Cooling device with a plurality of fin pitches

A cooling device and fin spacing technology, applied in cooling/ventilation/heating transformation, heat sinks, indirect heat exchangers, etc., can solve the problems of larger cooling device size, difficulty in ensuring installation space, and high power consumption for driving fans. , to achieve the effect of suppressing temperature rise, saving installation space, and realizing cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

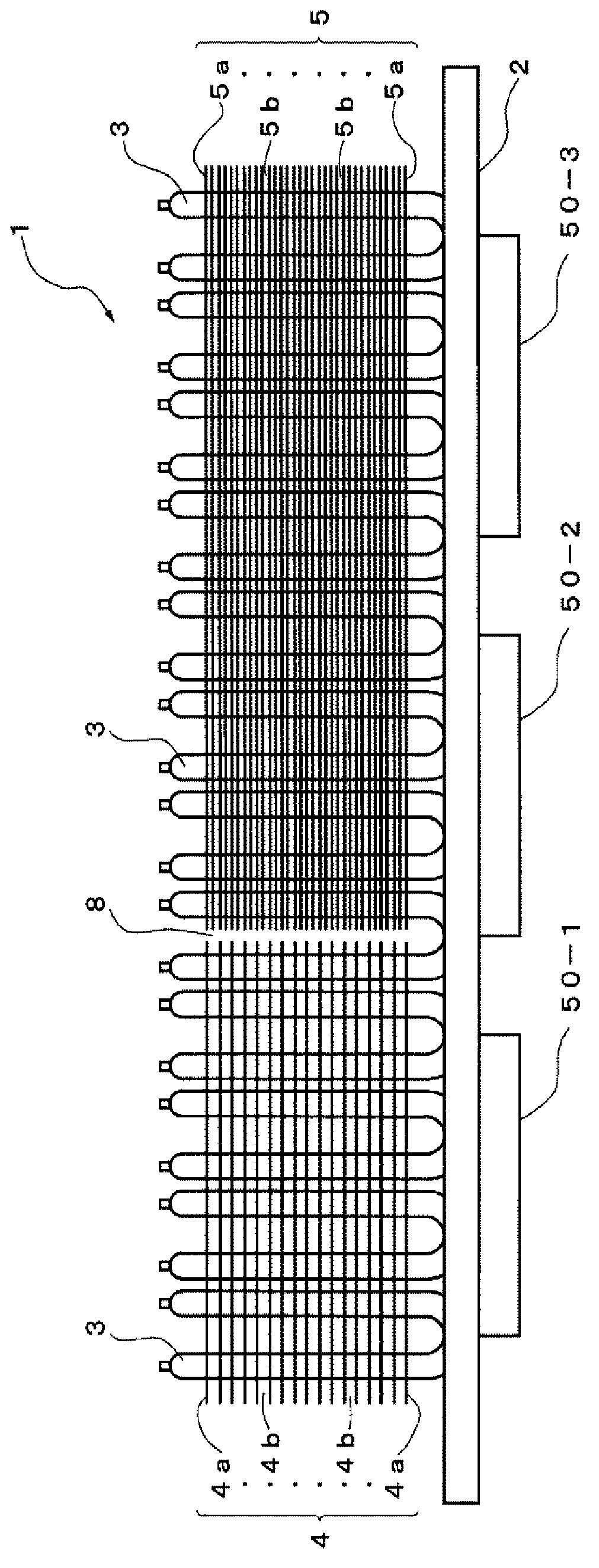

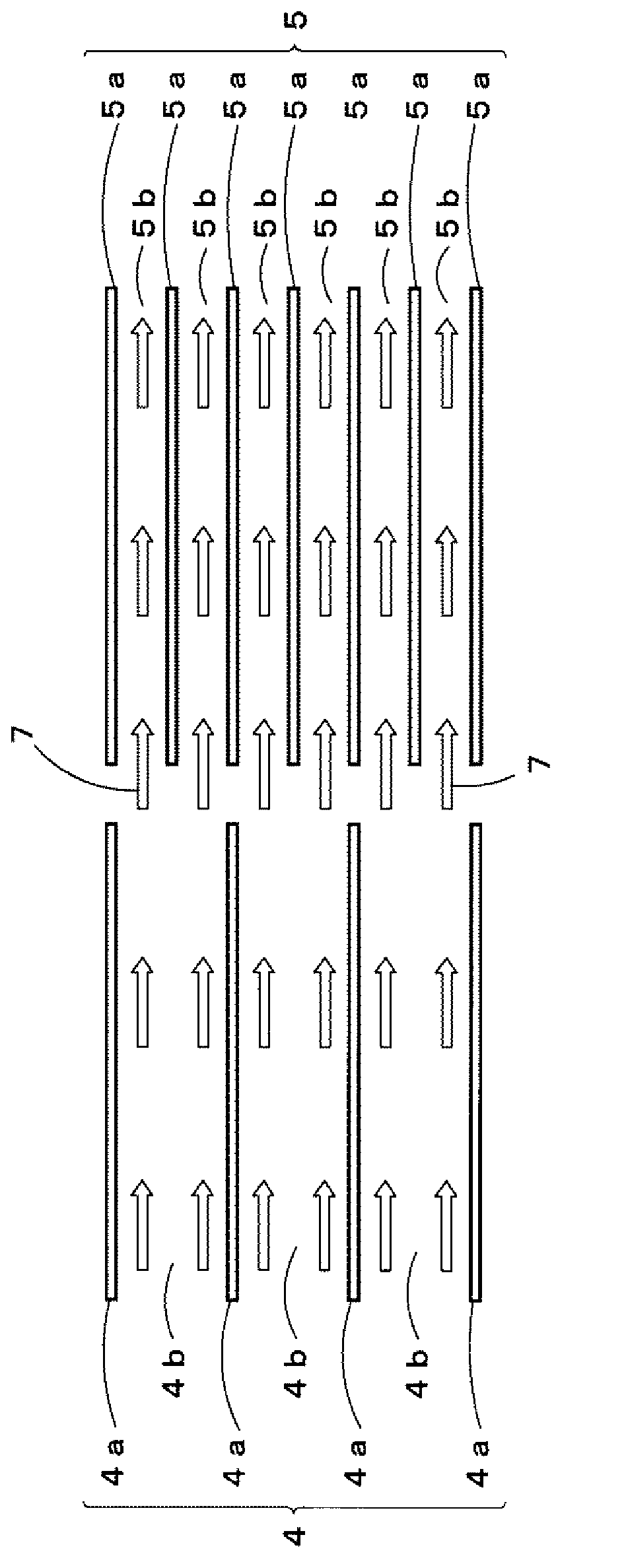

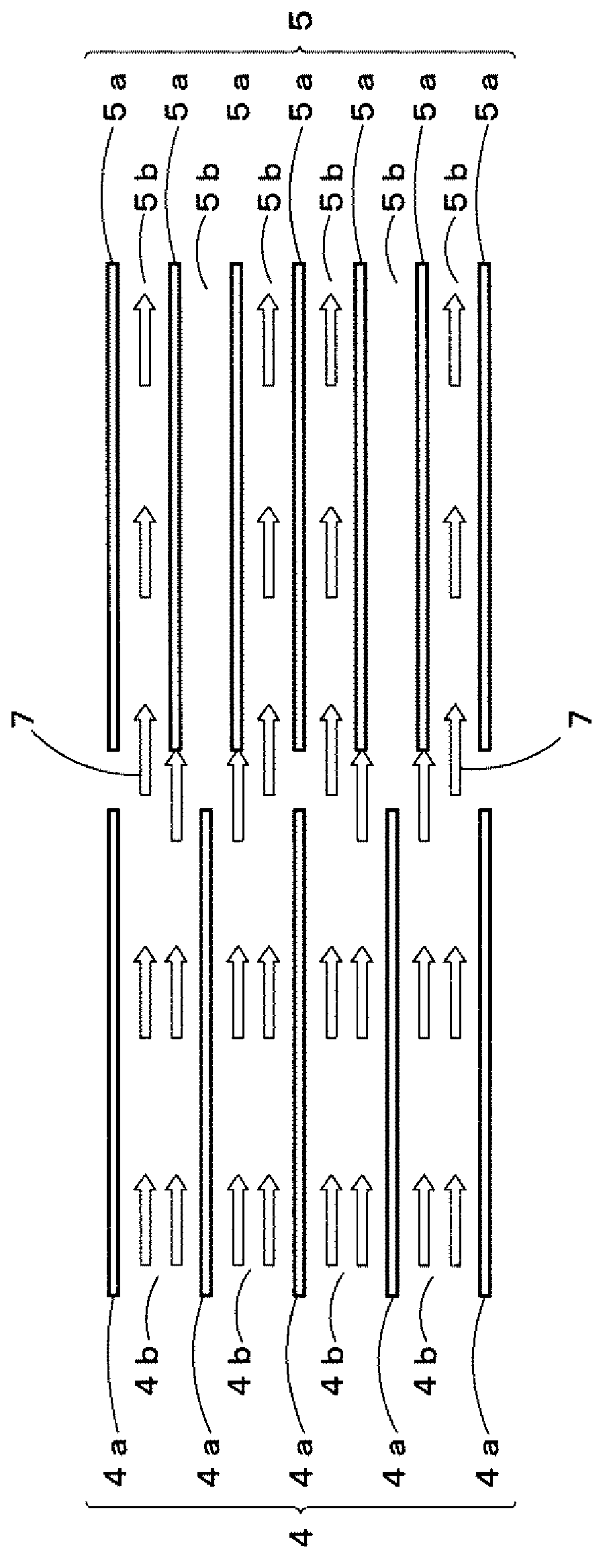

[0036] Hereinafter, a cooling device according to a first embodiment of the present invention will be described using the drawings. Such as figure 1 As shown, the cooling device 1 of the first embodiment of the present invention is a heat pipe cooling device, including a flat heat receiving block 2, and a plurality of U-shaped heat pipes installed in the vertical direction on the surface of the heat receiving block 2 3. The first cooling fin group 4 and the second cooling fin group 5 installed on the heat pipe 3 . The first cooling fin group 4 includes a plurality of ( figure 1 17 among them) the first fin 4a, the first fin 4a is a rectangular thin plate. The second cooling fin group 5 includes a plurality of ( figure 1 33 among them) the second fin 5a, the second fin 5a is a rectangular thin plate.

[0037] And, on the side that heat pipe 3 is not installed, i.e. the back side of heat receiving block 2, figure 1 From left to right, thermally connect the body to be co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com