Multi-component aqueous primer coating composition and a coating method thereof

A water-based primer and multi-component technology, applied in primers, polyurea/polyurethane coatings, coatings, etc., can solve the problems of insufficient adhesion, water resistance, adhesion, and finishing, and achieve good finishing and water-resistant adhesion excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

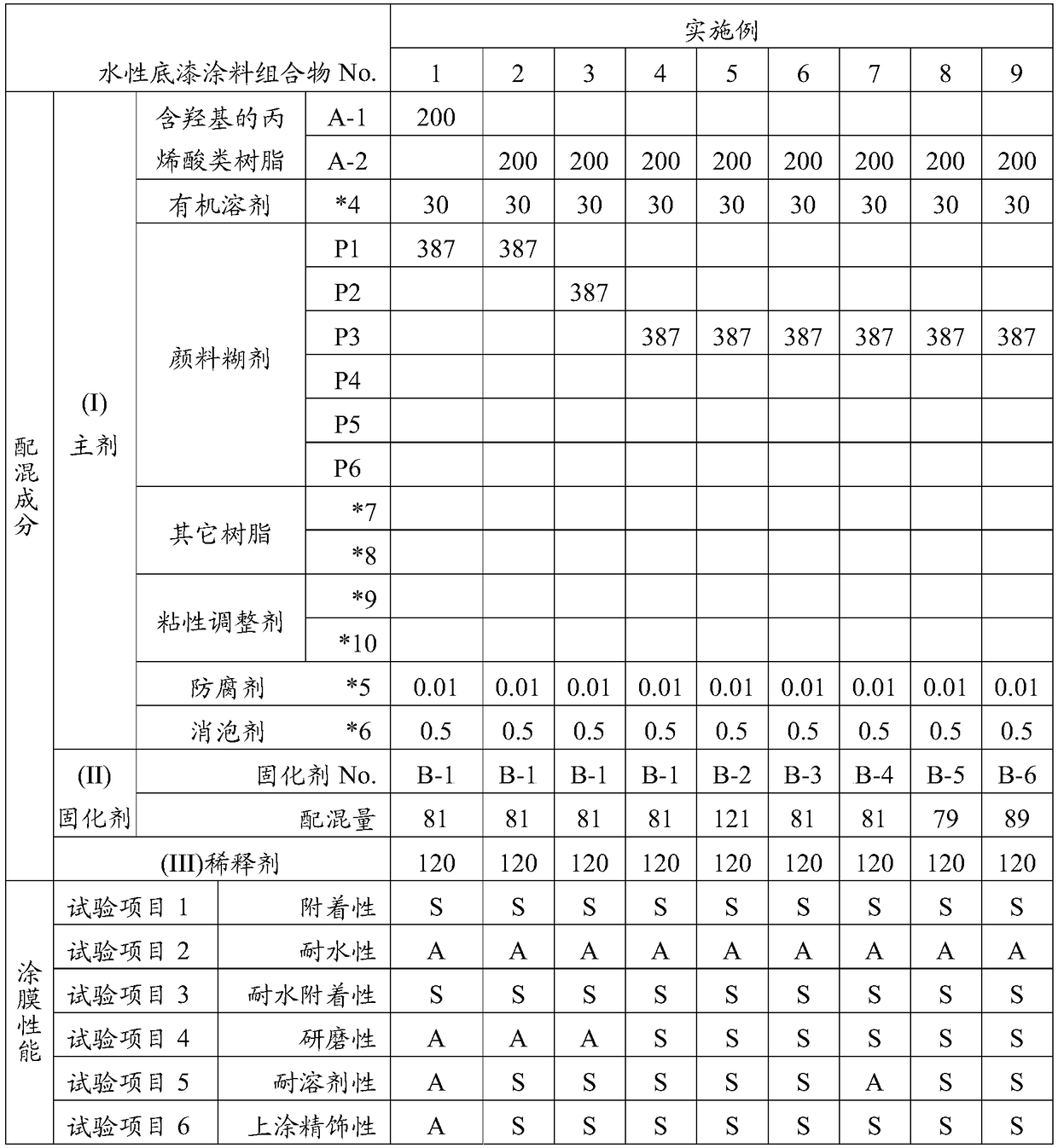

Examples

manufacture example 1

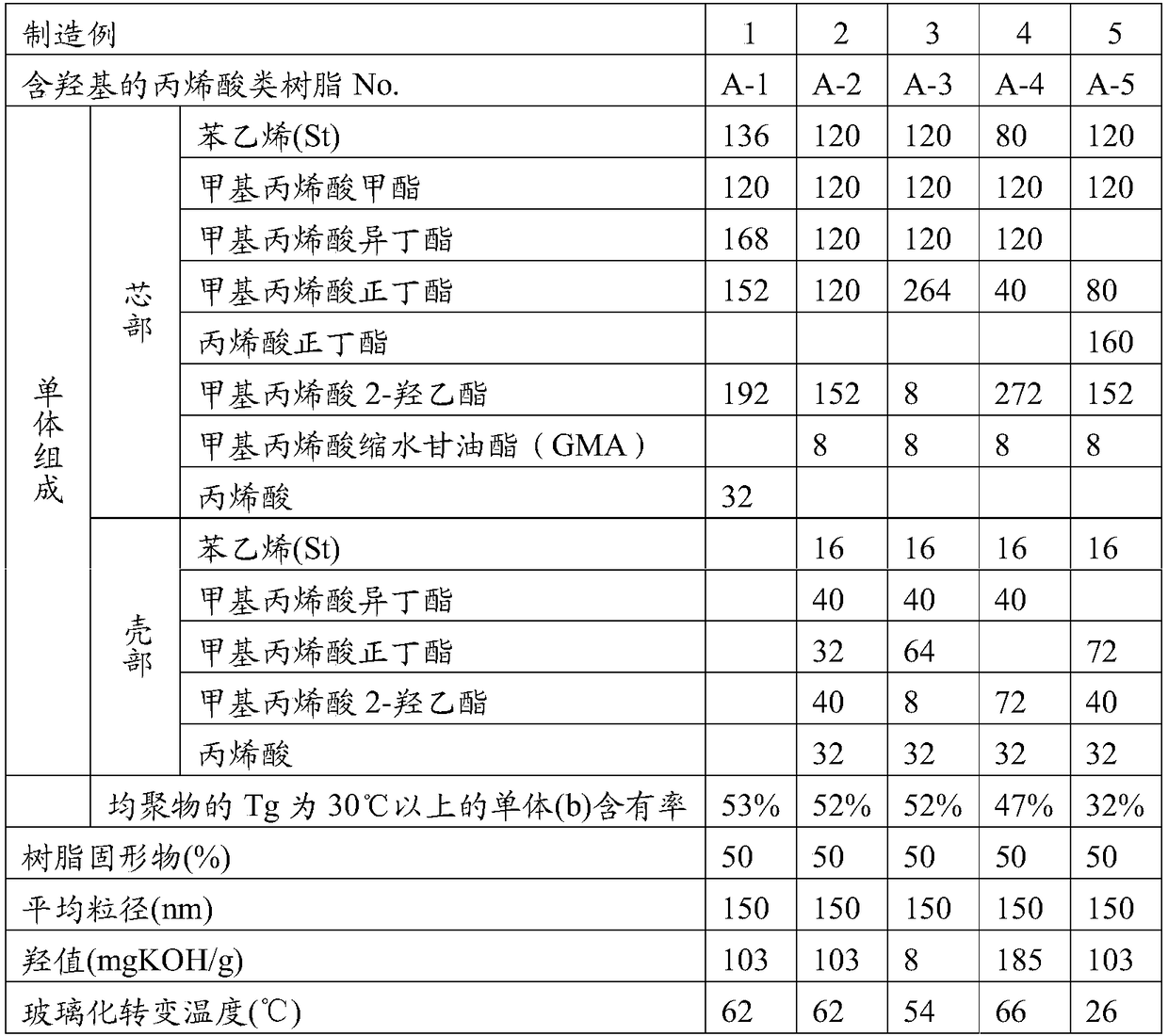

[0159] (Production Example 1) Production of hydroxyl-containing acrylic resin

[0160] Add 300 parts of deionized water and 1 part of sodium dodecylbenzenesulfonate to a 2-liter glass reaction vessel equipped with a stirrer, a thermometer, and a condenser, replace the air inside with nitrogen, and raise the temperature while stirring. It melts at an internal temperature of 82°C. In another container, add 320 parts of deionized water, 40 parts of sodium dodecylbenzenesulfonate, and 2 parts of ammonium persulfate, stir well, and add 136 parts of styrene and 120 parts of methyl methacrylate to it. , a monomer mixture of 168 parts of isobutyl methacrylate, 152 parts of n-butyl methacrylate, 192 parts of 2-hydroxyethyl methacrylate and 32 parts of acrylic acid was stirred to make an emulsion, and it took 4 hours to mix the The emulsion was continuously added dropwise to the previous reaction vessel.

[0161] After completion of the dropwise addition, it was further stirred at 82°...

manufacture example 2

[0162] (Production example 2) Production of hydroxyl-containing acrylic resin

[0163]Add 300 parts of deionized water and 1 part of sodium dodecylbenzenesulfonate to a 2-liter glass reaction vessel equipped with a stirrer, a thermometer, and a condenser, replace the air inside with nitrogen, and raise the temperature while stirring. It melts at an internal temperature of 82°C. Add 320 parts of deionized water, 20 parts of sodium dodecylbenzenesulfonate, and 1 part of ammonium persulfate to another container, stir well, add 120 parts of styrene, 120 parts of methyl methacrylate, A monomer mixture of 120 parts of isobutyl methacrylate, 120 parts of n-butyl methacrylate, 152 parts of 2-hydroxyethyl methacrylate, and 8 parts of glycidyl methacrylate is stirred to make an emulsion. This emulsion was continuously added dropwise to the previous reaction container for 2 hours.

[0164] After the dropwise addition, after aging at the same temperature for 30 minutes, add 160 parts of...

manufacture example 6

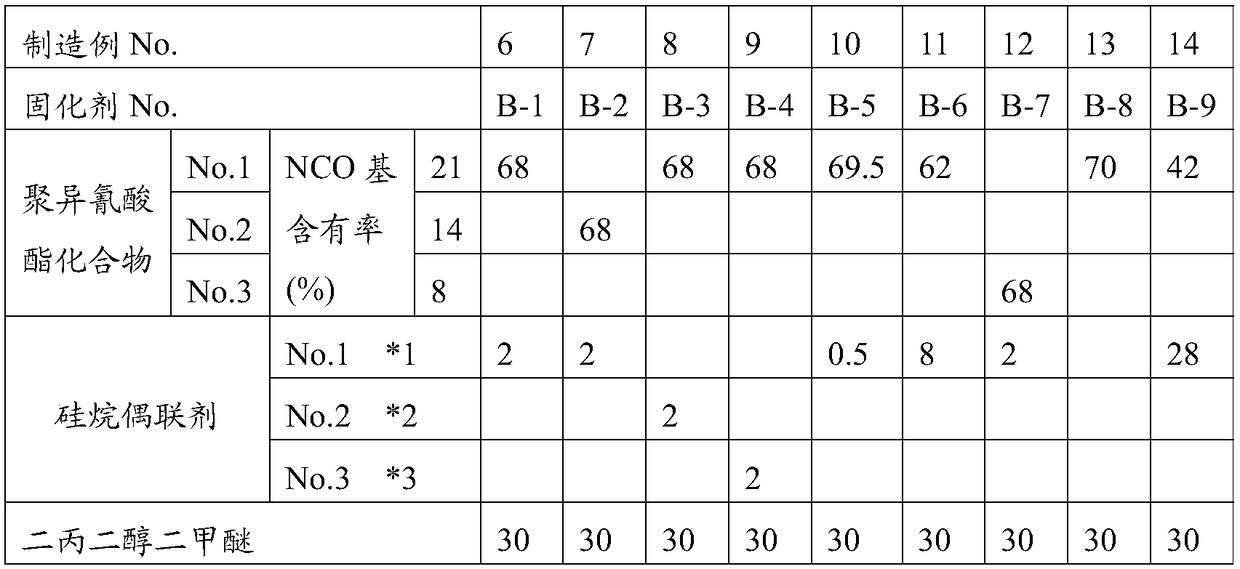

[0170] (Manufacture example 6) Manufacture of curing agent component

[0171] Add 68 parts of commercially available polyisocyanate compound No.1 (solid content 100%) with an isocyanate group content rate of 21%, and 3-glycidoxypropyltrimethoxysilane 2 as silane coupling agent No.1. part and 30 parts of dipropylene glycol dimethyl ether (a water-soluble solvent not having a hydroxyl group), and stirred for 30 minutes to prepare a curing agent (B-1) with a solid content of 70%.

[0172] (Production Examples 7 to 14) Production of curing agent components

[0173] In Production Example 6, the types and amounts of the polyisocyanate compound and the silane coupling agent were set as in Table 2, except that, in the same manner as in Production Example 6, curing agents (B-2) to (B-2) were obtained. 9). Table 2 shows the formulations of Production Examples 6-14.

[0174] 【Table 2】

[0175]

[0176] Polyisocyanate compound No.1-3 and *1-3 in a table|surface mean the following. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com