Gas turbine

A gas turbine and combustion gas technology, which is applied in the direction of gas turbine devices, mechanical equipment, engine functions, etc., can solve the problems of reduced air for combustion, longer start-up time, and rise in combustion temperature, so as to suppress the increase of NOx emissions and suppress the output Inefficiency and the effect of suppressing pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

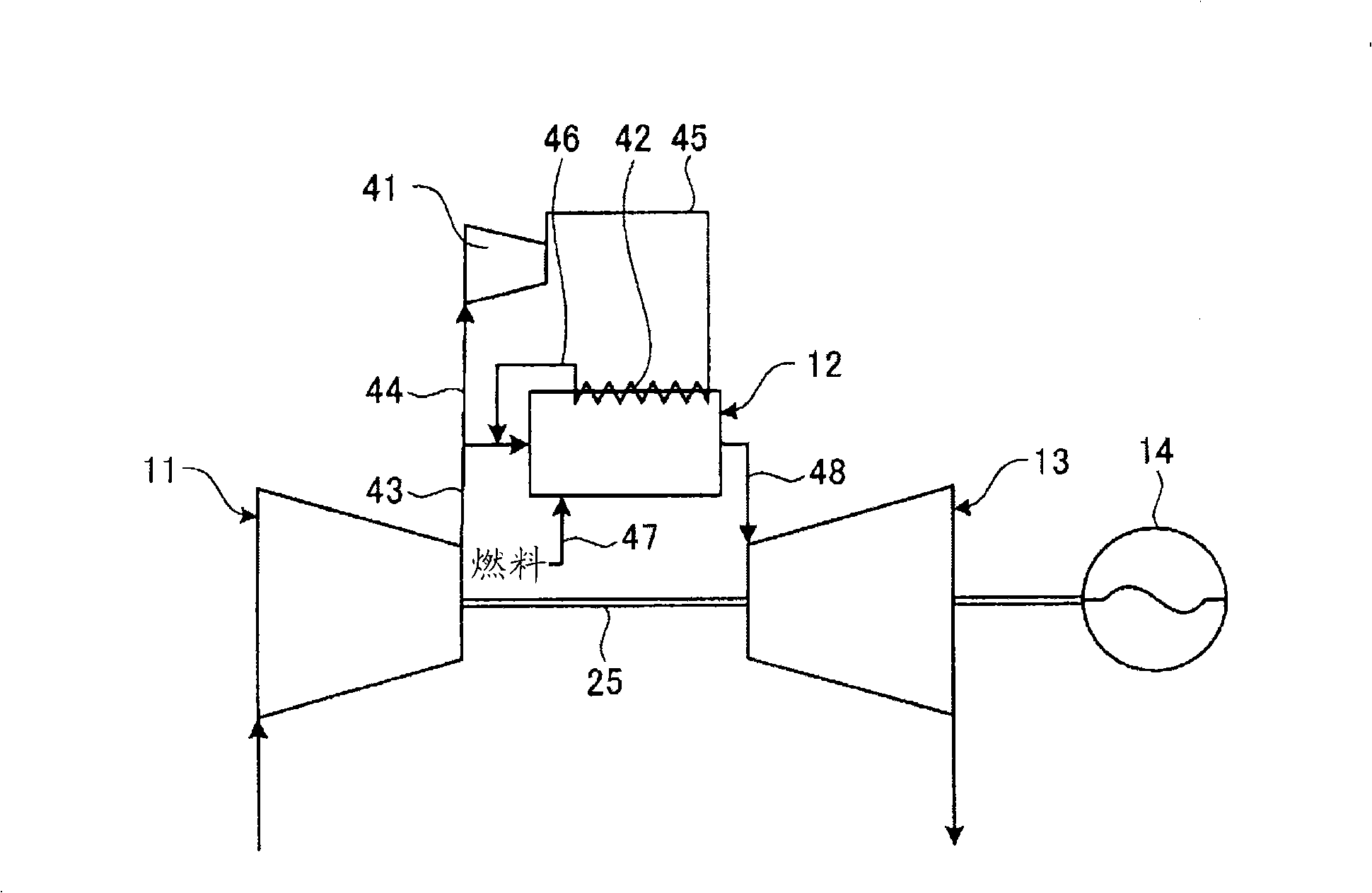

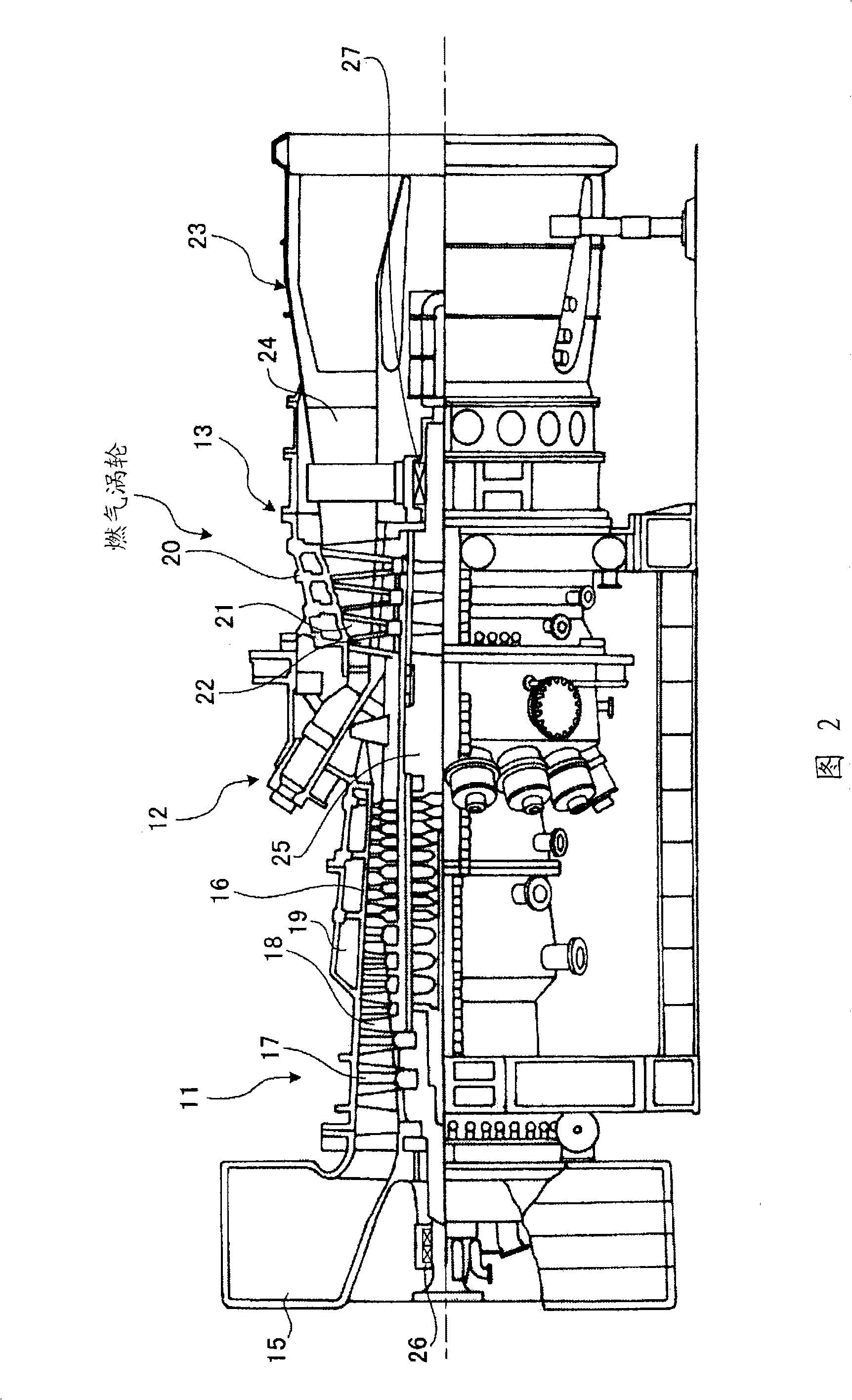

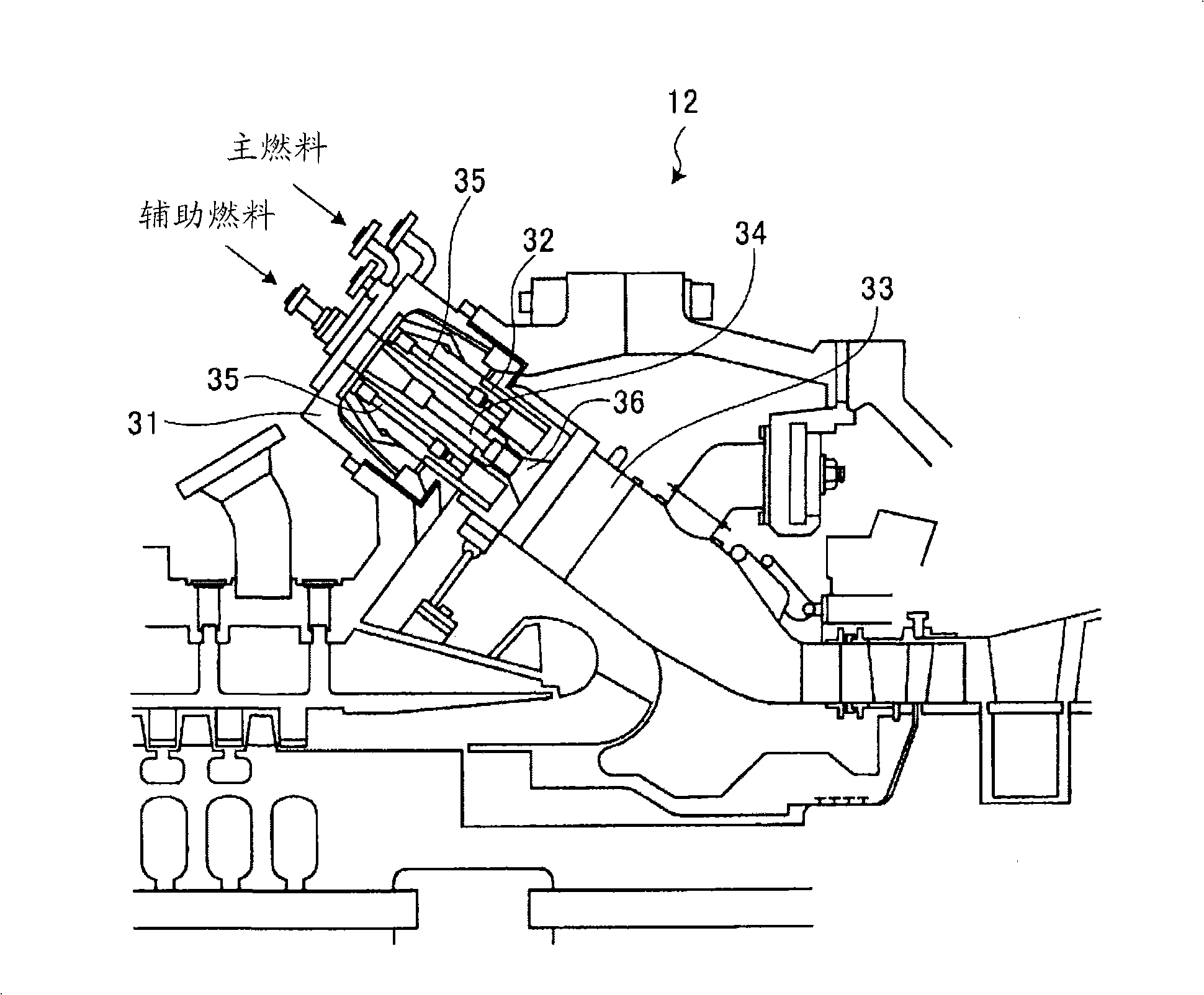

[0069] figure 1 is a schematic diagram showing a gas turbine according to Embodiment 1 of the present invention, figure 2 is a schematic configuration diagram showing the gas turbine of Embodiment 1, image 3 It is a schematic configuration diagram showing the combustor of the gas turbine of the first embodiment.

[0070] Such as figure 1 and figure 2 As shown, the gas turbine in Embodiment 1 is composed of a compressor 11 , a combustor 12 , and a turbine 13 , and a generator 14 is connected to the turbine 13 . The compressor 11 has an air inlet 15 for taking in air, and a plurality of fixed impellers 17 and moving impellers 18 are arranged alternately in a compressor cylinder chamber 16 , and an air extraction manifold 19 is provided outside the compressor cylinder chamber 16 . The combustor 12 supplies fuel to the compressed air compressed by the compressor 11, and ignites it with a torch to burn it. In the turbine 13 , a plurality of fixed impellers 21 and movable im...

Embodiment 2

[0084] Pic 4-1 is a schematic view showing a combustor cooling device for a gas turbine according to Embodiment 2 of the present invention, Figure 4-2 to Figure 4-4 It is a schematic diagram showing a modified example of the gas turbine combustor cooling device of the second embodiment. Components having the same functions as those already described in the above-mentioned embodiments are assigned the same reference numerals, and redundant descriptions are omitted.

[0085] Such as Pic 4-1 As shown, in the gas turbine of Embodiment 2, the combustor cooling device 51 is a plurality of cooling passages formed in the wall portion of the inner tube 52 constituting the combustor 12 . Specifically, in the combustor cooling device 51 , a plurality of cooling passages 53 are formed in the wall portion of the inner tube 52 along its longitudinal direction (flow direction of combustion gas). Further, an annular head 54 is fixed to the outer peripheral portion of the inner cylinder ...

Embodiment 3

[0096] Figure 5 is a schematic diagram showing a gas turbine according to Embodiment 3 of the present invention. Components having the same functions as those already described in the above-mentioned embodiments are assigned the same reference numerals, and redundant descriptions are omitted.

[0097] Such as Figure 5 As shown, in the gas turbine of Embodiment 3, the compressor 11 is connected to the combustor 12 via the compressed air supply line 43 , and is connected to the pressure booster 41 via the compressed air branch line 44 branching off from the compressed air supply line 43 , the pressure booster 41 is connected to the burner cooling device 42 via the cooling air supply line 45, the water supply line 71 is connected to the cooling air supply line 45, and the water injection device (moisture addition mechanism) is installed on the water supply line 71. )72. In addition, the combustor cooling device 42 is connected to the compressed air supply line 43 via the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com