Redispersible latex powder and preparation method thereof

A technology for redispersible latex powder and composite emulsion, applied in the field of preparation of redispersible latex powder, can solve the problems of unstable thermodynamic shape of soft core hard shell particles, reduced water resistance of redispersible latex powder, difficulty, etc., and achieve excellent flow The effect of improving adhesion and preventing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

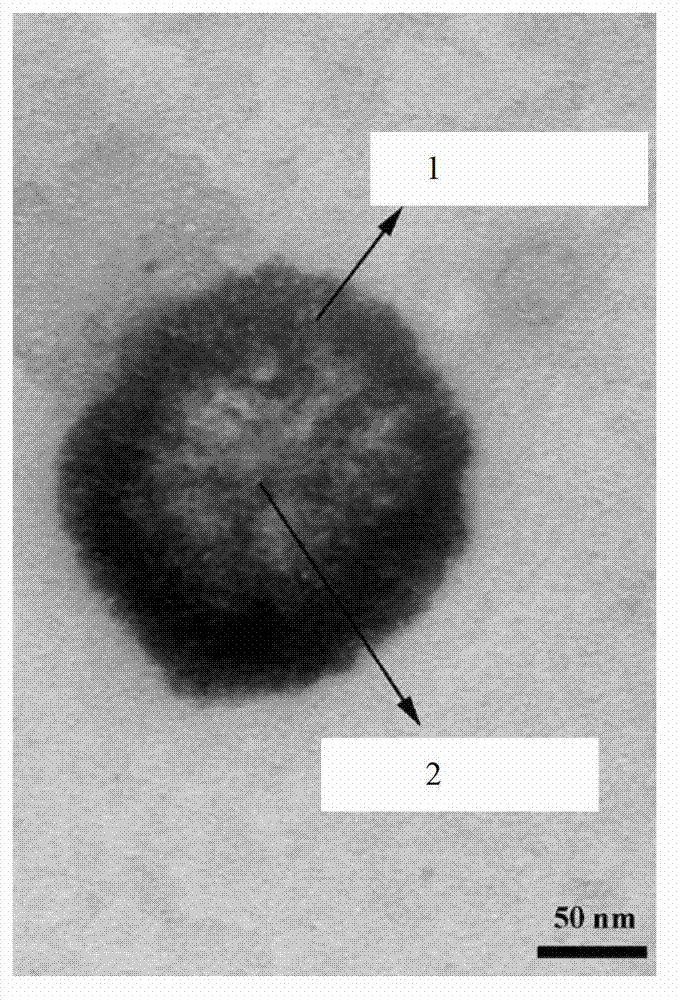

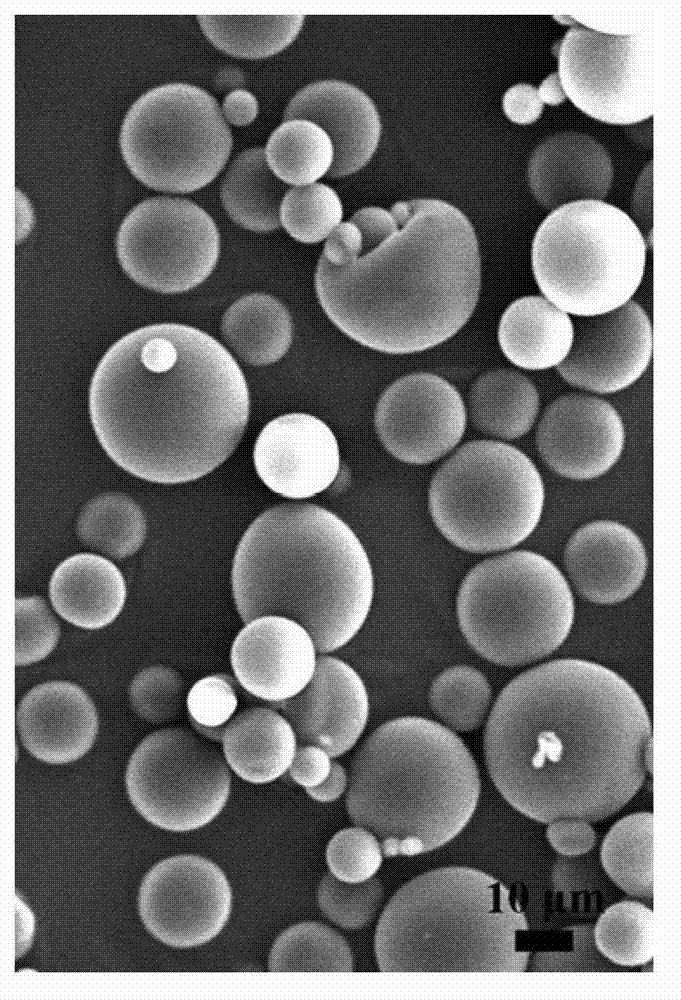

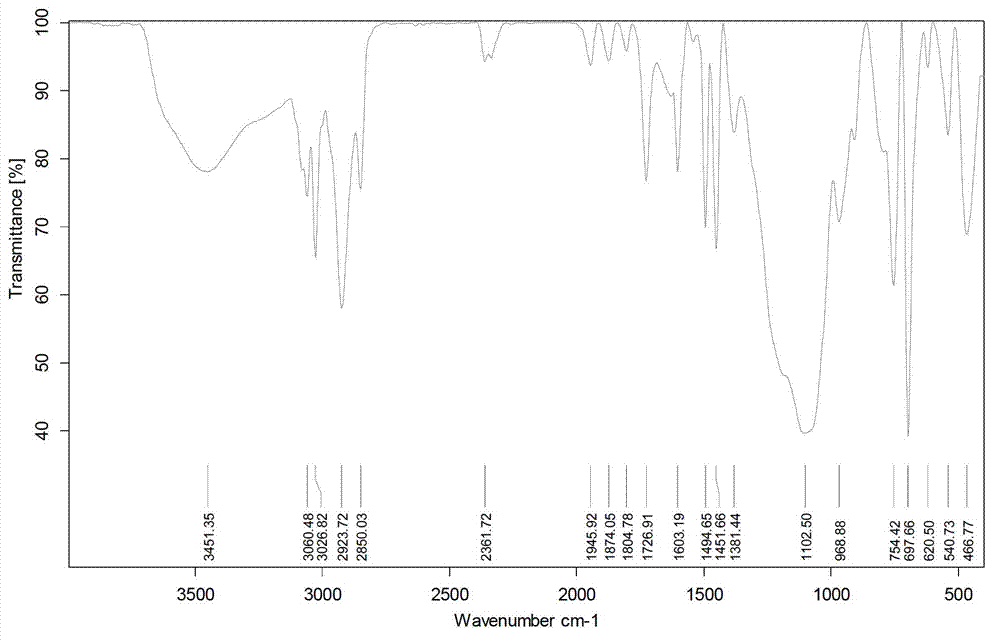

[0044] 1) Preparation of composite emulsion with inorganic coated polymer core-shell particle structure

[0045] Step 1: Synthesis of Cationic Emulsion

[0046] The cationic unsaturated monomer is (3-methacryloxy)ethyltrimethylammonium chloride, the silane unsaturated monomer is γ-methacryloxypropyltrimethoxysilane, and the basic unsaturated mono The body composition is methyl methacrylate and butyl acrylate, the emulsifier is dodecyltrimethylammonium chloride, the initiator is azobisisobutyronitrile, and its component formula is as follows:

[0047]

[0048]

[0049] First, 0.4 g of azobisisobutyronitrile was dissolved in a mixed unsaturated monomer composed of 21.6 g of methyl methacrylate and 32.4 g of butyl acrylate. Pre-dissolve 0.2 g of dodecyltrimethylammonium chloride in 150 g of water, add it into a reaction kettle equipped with a thermometer, a stirrer, a temperature-controlled heating device and a condensing reflux device, and heat to a constant temperature o...

Embodiment 2

[0058] 1) Preparation of composite emulsion with inorganic coated polymer core-shell particle structure

[0059] Step 1: Synthesis of Cationic Emulsion

[0060] The cationic unsaturated monomer is diallyl dimethyl ammonium chloride, the silane unsaturated monomer is vinyltriethoxysilane, the basic unsaturated monomer is composed of methyl methacrylate, butyl acrylate, emulsifier Be lauryl dimethyl benzyl ammonium chloride, initiator is azobisisobutylamidine hydrochloride, and its component formula is as follows:

[0061]

[0062] First, dissolve 0.4 g of azobisisobutylamidine hydrochloride in 50 g of water, mix 28.8 g of methyl methacrylate, 25.2 g of butyl acrylate, and 1 g of vinyltriethoxysilane to form an unsaturated monomer . Pre-dissolve 0.2 g of dodecyltrimethylammonium chloride in 50 g of water, add it into a reaction kettle equipped with a thermometer, a stirrer, a temperature control heating device and a condensing reflux device, and heat to a constant temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com