Pigment disperse sizing agent and electrophoretic paint

A technology of pigment dispersion and electrophoretic coating, applied in the direction of pigment slurry, electrophoretic coating, epoxy resin coating, etc., can solve the problem of insufficient redispersibility of coating, achieve excellent storage stability, temporarily stop reduction, save trouble and cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0149] Production Example 1 Production Example of Pigment Dispersion Resin No.1 Solution

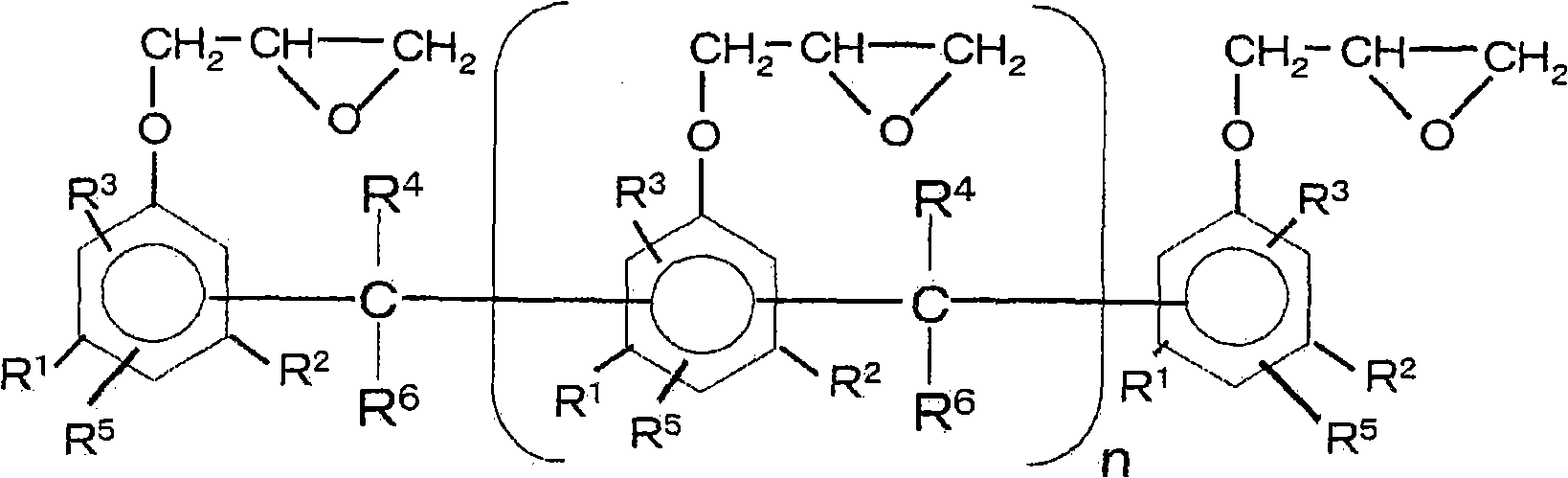

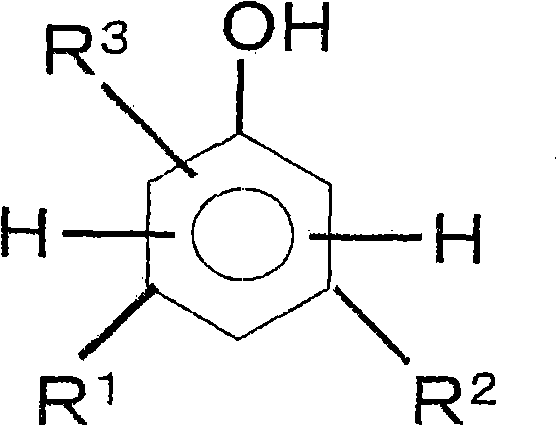

[0150] Add 390 parts of bisphenol A, 240 parts of polycaprolactone diol (number average molecular weight about 1200) and 0.2 part of dimethylbenzyl to 1010 parts of jER828EL (manufactured by Japan Electronics Co., Ltd., trade name: epoxy resin) Amines were reacted at 130°C until the epoxy equivalent weight became about 1090.

[0151] Next, add 134 parts of dimethylethanolamine and 90 parts of acetic acid, react at 120°C for 4 hours, add ethylene glycol monobutyl ether to adjust the solid content, and obtain a pigment dispersion of ammonium salt type resin with a solid content of 60%. Use resin No.1 solution. Pigment dispersion resin No. 1 had an ammonium salt value of 44 mgKOH / g and a number average molecular weight of 3,000.

manufacture example 2

[0152] Production Example 2 Production Example of Pigment Dispersion Resin No. 2 Solution

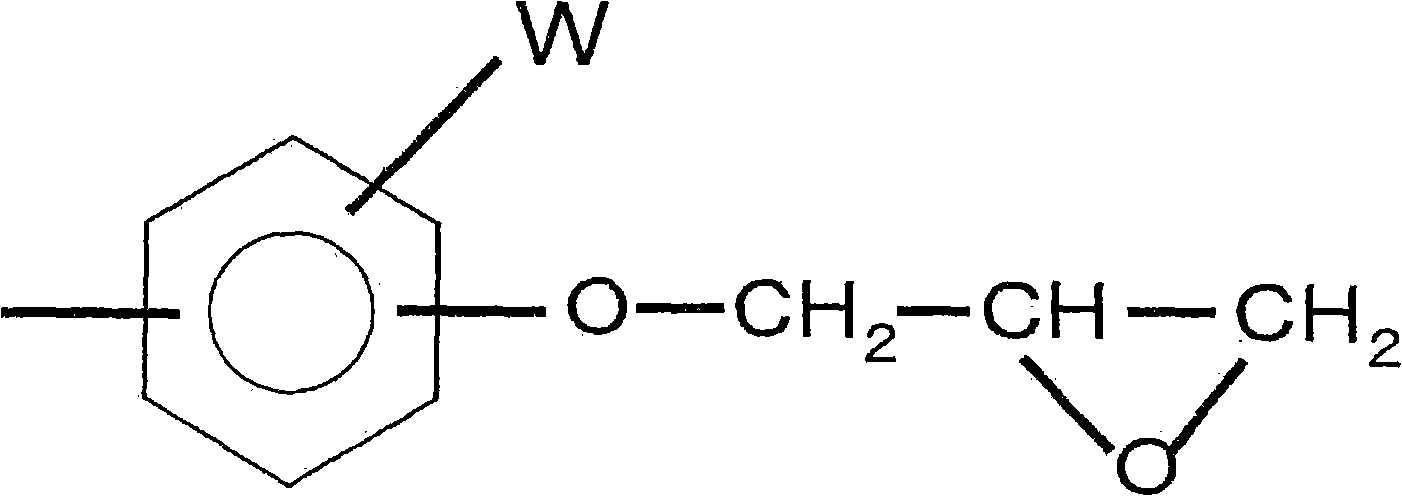

[0153] 450 parts of nonylphenol and 960 parts of CNE195LB (Note 1) were placed in a flask equipped with a stirrer, a thermometer, a separatory funnel, and a reflux cooler, and they were heated slowly while mixing and stirring, and allowed to react at 160°C. Then, 430 parts of ε-caprolactone was charged, and it heated up to 170 degreeC, and it was made to react. Further, 105 parts of diethanolamine and 124 parts of N-methylethanolamine were reacted to confirm that the epoxy value was 0, and ethylene glycol monobutyl ether was added to adjust the solid content to obtain a pigment dispersion resin No. 2 solution with a solid content of 60%.

[0154] The hydroxyl value of this pigment dispersion resin No. 2 was 150 mgKOH / g, the amine value was 70 mgKOH / g, and the number average molecular weight was 2200.

[0155] (Note 1) CNE195LB: Manufactured by Changchun Japan Co., Ltd., trade name: cre...

manufacture example 3

[0156] Production Example 3 Production of Pigment Dispersion Slurry No.1

[0157] Add 10.0 parts of pigment dispersion resin No.1 (6.0 parts of solid content) with a solid content of 60%, 20 parts of JR-600E (Note 2), 3.0 parts of Bariferain BF-20 (Note 10), and Abicel RC-N81 (Note 10). 12) 3.0 parts, 1.0 parts of KW-140E (Note 14), 2.0 parts of bismuth hydroxide, 1 part of dioctyltin oxide, 23.4 parts of deionized water, dispersed in a ball mill for 20 hours and then taken out to obtain a pigment dispersion with a solid content of 55%. Slurry No.1.

[0158] Production Examples 4-14 Production of Pigment Dispersion Slurries No.2-No.12

[0159] Except that the mixing content is shown in Table 1, it carried out similarly to the pigment dispersion slurry No. 1, and obtained the pigment dispersion slurry No. 2 - No. 12.

[0160]

[0161] (Note 2) JR-600E: Made by Teika Co., Ltd., for TiO 2 Coated with 3.8% Al 2 o 3 titanium dioxide

[0162] (Note 3) JR-603: Made by Teika ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com