Cooling water jacket based on laminated plate structure and electric spindle

A cooling water jacket, plate structure technology, applied in maintenance and safety accessories, large fixed members, metal processing machinery parts, etc., can solve problems such as high heat flux density, difficulty in meeting high heat flux density heat dissipation requirements, and increased motor stator heat generation. , to achieve the effect of improving heat transfer coefficient, rapid cooling, and improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

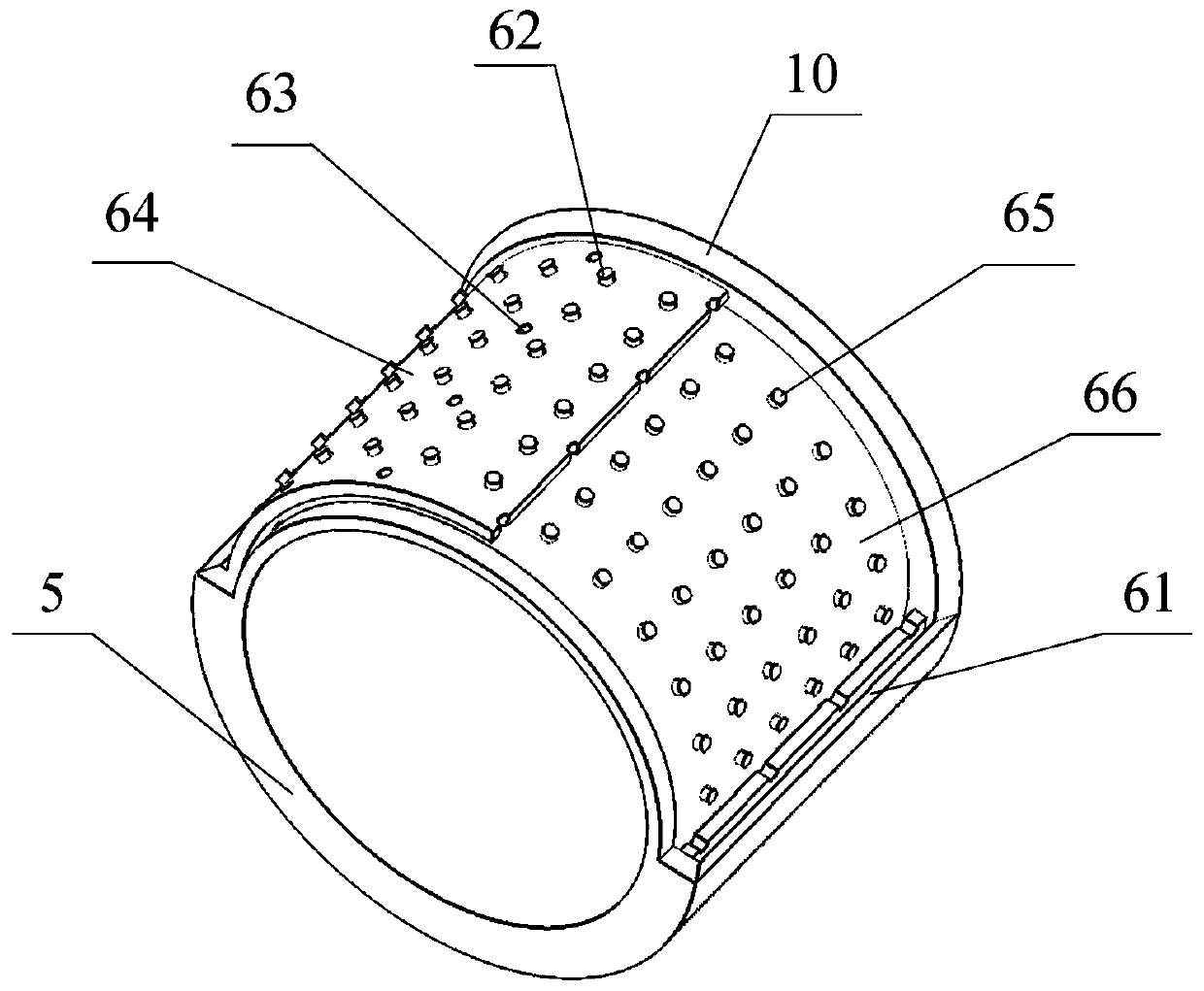

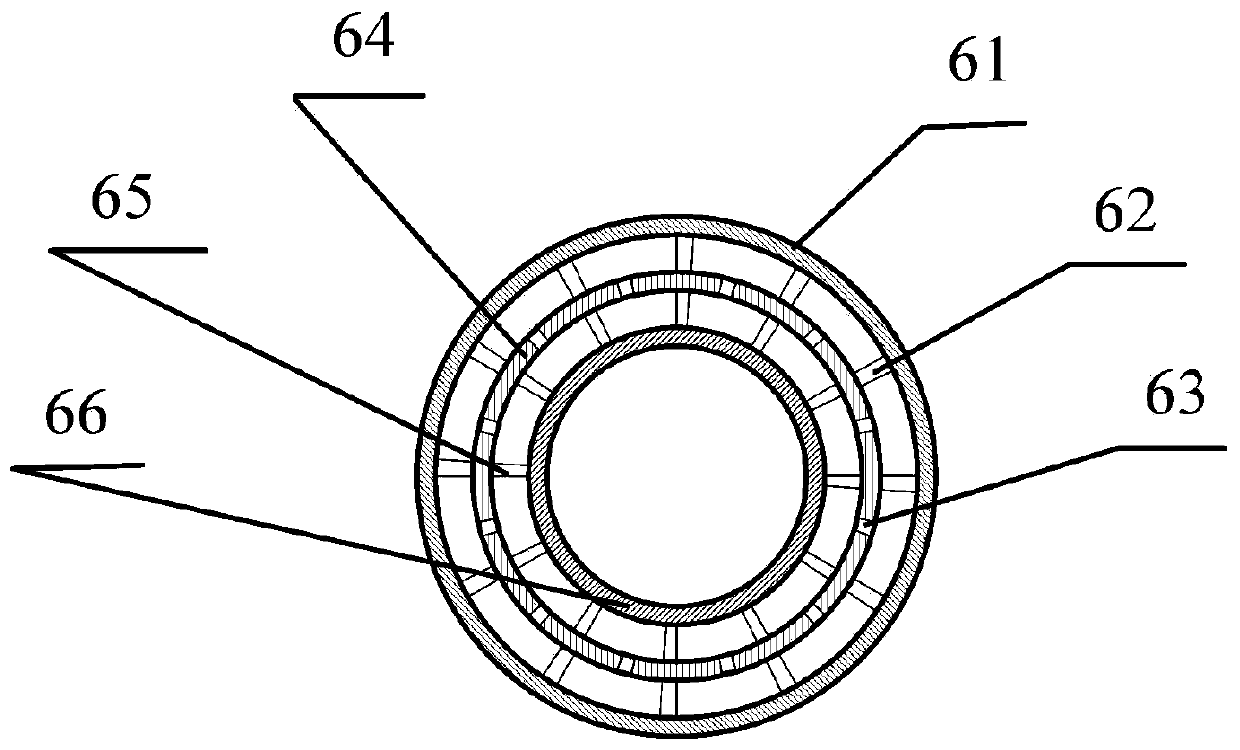

[0035] The embodiment of the present invention discloses a cooling water jacket based on laminate structure, the structure is as follows figure 1 and figure 2 As shown, it includes a water jacket body, one end of the water jacket body is provided with a front end cover 5, and the other end of the water jacket body is provided with a rear end cover 10, and the water jacket body includes a target ring 66, an impact ring 64 and The outer ring 61 of the water jacket and the impact ring 64 are provided with several groups of impact through holes 63 along the thickness direction, an annular jet chamber is formed between the impact ring 64 and the target ring 66, and an annular jet chamber is formed between the impact ring 64 and the outer ring 61 of the water jacket. Pressure chamber. The height of the annular jet chamber and / or the pressure-stabilizing chamber is 1mm-5mm. The coolant enters the surface of the target ring 66 through the array of impact holes 63 to form impact coo...

Embodiment 2

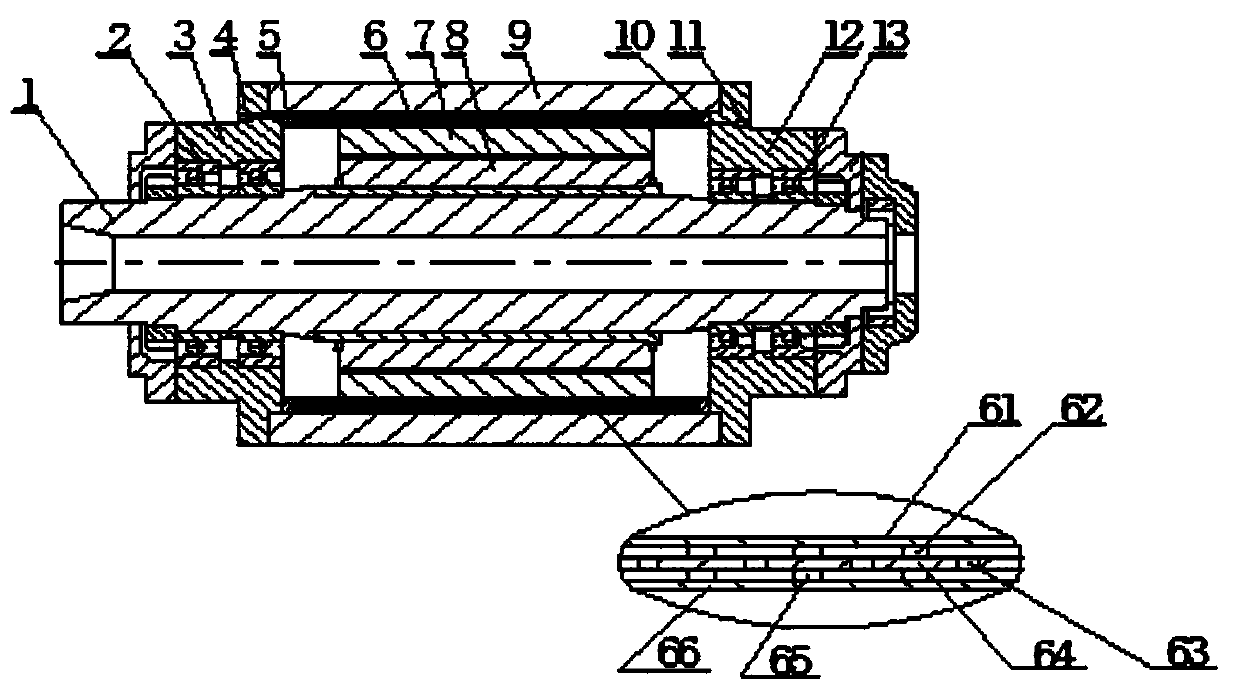

[0044] The invention also discloses an electric spindle, the structure of which is as follows: image 3 As shown, it includes a mandrel 1 , a rotor 8 , a stator 7 , a cooling water jacket 6 and a housing 9 that are tightly fitted in sequence from the inside to the outside. The cooling water jacket 6 is a cooling water jacket based on a laminate structure.

[0045] There are front bearings 2 and rear bearings 13 at the front and back of the mandrel 1, respectively, for supporting the mandrel 1; the rotor 8 is placed on the mandrel 1, and the stator 7 is placed on the outside of the rotor 8 with a certain gap between it and the rotor 8. The cooling water jacket 6 based on the laminate cooling structure is fixed on the outside of the stator 7 .

[0046] The rotor 8 is in interference fit with the mandrel 1 to output torque; there is a certain gap between the rotor 8 and the stator 7 so that they can rotate relative to each other. The outside of the stator 7 is in interference fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com