Method of forming multilayered coating film, multilayered coating film, and coated article

A multi-layer coating film and coating layer technology, which is applied in the direction of surface coating liquid devices, coatings, starch coatings, etc., to achieve the effects of less emissions, less environmental load, and excellent alkali resistance and solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

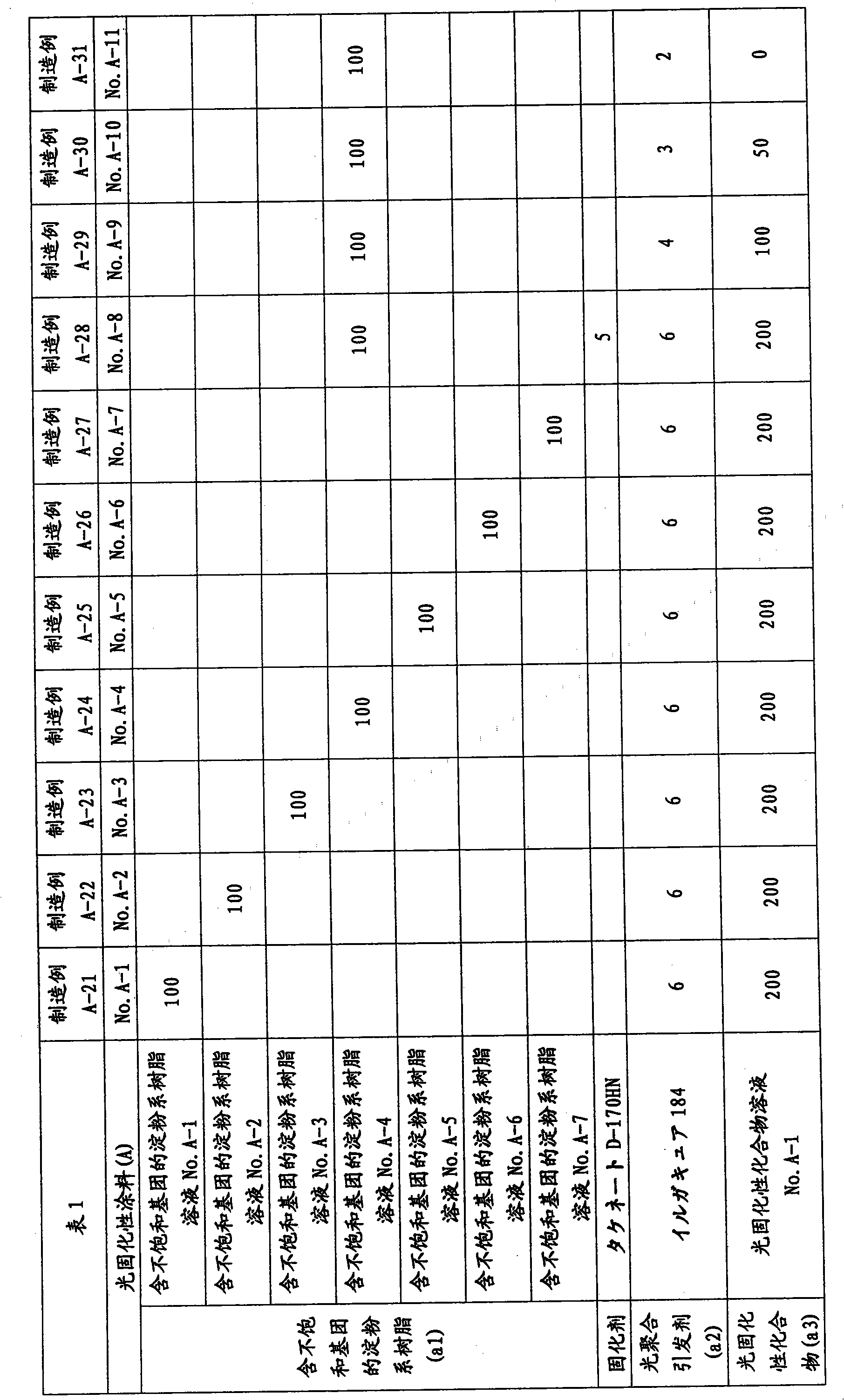

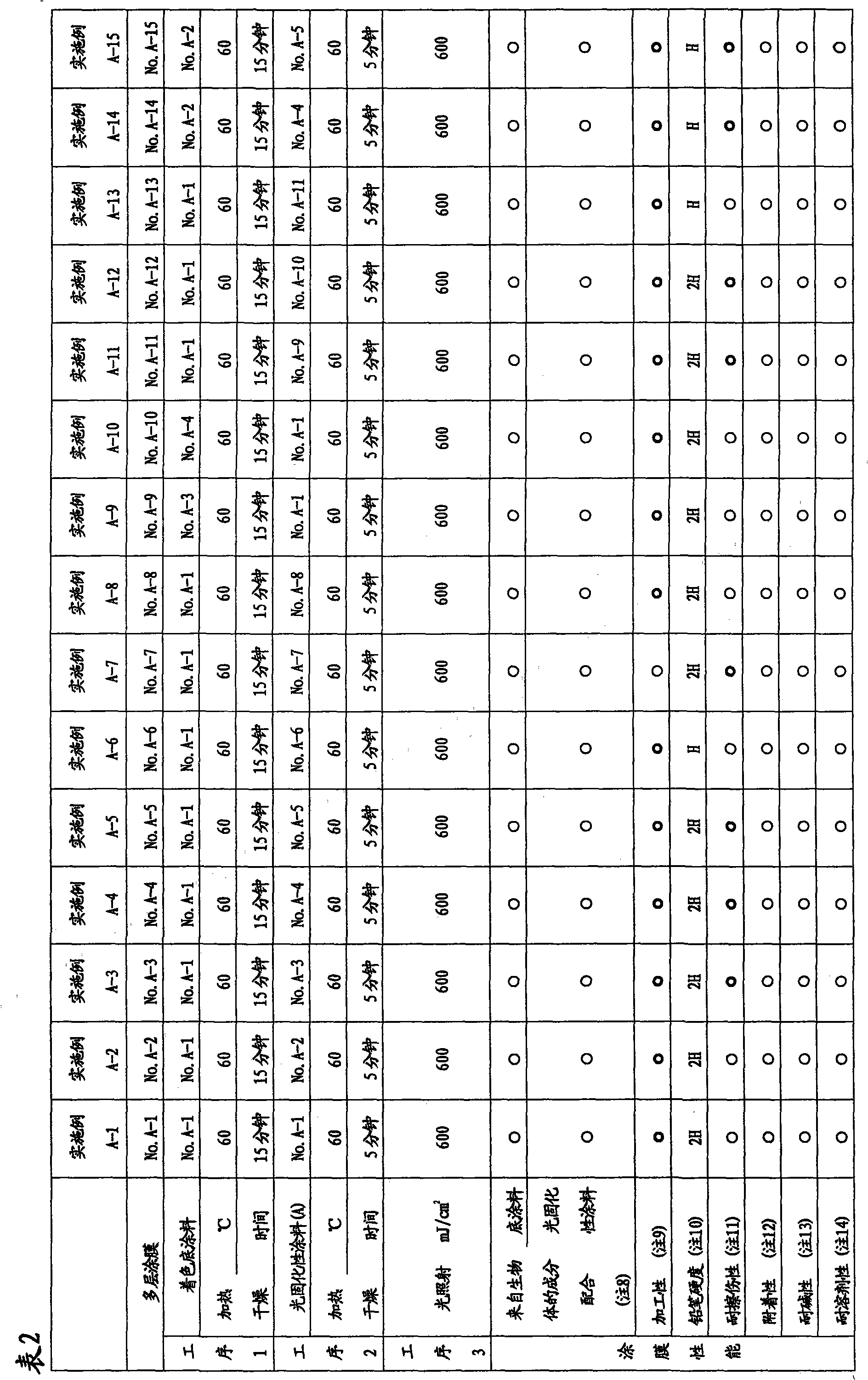

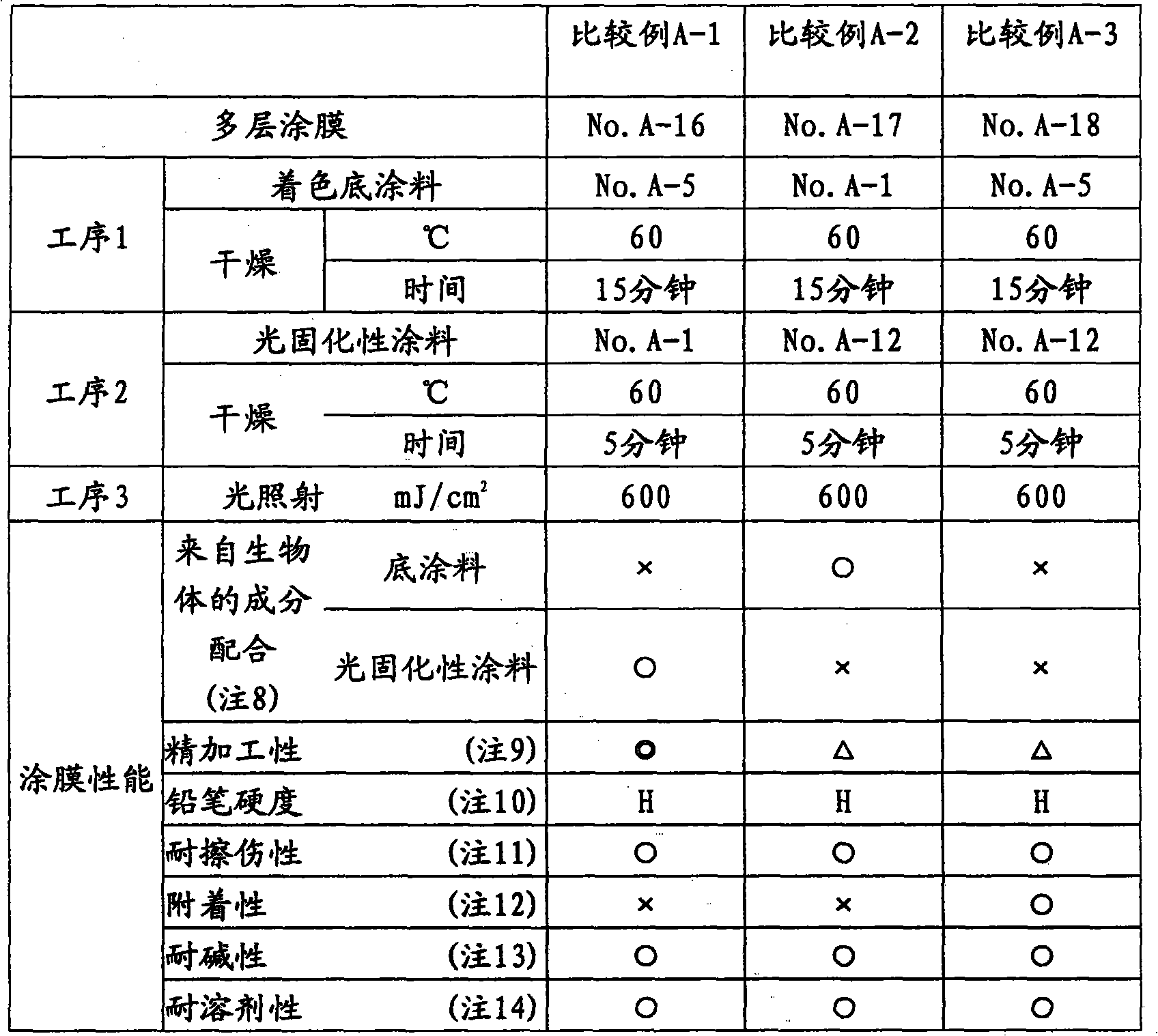

[0165] Hereinafter, the present invention will be described more specifically with reference to examples, but the present invention is not limited to these examples. In addition, unless otherwise specified, "part" and "%" are "parts by mass" and "% by mass".

[0166] [Example concerning multilayer coating film having a coating film layer formed of photocurable paint (A)]

manufacture example A-1

[0167] [Production example A-1] Production example of modified starch No.A-1 (corresponding to modified starch (a10))

[0168] Suspend 25 parts of high amylose corn starch (hydroxyl value 500 mgKOH / g) in 200 parts of dimethyl sulfoxide (DMSO), heat up to 90°C while stirring, and keep at this temperature for 20 minutes to make it gelatinized. To this solution, 20 parts of sodium bicarbonate was added as a catalyst, 90 degreeC was maintained, 17 parts of vinyl laurates were added, and it was made to react at this temperature for 1 hour. Then, 37 parts of vinyl acetate were added, and it was made to react also at 80 degreeC for 1 hour. Thereafter, the reaction solution was poured into tap water, stirred at a high speed, pulverized, filtered, and dehydrated to obtain modified starch No.A-1.

manufacture example A-2

[0169] [Production example A-2] Production example of polyurethane resin solution No.A-1 (corresponding to product (I))

[0170] 125 parts of toluene and 377 parts of isophorone diisocyanate (equivalent to polyisocyanate compounds) were placed in a 1 L reaction vessel equipped with a thermometer, a thermostat, a stirrer, a cooling pipe, and a dropping device, and the reaction was carried out under a nitrogen atmosphere. Stir to mix and heat up to 80°C.

[0171] Next, 123 parts of 1,4-butanediol (equivalent to polyhydric alcohol) was added dropwise over 3 hours, and after the dropwise addition was completed, it was aged at 80°C for 30 minutes to prepare a polyurethane resin solution No. A-1. In addition, the NCO value of the resin solid content of polyurethane resin solution No. A-1 was 55 mgNCO / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com