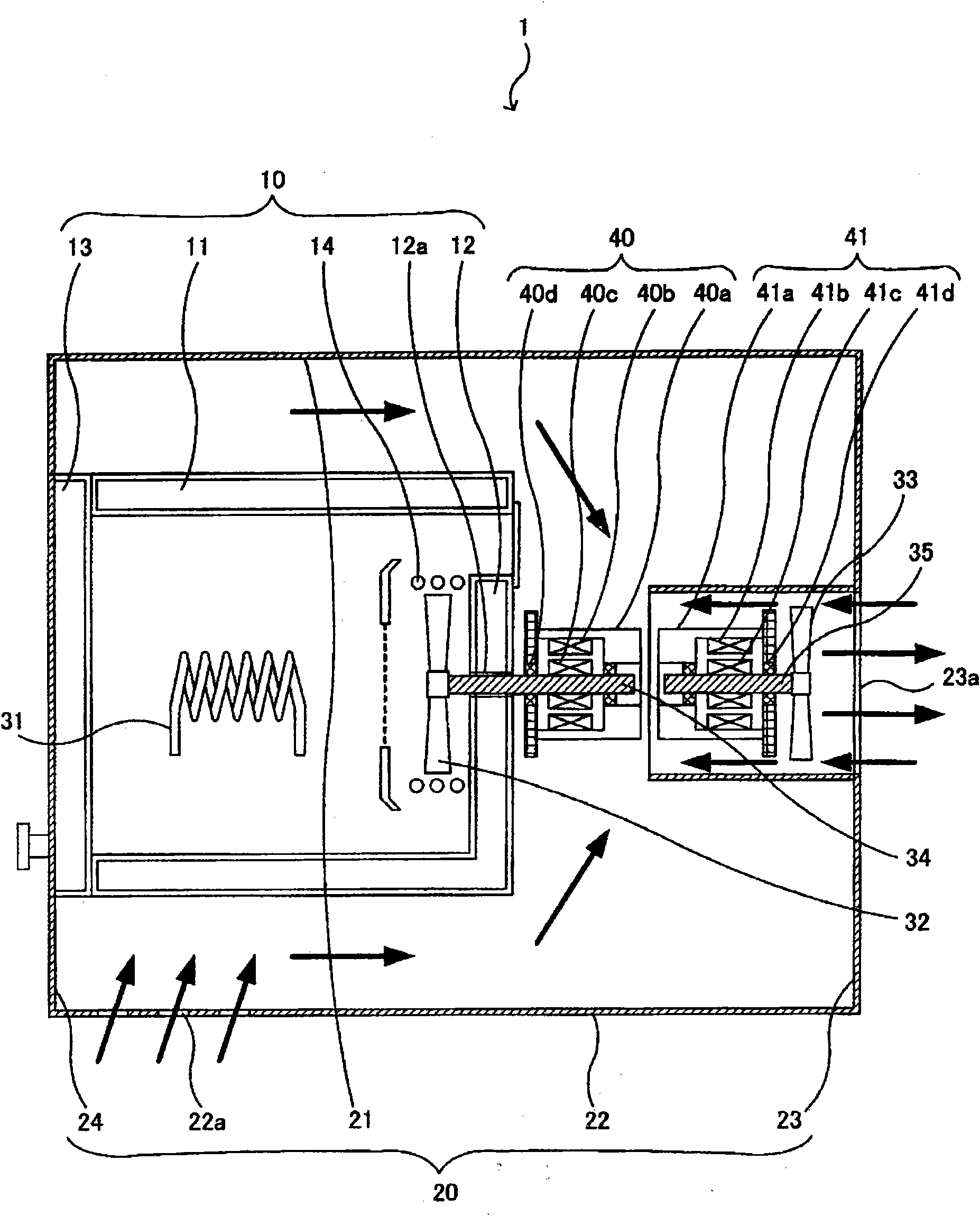

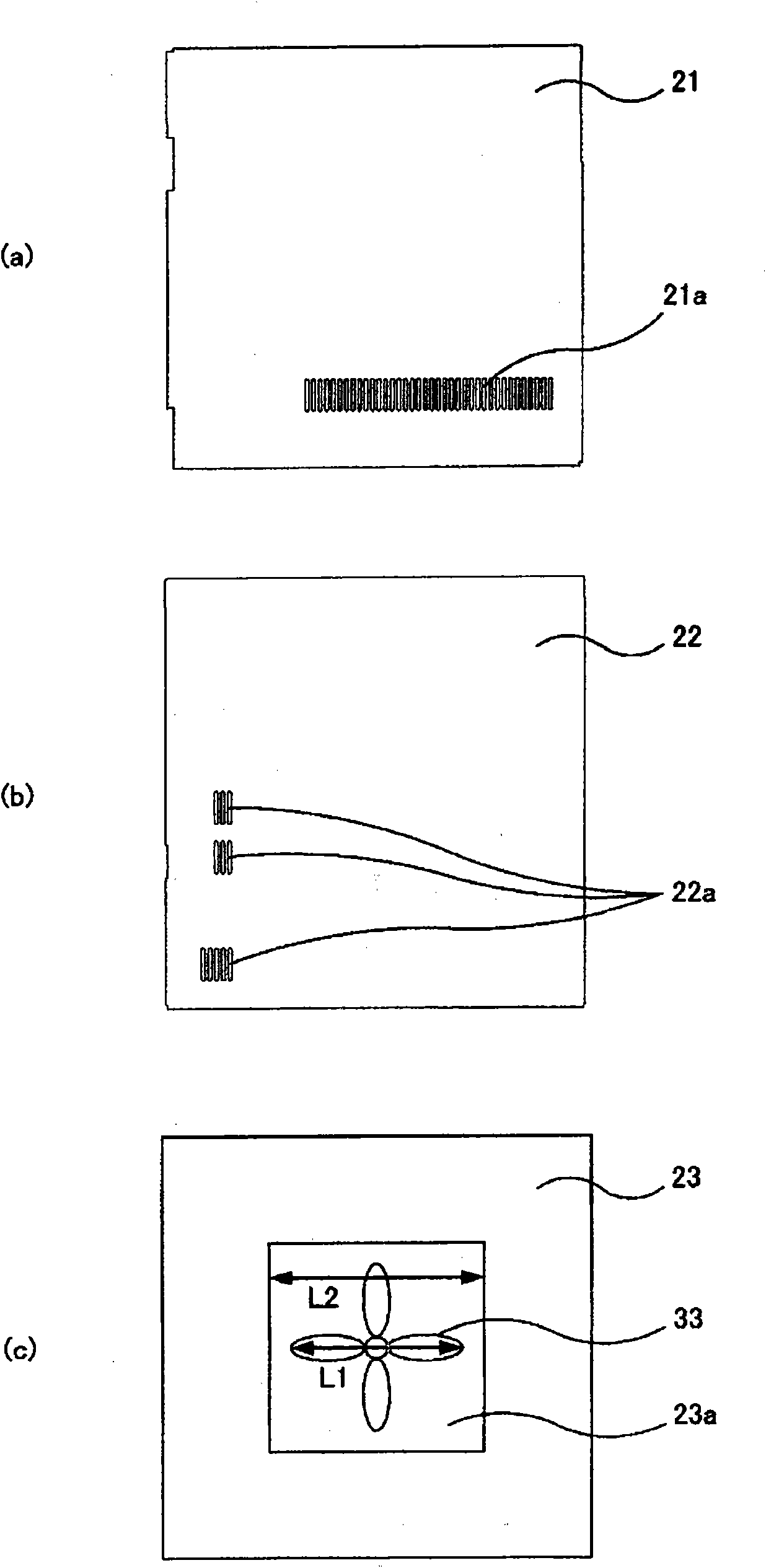

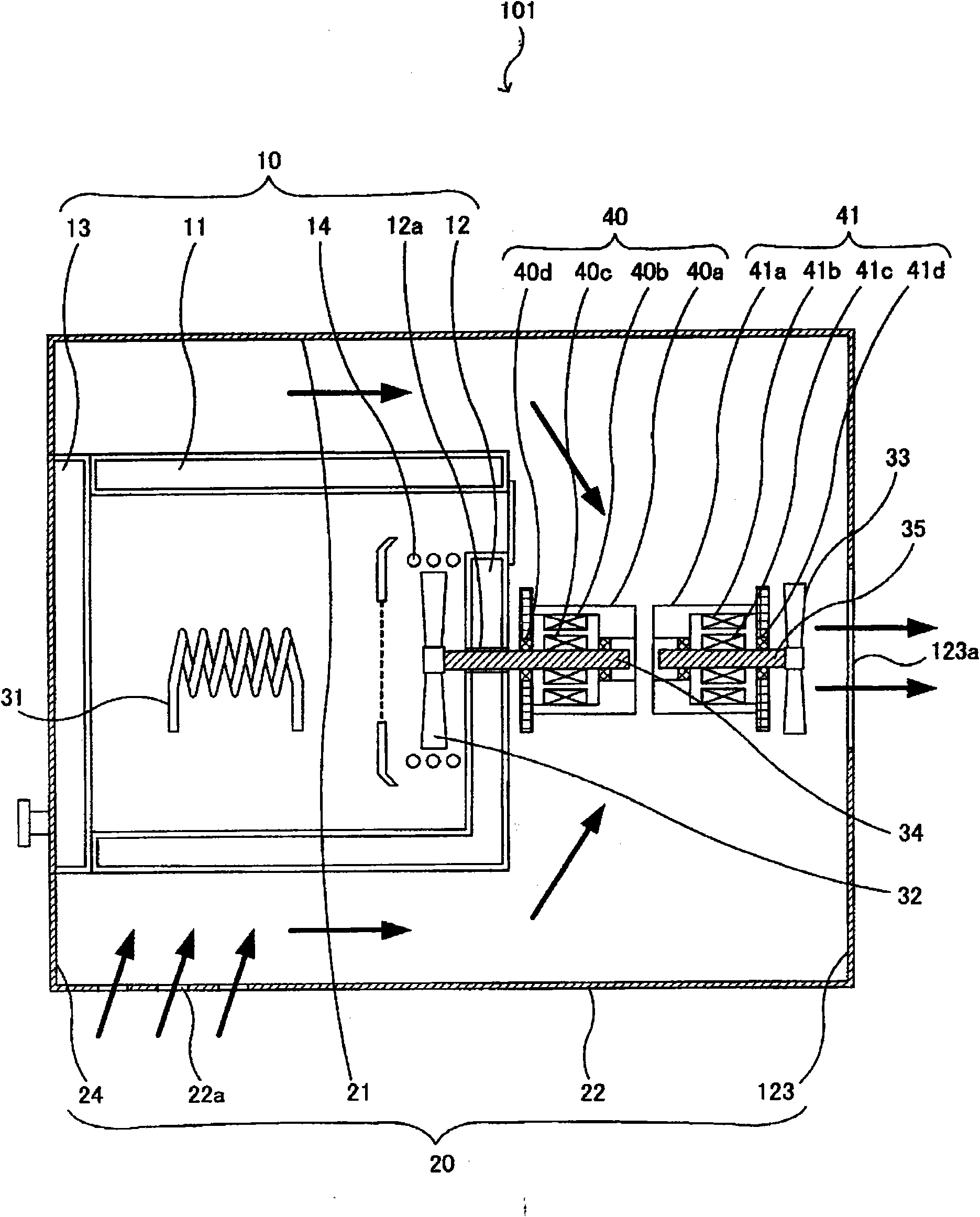

Refrigerator

InactiveCN106568270AReduce frostingReduce the frequency of defrostingDomestic refrigeratorsEvaporators/condensersEngineeringCold store

It is possible to provide a refrigerator which can suppress the temperature rise in the storage room and realize the freshness of food and the like. The refrigerator includes a storage compartment divided into at least a refrigerating compartment 3 and a freezing compartment 4, an evaporator 22 provided in a cooling chamber 8 connected to the storage compartment via the supply ducts 9 and 10, and a fan 13 for cooling the evaporator 22 Air is supplied from the cooling chamber 8 to the storage compartment, the duct opening and closing device 11 is inserted into the supply duct 10 connected to the refrigerating compartment 3, the second air duct opening and closing device 12 is inserted into the supply duct 9 connected to the freezing compartment 4, A second evaporator 23 provided inside or around the freezing compartment 4 and connected to the refrigerant passage B connected to the evaporator 22, and a switching unit 25 for switching whether or not the refrigerant flows to the evaporator 22 or the second evaporator 23. The refrigerator can suppress the temperature rise of the storage compartment and maintain the freshness of the food and the like at a high degree.

Owner:HAIER SMART HOME CO LTD +1

Gas chromatograph

Provided is a gas chromatograph capable of properly cooling a motor and a casing. The gas chromatograph comprises a thermostat (10) which is configured inside a casing (20) in such a manner to be spaced from walls; a first shaft (34) which, with a rod shape extended along a predetermined direction, has one end portion connected with a first blade (32) and is rotated via a first electric motor (40) around a central shaft in the predetermined direction; and a second shaft (35) which, with a rod shape extended along the predetermined direction, has one end portion connected with a second blade (33) and is rotated via a second electric motor (41) around the central shaft in the predetermined direction. To allow air to flow between the casing (20) and the thermostat (10) along the predetermined direction, the front portion of the casing (20) is provided with front opening portions (21a, 22a), and the rear portion of the casing (20) is provided with a rear opening portion (23a). In a plane perpendicular to the predetermined direction, the area of the rear opening portion (23a) is larger than the rotation area of the second blade (33). A cylindrical pipe (23b) is formed and is extended along the predetermined direction from the edge portion of the rear opening portion (23a).

Owner:SHIMADZU SEISAKUSHO CO LTD

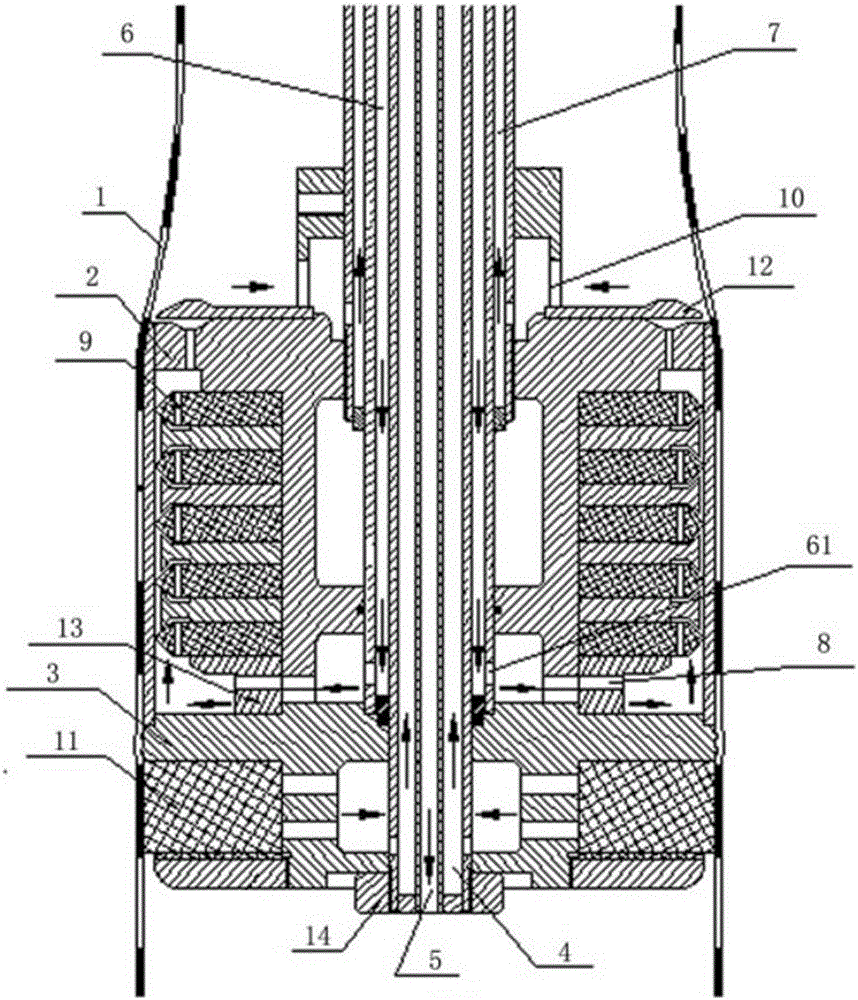

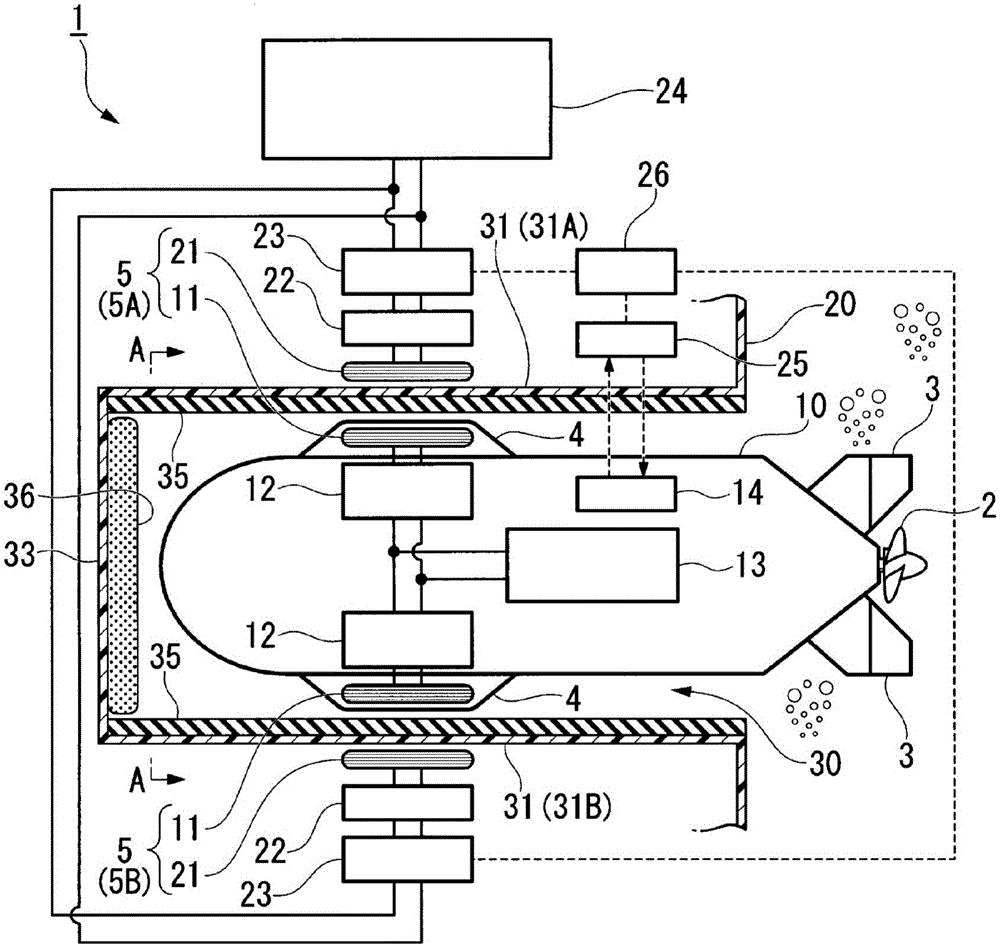

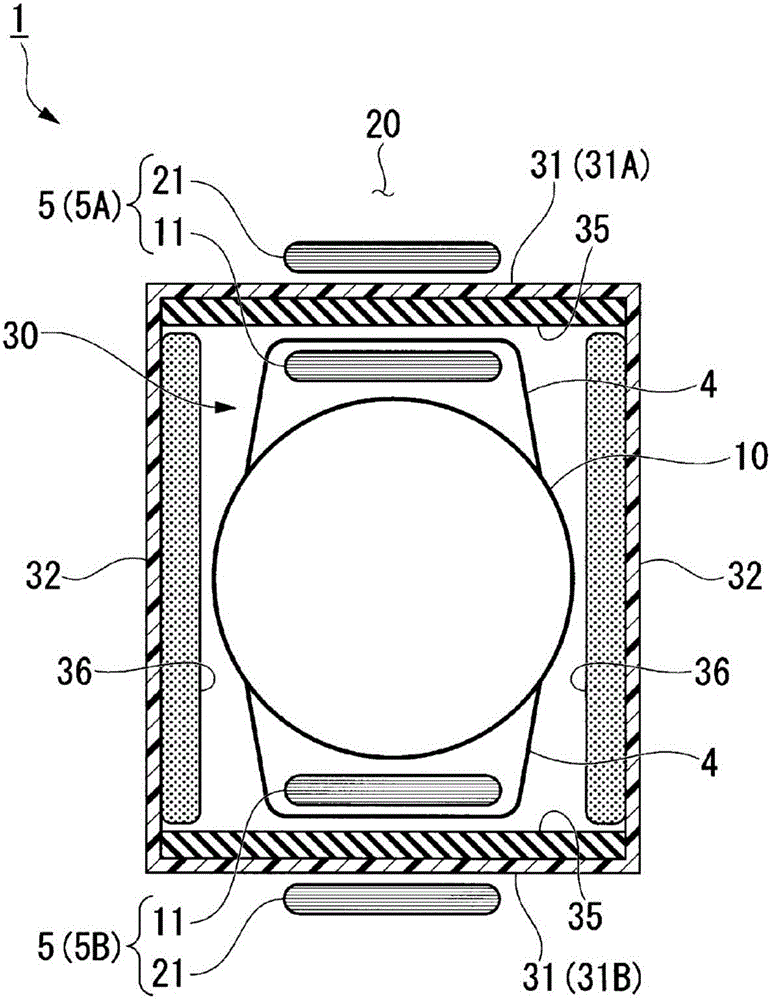

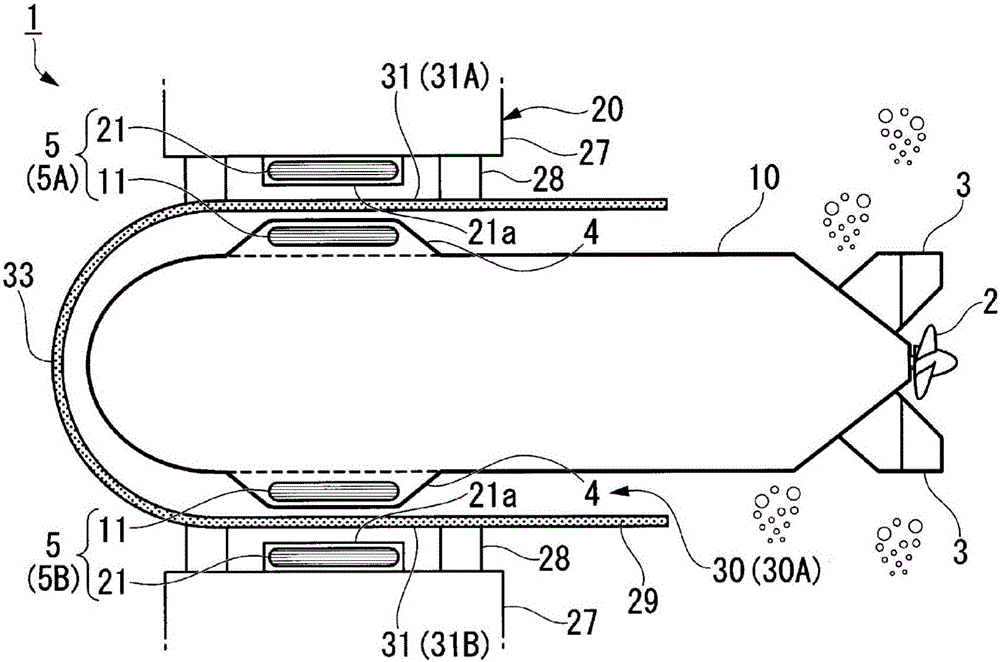

Power transmitting device, power receiving device, and wireless power supply system

ActiveCN106464025ASuppresses cooling efficiency dropGuaranteed temperatureRail devicesBatteries circuit arrangementsElectricityEngineering

A platform (20) of the present invention uses a coil pair (5) provided in an opposable manner to wirelessly supply power to an underwater moving body (10) having a relatively movable relationship. The platform (20) has: a recess portion (30) that can house at least a part of the underwater moving body (10) with a space therebetween; a coil (21) that forms a first coil pair (5A) opposable on one side of the opposing wall portions (31) of the recess portion (30); and another coil (21) that forms a second coil pair (5B) opposable on the other side of the opposing wall portions (31) of the recess portion (30).

Owner:IHI CORP

Hot area structure of MW-level solid oxide fuel cell power generation system and operation method of hot area structure

ActiveCN113903949ALarge amount of processingIncrease profitFuel cell heat exchangeAir preheaterElectric efficiency

The invention relates to a hot area structure of an MW-level solid oxide fuel cell power generation system. The hot area structure comprises a heat insulation shell, a two-section air preheater, a desulfurizer, a steam generator, a pre-converter, a reformer, a combustor and corresponding gas pipelines. The hot area structure is large in fuel handling capacity, small in hot area space and compact in internal device arrangement, meanwhile, achieves fuel treatment, air preheating, tail gas treatment and waste heat utilization and meets the requirements of the MW-level solid oxide fuel cell power generation system adopting natural gas, methane, marsh gas and the like as fuel; an anode tail gas recycling process is adopted, so that the fuel utilization rate is improved, the water-carbon ratio is reduced, and the electric efficiency and the thermal efficiency of the SOFC power generation system are favorably improved; and the two-section air preheater is adopted, the air preheater high-temperature section and the air preheater low-temperature section of smoke are fully utilized, the smoke exhaust temperature is effectively reduced, and it is guaranteed that air at the cathode inlet of an SOFC cell stack reaches the proper temperature.

Owner:广东佛燃科技有限公司

Rotating motor

ActiveCN104518612ASupply pressure reductionCurb supply shortageCooling/ventillation arrangementEngineeringCooling fluid

The invention provides a rotating motor capable of cooling the inside properly. A refrigerant supply mechanism (30) of the rotating motor (12) supplies cooling fluid (42) from a position of one end side closer to a rotating shaft than a bottom surface of a cylindrical member (52) to the bottom surface (70). The bottom surface (70) has a first through hole (86) and a second through hole (88) which axially run through along the rotating shaft (50), and the cooling fluid (42) is supplied into the cylindrical member (52) through the first through hole (86) and the second through hole (88). On the inner side of the cylindrical member (52), an outlet side opening part (92) of the first through hole (86) is formed in a position closer to a radial outer side than the rotating shaft (50), and an outlet side opening part (96) of the second through hole (88) is formed in a position closer to a radial outer side than the outlet side opening part (92) of the first through hole (86).

Owner:HONDA MOTOR CO LTD

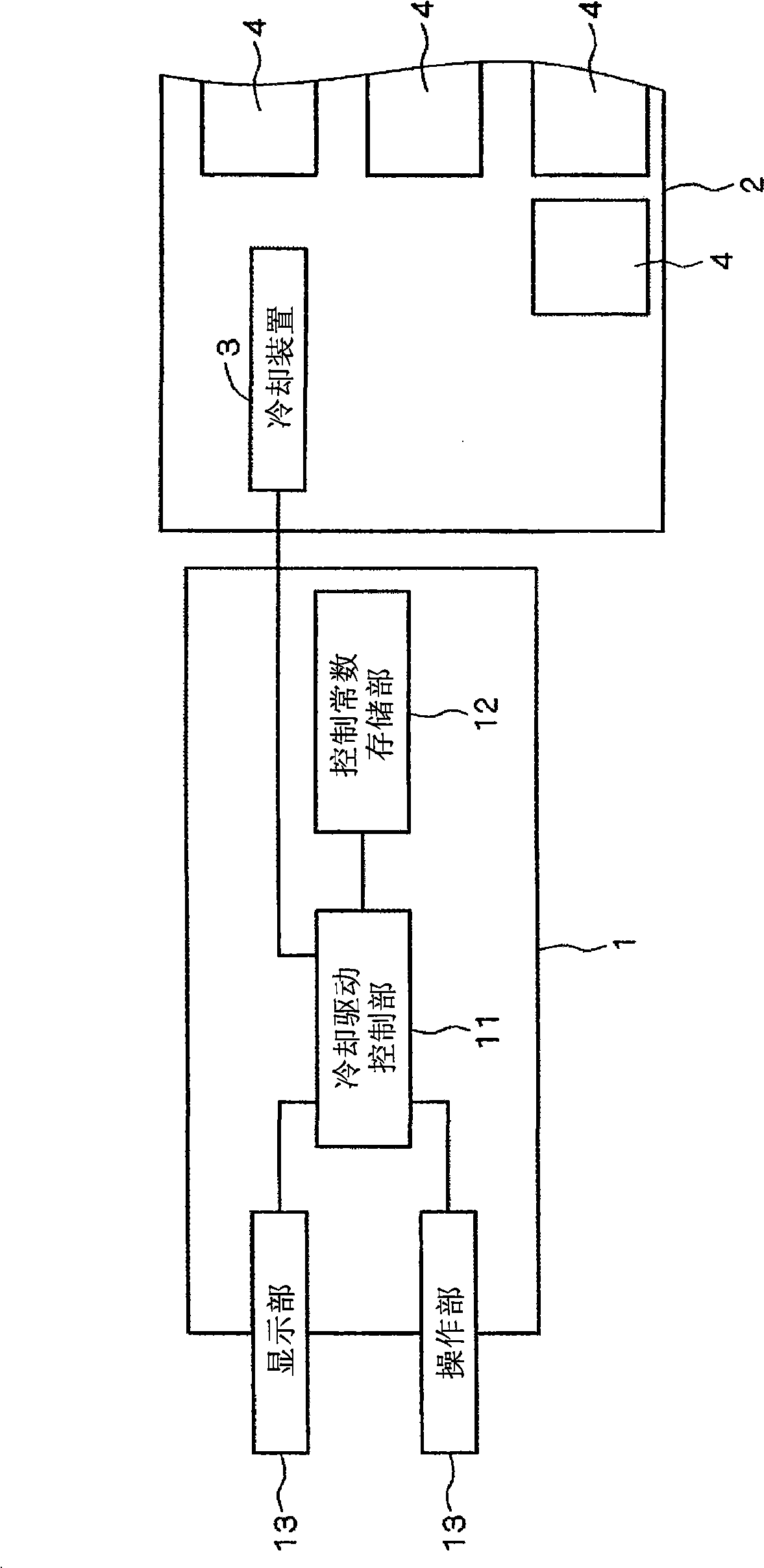

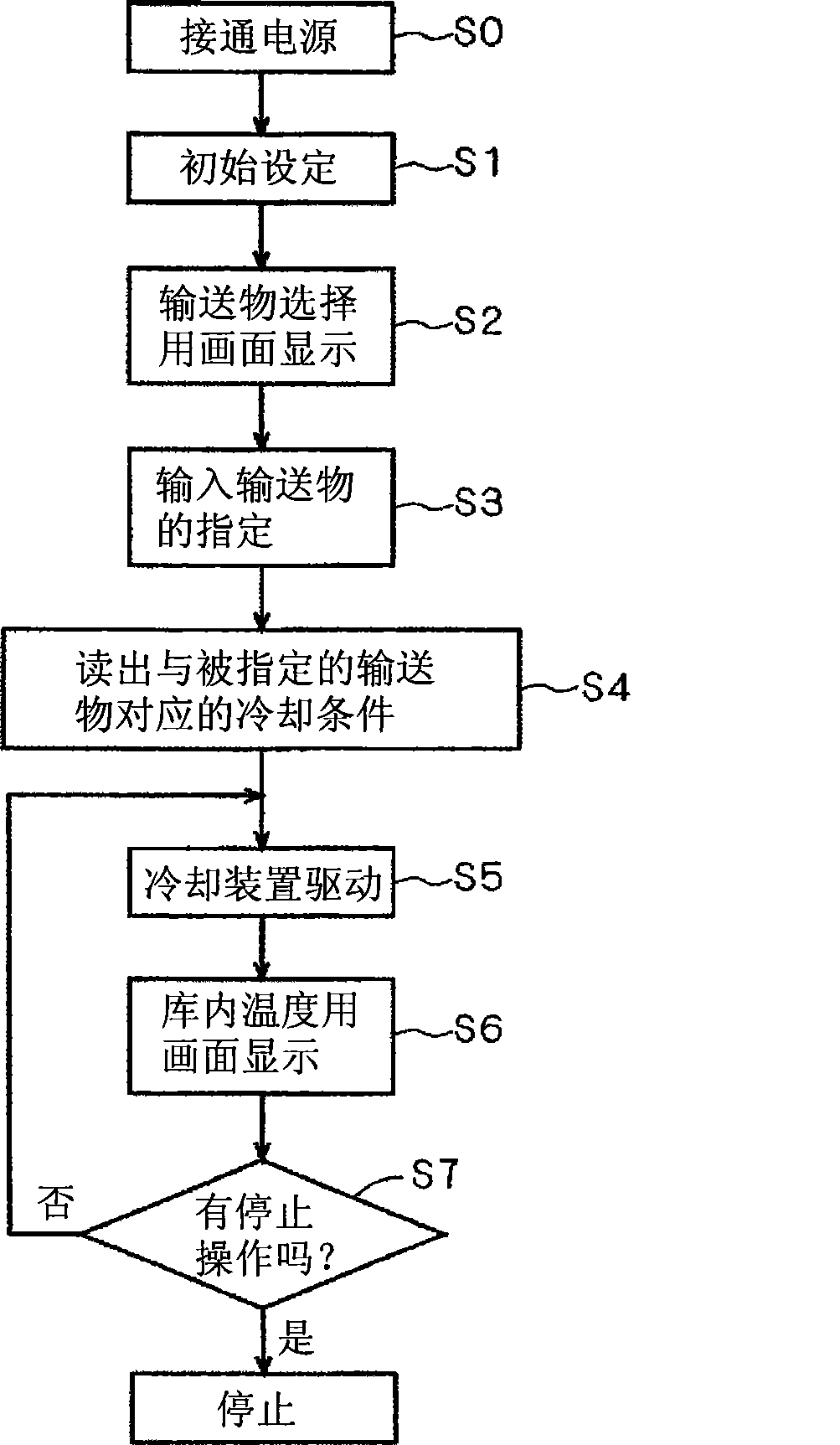

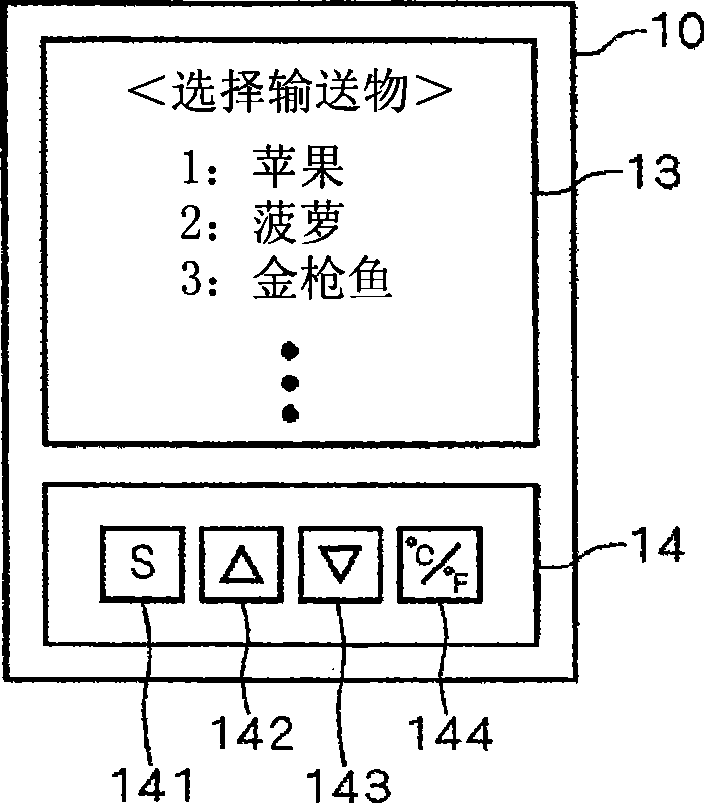

Control circuit for cooling apparatus, cooling system and method for controlling cooling apparatus

ActiveCN101535746AProper coolingLighting and heating apparatusDomestic refrigeratorsEngineeringControl circuit

The present invention provides a control circuit for cooling apparatus, cooling system and method for controlling cooling apparatus. A user specifies an object (4) to be cooled and makes a cooling apparatus (3) driven under cooling conditions which correspond to the object (4). A cooling drive control section (11) controls drive of the cooling apparatus (3). Data wherein information indicating the object (4) to be cooled by the cooling apparatus (3) is associated with a control constant which the cooling drive control section (11) uses for the object (4) is stored in the control constant storage section (12). The object (4) is specified by operating an operating section (14). The cooling drive control section (11) reads the control constant, which corresponds to the object (4) specified by the operating section (14), from the control constant storage section (12), and based on the read control constant, drive of the cooling apparatus (3) is controlled.

Owner:DAIKIN IND LTD

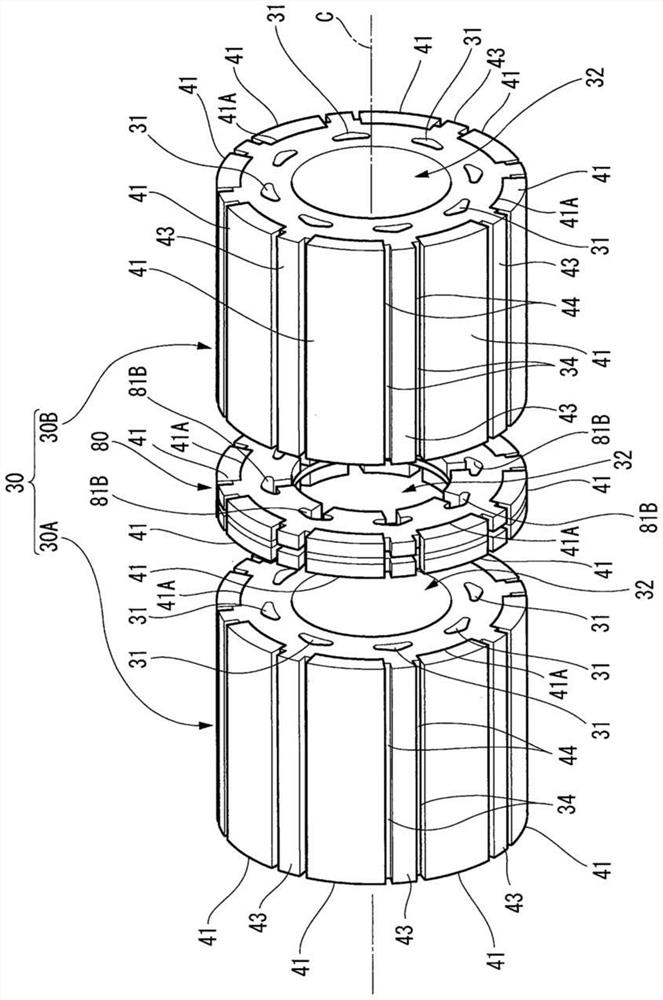

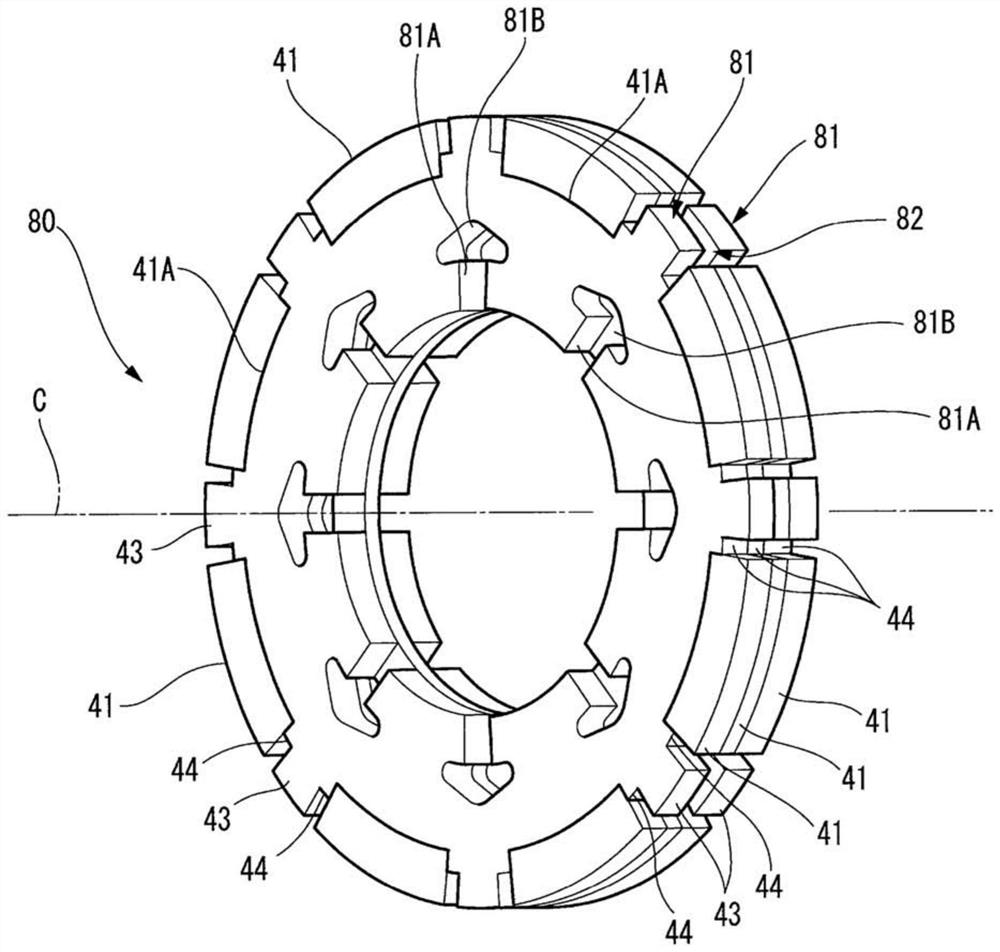

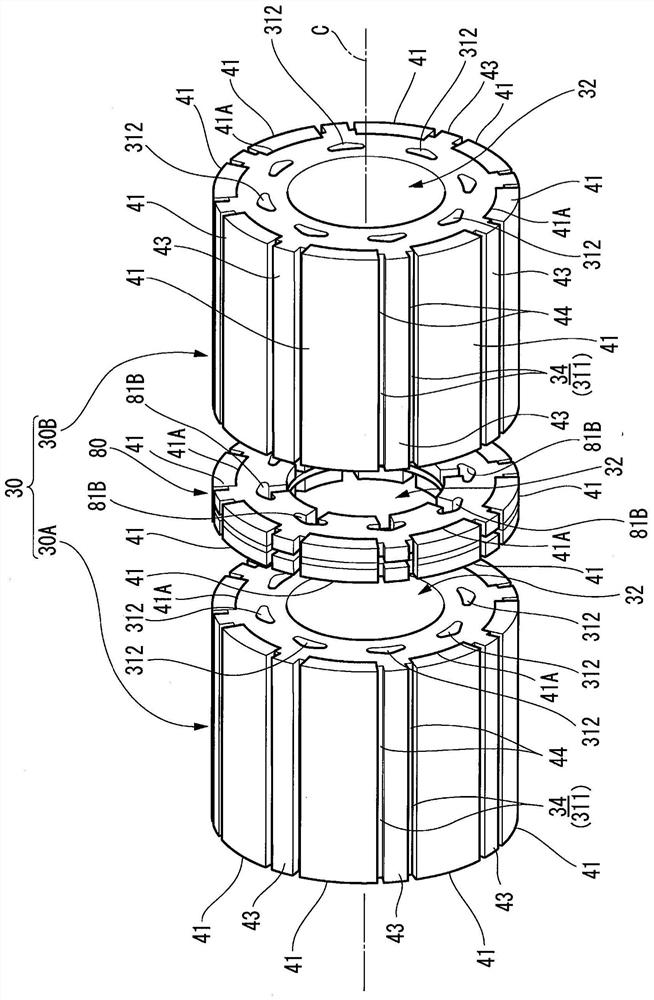

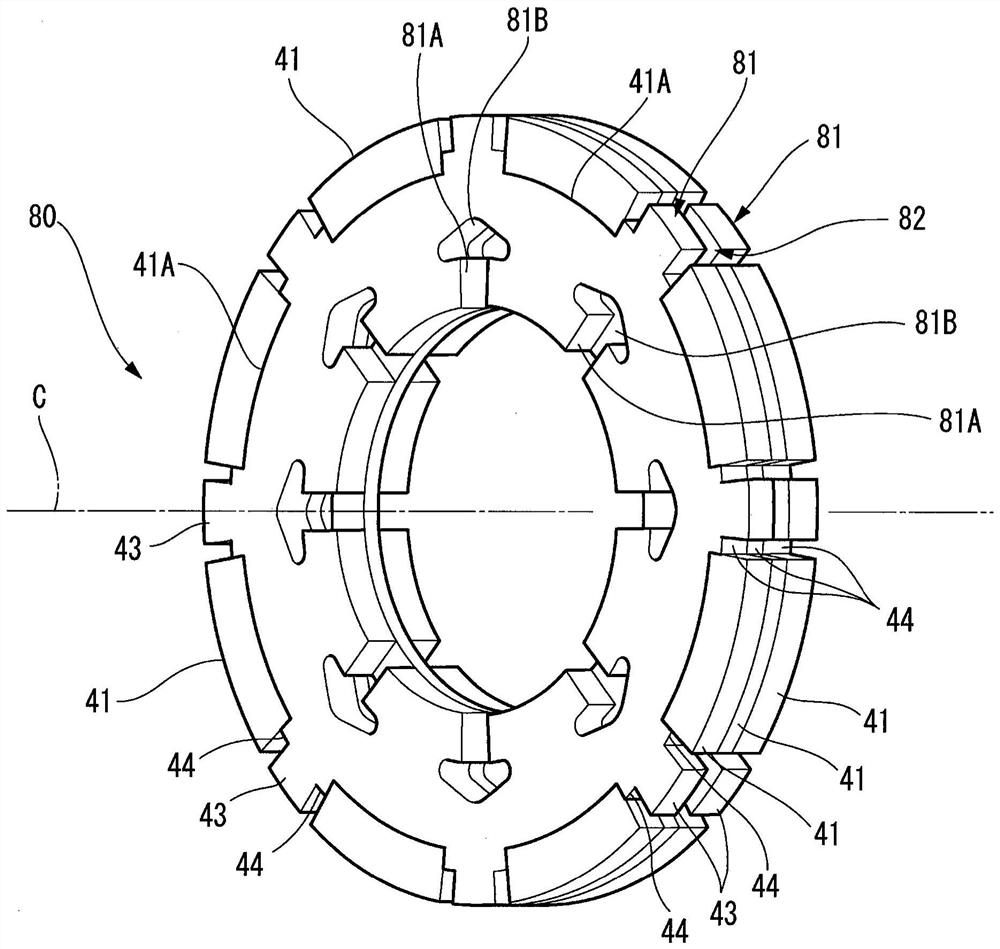

Rotor of rotary electric machine

ActiveCN111641281AProper coolingMagnetic circuit rotating partsCooling/ventillation arrangementRefrigerant distributionElectric machine

The invention provides a rotor of a rotary electric machine. The rotor can be properly cool a magnet arranged on the periphery of a rotor core. The rotor core (30) is provided with: a plurality of magnet attaching grooves (41A) formed on the outer peripheral surface of the rotor core and in which the magnets (41) are disposed; an in-core flow path (31) extending inside the rotor core in an axial direction of the rotor core; and a refrigerant distribution plate (80). The refrigerant distribution plate includes: a first refrigerant distribution plate (81) in which an inner-diameter-side refrigerant flow path (21) extending from an in-shaft flow path toward the in-core flow path (81A) as viewed from the axial direction is formed; and a second refrigerant distribution plate (82) in which an outer-diameter-side refrigerant flow path (82A) extending from the in-core flow path toward the magnet attaching groove as viewed from the axial direction is formed. The first refrigerant distribution plate and the second refrigerant distribution plate are stacked in the axial direction.

Owner:HONDA MOTOR CO LTD

Rotating electrical machine

InactiveCN108075607APrevent from gettingGuaranteed detection accuracyStructural associationCooling/ventillation arrangementElectric machinePhysics

The invention relates to a rotating electrical machine. A cooling structure for a rotating electrical machine includes a rotating electrical machine, a temperature sensor, and a first discharge mechanism. A plurality of discharge holes of the first discharge mechanism is disposed in a region excluding an avoidance region. The avoidance region is the same region as an arrangement region that is oneof a right side region and a left side region with respect to a vertical line passing an axis of the stator as seen in the axial direction of the stator core, the one of the right side region and theleft side region being a region in which the temperature sensor is arranged and the avoidance region is located above a lower end of the temperature sensor in the gravitation direction.

Owner:TOYOTA JIDOSHA KK

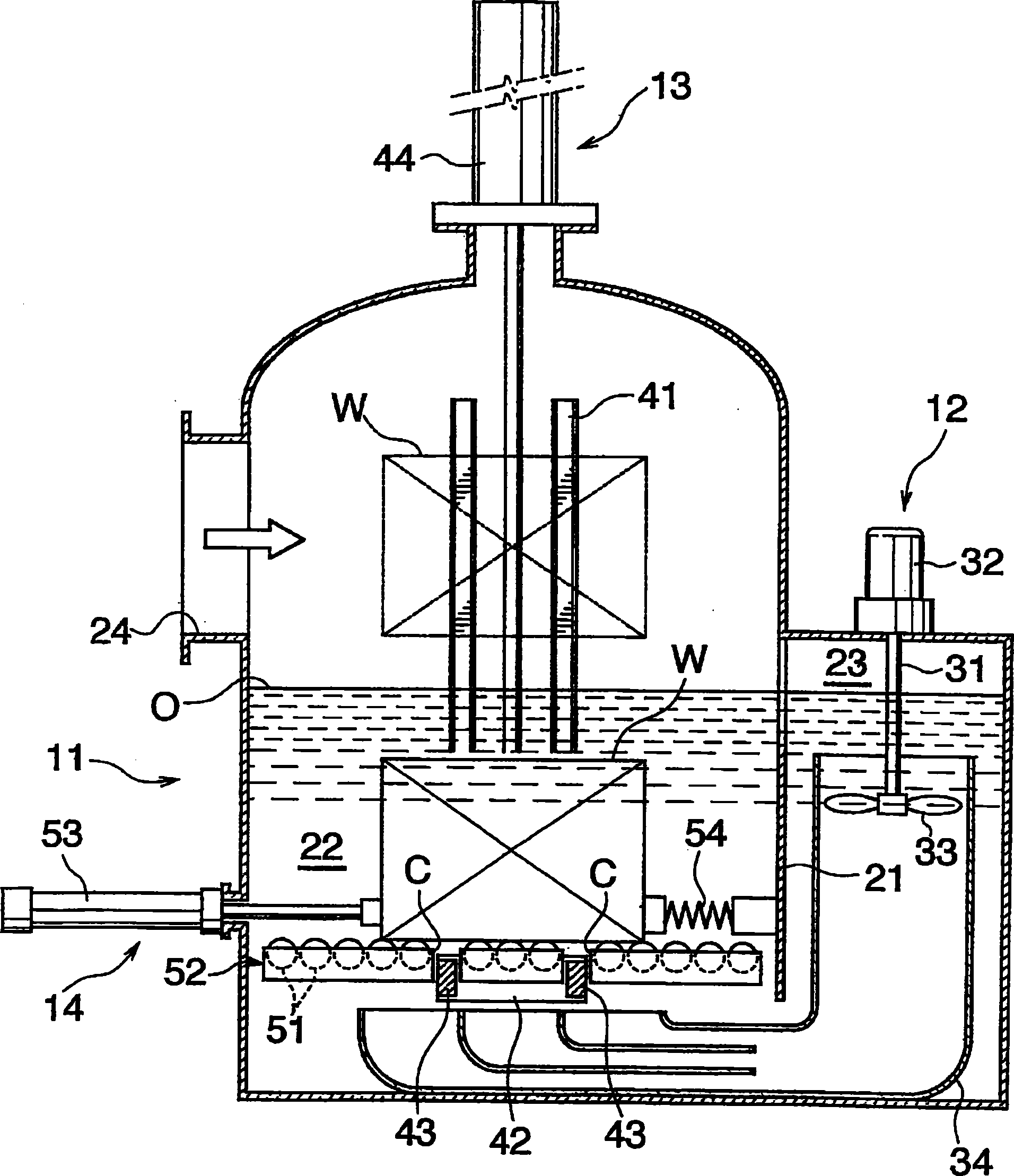

Method of quench hardening and device for use therein

InactiveCN1886523AUniform flow rateUniform cooling rateFurnace typesHeat treatment furnacesOil temperatureQuenching

A method of quench hardening that in order to reduce fluctuation of the cooling rate of coolant for treatment subject (S) and to inhibit fluctuations of carburized product quality and heat treatment strain, comprises agitating quenching oil (O) in oil bath (11) to thereby uniformalize the oil temperature, discontinuing the agitation, and immersing treatment subject (S) in the quenching oil (O) of the oil bath (11) wherein the treatment subject (S) is oscillated in the longitudinal and / or lateral direction with a cycle of 2 to 10 sec.

Owner:KOYO THERMO SYST CO LTD

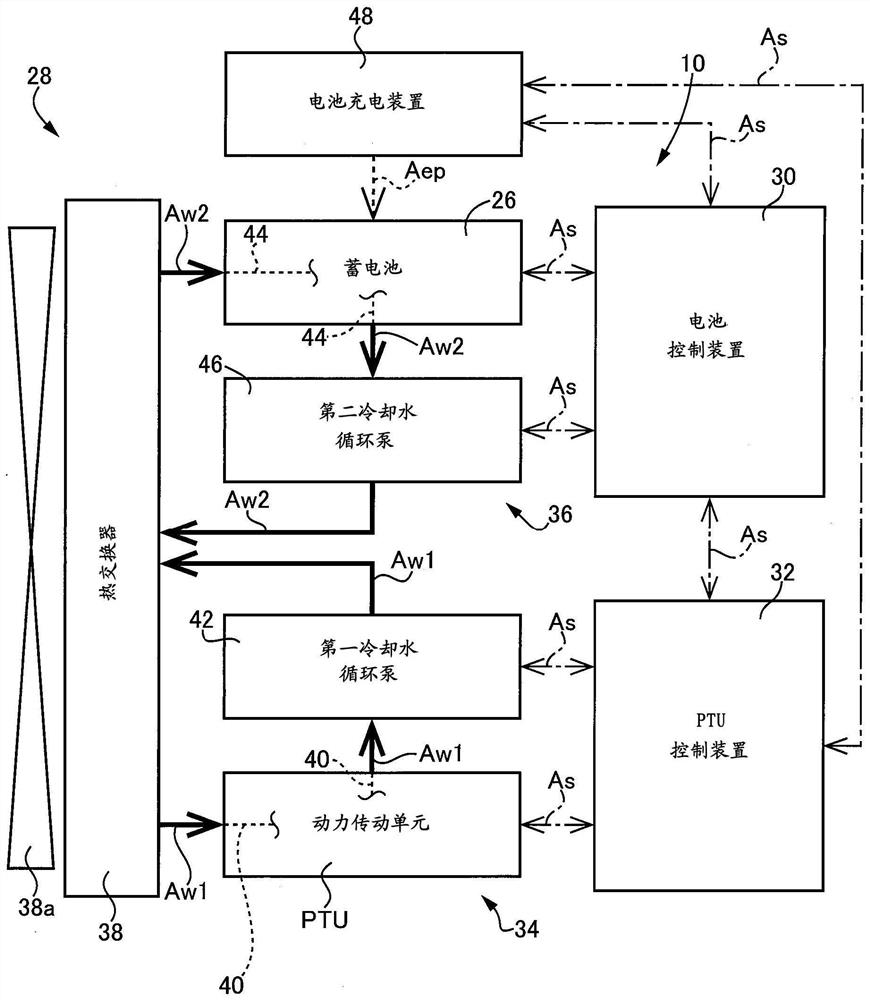

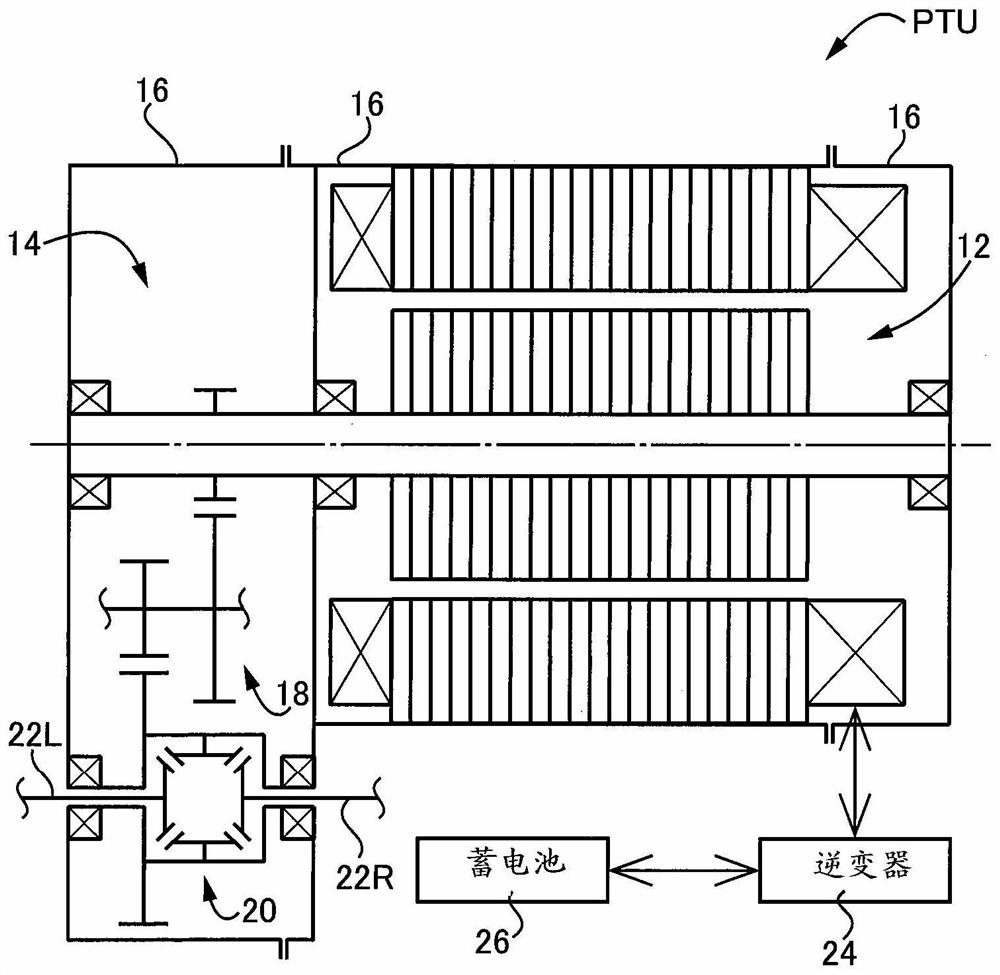

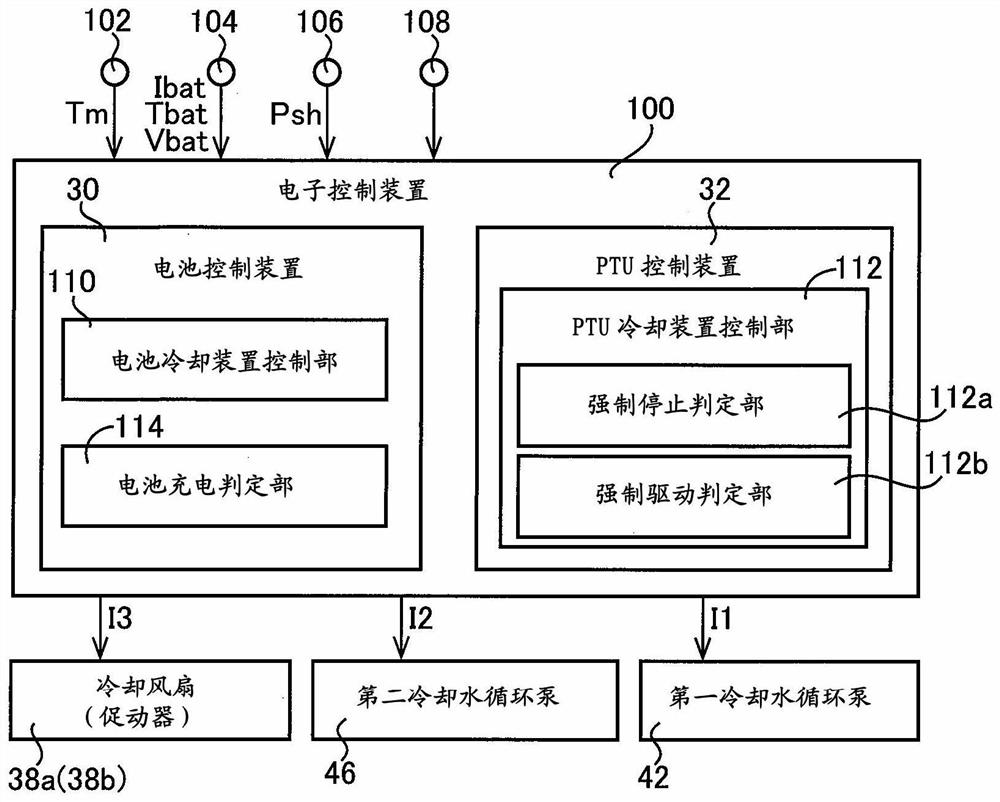

Control device of vehicle cooling device

InactiveCN111688459AImprove cooling effectProper coolingCell temperature controlElectric propulsion mountingEngineeringHeat exchanger

A control device of a vehicle cooling device is provided, which can properly improve cooling performance on a storage battery when the storage battery is in a charging state. When the storage battery(26) is in a charging state, a flow of cooling water (W) flowing in a PTU cooling circuit (40) is stopped. Accordingly, when the storage battery (26) is in a charging state, the cooling water (W) withheat transferred from a power transmission unit (PTU) does not flow back to a heat exchanger (38) through the PTU cooling circuit (40), so that the cooling performance on the storage battery (26) canbe properly improved when the storage battery is in a charging state.

Owner:TOYOTA JIDOSHA KK

Automatic Silk Reeling Locomotive Thread Thread Adding Device and Its Control Technology

ActiveCN108754628BImprove threading efficiencyReduce volatilitySilk reelingWater flowMechanical engineering

The invention discloses an automatic silk reeling machine headstock brushing end cocoon feeding device and a control technology thereof. The cocoon feeding device comprises a brushing-picking end cocoon without end cooling mechanism arranged on an end picking pot (10) and a mixed cocoon conveying mechanism connected with the brushing-picking end cocoon without end cooling mechanism, the output side of the mixed cocoon conveying mechanism is arranged on a high-temperature cocoon feeding opening of an end brushing pot (2), and a water flow system cooperates with the end picking pot (10) and thebrushing-picking end cocoon without end cooling mechanism; the control technology comprises the following steps that 1) the brushing-picking end cocoon without end cooling mechanism cools brushing-picking end cocoons without ends in the end picking pot (10); 2) the mixed cocoon conveying mechanism mixes the cooled brushing-picking end cocoons without ends and reeling silk dropping end cocoons andconveys the cooled brushing-picking end cocoons without ends and the reeling silk dropping end cocoons to the end brushing pot (2) for end brushing; 3) new cocoons are supplemented to the end brushingpot (2); the cooled brushing-picking end cocoons without ends in the end picking pot and the reeling silk dropping end cocoons are mixed and added in the end brushing pot, and therefore the stabilityof the brushing end cocoon setting quantity is improved, and the temperature fluctuation is reduced.

Owner:SICHUAN RES INST OF SILK SCI +1

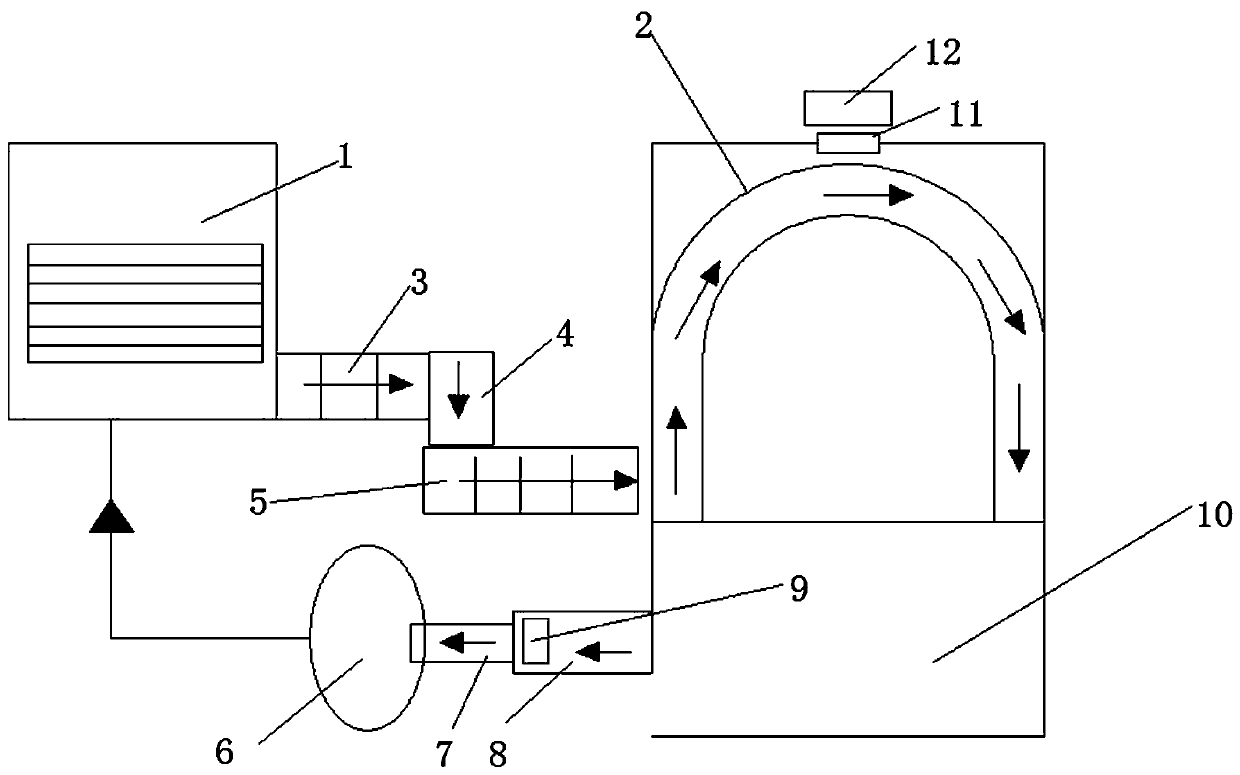

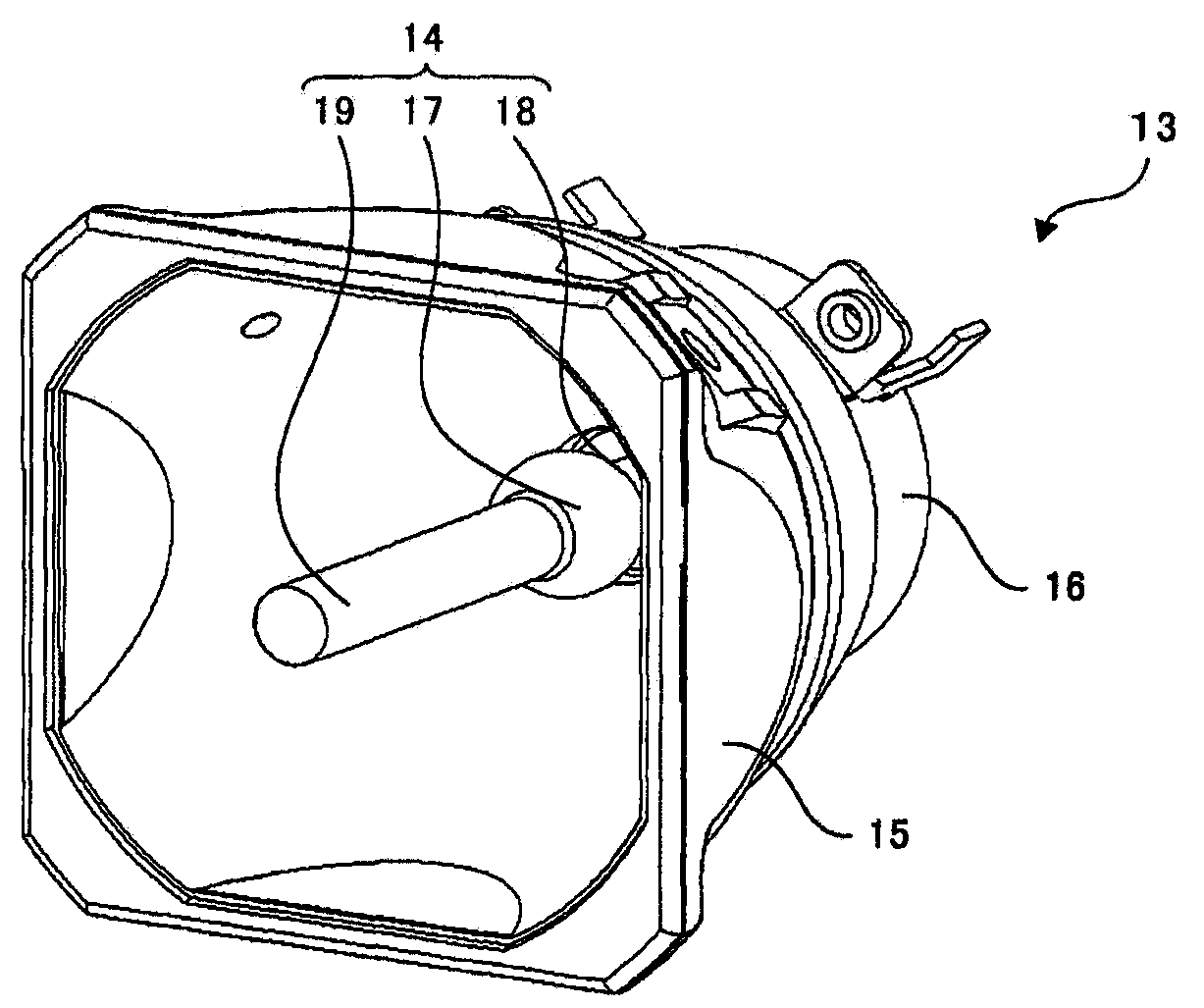

Light source device and projecting display device provided with light source device

InactiveCN104412041AProper coolingAppropriate (uniform coolingLighting heating/cooling arrangementsProjectorsPhysicsLight source

Provided is a light source device that can more uniformly cool a light-emitting tube. The light source device is provided with a reflector (15), a light-emitting tube (14), a blower (12), a first duct (21), and a second duct (41). The reflector (15) has a through hole. The light-emitting tube (14) contains a light-emitting section (17) and a sealing section (18) extending from the light-emitting section (17). Also, the sealing section (18) is passed through the through hole. The blower (12) generates cooling wind. The first duct (21) leads the cooling wind to the light-emitting section (17). The second duct (41) leads the cooling wind to the sealing section (18).

Owner:NEC DISPLAY SOLUTIONS LTD

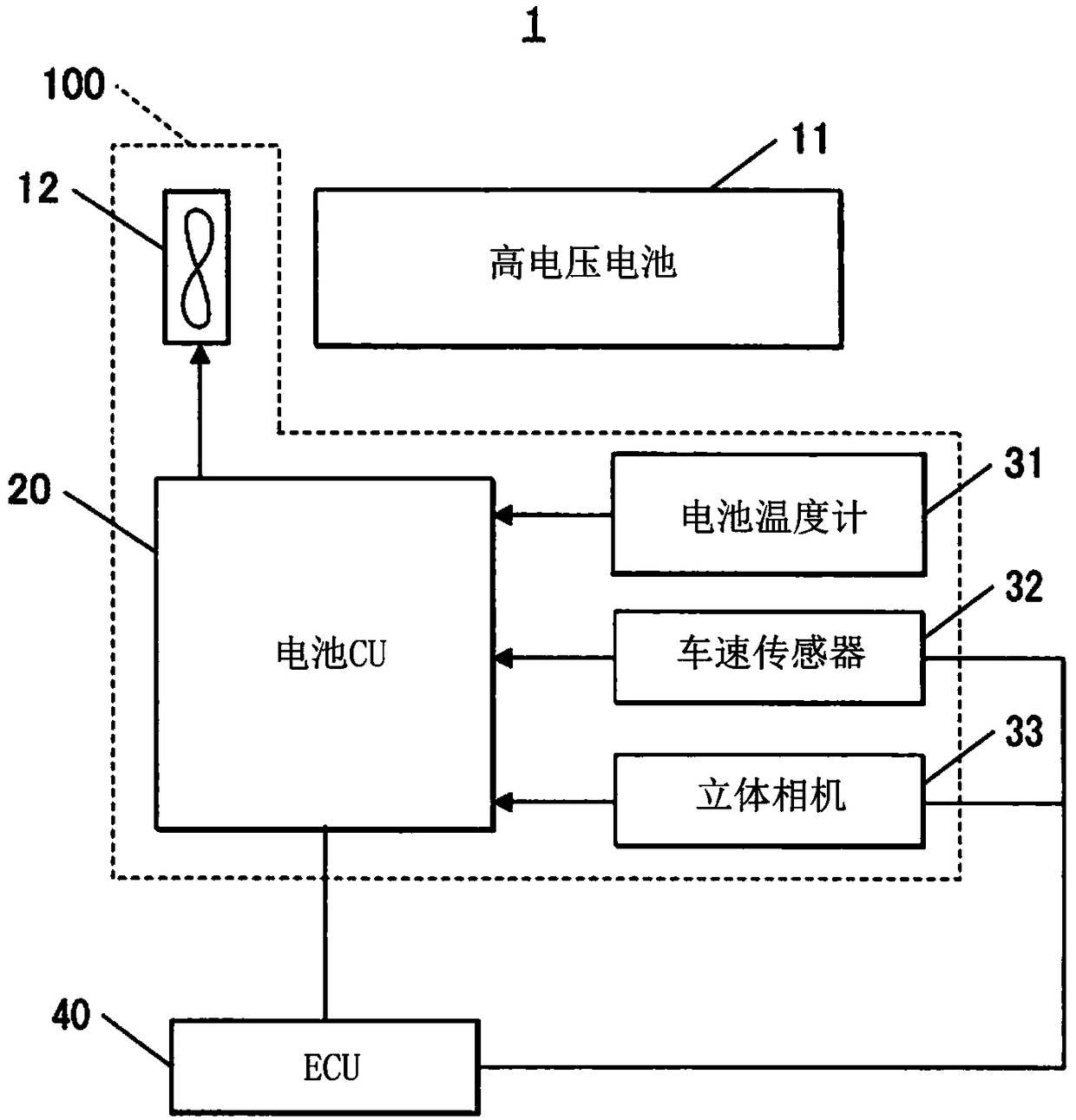

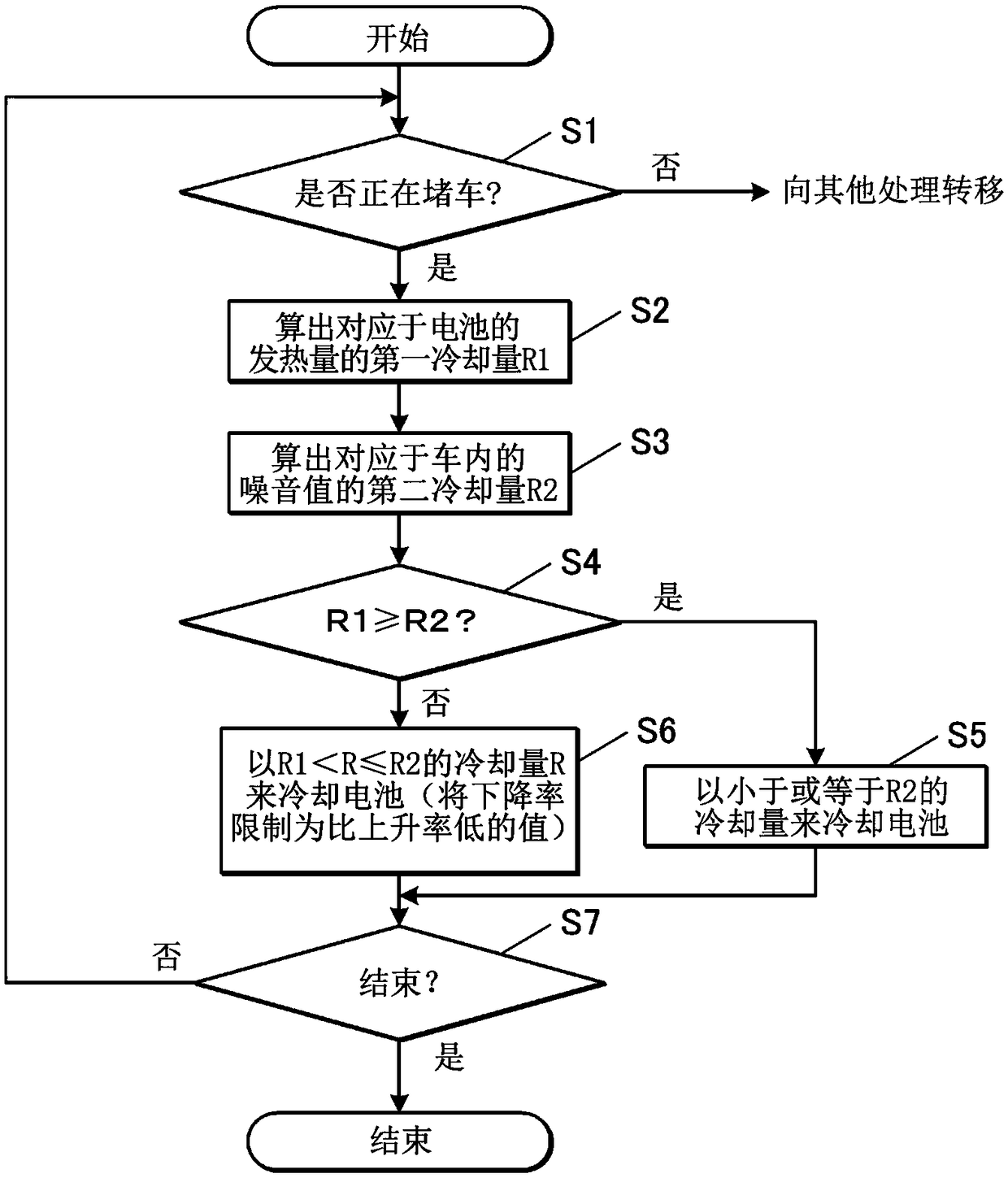

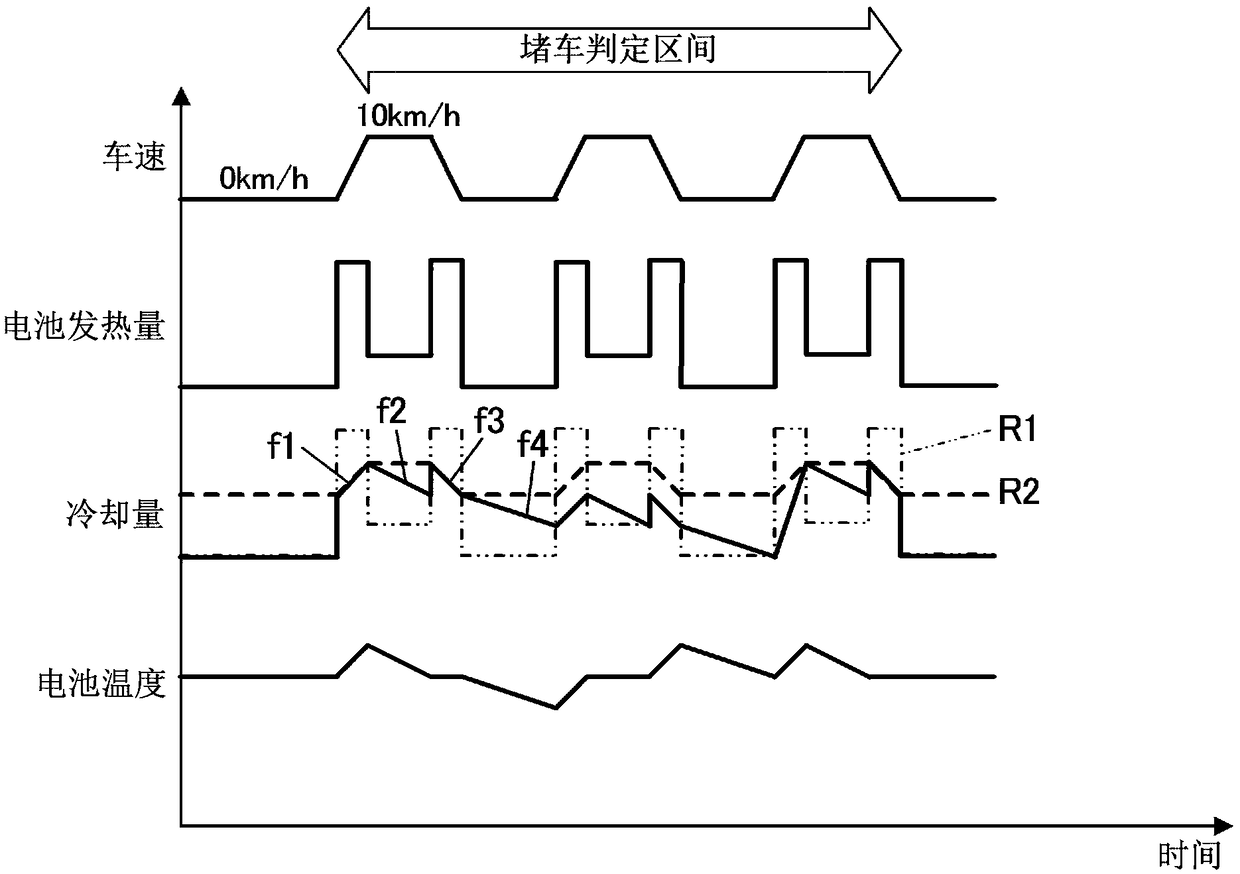

In-vehicle device cooling device

ActiveCN109473737AKeep quietImprove cooling effectHybrid vehiclesElectric devicesIn vehicleMechanical engineering

The present invention provides an in-vehicle device cooling device capable of appropriately cooling a heat generating device while maintaining quietness in the vehicle during traffic jam. The in-vehicle device cooling device (100) includes a cooling fan (12) that cool a high-voltage battery (11) mounted on the vehicle and a battery (CU20). The battery (CU20) determines whether the traveling path of the vehicle is jamming, and calculates a first cooling amount (R1) corresponding to the heat generation amount of the high-voltage battery (11) and a second cooling amount (R2) corresponding to thenoise value in the vehicle. Further, when it is determined that the traveling path is in traffic jam and the first cooling amount (R1) is smaller than the second cooling amount (R2), the battery (CU20) limits the rate of decrease of the cooling amount to be lower than the rising rate, and the cooling fan is operated in such a manner that the high-voltage battery is cooled by a cooling amount larger than the first cooling amount (R1) and less than or equal to the second cooling amount (R2).

Owner:SUBARU CORP

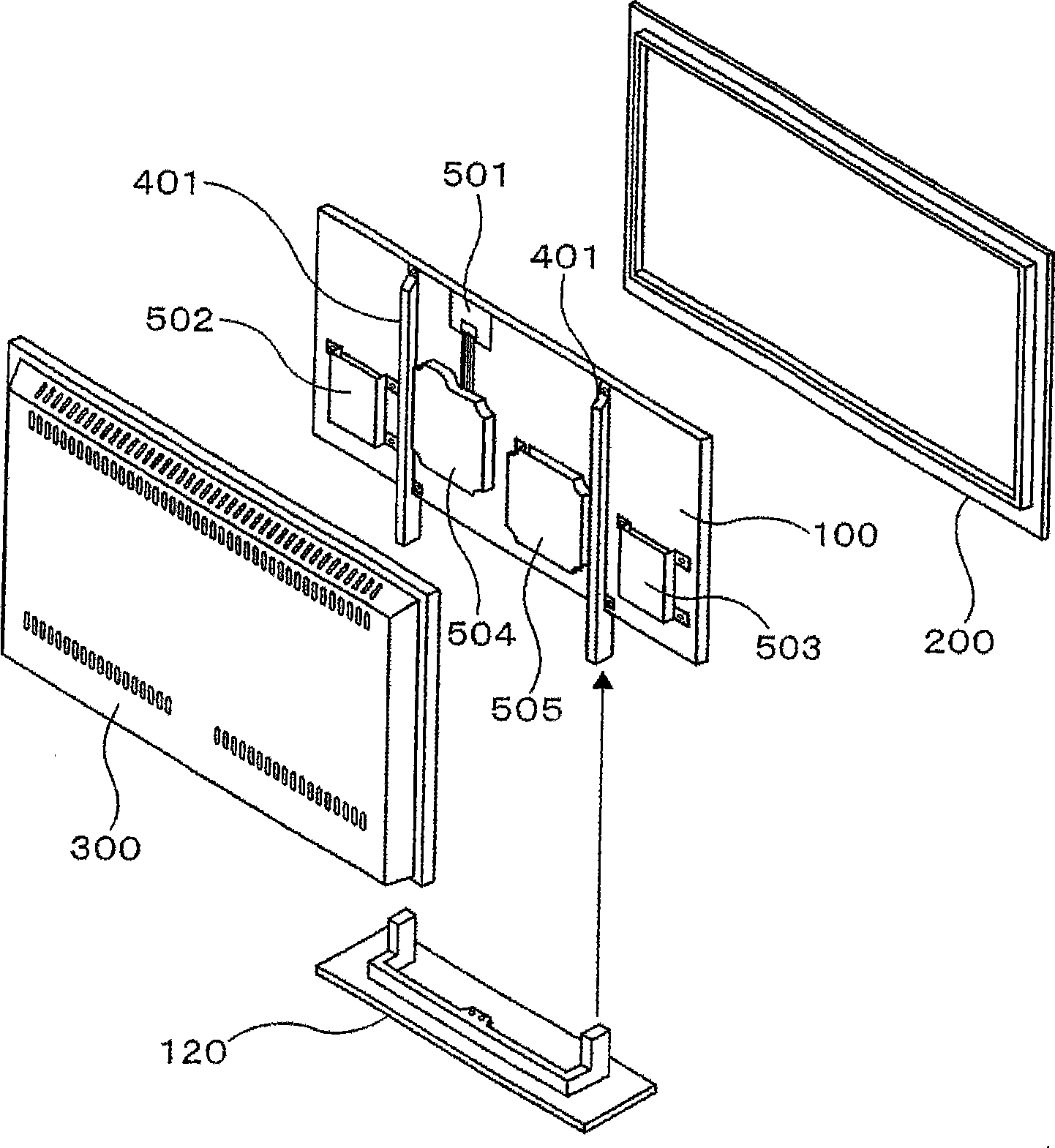

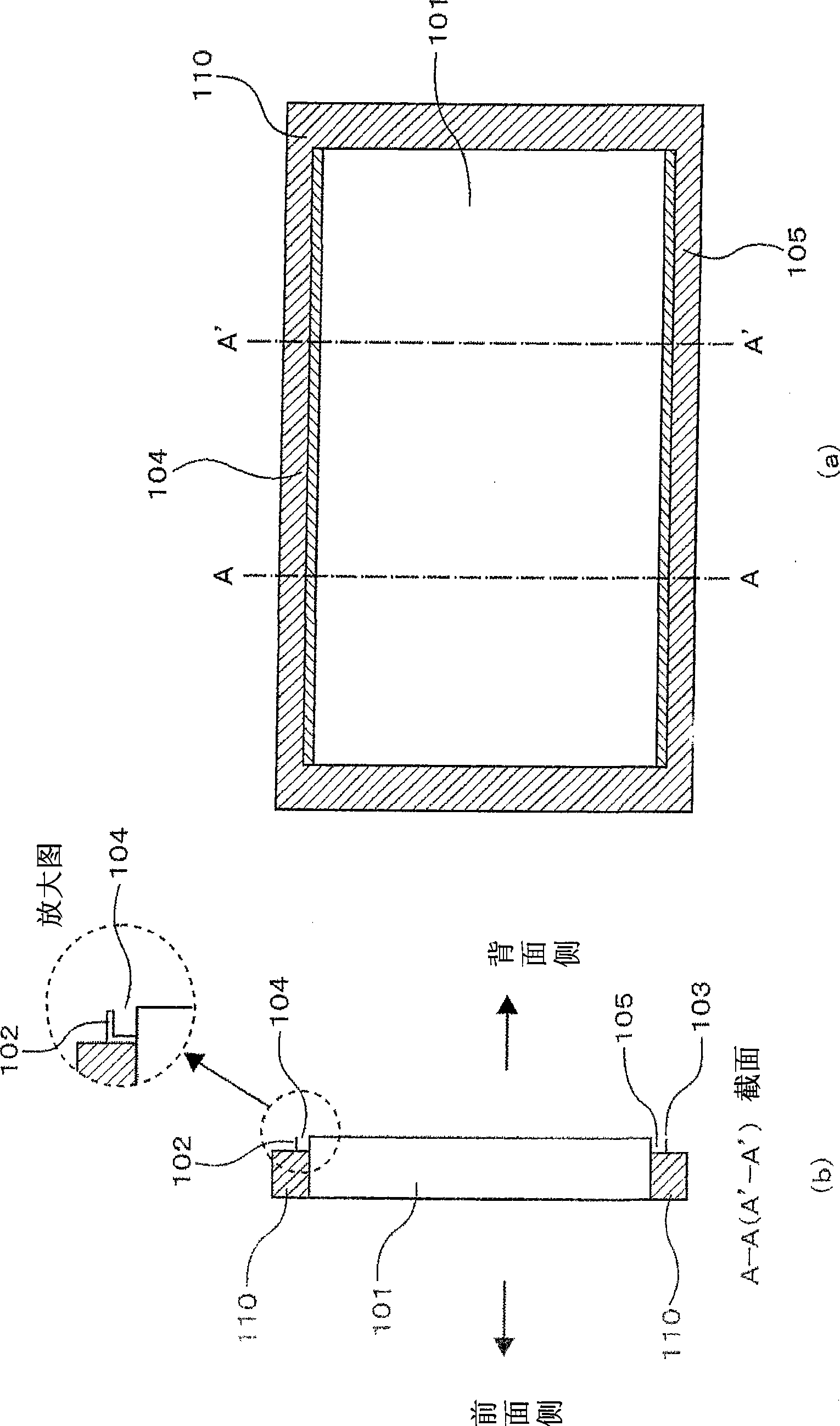

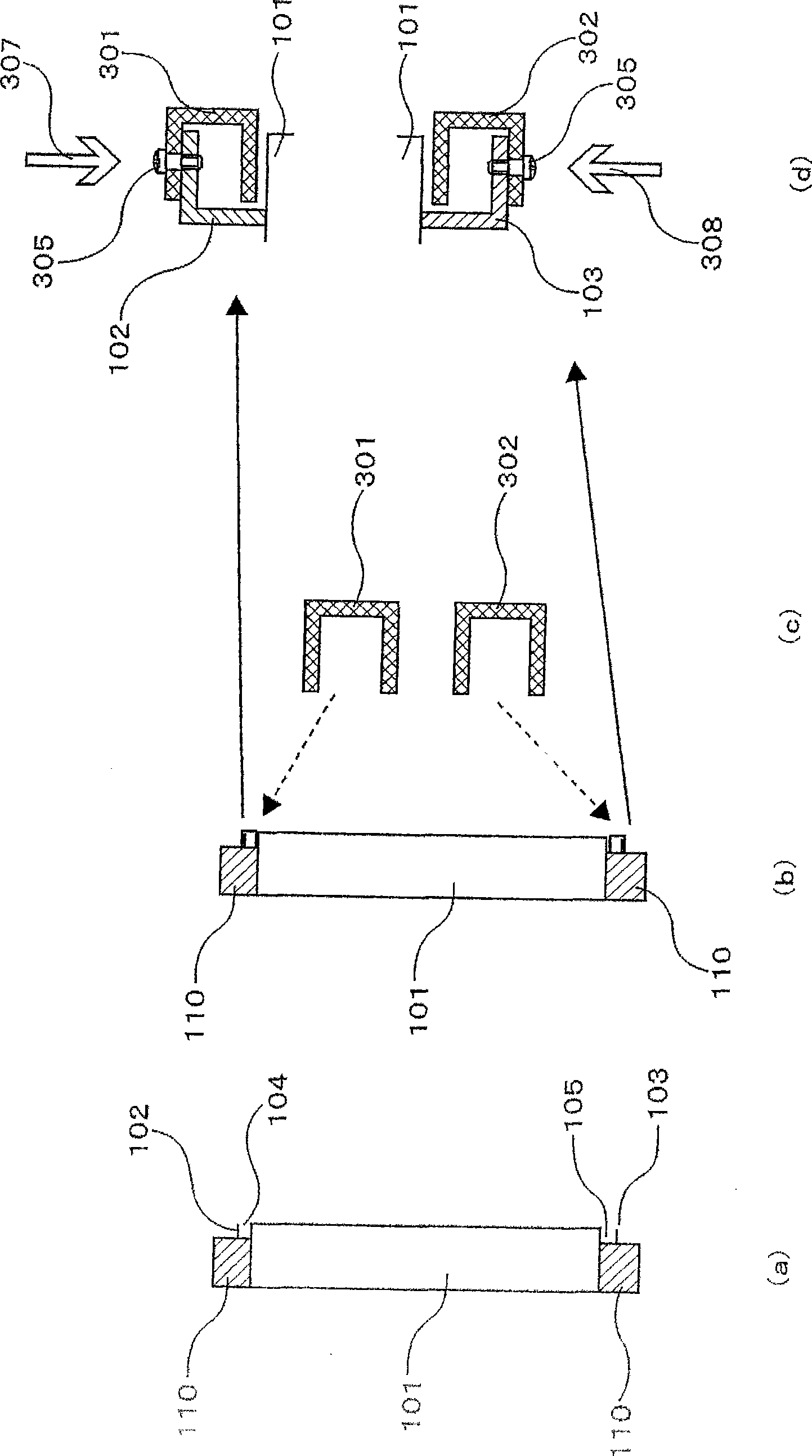

A display apparatus for displaying an image

ActiveCN101533163AProper coolingFull strengthTelevision system detailsCasings with display/control unitsComputer moduleLarge size

The invention provides a display apparatus for displaying an image that is allowed to incorporate a panel module with excellent mechanical strength even if a screen is upsized and the apparatus is slimmed down. Strengthening units are mounted along a horizontal direction on canopies provided on an upper portion and a lower portion of a panel module constituting a display unit of a large-size, thin image display apparatus. Also, supporting members are mounted on the upper and lower strengthening units in such a manner that the supporting members bridge between the upper and lower strengtheningunits, so that a stand, or a chain or a string to be used when hanging the image display apparatus is mountable to the supporting members. This prevents direct application of external force to the panel module.

Owner:MAXELL HLDG LTD

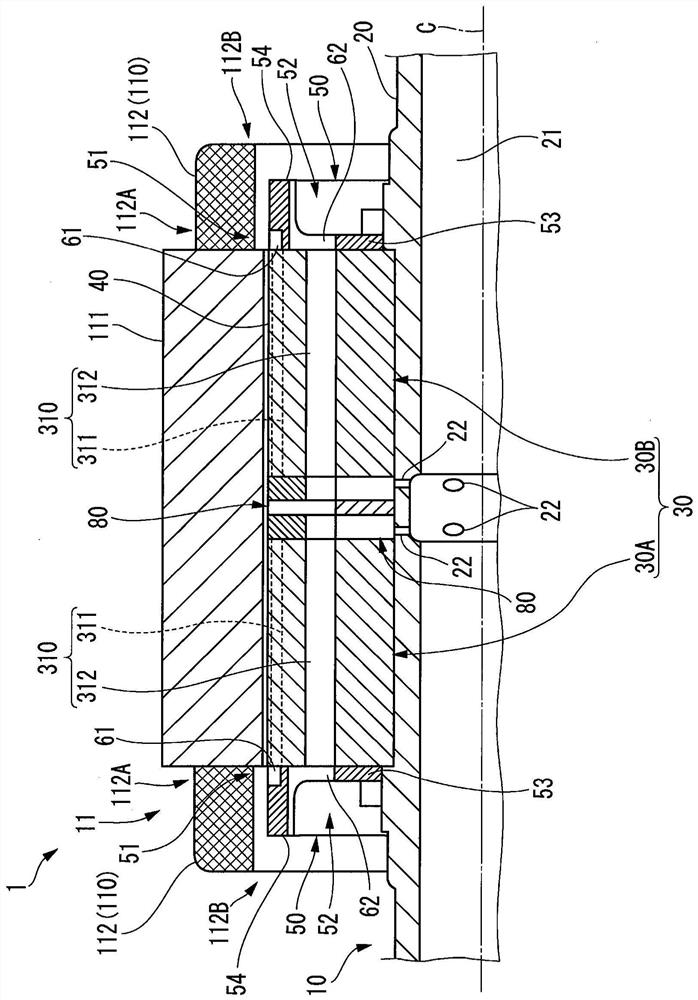

Rotating electric machine

ActiveCN112039246AProper coolingProper supply of cooling mediumMagnetic circuit rotating partsCooling/ventillation arrangementElectric machinePhysics

Provided is a rotating electric machine that is capable of appropriately cooling a coil end portion. The rotating electric machine (1) is provided with a rotor (10) and a stator (11) which face each other with a prescribed gap therebetween in the radial direction. A rotor (10) is provided with: a rotor core (30) having a first cooling medium flow path (311) and a second cooling medium flow path (312); and an end plate (50) disposed on at least one side in the axial direction of the rotor core. A stator is provided with: a stator core (111); and a coil end portion (112) protruding from at leastone axial side of the stator core. The end plate has: a root-side cooling medium supply unit (51) that communicates with the first cooling medium flow path and supplies a cooling medium to a root region (112A) of the coil end; and a tip-side cooling medium supply unit (52) that communicates with the second cooling medium flow path and supplies a cooling medium to a tip region (112B) of the coil end.

Owner:HONDA MOTOR CO LTD

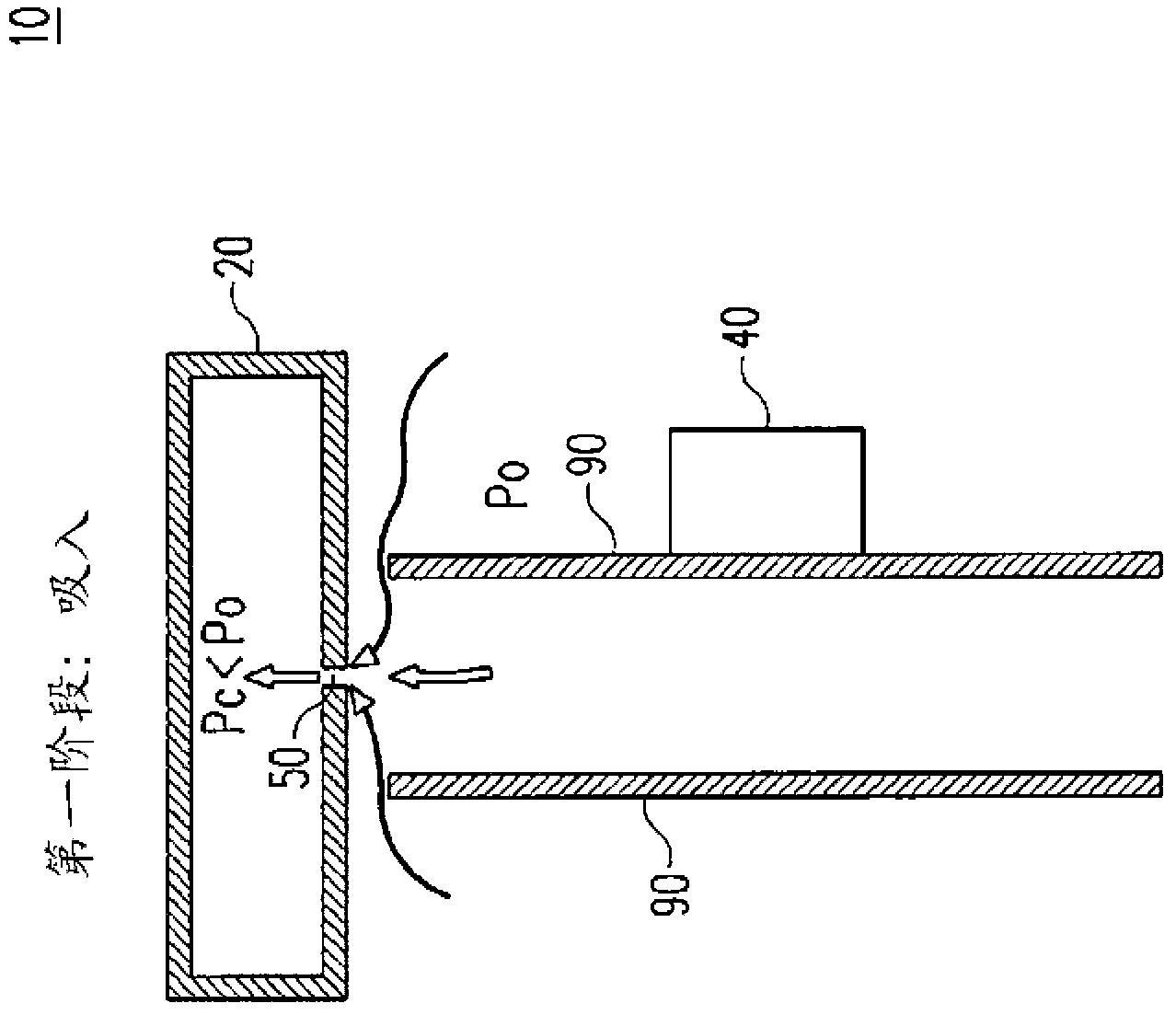

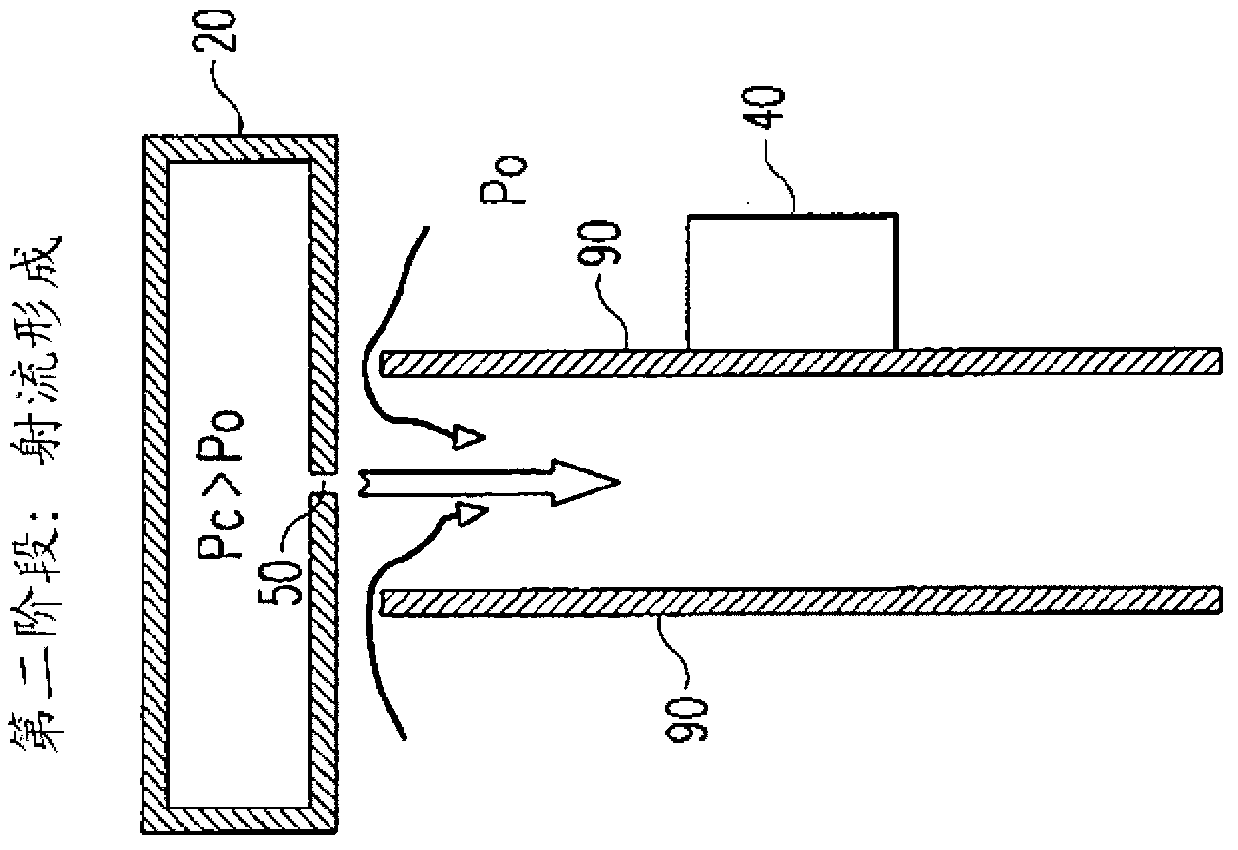

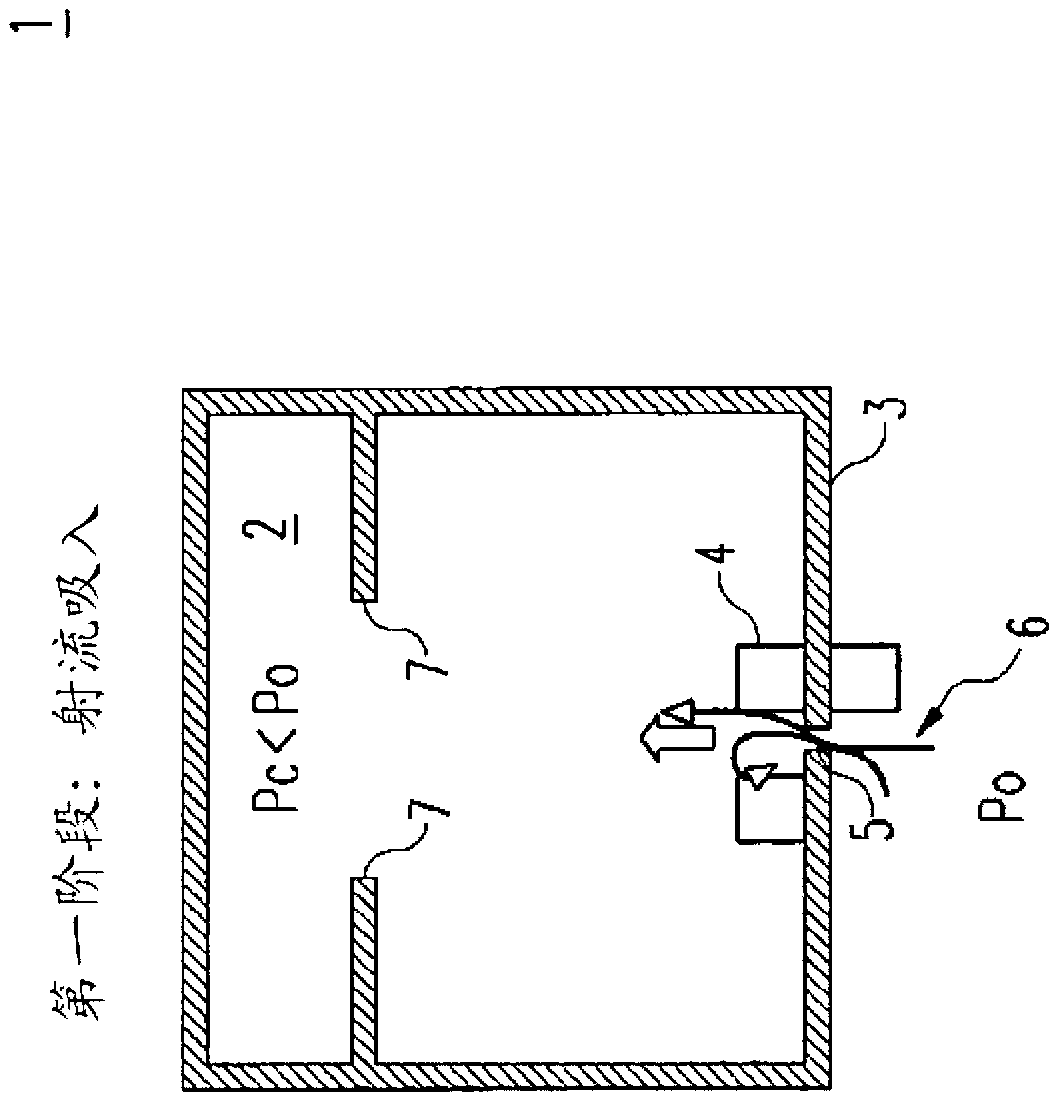

Cooling system and method for electronic components

InactiveCN103299128ACompact structureImprove cooling effectPoint-like light sourceSemiconductor/solid-state device detailsEngineeringElectronic component

The present invention is directed to a cooling system (1) for electronic components (4). The cooling system (1) comprises means (7) for producing cyclic air pressure fluctuations, wherein the electronic components (4) are distanced from the pressure producing means (7). In the vicinity of the electronic components (4) are situated means (5), preferably restrictions like holes, which are affected by the cyclic air pressure fluctuations, and which produce cyclic air jets (6). The air jets (6) affect the surface of the electronic component (4), and since the air jets (6) originate directly in the vicinity of the electronic components (4), an efficient heat transfer is affected. Preferably, the pressure producing means (7) actuate a pressure Pc inside a chamber (2), and turbulent air jets (6) are produced through holes (5) of a substrate (3), onto which electronic components (4) are mounted.

Owner:TRIDONIC JENNERSDORF GMBH

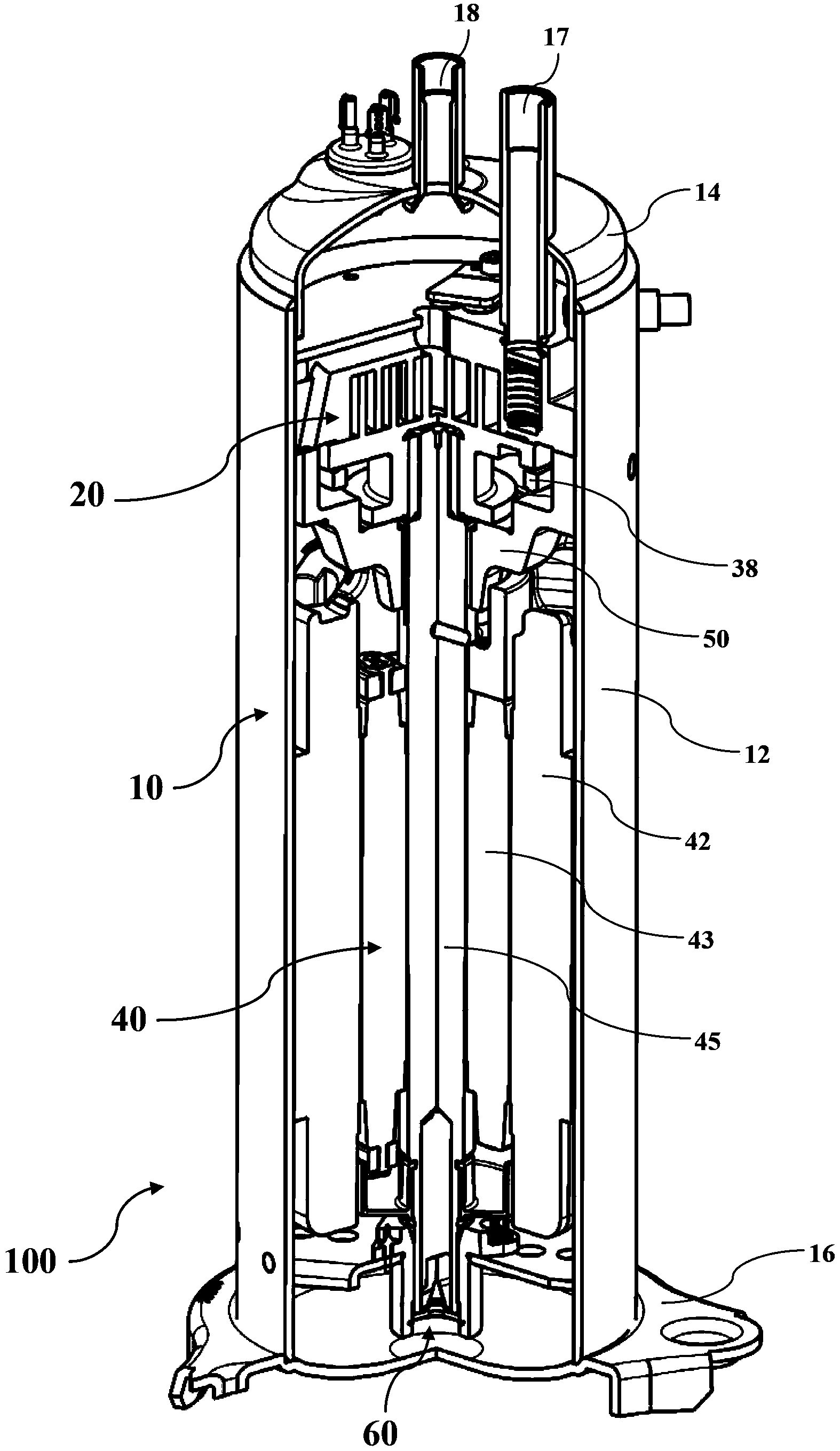

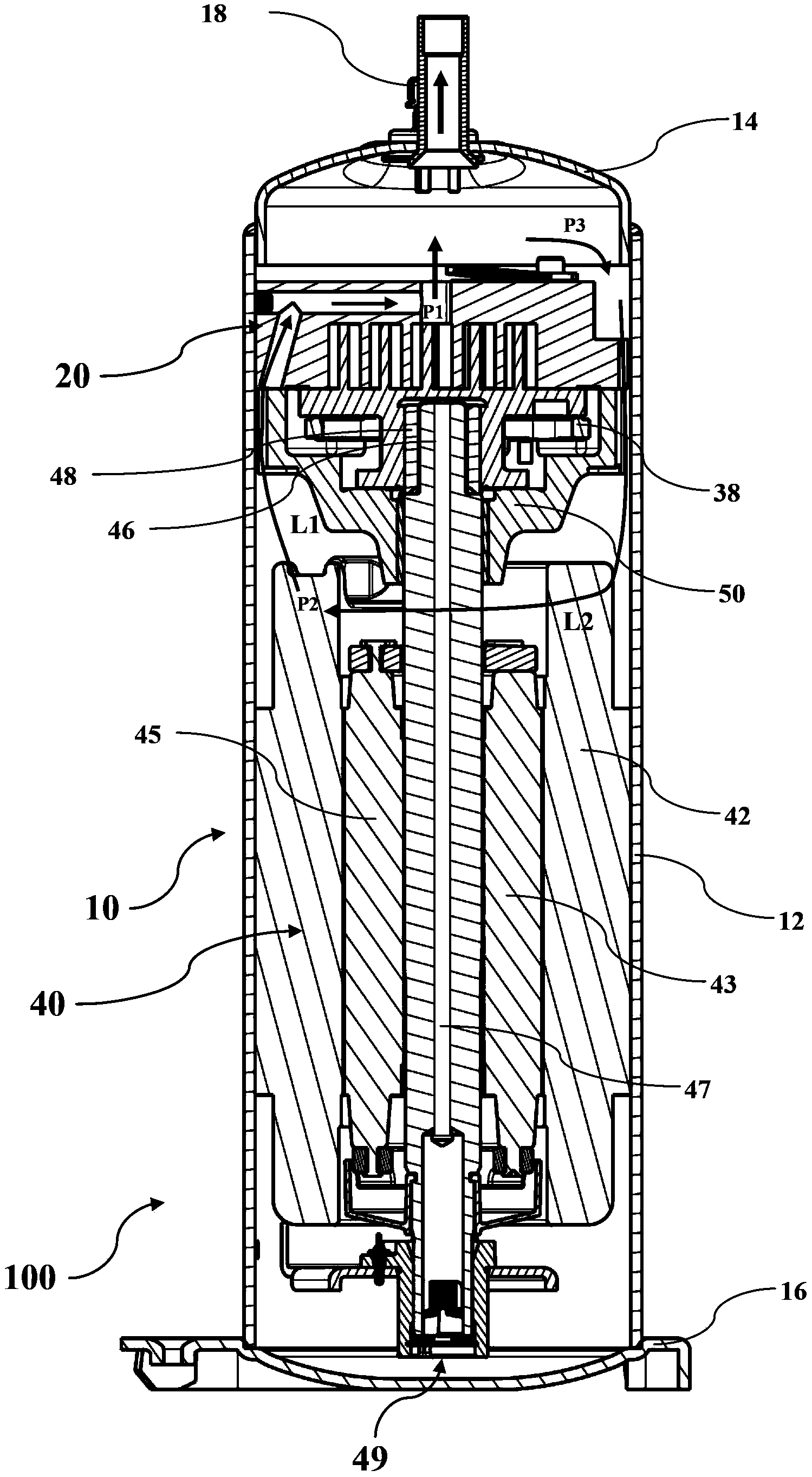

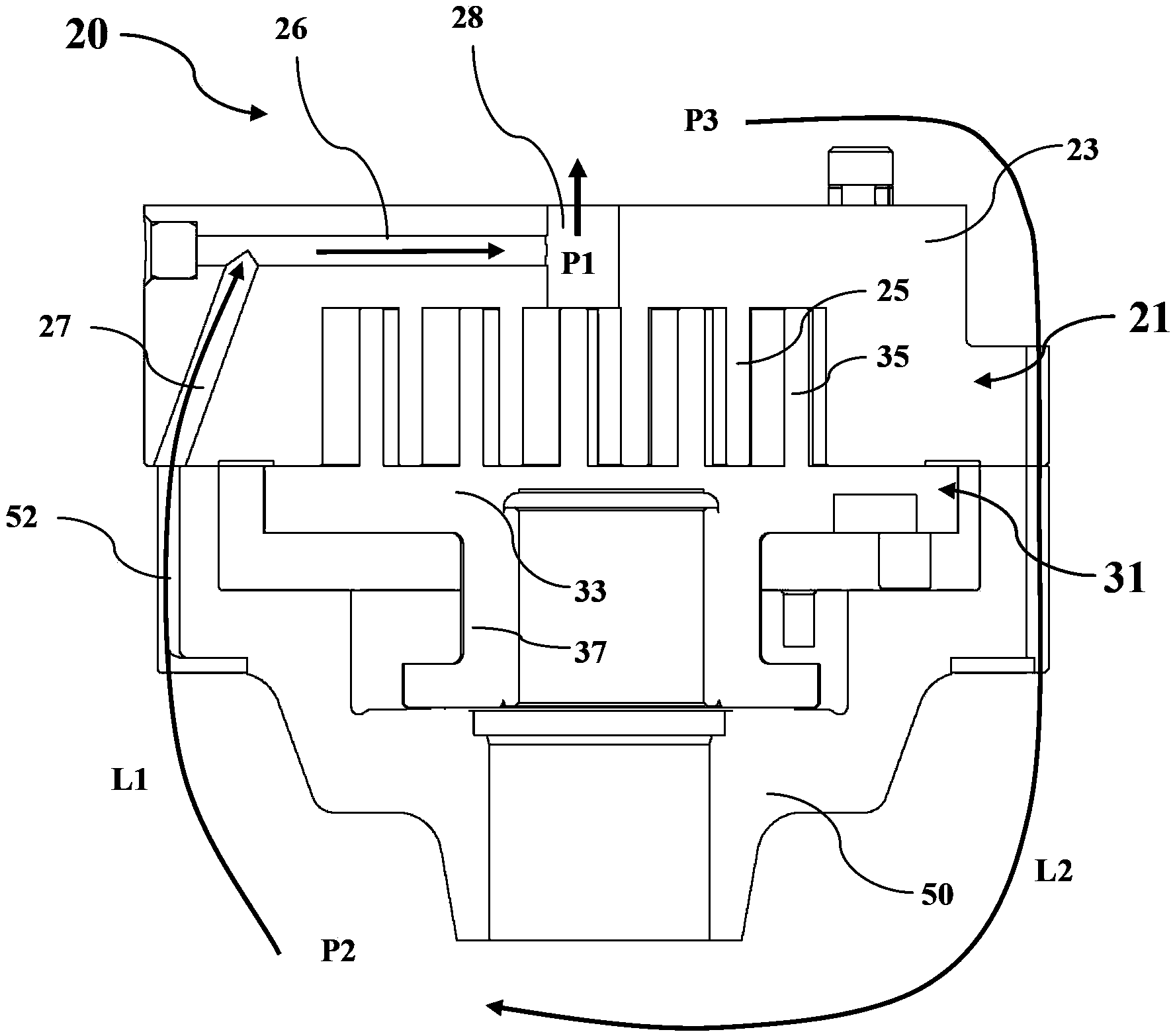

Compressor

ActiveCN103807144AOptimize cooling pathsAchieve coolingPositive displacement pump componentsPositive-displacement liquid enginesEngineering

Owner:EMERSON CLIMATE TECH (SUZHOU) CO LTD

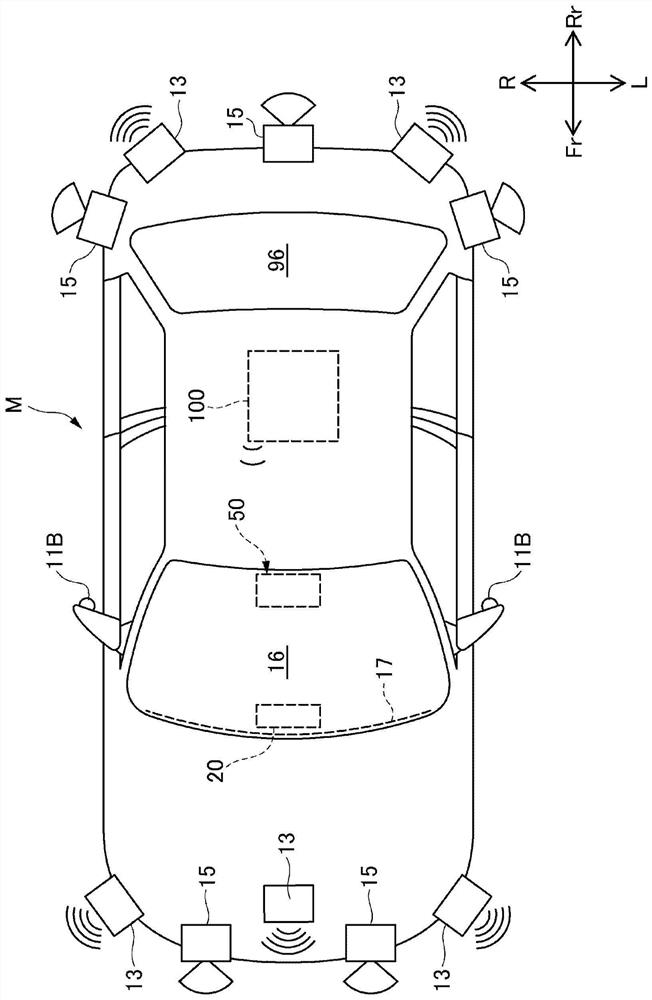

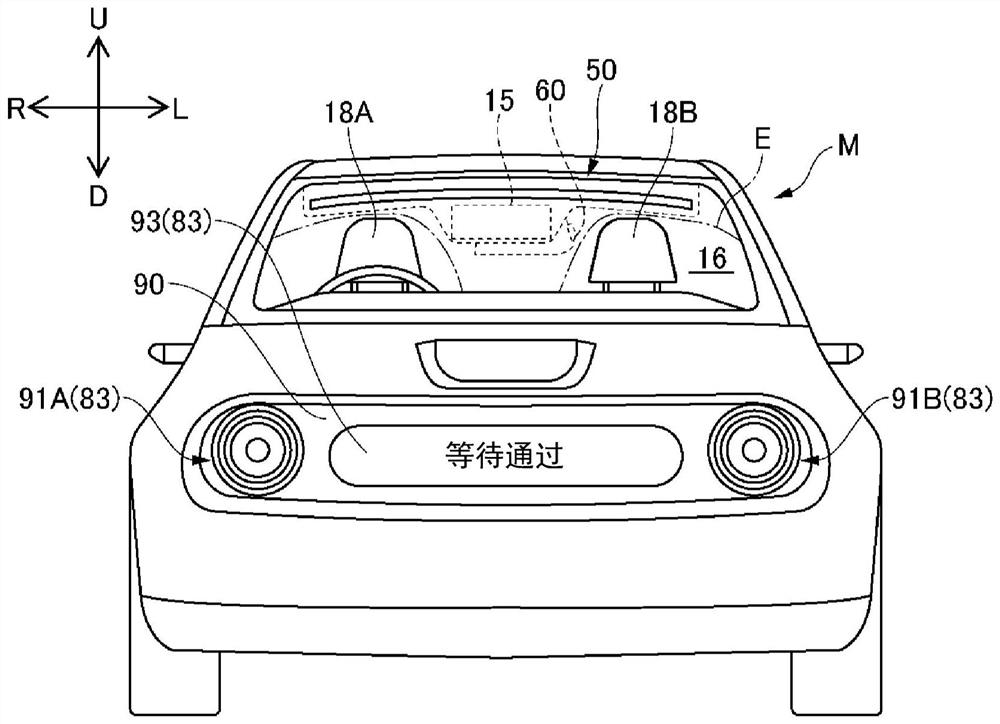

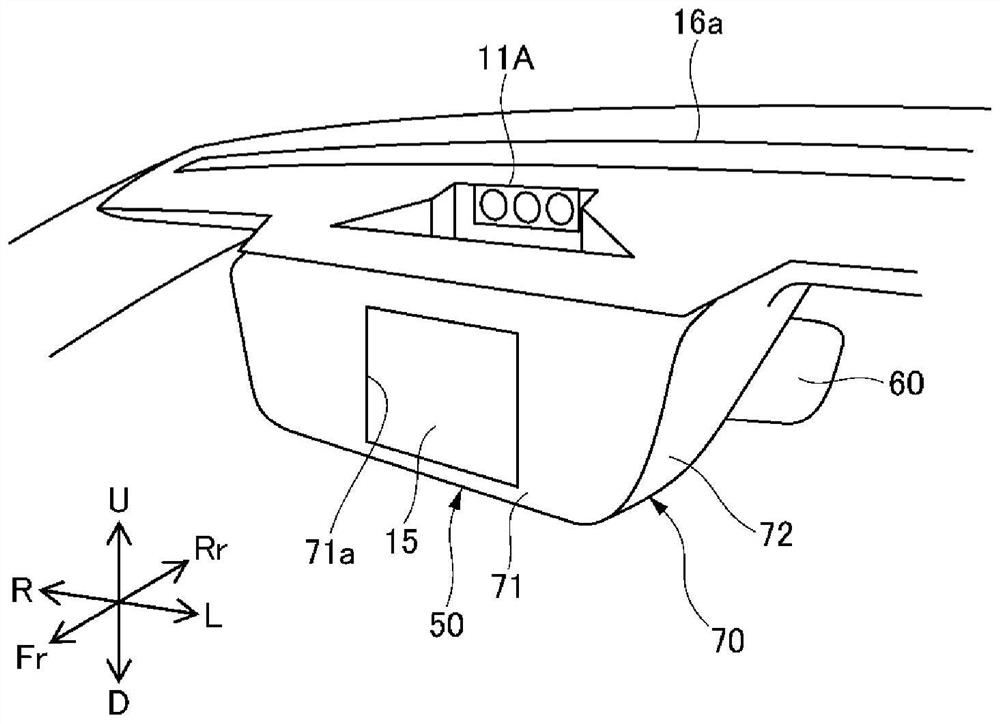

Moving body

PendingCN114126340AImprove cooling effectProper coolingVehicle heating/cooling devicesModifications by conduction heat transferEngineeringMechanical engineering

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com