Cationic electrodeposition coating composition

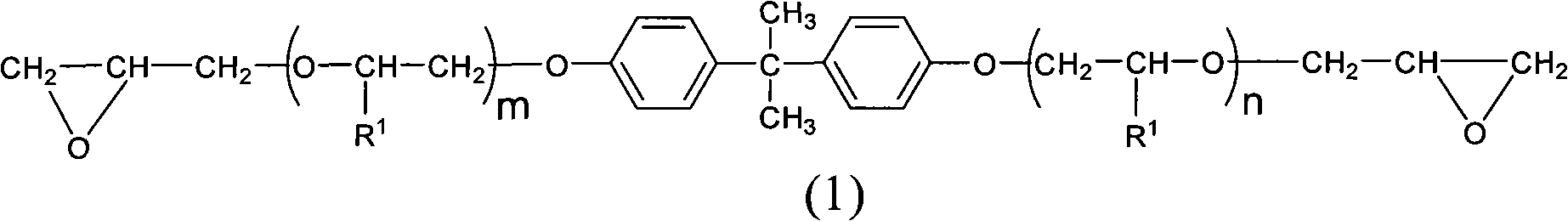

一种阳离子电沉积、组合物的技术,应用在环氧树脂涂料、涂层、薄料处理等方向,能够解决不能提供抗腐蚀性精加工性等问题,达到改善电沉积涂装适用性和精加工性、优异抗腐蚀性和精加工性、高粘合性质的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0131] The present invention is explained in detail below with reference to Preparation Examples, Examples, and Comparative Examples; however, the present invention is not limited thereto. "Parts" in each example means parts by mass and "%" means % by mass.

[0132] Preparation of Amino-Containing Modified Epoxy Resin (A)

preparation Embodiment 1

[0133] Preparation Example 1: Preparation Example of Base Resin No.1

[0134] In a 2-liter flask equipped with a thermometer, reflux condenser and stirrer, add 185 parts of Denacol EX-821 (Note 1), 950 parts of jER828EL (Note 5), 456 parts of bisphenol A and 0.8 parts of Tetra Butyl ammonium bromide. The mixture was reacted at 160° C. until the epoxy equivalent became 800.

[0135] Subsequently, 359 parts of methyl isobutyl ketone, and 150 parts of diethanolamine, and 127 parts of diethylenetriamine and methyl isobutyl ketone imide (purity 84%, methyl isobutyl ketone solution), and then allowed to react at 120° C. for 4 hours. A solution of base resin No. 1, which is an amino group-containing modified epoxy resin with a resin solid content of 80%, was thus obtained. Base resin No. 1 had an amine value of 69 mg KOH / g, and a number average molecular weight of 2,400.

preparation Embodiment 2

[0136] Preparation Example 2: Preparation Example of Base Resin No.2

[0137] In a 2-liter flask equipped with a thermometer, reflux condenser and stirrer, add 471 parts of Denacol EX-931 (Note 2), 950 parts of jER828 EL (Note 5), 456 parts of bisphenol A and 0.8 parts of Tetrabutylammonium bromide. The mixture was reacted at 160° C. until the epoxy equivalent became 950.

[0138] Subsequently, 430 parts of methyl isobutyl ketone, and 150 parts of diethanolamine, and 127 parts of diethylenetriamine and methyl isobutyl ketone imide (purity 84%, methyl isobutyl ketone solution), and then allowed to react at 120° C. for 4 hours. A solution of base resin No. 2, which is an amino group-containing modified epoxy resin with a resin solid content of 80%, was thus obtained. Base resin No. 2 had an amine value of 60 mg KOH / g, and a number average molecular weight of 2,500.

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid containing ratio | aaaaa | aaaaa |

| solid containing ratio | aaaaa | aaaaa |

| solid containing ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com