Patents

Literature

161results about How to "Solve Cooling Problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

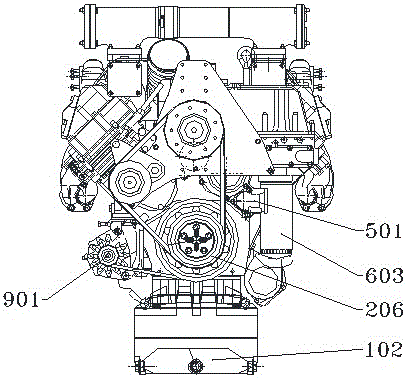

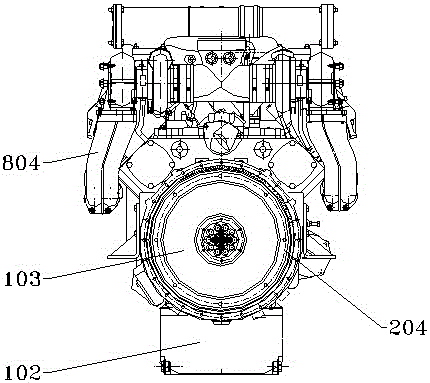

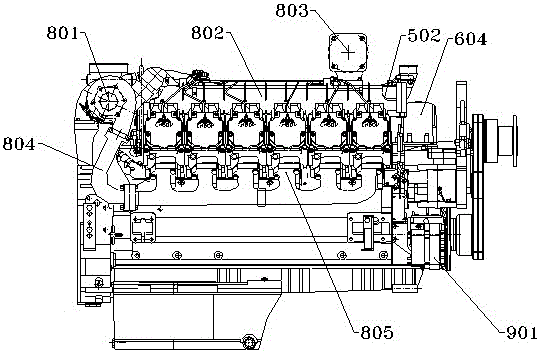

12-cylinder water cooling diesel engine

The invention discloses a 12-cylinder water cooling diesel engine. The engine comprises a crank connecting rod mechanism arranged on a fixed part, a gas distribution mechanism, a transmission mechanism, a cooling system, a lubricating system, a fuel supply system, an intake / exhaust system, an electric system and a starting mechanism. The water cooling engine widens the power range, increases the power from traditional 195-499 kW to 780 kW, preferably exerts the characteristics of high power, small size, compact structure and low fuel consumption of the series of diesel engines, adapts to the market demands, satisfies the use requirements of users, is better in market competitiveness, can be applied to such fields as engineering machinery and generator sets, and widens the application field of 132-series engines.

Owner:HEBEI HUABEI DIESEL ENGINE

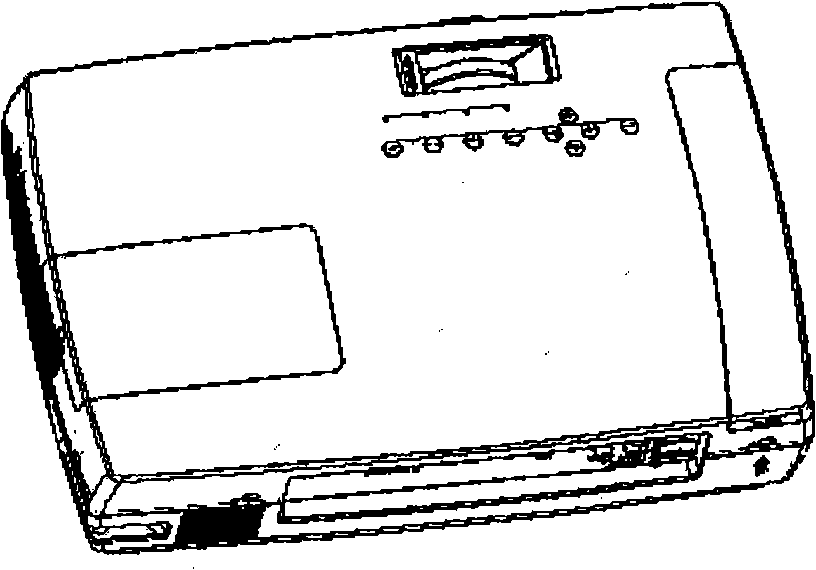

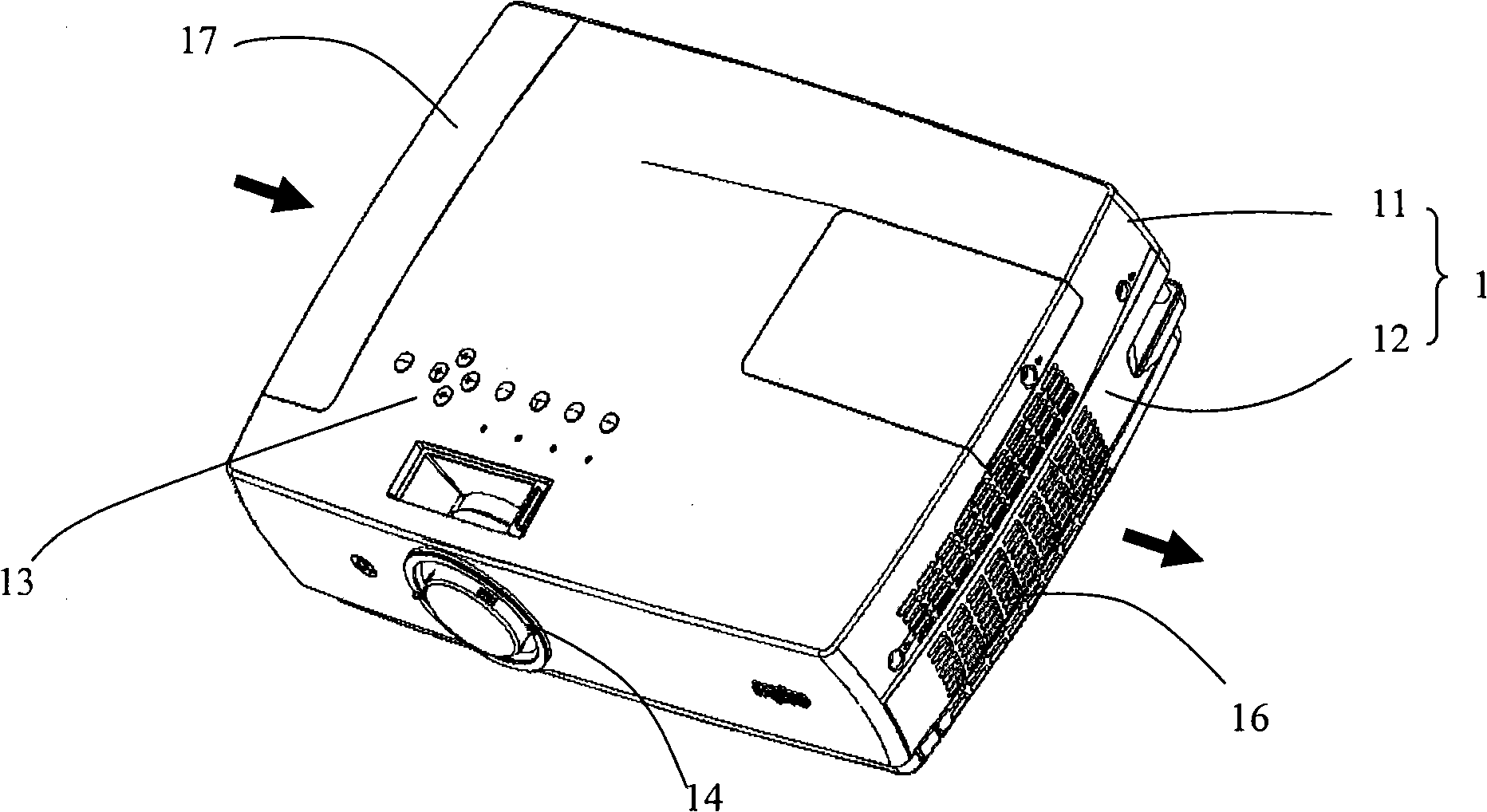

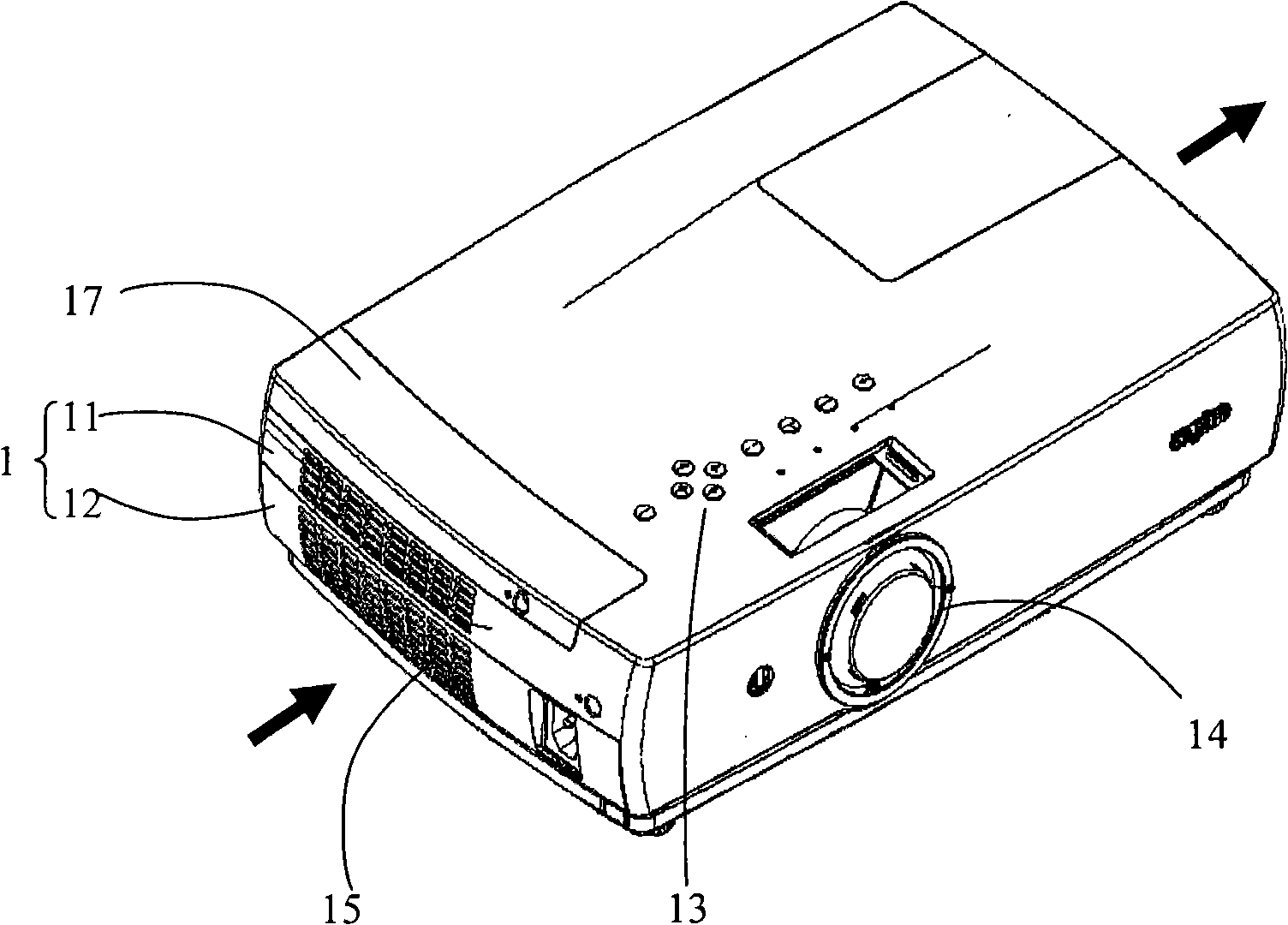

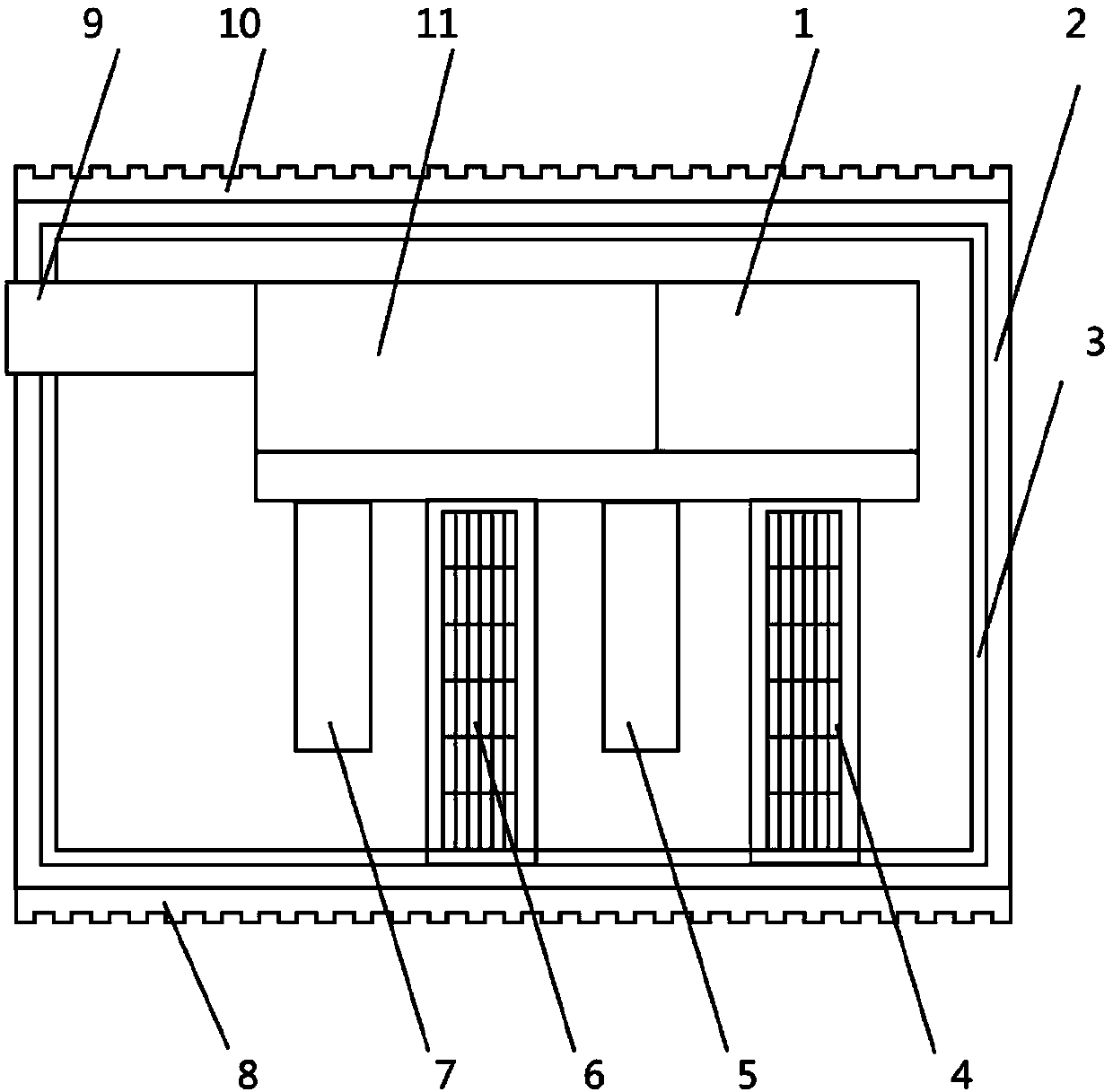

Cooling system and projecting apparatus adopting same

ActiveCN101576706AAvoid enteringImprove dust resistanceProjectorsCooling/ventilation/heating modificationsWaste managementAir channel

The invention provides a cooling system and a projecting apparatus adopting the same. The projecting apparatus comprises a shell and also comprises optical components, a lamp bulb assembly and a power supply component which are arranged in the shell. The cooling system comprises an air inlet, an air outlet, a dust preventing component, a cooling air channel, a lamp bulb component air-cooling unit, a power supply air-cooling unit and an exhauster; the air inlet and the air outlet are respectively arranged at two opposite narrower sides of the shell; the dust preventing component is arranged in the shell and clings to the air inlet; the cooling air channel clings to the dust preventing component and is internally provided with a plurality of fans and air guiding pipes which correspond to the fans, wherein the air guiding pipes lead to all the optical components; the lamp bulb component air-cooling unit and the power supply air-cooling unit collect the air-cooled exhausted air at the air outlet; and the exhauster is arranged in the shell and near to the air outlet and discharges the collected exhausted air out of the shell. When the dust is prevented, heating components in the projecting device are fully cooled, and local hot air accumulation is avoided.

Owner:SANYO TECH CENT SHENZHEN +1

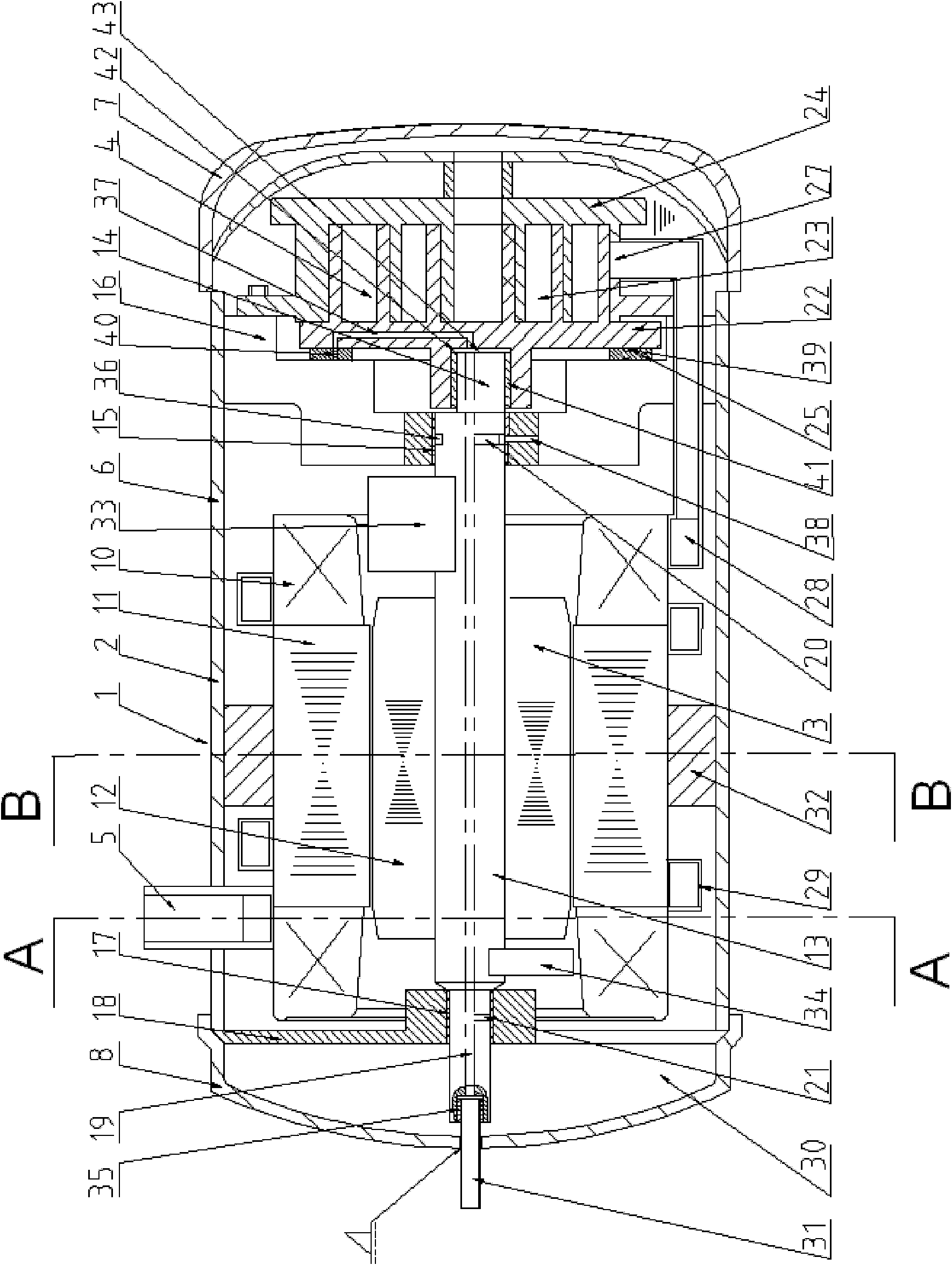

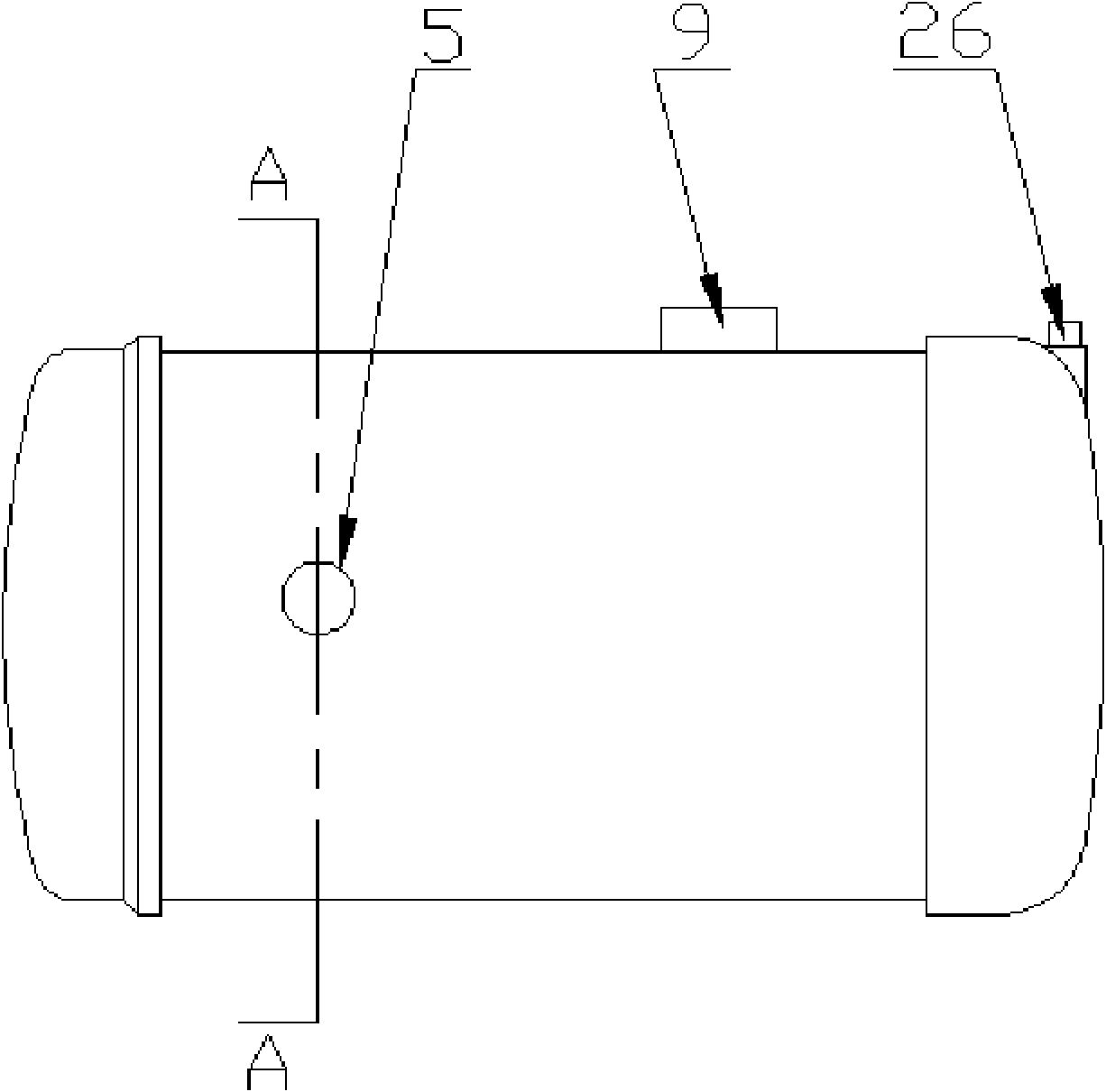

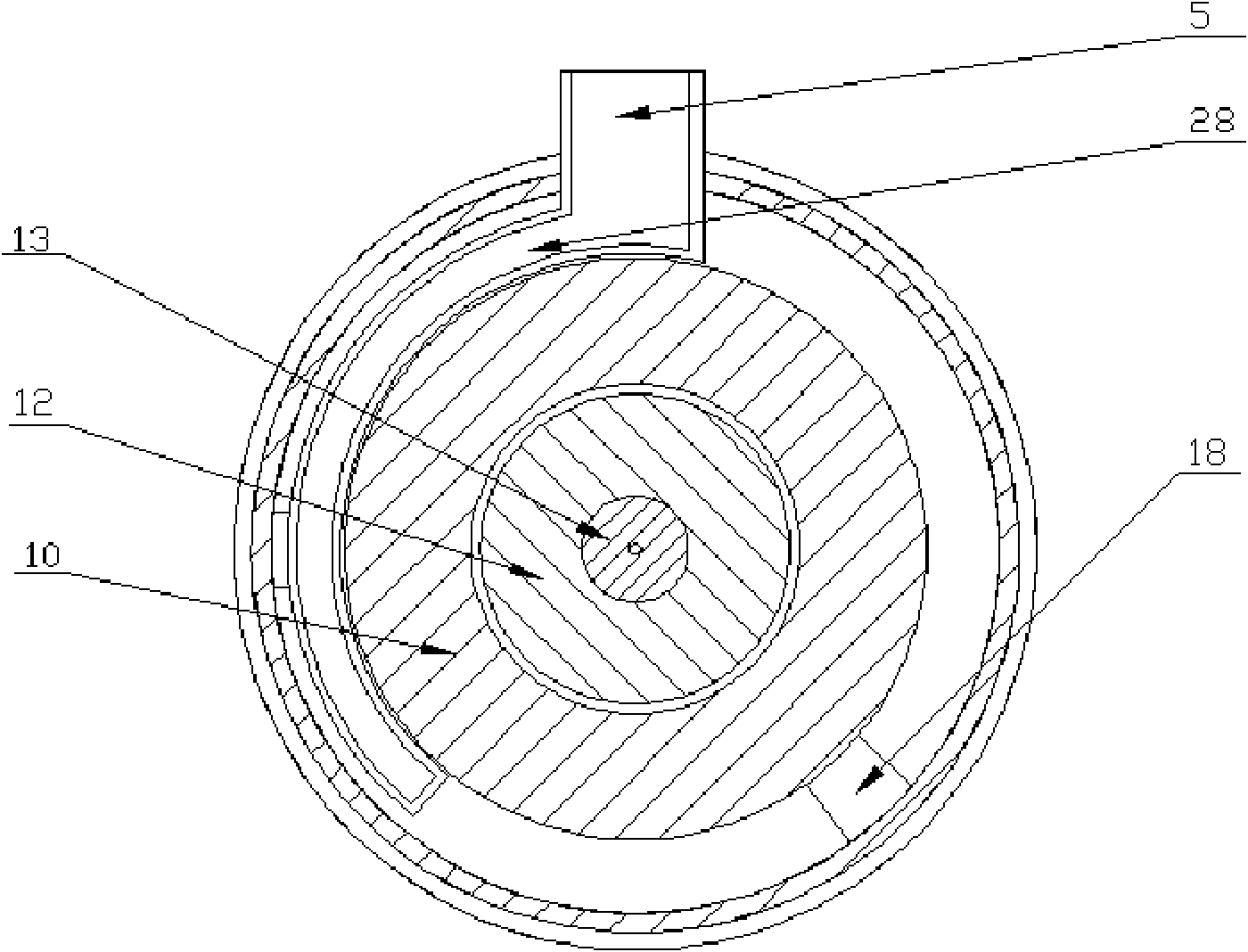

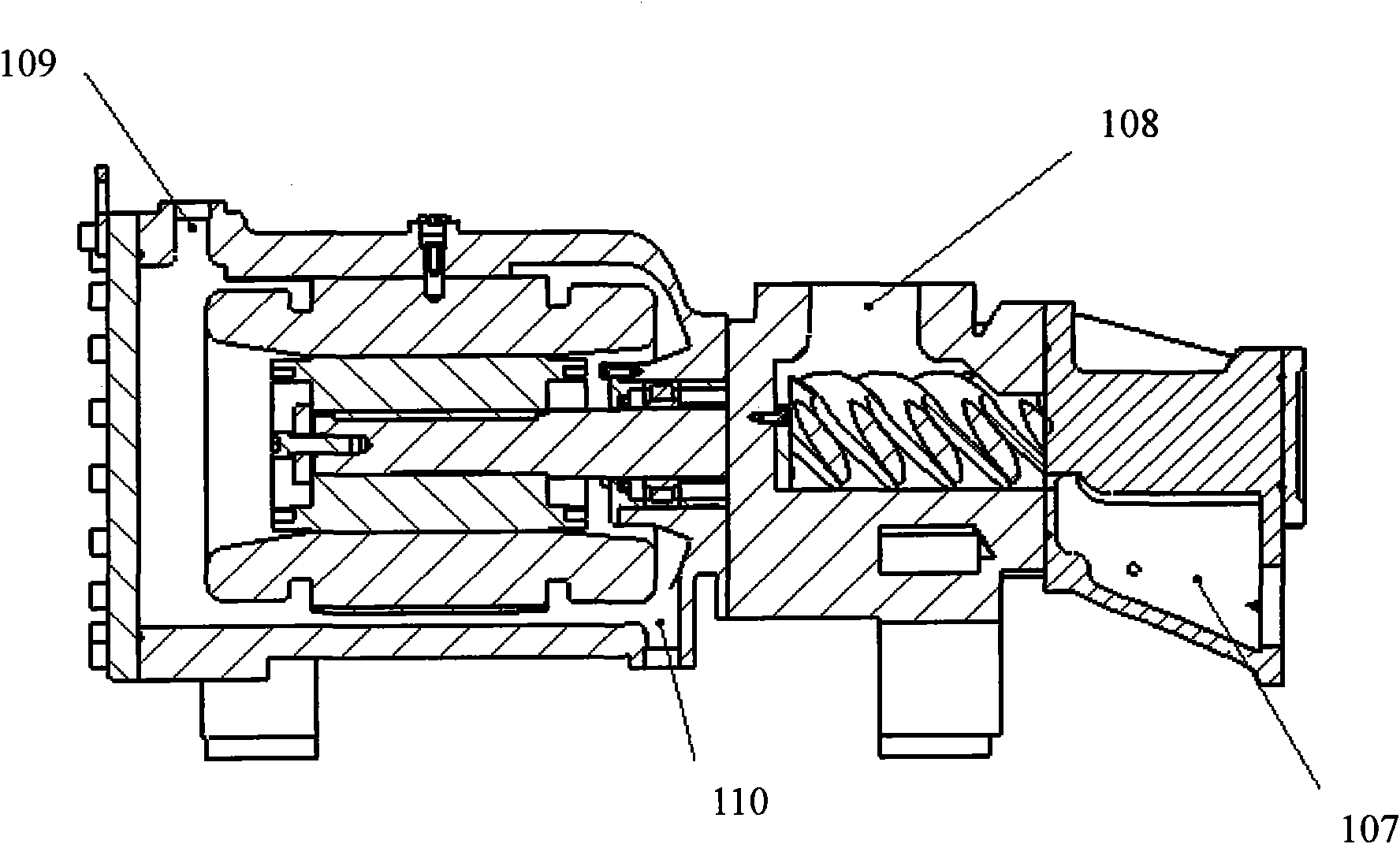

Fully-closed horizontal oil-injection scroll compressor

InactiveCN102032177ASolve Cooling ProblemsRotary piston pumpsRotary piston liquid enginesLubricationOil separation

The invention discloses a fully-closed horizontal oil-injection scroll compressor, which is an oil circulating system which can guarantee tightness of the compressor and lubrication of a bearing stress surface and the like and unifies lubrication of the bearing stress surface and oil-injection cooing of a compression cavity by a pressure difference at the same time. Under the action of the pressure difference, lubricating oil enters a central oil hole of a rotation shaft through an oil injection pipe, and then is supplied to the position to be lubricated through an oil hole, an oil guide channel inside a dynamic scroll, and other mechanisms, and finally falls back into an oil pool at the bottom of a shell under the action of the gravity after lubrication. Part of air inlet guide pipes with a porous structure are immersed into the oil pool at the bottom of the shell, and the lubricating oil enters the air inlet guide pipe through small holes, and is carried into the compression chamber, and the mixture of the lubricating oil and gas is discharged after the lubricating oil cools the compression chamber. After the mixture is subjected to gas-oil separation and the lubricating oil is cooled, the lubricating oil is injected into the central oil hole of the rotation shaft by the oil injection pipe for recycling. As the compression chamber is internally cooled by injecting oil on the premise of a fully-closed structure, the fully-closed horizontal oil-injection scroll compressor is particularly suitable for gases (such as natural gas, helium gas and the like) which have strict requirements on compression tightness and of which compression heat is high due to high isentropic indexes.

Owner:西安昊成能源科技有限公司

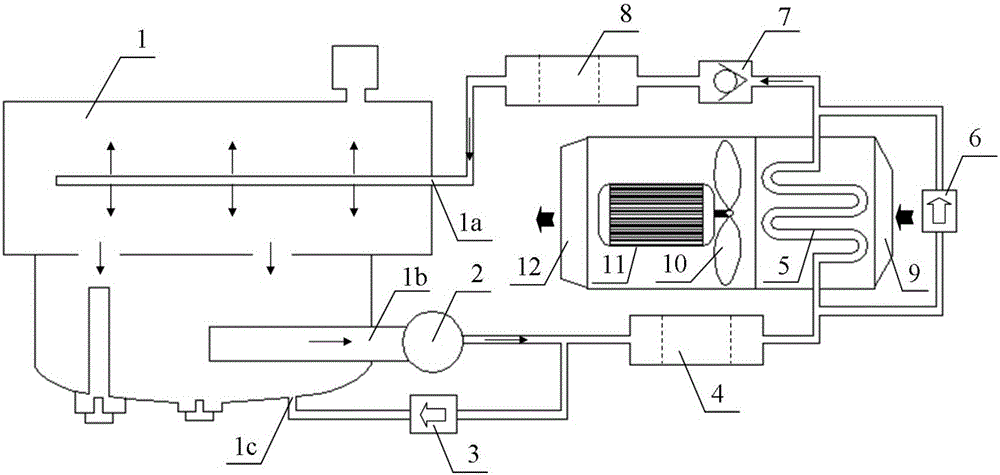

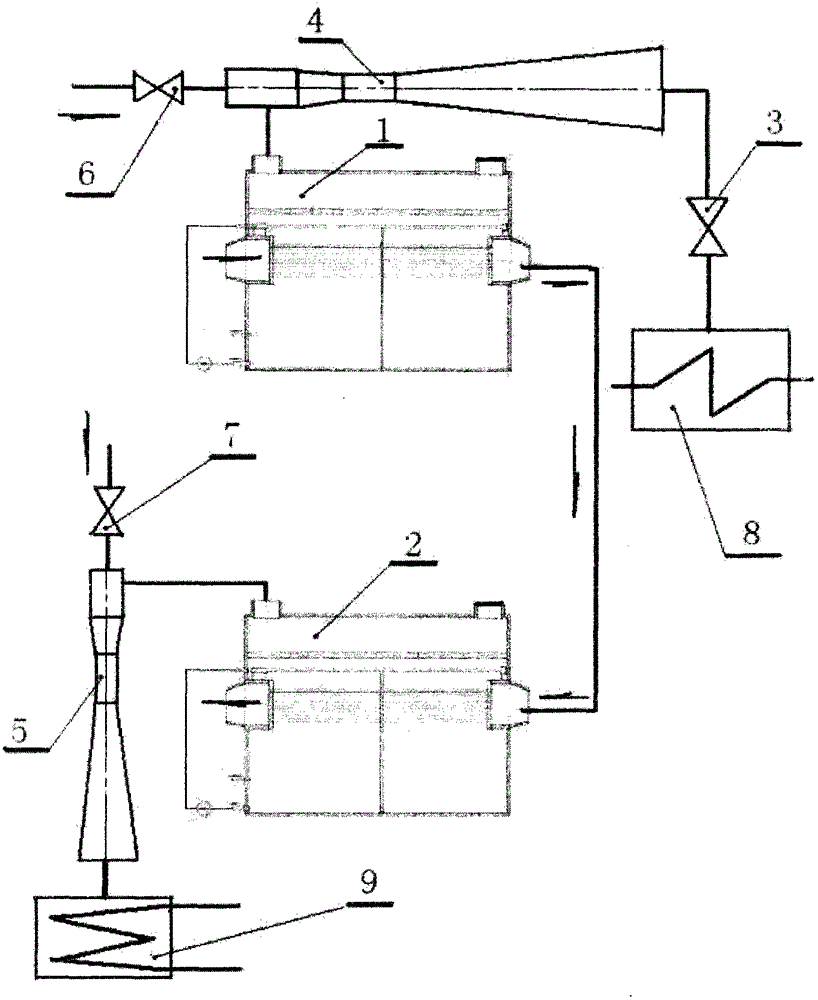

Centralized cooling system for wind turbine generator system

InactiveCN102518566ASolve Cooling ProblemsControl temperature riseGear lubrication/coolingMachines/enginesTemperature controlEngineering

The invention discloses a centralized cooling system for a wind turbine generator system. The centralized cooling system comprises a generator, a water pump, a tee, a first radiator, a second radiator, an oil-water heat exchanger and a gearbox, wherein the tee is connected with the water pump, the first radiator and the second radiator respectively; the first radiator, the generator and the water pump are communicated in turn; the second radiator, the oil-water heat exchanger and the water pump are communicated in turn; and the oil-water heat exchanger is connected with the gearbox. The centralized cooling system integrates the generator and a gearbox water cooling system to eliminate the redundancy of the system. Meanwhile, two electric temperature control valves are adopted in the system, and the flow rates of refrigerating media of the generator and the gearbox water cooling system can be respectively adjusted by automatically adjusting the opening of the temperature control valves according to water inlet temperature of the generator and the gearbox, so that temperature rise of the generator and the gearbox can be simultaneously controlled.

Owner:XIAN GEOHO ENERGY TECH

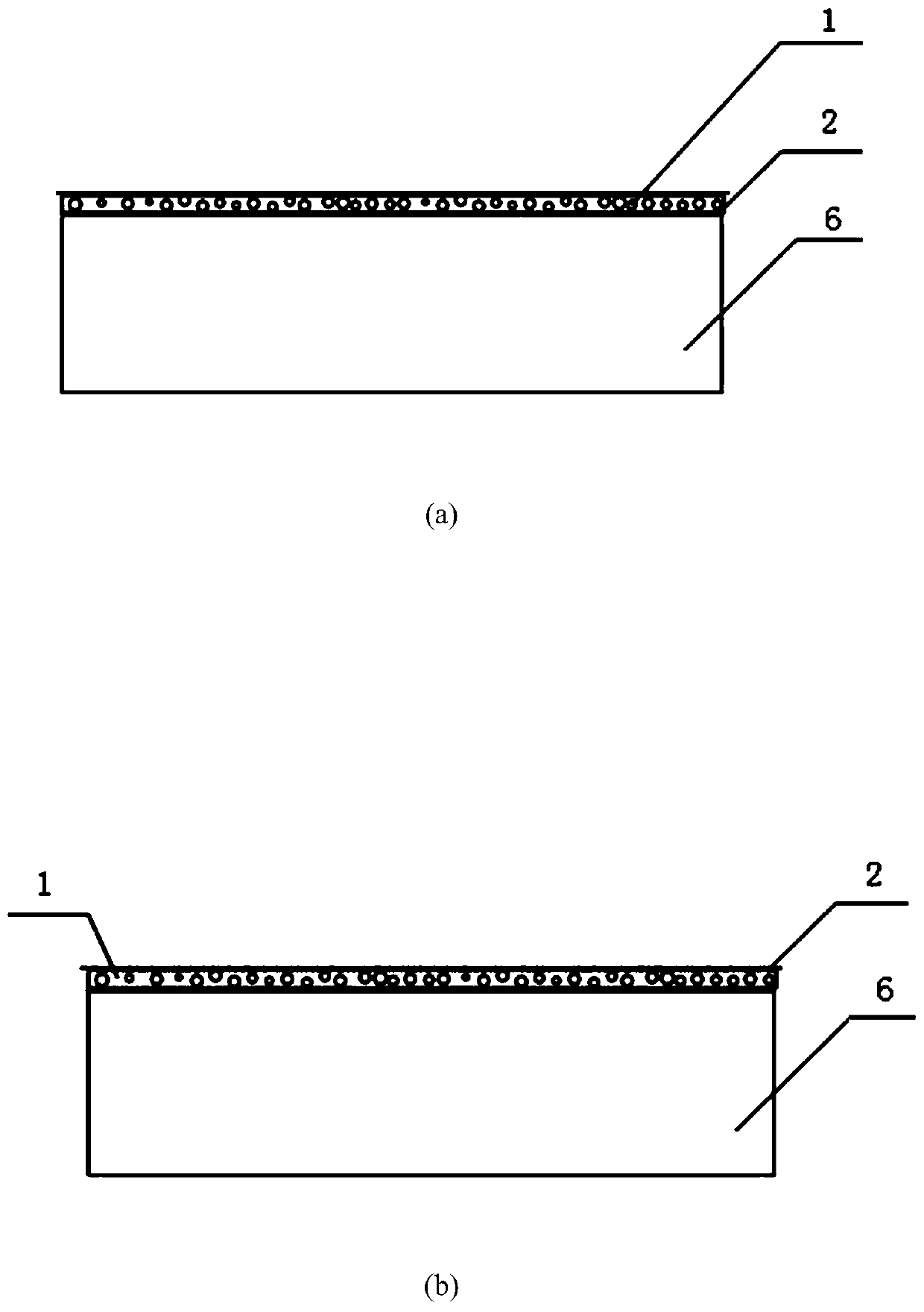

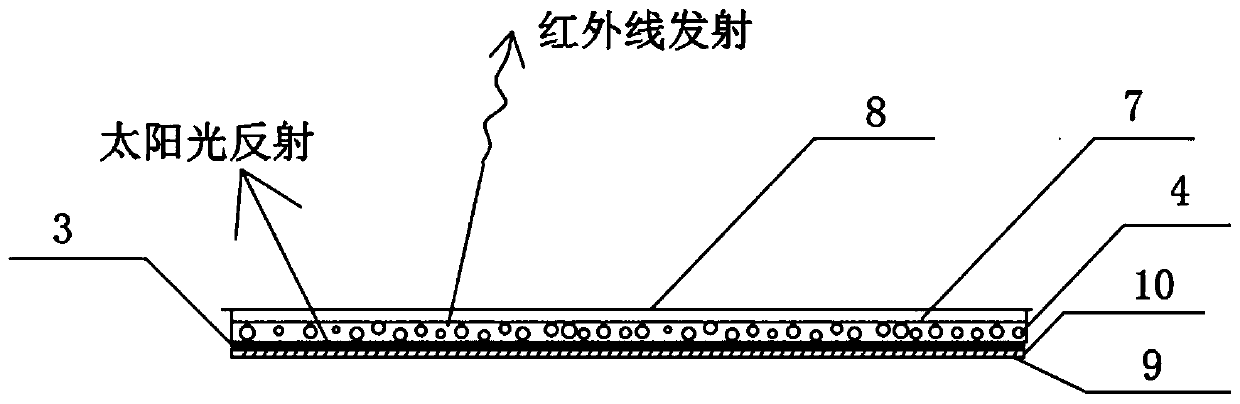

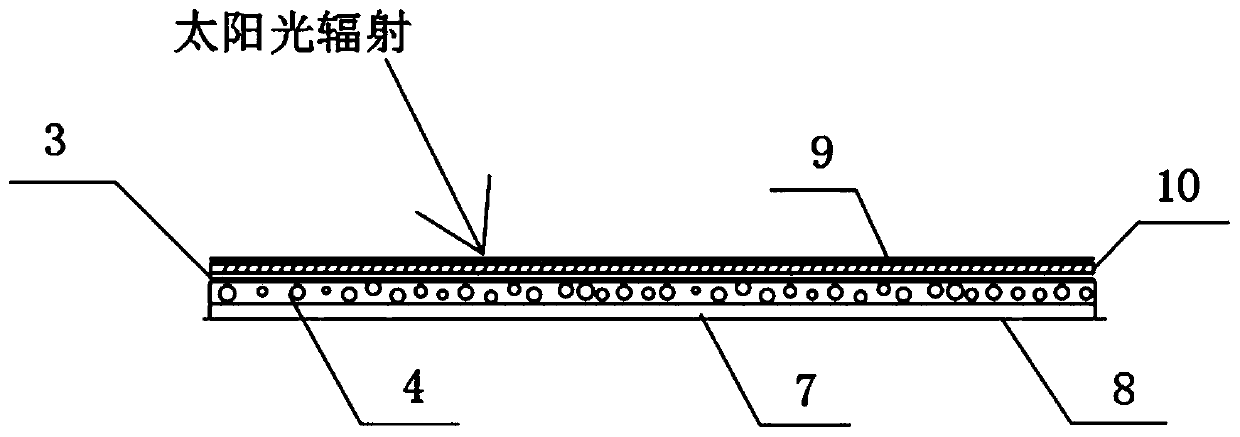

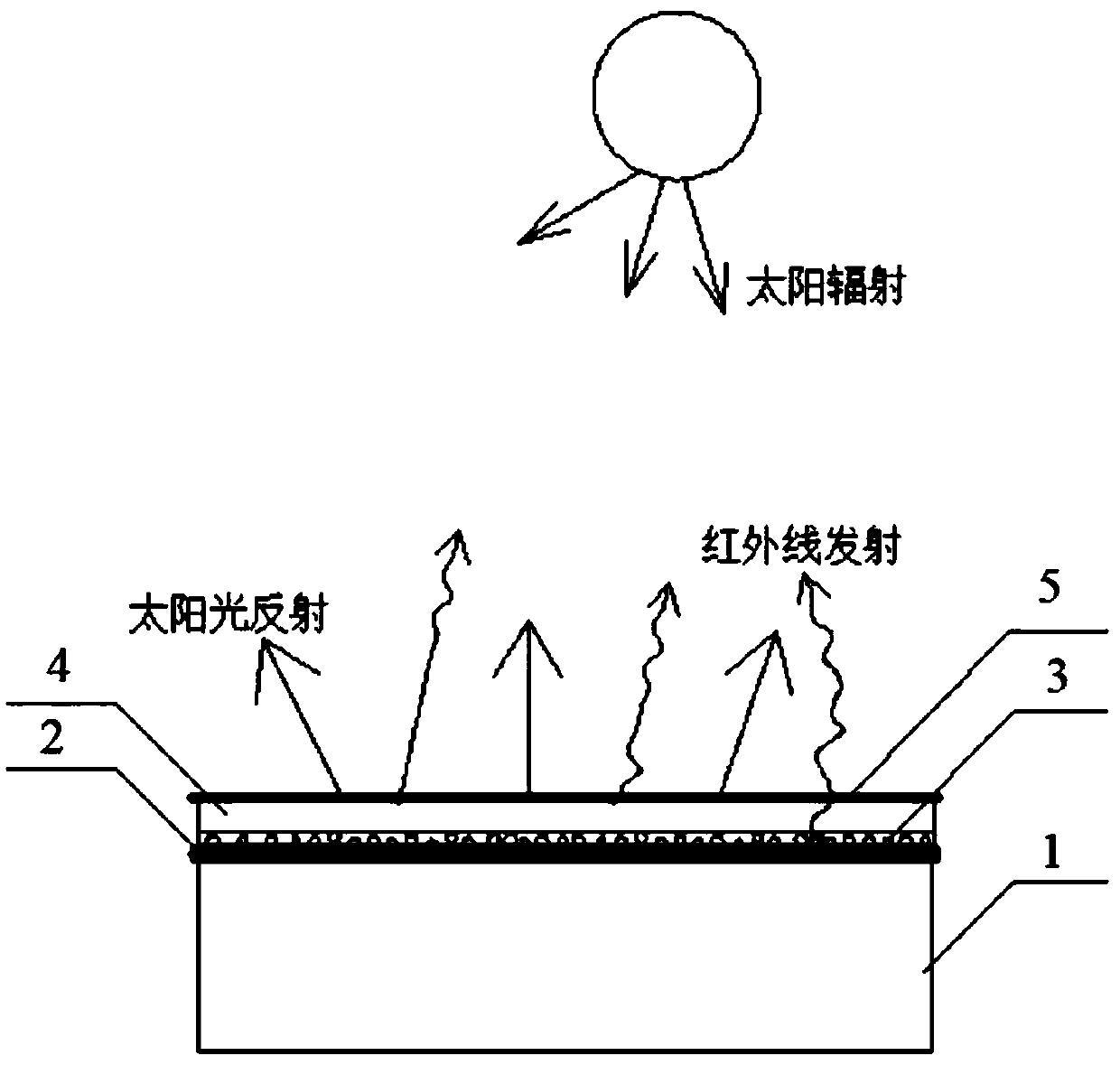

Winter and summer temperature adjusting device based on radiation cooling and solar energy utilization and construction method of winter and summer temperature adjusting device

PendingCN110567188AReduce radiant heatSolve Cooling ProblemsSynthetic resin layered productsLaminationInfraredOptoelectronics

The invention discloses a winter and summer temperature adjusting device based on radiation cooling and solar energy utilization and a construction method of the winter and summer temperature adjusting device. The winter and summer temperature adjusting device is constituted by a radiation cooling structure and a heat absorbing layer; the radiation cooling structure is composed of a reflecting layer, an emission layer and a wind screen, the emission layer is arranged between the reflecting layer and the wind screen, the wind screen is composed of an air layer and a covering material layer, andthe air layer is located between the emission layer and the covering material layer; the reflecting layer reflects sunlight out, and the emission layer emits heat in a temperature-adjusted medium outin an infrared ray mode; and the heat absorbing layer is composed of a solar heat-absorbing material layer and a metal plate, and the metal plate is located between the solar heat-absorbing materiallayer and the reflecting layer of the radiation cooling structure and is closely combined with the radiation cooling structure. The winter and summer temperature adjusting device can provide passive temperature decreasing and increasing for certain occasions and equipment, and achieves the energy saving effect.

Owner:TIANJIN UNIV

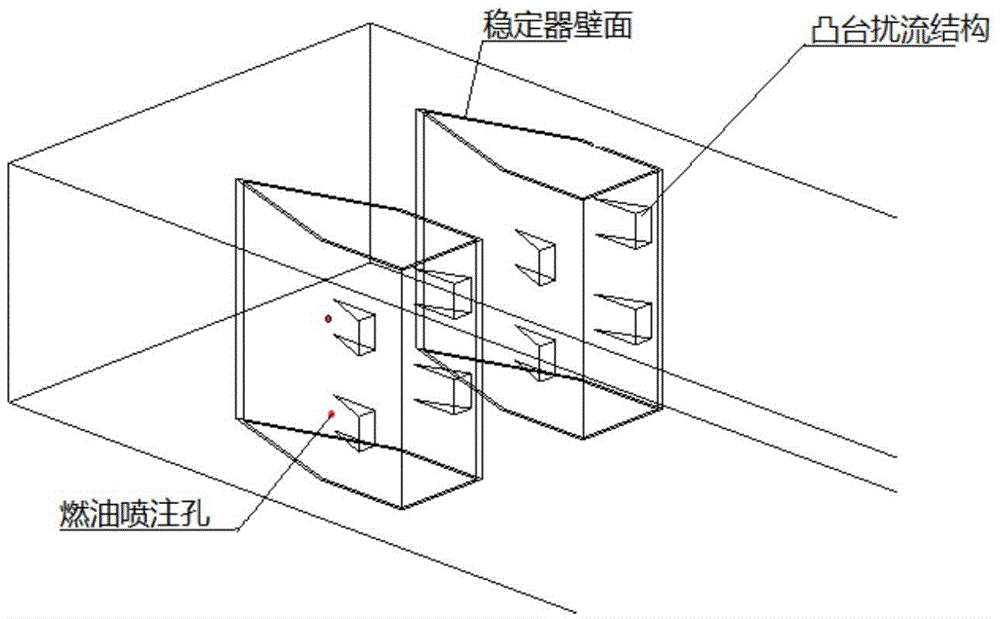

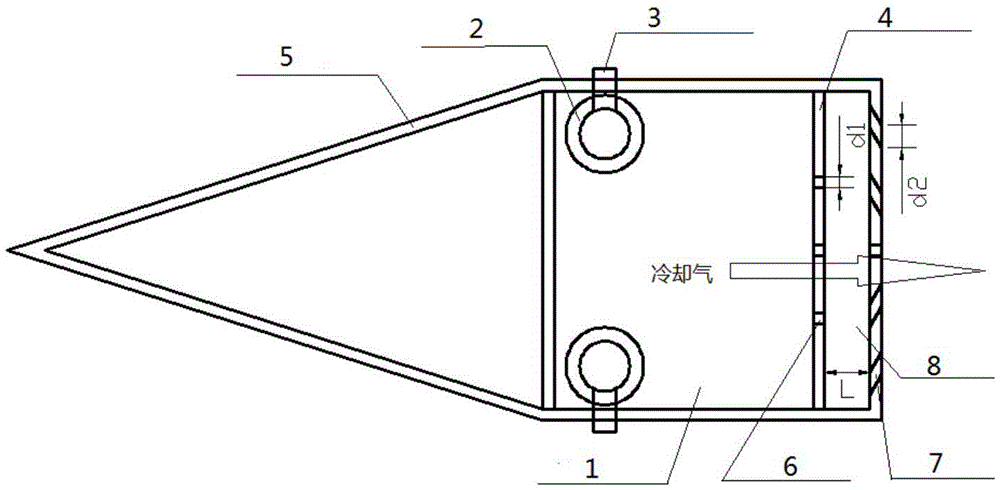

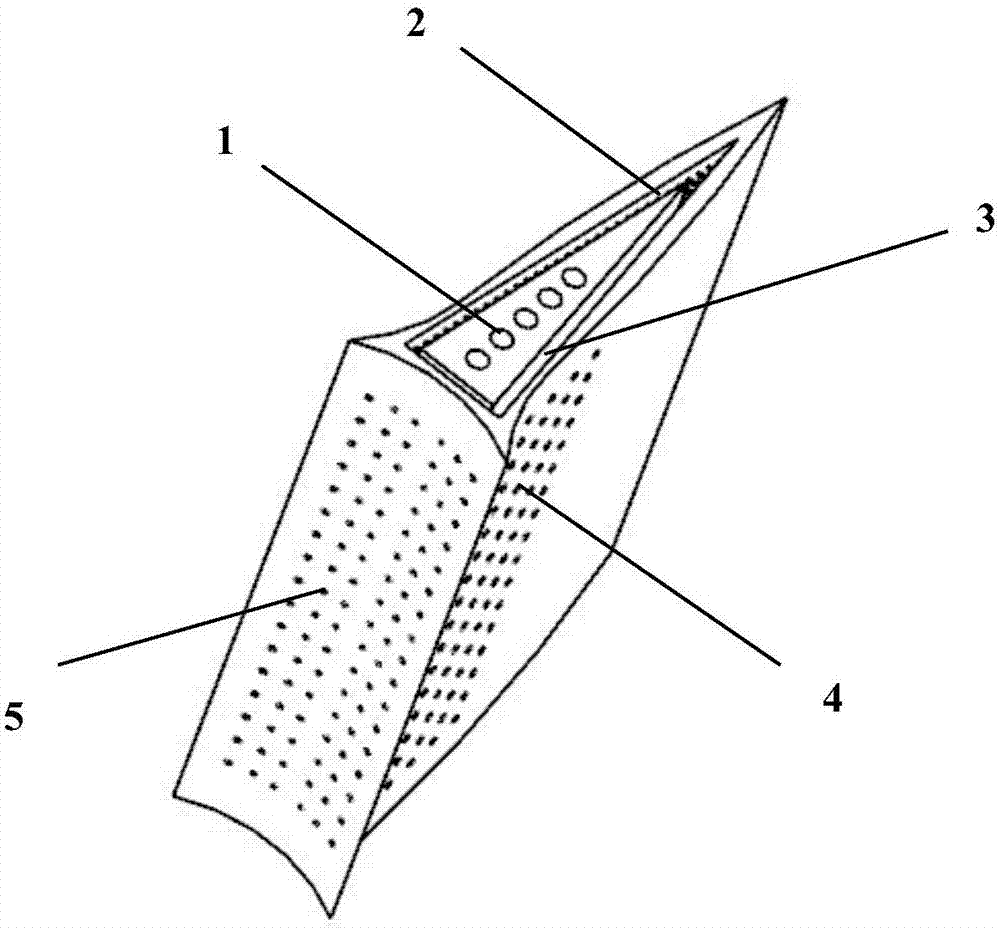

Integrally-designed flame stabilizer with novel cooling structure

InactiveCN105650677AAvoid cokingAvoid cloggingContinuous combustion chamberCold airStructural reliability

The invention discloses an integrally-designed flame stabilizer with a novel cooling structure. The integrally-designed flame stabilizer comprises a cold air cavity, a fuel guide pipe, fuel injection holes, a partition plate, a shell, impact holes of the shell and cooling holes of the shell. The integrally-designed flame stabilizer with the novel cooling structure has the functions of adjusting the position and size of a backflow area behind the stabilizer and controlling the wall temperature of the bottom end of the stabilizer besides the function of being capable of providing the backflow area facilitating flame stabilization under different work conditions. On the one hand, cooling gas flowing out of the cooling holes in the bottom end face of the stabilizer cools the wall face, the structural reliability of the stabilizer in high-temperature gas is improved, and the service life of the stabilizer in the high-temperature gas is prolonged; and on the other hand, the pressure and flow of the cooling gas are adjusted, and therefore the axial position and size of the backflow area can be controlled, the downstream combustion character of the stabilizer can be actively controlled, the flame stabilization performance in high-temperature and high-speed gas flow can be improved, and oscillating combustion can be restrained.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Data center liquid cooling and air cooling combined cooling device

PendingCN106604618AImprove heat transfer efficiencyIncrease the temperature difference of cold storageDigital data processing detailsCooling/ventilation/heating modificationsComputer equipmentEngineering

The invention discloses a data center liquid cooling and air cooling combined cooling device comprising a liquid cooling mechanism and an air-liquid heat exchanger; the liquid cooling mechanism is arranged in computer equipment, and connected with high heating components in the computer equipment; one side of the computer equipment is provided with an air inlet; the air-liquid heat exchanger used for cooling the air entering the computer equipment is arranged outside the computer equipment; the liquid cooling mechanism and the air-liquid heat exchanger are connected in series or parallel through a liquid cycle pipeline; liquid cycle can cool down the high heating components in the computer equipment; the air-liquid heat exchanger arranged outside the computer equipment can cool down the air entering the computer equipment, thus taking away heats of low heating components (like a hard disc, or a north-south bridge chip), so one liquid cycle system can use the liquid cooling-air cooling combined mode to take away the heating of the whole computer equipment.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

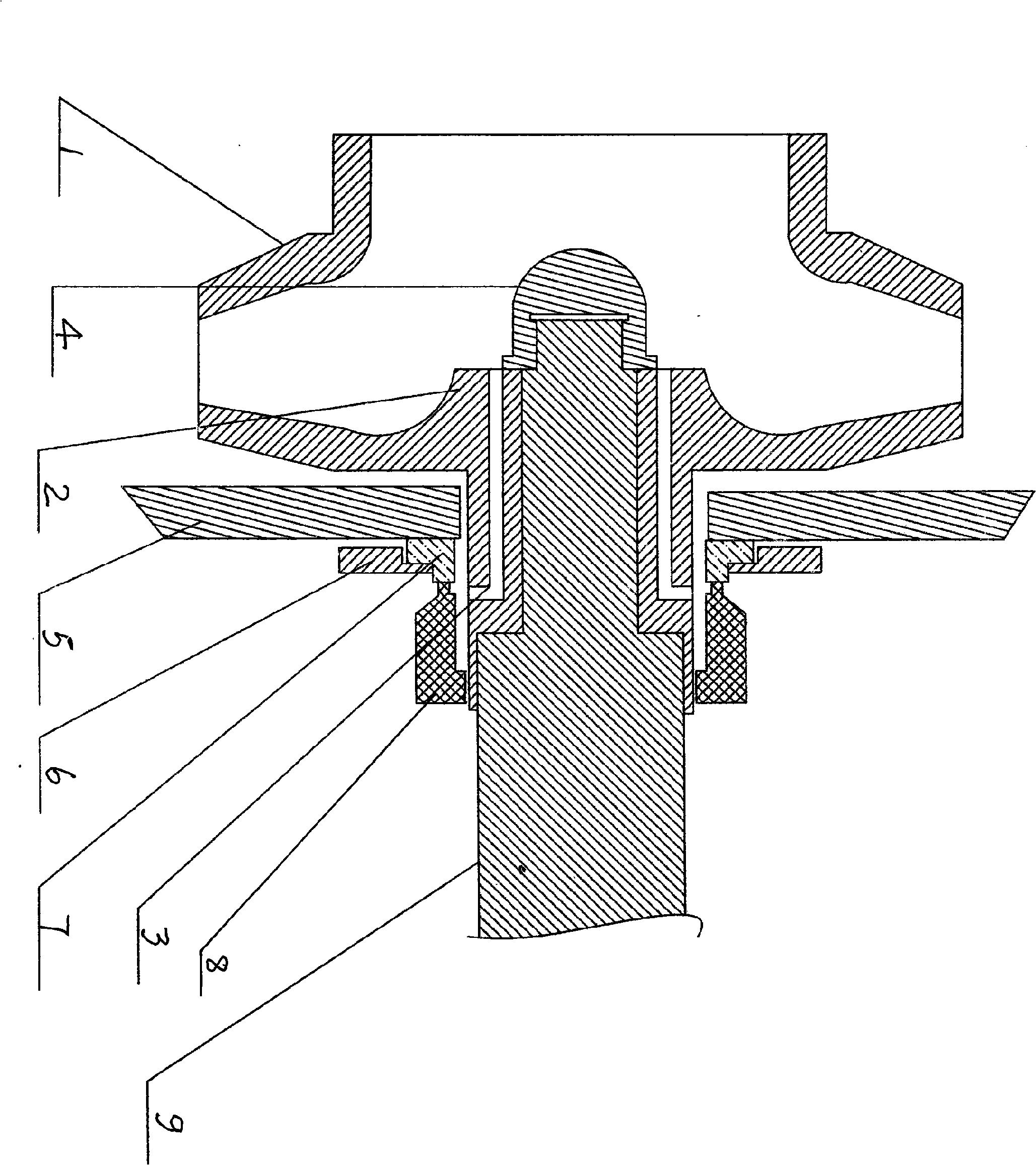

Adjustable ultra high power coherent jet oxygen lance nozzle for converter steel melting

InactiveCN101487073AReduce manufacturing costIncrease profitManufacturing convertersOxygen utilization rateEngineering

The invention relates to an adjustable integral ultrahigh power coherent oxygen lance nozzle for converter steel making, which comprises a nozzle, the nozzle comprises a cooling system and an injecting oxygen system which is arranged inside the cooling system and comprises an inner nozzle and a plurality of accessory holes, wherein, an inner nozzle is movably connected with the central position of the nozzle and the accessory holes are evenly arranged around the inner nozzle, which can ensure that the streams injected by the inner nozzle do not decay too soon, thus forming a strong air column attacking steel liquid level; and a flow field of molten metal with convection from the periphery to the inside forms according to the property of liquid flow field and the structure of furnace type, thus leading to the full reaction of oxygen and the impurities in steel liquid. The oxygen lance nozzle can directly match with the current oxygen lance only by replacing the nozzle. By testing, the oxygen lance nozzle can improve the oxygen utilization rate by 20 percent and reduces steelmaking cost. As the lance position is high, the phenomena of splashing, lance-sticking, slag mound and the like, do not easily appear during the steel making process, and the life of the oxygen lance can be improved by three to five times.

Owner:刘旭刚

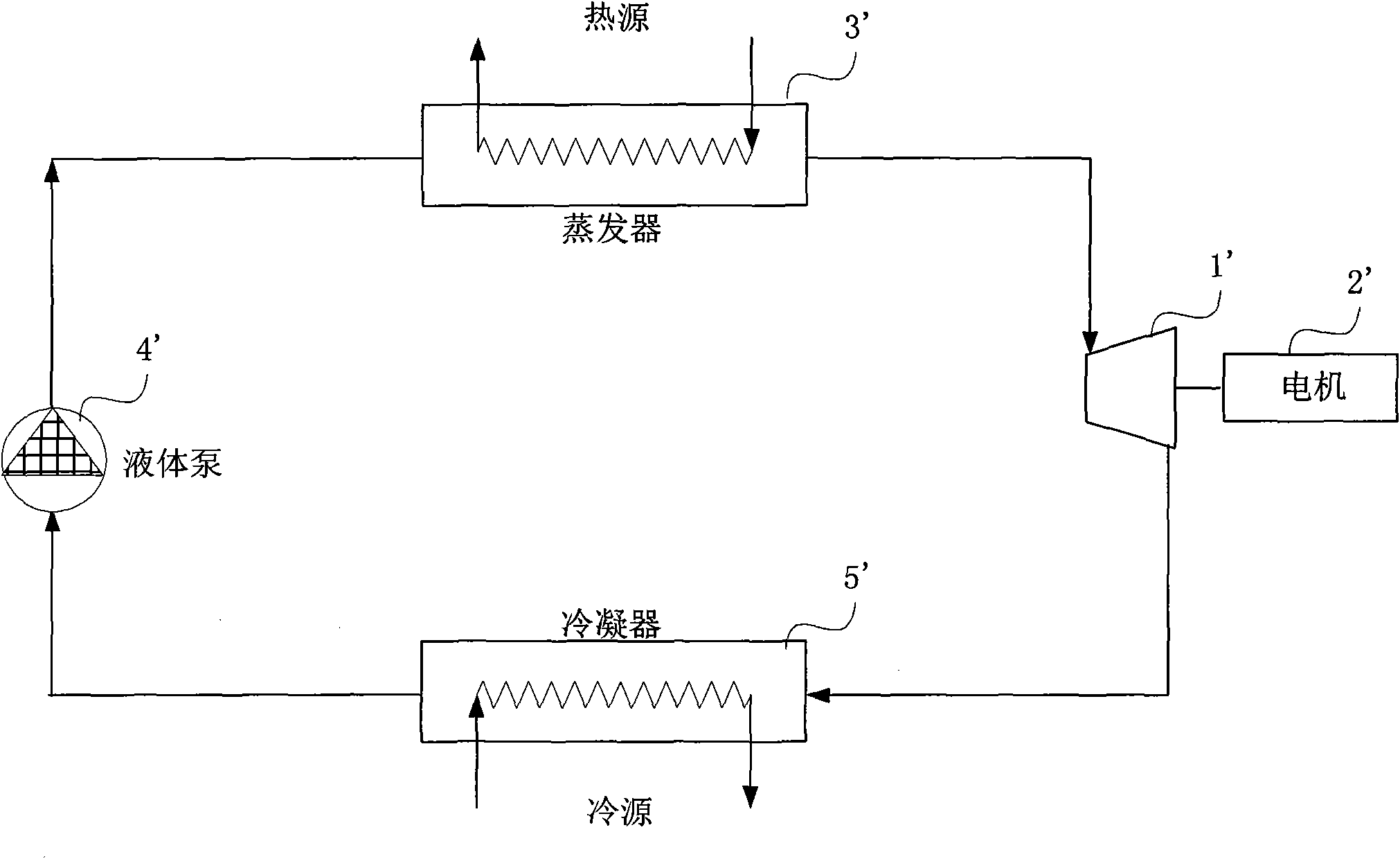

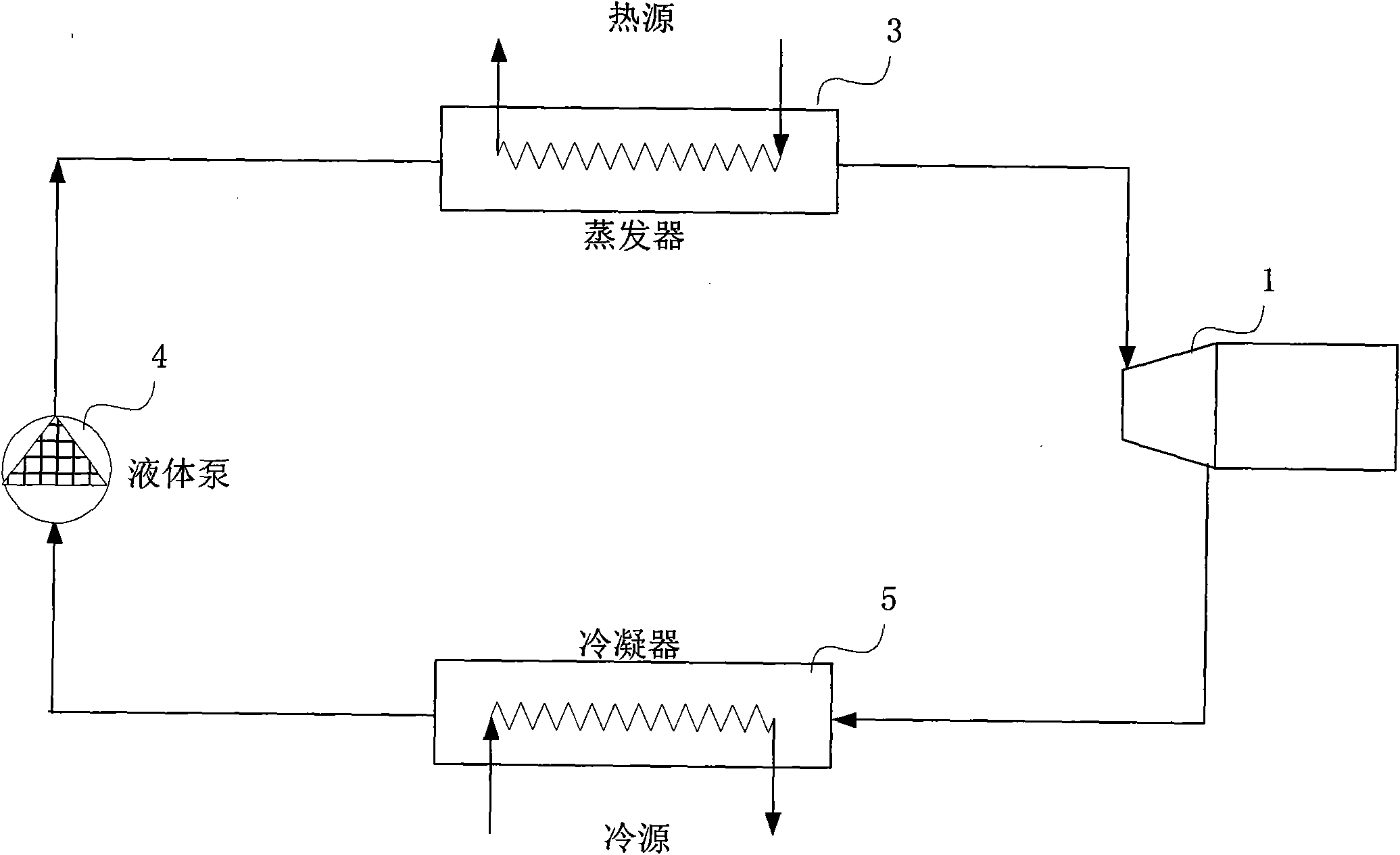

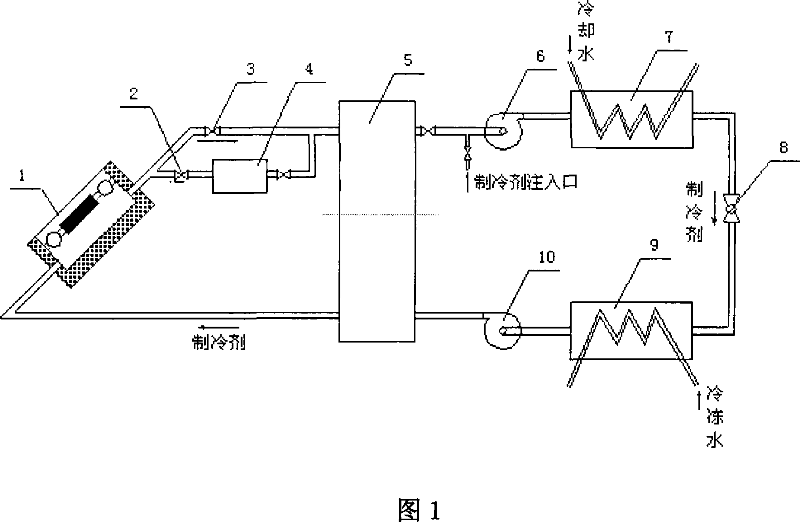

Screw expansion generating device

ActiveCN102061944ACircumstances to avoid leakageImprove cooling effectRotary/oscillating piston combinations for elastic fluidsSealing arrangements for enginesElectricityInjection port

The invention discloses a screw expansion generating device which can be used for organic Rankine cycle. The screw expansion generating device comprises a semi-closed or full-closed shell; the shell comprises an expansion machine cavity and a generator cavity; the expansion machine cavity and the generator cavity are not communicated; the expansion machine cavity is internally provided with a screw expansion machine, and the generator cavity is internally provided with a generator; a rotor of the screw expansion machine is fixedly connected with a rotor of the generator; the generating device drives the generator to generate electricity by rotation of the rotor of the screw expansion machine; the generator cavity is provided with a liquid refrigeration working medium injection port and a refrigeration working medium outlet; and the generator is cooled by evaporation of the liquid refrigeration working medium. The screw expansion generating device is semi-closed or full-closed, the screw expansion machine and the generator are integrally arranged in the shell, the generator can be a synchronous generator and can also be an asynchronous generator, and the condition of refrigeration working medium leakage when the screw expansion generator generates electricity can be avoided.

Owner:SHANGHAI POWER TECH SCREW MACHINERY

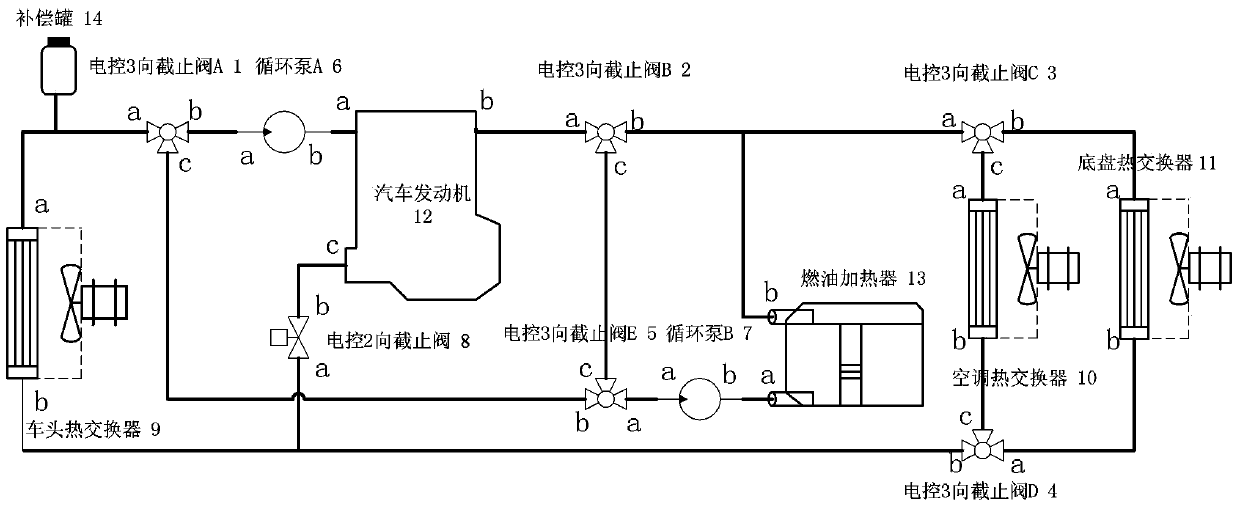

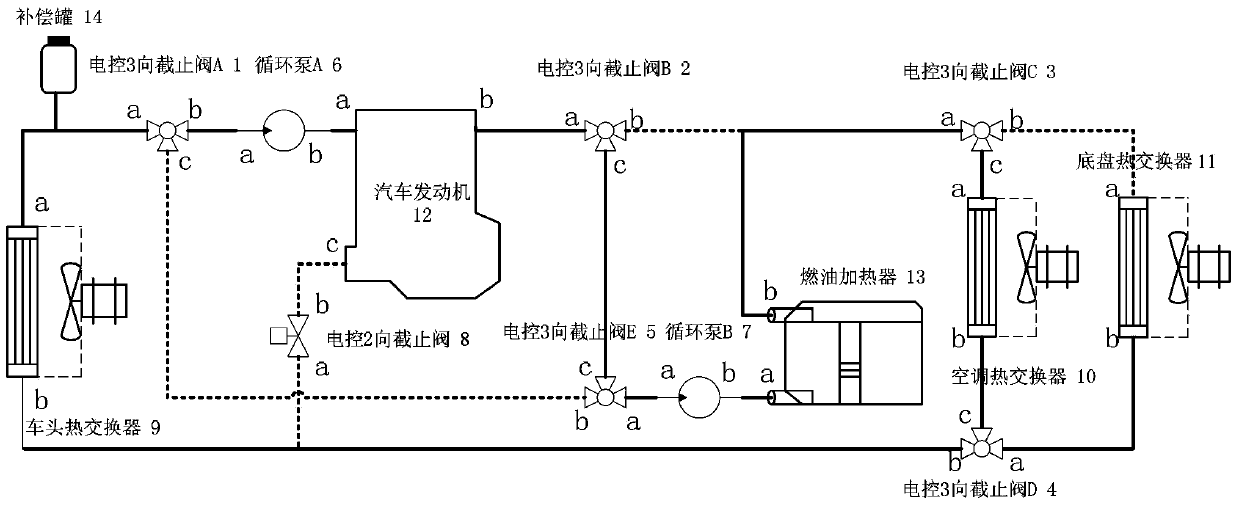

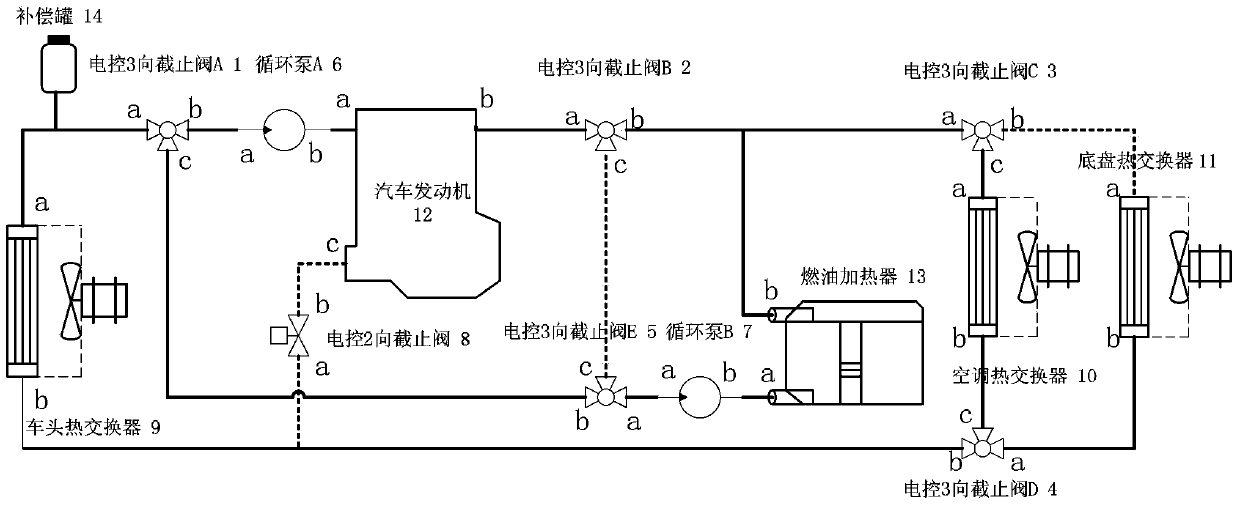

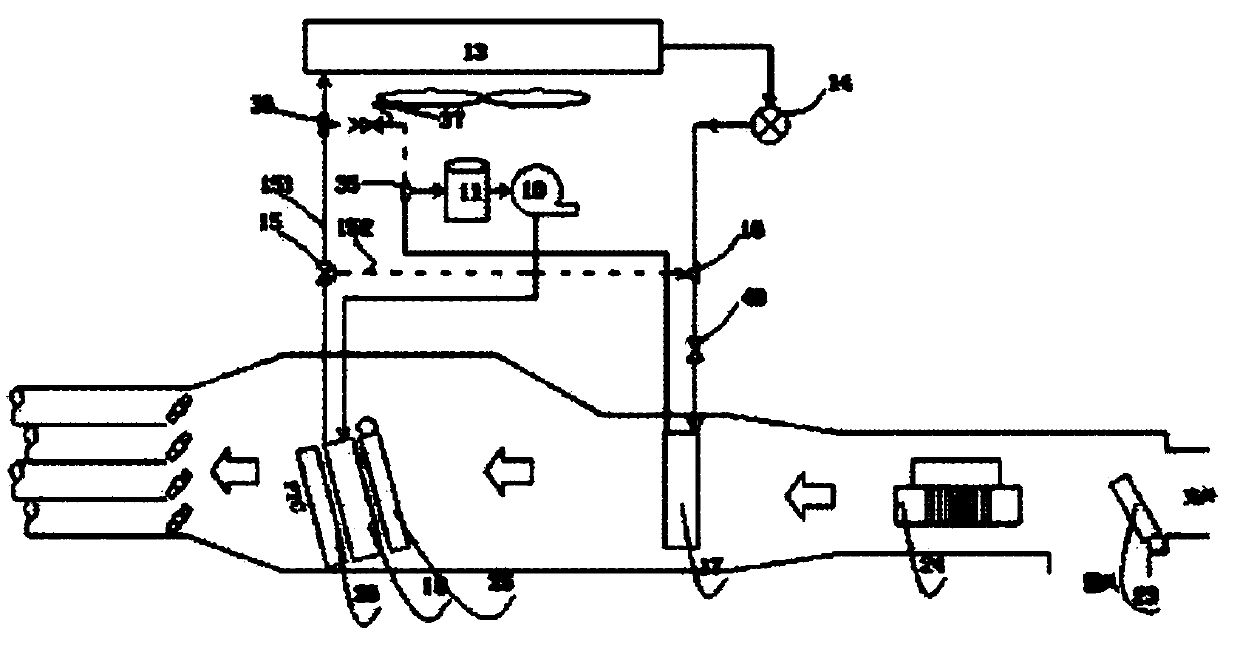

Automotive heating system and radiating system using fuel heaters and using methods thereof

InactiveCN103419598ASolve the cooling effectSolve Cooling ProblemsLiquid coolingAir-treating devicesElectric controlCirculating pump

The invention discloses an automotive heating system and radiating system using fuel heaters and using methods thereof and belongs to the field of automotive integral heating systems and engine cooling systems. The automotive integral heating system comprises a compensating tank, an electric control three-way stop valve, a circulation pump, an air-conditioner heat exchanger, an automotive head heat exchanger, an automotive engine and a fuel heater. The engine cooling system comprises a compensating tank, an electric control three-way stop valve, an electric control two-way stop valve, a circulation pump, a chassis heat exchanger, an automotive head heat exchanger, an automotive engine and a fuel heater. In winter, the automotive integral heating system can preheat the engine and increase in-car temperature fast, reduce emission of exhaust gas generated when the engine is in an idle state, and improve the comfort level of passengers. In summer, due to the arrangement of the engine cooling system, the cooling speed of the automotive engine is increased.

Owner:CHANGZHOU UNIV

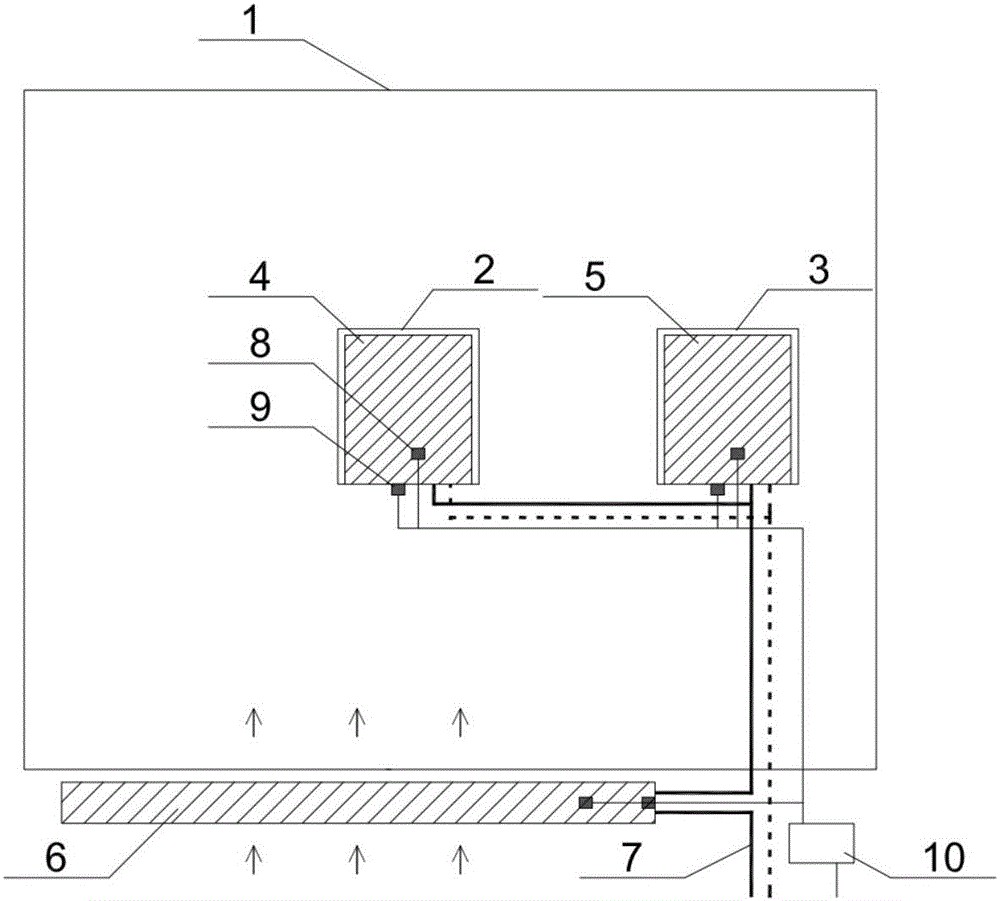

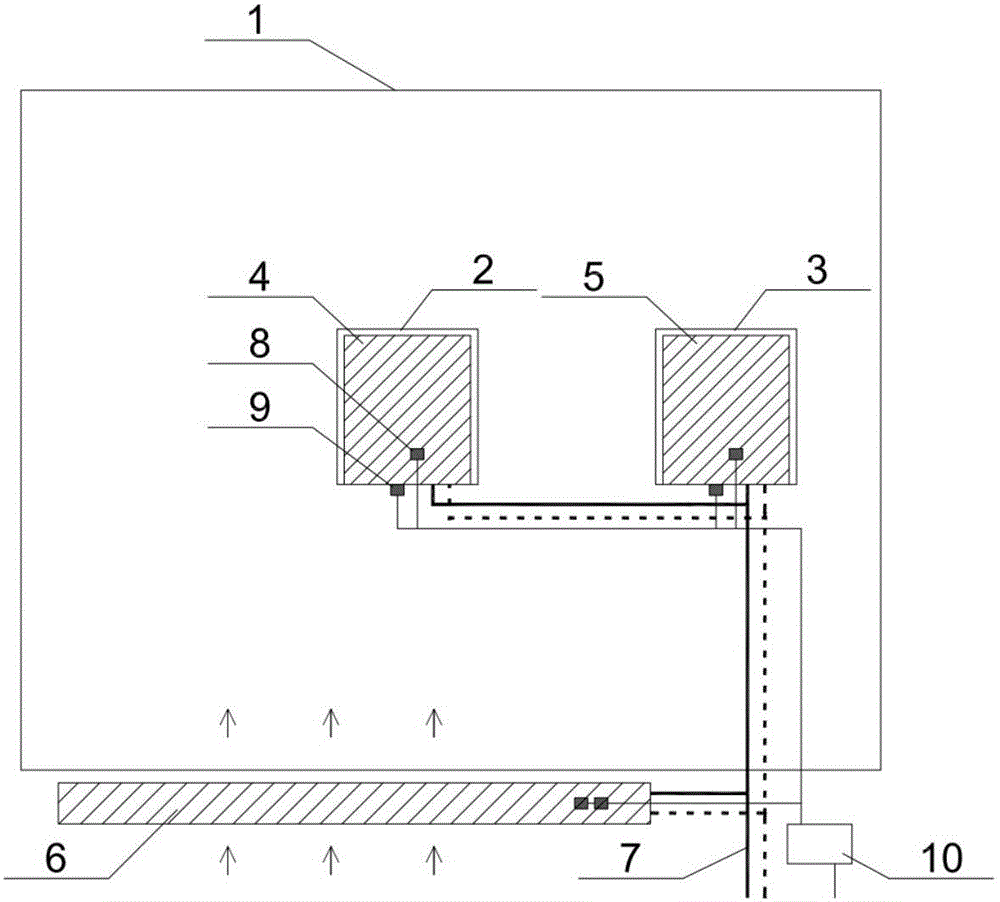

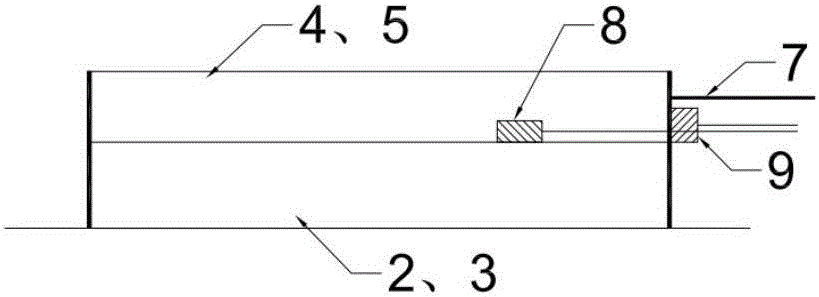

Combined cooling type rectification support plate flame stabilizer

PendingCN107191968AAvoid ablationGuaranteed to workContinuous combustion chamberShock coolingEngineering

Owner:NORTHWESTERN POLYTECHNICAL UNIV

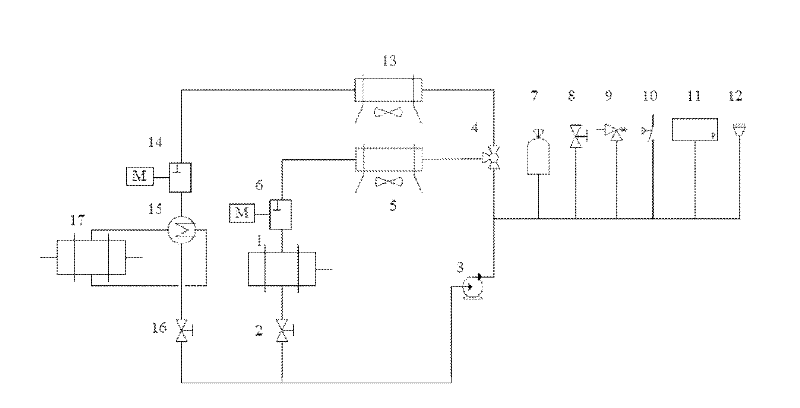

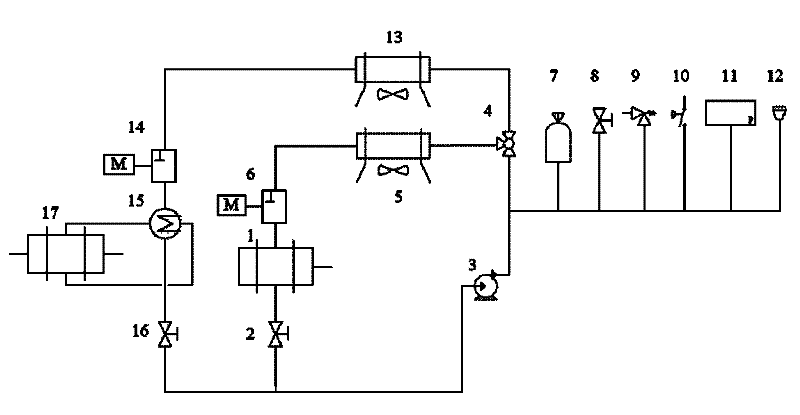

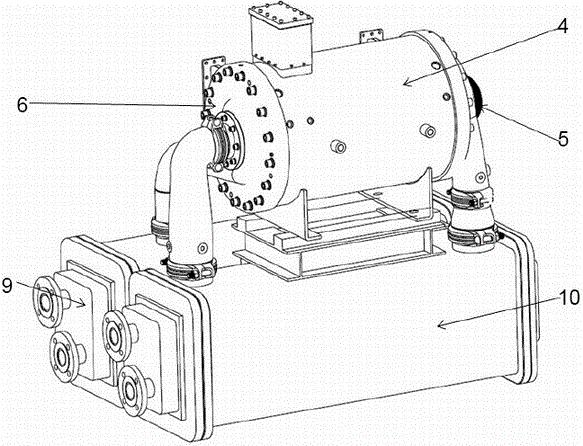

Airborne power generator cooling device

ActiveCN106505797ASolve Cooling ProblemsReduce adverse effectsCooling/ventillation arrangementAviationLow speed

The invention belongs to the aviation field, and relates to an airborne power generator cooling device, which is characterized by comprising a power generator set (1), an oil pump (2), a pressure relief valve (3), a first filter (4), a lubricating oil air cooling system, a temperature bypass valve (6), a non-return valve (7) and a second filter (8). The invention provides an airborne power generator cooling device, which solves the problem of cooling of the power generator in an aircraft full flight envelope range, particularly, in a low-speed condition, and avoids bad influences on the performance of the engine and the engine compartment appearance design.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

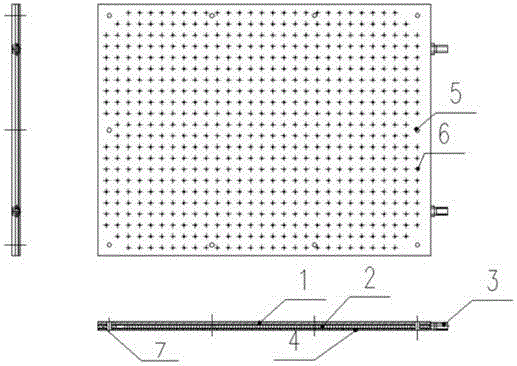

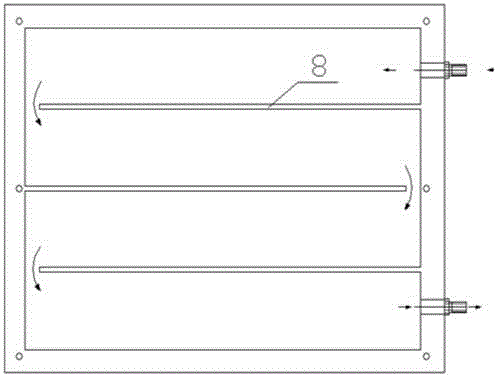

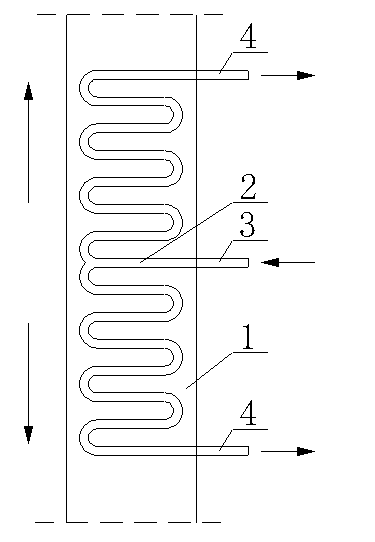

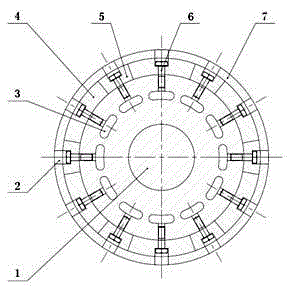

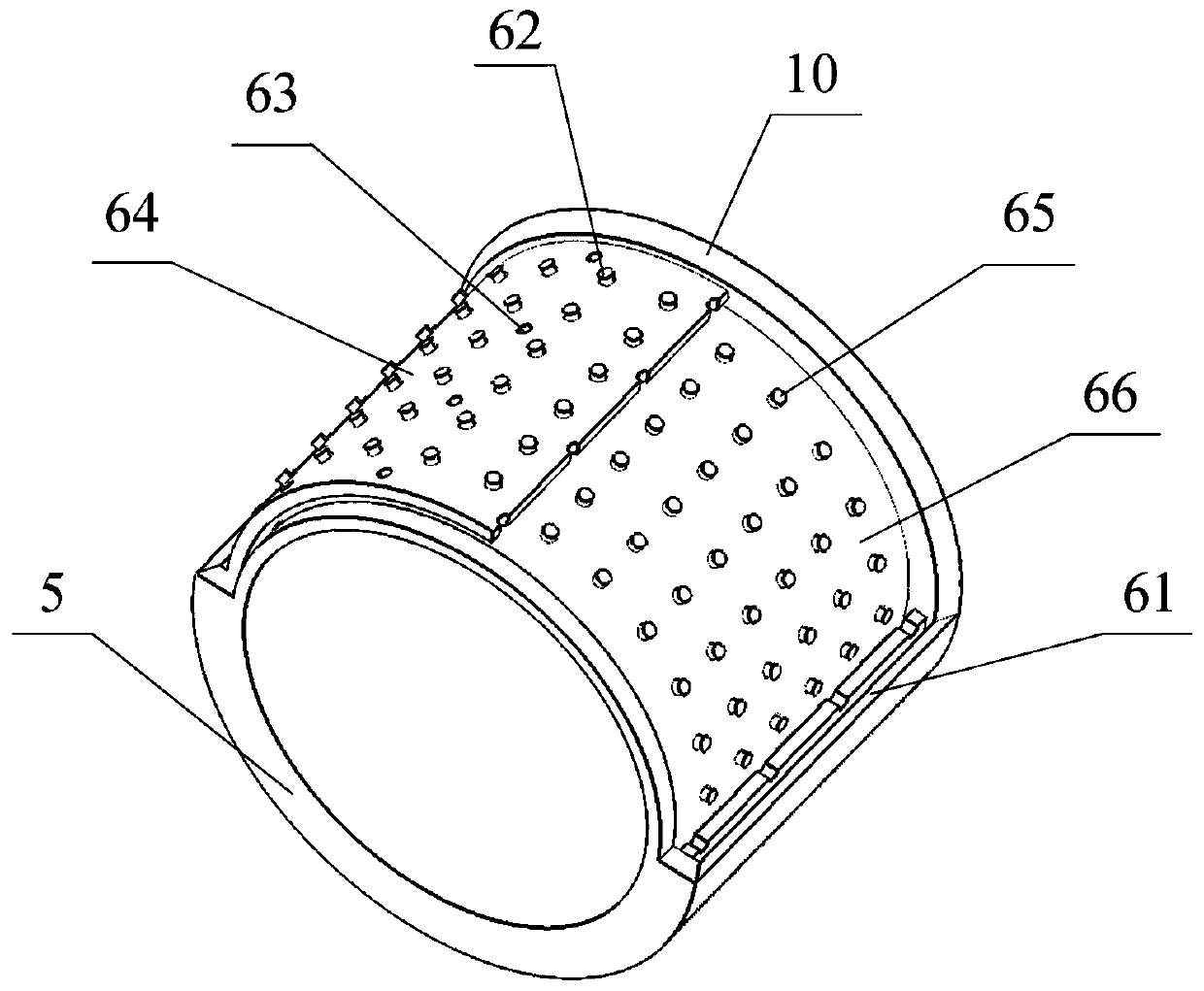

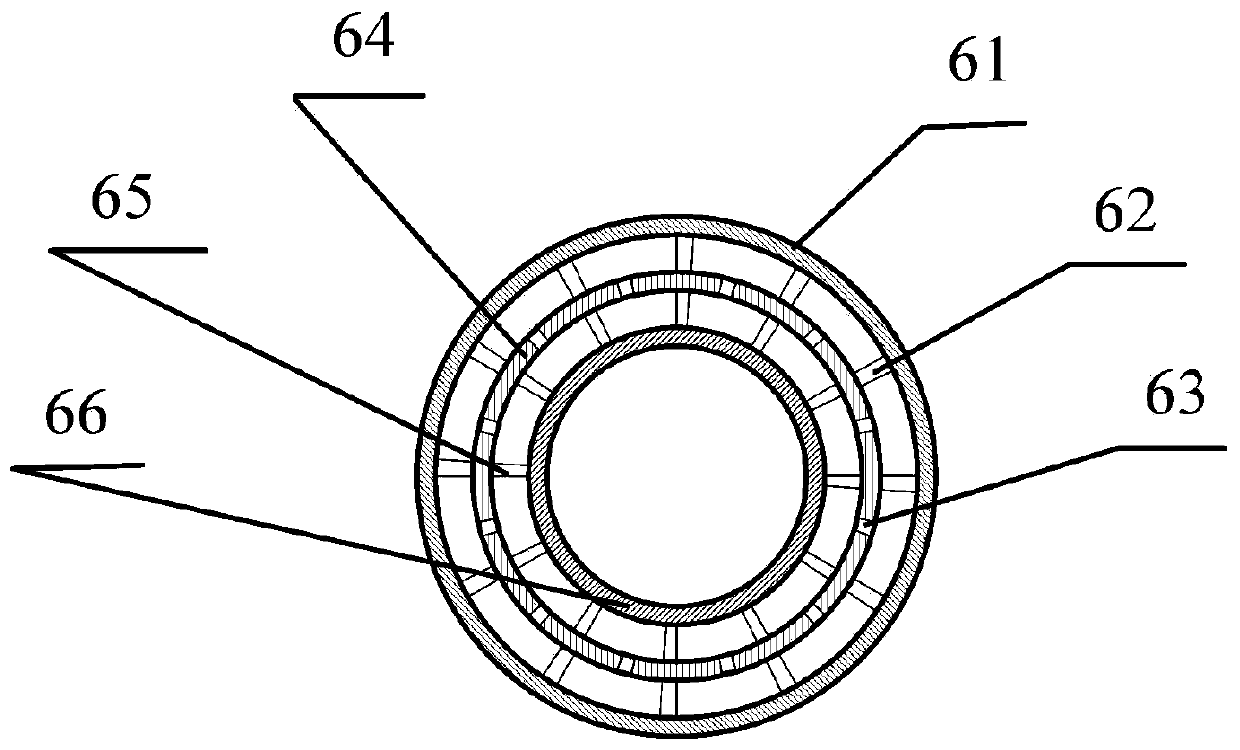

Water cooling plate

InactiveCN105806134ASimple structureEasy to process and produceHeat exchanger casingsLaminated elementsLiquid mediumEngineering

The invention relates to a water-cooled plate. A heating element is fixedly installed through a threaded hole for installing the heating element on the working plate to ensure good thermal contact. The circulating liquid cooling medium enters the water-cooled plate from the inlet of the water-cooled plate. The flow channel in the plate is formed by the opening of the middle partition plate, which is generally in the shape of a baffle. There are cooling fins in the flow channel, and the partition plate and cooling fins are welded to the upper and lower plates. , the heat is transferred to the circulating cooling liquid medium through the cooling fins, and after sufficient heat exchange, the cooling medium flows out from the outlet of the water-cooled plate, taking away the waste heat generated by the heating element. The water-cooled plate of the present invention has the advantages of simple structure, easy processing and production, low cost, convenient installation, high cooling efficiency, etc., and can effectively solve the problem of cooling the heating element under high power density, thereby getting rid of the low efficiency of traditional coolers and high-efficiency coolers The structure is complex and the cost is high.

Owner:CHINA WEAPON EQUIP RES INST +1

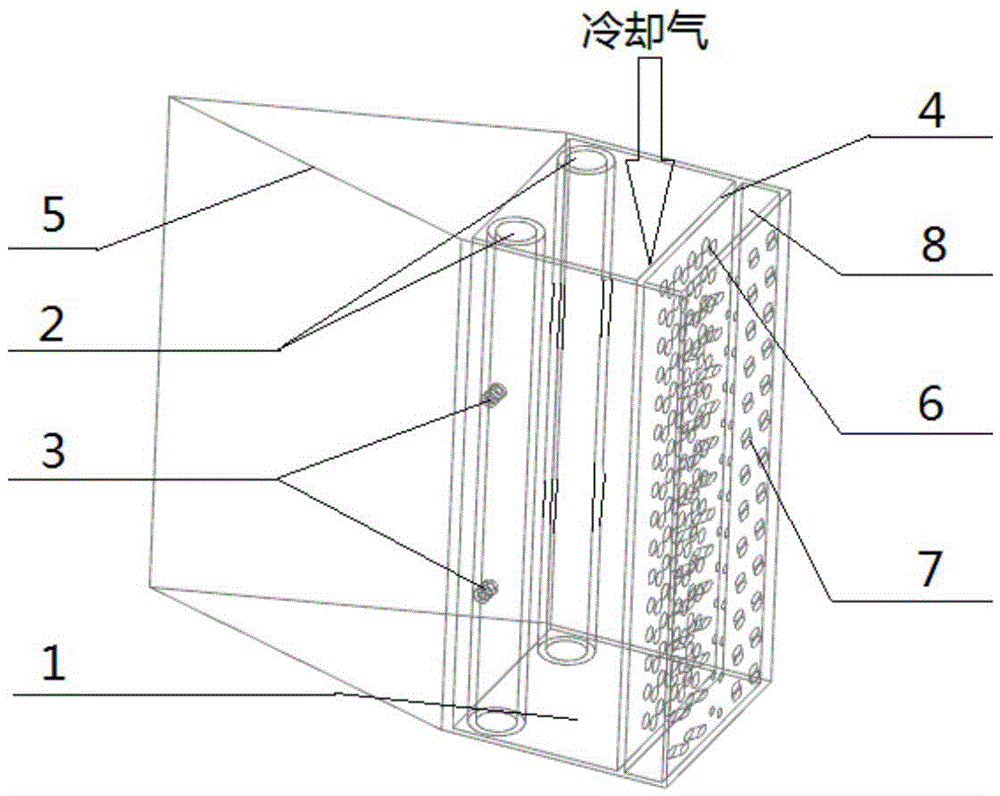

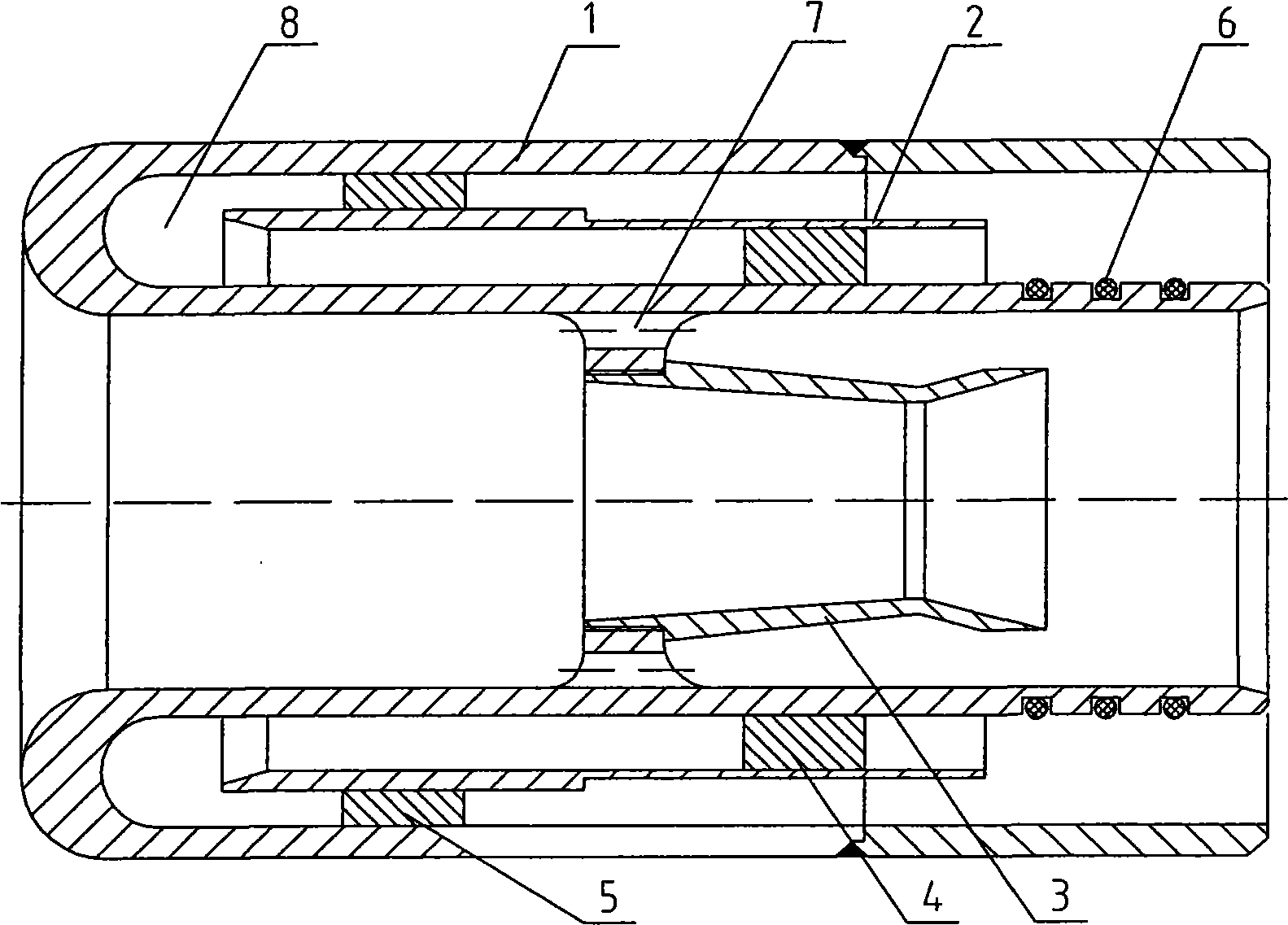

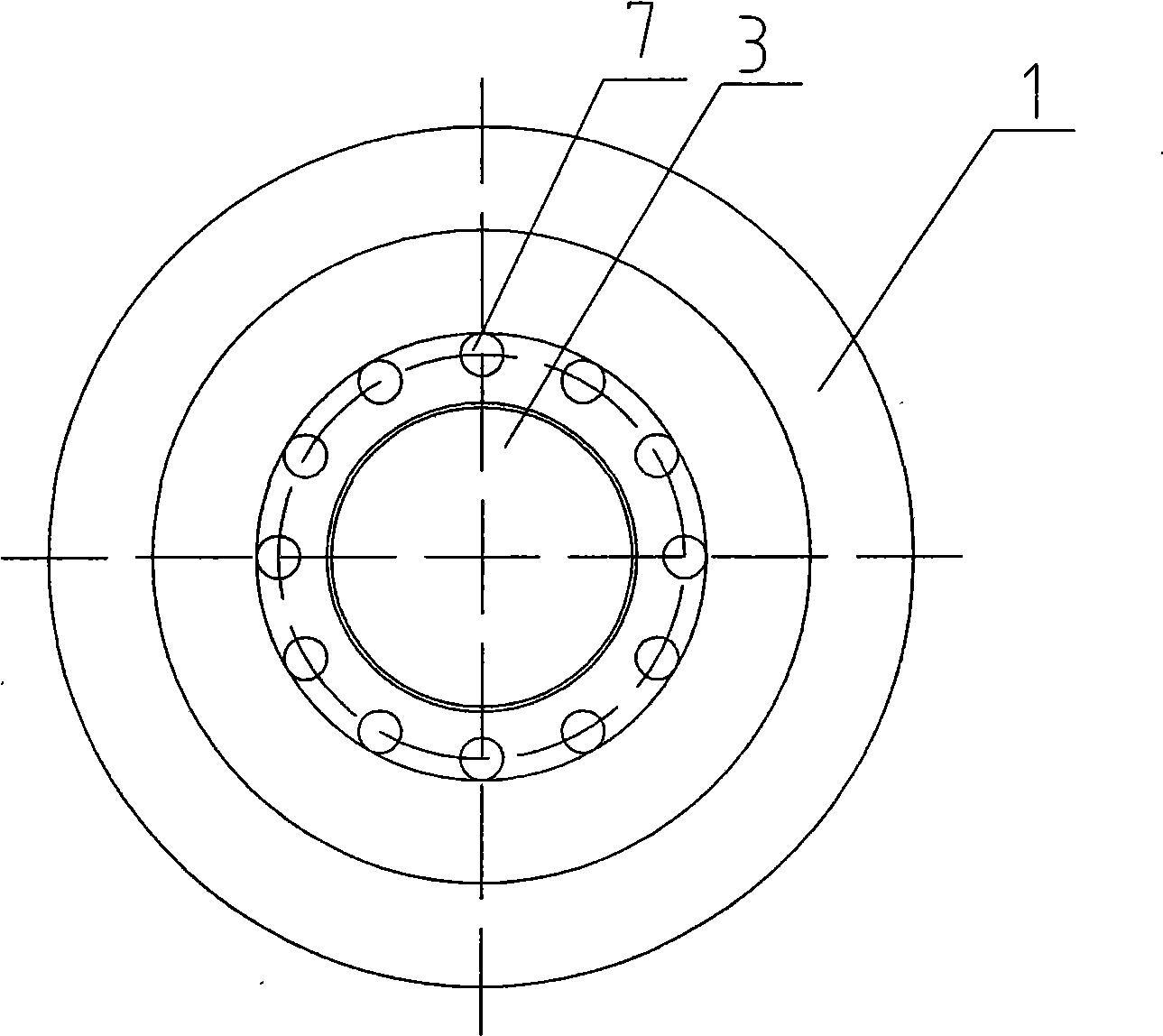

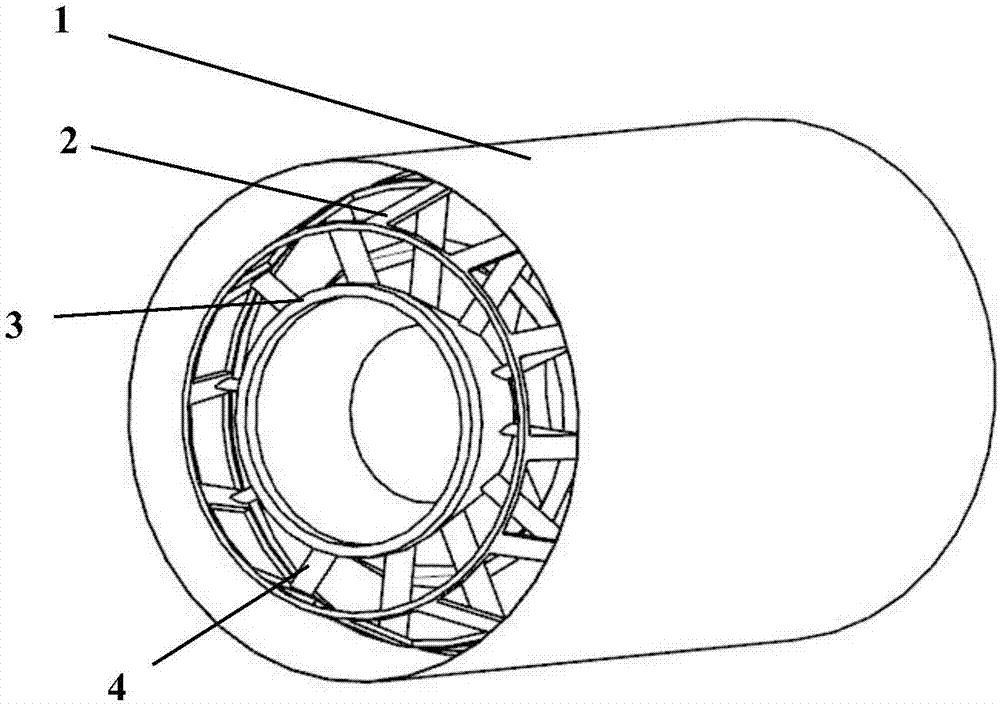

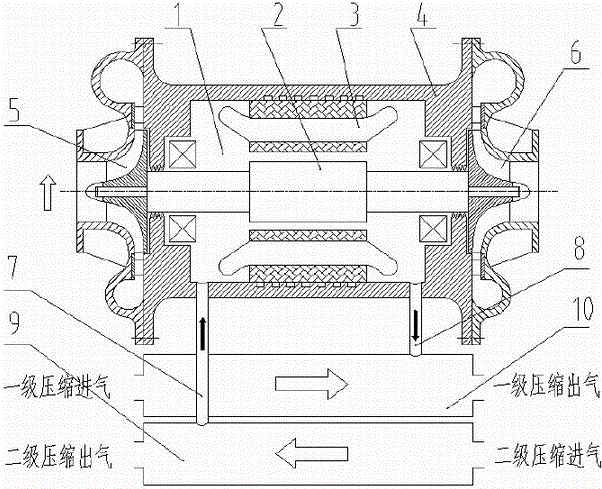

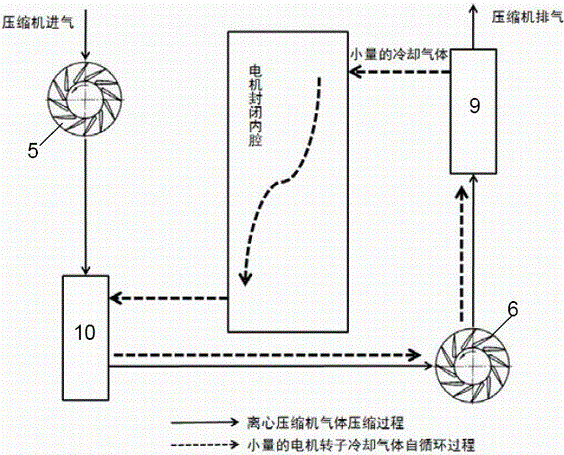

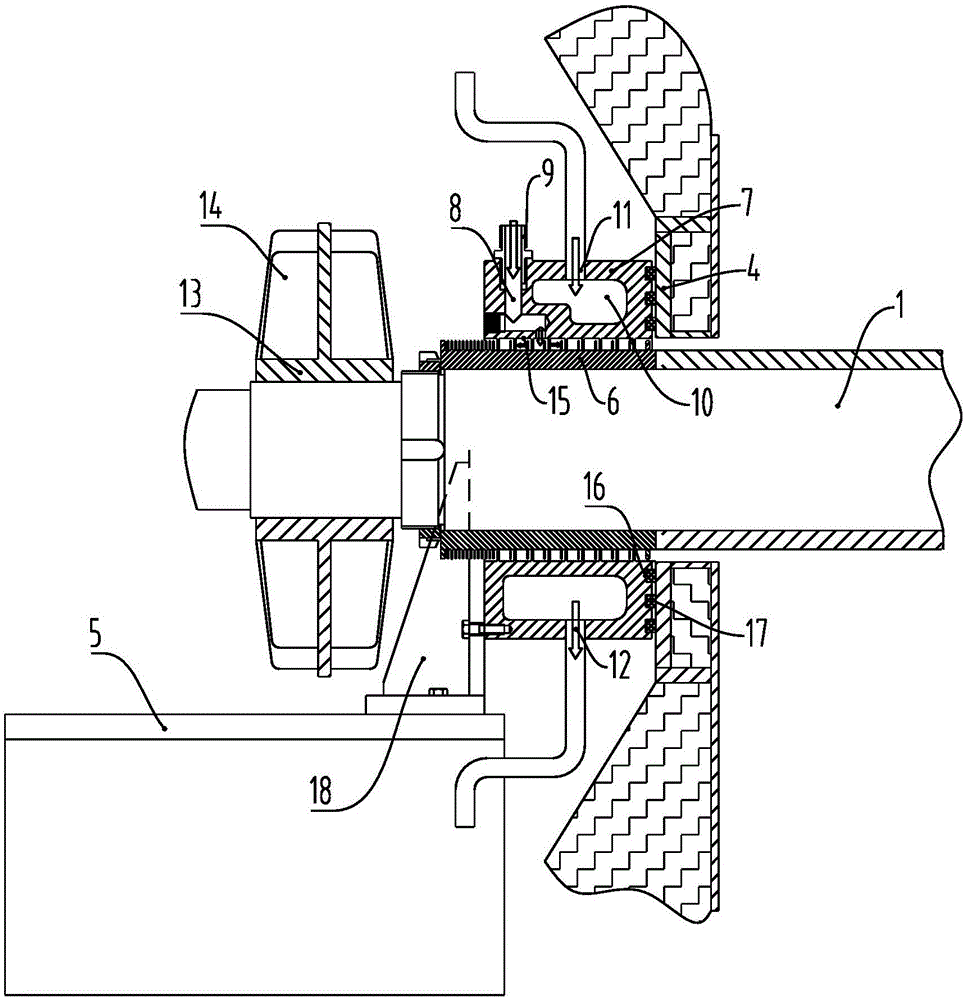

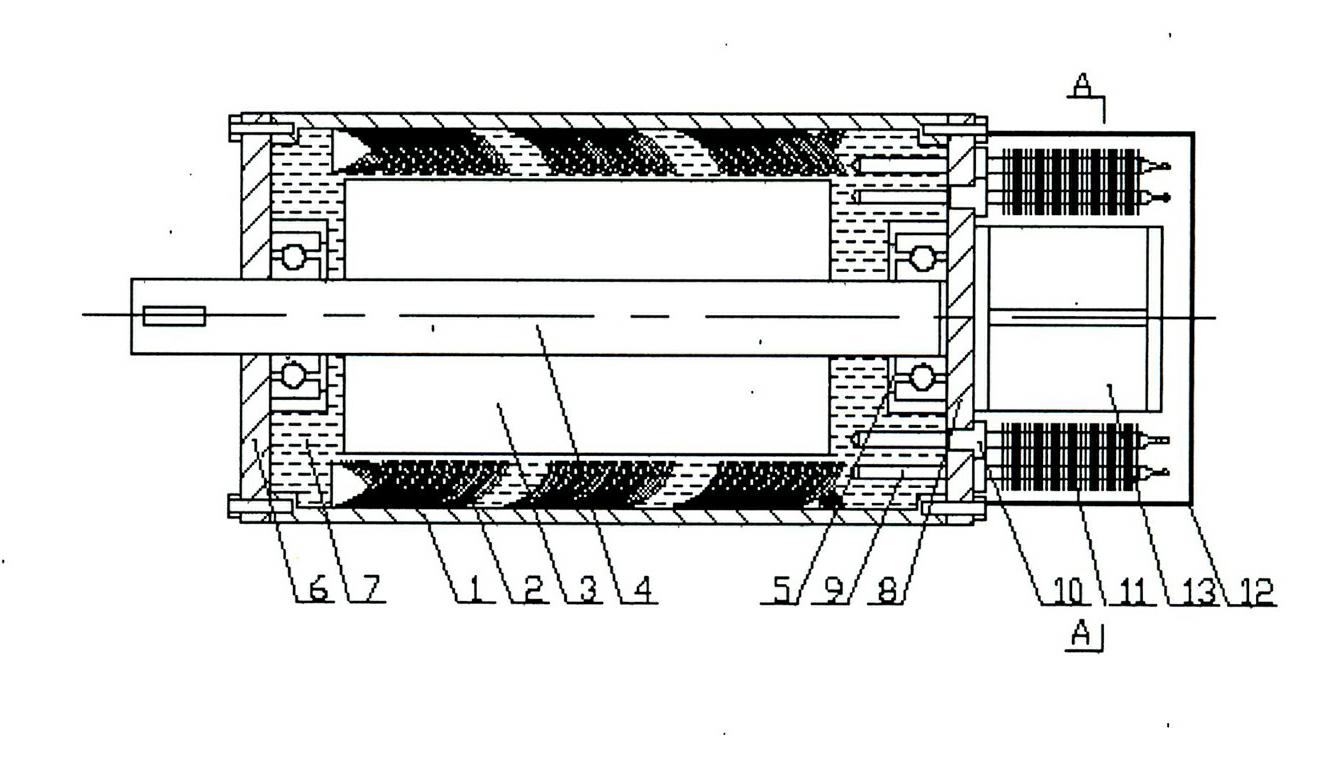

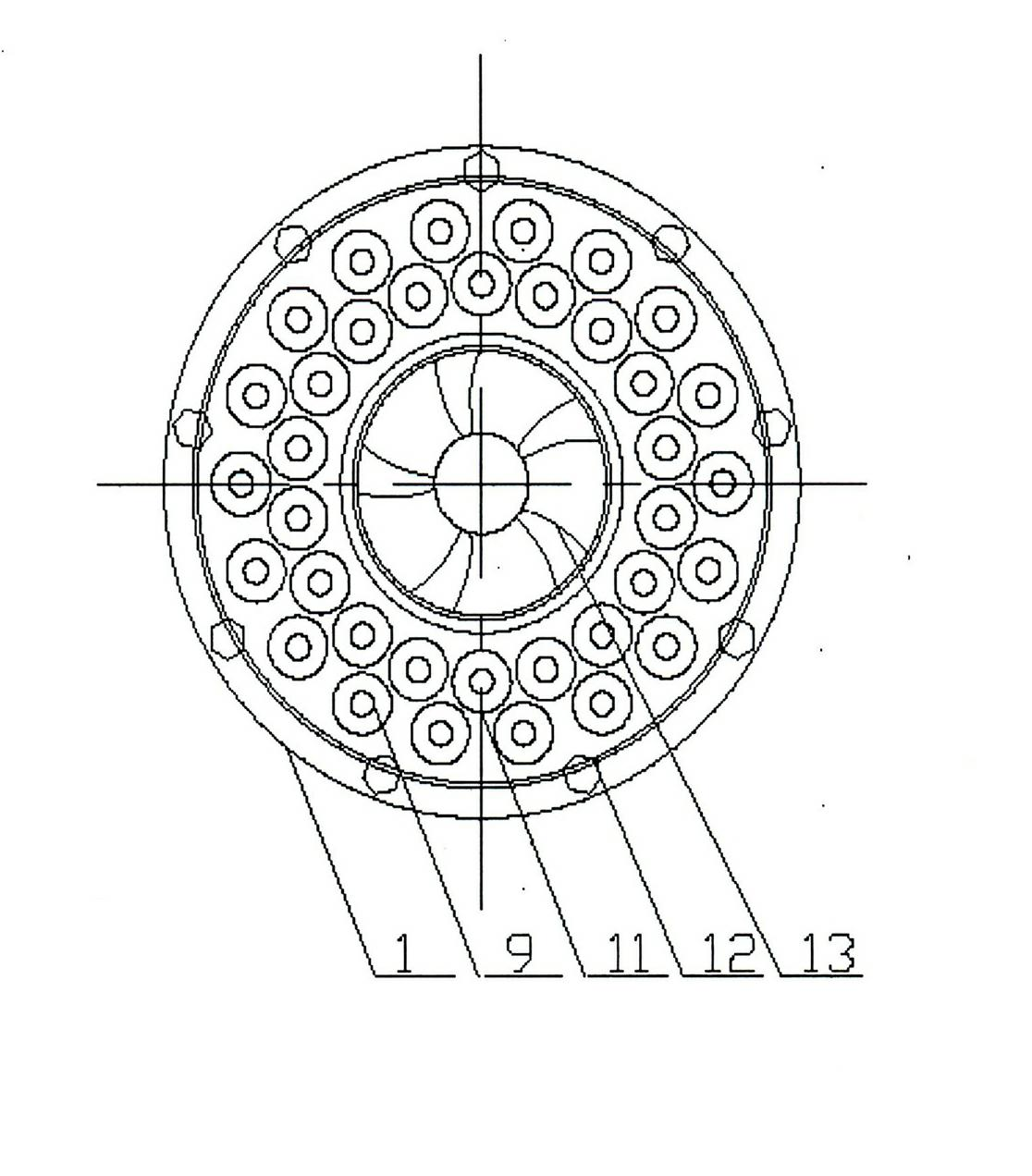

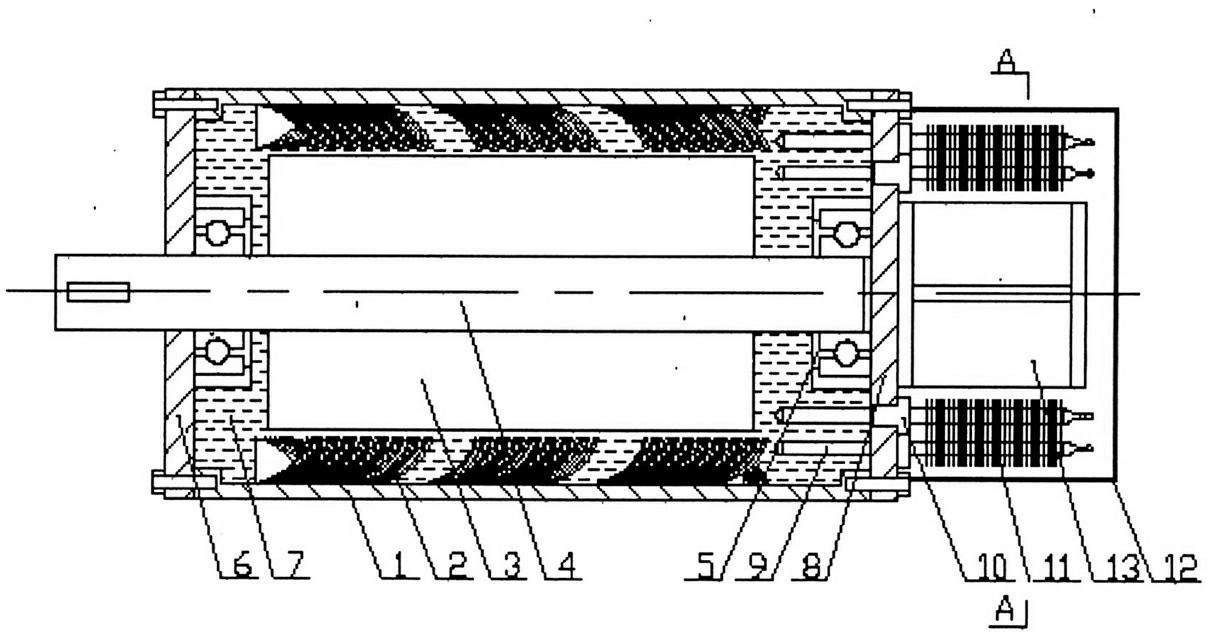

Rotor self-circulation cooling system and cooling method for high-speed motor direct-drive turbomachinery

ActiveCN106655574ASolve Cooling ProblemsHigh densityMagnetic circuit rotating partsCooling/ventillation arrangementStator coilEngineering

The invention relates to a rotor self-circulation cooling system and cooling method for a high-speed motor direct-drive turbomachinery. A motor rotor is arranged in the middle of the interior of a shell; a bearing pedestal and a bearing are mounted between the two sides of the motor rotor and the inner wall of the shell; a stator coil is arranged on the periphery of the motor stator; a motor inner cavity is formed in the internal space of the shell; a first-stage compressor is arranged at one end of the shell while a second-stage compressor is arranged at the other end of the shell; a rotor inner cavity cooling air inlet pipe and an air outlet pipe are arranged on the shell separately; and the air inlet pipe is connected with a compressor second-stage cooler while the air outlet pipe is connected with a compressor first-stage cooler. A little cooling gas enters the motor inner cavity from the second-stage cooler to take away heat of the motor rotor, and then enters the first-stage cooler to be cooled and to be compressed through the second-stage compressor, and then enters the second-stage cooler to be cooled and then enters the motor inner cavity so as to complete the self-circulation process of a little motor rotor cooling gas. By virtue of the rotor self-circulation cooling system and cooling method, the heat exchange efficiency can be improved; the comprehensive energy consumption is low; and parts of an external air source, a cooling fan and the like are not required in the cooling process.

Owner:SHANGHAI UNITED COMPRESSOR

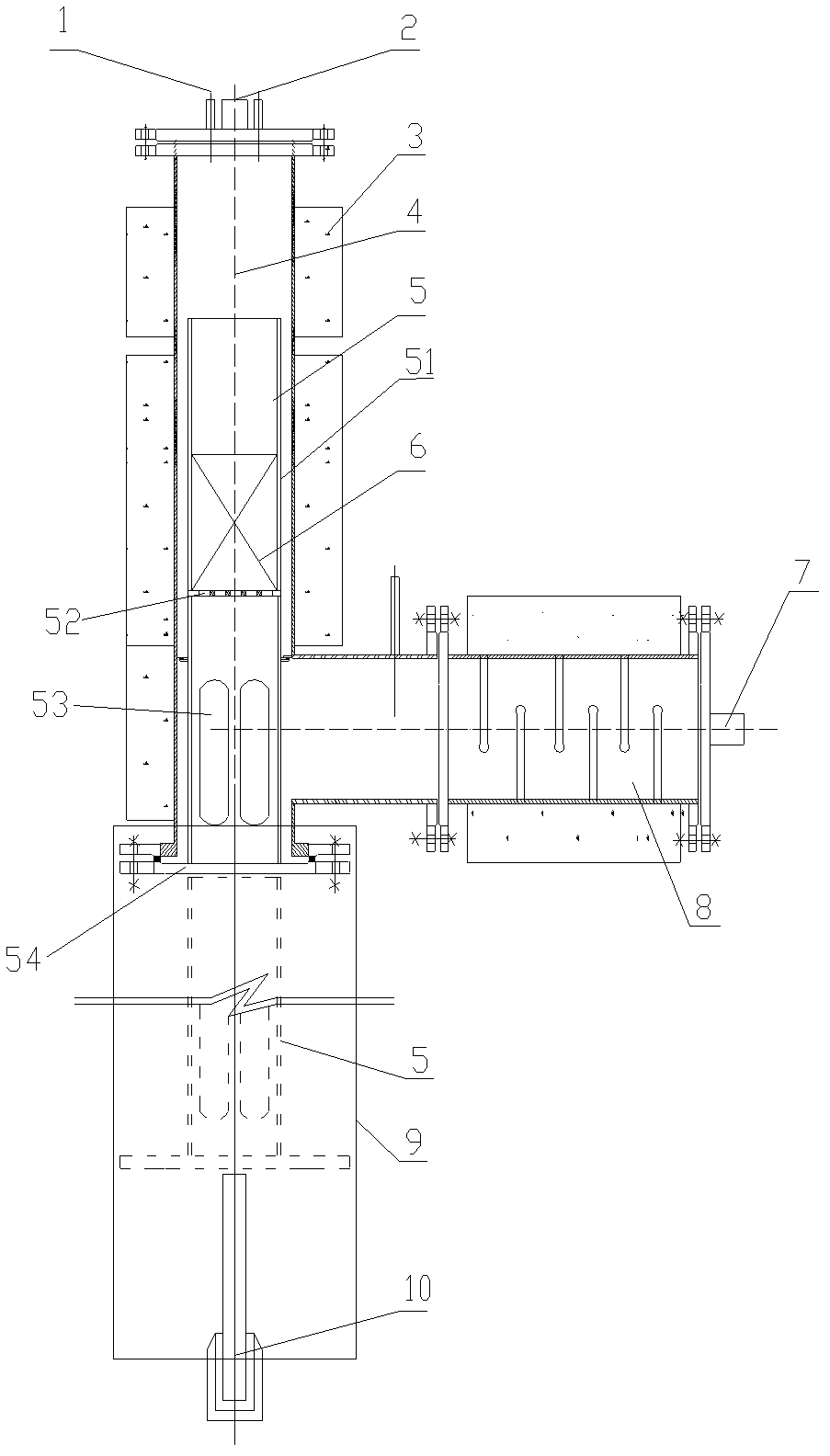

Reactor for semi-continuous production of carbon nano tube

InactiveCN102530921AEasy accessThe thermal effect is stableCarbon nanotubesNanotechnologyCarbon nanotubeThermocouple

The invention discloses a reactor for semi-continuous production of a carbon nano tube, and relates to a reactor for producing a carbon nano tube. The reactor for semi-continuous production of the carbon nano tube has the advantages of simple structure, short operation cycle, low energy consumption, high space-time utilization rate of the equipment and the like, is convenient to operate and can enable a solid product to be quickly removed out of the reactor in high-temperature working condition. The reactor is provided with a reactor body, a saggar, a carbon nano tube bed layer, a gas preheater, a cooler and a saggar lifting air pump, wherein the top of the reactor body is provided with a thermocouple lead-out point and a tail gas outlet; the upper part of the reactor body is provided with a heating layer; the saggar is arranged in the reactor body; the carbon nano tube bed layer is arranged in the saggar; a raw gas inlet is arranged on one side of the gas preheater; a heating galvanic couple rod is arranged in the gas preheater; the gas preheater is arranged on one side of the lower part of the reactor body and connected with the reactor body; the cooler is arranged at the lower part of the reactor body and forms a vertical trapezoidal structure with the reactor body and the gas preheater; and the saggar lifting air pump is arranged in the cooler.

Owner:XIAMEN UNIV

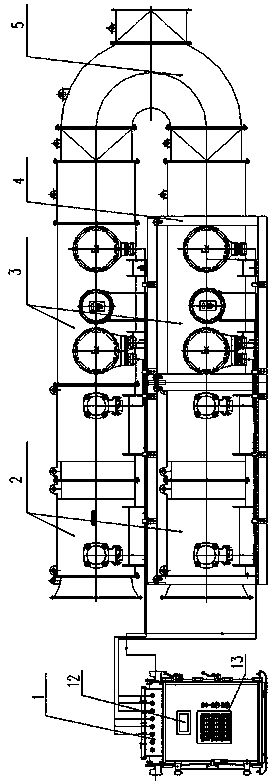

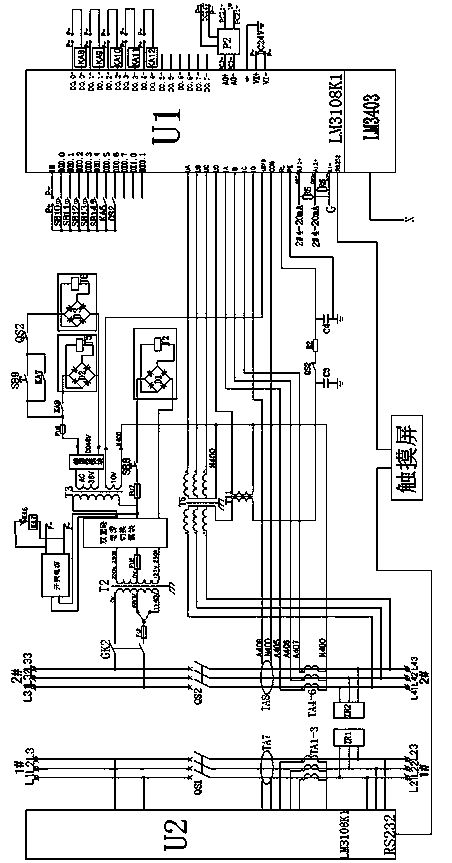

Intelligent coal mine local ventilation system

ActiveCN103591041AAutomatic speed adjustmentImprove safety and reliabilityTunnel/mines ventillationPump controlAuto regulationComputer module

The invention discloses an intelligent coal mine local ventilation system which comprises a mining flame-proof type two-circuit feeder switch, two passageway type anti-explosion frequency converters and two local ventilation machines. The mining flame-proof type two-circuit feeder switch is connected with an information collecting module under a coal mine, supplies power for the two anti-explosion frequency converters respectively and controls the two anti-explosion frequency converters to work. The two anti-explosion frequency converters are connected with the two local ventilation machines respectively, and air flow automatic switching devices are further arranged at air outlets of the two local ventilation machines. Under the control of the mining flame-proof type intelligent two-circuit feeder switch, rotation speed of a fan is automatically adjusted, air is supplied according to needs, gas is intelligently exhausted, energy is saved, consumption is reduced, disasters are prevented, and safety and reliability of the local ventilation system are improved.

Owner:WOLONG ELECTRIC NANYANG EXPLOSION PROTECTION GRP CO LTD

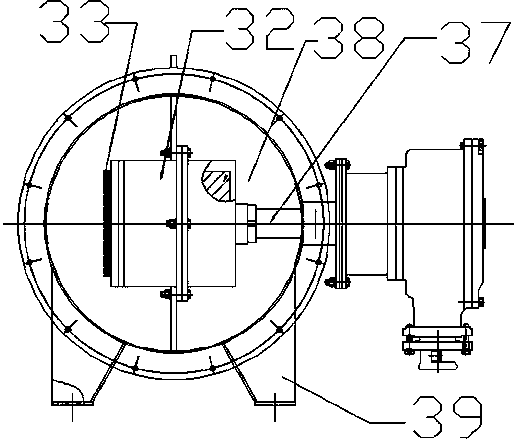

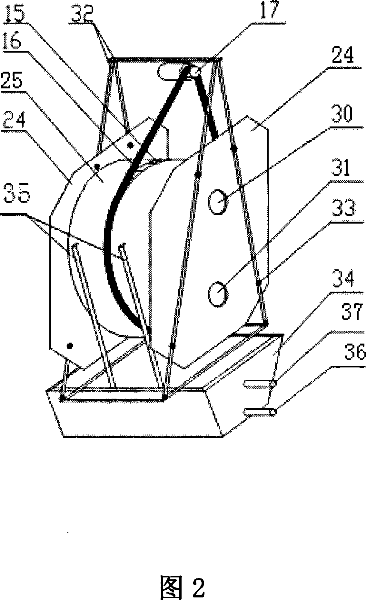

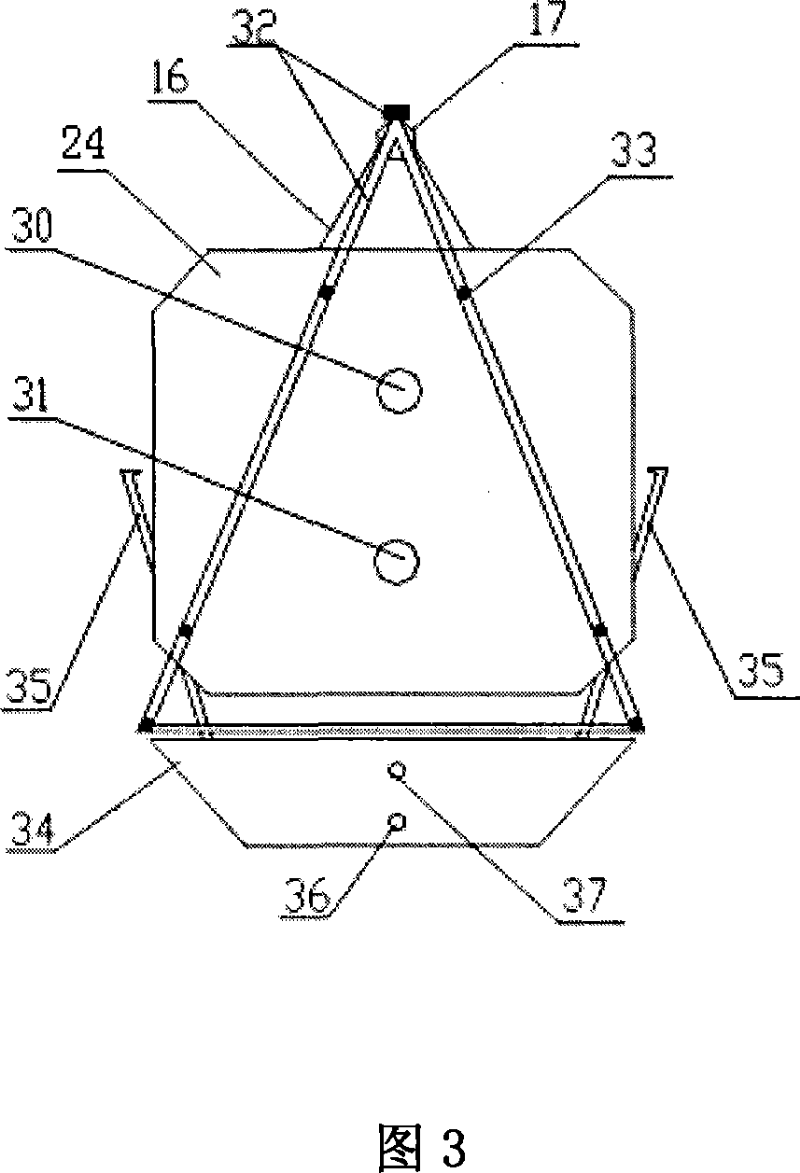

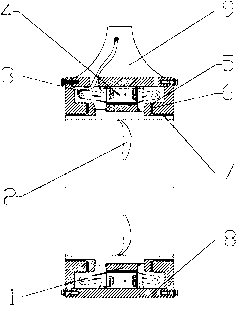

Absorber used in solar refrigeration equipment

InactiveCN101038112AEnables continuous cooling processPrevent leakageAbsorbers/adsorbersEngineeringRefrigeration

The present invention provides a rotary absorber for solving the fault existing in heat exchanging and energy lost of existing solar solid absorber. The rotary absorber includes a rotary wheel, a cooling device and a rotary device. The rotary absorber is characterized in that the rotary wheel includes a rotary wheel housing connected to the rotary device, a wheel body and front, rear block plates fixed on the two end surfaces of the wheel body. The wheel body includes a rotary shaft and a wheel hub which is disposed with radiate wedge-shaped absorb beds on the circumferential direction. A wedge-shaped mass transfer passage is disposed between each two adjacent wedge-shaped absorb beds, the radiate end circle of the wedge-shaped absorb bed is fixed on the inner wall of the rotary wheel housing; the two end surfaces of the wheel body and the rotary wheel housing form a round concave, the inner side of the front and rear cover plates are respectively disposed with round platforms having the same diameter with the round concave. The round platforms are disposed with V shape clapboard and bearing seat, and are embedded into the round concave of the rotary wheel housing to divide the two end surface of the wheel body into upper and lower two regions.

Owner:CHANGAN UNIV

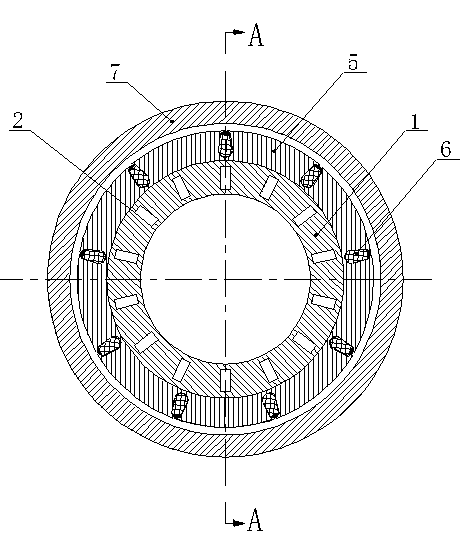

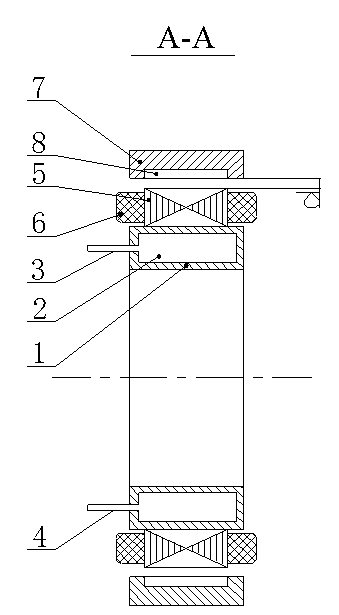

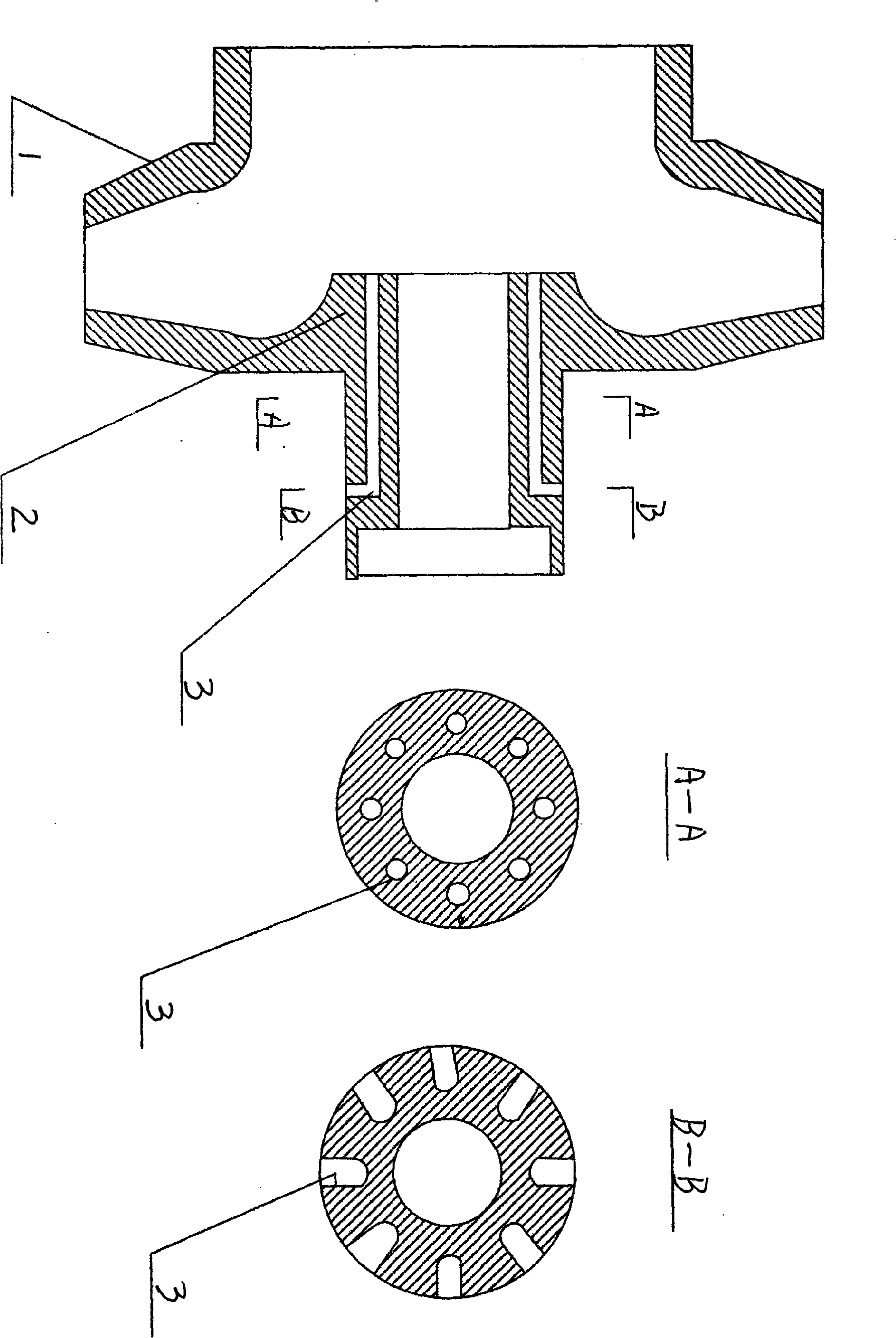

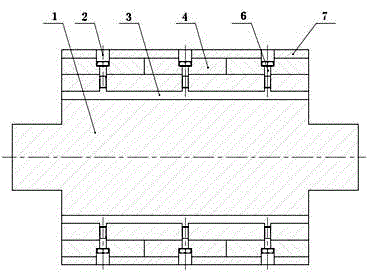

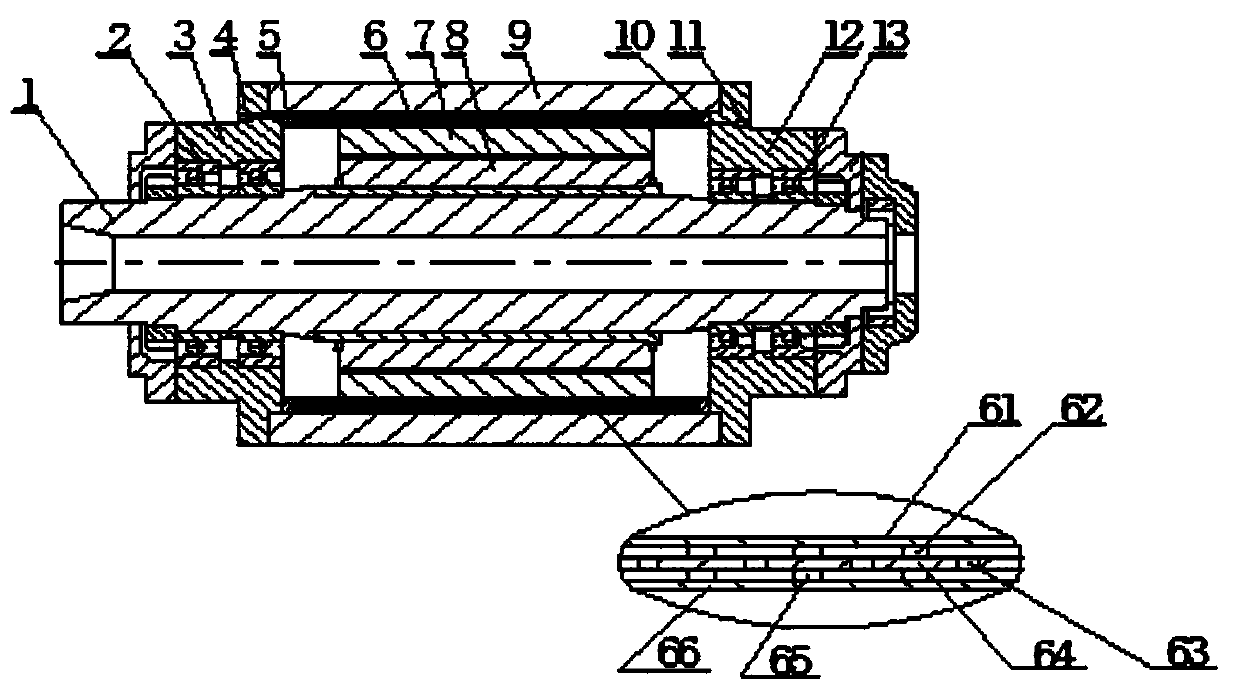

Shafting-free outer rotor permanent-magnet synchronous motor with stator water-cooling structure

InactiveCN103124127ASolving Stator Cooling ProblemsSolve Cooling ProblemsSynchronous machine detailsSupports/enclosures/casingsSynchronous motorElectric machine

The invention discloses a shafting-free outer rotor permanent-magnet synchronous motor with a stator water-cooling structure, belongs to the field of motors and aims to solve the problems that structures of most of technical schemes for cooling motors are complicated, manufacturing costs of the motors are increased, and a motor stator can not be effectively cooled. The shafting-free outer rotor permanent-magnet synchronous motor comprises a rotor and a stator, the rotor is arranged outside the stator, an air gap is reserved between the rotor and the stator, the rotor comprises rotor magnetic steel and a plurality of permanent magnets, the plurality of permanent magnets are uniformly distributed along the inner circumference surface of the rotor magnetic steel, the stator comprises a stator core and stator windings, a plurality of stator slots are uniformly arranged in the stator core along the peripheral direction, the stator windings are embedded into the stator slots, the stator further comprises a stator casing, the stator casing is arranged on the inner circle surface of the stator core, an S-shaped cold water diversion trench, a water inlet pipeline and a water outlet pipeline are mounted in the stator casing, and the water inlet pipeline and the water outlet pipeline extend out of an end face of the stator casing and are communicated with the cold water diversion trench.

Owner:HARBIN INST OF TECH

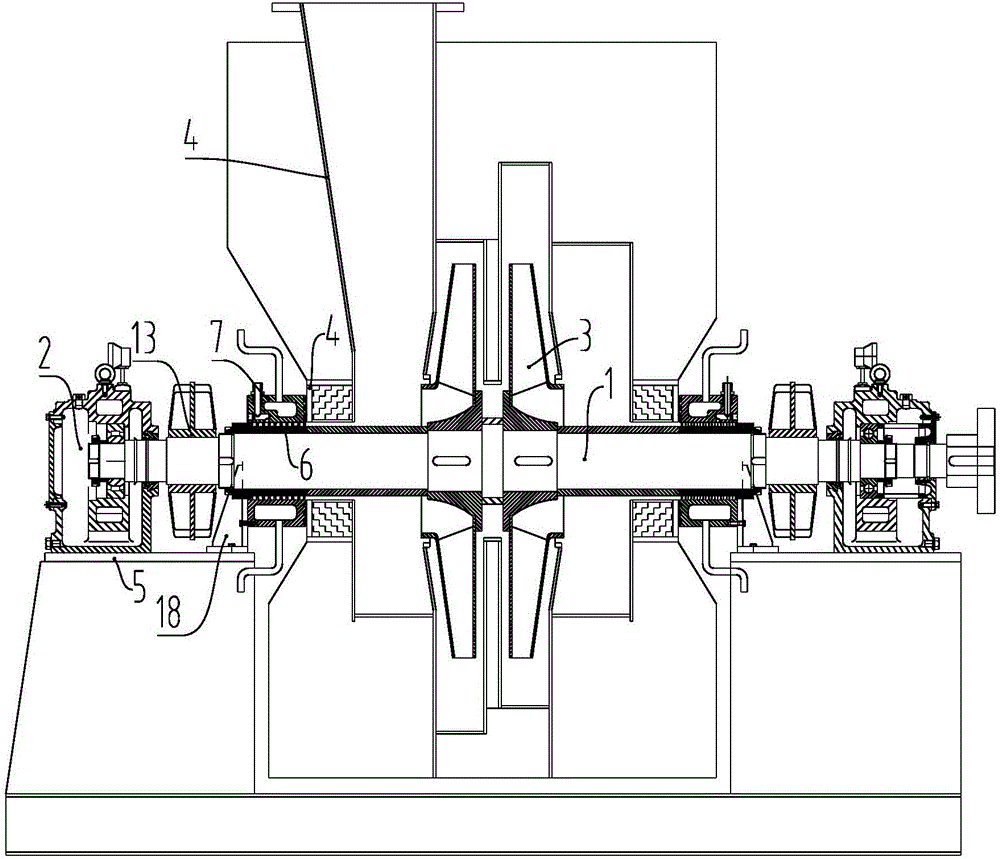

Fan for ultrahigh-temperature flue gas treatment

The invention relates to the technical field of fans and particularly relates to a fan for ultrahigh-temperature flue gas treatment, which is capable of working at the temperature of 650 DEG C and resistant to the highest temperature of 800 DEG C. The fan comprises a main shaft, bearing boxes arranged at two ends of the main shaft, an impeller arranged on the main shaft and a machine shell; each bearing box is arranged on a base; the main shaft is provided with sealing and cooling assemblies respectively located at two sides of the machine shell; and each sealing and cooling assembly comprises a sealing assembly and a cooling assembly which are arranged on the main shaft of the fan. Two sides of the machine shell of the fan are provided with the sealing and cooling assemblies for sealing and cooling the machine shell and the main shaft, and the sealing assembly and the cooling assembly are of an integral structure, so that the fan is simpler in structure; due to the adoption of the sealing and cooling assemblies, the sealing and cooling effects of the fan are good, and the problems of high-temperature flue gas leakage and high-temperature main shaft cooling can be effectively solved; and the temperature on the position of a bearing on the main shaft can be reduced to be lower than 60 DEG C, so that the normal operation of the fan at high temperature can be ensured.

Owner:四川三维鼓风机有限公司

Multifunctional mechanical sealing axle sleeve

InactiveCN101338764AExtended service lifeShortened cantilever ratioPump componentsPumpsMechanical engineeringImpurity

Owner:王加华

Heat-pipe module heat dissipation oil bath electromotor

InactiveCN102427285AGuaranteed uptimeDistribute quicklyCooling/ventillation arrangementVena contracta diameterHeat transmission

The invention provides a heat-pipe module heat dissipation oil bath electromotor. The electromotor is characterized in that a shell end plate which is not passed by a motor shaft is an orifice plate, a heat pipe is arranged in each through hole, and the middle of each heat pipe is fixed by a connecting piece and sealed on an end plate; heat transmission working substance is arranged in the heat pipe, the heat absorption section of the heat pipe is positioned in the shell, the heat dissipation section is positioned outside of the shell, the shell end plate provided with the heat pipe is provided with a fan; the heat dissipation sections of the heat pipes are externally provided with a protective cover which holds the heat pipes, and a fin, a gill and a spiral piece; and a heat transmission module is fixed on an electromotor shell so as to rapidly emit heat, the normal operation of the electromotor is guaranteed, and particularly a cooling problem of a high power motor is solved.

Owner:DALIAN SHANGLIDE HEAT CONDUCTION TECH

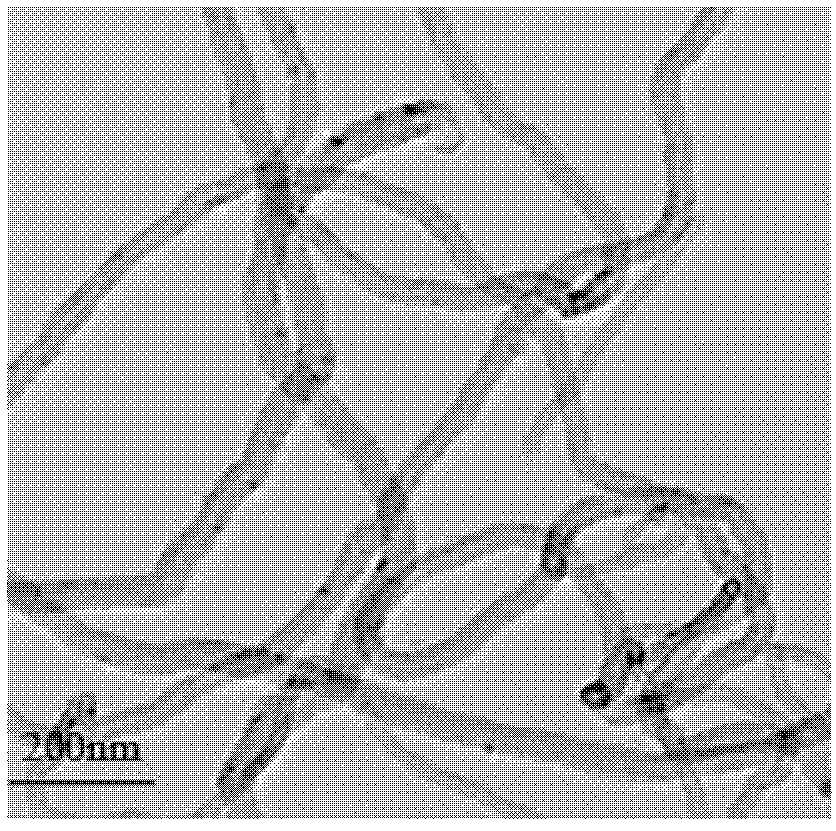

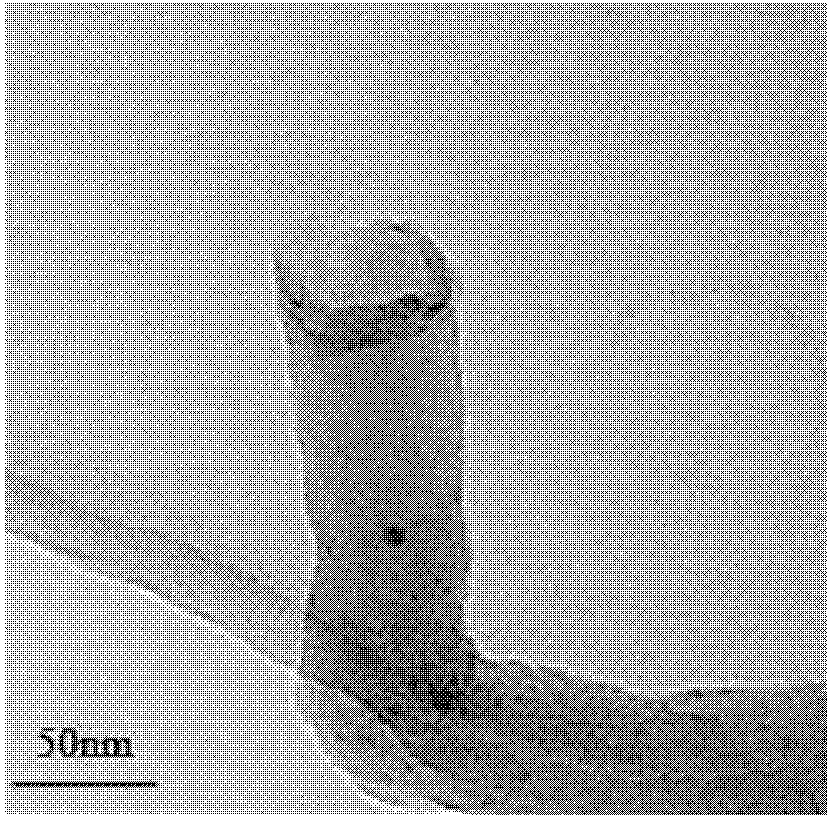

High-temperature-resistant high-infrared-emission passive radiation cooling structure and cooling method

The invention discloses a high-temperature-resistant high-infrared-emission passive radiation cooling structure and a cooling method. According to the high-temperature-resistant high-infrared-emissionpassive radiation cooling structure, polystyrene is dissolved in tetrahydrofuran, after the polystyrene is completely dissolved, pure water is added, and then a precursor solution is obtained; the tetrahydrofuran is evaporated, the polystyrene is separated from water and forms micropores, and then a cooling material layer is formed; the cooling material layer is attached to the surface of a heatconducting material layer; the cooling material layer is covered with a covering layer; a heat insulation cavity layer is formed between the cooling material layer and the covering layer; the heat conducting material layer, the cooling material layer, the heat insulation cavity layer and the covering layer form the passive radiation cooling structure; the heat conducting material layer makes contact with a cooled body, the covering layer is exposed in the outdoor environment, and the cooling material layer emits the heat of the cooled body in an infrared ray manner and reflects transmitted sunlight back. The high-temperature-resistant high-infrared-emission passive radiation cooling structure can provide passive type cooling for some occasions and equipment and achieves the cooling function.

Owner:TIANJIN UNIV

Closed water cooling system with double-evaporative cooling pressure

ActiveCN102748963ALower evaporation temperatureImprove cooling effectSteam/vapor condensersStationary conduit assembliesCooling towerNuclear engineering

The invention discloses a closed water cooling system with a double-evaporative cooling pressure, which provides the closed water cooling system used in an air-cooled thermal power set. The closed water cooling system comprises a direct-current evaporating and cooling closed water chiller A, a direct-current evaporating and cooling closed water chiller B, a vacuum butterfly valve, a vapor injector A, a vapor injector B, five sections of steam extracting and entering regulating valve, a plant steam aiding and entering regulating valve, a NO. 8 low pressure heater, a condenser, a liquid level sensor and a DCS (distributed control system); pipe sides of the two direct-current evaporating and cooling closed water chillers A and B are connected in series; and an evaporating and cooling pressure at a casing side of B is lower than that of A, thus the problem that output power of a turbo generator set is limited by an overhigh temperature of closed water is solved, cooling conditions of a host machine and an auxiliary machine are improved, heat output by hot closed water is recycled as much as possible, and power consumption of the closed water system is lowered. By the adoption of the closed water cooling system, no wet-type mechanical ventilated cooling tower is needed for open circulated water cooling, the occupation area of the cooling tower is reduced, the investment on capital construction is reduced, the electricity consumption is decreased, and the water consumption is zero.

Owner:章礼道

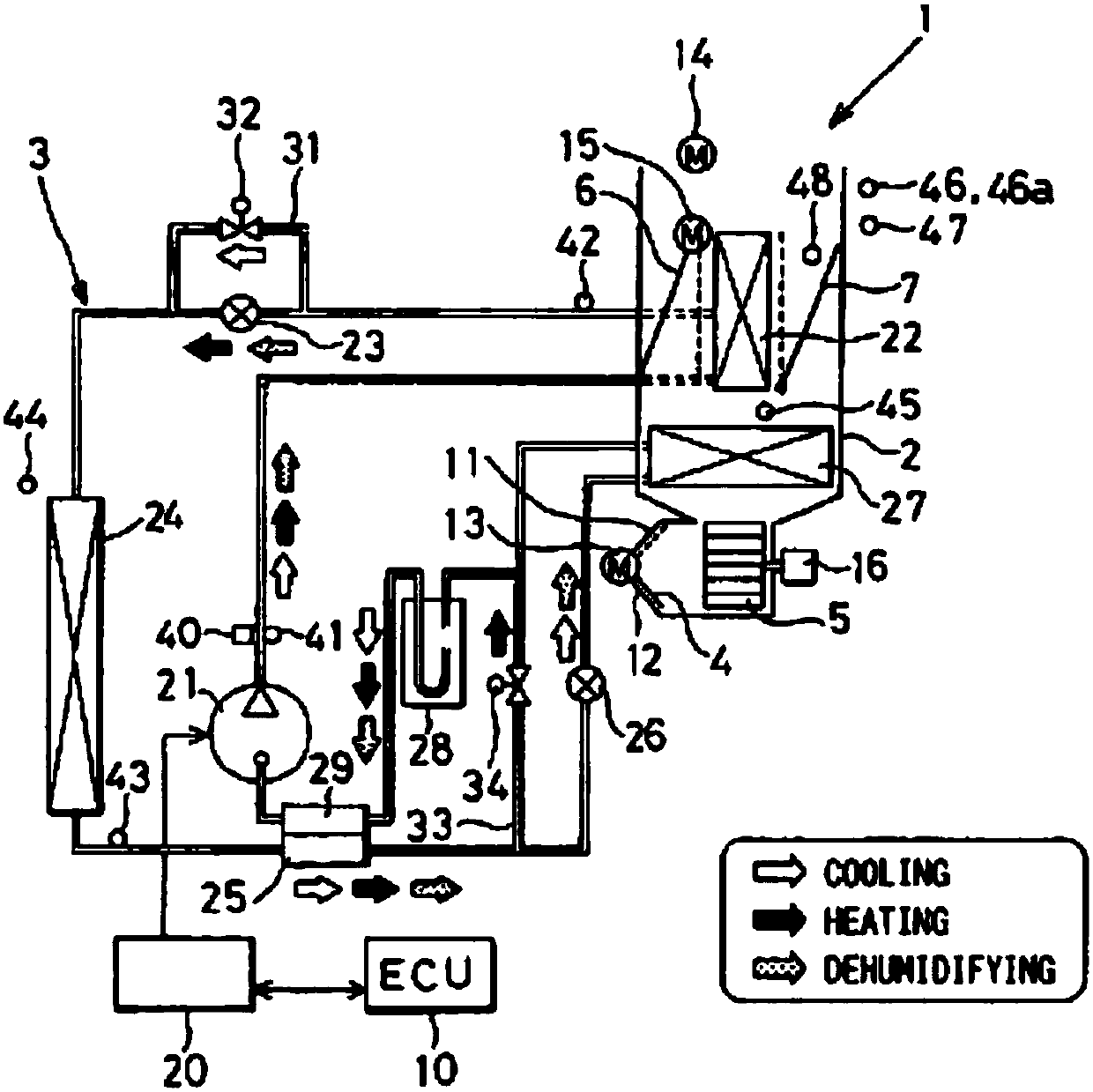

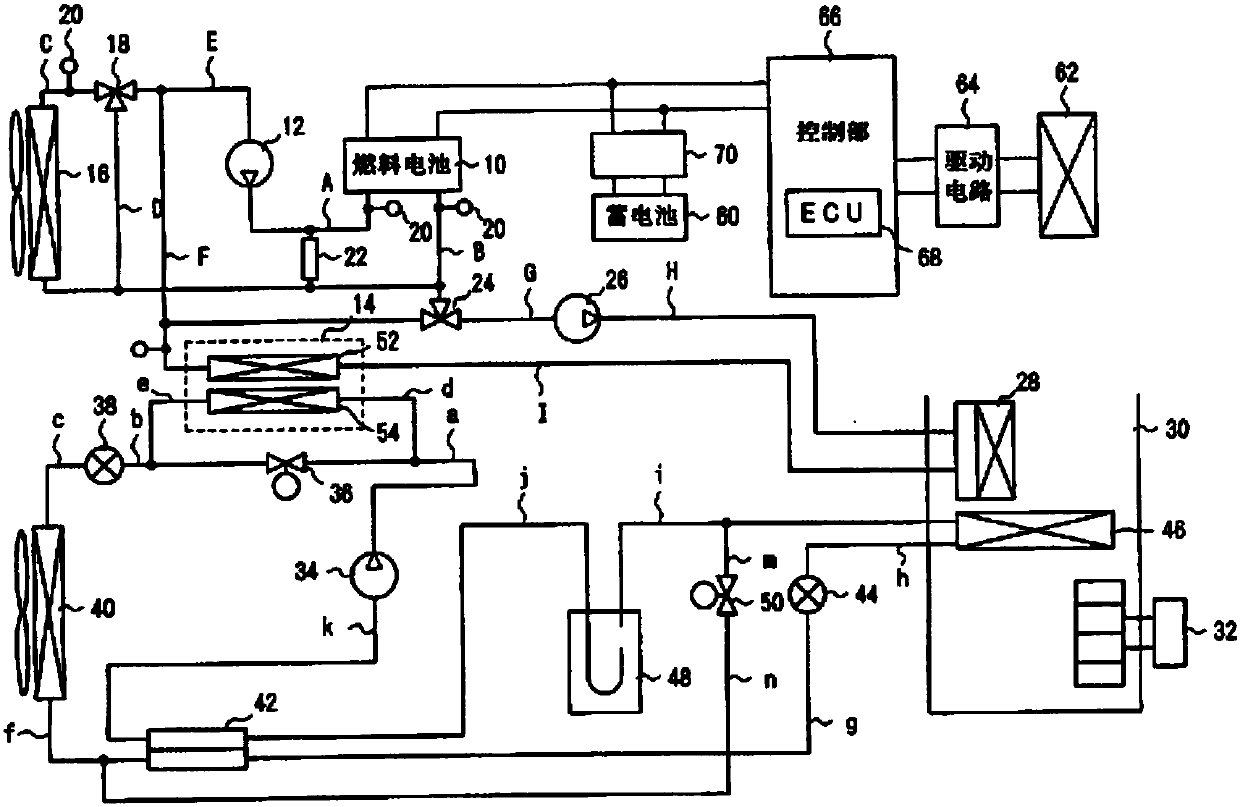

Air conditioning heat pump system of automobile

ActiveCN107782020AReduce lossIncrease mileageMechanical apparatusHeat pumpsPlate heat exchangerVapor–liquid separator

The invention discloses an air conditioning heat pump system of an automobile. The air conditioning heat pump system comprises a compressor, an external condenser, a second expansion valve, an evaporator and a gas-liquid separator. The compressor is serially connected with the external condenser by a plate heat exchanger, a first expansion valve and a bypass pipe are arranged between the plate heat exchanger and the external condenser, the bypass pipe is parallel to the first expansion valve, and the external condenser, the gas-liquid separator and the second expansion valve are communicated with one another via a first three-way electromagnetic valve; the plate heat exchanger is used as a channel during refrigerating, and heat of refrigerants can be absorbed by the plate heat exchanger during heating and can be used as a heat source for providing heat exchange heat for the inside of the automobile. The heat sources can be provided for the HVAC (heating ventilation air conditioning) system by the plate heat exchanger via a first circulating water channel, preheated heat sources can be provided for batteries via a second circulating water channel, an economizer is further arranged in a third refrigerating system, and cooling cold sources can be provided for the batteries via a third circulating water channel.

Owner:ZHEJIANG DUNAN ARTIFICIAL ENVIRONMENT

Cooling method and cooling device of end pump laser

The invention discloses a cooling method and a cooling device of an end pump laser. The end pump laser comprises a laser cavity and a laser crystal bar located in the laser cavity, a pumping mode of an end pump is adopted, and pumping lasers are focused inside the laser crystal bar. According to the cooling method of the end pump laser, a plurality of spraying devices are arranged on a cavity wall of the laser cavity, the spraying devices spray water mist to the laser crystal bar, an air inlet and an air outlet are arranged in the laser cavity and in the direction parallel with the laser crystal bar, and air flow in the laser cavity flows from the air inlet to the air outlet. The cooling method and the cooling device of the end pump laser are compact in structure, are good in cooling effect, and successfully resolve the problem that the end pump laser which can not be cooled with water can be cooled under the condition of high injection power.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Projector capable of being used for underwater working

InactiveCN103424964ASolve Cooling ProblemsMoisture-proof and dust-proofProjectorsWater leakageHeat conducting

The invention discloses a projector capable of being used for underwater working. The whole projector is sealed in a waterproof box body shell made of heat conducting materials. A liquid cooling device and a semiconductor cooling device are arranged in the projector, a sealed type cooling system is formed, and the liquid cooling device and the semiconductor cooling device are both connected with the box body shell. The waterproof projector is of a sealed type structure, the sealed waterproof box body shell made of the heat conducting materials can guarantee the fact that the whole projector is tight without water leakage, moisture-resistant and dustproof effect is achieved, and heat in a box body can be conducted out of the box body shell. The liquid cooling device and the semiconductor cooling device are arranged in the projector to form the sealed type cooling system, and accordingly the problem of radiating cooling of a sealed structure is solved. The projector completely overcomes the shortcomings in the prior art and can be completely used for underwater working and be completely suitable for being used in various bad environments such as a wet sealed environment, an environment with a large amount of dust, a high-temperature environment and an environment with bad radiating.

Owner:吴佳明

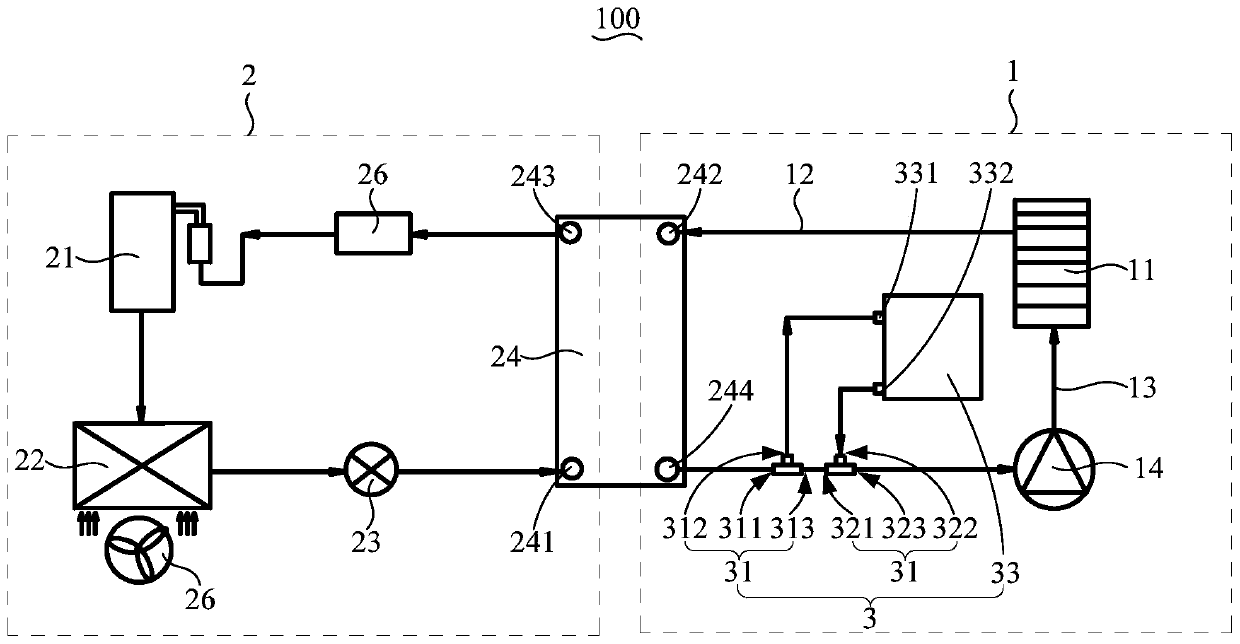

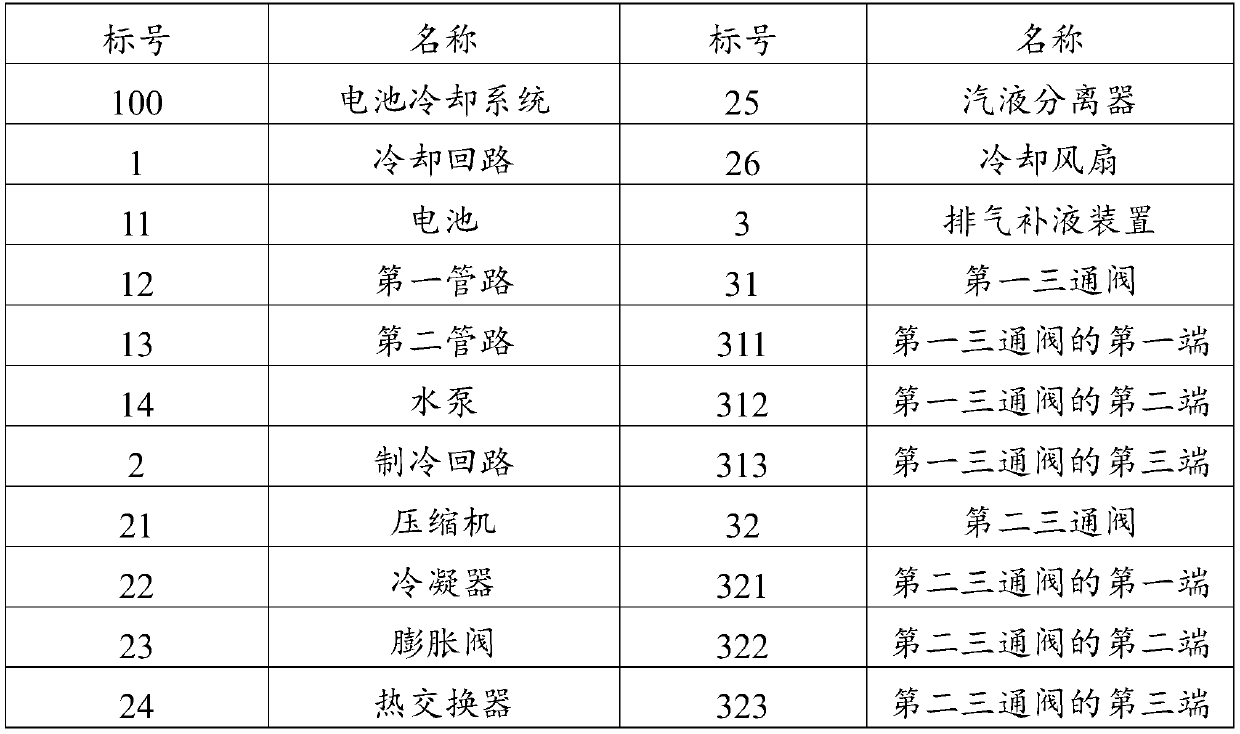

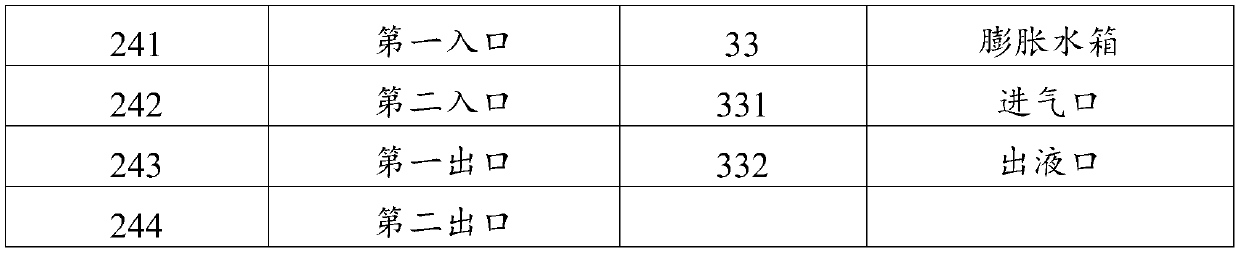

Battery cooling system and electric bus

InactiveCN110137622AAchieve coolingEfficient exclusionSecondary cellsVehicular energy storagePower batteryRefrigeration

The invention discloses a battery cooling system and an electric bus. The battery cooling system comprises a cooling circuit and a refrigeration circuit which are arranged in parallel. The refrigeration circuit comprises a compressor, a condenser, an expansion valve and a heat exchanger which are sequentially connected in series. The cooling circuit comprises a battery which is connected in serieswith the heat exchanger. The battery cooling system further comprises an exhaust rehydration device arranged in the cooling circuit. The exhaust rehydration device is arranged between the heat exchanger and the battery. The aim of that invention is to solve the cooling problem of the power battery of the electric bus in case of charging and discharging, and the air in the system can be effectively discharged and the battery coolant can be replenished so as to improve the heat exchange efficiency of the cooling system.

Owner:SHENZHEN SKYWORTH AIR CONDITIONING TECH CO LTD

High-speed permanent magnet motor rotor structure

InactiveCN102946157AConvenient finishingLow heating temperatureMagnetic circuit rotating partsPhysicsHigh intensity

The invention relates to a high-speed permanent magnet motor rotor structure. Radial bolt holes and axial ventilation holes are formed in a rotor, wherein the radial bolt holes are communicated with the axial ventilation holes; a permanent magnet block and a magnetic pole interval are fixedly arranged on the rotor through bolts; and jackets are thermally sheathed outside the permanent magnet block and the magnetic pole interval on the rotor and are made of titanium alloy or high-strength metal, and the jackets are retracted and then are tightly hooped on the rotor. According to the high-speed permanent magnet motor rotor structure disclosed by the invention, a permanent magnet is fixed by adopting the bolts, the problem of mutual exclusion between a partitioning block and the permanent magnet in the matching process of the thermal sheathing is solved and the work difficulty during thermal sheathing of a permanent magnet motor is reduced; after the permanent magnet is fixed by the bolts, the finish machining of the surface can be conveniently carried out and the heating temperature of the jackets during thermal sleeving is reduced; after the jacks are assembled, the bolts can be unscrewed; bolt holes can be used as the radial ventilation holes; the radial ventilation holes and the axial ventilation holes form a ventilating and cooling system of the rotor; and the bolts are finally unscrewed, and thus the problem of stress concentration caused by the bolts is solved.

Owner:中国船舶重工集团公司第七0四研究所

Thruster adopting water lubricated bearings

InactiveCN102910276AUltra-compact all-in-one designSmall sizeRotary propellersPropellerConductor Coil

The invention relates to a thruster adopting water lubricated bearings, which comprises a rotor, a propeller blade, a motor stator core and a thruster casing. The propeller blade is arranged in the rotor; a waterproof winding is embedded in the motor stator core; and the rotor is connected with the thruster casing through the water lubricated bearings. The water lubricated bearings comprise an axial water lubricated bearing and a radial water lubricated bearing; the axial water lubricated bearing is arranged between an axial boss of the rotor and the thruster casing and used for the axial positioning of the rotor; and the radial water lubricated bearing is arranged between the outer diameter of the rotor and the thruster casing and used for the radial positioning of the rotor. The thruster adopts the structural mode of the integration of the propeller blade and the rotor of a motor, the waterproof motor winding and the water lubricated bearings, and can realize simplification and reliability.

Owner:SHANGHAI MARINE EQUIP RES INST

Cooling water jacket based on laminated plate structure and electric spindle

ActiveCN111421383AIncrease the heat exchange areaImprove heat transfer coefficientLarge fixed membersMaintainance and safety accessoriesJet flowWater jacket

The invention discloses a cooling water jacket based on a laminated plate structure. The cooling water jacket comprises a water jacket body. A front end cover is arranged at one end of the water jacket body, and a rear end cover is arranged at the other end of the water jacket body. The water jacket body comprises a target ring, an impact ring and a water jacket outer ring which are sequentially connected in a sleeving mode from inside to outside. A plurality of sets of impact through holes are formed in the thickness direction of the impact ring. A ring-shaped jet flow chamber is formed between the impact ring and the target ring. A stable pressure cavity is formed between the impact ring and the water jacket outer ring. The invention further discloses an electric spindle. The electric spindle comprises the cooling water jacket based on the laminated plate structure. By adoption of the cooling water jacket, cooling liquid enters the target ring through the arrayed impact through holes, so that jet flow impact cooling is formed; and then forced-convection heat transfer is conducted inside the structure. Due to the existence of turbulent flow pillars, the heat transfer area and heattransfer coefficient are increased, the cooling problem of the electric spindle can be effectively solved, and thus machining precision of the machine tool electric spindle is improved.

Owner:XIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com