Clamp for grinding spherical pad

A technology of spherical gaskets and fixtures, which is applied in the direction of spherical grinders, grinding/polishing equipment, grinding machines, etc., can solve the problems of high cost, spherical error, poor finish, low efficiency, etc., and achieve good positioning, high spherical accuracy and Surface smoothness, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

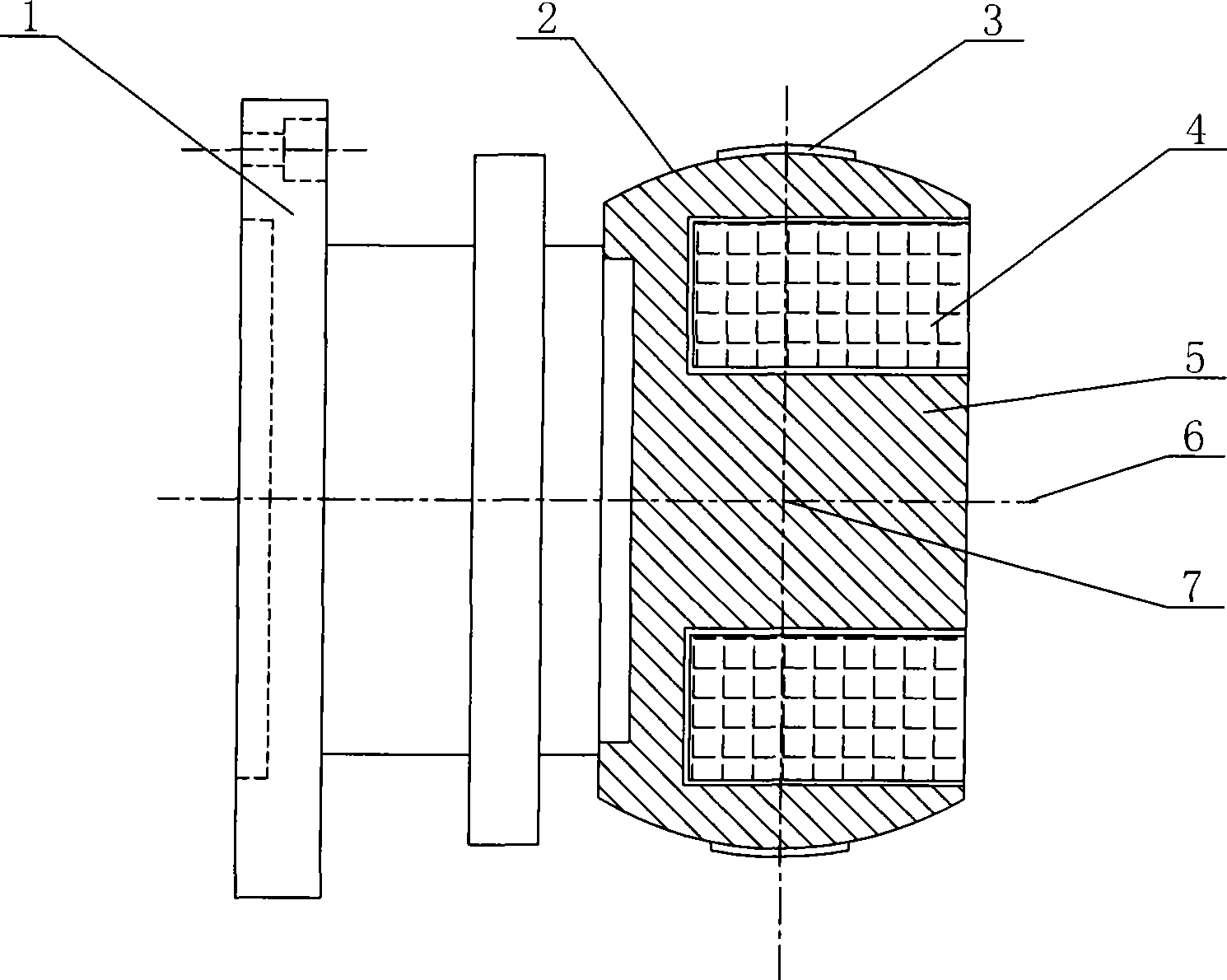

[0014] The accompanying drawings show the technical solution of the present invention and its embodiments, and the relevant details and working principles of the embodiments will be further described below in conjunction with the accompanying drawings.

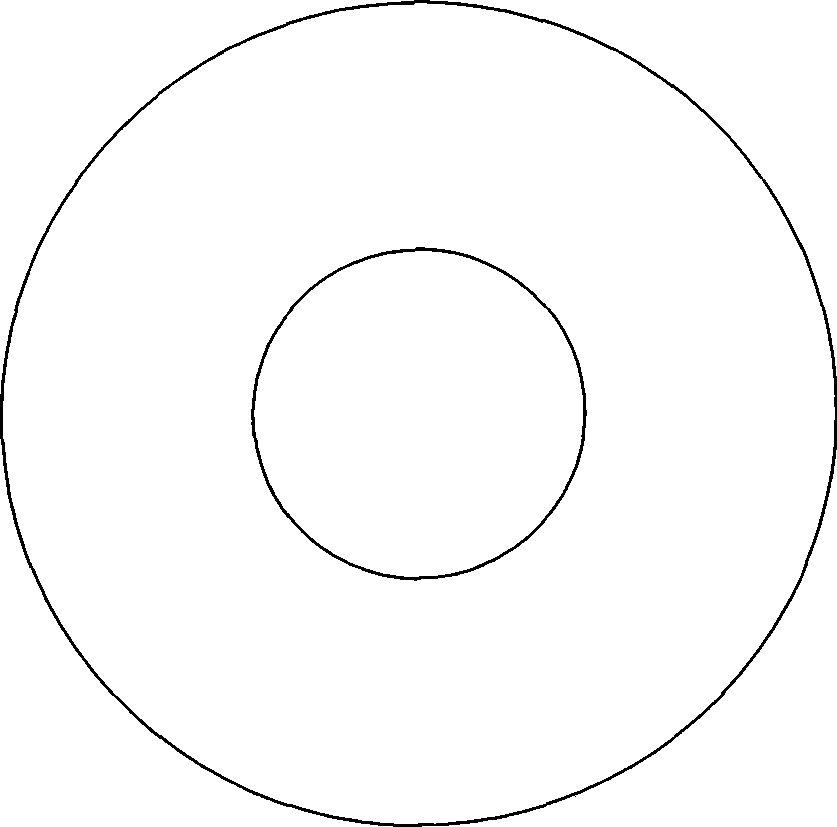

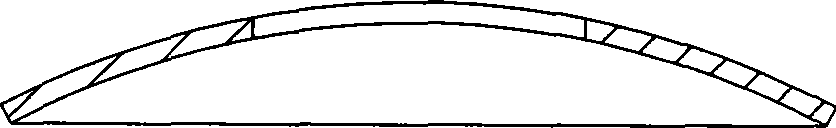

[0015] Refer to attached image 3 , 4 , 5, the jig for grinding spherical gaskets includes a fixedly connected flange 1 and a chuck 5, the chuck 5 has the same spherical arc surface 2 as the spherical gasket, and its spherical center 7 is located at the center of the jig On the rotation axis 6, an electromagnetic coil 4 is provided inside the chuck 5, and a positioning pin 3 is provided on the spherical arc surface 2 of the chuck, and the axis of the positioning pin 3 passes through the center 7 of the spherical surface and is perpendicular to the rotation axis of the clamp 6. The outer diameter of the positioning pin 3 matches the diameter of the inner hole of the spherical gasket. The number of positioning pins is set accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com