Stator for rotary electric machine

A technology for a rotating electrical machine and a stator, which is applied in the field of stators and can solve the problems of complicated manufacturing processes of rotating electrical machines, high manufacturing costs, and poor cooling efficiency in slots.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

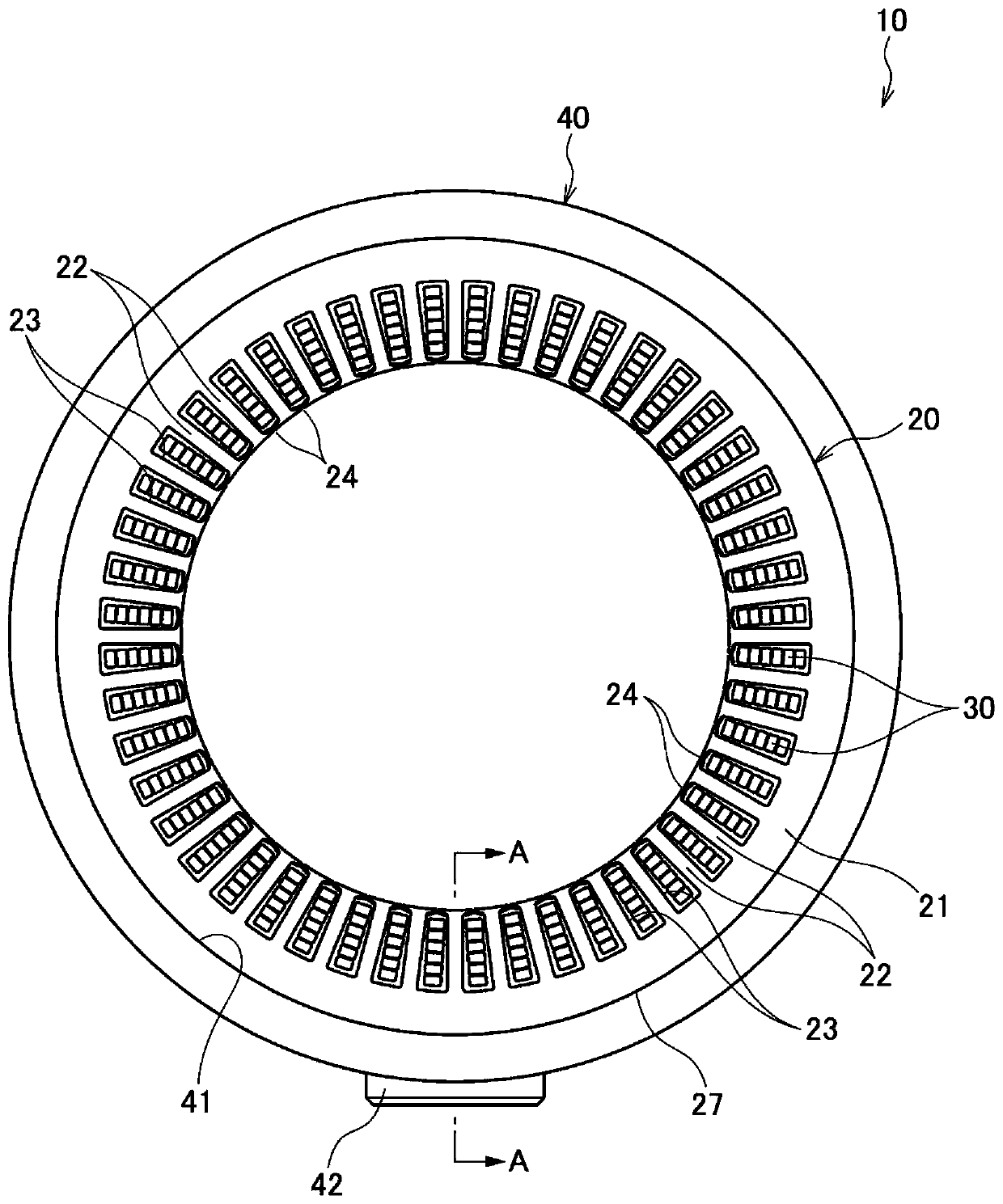

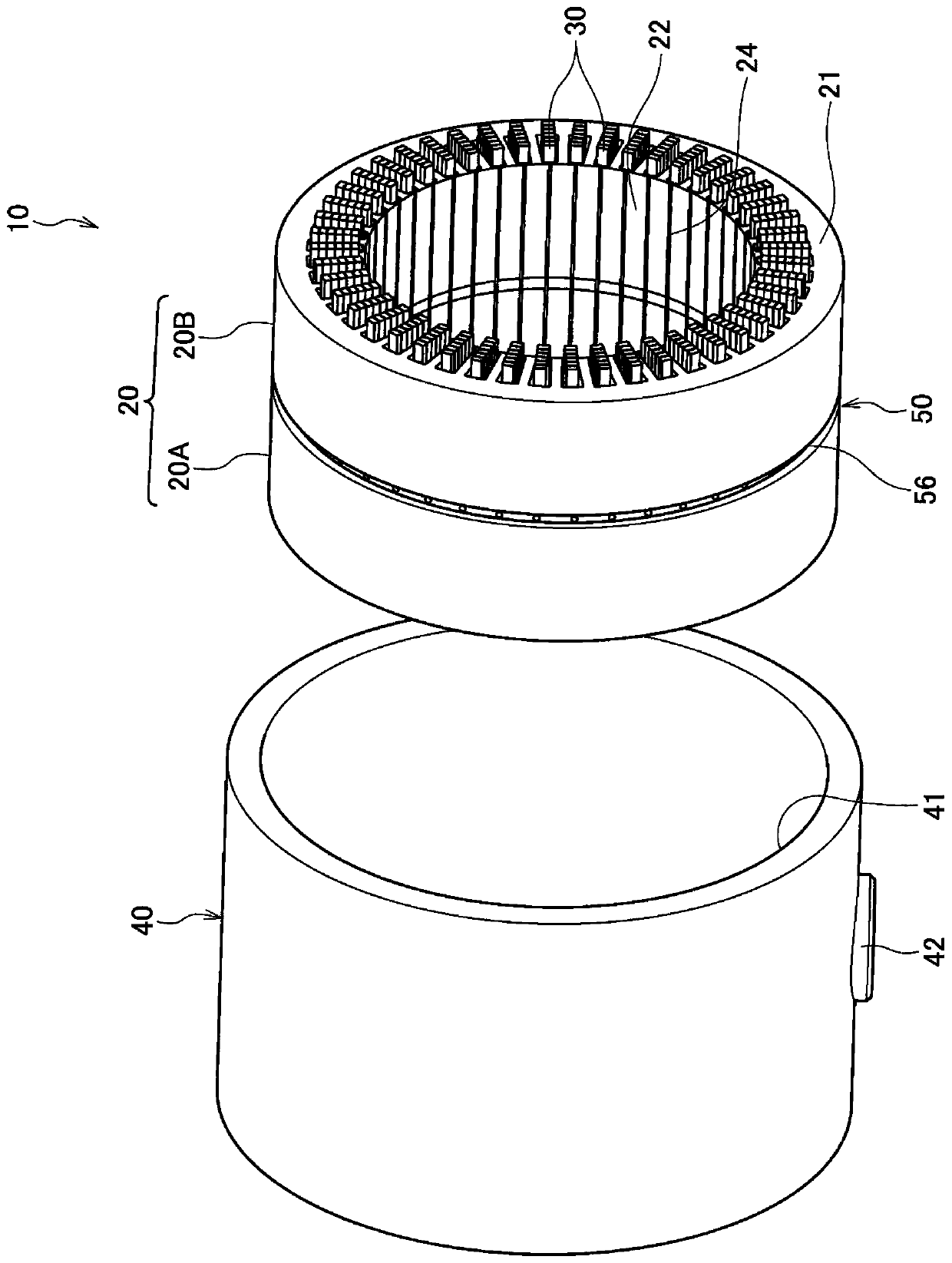

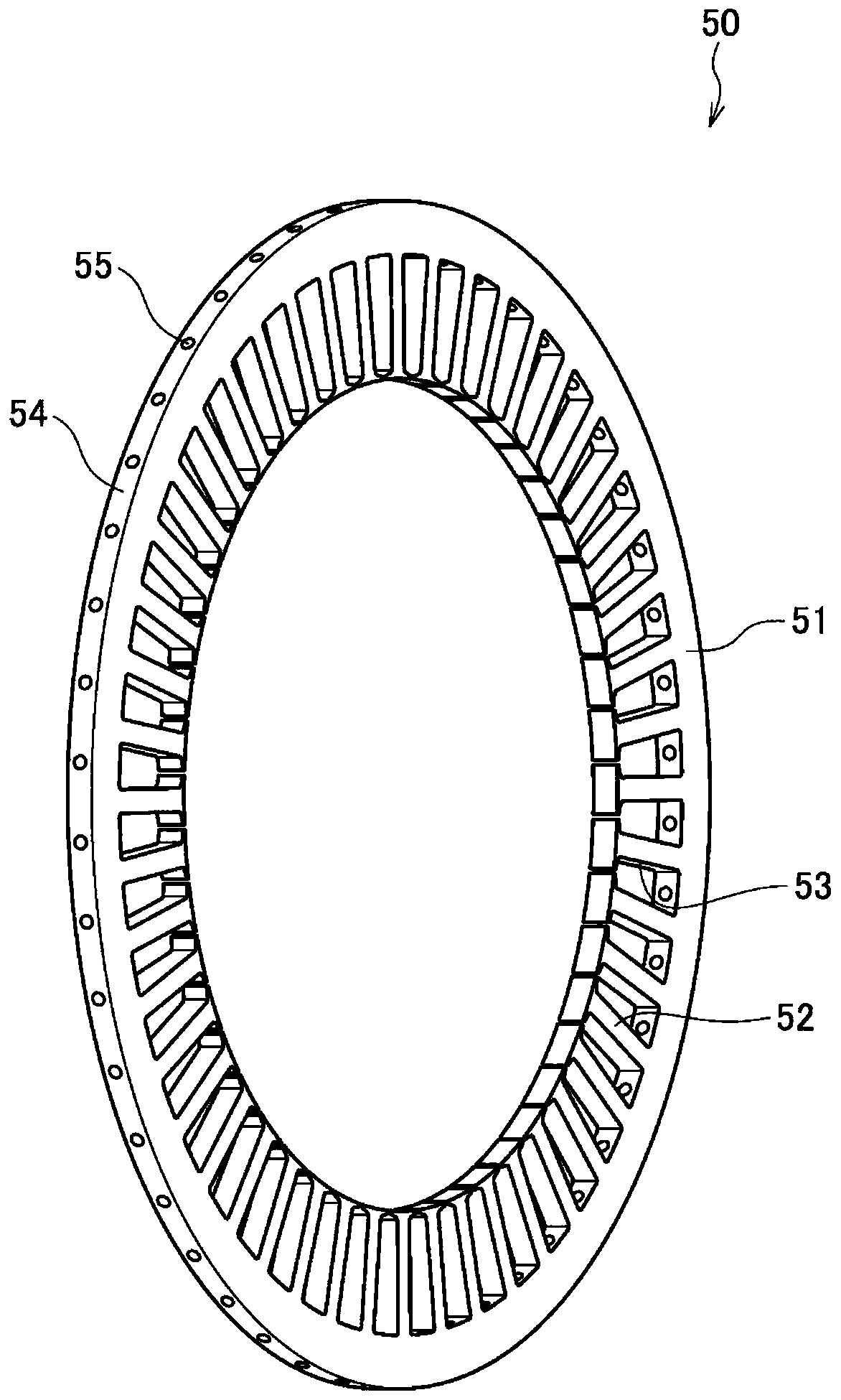

[0045] Below, refer to Figure 1 to Figure 7 , the stator 10 of the rotating electrical machine of this embodiment will be described.

[0046] Such as figure 1 and figure 2 As shown, the stator 10 of the electric rotating machine includes: a stator core 20 ; a coil 30 ; a case 40 holding the stator core 20 ; and a refrigerant distribution plate 50 inserted into the stator core 20 .

[0047] The stator core 20 includes a pair of stator core portions 20A, 20B formed by laminating a plurality of electromagnetic steel sheets. The axial length (stack thickness) of a pair of stator core part 20A, 20B is set to be substantially the same. The pair of stator core parts 20A, 20B is formed by laminating a plurality of electromagnetic steel sheets of the same shape, and has a stator yoke 21 formed in an annular shape, a plurality of teeth 22 protruding radially inward from the stator yoke 21 , and a plurality of slots 23 formed between adjacent teeth 22 . Insulation treatment is per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com