Patents

Literature

127results about How to "Convenient finishing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

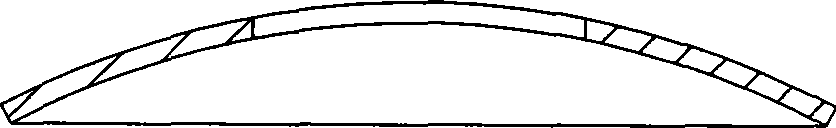

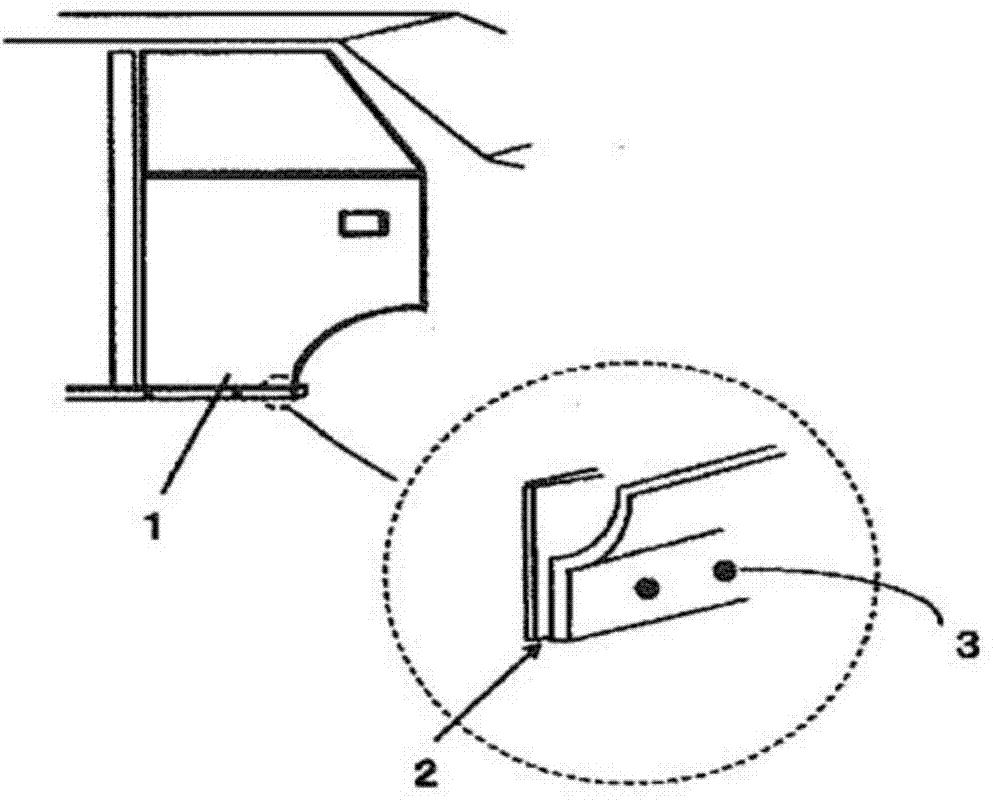

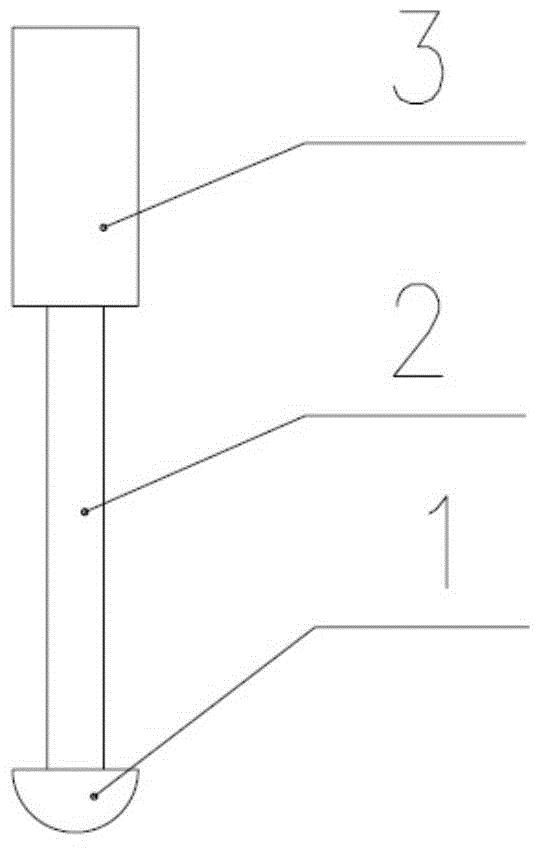

Clamp for grinding spherical pad

InactiveCN101391391AImprove efficiencyReduce processing costsSpherical surface grinding machinesBiomedical engineeringSurface smoothness

The invention discloses a fixture which is used for grinding a spherical gasket and is characterized in that the fixture comprises a flange and a clamp head which are fixedly connected; the clamp head has a same spherical arc surface as the spherical gasket, and the inside of the clamp head is provided with an electromagnetic coil. The fixture can fast clamp and fix a plurality of spherical gaskets, and is convenient for the processing device to finely process the spherical gasket with high efficiency. The accuracy and the surface smoothness of the spherical gasket are greatly increased without greatly increasing the processing cost..

Owner:RUIAN VEHICLE FITTING FACTORY

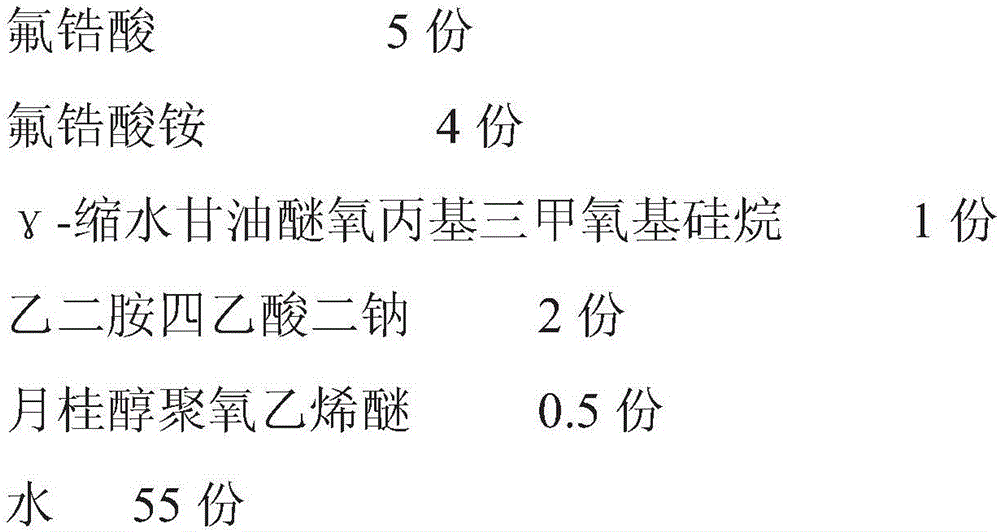

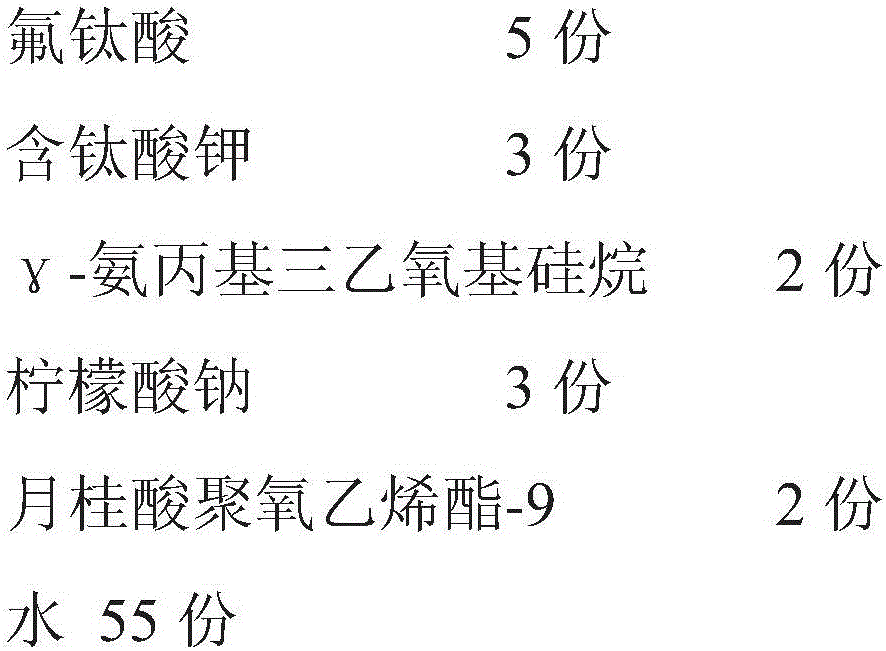

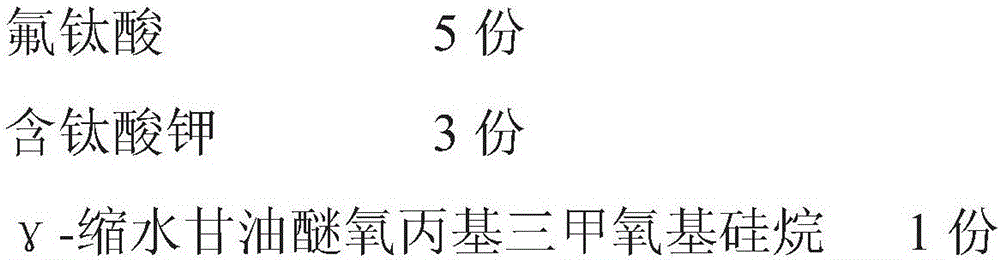

Graphene-based coating agent

ActiveCN106011816AImprove corrosion resistanceImprove performanceMetallic material coating processesGraphiteGraphene

The invention discloses a graphene-based coating agent. The graphene-based coating agent comprises, 0.1-1 part of nano-graphite, 1-3 parts of a graphene dispersing agent, 2-10 parts of fluorine-bearing acid, 2-10 parts of fluorine-bearing acid salt, 1-2 parts of a silane coupling agent, 2-5 parts of a complexing agent, 0-2 parts of a surface wetting agent and 70-95 parts of water. The graphene-based coating agent has the advantages of short film forming time, good film forming property and environment friendliness. An inorganic film formed on the surface of metal through the graphene-based coating agent has excellent lubricity and corrosion resistance and is thin. The formed inorganic nanofilm has excellent conductivity, lubricating property and corrosion resistance and has higher corrosion resistance and longer salt mist time, and therefore corrosion resistance of a metal substrate is better improved, surface impedance of the metal is not influenced after the film is formed, and finish machining of the metal is better facilitated.

Owner:苏州禾川化学技术服务有限公司

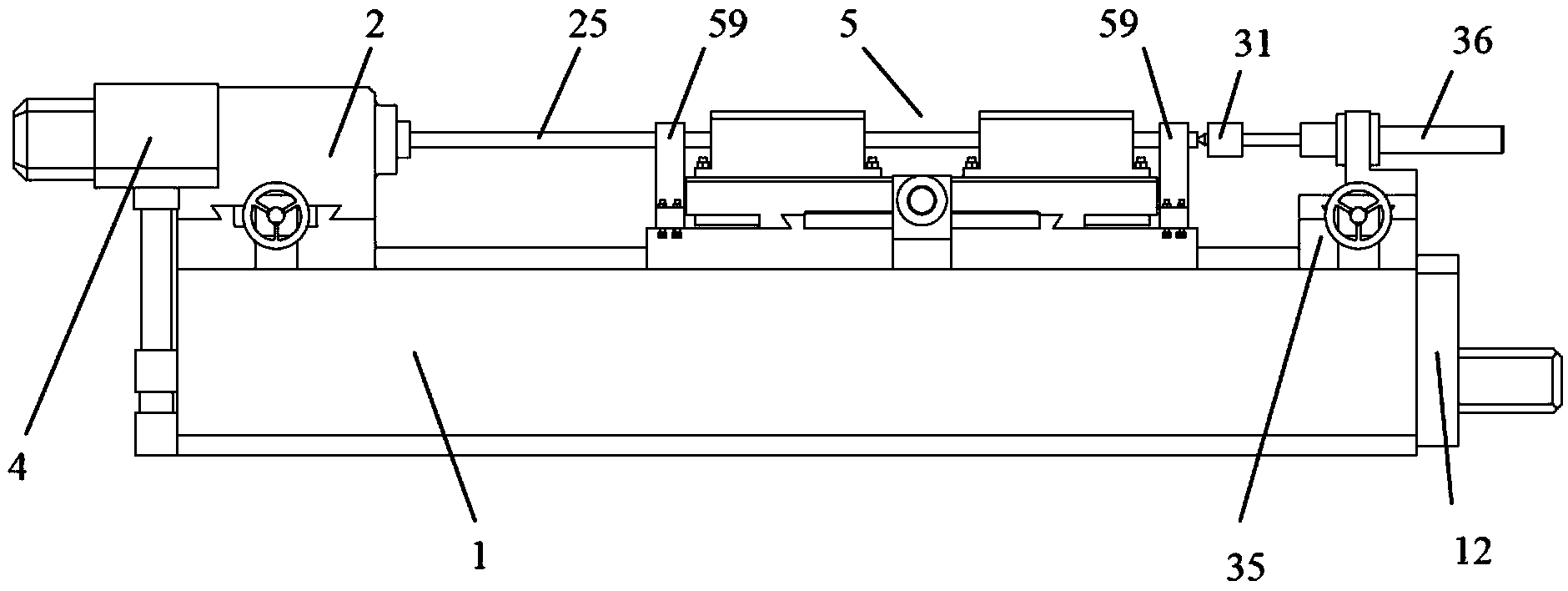

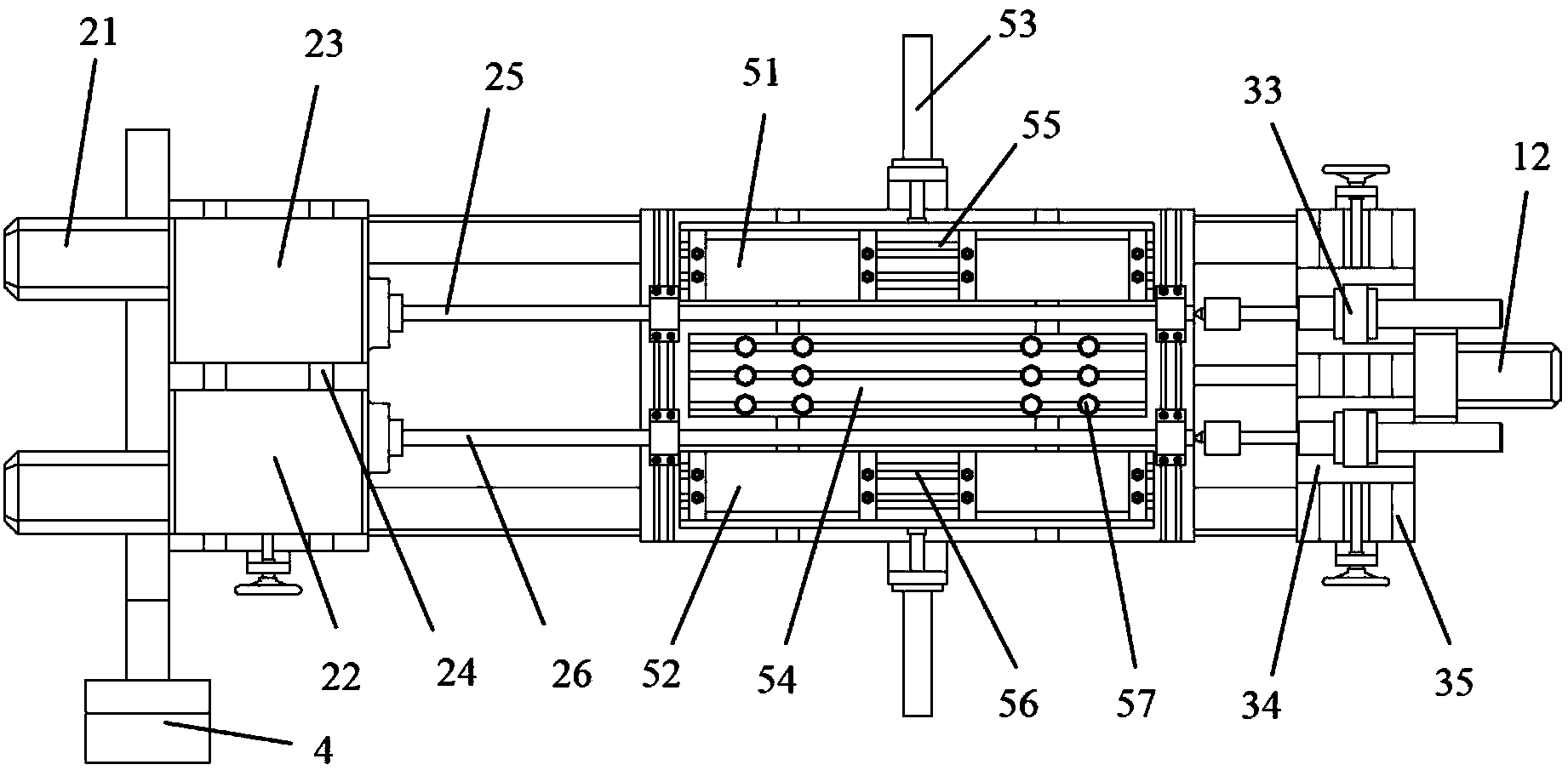

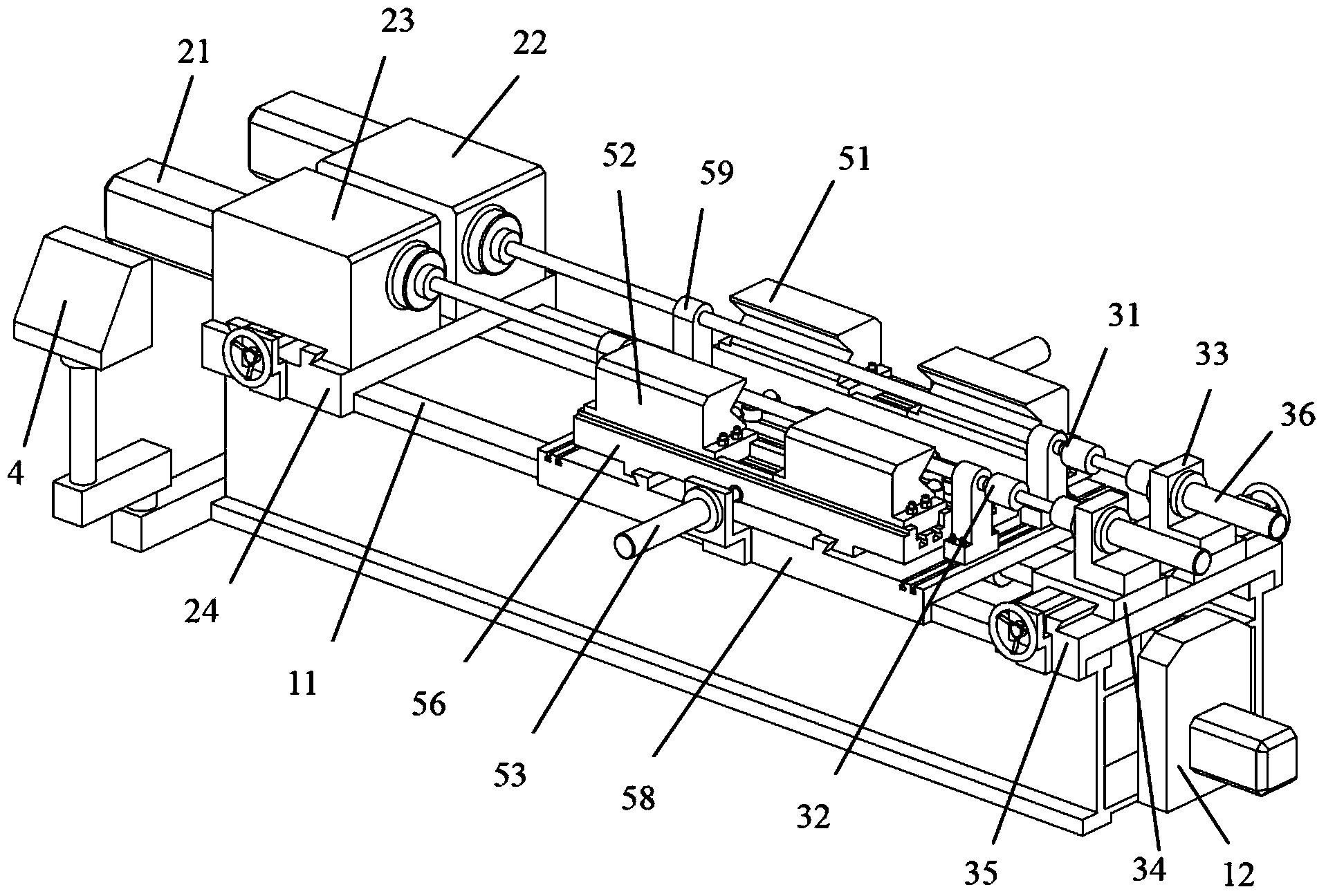

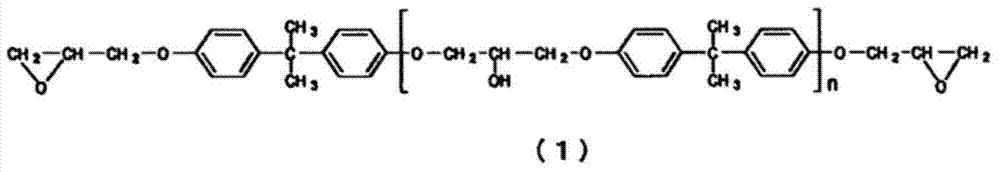

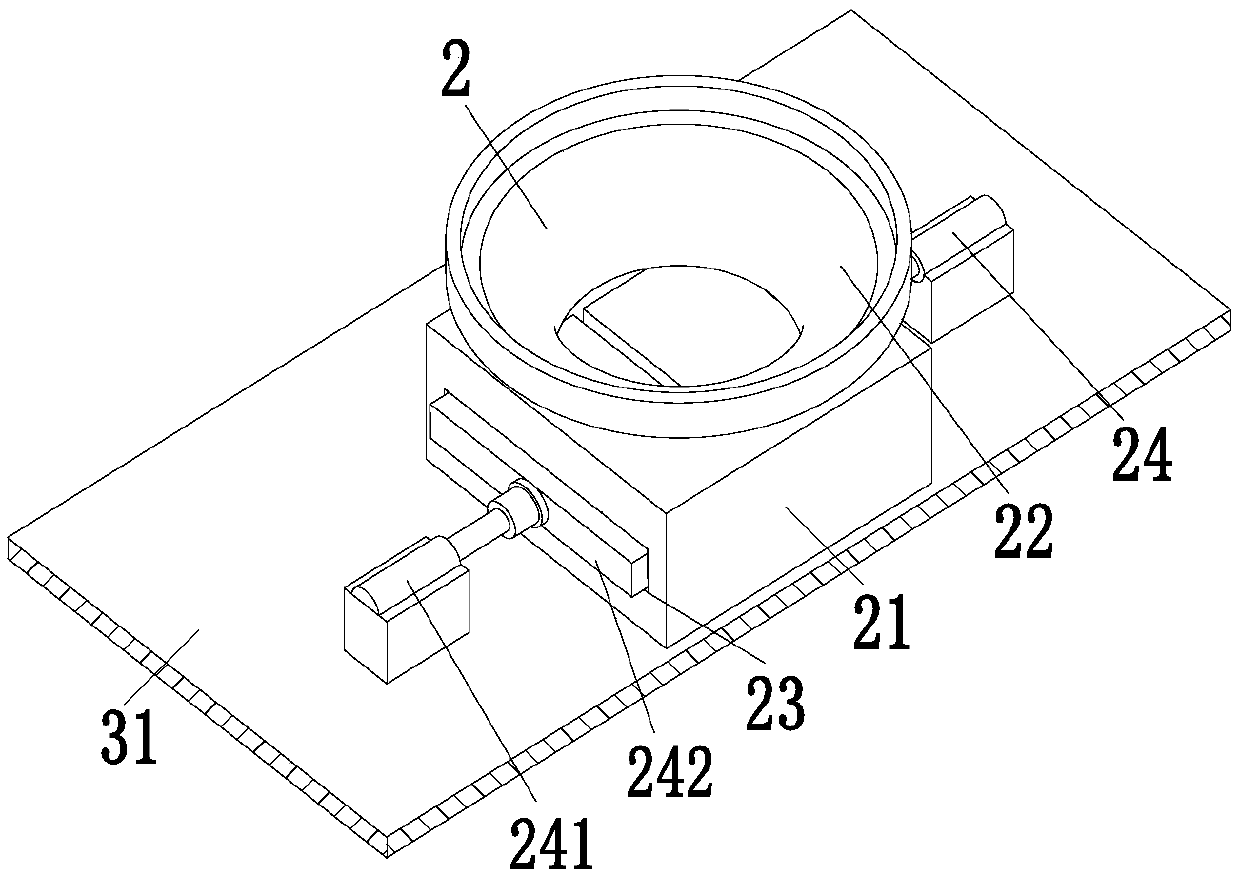

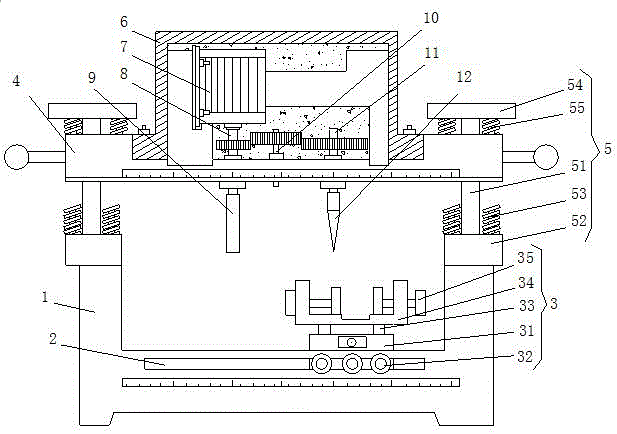

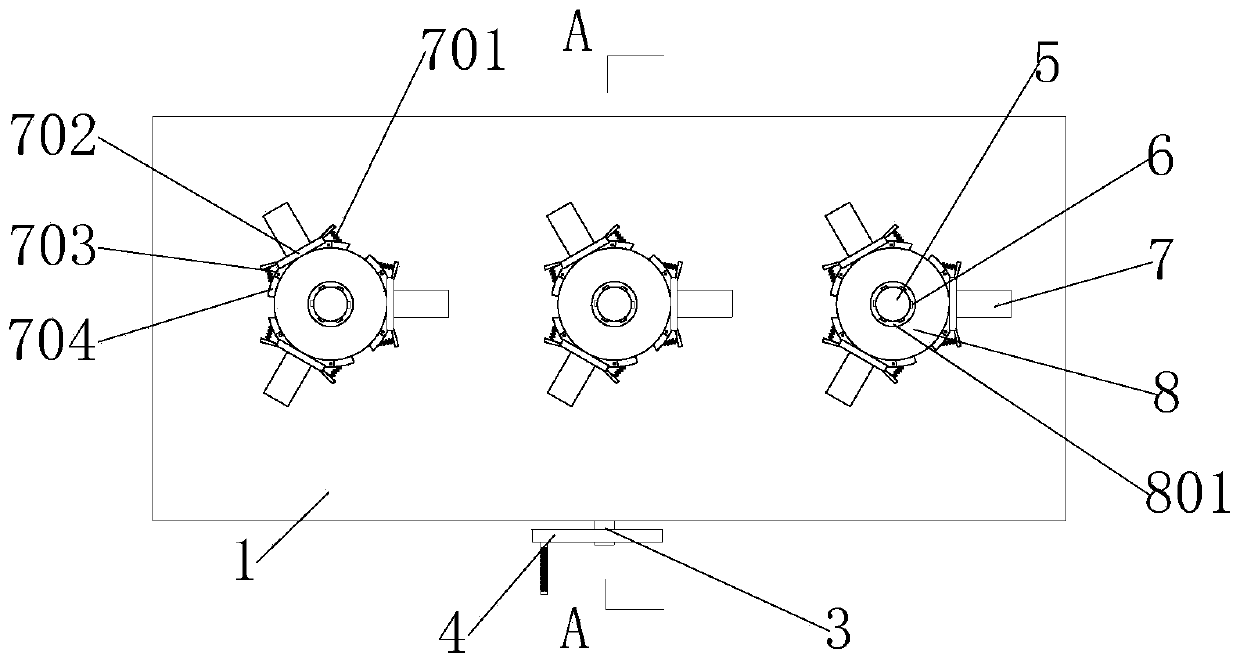

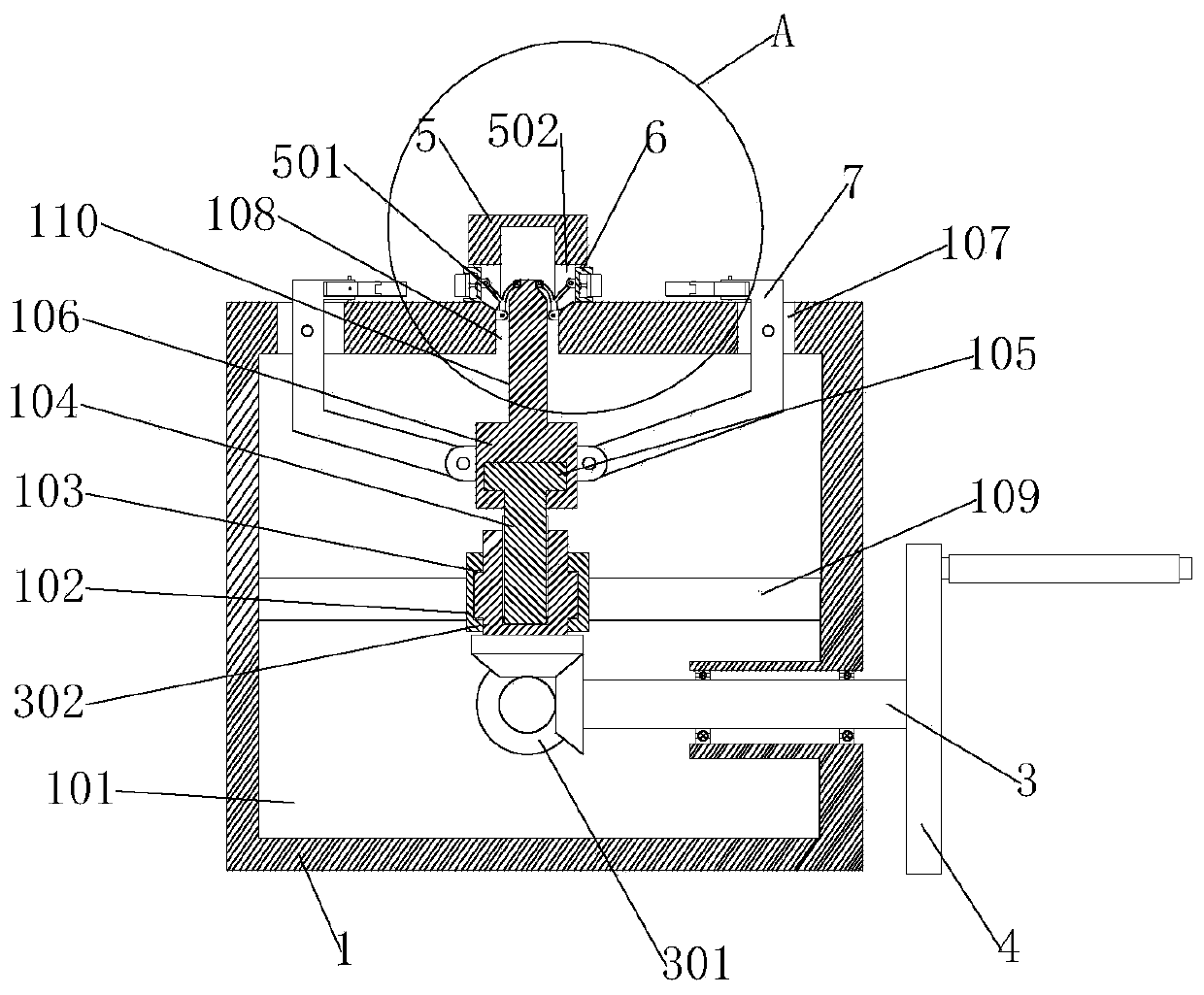

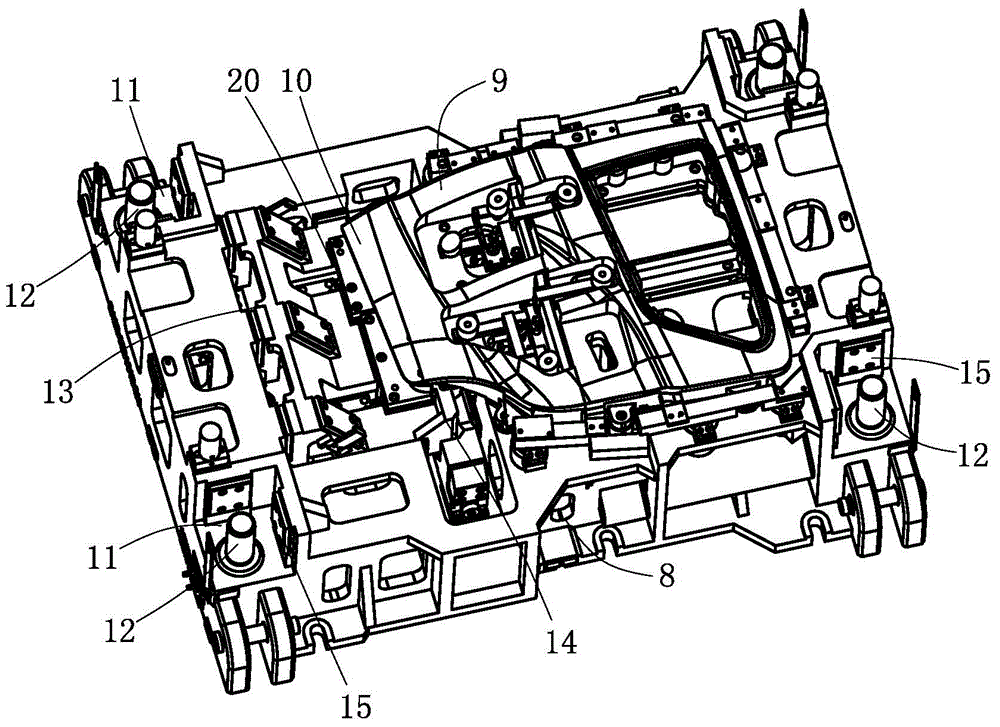

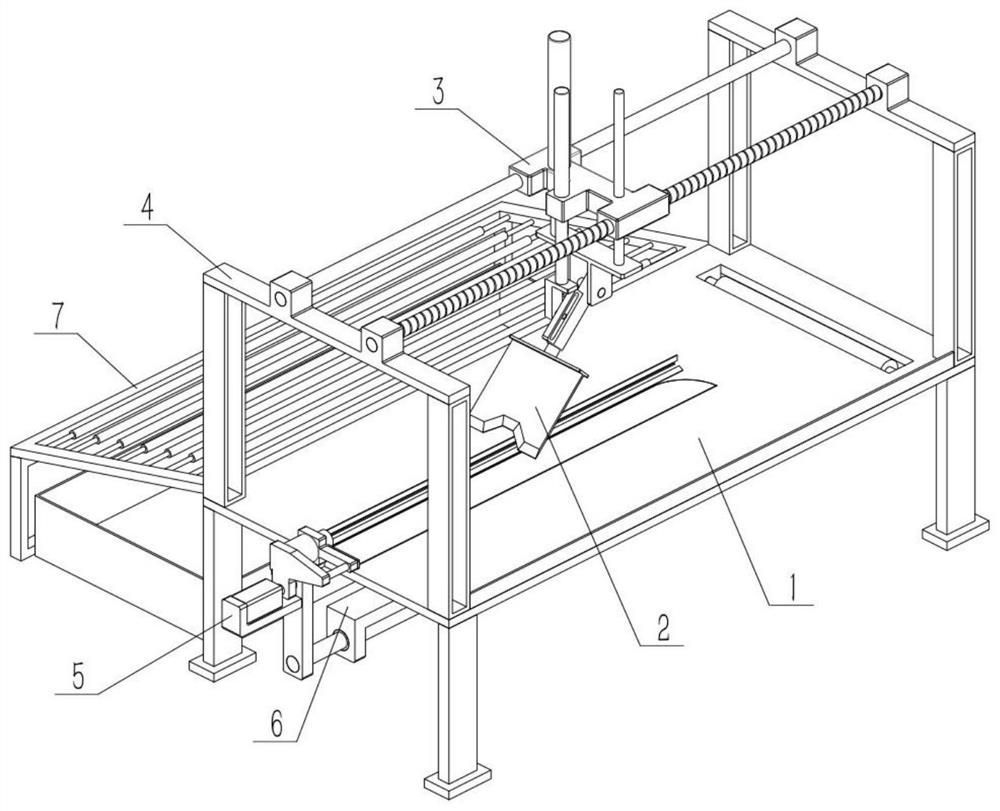

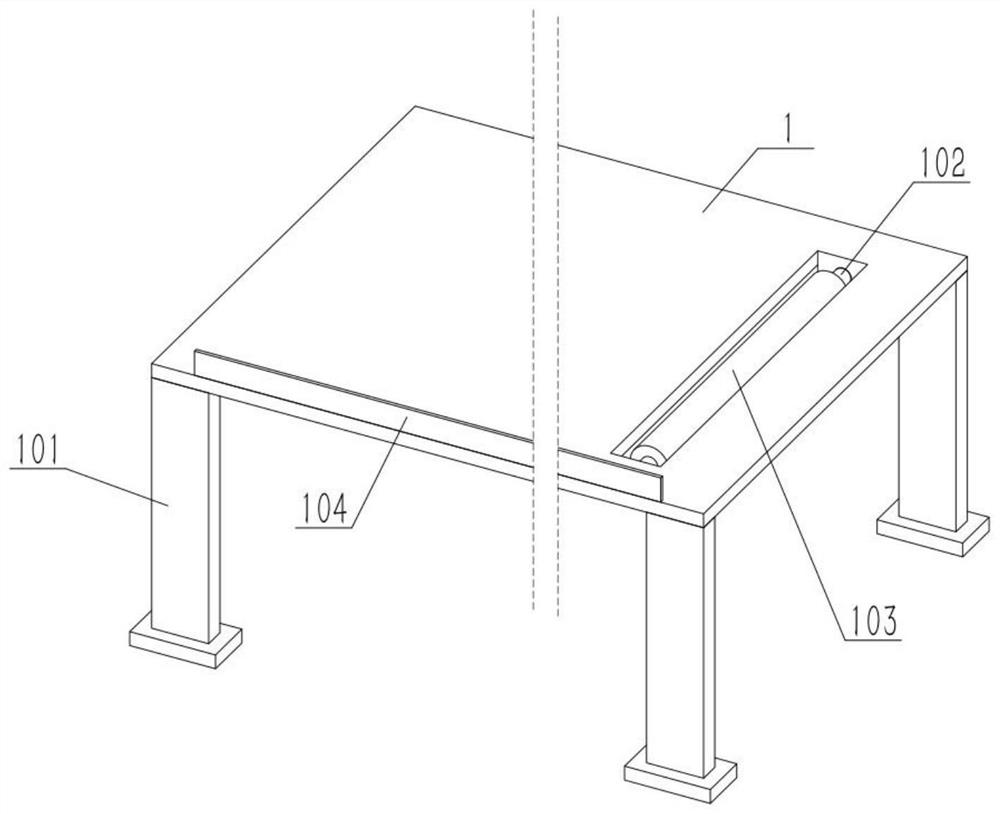

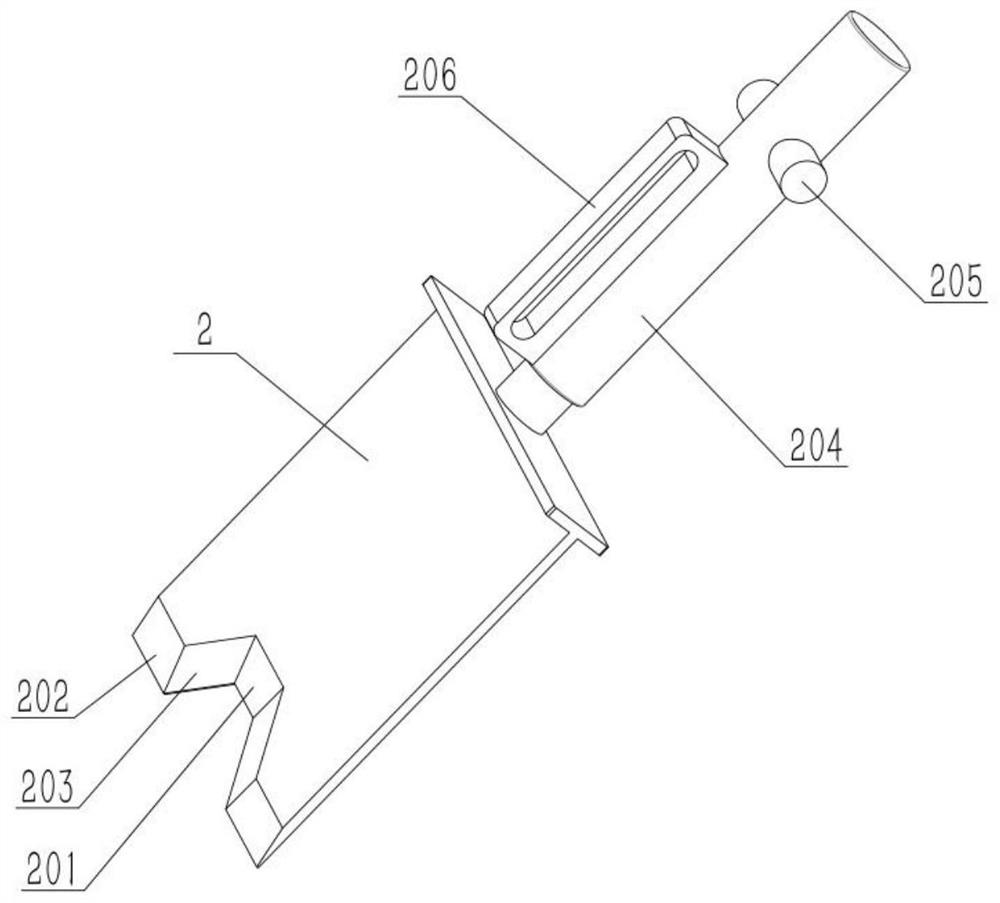

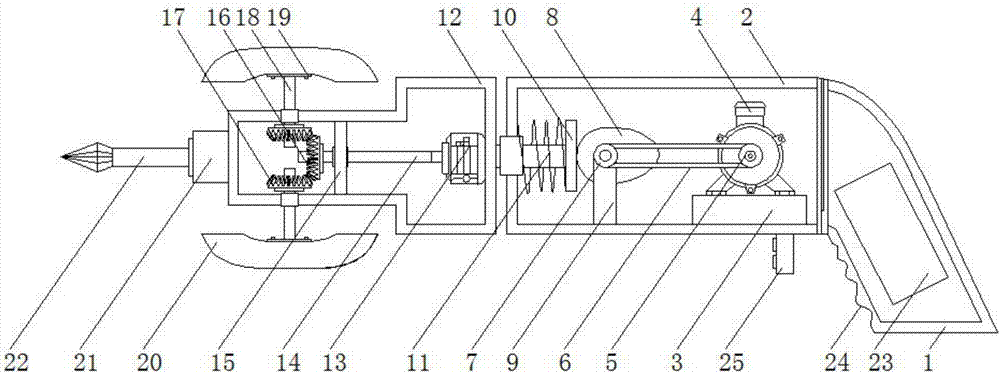

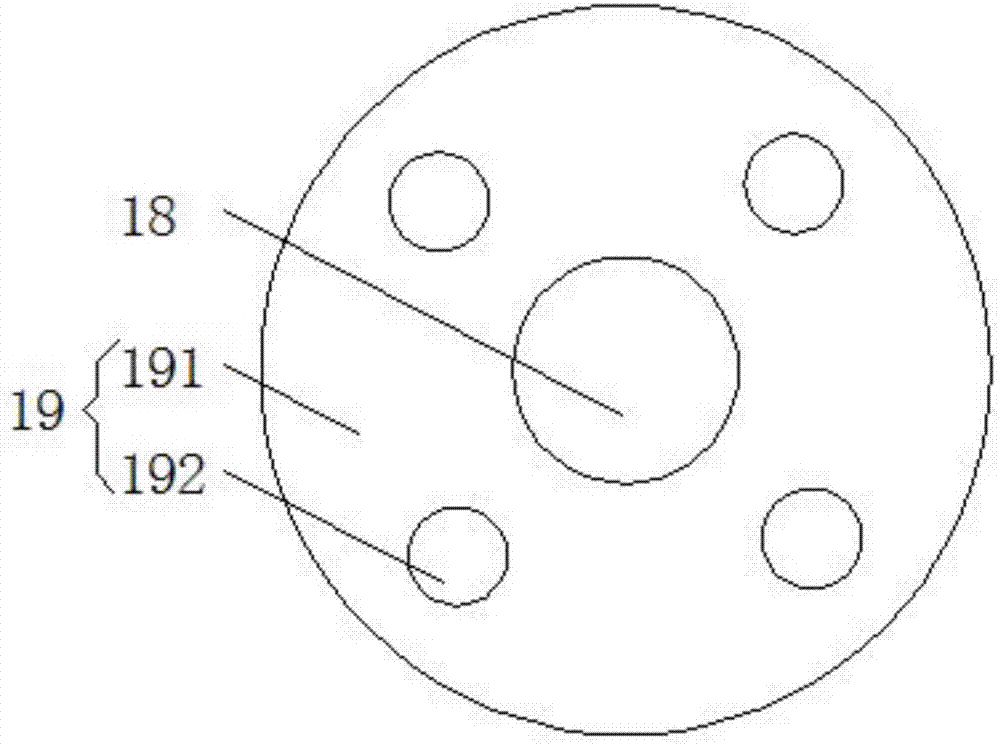

Track shoe pin hole machining equipment

ActiveCN104249196AConvenient finishingEfficient and high-quality finishingFeeding apparatusPositioning apparatusEngineeringBrake shoe

The invention discloses track shoe pin hole machining equipment. The track shoe pin hole machining equipment comprises a base, and a clamping mechanism, a machining mechanism and a feeding mechanism mounted on the base. The clamping mechanism is used for clamping track shoes and keeping the track shoes in the machining direction, the machining mechanism is used for machining pin holes, the feeding mechanism is used for enabling the clamping mechanism and the machining mechanism to move relatively after the track shoes are kept in the machining direction, and the machining mechanism machines the pin holes in the track shoes kept in the machining direction in the process of relative movement of the clamping mechanism and the machining mechanism. The track shoe pin hole machining equipment is specially used for machining the pin holes of the track shoes, the track shoes are kept in the machining direction through the clamping mechanism according to the unique structural design of the track shoes, then the pin holes of the track shoes kept in the machining direction are subjected to finish machining through the machining mechanism, and machining efficiency and effect can be improved effectively.

Owner:ZOOMLION HEAVY IND CO LTD

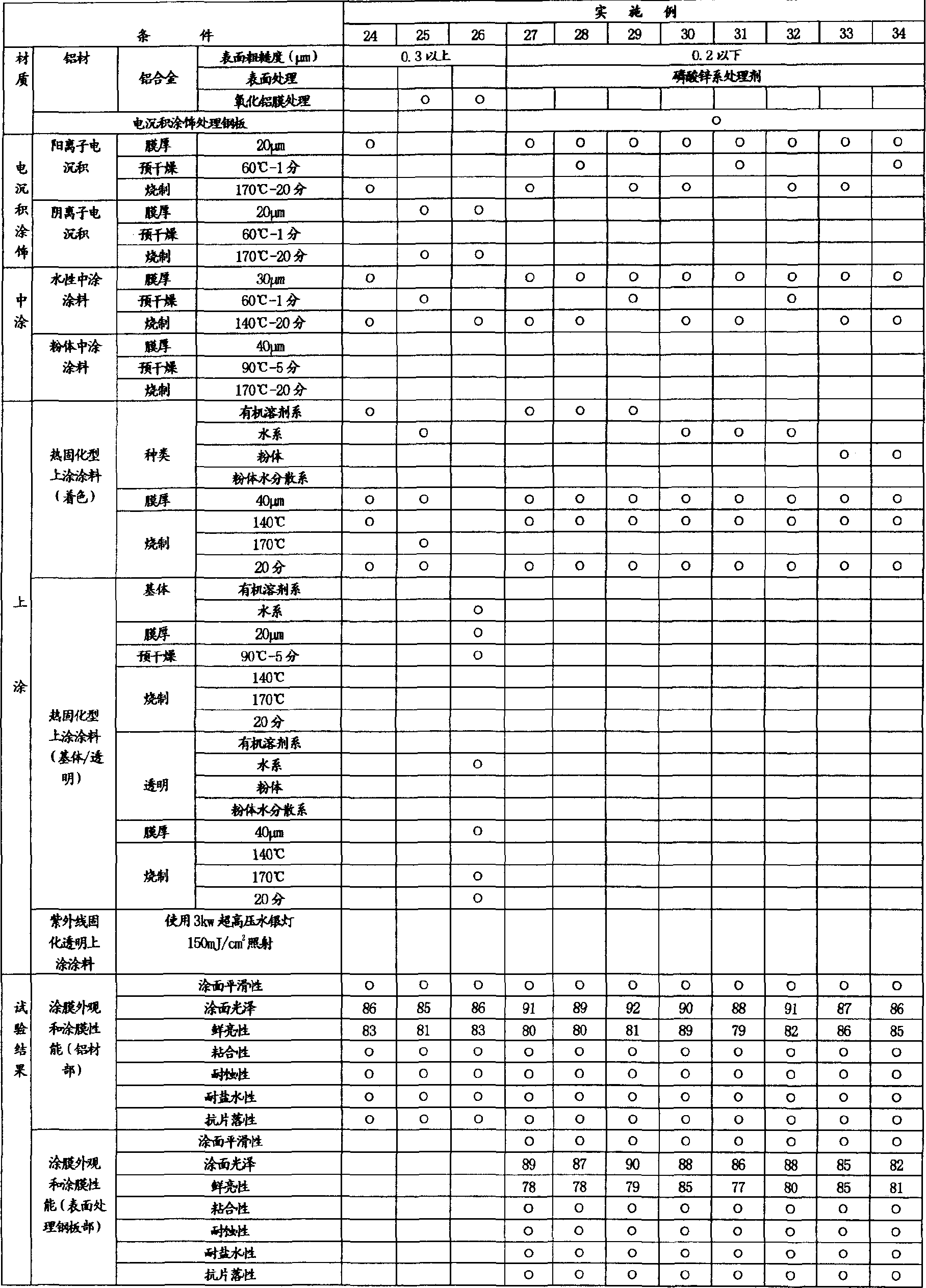

Paint-applying method for car body

InactiveCN1460561AGood lookingExcellent film performancePretreated surfacesCoatingsAlloyFilm material

In an external plate part and / or an internal plate part of the body of an automobile of which the main material is constituted of an aluminum material, an aluminum-coated steel material or a heterogeneous metal material being a combination of the aluminum material with a steel material, the relative roughness of the aluminum material is 0.2 [mu]m or below in Ra, while the aluminum material is a base material of a JIS A6000 series aluminum alloy and is subjected to oxide film coating treatment, and the film decorative film material is stuck to the surface of the aluminum material or the aluminum-coated steel material, according to this method of sticking the decorative film material to the body of the automobile, which is excellent in finish properties and a performance.

Owner:KANSAI PAINT CO LTD

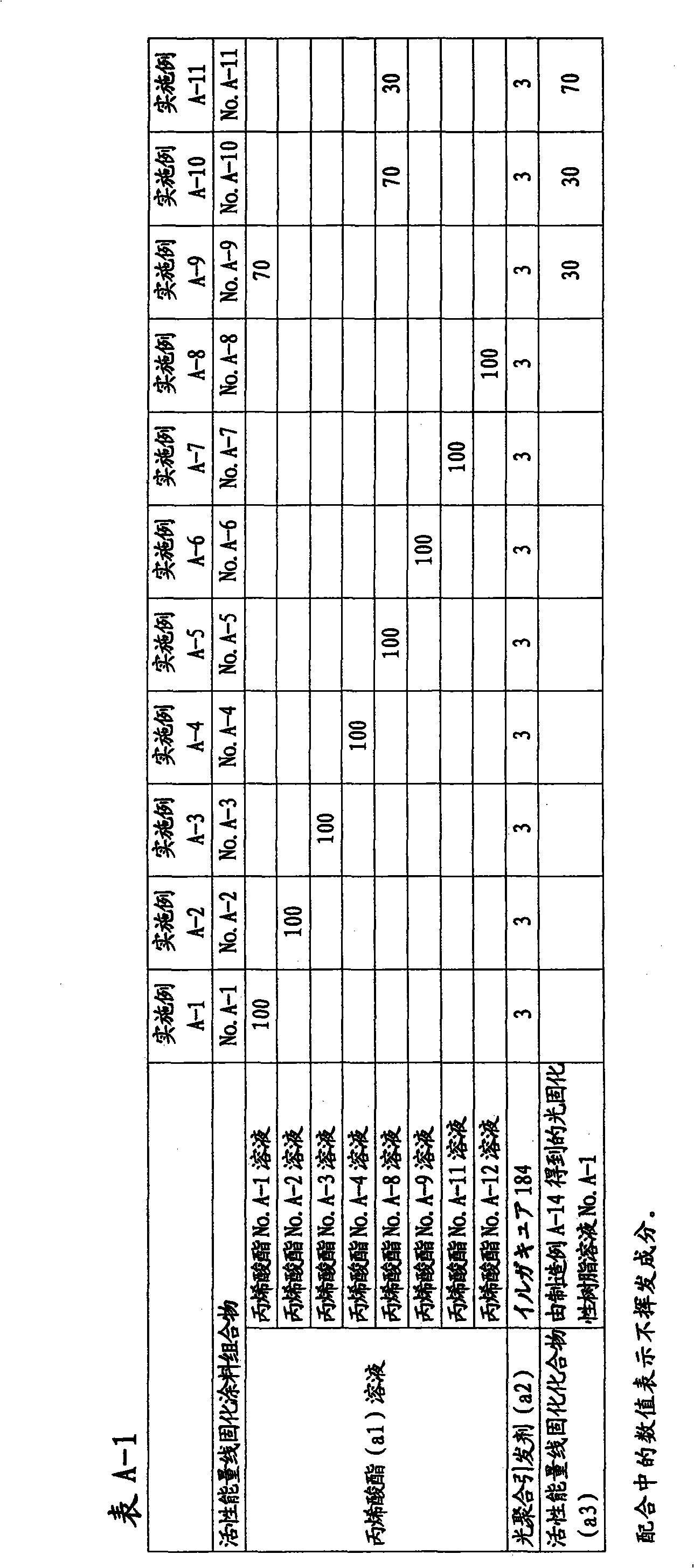

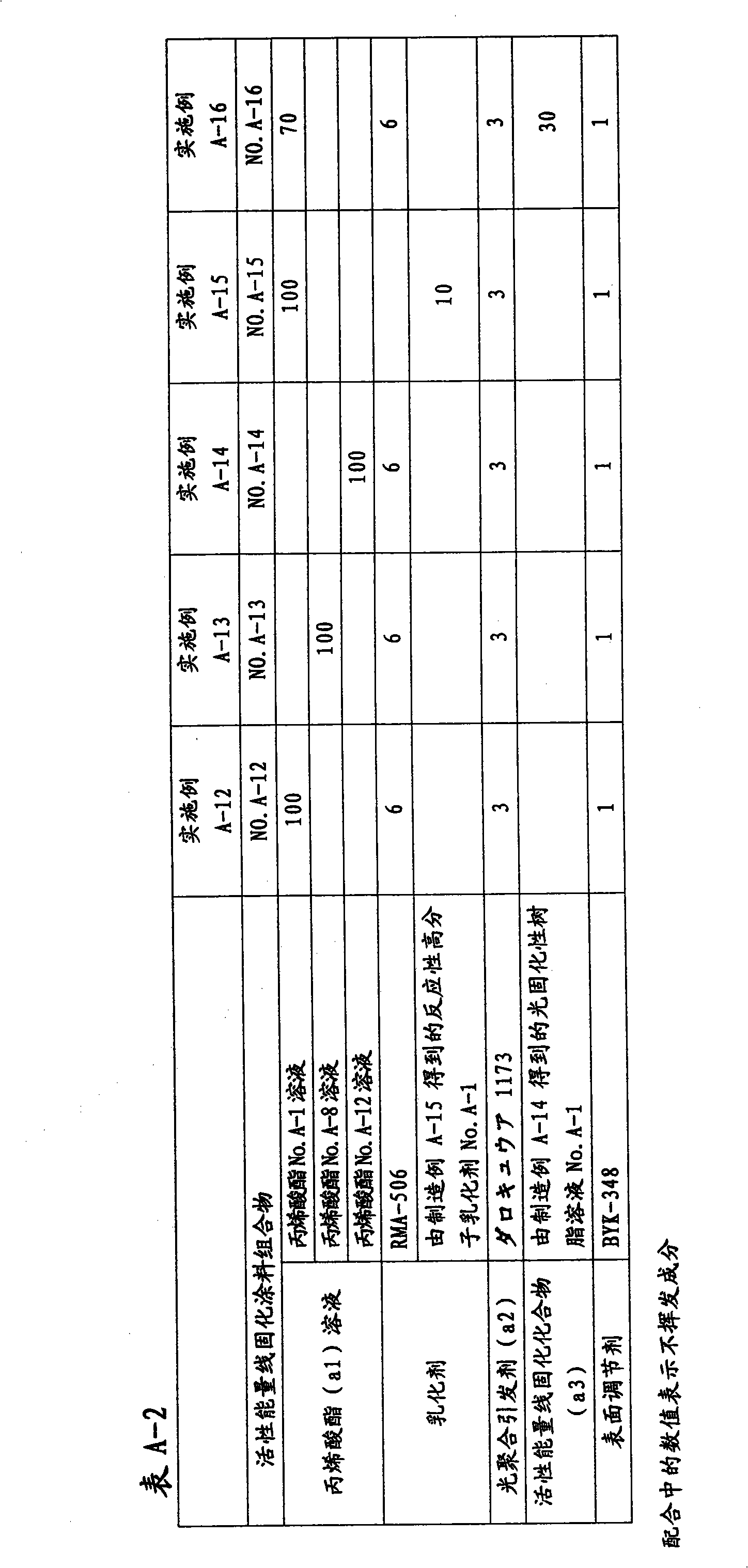

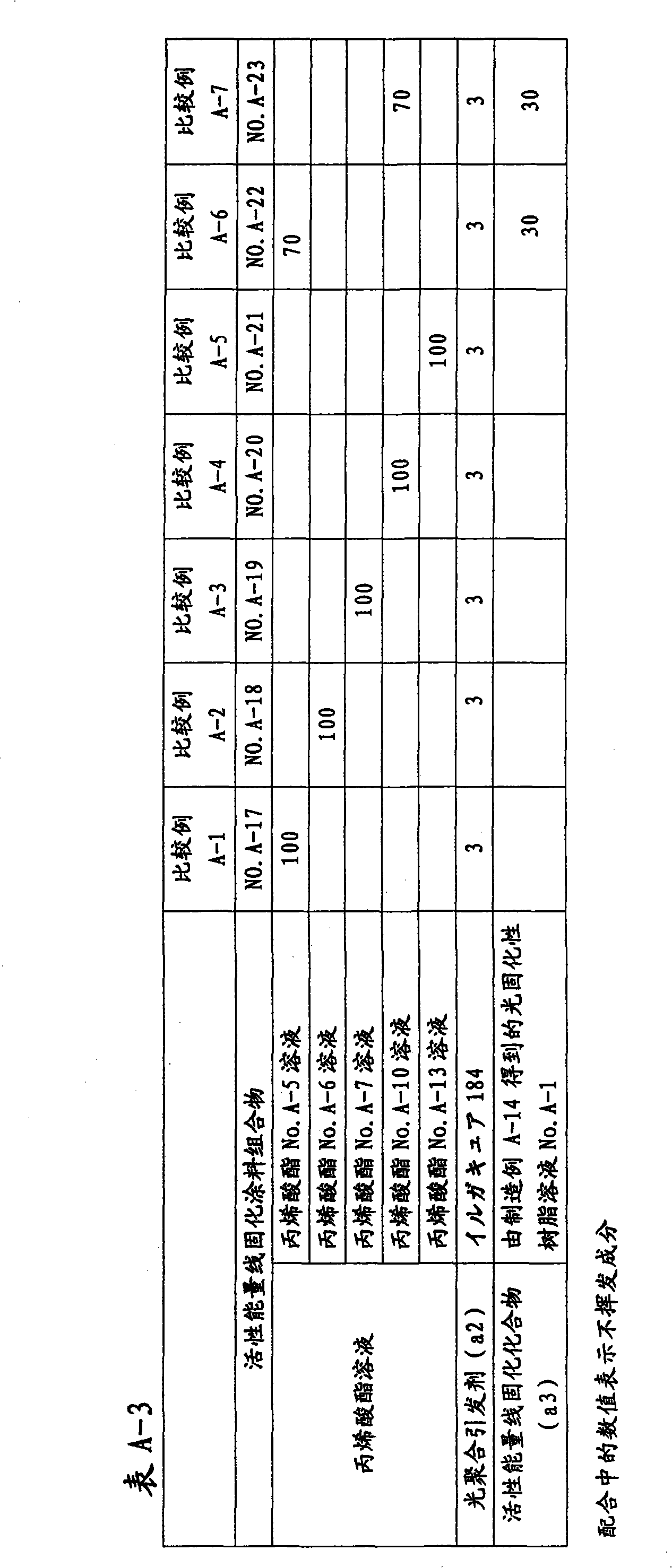

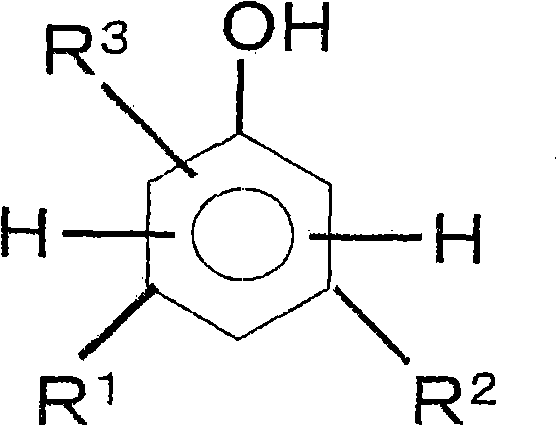

Active energy ray-curable coating composition, method for formation of coating film, and coated article

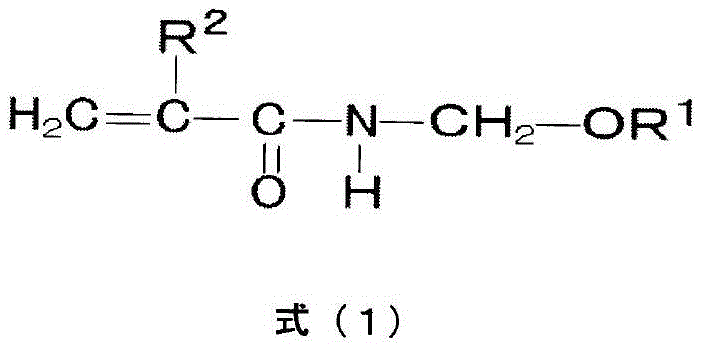

InactiveCN101945955AEmission reductionReduce pollutionPretreated surfacesEmulsion paintsWeather resistanceHardness

Disclosed is an active energy ray-curable coating composition which is characterized by comprising: (a1) an acrylic acid ester of a non-cyclic oligosaccharide or a derivative thereof, which has an weight average molecular weight of 400 to 2,000 and contains 3.0 to 12.0 acryloyl groups on average per molecule; and (a2) a photopolymerization initiator. The active energy ray-curable coating composition is a bio-derived active energy ray-curable coating composition, and can form a coating film having excellent finished appearance, pencil hardness, scratch resistance, weather resistance and solvent resistance.

Owner:KANSAI PAINT CO LTD

Pigment disperse sizing agent and electrophoretic paint

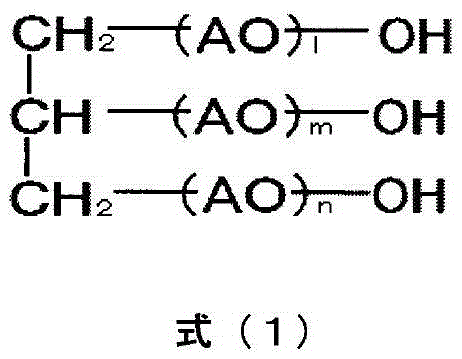

ActiveCN101353501AGood redispersibilityGood storage stabilityPaints for electrolytic applicationsEpoxy resin coatingsCelluloseSolid component

The purpose of the invention is to provide a pigment dispersing paste capable of saving energy of coating apparatus and saving redispersibility of dye of the apparatus and electrophoretic paint. Specifically, the invention relates to a pigment dispersing paste for electrophoretic paint, containing pigment dispersing resin (A), tinting color (B), color filler (C) and cellulose composition (D); responding to the solid component 100 weight parts of the resin (A), the paste is characterized by containing: (1) 60 to 800 weight parts of (b1) titanium dioxide coated by 0.1 to 10.0 weight parts of Al2O3 without SiO2 on 100 weight parts of titanium dioxide as matrix; and / or (b2) ferric oxide as the of tinting color (B); (2) 2 to 200 weight parts of micro barium sulfate with the mean grain size of linear particle being 0.01 to 0.1 micron as the color filler (C); and (3) 1 to 50 weight parts of cellulose composition (D).

Owner:KANSAI PAINT CO LTD

Coating composition and method for forming coating film using same

InactiveCN103687918ACorrosion-inhibitingGap paintablePolyurea/polyurethane coatingsPaints for electrolytic applicationsSolid componentEpoxy

The present invention addresses the problem of providing a cationic electrodeposition coating having excellent covering power (clearance application properties), edge anticorrosion properties, and finish properties. The present invention provides a cationic electrodeposition coating composition comprising: a specific amino-group-containing epoxy resin (A); blocked polyisocyanate (B) obtained by reacting an active hydrogen-containing component containing propylene glycol, and a polyisocyanate compound; and 0.1-20 mass parts of a cationic electrodepositing gelled microparticulate polymer (C) obtained by crosslinking an acrylic copolymer containing hydrolyzable alkoxysilane groups and cationic groups, per a total of 100 mass parts of the solids fraction of the amino-group-containing epoxy resin (A) and the blocked polyisocyanate compound (B).

Owner:NISSAN MOTOR CO LTD

Peanut finishing classification screening machine and screening method thereof

InactiveCN109675799AAccurate classificationAvoid blockingSievingScreeningScreening effectAgricultural engineering

The invention relates to a peanut finishing classification screening machine and a screening method thereof. The machine comprises a base plate, a feeding device, a screening device and a sorting device; the screening device is mounted on the left side of the upper end of the base plate; the feeding device is arranged on the left side of the upper end of the screening device; the sorting device ismounted on the right side of the upper end of the base plate; and the sorting device is positioned on the right side of the screening device. The machine can solve the difficulties of weak screeningeffect during screening of peanuts by a traditional peanut screening machine, incapability of accurately classifying the peanuts, incapability of singly separating out broken peanuts, easy blockage ofelliptic peanuts on a screening plate during screening and influence on the screening effect, can achieve a function of automatically classifying and screening the peanuts, is excellent in screeningeffect, can accurately classify the peanuts, meanwhile, can singly separate out the peanuts broken to pieces, can prevent the peanuts from blocking the screening plate, and achieves excellent screening effect.

Owner:ANHUI KAILI CEREALS OILS & FOODSTUFFS

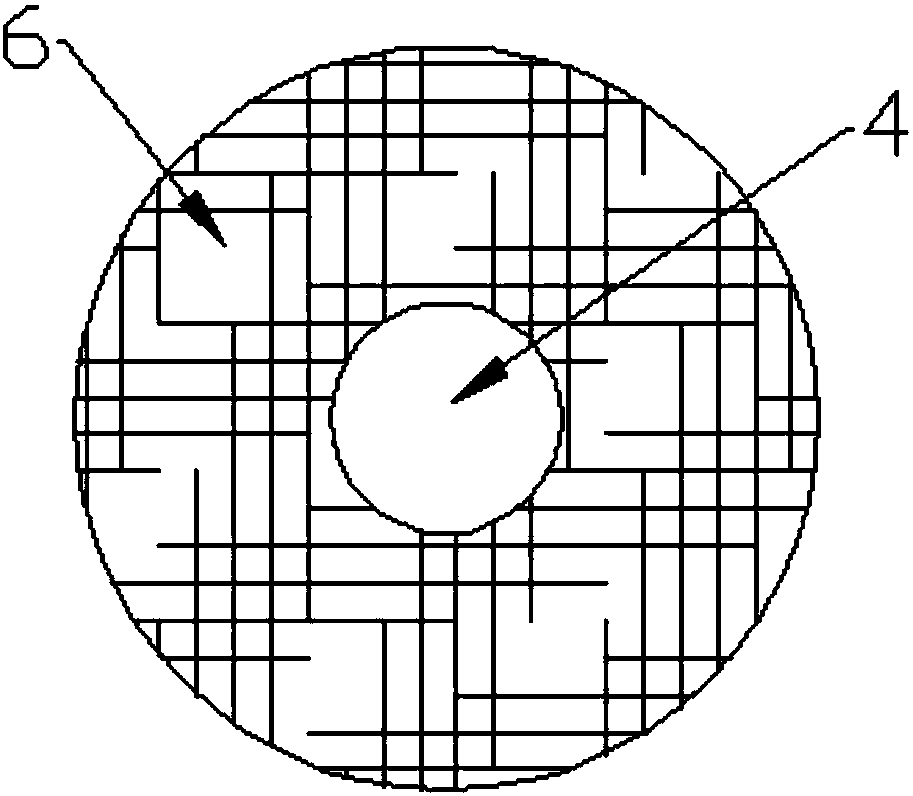

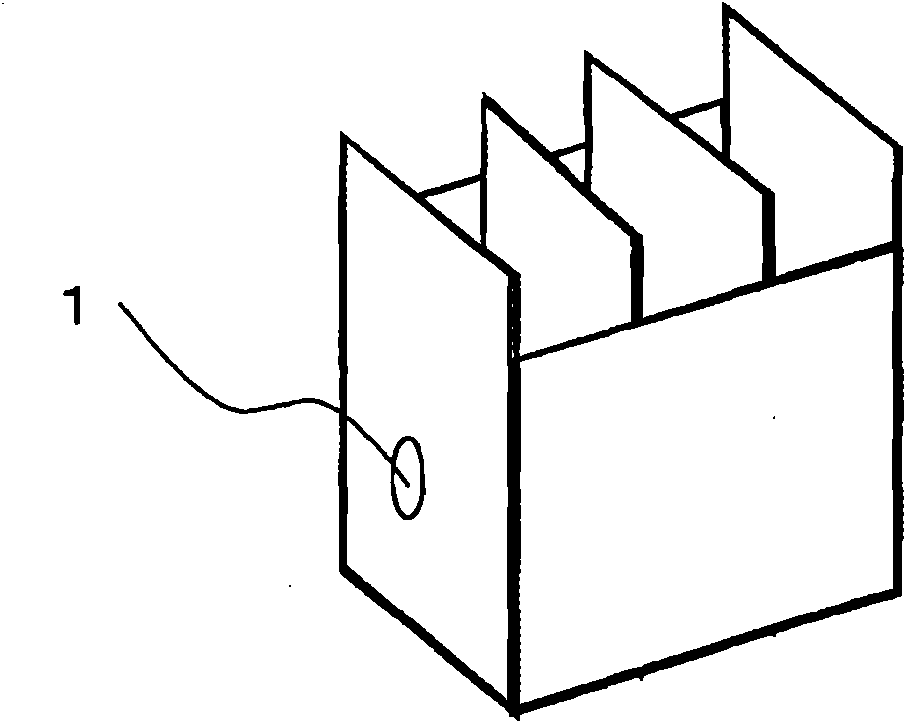

High-precision radiating grinding wheel

InactiveCN104416478AMeet the machining accuracy requirementsSolve the cooling problemBonded abrasive wheelsCircular discGraphite

The invention discloses a high-precision radiating grinding wheel, and relates to the field of industrial machinery. The high-precision radiating grinding wheel comprises a circular disc body which is divided into three layers, namely, a base layer, a heat transfer layer and a grinding layer which are sequentially arranged, wherein the base layer is prepared from aluminum alloy; the heat transfer layer is prepared from graphite; the grinding layer is prepared from microcrystalline fused alumina; a threaded hole is formed in the center of the circular disc body. The high-precision radiating grinding wheel has the advantage that the problems of the requirement on the processing precision of the grinding wheel, the radiating during processing, and the safety of connection of the grinding wheel and a grinding wheel can be solved.

Owner:SHANGHAI XIWANG ELECTRONICS TECH

Device for finish machining of mechanical part

ActiveCN106670817APrecise positioning processingImprove finishing effectOther manufacturing equipments/toolsMaintainance and safety accessoriesMechanical componentsEngineering

The invention discloses a device for finish machining of a mechanical part. The device comprises a machine platform and a base plate. A part horizontal moving device is movably connected in a groove formed in the middle of the top of the machine platform. The two sides of the top of the machine platform are provided with vertical moving devices to be connected with the base plate. A motor is arranged in a noise reduction box connected to the middle of the top of the base plate. A rotating shaft, an auxiliary shaft and a connecting shaft are located in the noise reduction box and correspondingly arranged in the middle of the top of the base plate in a penetrating mode. According to the device for finish machining of the mechanical part, vertical moving of a polishing column and a drill bit and horizontal moving of a part supporting plate can be achieved , so that accurate positioning machining of the mechanical part is achieved, the effect of part finishing machining is improved, additionally, the stability of the whole device when the device is used can be improved greatly, and the finish machining effect and the finishing machining efficiency of the mechanical part are improved.

Owner:湘潭尚德机电科技有限公司

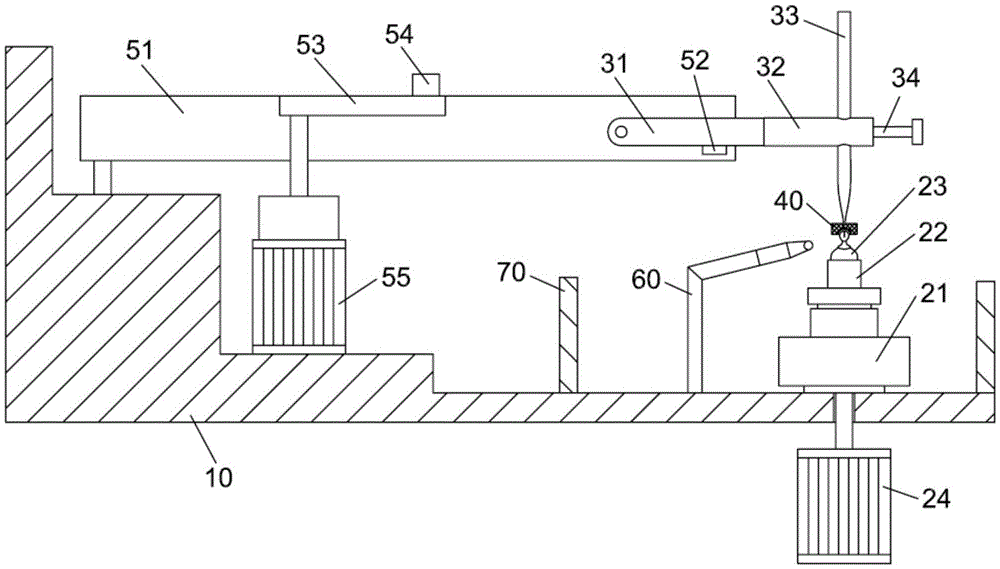

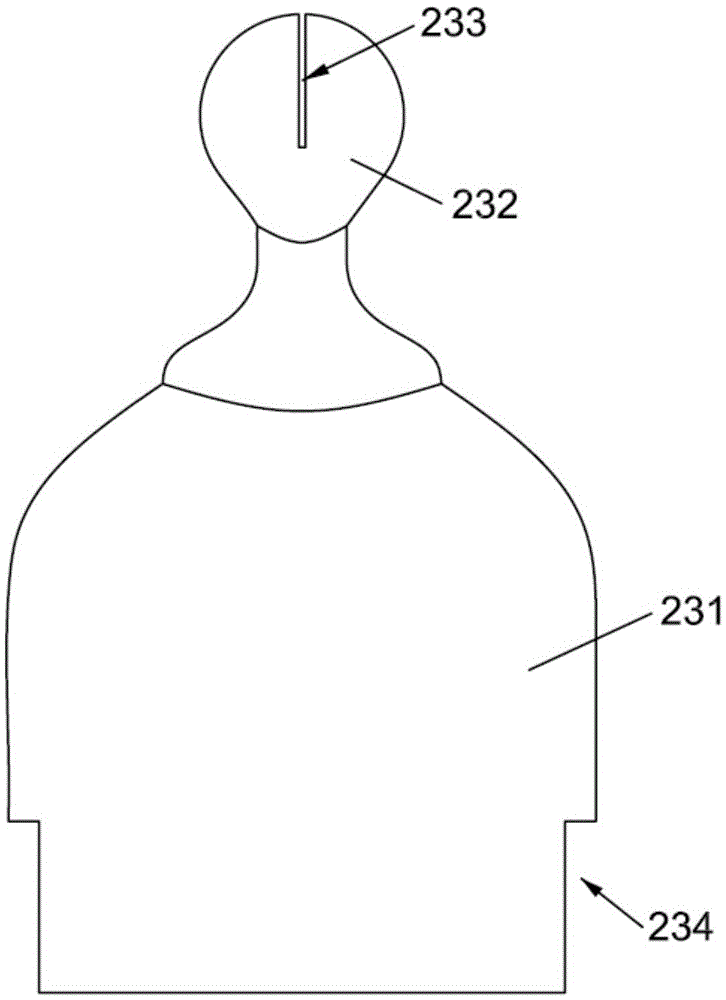

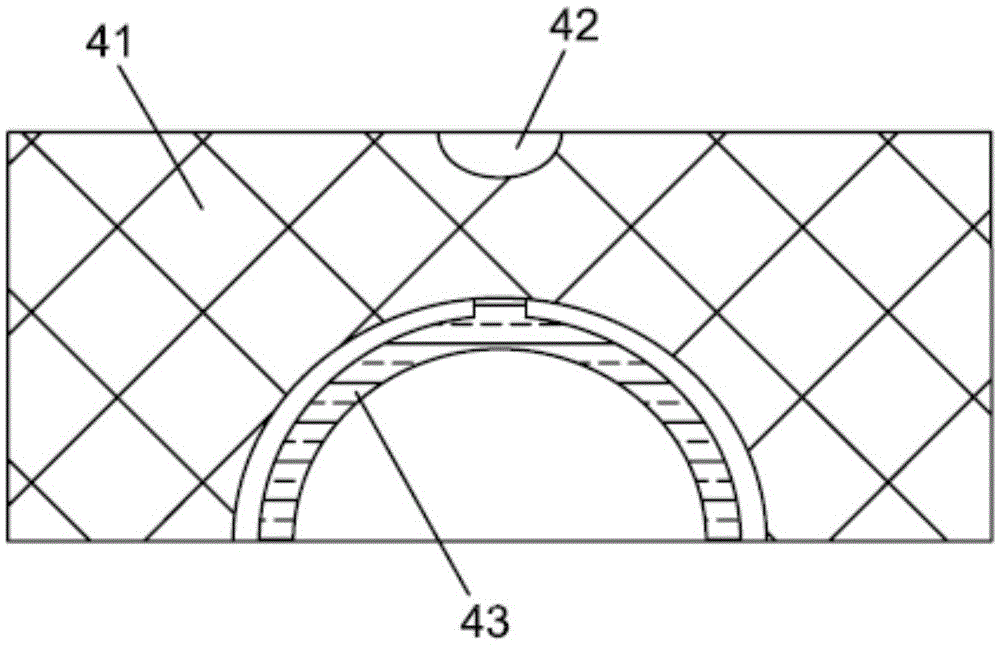

Finish machining device and method for concave surface of optical lens

ActiveCN105538088ASimple structureEasy to operateGrinding machine componentsOptical surface grinding machinesSpherical angleOptic lens

The invention discloses a finish machining device and method for a concave surface of an optical lens. The finish machining device comprises a rack, a polishing assembly, a pressing assembly, a lens tool and a swing assembly used for driving the lens tool to swing. A polishing head comprises an installation base and a polishing ball. The polishing ball is provided with a polishing groove used for polishing the optical lens. The polishing head is arranged to be the polishing ball, and the purpose of machining the concave surface of the optical lens with the large spherical angle is achieved. A cutting edge is formed on the edge of the polishing groove in the polishing ball and used for polishing the optical lens, and cutting chips can be guided out. The swing assembly drives the lens tool to swing on the polishing ball, then a polishing spherical face is formed, and all-round grinding is conducted on the concave surface of the optical lens. The finish machining device is simple in structure, convenient to operate and good in finish machining effect.

Owner:大英彰骏光电科技有限公司

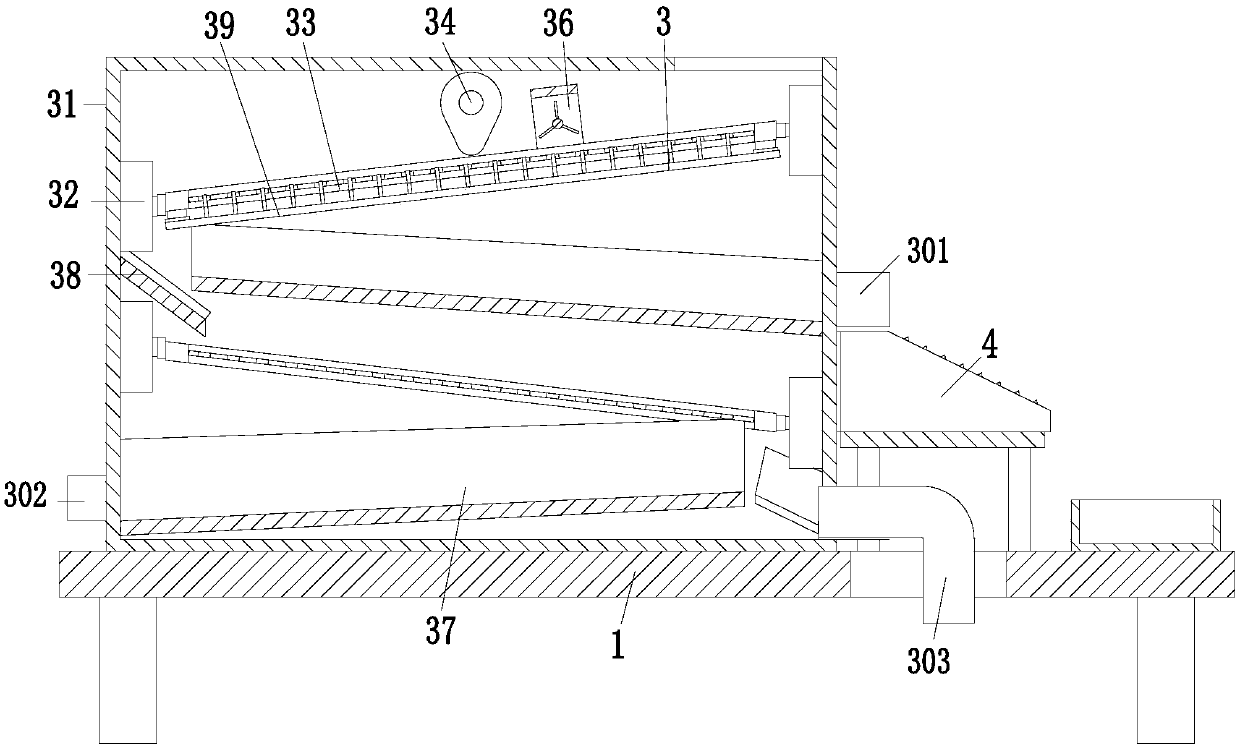

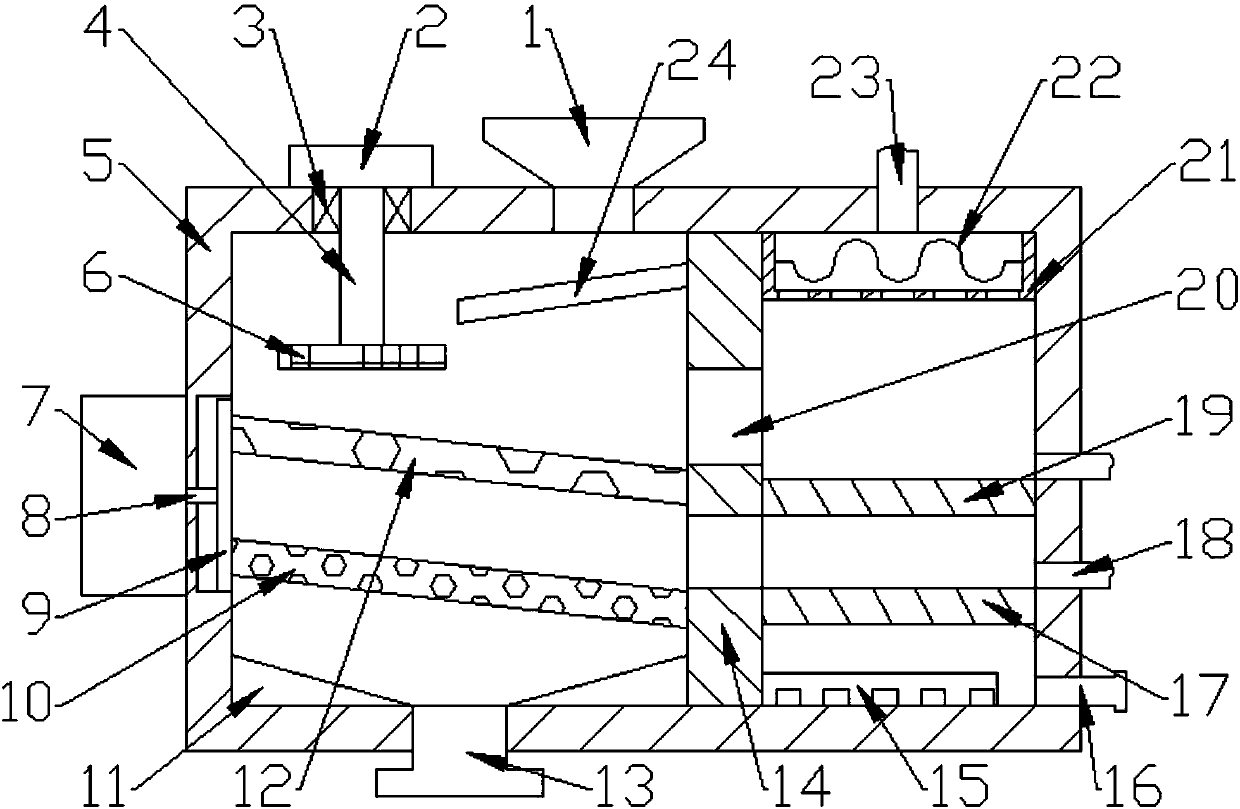

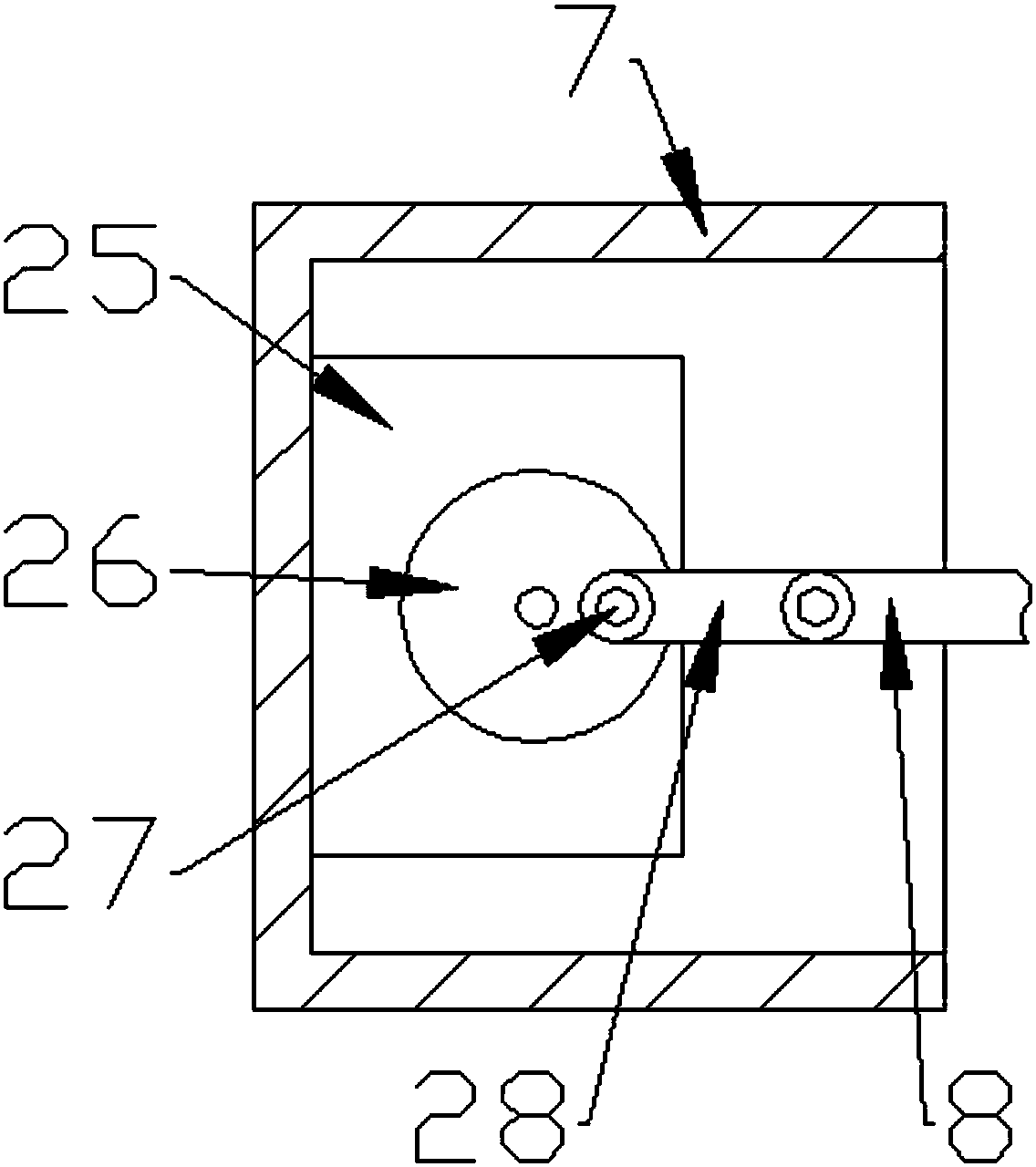

Tea screening and drying finish processing device

PendingCN107626572AGood filtering effectConvenient finishingSievingPre-extraction tea treatmentResistance wirePrimary screening

The invention provides a tea screening and drying finish processing device. The tea screening and drying finish processing device comprises a processing box; a fixed feed port is welded to the middlepart of the upper surface of the processing box; a material guide plate is arranged below the feed port; a magnetic plate is arranged below the left side of the material guide plate; a secondary screening net plate is arranged below a primary screening net plate; the left end of the secondary screening net plate and the left end of the primary screening net plate are fixed to a transmission plate,and the transmission plate is inlaid in the inner wall of the left side of the processing box; a transmission rod is fixed to the left end of the transmission plate and is leftwards connected into ascreening box; transmission hinges are arranged at the end part of the transmission rod; a partition plate is vertically welded to the inner upper wall and the inner lower wall of the middle part of the processing box; material guiding ports are formed in the positions below the secondary screening net plate and the primary screening net plate separately; a drying box is welded to the right uppercorner of the processing box; and a drying resistance wire is arranged in the drying box. The tea screening and drying finish processing device has the advantages of being simple and convenient to useand operate, capable of carrying out screening and drying simultaneously, good in finish processing effect and high in practicability.

Owner:余金龙

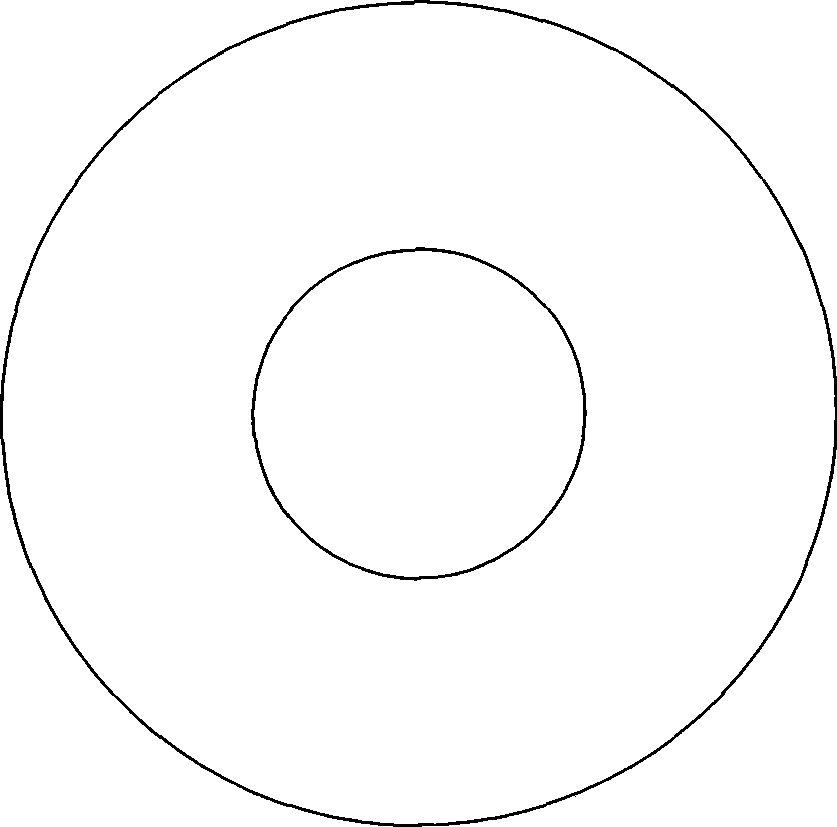

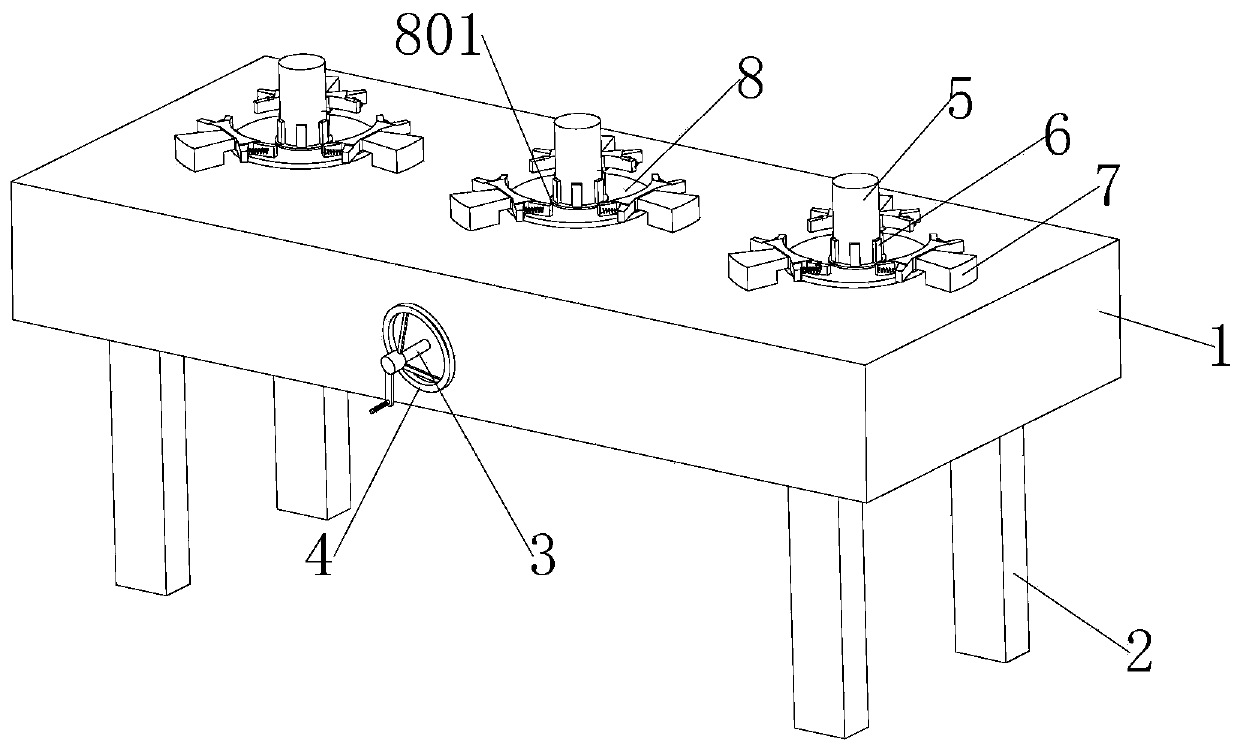

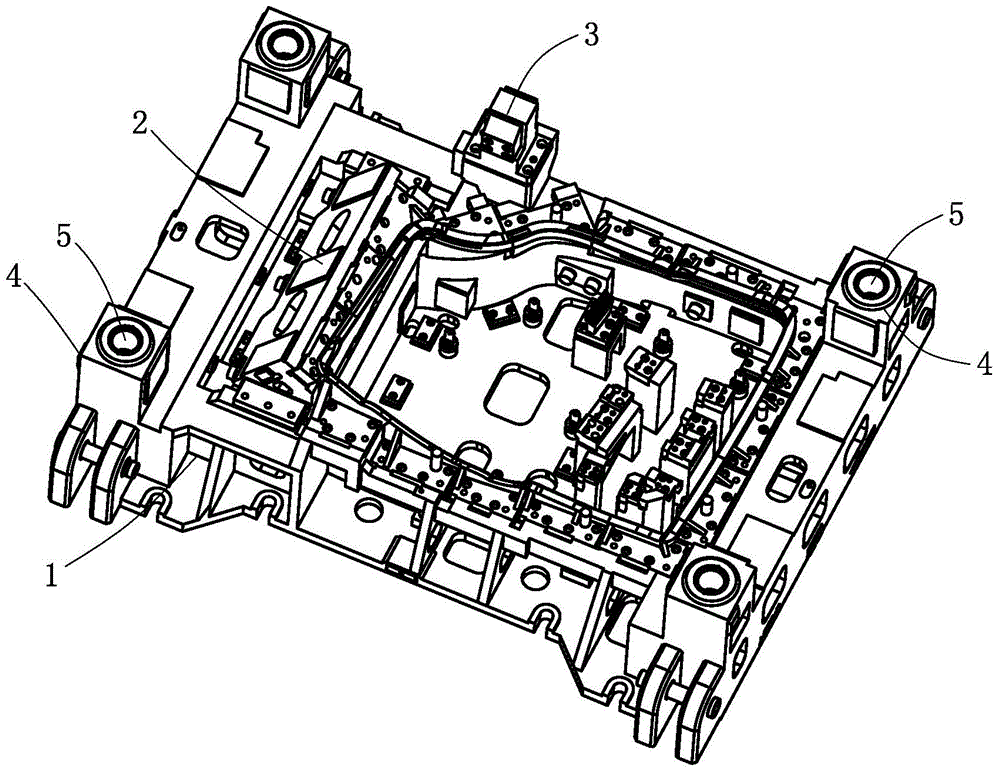

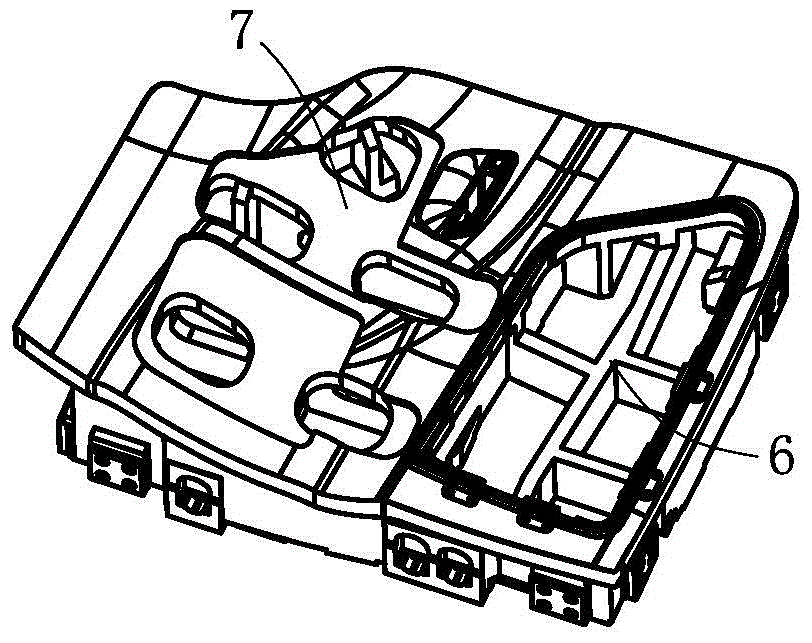

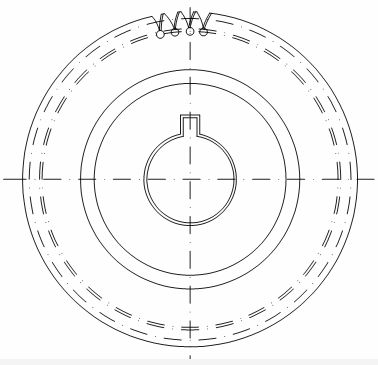

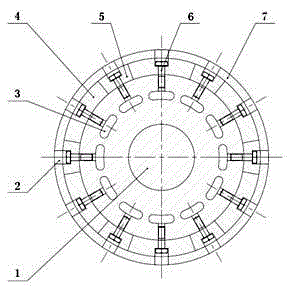

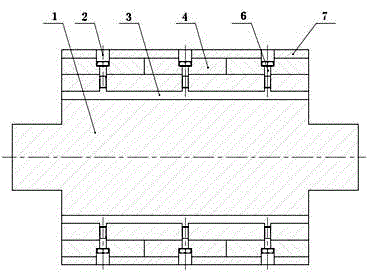

Manufacturing surface finishing clamp for water pump impeller

InactiveCN110842706AConvenient finishingEasy to finish grindingGrinding machinesGrinding work supportsImpellerCircular disc

The invention discloses a manufacturing surface finishing clamp for a water pump impeller, and relates to the technical field of clamp clamping. The manufacturing surface finishing clamp comprises a workbench, the top end of the workbench is arranged as a horizontal table top, a plurality of disc-shaped positioning tables are arranged on the table top of the workbench, a disc-shaped positioning boss is arranged at the circle center position of the top end of each positioning table, a guide rod upright on the corresponding table top is arranged at the top end of each positioning boss, a plurality of sliding grooves are formed in the outer wall, adjacent to the top end of the corresponding positioning boss, of each guide rod, and an ejector rod receding hole is formed in the inner wall of each guide rod. According to the manufacturing surface finishing clamp for the water pump impeller, the guide rods are arranged at the top ends of the positioning tables, the center hole of the water pump impeller sleeves the guide rods, a plurality of outer clamping jaws are arranged on the outer ring of each positioning table at equal intervals, and the water pump impeller can be subjected to outside clamping through clamping of the outer clamping jaws. The inner ring of the water pump impeller is convenient to finish and grind.

Owner:方坤棉

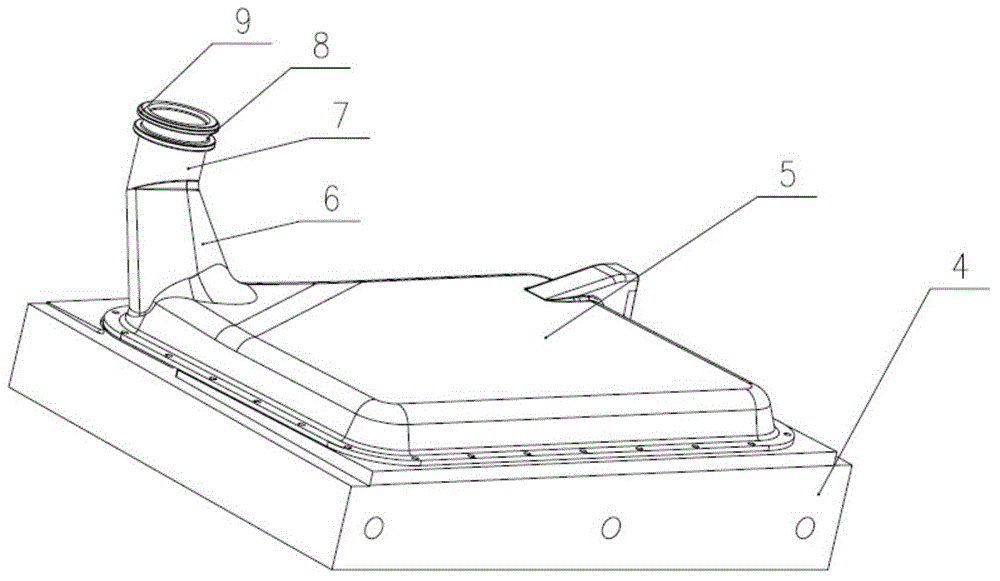

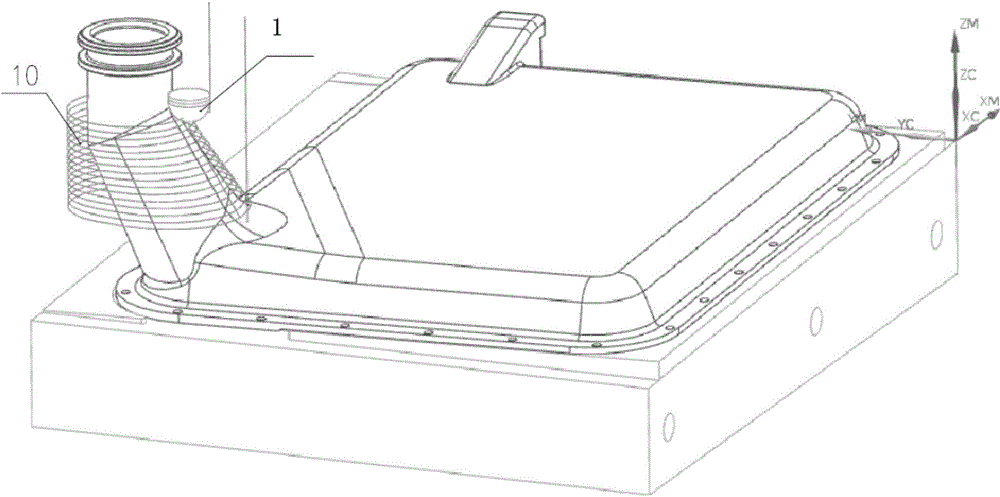

Automobile external covering part stamping die achieving lateral reshaping by using hydraulic system to drive sliding blocks

ActiveCN104972003AImprove product qualityConvenient finishingShaping toolsHydraulic cylinderMachining

The invention discloses an automobile external covering part stamping die achieving lateral reshaping by using a hydraulic system to drive sliding blocks and belongs to the technical field of stamping dies. The automobile external covering part stamping die comprises an upper die body and a lower die body. The lower die body is provided with a workpiece male die base. A rotary die body is rotatably mounted on the upper die body through an articulated shaft. One end of the rotary die body is connected with a hydraulic cylinder. The bottom of the other end of the rotary die body is connected with a translational pad base. The translational pedestal is provided with protruding pad parts. The rotary die body is provided with grooves. The workpiece male die comprises a male die body and a negative-angle die body. A sliding bevel is arranged between the negative-angle die body and the male die body. The upper die body is provided with a workpiece female base. The upper die body is provided with a tapered wedge sliding base. A pressing plate is fixedly arranged on the tapered wedge sliding base. First reset springs are arranged between the tapered wedge sliding base and the upper die body. The lower die body is provided with a tapered wedge fixing base. The automobile external covering part stamping die can be used for stamping and forming negative-angle products, and the quality of the stamped and formed product is stable; the service life is long, and the automobile external covering part stamping die is widely applied to machining of automobile covering parts.

Owner:豪尔沃(山东)机械科技有限公司

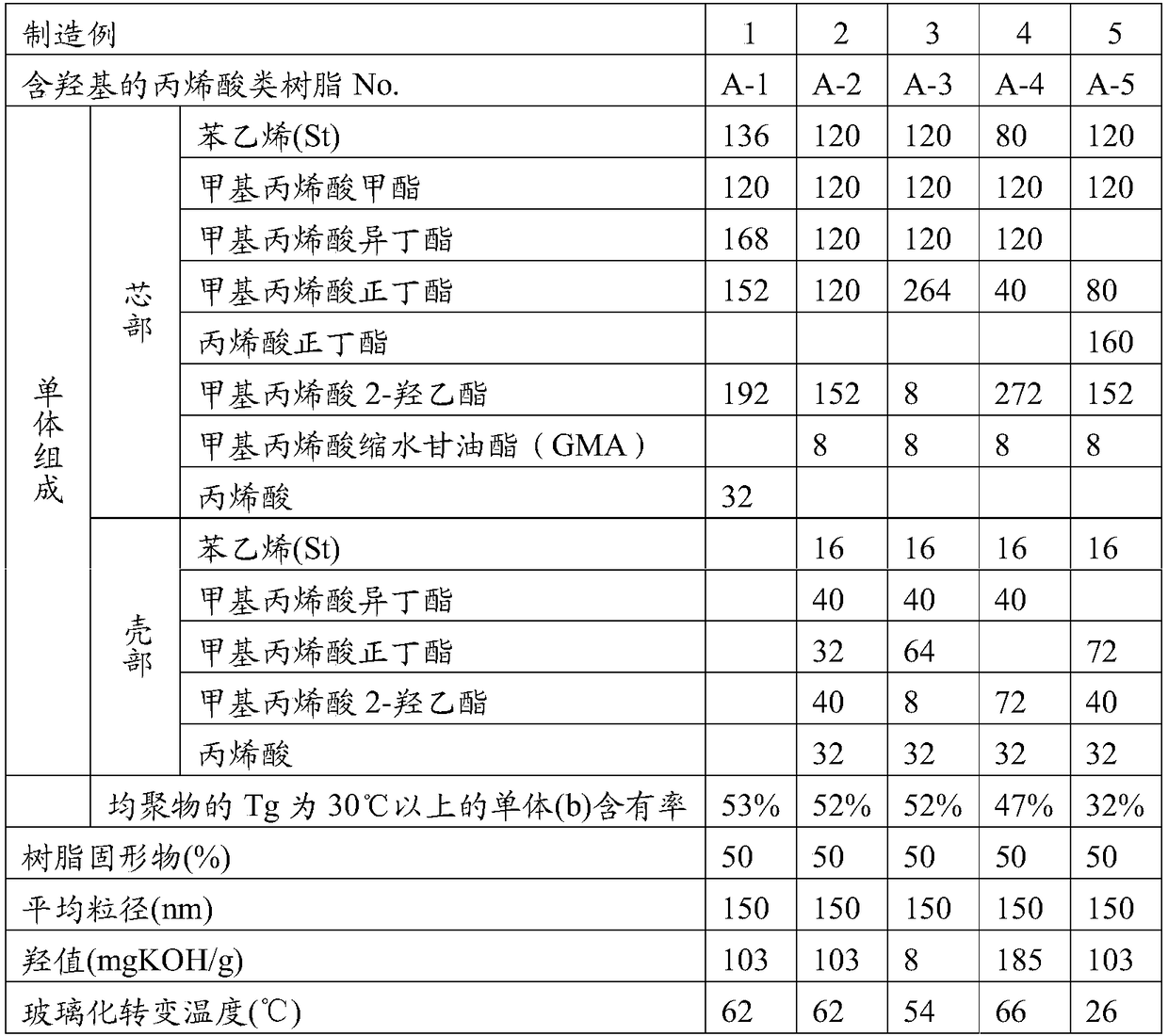

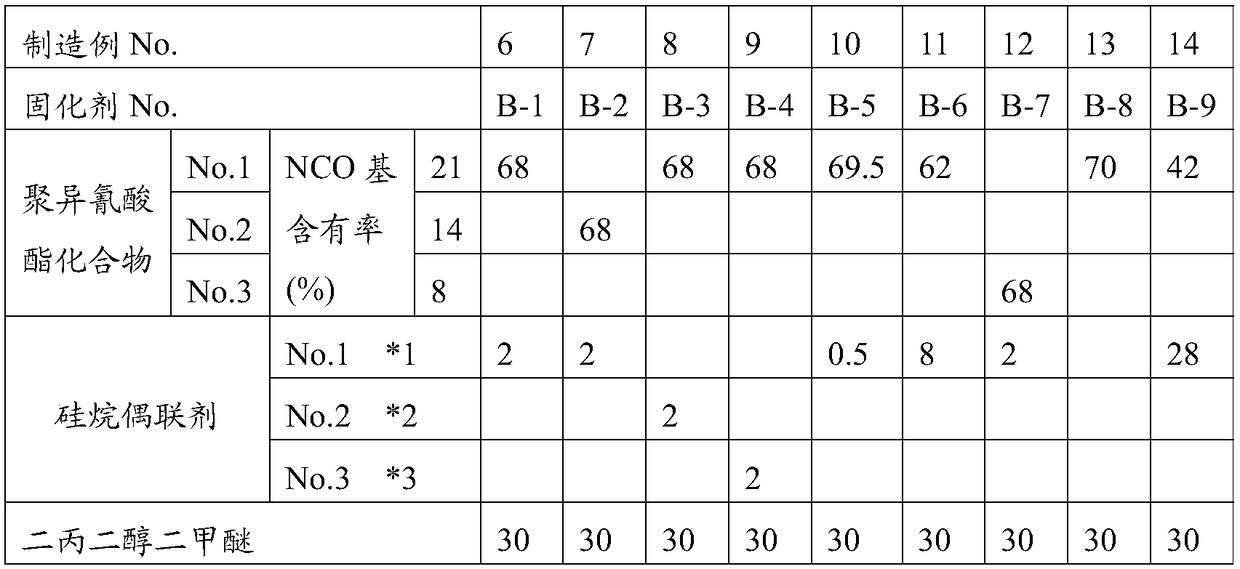

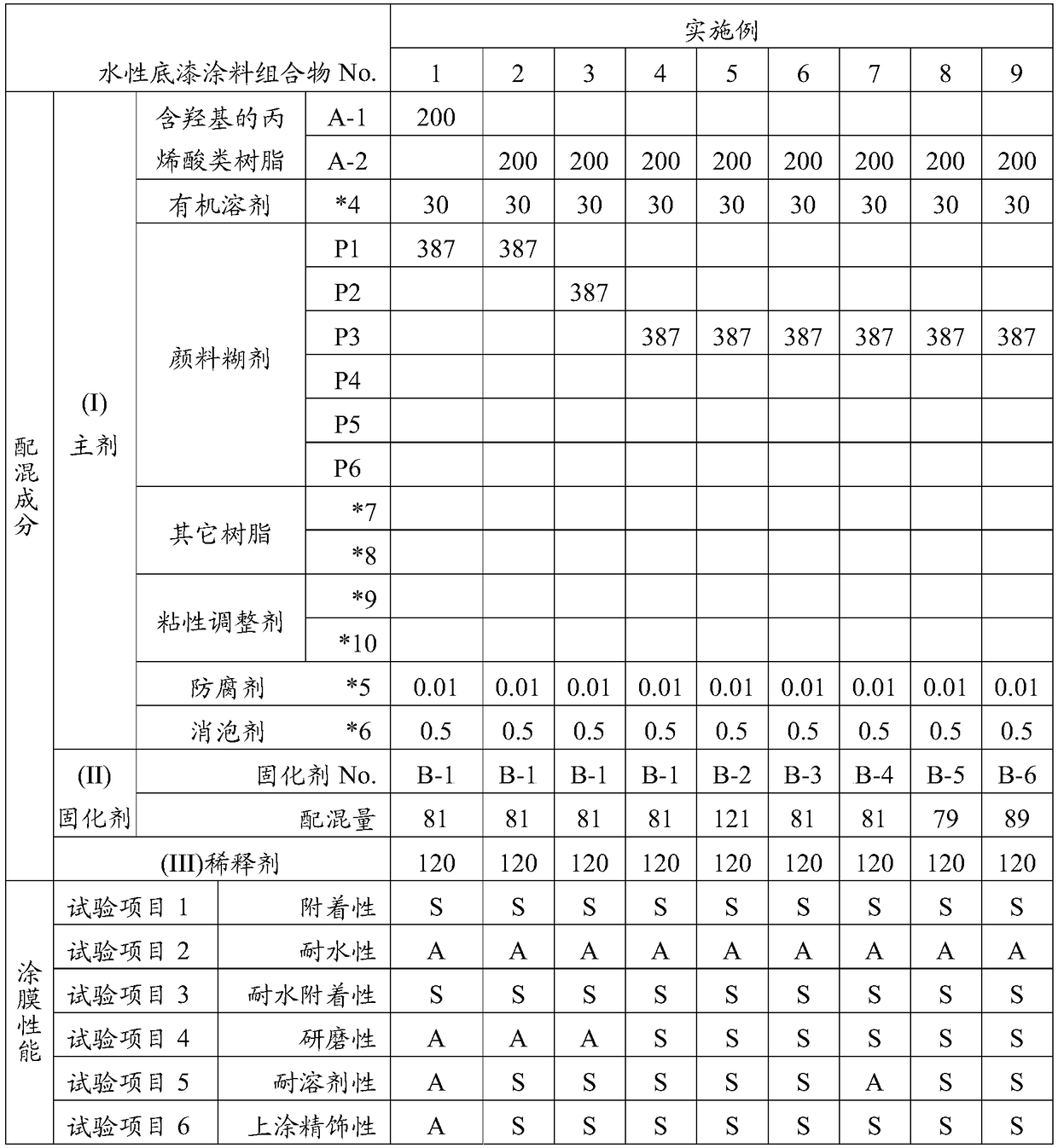

Multi-component aqueous primer coating composition and a coating method thereof

ActiveCN108727955AGood finishingExcellent water resistance and adhesionPolyurea/polyurethane coatingsPriming paintsAcrylic resinWater resistant

The present invention provides a multi-component aqueous primer coating composition and a coating method thereof which can form a coating film primer which is excellent in adhesion, particularly water-resistant adhesion. The multi-component aqueous primer coating composition which is a multi-component aqueous primer coating composition comprises a main component (I) and a curing agent component (II), wherein the main component (I) a hydroxyl group-containing acrylic resin (A) and a pigment (B) having a hydroxyl value in the range of 15 to 180 mgKOH / g and a glass transition temperature of 30 to70 DEG C, and the curing agent component (II) contains the polyisocyanate compound (C) having a content of 10% by mass or more of an isocyanate group, the main component (I) and / or the curing agent (II) component contains a silane coupling agent (D), and the content of the component (D) is a curing agent component (the mass of II) is in the range of 0.01 to 10% by mass.

Owner:KANSAI PAINT CO LTD

Fish seafood processing device

ActiveCN112244073AFixedConvenient finishingFish washing/descalingClimate change adaptationFish processingZoology

The invention relates to fish processing, in particular to a fish seafood processing device. The fish seafood processing device comprises a machining table top, supporting legs I, a plate cutter, a concave cutting edge, convex cutting edges, inclined cutting edges and an electric push rod I. The four corners of the lower end of the machining table top are each fixedly connected with one supportingleg I, the plate cutter is obliquely arranged on the upper part of the machining table top with the left portion lower than the right portion, and the plate cutter is fixedly connected to the movableend of the electric push rod I. The electric push rod I is used for adjusting the position of the plate cutter in the inclination direction of the plate cutter and installed on the adjusting mechanism, the concave cutting edge is arranged in the middle of the left end of the plate cutter, the inclined cutting edges are connected with the front end and the rear end of the concave cutting edge, andthe outer ends of the two inclined cutting edges are each connected with one convex cutting edge. The valuable big deep-sea fish can be subjected finish processing, the deep-sea fish does not need tobe clamped during finish process, and a clamping mechanism is not needed.

Owner:湛江市海洲水产有限公司

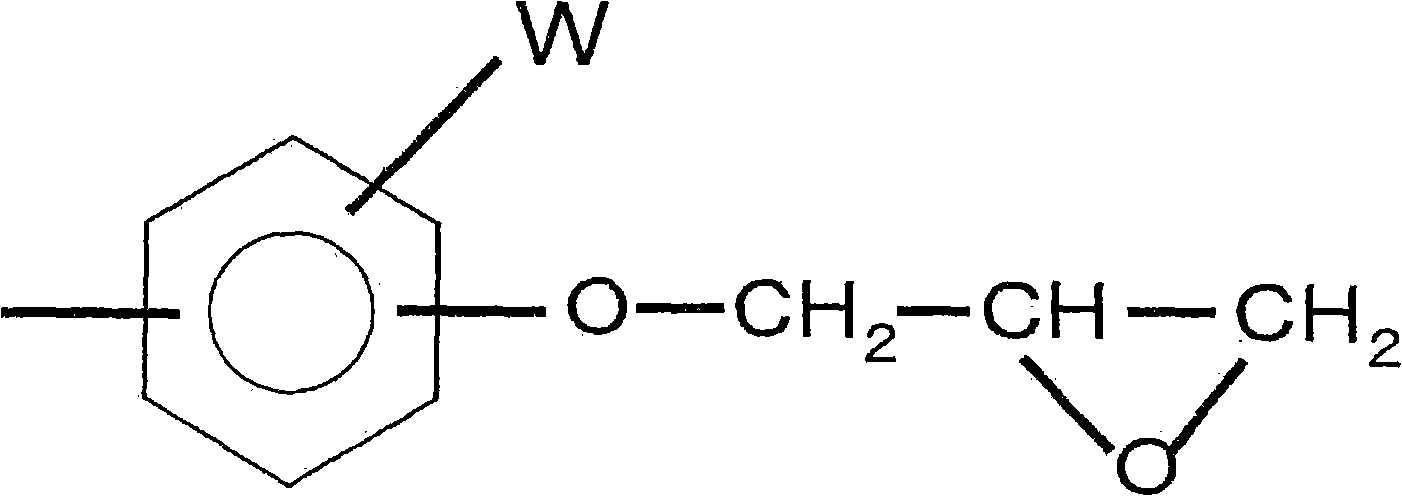

Cationic electrodeposition coating composition

ActiveCN101899252AExcellent applicability for electrodeposition coatingImprove corrosion resistanceThin material handlingEpoxy resin coatingsEpoxySolid mass

An object of the present invention is to provide a coating composition that has excellent electrodeposition coating applicability onto hot dip galvanized steel sheets, and that provides a cationic electrodeposition coating film having a superior finish and excellent anti-corrosion properties. The present invention provides a cationic electrodeposition coating composition having: amino group-containing modified epoxy resin (A), phenolic hydroxy group-containing resin (B), and blocked polyisocyanate curing agent (C), the components (A), (B), and (C) being contained in amounts of 5 to 50 mass %,20 to 75 mass %, and 10 to 40 mass %, respectively, based on the total solids mass of the components (A), (B), and (C).

Owner:KANSAI PAINT CO LTD

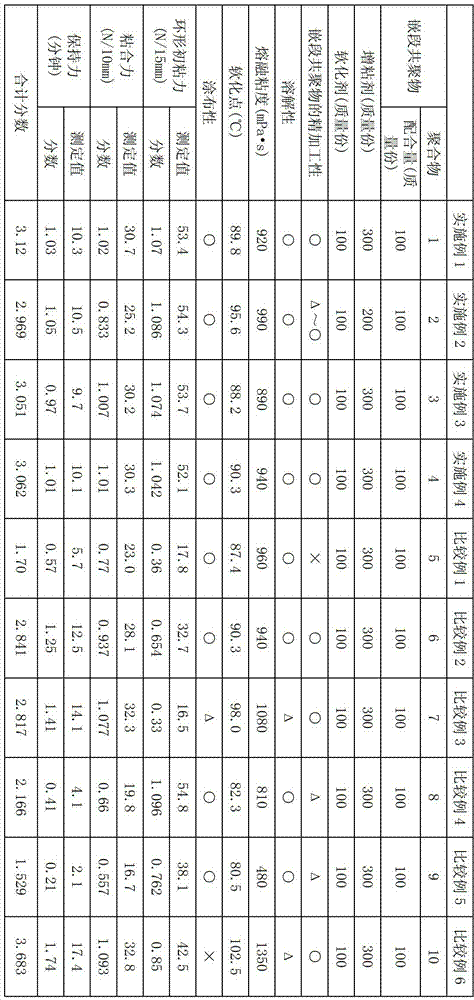

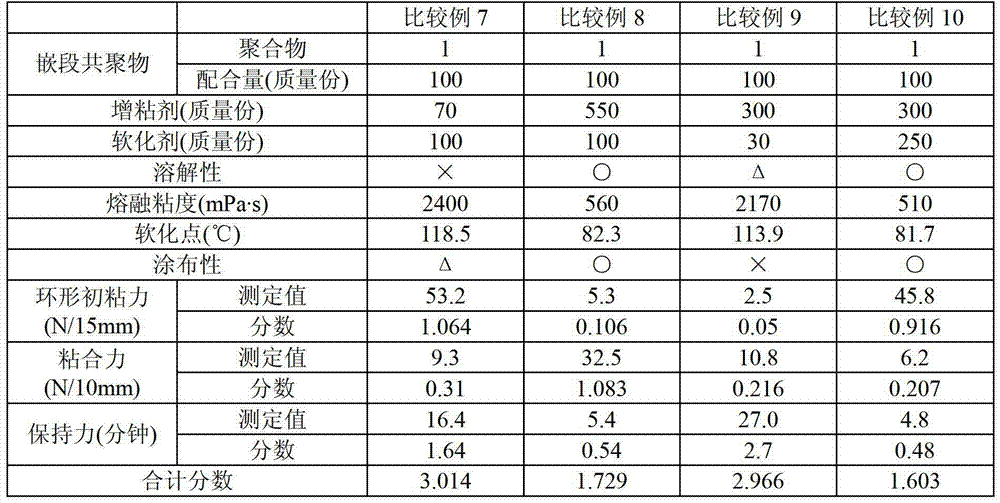

Block copolymer for adhesive, production method therefor, and adhesive composition

To provide a block copolymer for adhesive that has a good finish, and an adhesive composition that has an excellent adhesive property and a good performance balance, and further an excellent solubility and coatability. [Solution] A block copolymer for adhesive, containing at least two polymer blocks of vinyl aromatic monomer unit (A) and at least one polymer block (B) containing conjugated diene monomer unit as a main component, wherein the amount (% by mass) of polymer blocks of vinyl aromatic monomer unit in the polymer block of vinyl aromatic monomer unit (A) is 95.0 to 99.0% relative to the total amount of vinyl aromatic monomer unit (% by mass) that has been used for polymerizing the polymer block of vinyl aromatic monomer unit (A), and the block copolymer for adhesive selectively contains block copolymer components (a) to (d); that have a specific structure provided with the polymer blocks (A) and (B).

Owner:ASAHI KASEI KK

Multilayer coating film forming method

ActiveCN105772374AGood finishingConvenient finishingLiquid surface applicatorsAnti-corrosive paintsEpoxySolid component

The invention provides a multilayer coating film forming method. The invention provides a coating article through wet-on-wet coating, which has excellent finish machining performance, anti-corrosion property, weather fastness and cracking resistance, and low coating glossiness difference caused by burning and fixing. The multilayer coating film forming method forms an uncured coating employing a primer coating compound (A) on a coated subject, forms a finishing coat coating employing a specific finishing coat coating compound (B) on the uncured coating, and simultaneously dries the two coatings, wherein the primer coating compound (A) includes epoxy resin (a1), and 1-70 parts by mass of a rust resisting pigment (a2), 40-150 parts by mass of a tinting pigment (a3) and 40-150 parts by mass of a filler pigment (a4) employing 100 parts by mass of solid components of the epoxy resin (a1) as a standard; the total weight of the solid components of the epoxy resin (a1) is 100g; the total oil absorption of the rust resisting pigment (a2), the tinting pigment (a3) and the filler pigment (a4) is 16-50 ml.

Owner:KANSAI PAINT CO LTD

Preparation method for Al2O3 dispersion strengthened copper-based oil bearing

A preparation method for an Al2O3 dispersion strengthened copper-based oil bearing comprises the steps that Al2O3 dispersion copper alloy powder and tin powder are mixed proportionally and evenly; mixed powder is subjected to diffusion alloying treatment, and Al2O3 dispersion strengthened copper-tin diffusion alloying powder is obtained after crushing, screening and blending; the obtained diffusion alloying powder is subjected to die forming, and a bearing green body is prepared; and the obtained bearing green body is sintered and then subjected to oil immersion and finishing, and the Al2O3 dispersion strengthened copper-based oil bearing is obtained. The dispersion strengthened copper-based oil bearing prepared through the method has the good strength, hardness and precision, the defects that existing bronze oil bearings are low in strength, poor in abrasion resistance, low in precision and the like commonly are overcome, and the method is suitable for scale production.

Owner:GUANGDONG INST OF MATERIALS & PROCESSING +1

Surface machining method for obtrusive hollow cylinder and ball end mill

InactiveCN104668642AReduce the number of clampingIncrease productivityMilling cuttersMilling equipment detailsMilling cutterEngineering

The invention discloses a surface machining method for an obtrusive hollow cylinder and a ball end mill, in particular to the machining method and the ball end mill which use an ordinary three-shaft vertical machine, and can reduce clamping frequency, improve machining efficiency and machining stability. The machining method comprises course machining and fine machining, wherein the fine machining comprises the following steps: 1, semifinishing a round groove, a cylindrical face and a circular truncated cone curved face by a T-shaped milling cutter, wherein the unilateral margins of the round groove and the cylindrical face are both 0.15 mm, and the machining margin of the circular truncated cone curved face is 0.12 mm; 2, finishing the round groove, the cylindrical face and the circular truncated cone curved face by the T-shaped milling cutter, wherein the parameters of the T-shaped milling cutter are the same as the parameters in step 1, the margins for machining the round groove and the cylindrical face are 0 mm, namely, machining is in place, and the unilateral margin of the circular truncated cone curved face is 0.08 mm; 3, finishing the circular truncated cone curved face by adopting the specially made ball end mill, wherein the smallest cutting length is 0.1 mm. For the specially made ball end mill, the diameter of the cutter bar is smaller than that of the bulb. The machining quality of a part is ensured by the method and use of the ball end mill.

Owner:TIANJIN UNIV OF COMMERCE

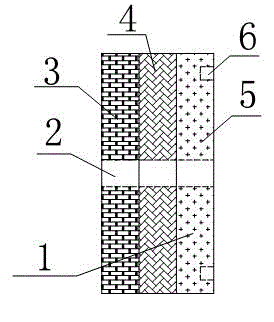

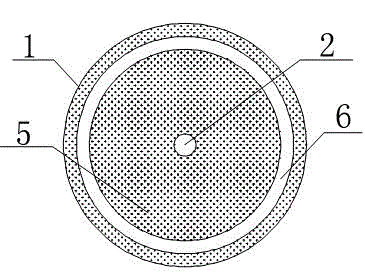

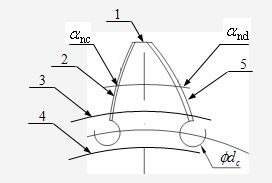

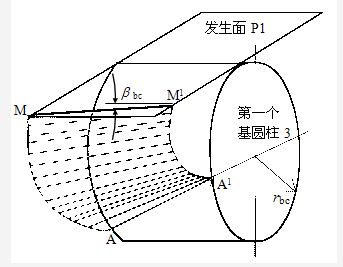

Involute gear-shaving cutter

InactiveCN102554365AIncreased pressure angleImprove carrying capacityGear teeth manufacturing toolsGear teethInvolute gearGreek letter alpha

The invention discloses an involute gear-shaving cutter and belongs to the technical field of wheel gears. The involute gear-shaving cutter is characterized in that base cylinders with different diameters are used for generating tooth profile curved surfaces with a respective reference circle pressure angle alpha nc and alpha nd on the two sides of a tooth profile of the nvolute gear-shaving cutter, and the alpha nc is greater than the alpha nd. The gear-shaving cutter is specially designed for an asymmetric involute gear with double pressure angles and can be used for solving the problem that the existing gear-shaving cutter cannot process the asymmetric involute gear with double pressure angles. The tooth profile of the novel gear-shaving cutter mainly comprises a tooth crest 1, a left side tooth surface 2 generated by a first base cylinder 3 and a right side tooth surface 5 generated by a second base cylinder 4. Compared with the existing involute gear-shaving cutter, the involute gear-shaving cutter provided by the invention can carry out finish machining on the asymmetric involute gear with double pressure angles conveniently, rapidly and efficiently, thus the being wide in market prospect and having huge social and economical benefits.

Owner:JIANGSU UNIV

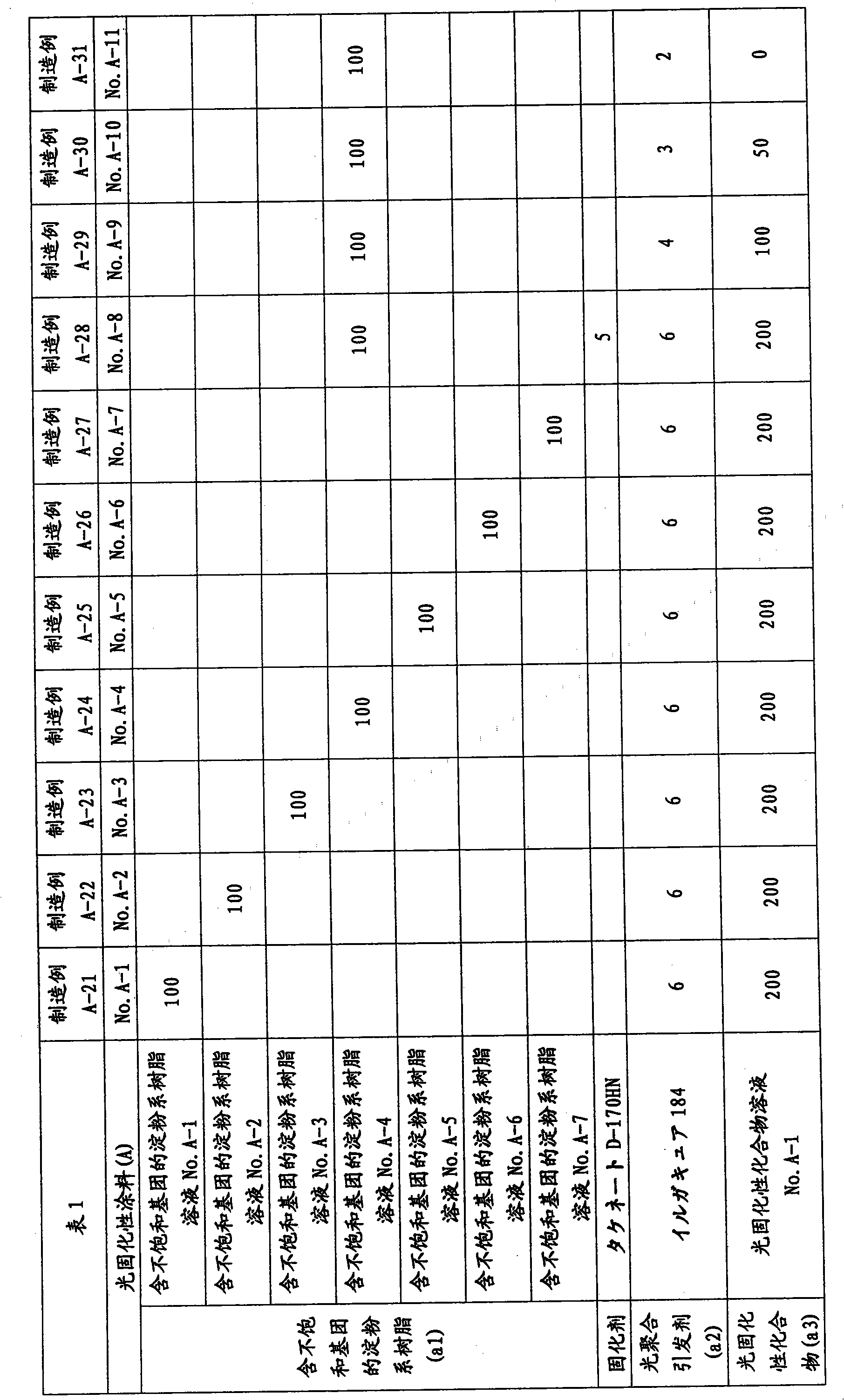

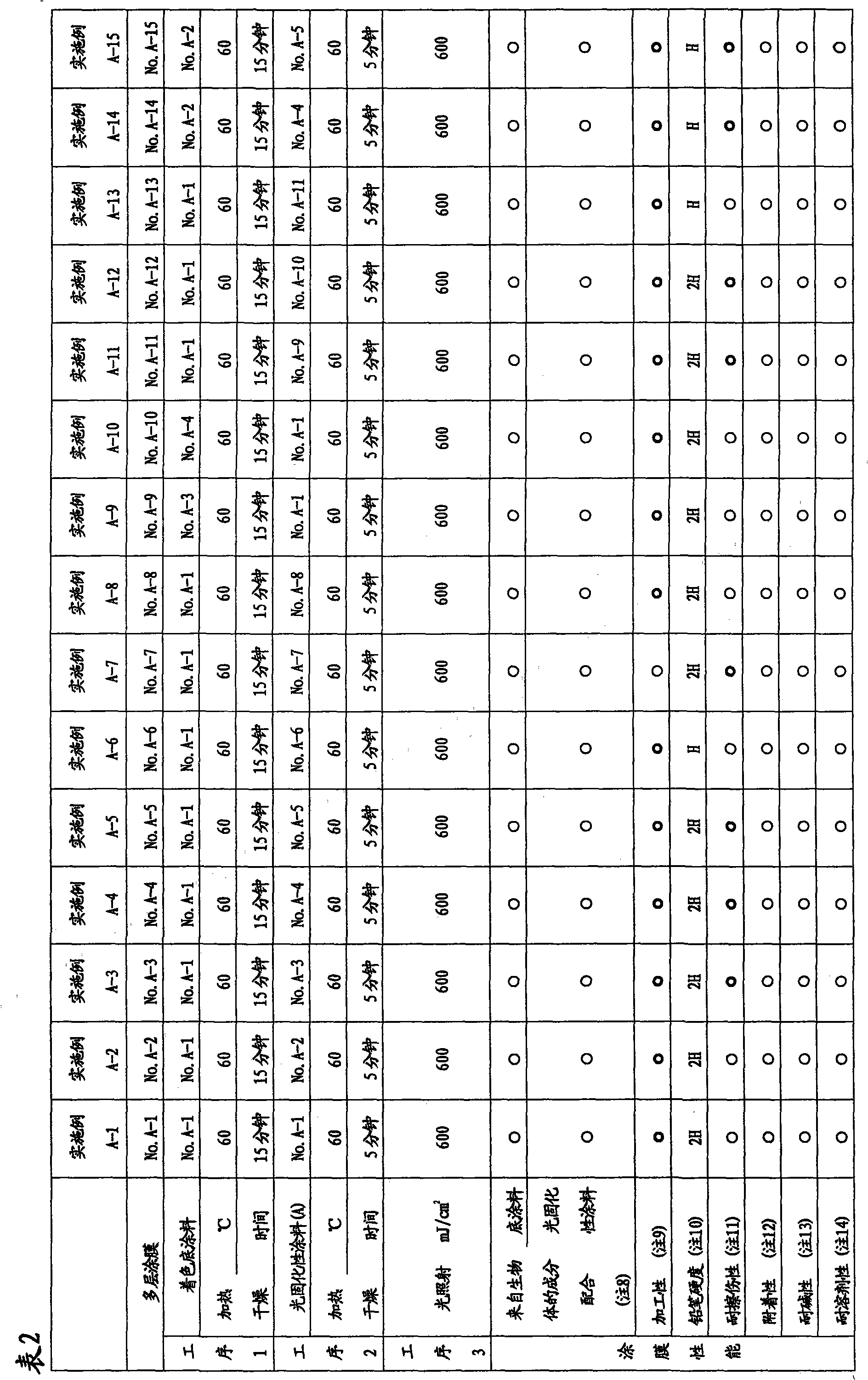

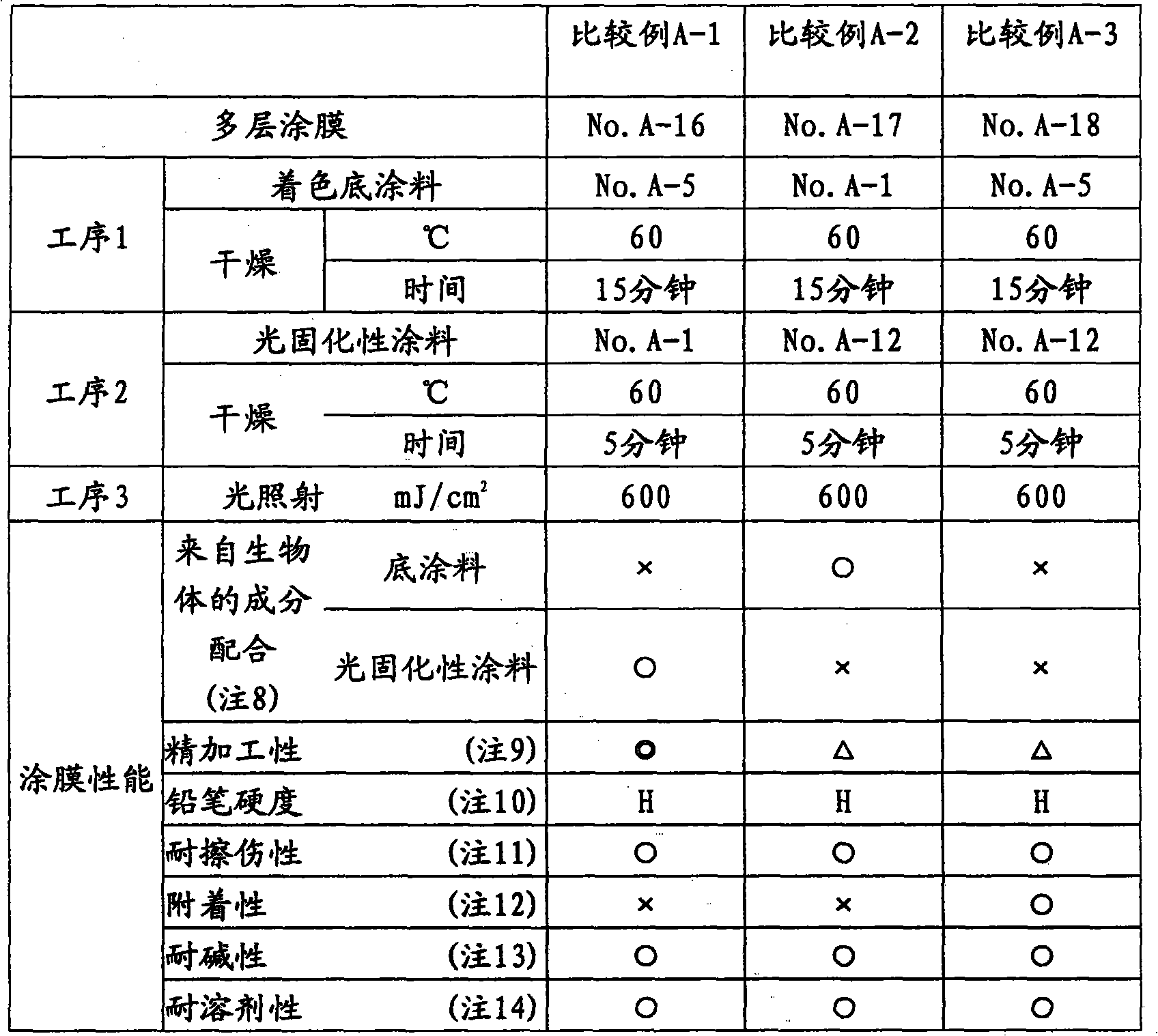

Method of forming multilayered coating film, multilayered coating film, and coated article

InactiveCN101896287AGood finishingGood adhesionStarch dervative coatingsPretreated surfacesHardnessSolvent

A method of forming a multilayered coating film which comprises: a step in which a starch-based colored base coating material containing a starch-based resin is applied to a work to be coated to form a coating film; a step in which a photocurable coating material (B) comprising a photocurable compound and / or photocurable resin (b1), a photopolymerization initiator (b2), and a starch-based resin (b3) is applied to that coating film to form a coating film; and a step in which the coating film of the photocurable coating material (B) is irradiated with light to cure this coating film. As the photocurable coating material (A) or (B) is used a coating material based on a starch derived from a vegetable. This method can form a multilayered coating film excellent in finish, pencil hardness, marring resistance, adhesion, alkali resistance, and solvent resistance.

Owner:KANSAI PAINT CO LTD

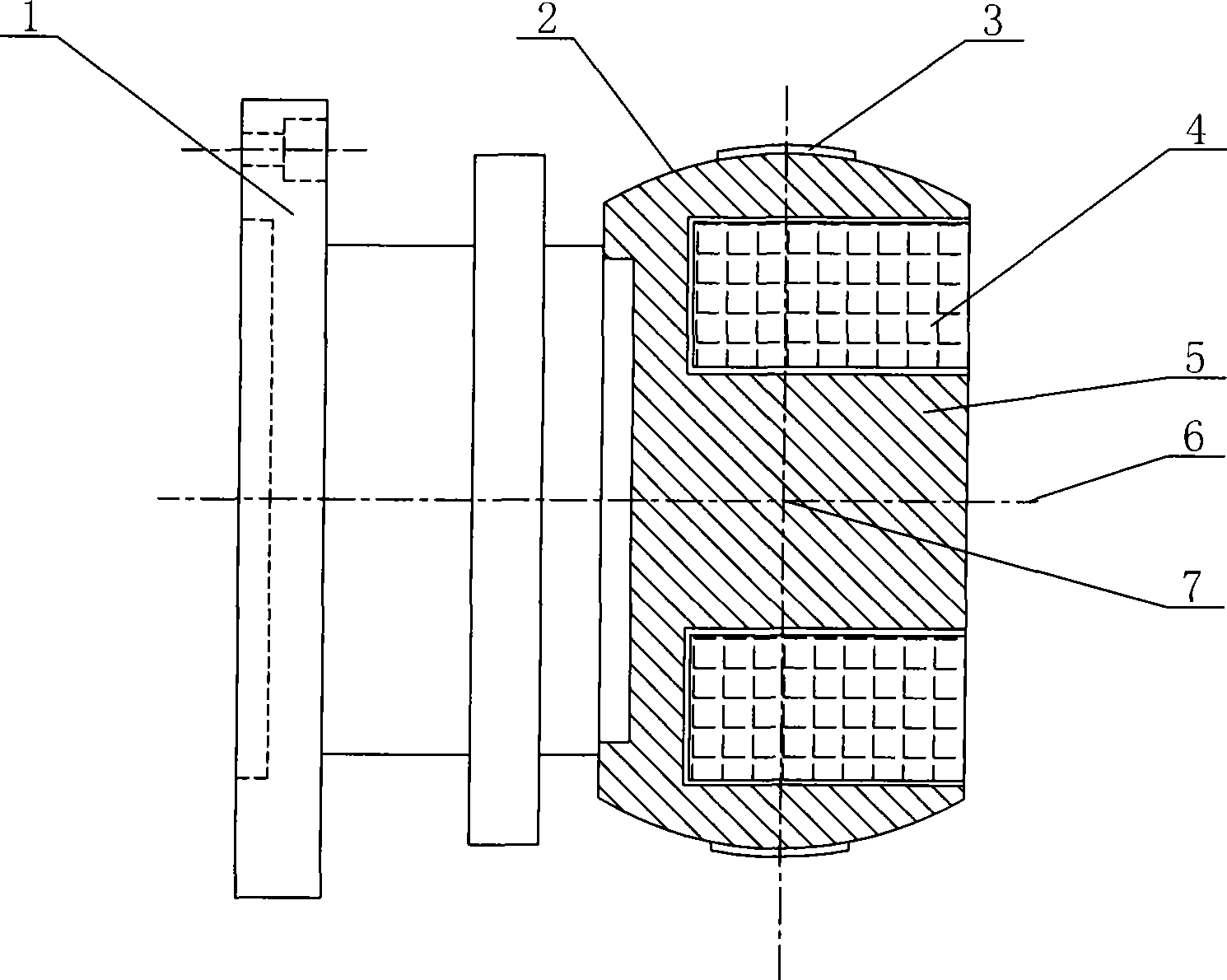

High-speed permanent magnet motor rotor structure

InactiveCN102946157AConvenient finishingLow heating temperatureMagnetic circuit rotating partsPhysicsHigh intensity

The invention relates to a high-speed permanent magnet motor rotor structure. Radial bolt holes and axial ventilation holes are formed in a rotor, wherein the radial bolt holes are communicated with the axial ventilation holes; a permanent magnet block and a magnetic pole interval are fixedly arranged on the rotor through bolts; and jackets are thermally sheathed outside the permanent magnet block and the magnetic pole interval on the rotor and are made of titanium alloy or high-strength metal, and the jackets are retracted and then are tightly hooped on the rotor. According to the high-speed permanent magnet motor rotor structure disclosed by the invention, a permanent magnet is fixed by adopting the bolts, the problem of mutual exclusion between a partitioning block and the permanent magnet in the matching process of the thermal sheathing is solved and the work difficulty during thermal sheathing of a permanent magnet motor is reduced; after the permanent magnet is fixed by the bolts, the finish machining of the surface can be conveniently carried out and the heating temperature of the jackets during thermal sleeving is reduced; after the jacks are assembled, the bolts can be unscrewed; bolt holes can be used as the radial ventilation holes; the radial ventilation holes and the axial ventilation holes form a ventilating and cooling system of the rotor; and the bolts are finally unscrewed, and thus the problem of stress concentration caused by the bolts is solved.

Owner:中国船舶重工集团公司第七0四研究所

Device for removing sand on casting blank conveniently

The invention discloses a device for removing sand on a casting blank conveniently and relates to the technical field of mechanical equipment. The device for removing the sand on the casting blank conveniently comprises a handle. A shell is connected to one side of the handle in a clamped mode, and a fixed block is fixedly connected to the bottom of the inner wall of the shell. A first motor is fixedly connected to the top of the fixed block, and an output shaft of the first motor is fixedly connected with a first belt wheel. The surface of the first belt wheel is in transmission connection with a second belt wheel through a belt, a cam is fixedly connected to the back side of the second belt wheel, and a push rod is arranged on one side of the cam. The end, away from the cam, of the pushing rod penetrates through the shell and extends out of the shell. The end, located outside the shell, of the push rod is fixedly connected with a fixed box. By adoption of the device for removing the sand on the casting blank, sand blocks on the inner wall of a casting can be polished away easily, sand blocks located at corners of the casting can be knocked down, and time and labor are saved; and the sand removing effect is good, and finish machining can be conducted conveniently.

Owner:合肥众望电气科技有限公司

Production line for manufacturing hollow chopsticks from stainless steel stretched circular pipe

InactiveCN1850434AGood for finishingSmooth appearanceOther manufacturing equipments/toolsMaterials scienceProduction line

The invention is about the production line of the hollow chopsticks by drawing stainless steel round pipe. The pipe with 0.33mm of thickness is transferred into a spin-forging machine to form the taper round pipe which is annealed to remove the material stress by industrial electrical furnace. The pipe is washed by acid to remove oxide skin and to become bright. The big head of the pipe is pressed by the four-wheel extruder to become the taper square pipe and refined by the horizontal punching machine. The small round head is annealed partially and sealed by rolling spinning. The tetraquetrous taper square cap is punched by a vertical punching module and welded by the resistance welding. At last the chopsticks are polished and carved with calligraphy and painting.

Owner:张立斌 +1

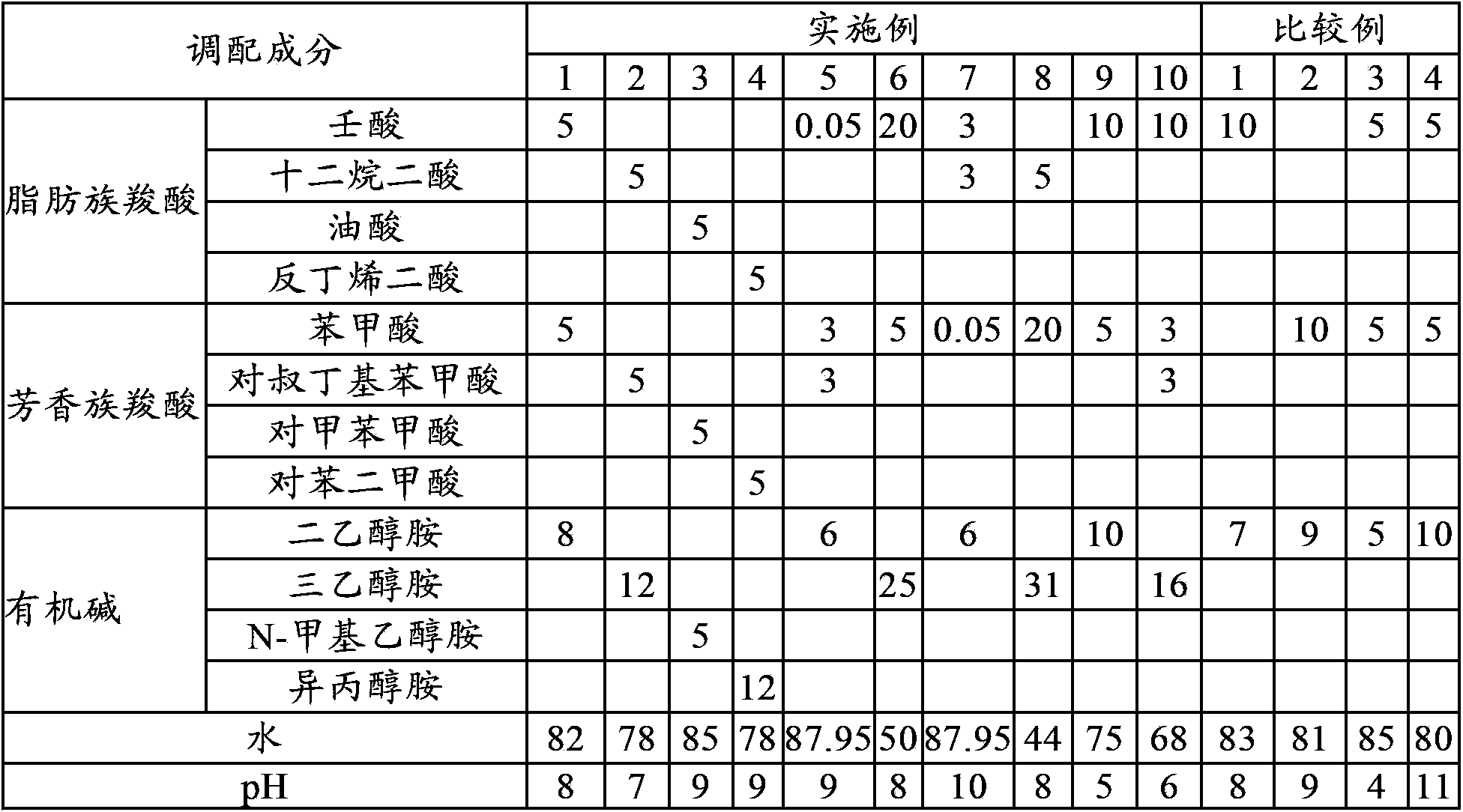

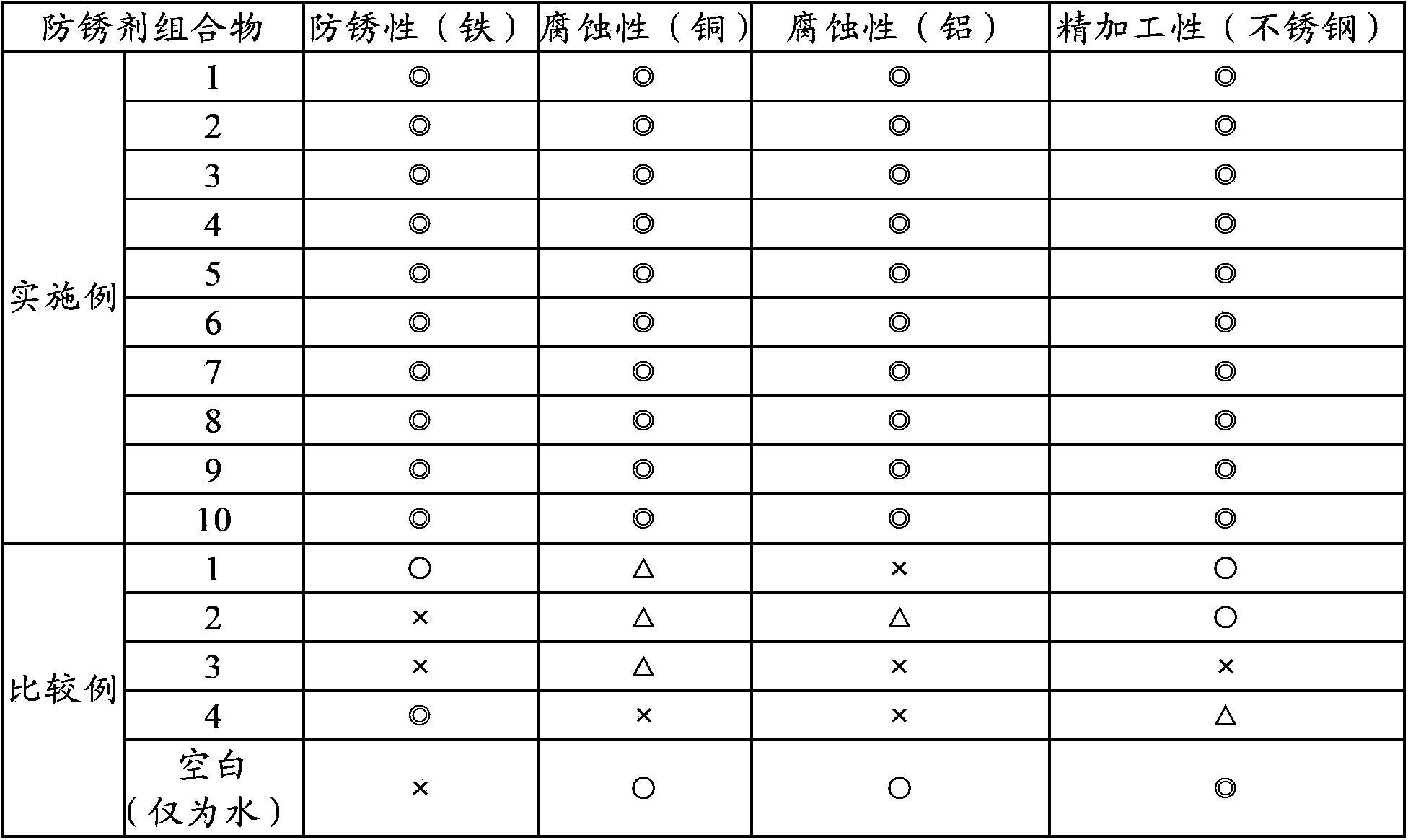

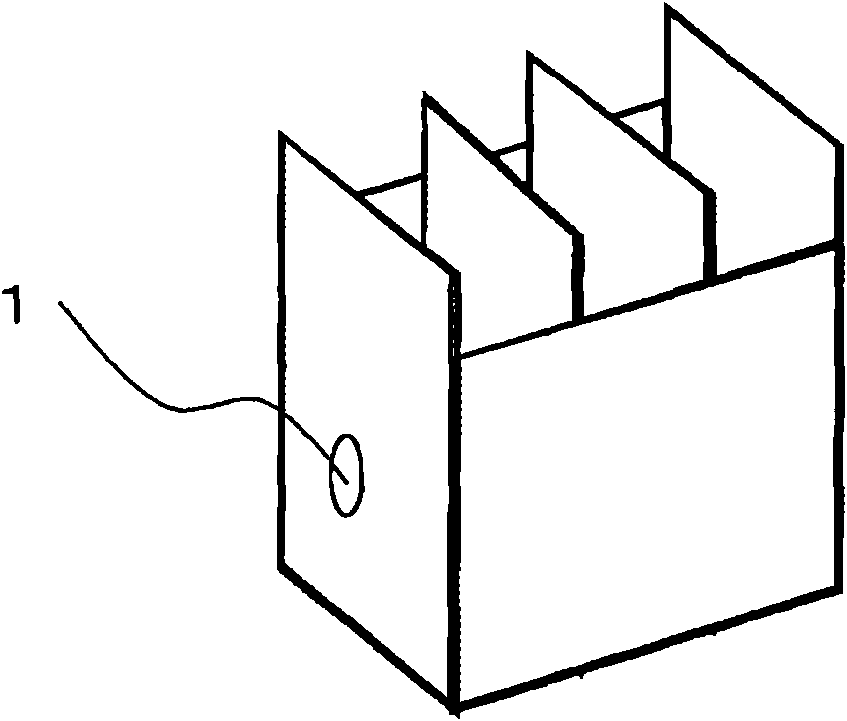

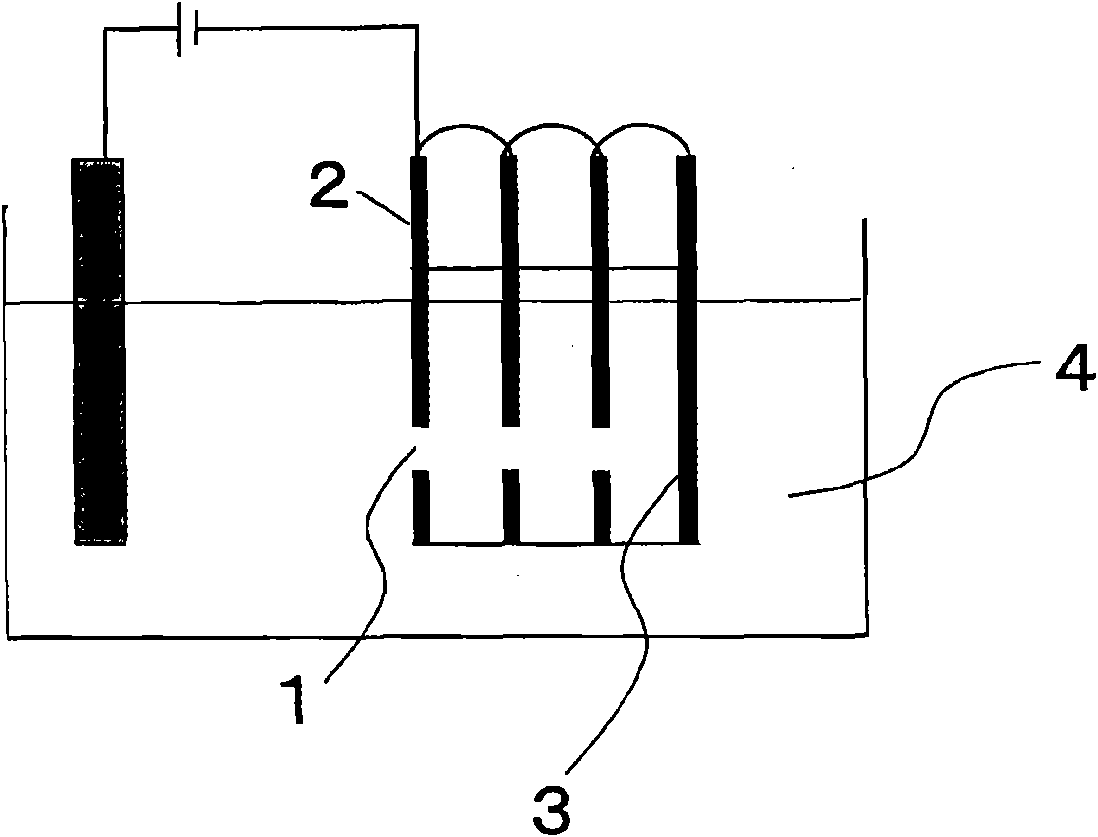

Antirust agent composition and antirust method using the same

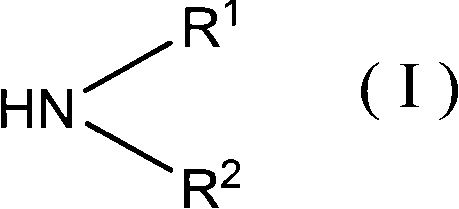

The invention provides an antirust agent composition and an antirust method using the same. The antirust agent composition comprises a aliphatic carboxylic acid represented by general formula (1), and a aromatic carboxylic acid represented by general formula (2), and is formed by using organic base through adjustment in the way of changing pH to be in the range of 5 to 10, and can be used both for ferrous metal raw materials and non-ferrous metal raw materials. The antirust performance and finish machining performance are excellent, and an antirust method can be provided by using the antirust agent composition. R1-(COOH)n (1), in the formula (1), R1 represents an alkyl group in the form of a straight chain or branches which acts as an alkyl group, an alkenyl group or an alkanol group with the carbon number being 1 to 17, and n represents a number of 1 to 3. R2-(COOH)n (2), in the formula (2), R2 represents an aromatic alkyl group, and n represents a number of 1 to 3.

Owner:DAI ICHI KOGYO SEIYAKU CO LTD

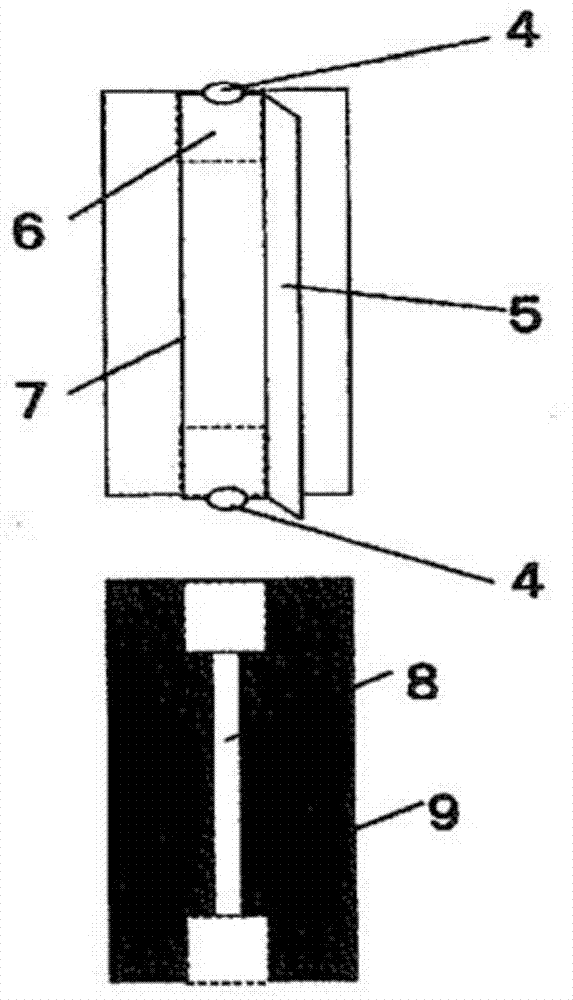

Cationic electrodeposition coating composition

InactiveCN101870843AConvenient finishingEasy to processPolyurea/polyurethane coatingsPaints for electrolytic applicationsFirming agentBis epoxide

An object of the present invention is to provide a coating composition that has excellent throwing power and electrodeposition coating applicability onto hot dip galvanized steel sheets, and that provides a cationic electrodeposition coating film having a superior finish and excellent anti-corrosion properties, and a multilayer coating film with a superior finish formed on the cationic electrodeposition coating film by a 3C1B process. The present invention provides a cationic electrodeposition coating composition having amino group-containing epoxy resin (A) obtained by reacting epoxy resin (A1) having an epoxy equivalent of 500 to 2,500 with amine compound (A2); and blocked polyisocyanate curing agent (B).

Owner:KANSAI PAINT CO LTD

Novel processing cutting fluid

InactiveCN103602372AIncreased durabilityFree from corrosionAdditivesThermal dilatationMachined surface

The invention discloses a novel processing cutting fluid, which is prepared from the following raw materials by weight: 2-6 parts of polyoxyethylene fatty acid, 3-7 parts of sodium benzoate, 25-35 parts of mineral oil, 10-15 parts of high potash soap, 8-14 parts of organic carboxylic acid salt and 3-9 parts of polyalkylene glycol. The cutting fluid provided by the invention can penetrate into contact surfaces of chips, a tool and a workpiece, adheres on a metal surface to form a lubricating film, reduces the friction coefficient, mitigates adhesion phenomenon, inhibits built-up edge and improves the roughness of the machined surface. The cutting fluid in its reach takes away a large amount of cutting heat from the tool, chips and workpiece surface closest to the heat source, so as to reduce cutting temperature, improve the durability of the tool, reduce thermal expansion of workpiece and cutter and improve the machining precision; and the fine crumbs and particles peeled off from a grinding wheel in the cutting are washed away off, so as to play the role of cleaning and prevent damages on the processing surface and the machine tool guide surface.

Owner:QINGDAO HAIBAN PLASTIC IND & TRADE

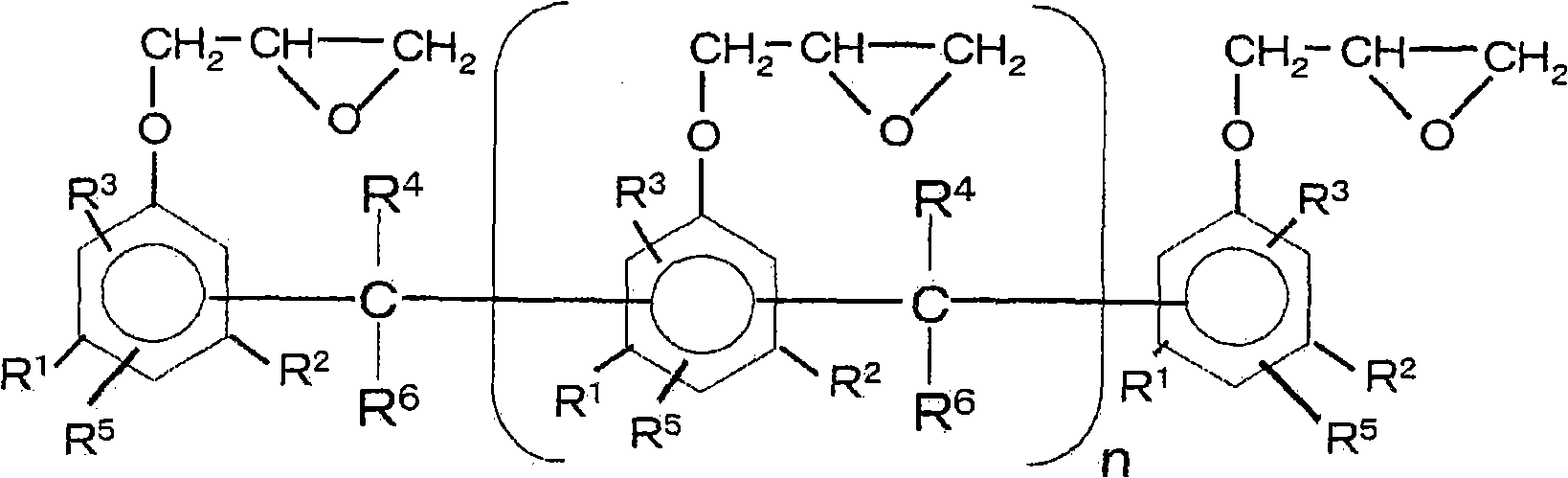

Coating composition and coated article

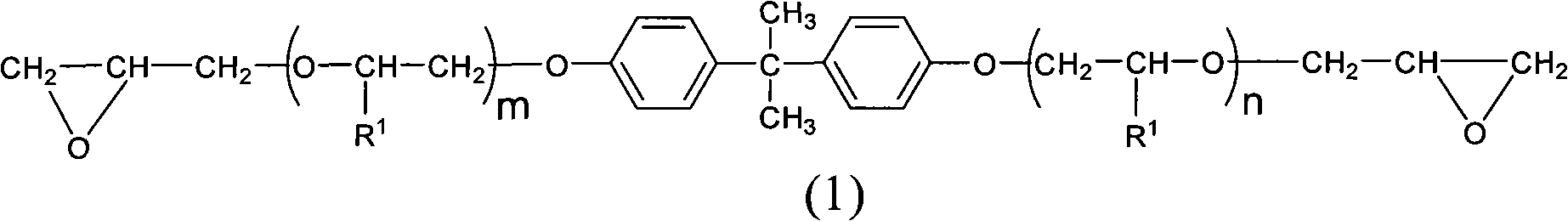

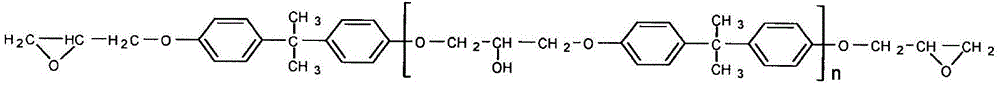

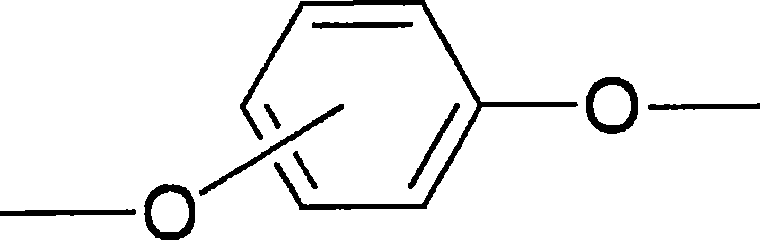

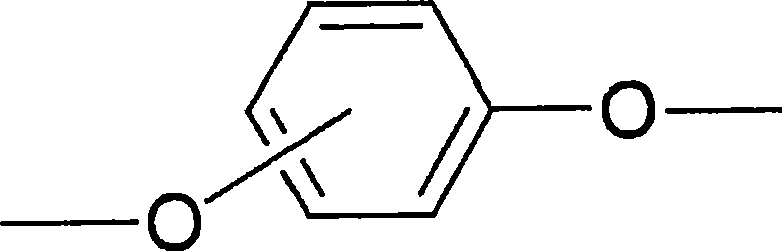

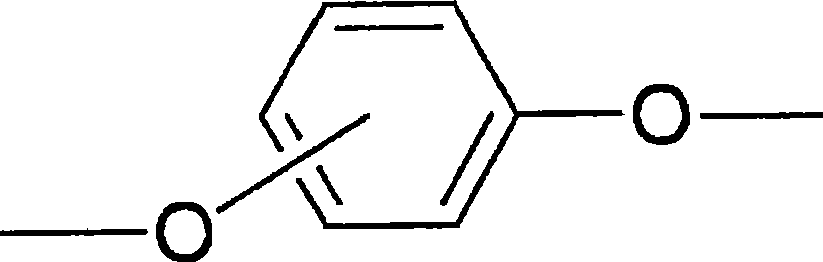

InactiveCN101445691AImprove corrosion resistanceExcellent exposure corrosion resistanceLayered productsAnti-corrosive paintsEpoxyHydroquinone Compound

The present invention relates to a coating composition that can form a coating film with excellent oxygen barrier properties. An object of the invention is to provide a coated article having excellent corrosion resistance using the coating composition. The present invention provides a coating composition comprising: a modified epoxy resin (A) containing a benzene diether structure represented by a specific formula (1), which is obtained by reacting diglycidyl ether (a1) with at least one phenol (a2) selected from resorcinol, hydroquinone, and catechol; and a crosslinking agent (B).

Owner:KANSAI PAINT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com