Patents

Literature

206results about How to "Improve colloidal stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ink jet ink

An ink jet ink composition comprising from about 0.5% to about 30% by weight of a pigment, a carrier and a hydrophobically capped oligomeric acrylamide dispersant in a ratio of dispersant:pigment from about 0.1:1 to about 5:1.

Owner:EASTMAN KODAK CO

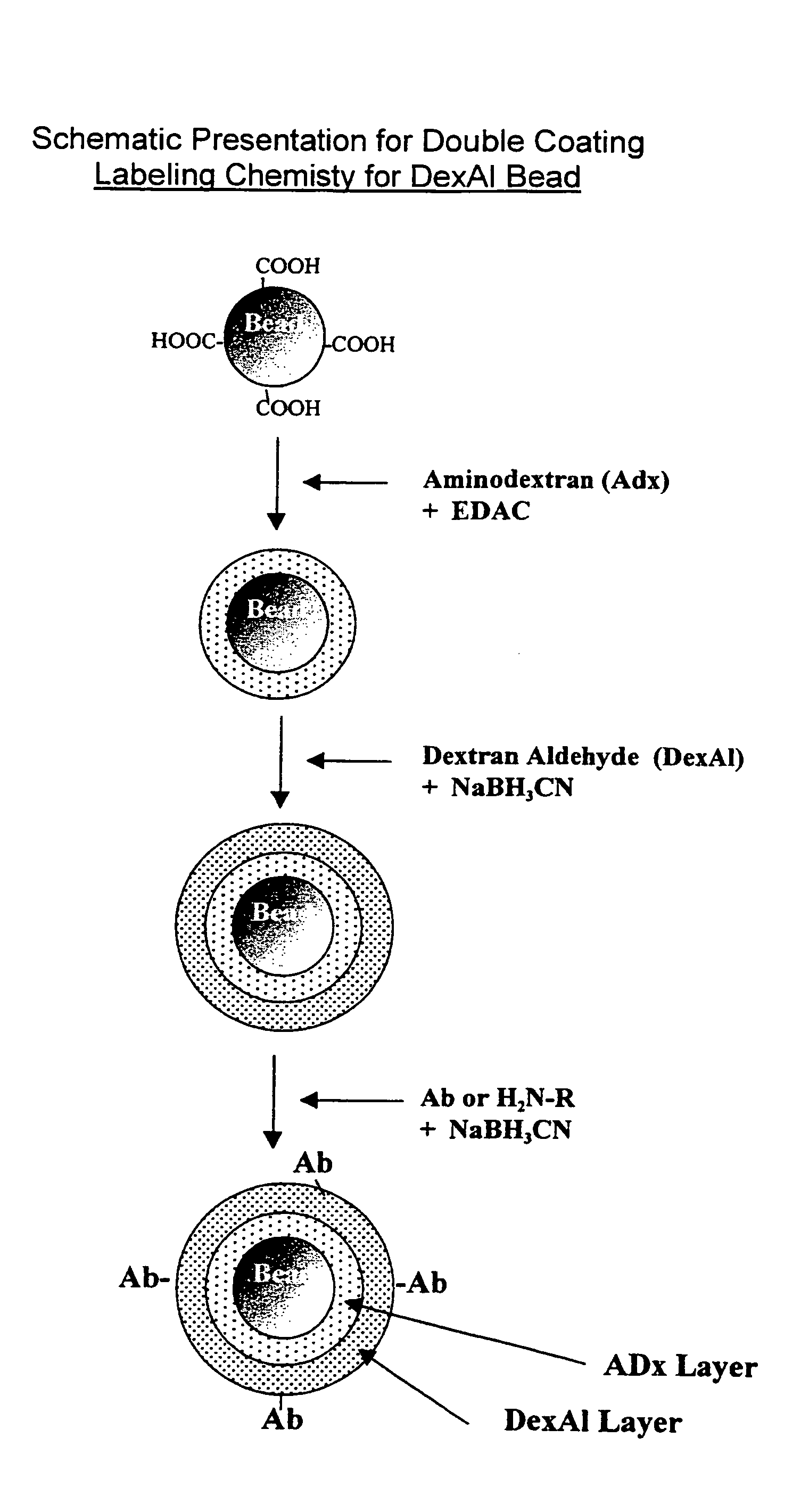

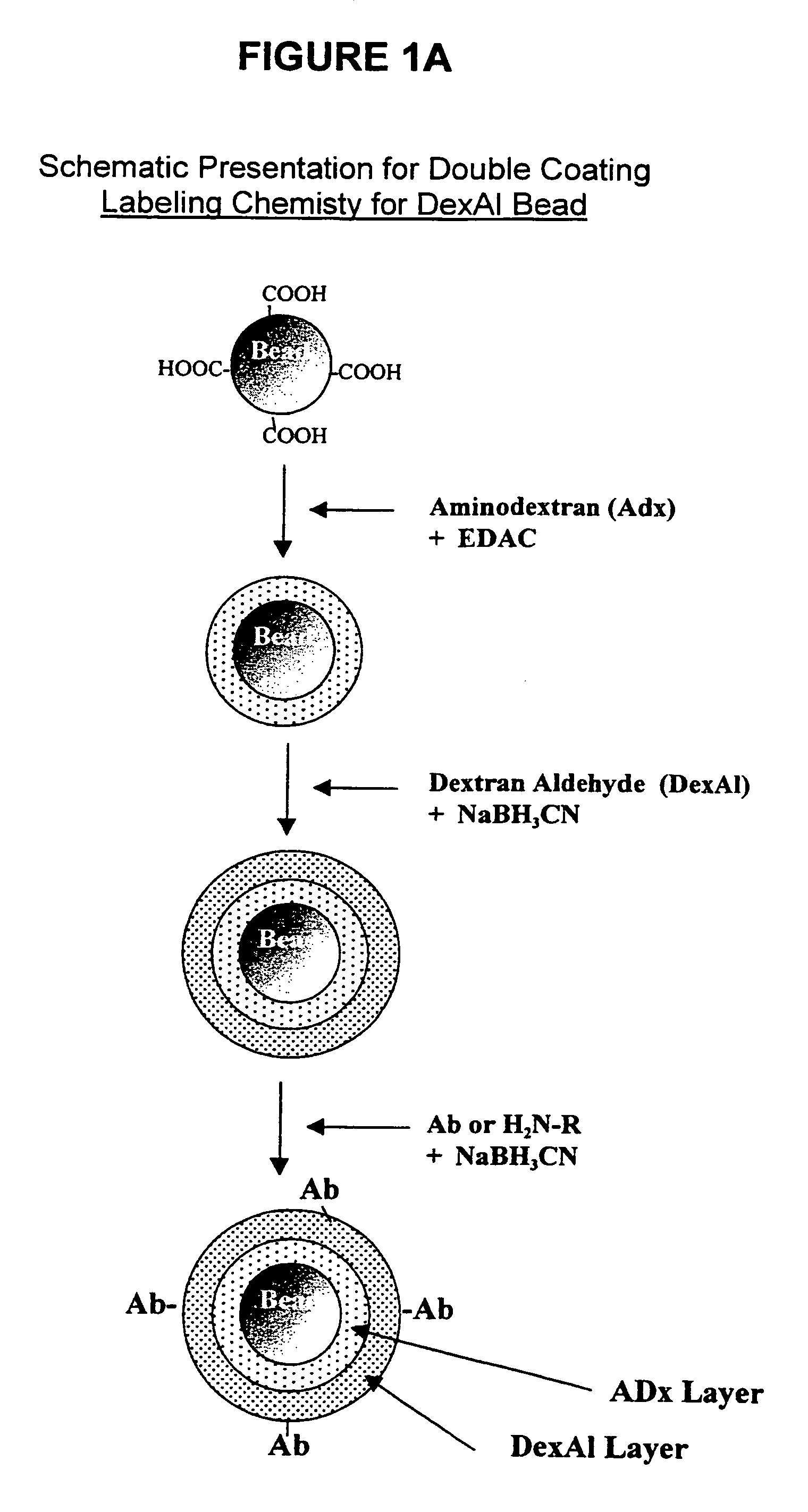

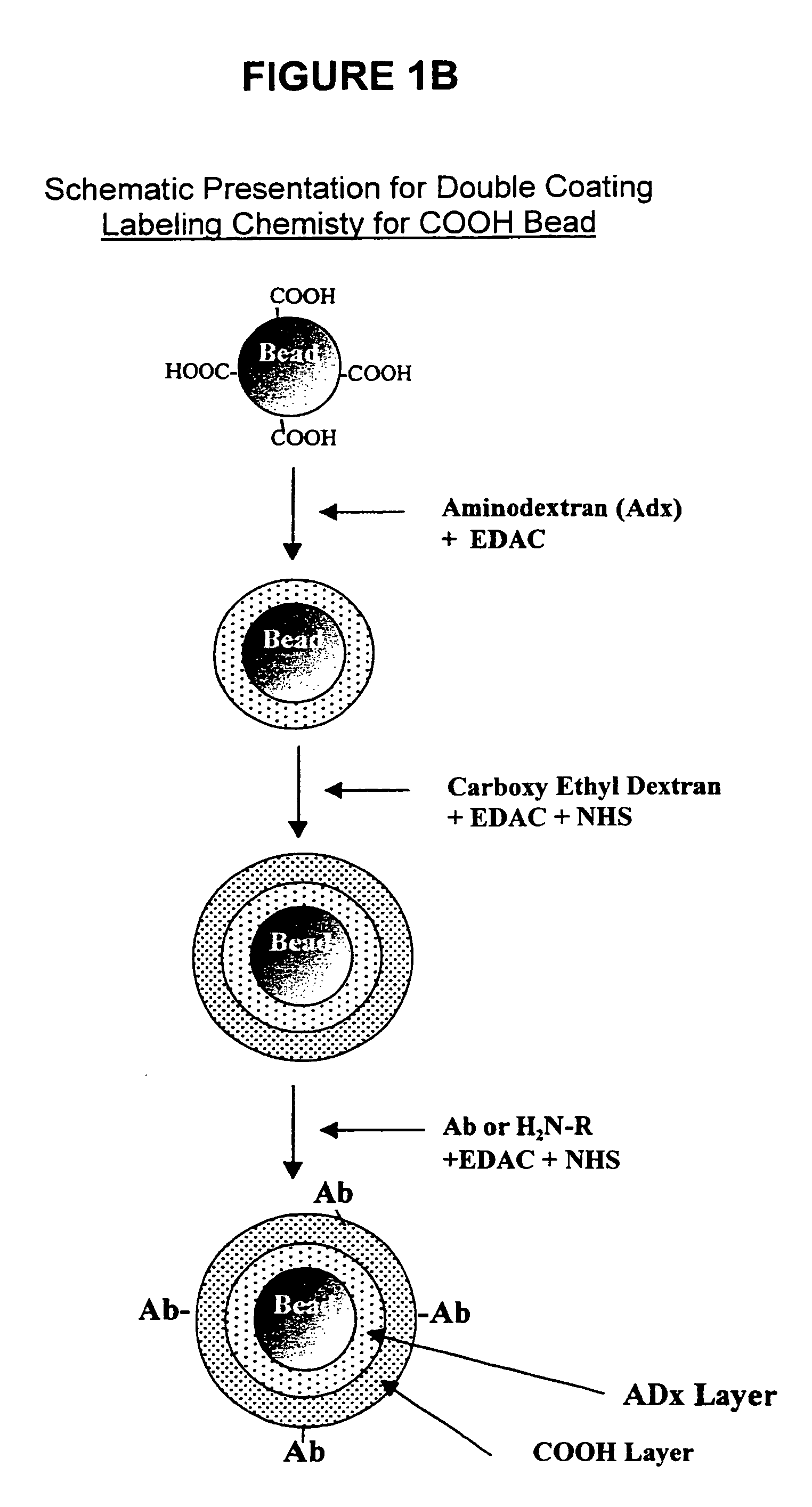

Carriers coated with polysaccharides, their preparation and use

InactiveUS7179660B1Increase coverageMinimizes unspecific bindingBioreactor/fermenter combinationsBiological substance pretreatmentsPolysaccharideSpontaneous reaction

A polysaccharide coated carrier having a coating of at least two successive layers of polysaccharide. The first polysaccharide layer spontaneously associates with a second polysaccharide layer and, optionally, the carrier. Each successive layer of polysaccharide spontaneously associates with a preceding layer. Spontaneous association occurs due to the presence of oppositely charged functional groups on each layer of polysaccharide or due to a spontaneous reaction between the functional groups the layers. The carrier may be any surface such as a tube, microtitration plate, bead, particle or the like and is suitable for use in diagnostic or therapeutic methods.

Owner:SIEMENS HEALTHCARE DIAGNOSTICS PRODS

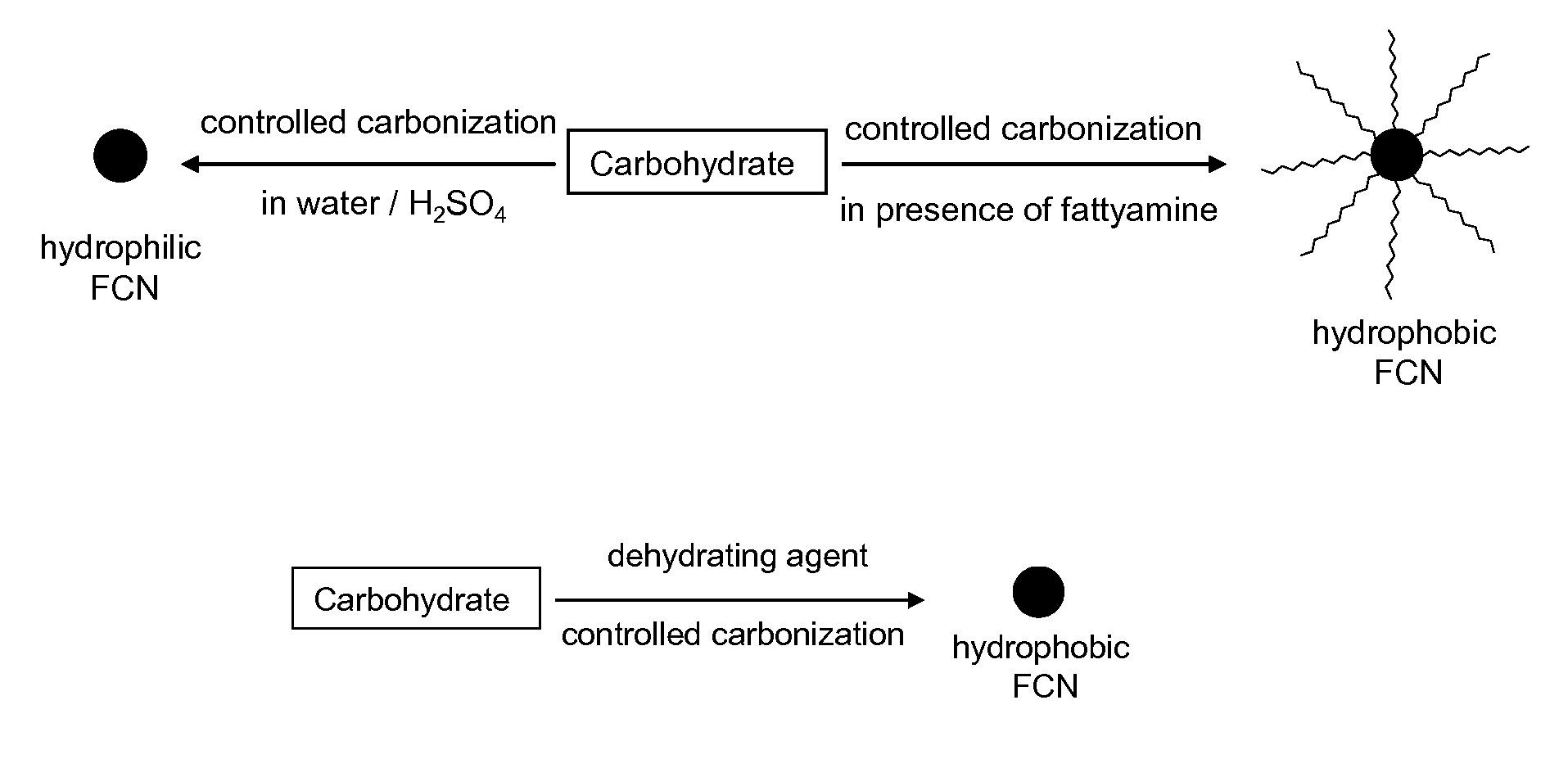

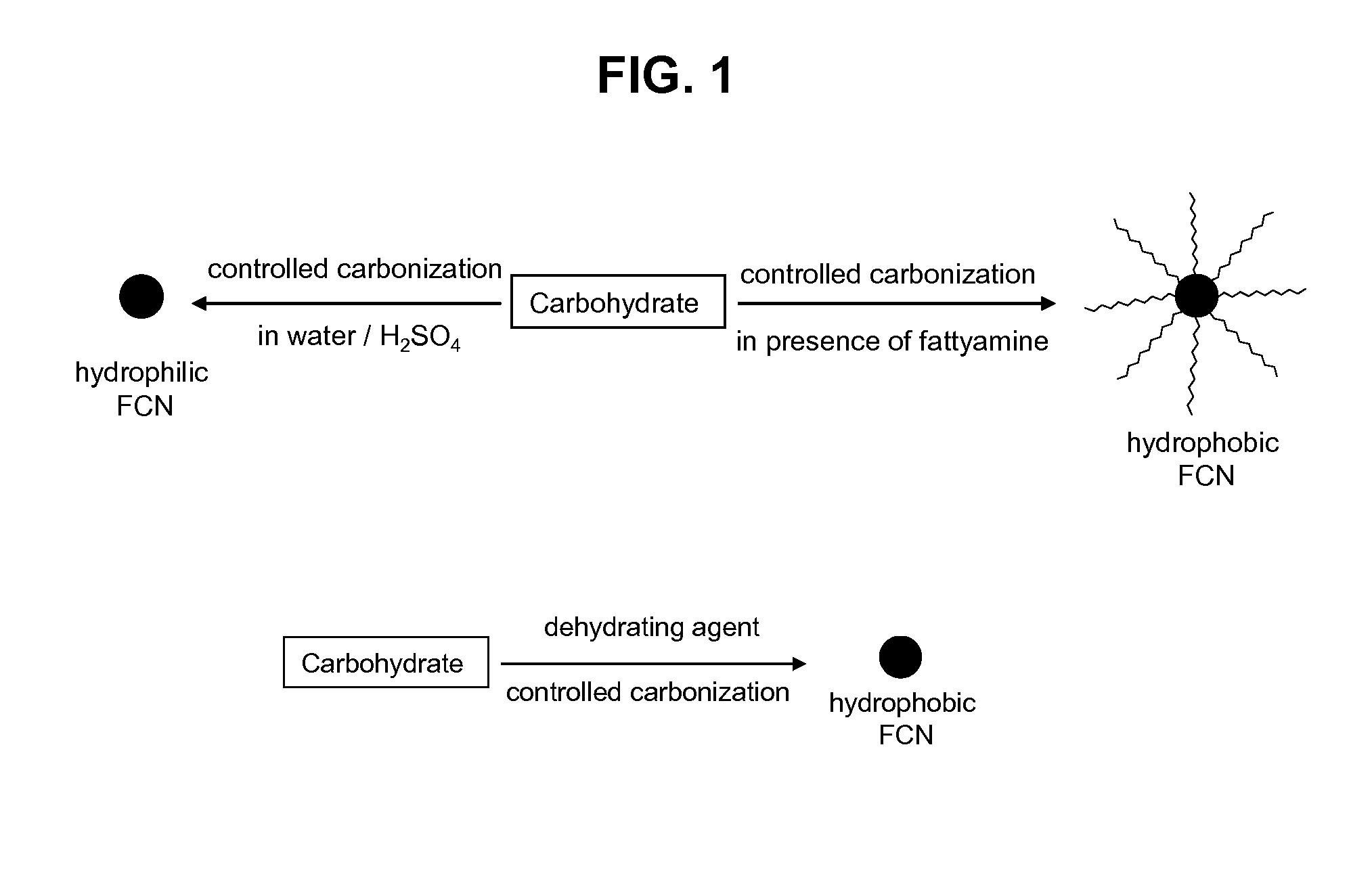

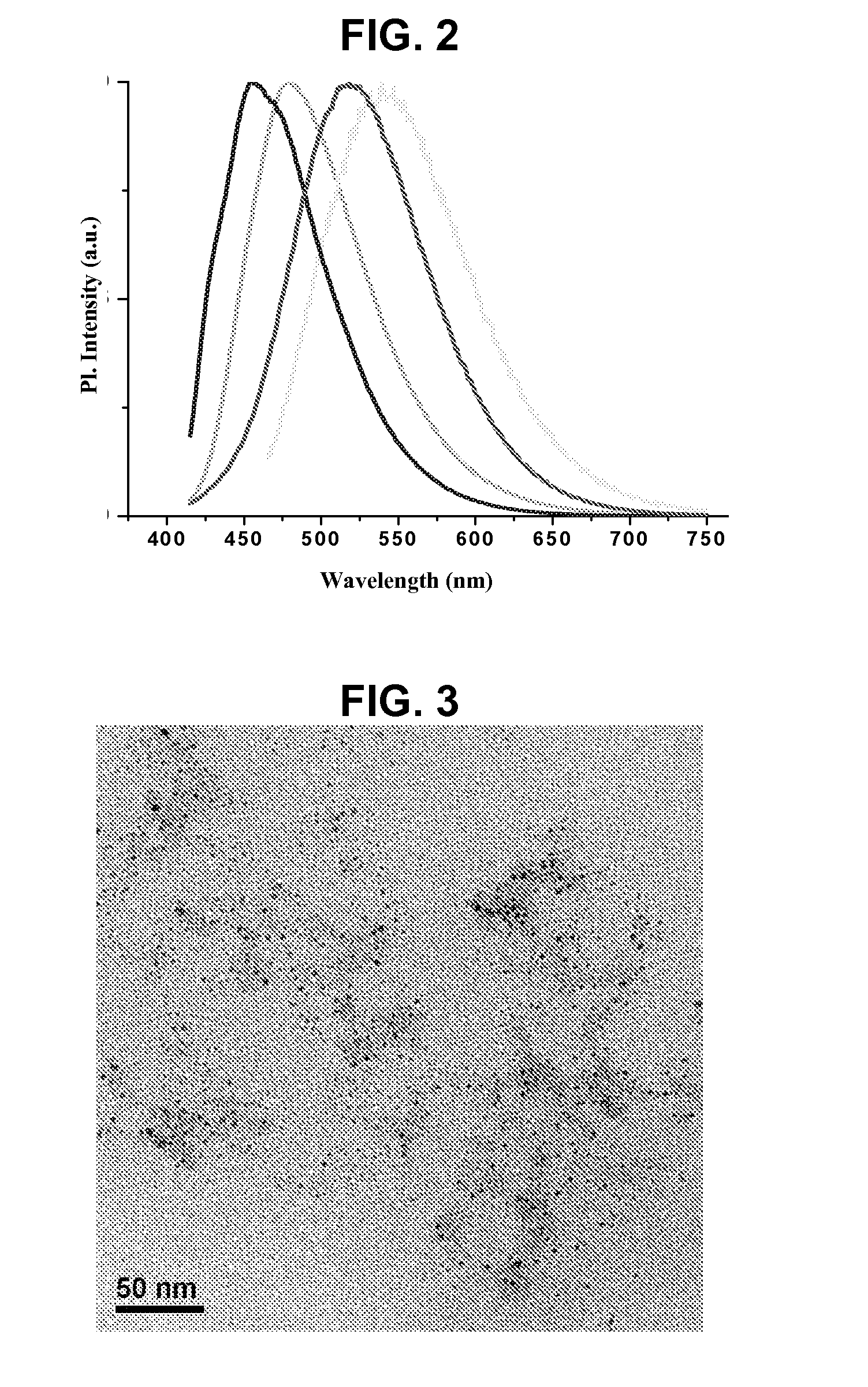

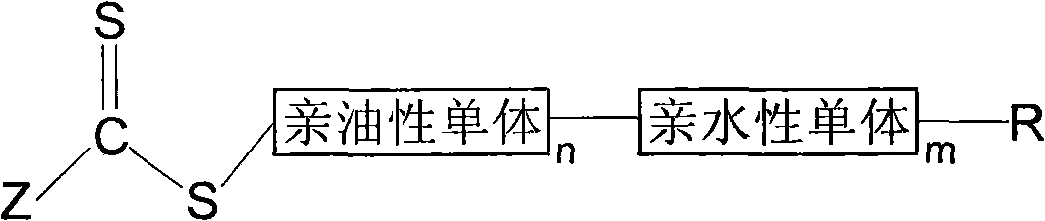

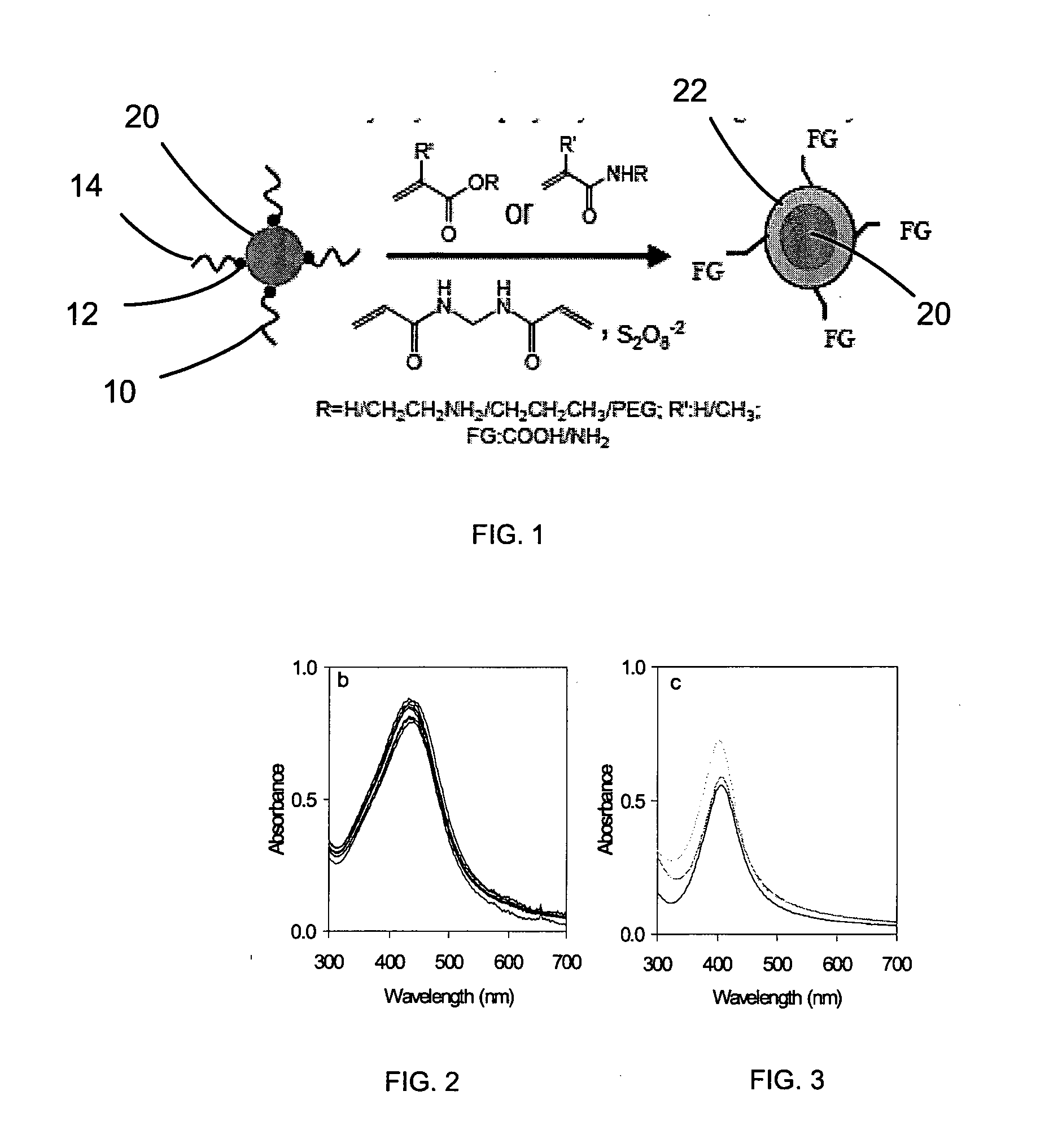

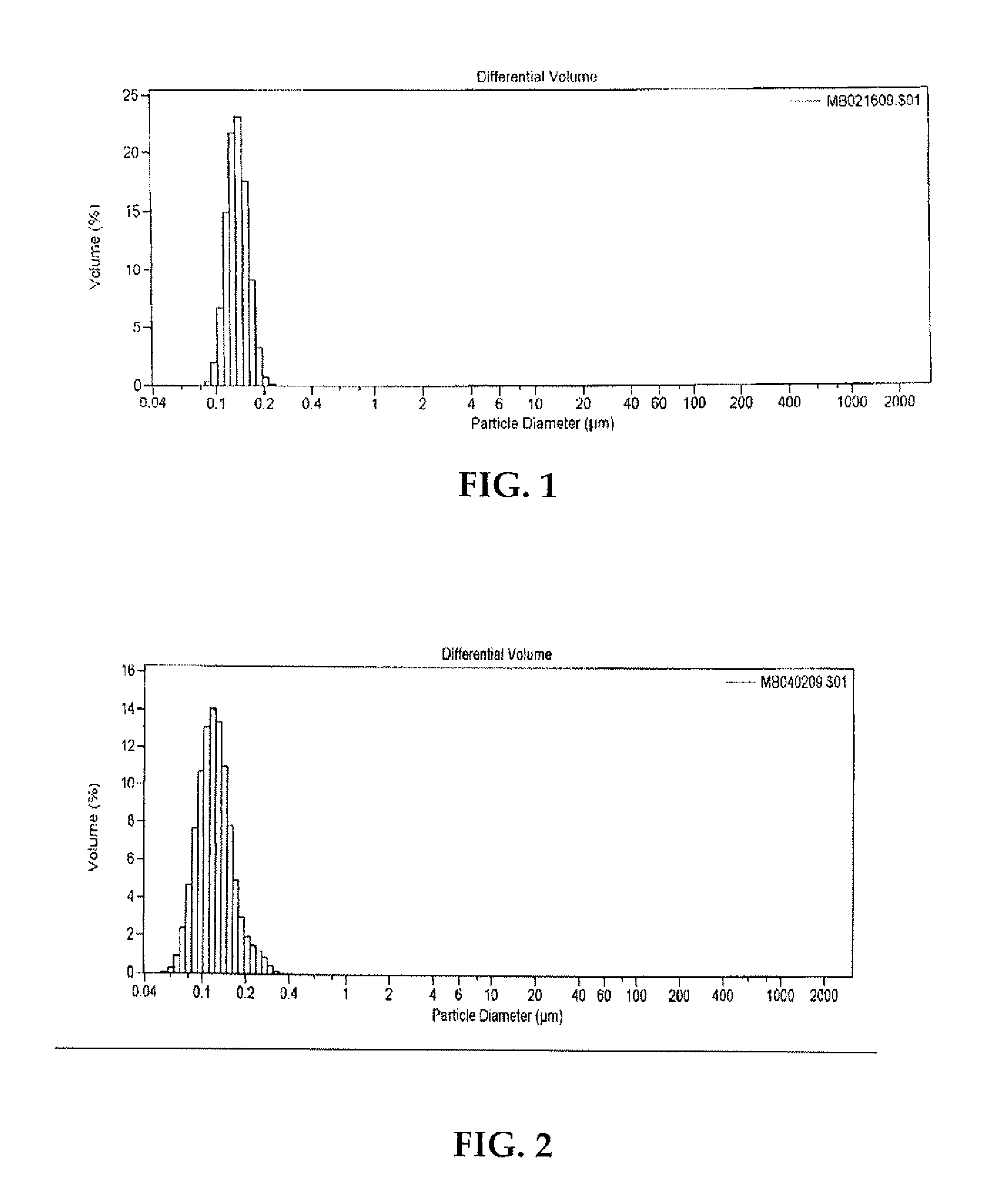

Highly fluorescent carbon nanoparticles and methods of preparing the same

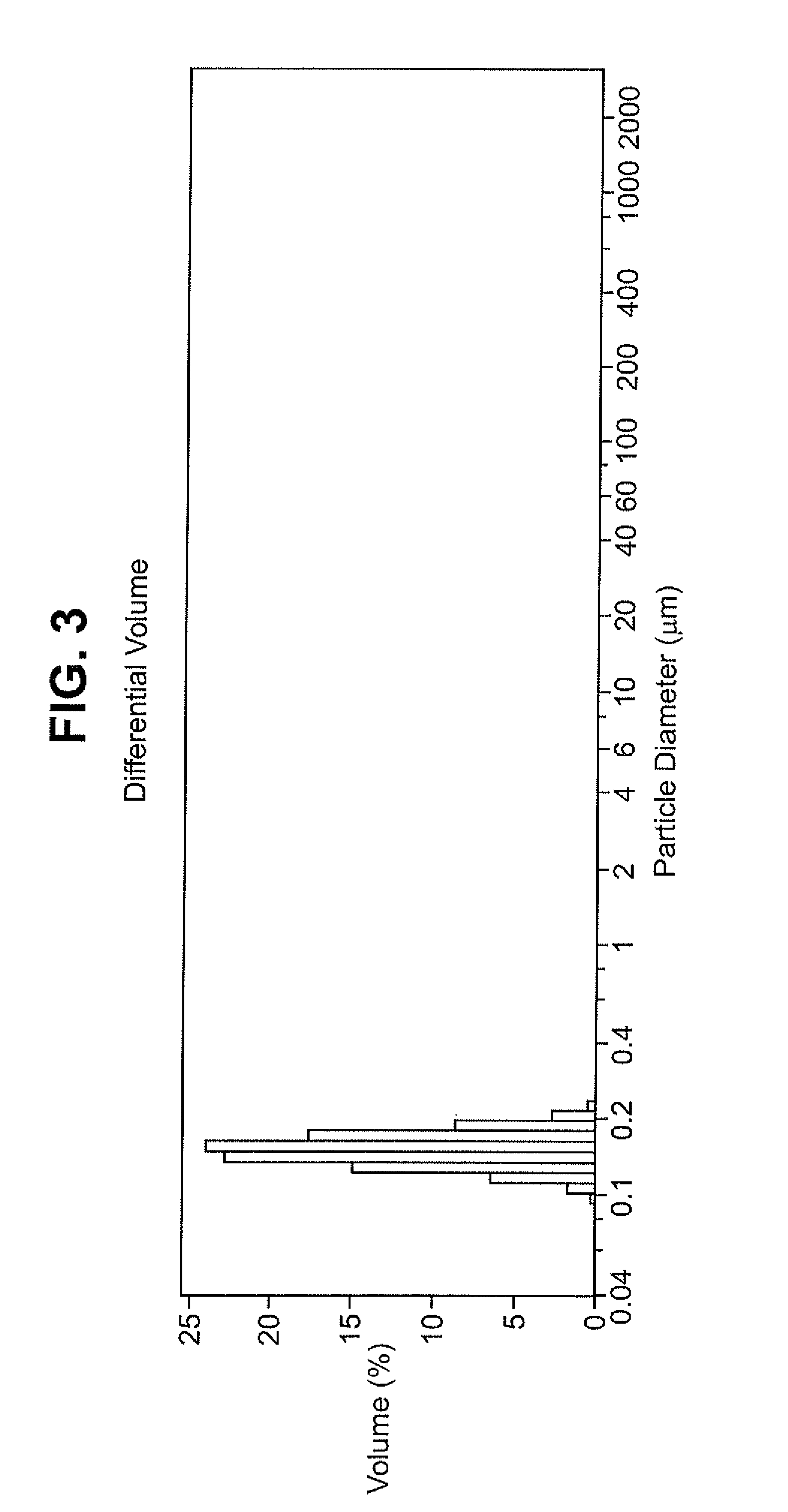

InactiveUS20120178099A1Small particle sizeImprove colloidal stabilityMaterial nanotechnologyNanosensorsQuantum yieldSynthesis methods

Highly fluorescent carbon nanoparticles (FCNs), with tunable emission colours of particle size between 1-10 nm also stable in solid form with high quantum yield (>5%) and its method of synthesis thereof yielding said carbon nanoparticles in milligram to gram scale in high synthesis yield (>80%). The present invention also provides for highly fluorescent carbon nanoparticle solution doped with heteroatom (such as oxygen, nitrogen) and its method of synthesis favoring yield of the said doped carbon nanoparticles of even smaller size ranging from 1-5 nm with narrow size distribution, and also provides for functionalized FCNs that are non-toxic, functional, soluble and stable fluorescent carbon nanoparticles with retained fluorescence for variety of end uses in biomedics, imaging applications, and detection techniques.

Owner:INDIAN ASSOC FOR THE CULTIVATION OF SCI AN AUTONOMOUS INST UNDER THE AEGIS OF DEPT OF SCI & TECH GOVERNMENT OF INDIA

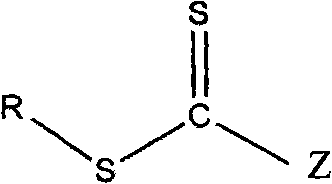

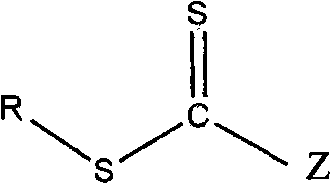

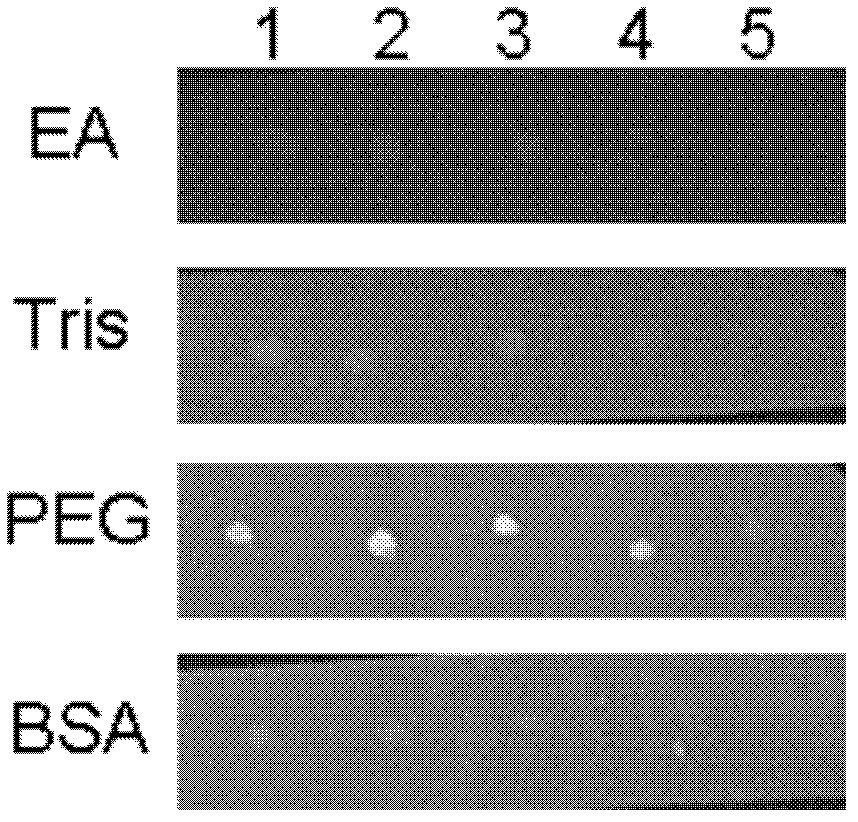

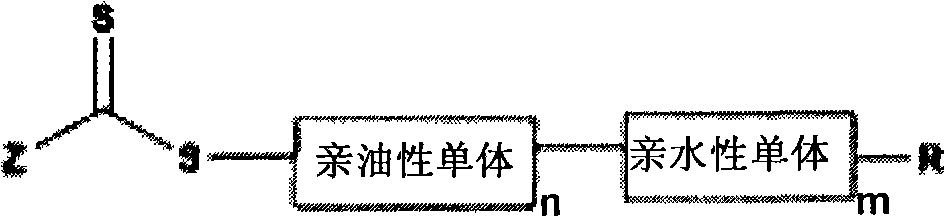

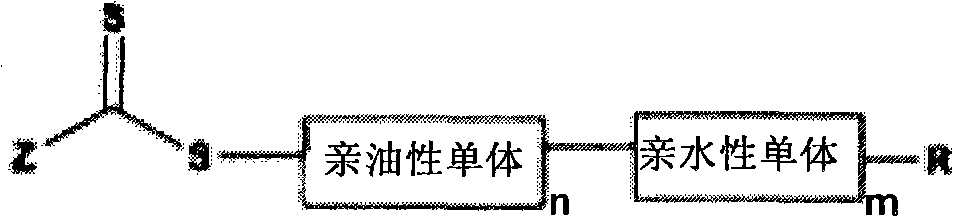

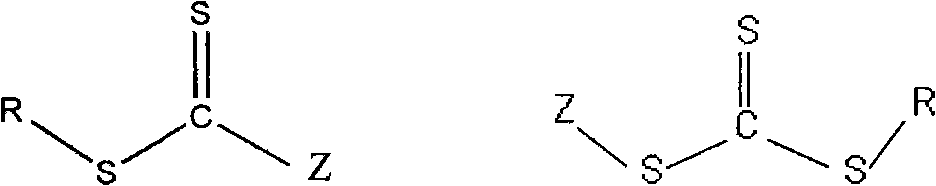

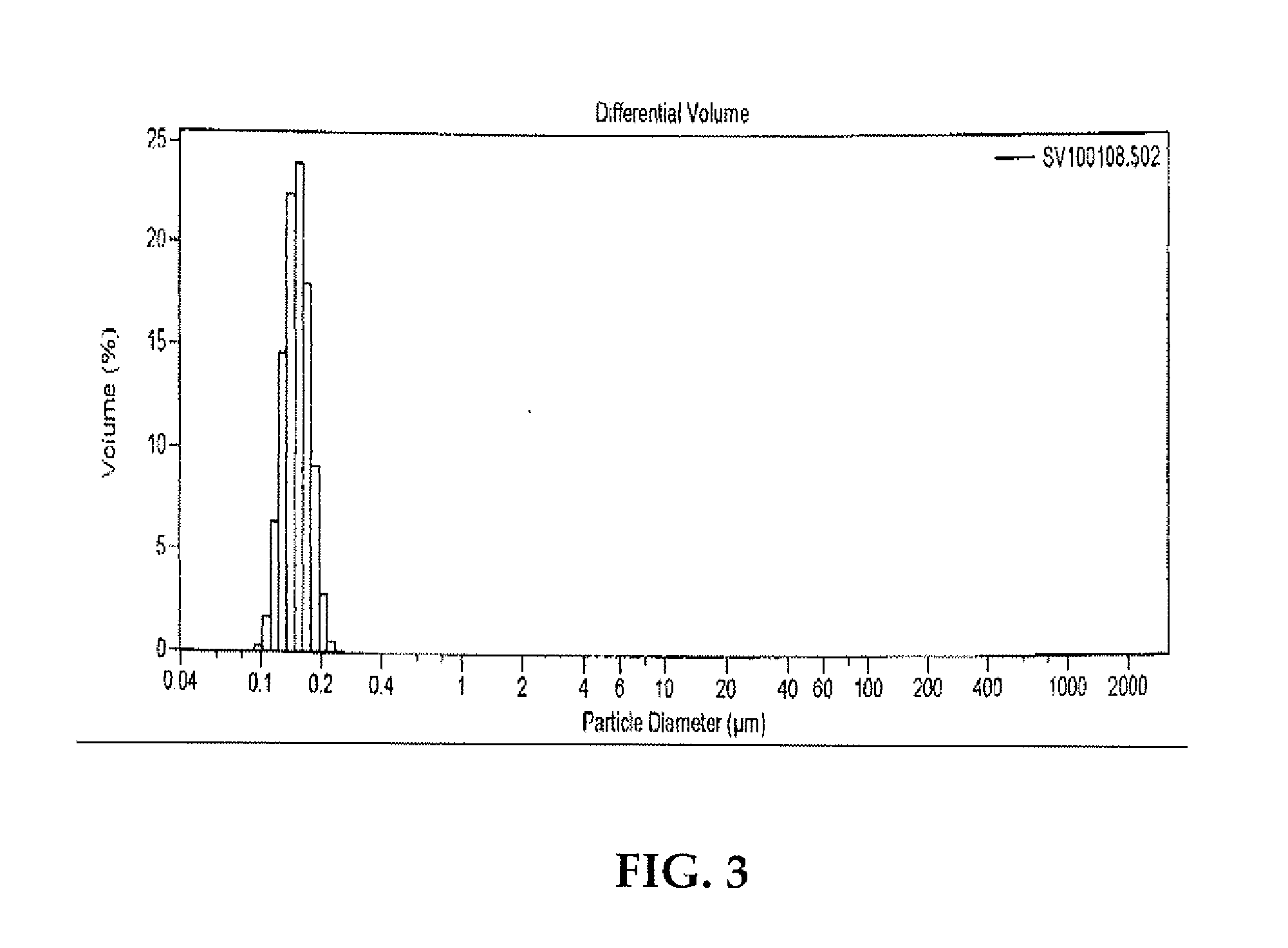

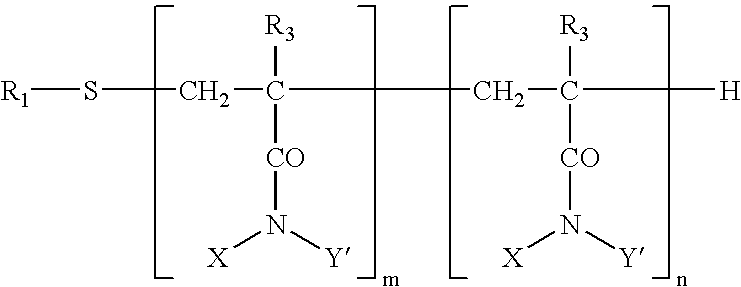

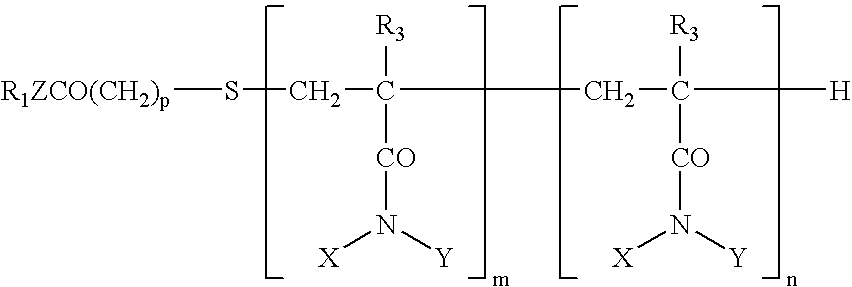

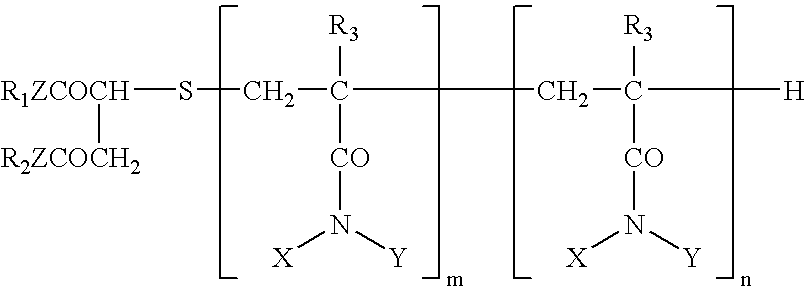

Implementation method of reversible addition fragmentation chain emulsion polymerization

The invention discloses an implementation method of reversible addition fragmentation chain emulsion polymerization. 20-40 parts by weight of water, 0.1-2 parts by weight of bipolar macromolecule reversible addition fragmentation chain reagent, 1-20 parts by weight of monomer and 0.005-0.2 part by weight of micromolecule reversible addition fragmentation chain reagent are added into a reactor, stirring to be uniform is carried out, stirring is carried out, nitrogen is led in, heating is carried out until the temperature is increased to be 50-80 DEG C, 0.004-0.08 part by weight of water soluble initiator is added, initiated polymerization is carried out for 10-60min, 0-2 parts by weight of alkaline aqueous solution is added, and polymerization is continued for 0.5-5h. The invention utilizes bipolar macromolecule reversible addition fragmentation chain reagent with special structure as emulsifier and chain transfer agent, micromolecule reversible addition fragmentation chain is combined with emulsion polymerization, alkali is replenished, so as to improve the stability of emulsion; besides, process is simple, energy consumption is low, reaction time is short, conversion rate is high, no traditional emulsifier is adopted, molecular weight is consistent with design value, and molecular weight distribution is less than 2.0, thus having good industrialization prospect.

Owner:ZHEJIANG UNIV

Transparent conductive film, method for producing same and method for forming pattern

InactiveUS20030224162A1Improve colloidal stabilityImprove conductivityElectric discharge heatingVacuum evaporation coatingOptical transmittanceTransparent conducting film

Disclosed is a method for producing a transparent conductive film comprising a coating step for coating a coating solution containing metal nanoparticles on a substrate to form a coated layer, a drying step for drying the coated layer and a baking step for baking the coated layer to obtain a transparent conductive film, wherein a metal in the metal nanoparticles is oxidized to a metal oxide during at least one of the coating step, the drying step and the baking step. According to this method, a transparent conductive film having a low specific resistance and a high light transmittance can be produced by coating.

Owner:FUJIFILM CORP

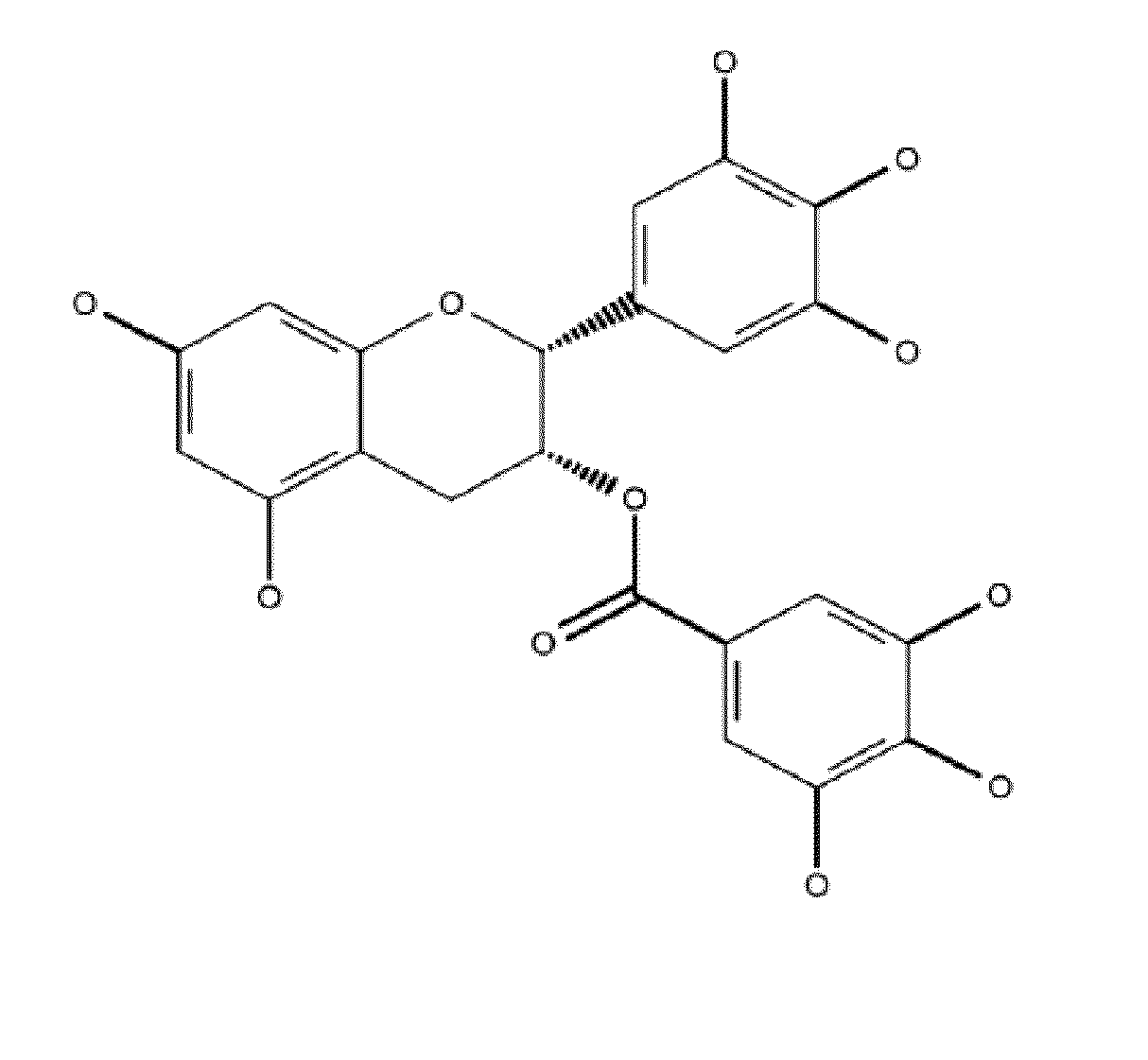

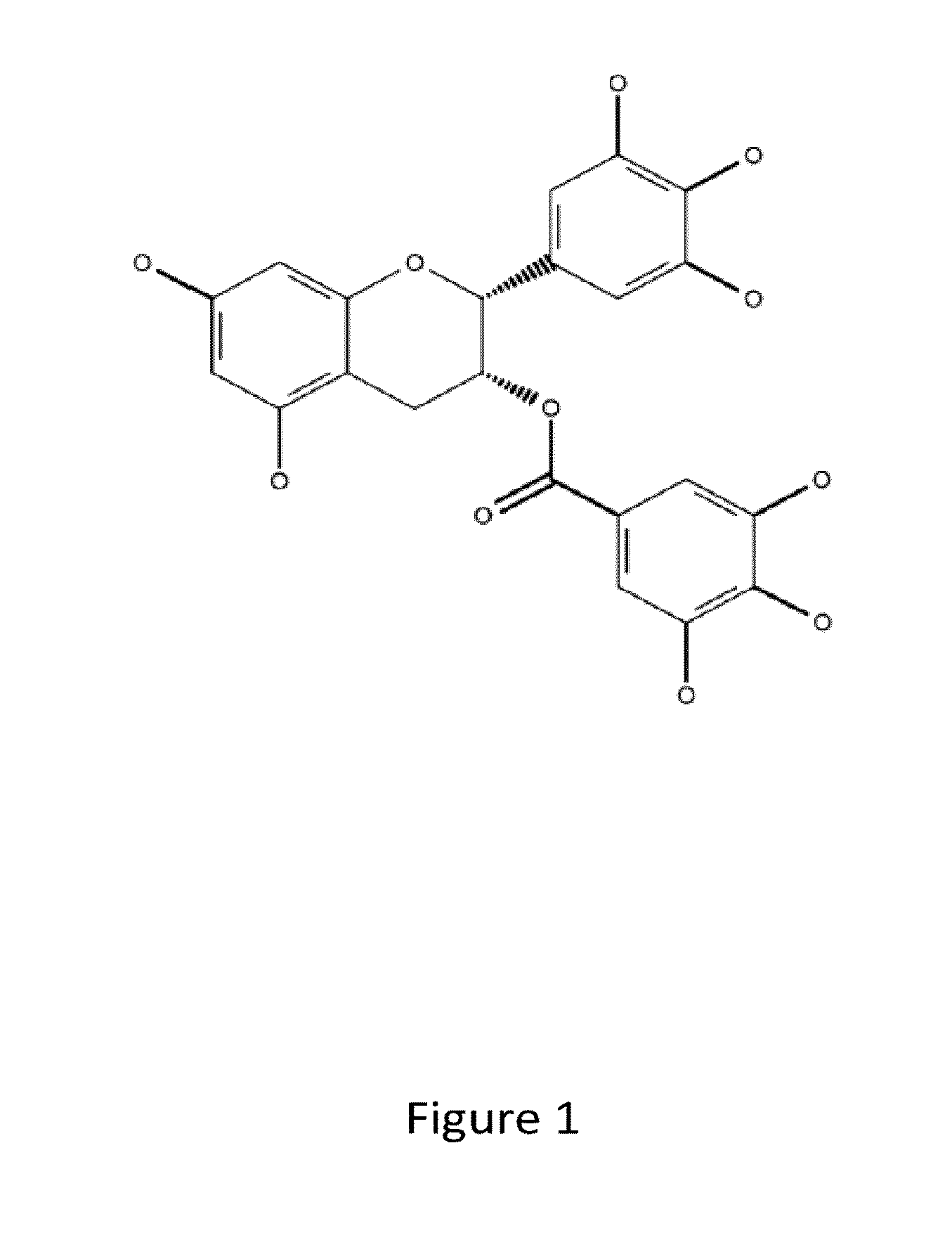

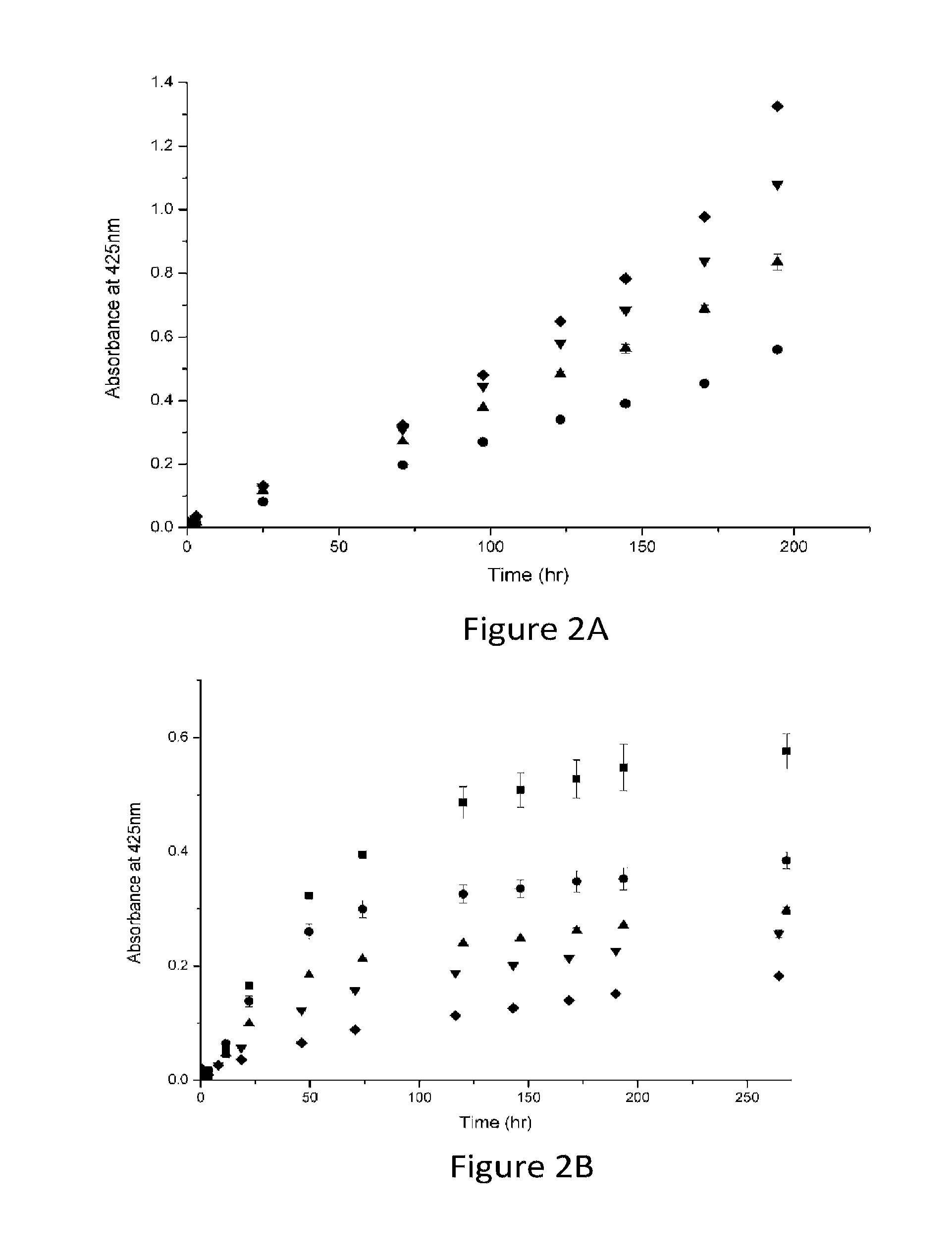

Denatured lactoglobulin and polyphenol coassemblies

ActiveUS20120093933A1Improve colloidal stabilityLess bitterPowder deliveryBiocideNanoparticlePolyphenol

The present invention is directed to co-assembled nanoparticle composition comprising denatured β-lactoglobulin and at least one nutraceutical compound, specifically polyphenols, such as EGCG, compositions comprising same and methods of preparing thereof.

Owner:TECHNION RES & DEV FOUND LTD

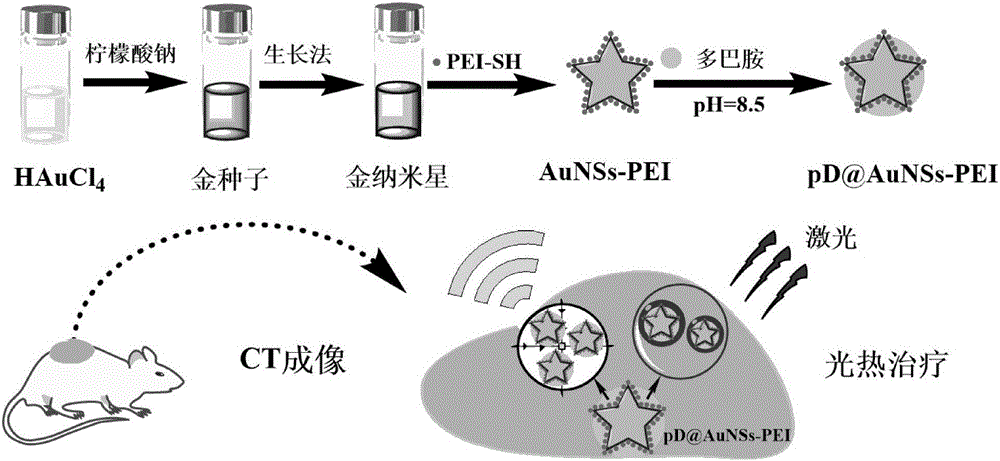

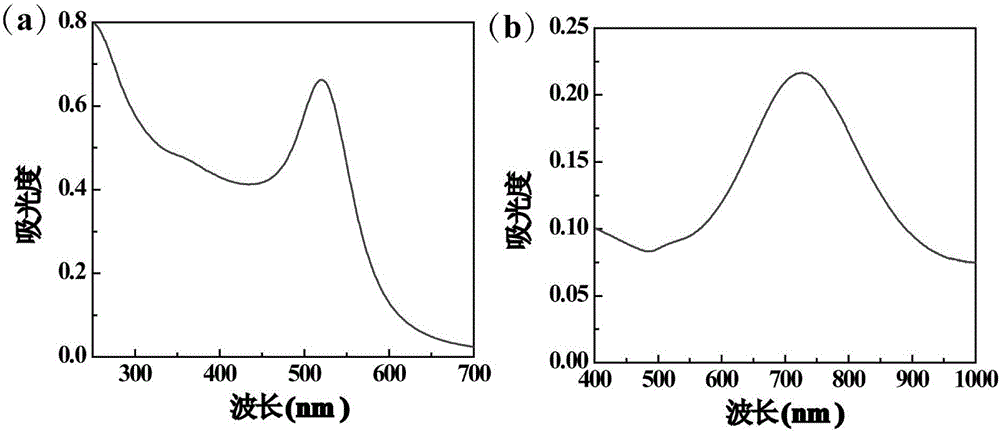

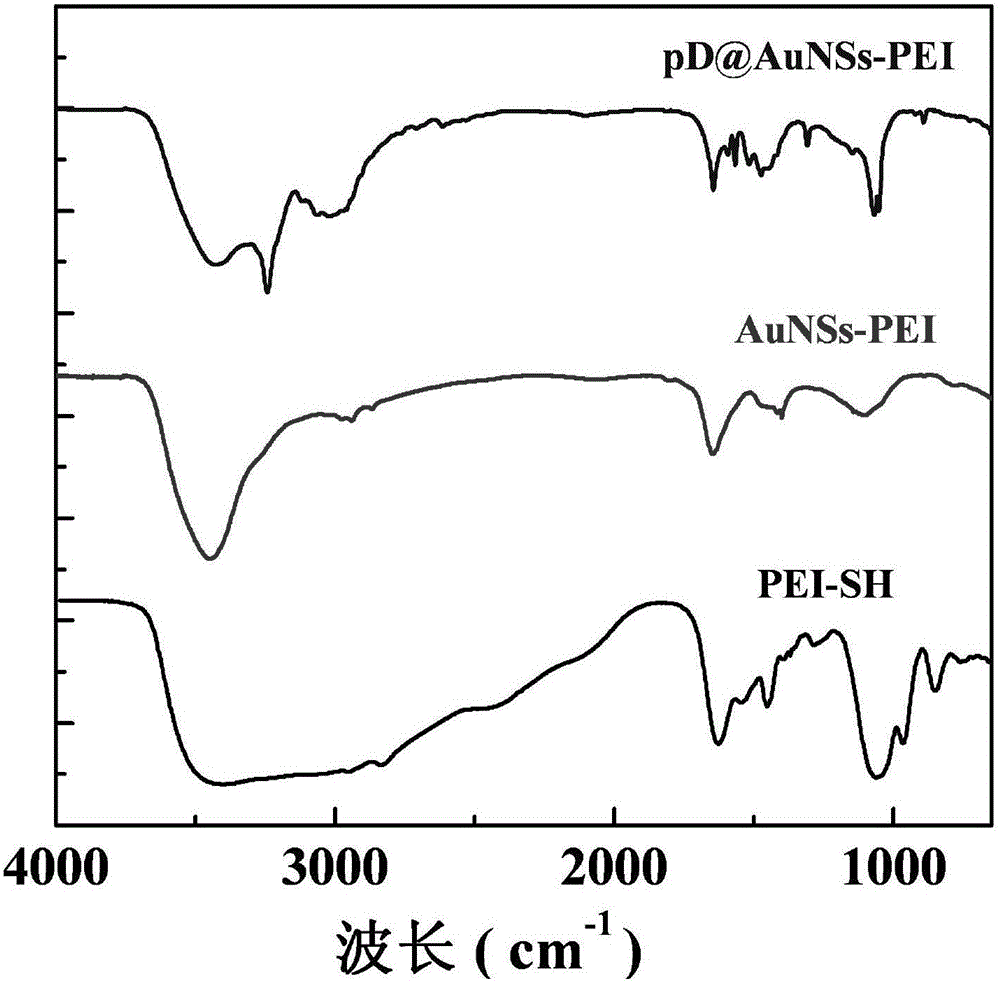

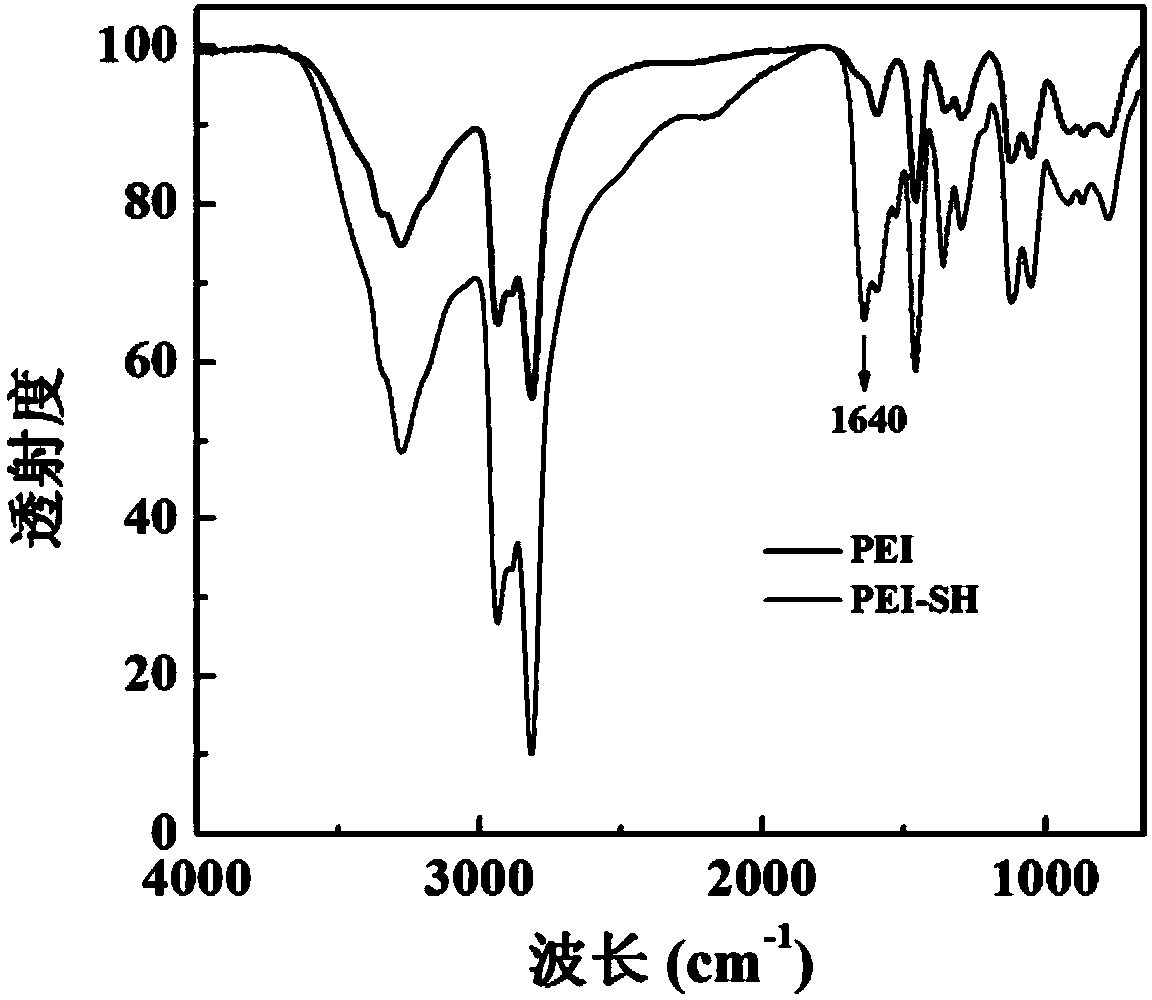

Preparation method for polydopamine-coated polyethyleneimine-stablized gold-nanometer-star photothermal treatment agent

InactiveCN105031647AGood photothermal therapy effectImprove light-to-heat conversion efficiencyEnergy modified materialsX-ray constrast preparationsTreatment fieldMercaptoacetic acid

The invention relates to a preparation method for polydopamine-coated polyethyleneimine-stablized gold-nanometer-star photothermal treatment agent. The preparation method comprises the following steps: preparing a gold seed solution from chloroauric acid and sodium citrate; activating mercaptoacetic acid with EDC, then adding an aqueous PEI solution and carrying out a reaction, dialysis, cooling and drying so as to obtain PEI-SH; adding dopamine hydrochloride into a Tris buffer so as to obtain dopamine Tris buffer; adding the gold seed solution into a chloroauric acid solution, adding a AgNO3 solution and an ascorbic acid solution under stirring, adding PEI-SH after stirring reaction and carrying out a reaction so as to obtain AuNSs-PEI; and adding AuNSs-PEI into the dopamine Tris buffer and carrying out stirring and centrifugation so as to obtain the photothermal treatment agent. The preparation method has the advantages of simplicity, mild reaction conditions, easy operation and industrialization prospects; and the prepared star-like nanometer agent has application potential in the fields of CT imaging diagnosis and photothermal treatment of cancers.

Owner:DONGHUA UNIV

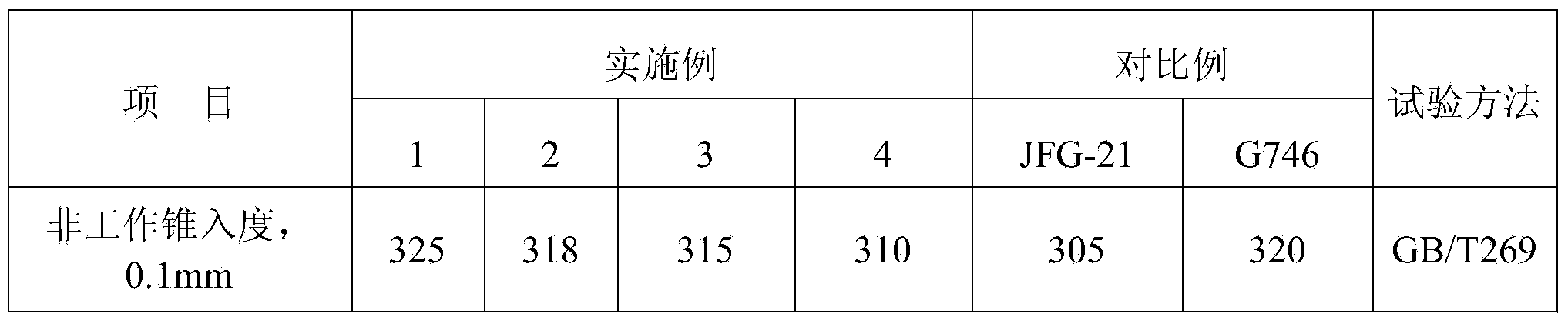

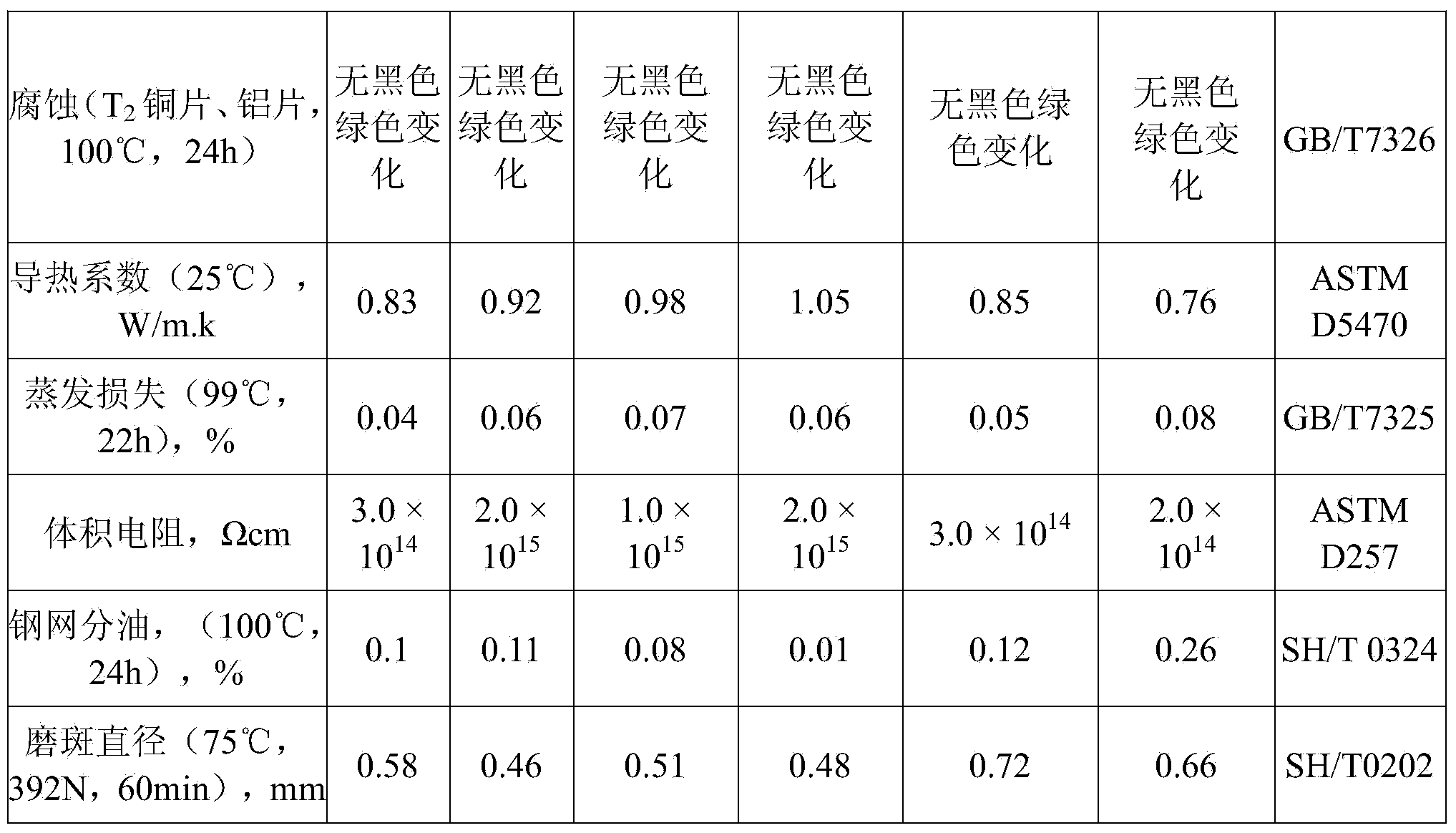

Insulating and heat-conducting silicone grease and preparation method thereof

InactiveCN103709757AImprove colloidal stabilityImprove stabilityHeat-exchange elementsAluminiumAntioxidant

The invention discloses insulating and heat-conducting silicone grease. The insulating and heat-conducting silicone grease consists of the following raw materials in parts by weight: 10-40 parts of organic silicon oil, 50-80 parts of heat-conducting powder, 0.5-4 parts of a structure improver, 0.5-3 parts of rheological aid, 0.5-5 parts of a friction modifier and 0.1-2 parts of an antioxidant. The insulating and heat-conducting silicone grease prepared by the invention is excellent in heat-conducting performance and low in cost, and is widely applicable to heat radiators requiring effective cooling in the industry, such as heat transmission for a gap where a diode and a substrate (aluminum or copper plate) are in contact, and heat conduction and insulation of a rectifier, electric and the like.

Owner:无锡中石油润滑脂有限责任公司

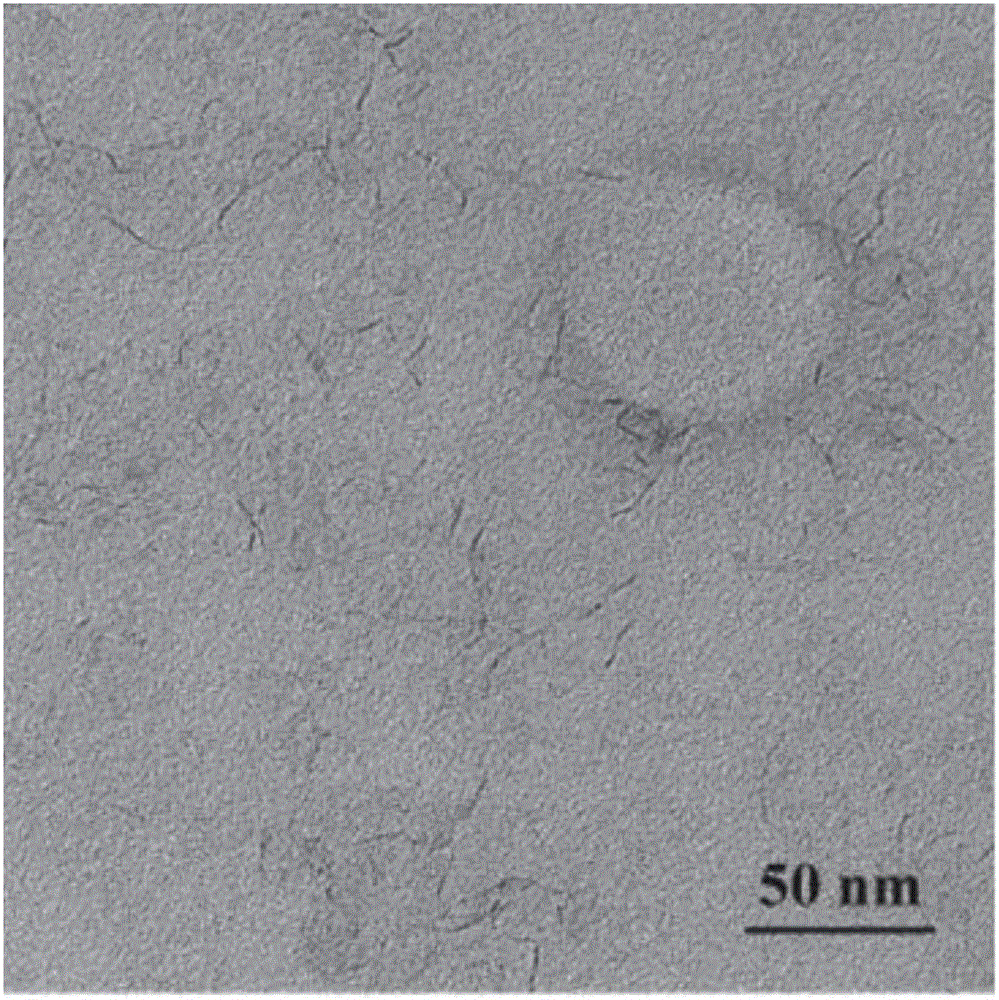

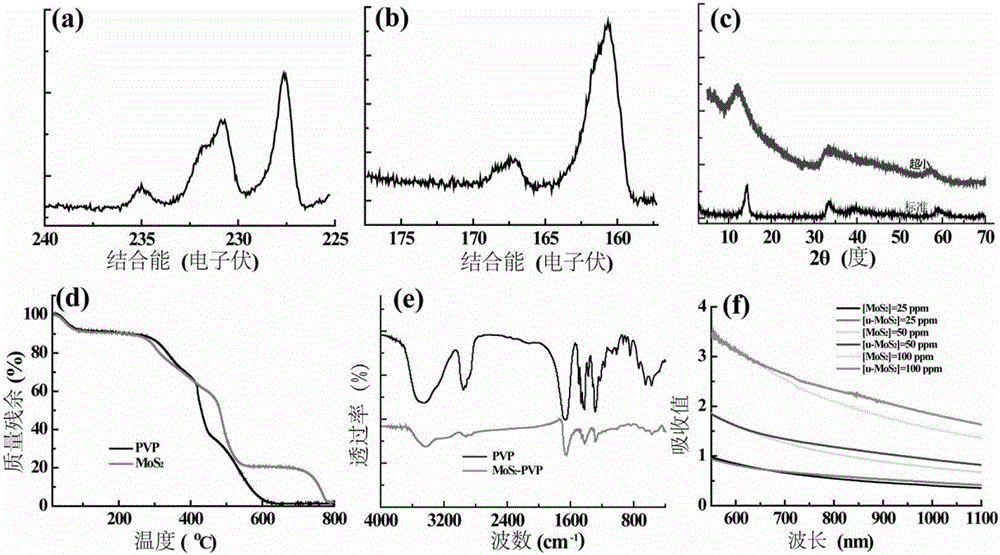

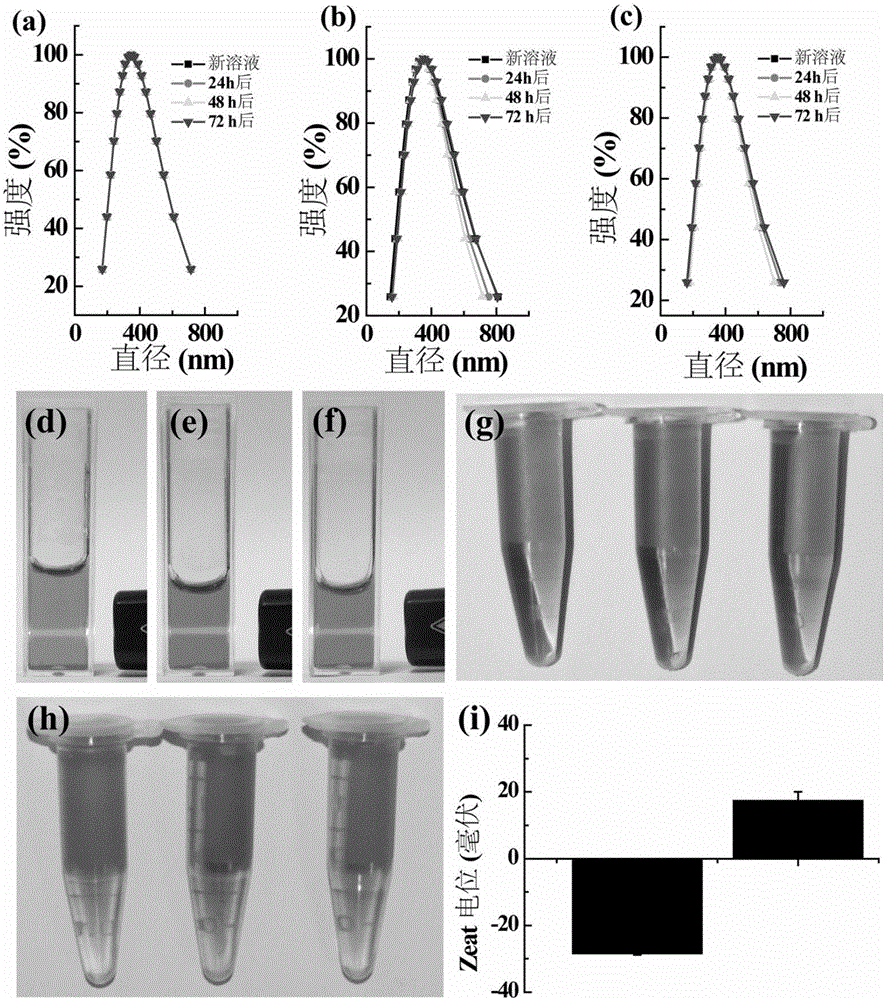

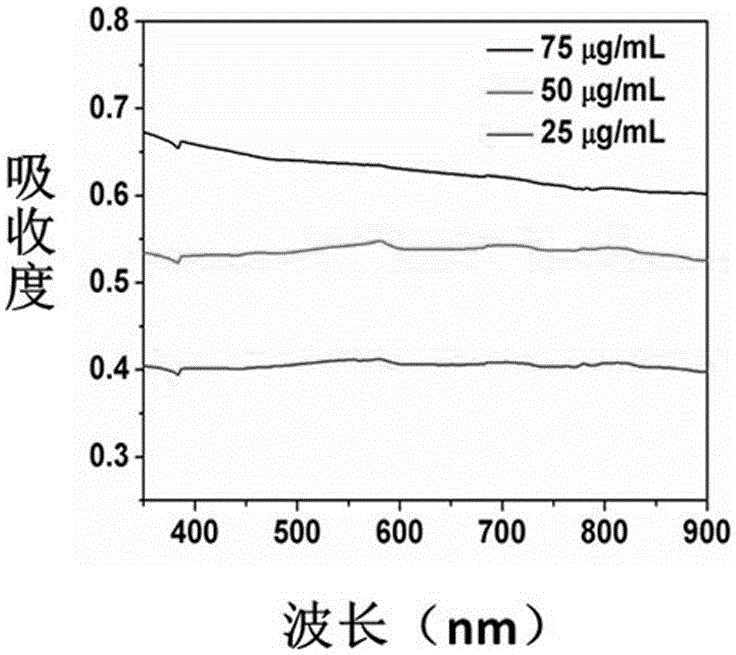

Ultra-small MoS2 nanosheet as well as preparation method and application thereof

InactiveCN106075438AImprove colloidal stabilityGood biocompatibilityEnergy modified materialsEchographic/ultrasound-imaging preparationsSulfurDistilled water

The invention discloses an ultra-small MoS2 nanosheet. The surface of the MoS2 nanosheet is modified with polyvinylpyrrolidone, and the diameter of the modified MoS2 nanosheet ranges from 15 nm to 25 nm. The invention further discloses a preparation method of the ultra-small MoS2 nanosheet. The preparation method comprises the following steps: a sulfur source and a molybdenum source are dissolved in water and stirred until the resources are completely dissolved; polyvinylpyrrolidone is dissolved in the solution of the sulfur source and the molybdenum source; the solution is transferred into a stainless steel reaction kettle with a polyphenyl lining for closed reaction, a reaction product is washed with an ethanolamine water solution and distilled water, and the ultra-small MoS2 nanosheet with the surface modified with polyvinylpyrrolidone is obtained. The invention further provides an application of the ultra-small MoS2 nanosheet as a photo-thermal conversion material. The ultra-small MoS2 nanosheet has good colloid stability, photo-thermal conversion capacity and photo-acoustic imaging capacity and has broad application prospect in the fields of tumor treatment and the like.

Owner:UNIV OF SHANGHAI FOR SCI & TECH +1

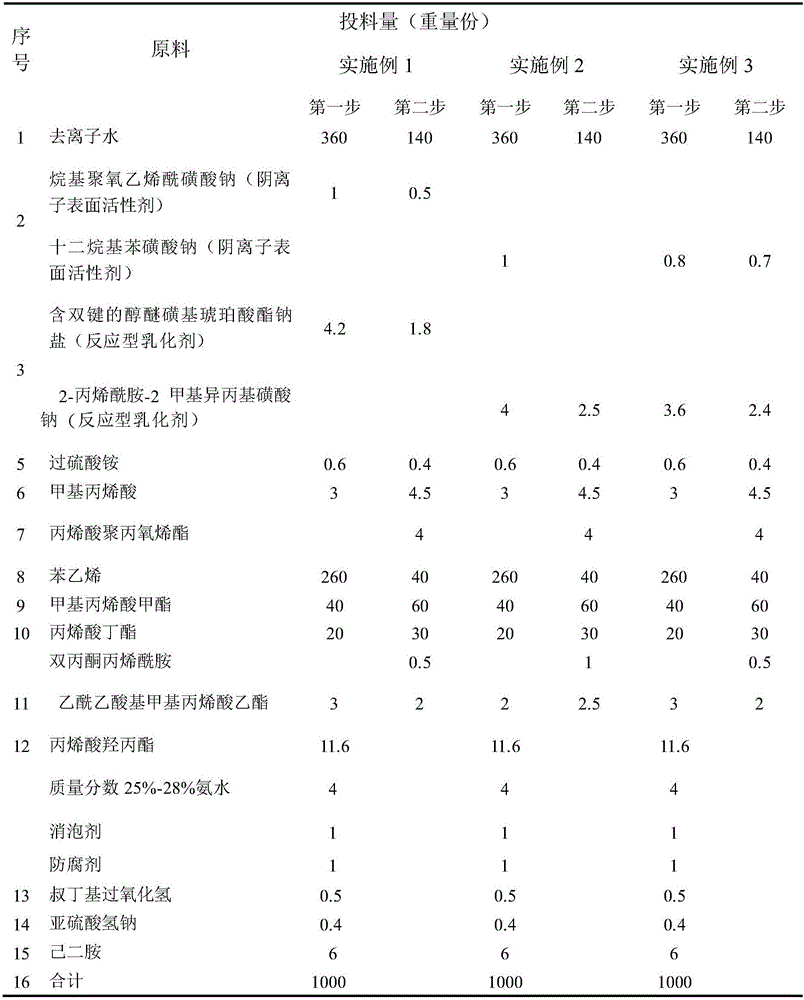

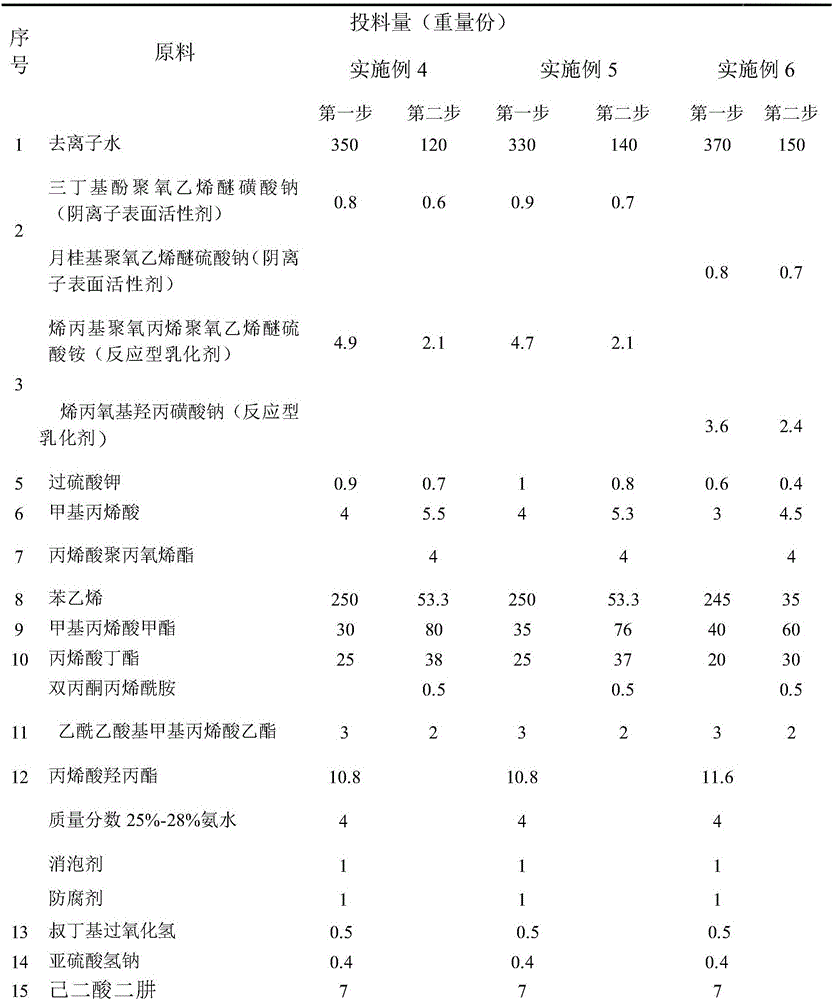

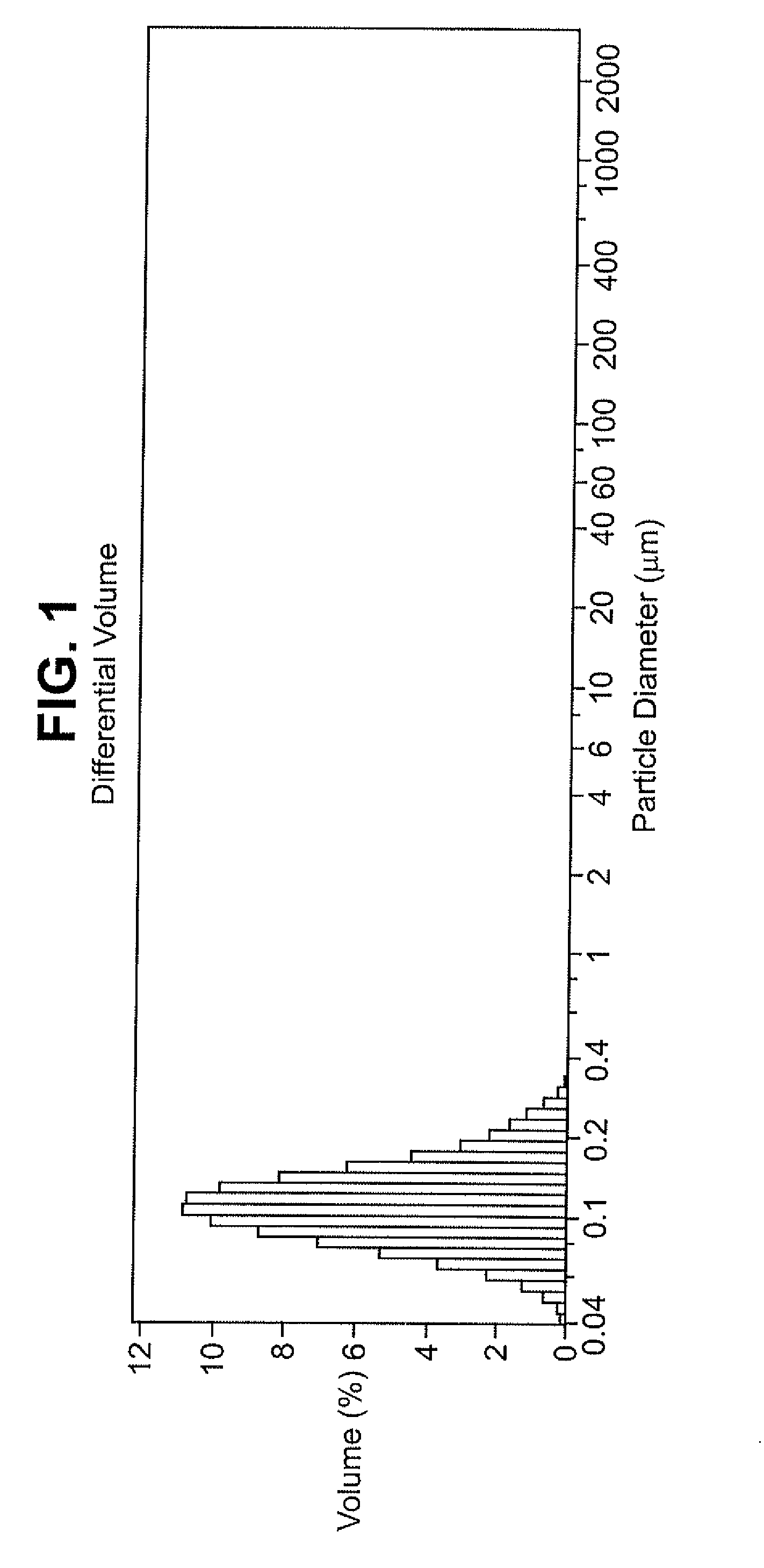

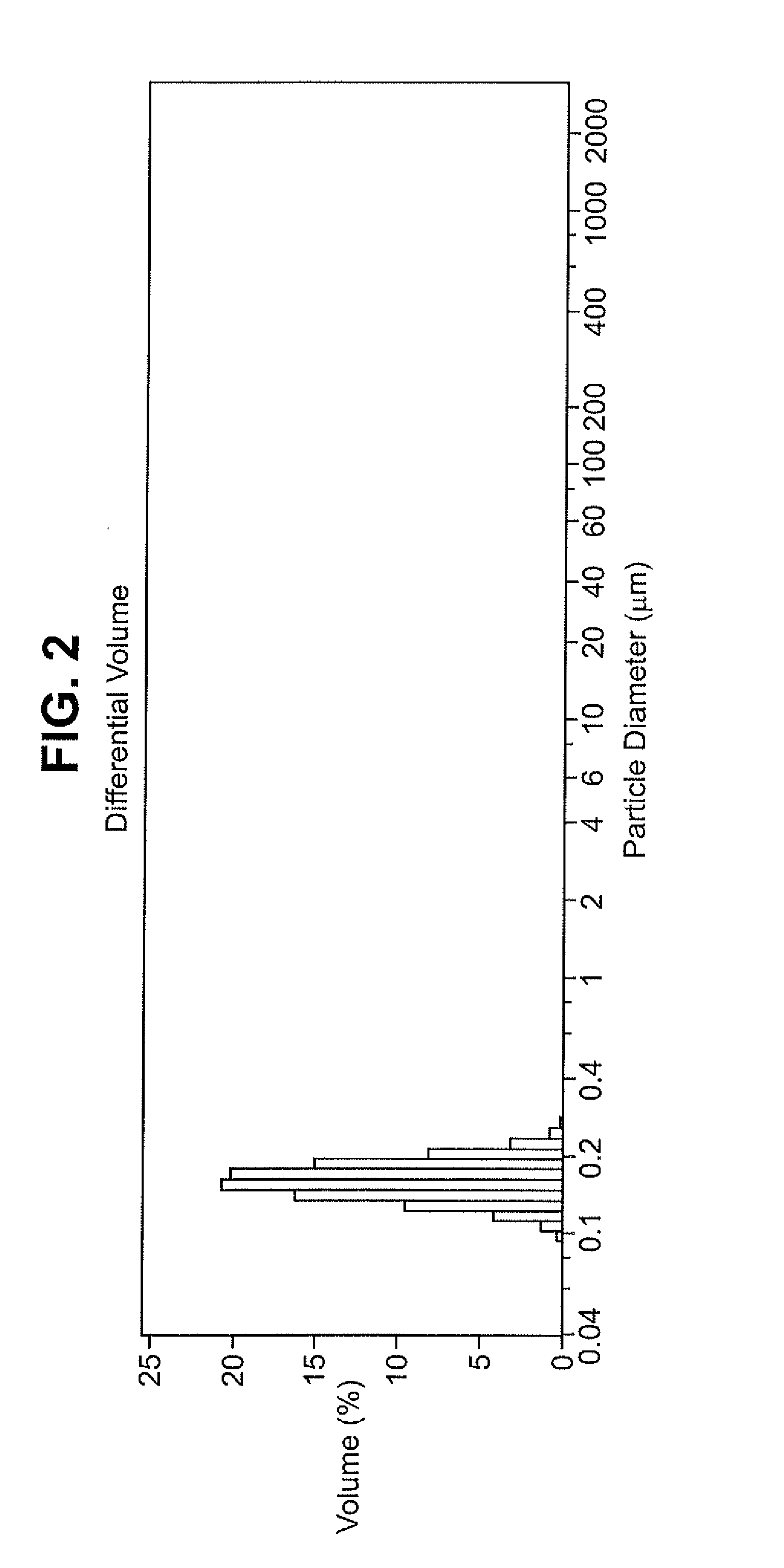

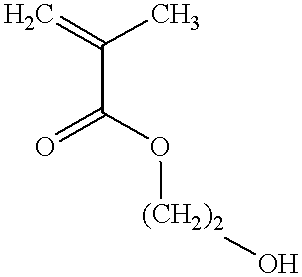

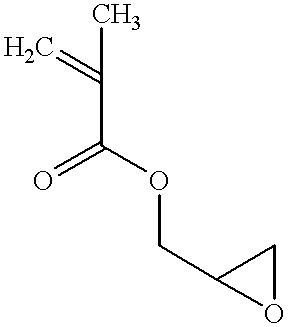

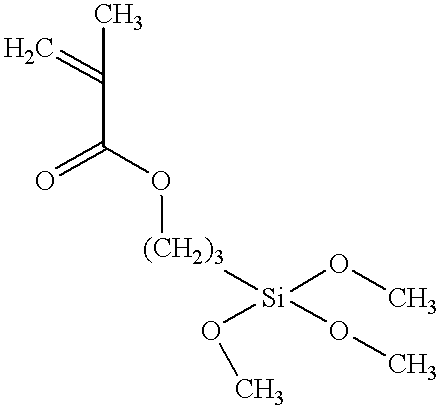

Acrylate copolymer emulsion, and aqueous industrial anticorrosive paint adopting acrylate copolymer emulsion as film forming substance

ActiveCN105859936AReduce the temperatureGuaranteed compactnessAnti-corrosive paintsCross-linkSodium bisulfate

The invention discloses an acrylate copolymer emulsion, and belongs to the technical field of aqueous coatings. The acrylate copolymer emulsion comprises, by weight, 450-550 parts of deionized water, 1-2 parts of an anionic surfactant, 5-8 parts of a reactive emulsifier, 3-15 parts of hydroxypropyl acrylate, 50-160 parts of methyl methacrylate, 20-75 parts of butyl acrylate, 200-410 parts of styrene, 5-10 parts of methacrylic acid, 3-10 parts of an adhesion function monomer, 2-9 parts of a cross-linking monomer, 3-10 parts of a cross-linking agent, 0.1-3 parts of an antifoaming agent, 0.8-2 parts of an initiator, 3-5 parts of ammonia water, 0.8-2 parts of an antiseptic, 0.1-1 part of tert-butyl hydroperoxide and 0.1-0.8 parts of sodium bisulfate. The invention also discloses an aqueous industrial anticorrosive coating adopting the acrylate copolymer emulsion as a film forming substance. The coating has the advantages of high adhesion to a substrate, high water resistance and high salt spray resistance.

Owner:HENGSHUI XINGUANG CHEM

Redispersible polymer powders stabilized with protective colloid compositions

A water redispersible polymer powder is produced by drying an aqueous mixture of a water insoluble film-forming polymer and a colloidal stabilizer which includes a chelating agent and at least one water soluble polymer. The amount of chelating agent is at least 0.1% by weight, based upon the weight of the water insoluble film-forming polymer, and the amount of the at least one water soluble polymer is at least 0.1% by weight, based upon the weight of the water insoluble film-forming polymer. Dispersions or polymer compositions containing a chelating agent and water soluble polymer as a colloidal stabilizer exhibit an unexpectedly low viscosity which facilitates spray drying and permits use of high solids content dispersions with low pressure spray drying to increase production efficiency. The colloidal stabilizer composition provides unexpectedly superior redispersibility for water insoluble film-forming polymers having very low carboxylation levels.

Owner:BERGMAN ROGER +5

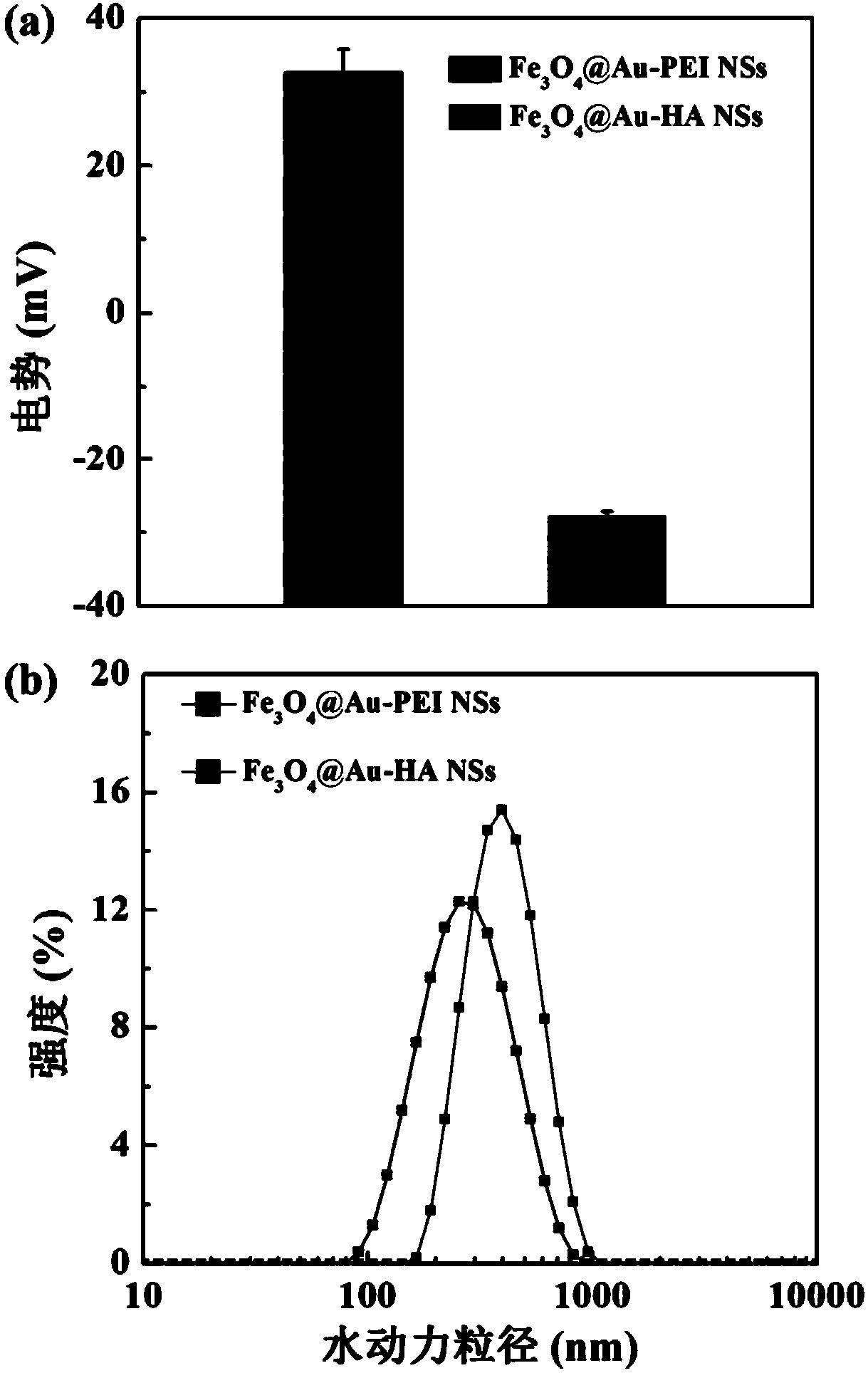

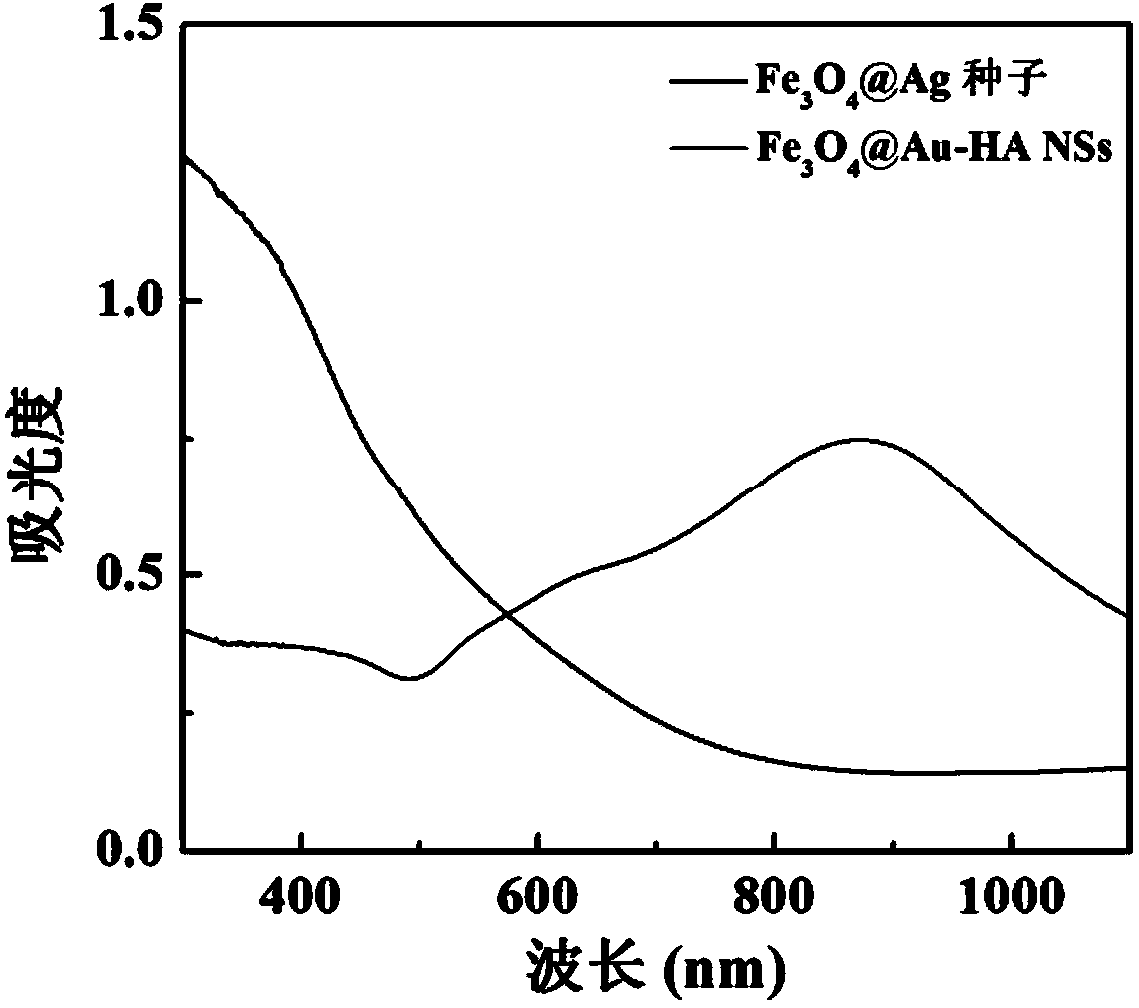

Preparation of nano particles with gold coating iron oxide star-shaped core-shell structure, imaging and thermotherapy application thereof

InactiveCN104162174ALow costGood water solubilityEnergy modified materialsX-ray constrast preparationsTreatment fieldIn vivo

The invention relates to a preparation of nano particles with gold coating iron oxide star-shaped core-shell structure, imaging and thermotherapy application thereof. The preparation method comprises the following steps: preparing PEI coating silver nano seed; synthesizing iron oxide nano particles having silver seed by a one-step hydrothermal method; preparing the star-shaped composite nano particles in a gold growth solution; and modifying polyethyleneimine (PEI) and hyaluronic acid (HA) on the surface of the star-shaped composite nano particles. The preparation has the advantages of mild reaction condition, simple technology and easy operation. The prepared nano particles with the gold coating iron oxide star-shaped core shell structure has good molecular imaging performance and thermotherapy antineoplastic effect, and has latent application value on in vivo tumour imaging diagnosis and photo-thermal treatment fields.

Owner:DONGHUA UNIV

Method for making positive working printing plates from a latex

InactiveUS6354209B1Easy to optimizeHigh printing durabilityDuplicating/marking methodsPlate printingHydrophobic polymerPlanographic printing

According to the present invention there is provided a method for making a lithographic printing plate including the steps of dispensing in a predetermined pattern a latex of particles of a hydrophobic polymer onto an optionally modified hydrophilic surface of a lithographic base, characterized in that the hydrophobic polymer and the optionally modified hydrophilic surface of the lithographic base have mutually reactive groups.

Owner:AGFA NV

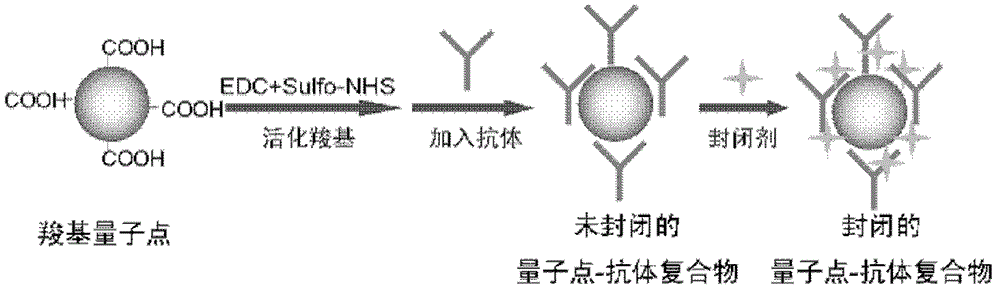

Method for utilizing covalence coupling to prepare photon point-antibody compound

InactiveCN103063828AImprove colloidal stabilityHigh sensitivityMaterial analysisChemistryConstellation

The invention discloses a method for utilizing covalence coupling to prepare a photon point-antibody compound. The method comprises the following steps of: after a photon point and antibody numerators are subjected to covalence coupling, sealing the unoccupied site of the surface of the photon point by use of a sealant, and connecting the sealant with an activating functional group on the surface of the photon point through a covalent bond, thereby forming the photon point-antibody compound. The method provided by the invention can keep a free space constellation of antibody numerators, the colloid stability of the nanometer particles is improved, the method provided by the invention is utilized to prepare the photon point-antibody compound, and the immunity detective sensitivity is improved; and the operation is simple and convenient, the immunity characteristic of the photon point-antibody compound is effectively improved, and the photon point is pushed to be applied on an immunity detection aspect.

Owner:韩焕兴 +2

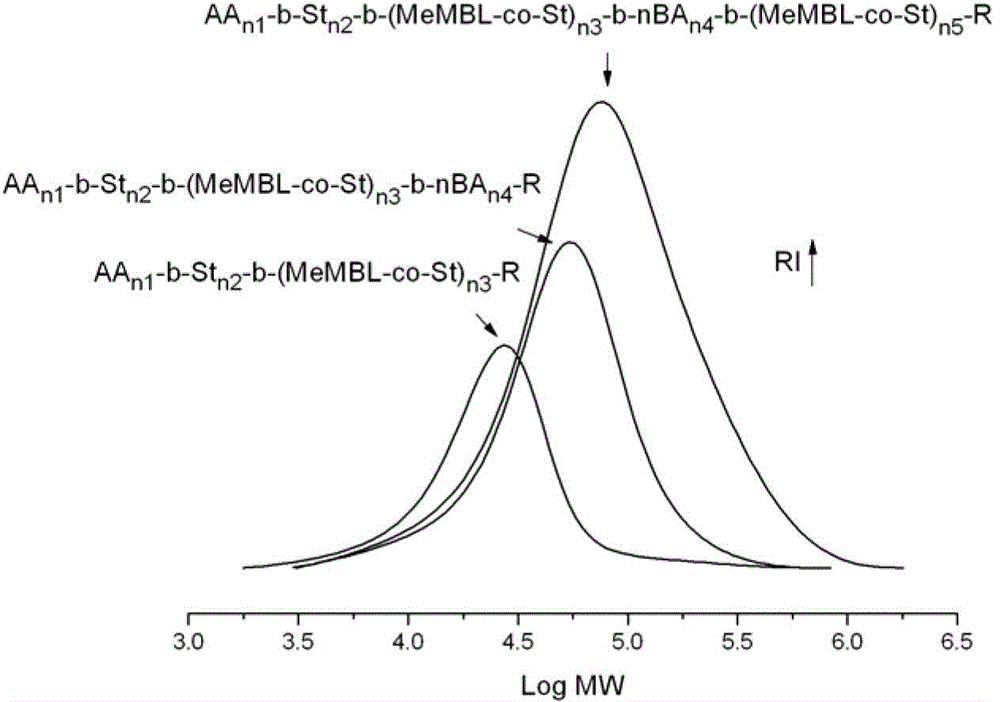

Method for preparing reversible addition-fragmentation chain transfer emulsion polymerization

The invention discloses a method for preparing reversible addition-fragmentation chain transfer emulsion polymerization. The method comprises the following steps: adding 0.1 to 2.5 portions of amphiphilic macromolecular reversible addition-fragmentation chain transfer reagent, 20 to 40 portions of water and 1 to 20 portions of monomer by weight into a reactor, and stirring and mixing the mixture; introducing nitrogen into the reactor; heating the reactor to a temperature of between 50 and 80 DEG C; and adding 0.005 to 0.05 portion of water-soluble initiator by weight into the reactor to initiate polymerization for 0.5 to 6 hours. The method has the advantages of simple flow equipment, low energy consumption, easy removal of water system reaction heat, short reaction inhibition period, high reaction speed, high final percent conversion and good emulsion stability, and the amphiphilic macromolecular reversible addition-fragmentation chain transfer reagent can be used as a chain transfer reagent and an emulsifier without adding conventional emulsifier in addition, has actual molecular weight in accordance with a molecular weight design value and distribution of the molecular weight less than 1.4, can be synthesized into a segmented copolymer through semicontinuously adding the monomer, and has good industrial prospect.

Owner:ZHEJIANG UNIV

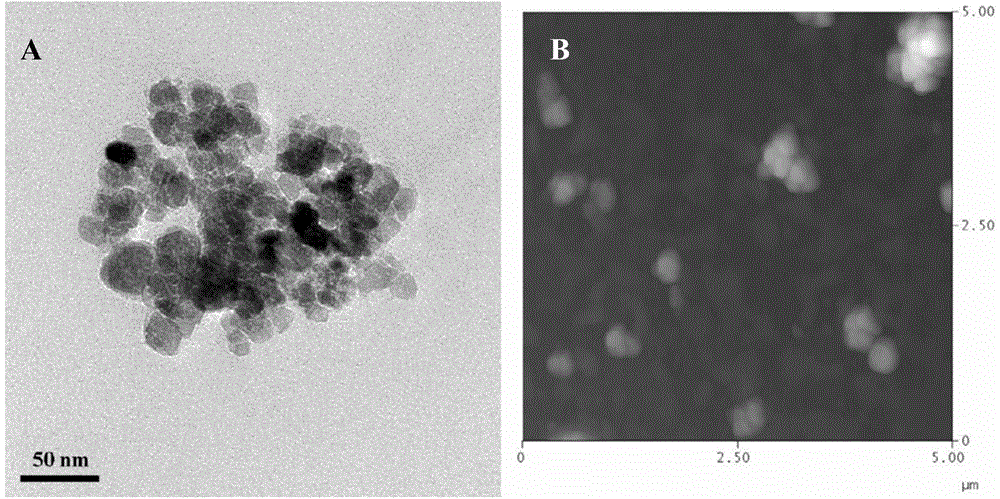

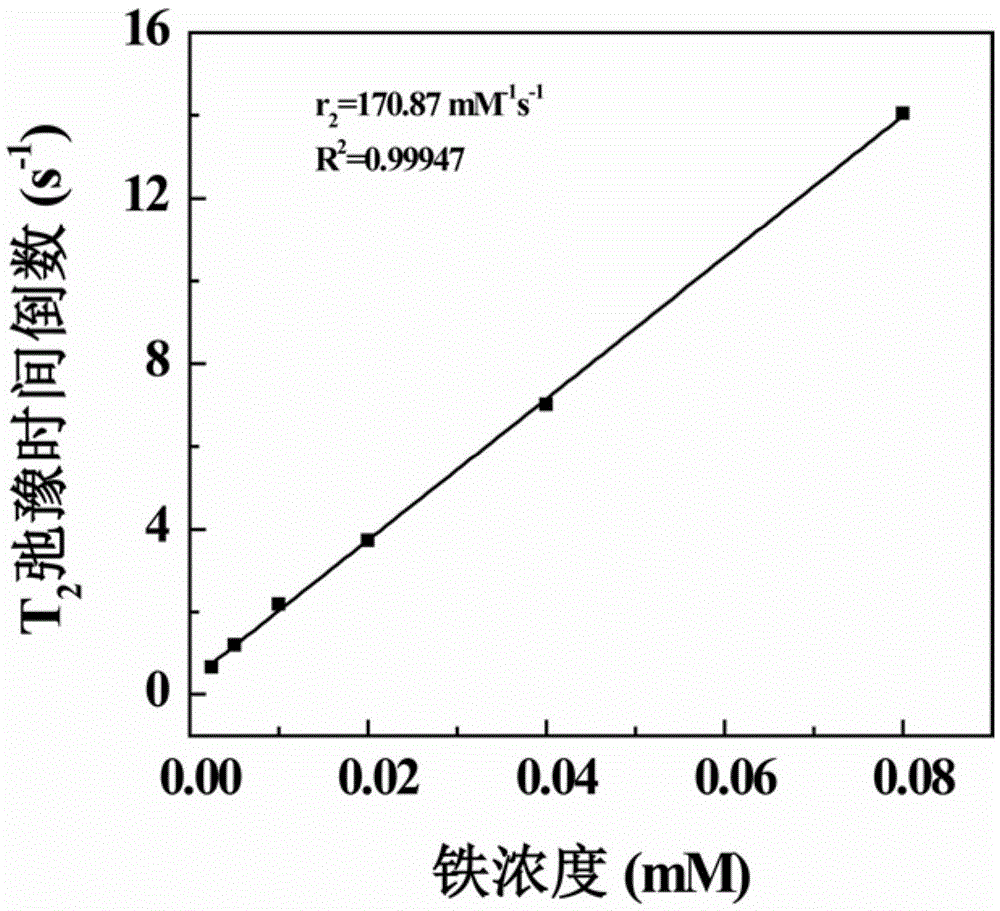

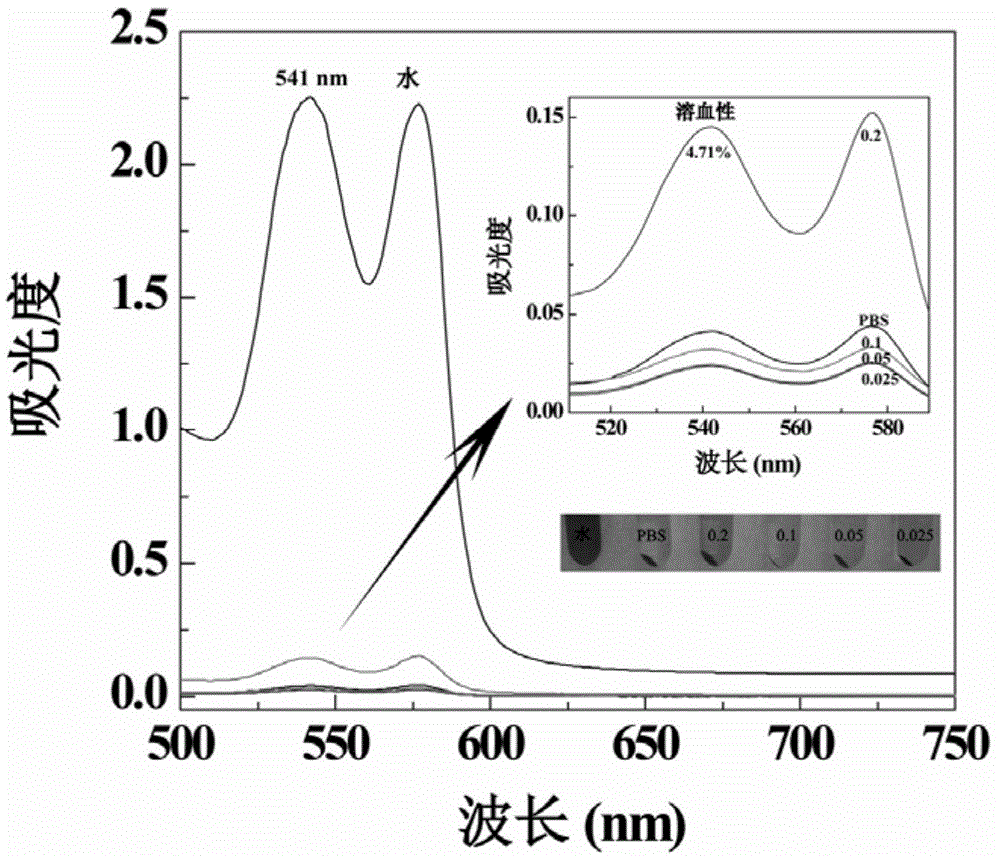

Preparation method of ferric oxide nanoparticle supported sodium alginate nanogel

InactiveCN104606687ASimple processEasy to operate and separateEmulsion deliveryIn-vivo testing preparationsSolubilityBiocompatibility Testing

The invention relates to a preparation method of ferric oxide nanoparticle supported sodium alginate nanogel. The preparation method comprises steps as follows: (1), PEI (polyethylenimine) coated Fe3O4 nano-particles (Fe3O4-PEI) are synthesized with a hydrothermal method; (2), an aqueous solution of sodium alginate is firstly activated by EDC (carbodiimide) and has a double emulsion reaction to form a W / O / W polymer emulsion; (3), Fe3O4-PEI in the step (1) is taken as a crosslinking agent and added into the polymer emulsion in the step (2) to have a crosslinking reaction, and the ferric oxide nanoparticle supported sodium alginate nanogel is obtained after an organic solvent and a surface active agent are removed. The method is very simple, and operation and separation are easy; meanwhile, sources of raw materials are extensive; the prepared sodium alginate nanogel has a smaller grain diameter, is uniformly distributed, high in relaxation rate and low in cost, has a remarkable radiography effect, simultaneously has excellent water solubility, gel stability, biocompatibility and blood compatibility, doesn't have a harmful effect on a living body, and has potential application value in the magnetic resonance imaging diagnosis field.

Owner:DONGHUA UNIV

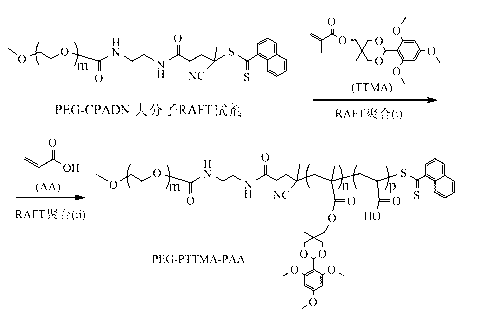

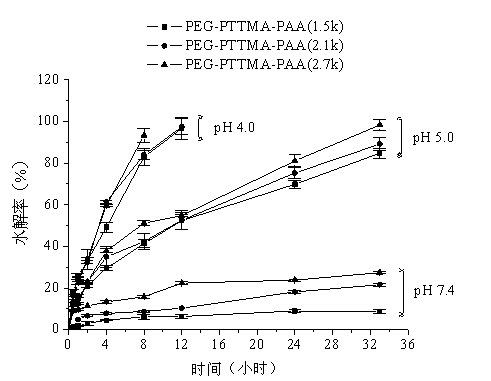

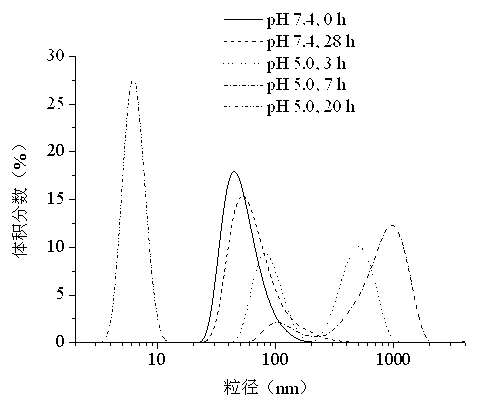

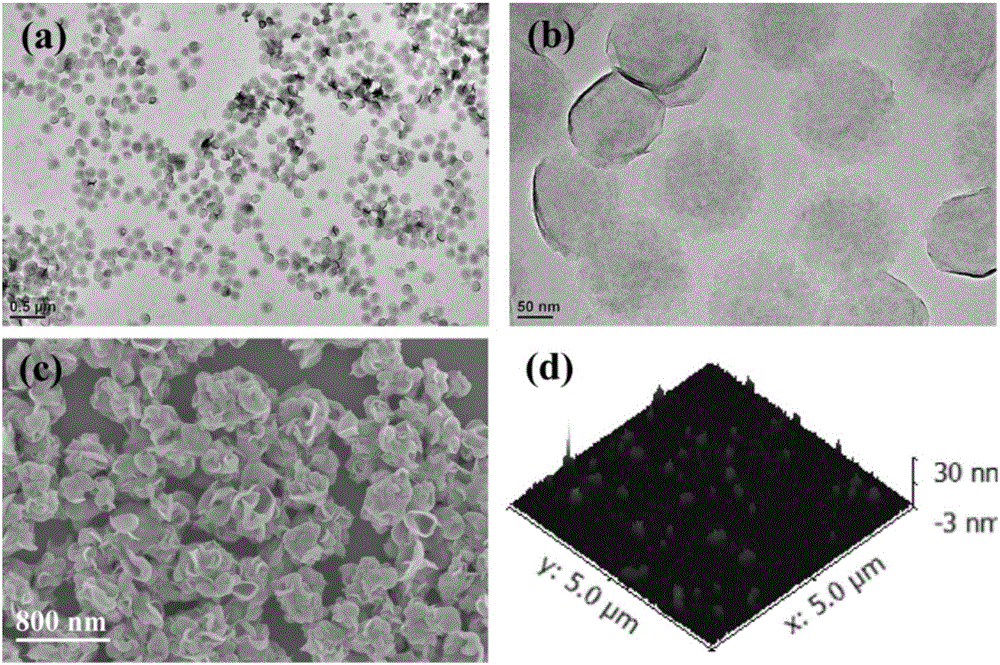

Acid-sensitive degradable polymer vesicle and preparation and application thereof

ActiveCN102911326AQuick releaseImprove colloidal stabilityPharmaceutical non-active ingredientsMicrocapsulesMethacrylatePolymer science

The invention discloses an acid-sensitive degradable polymer vesicle and preparation and application of the polymer vesicle. The polymer vesicle is formed by an A-B-C type block polymer, wherein the block A is polyethylene glycol and distributed on the external surface of the vesicle; the block B is hydrophobic pH-sensitive degradable polymer poly(trimethoxy benzaldehyde acetal-trimethylolethane-methacrylate) and forms a film core of the vesicle; and the block C is polyelectrolyte selected from one of polyacrylic acid, polymethacrylic acid, dimethylaminoethyl polymethacrylate, diethylaminoethyl polymethacrylate and diisopropylaminoethyl polymethacrylate, distributed on the inner wall of the vesicle film, and used for efficiently loading medicaments with opposite charges. The pH-sensitive degradable vesicle is simple in preparation method, can efficiently load micromolecular hydrophile anticancer medicaments, therapeutic protein medicaments, polypeptide medicaments and nucleic acid medicaments.

Owner:SUZHOU UNIV

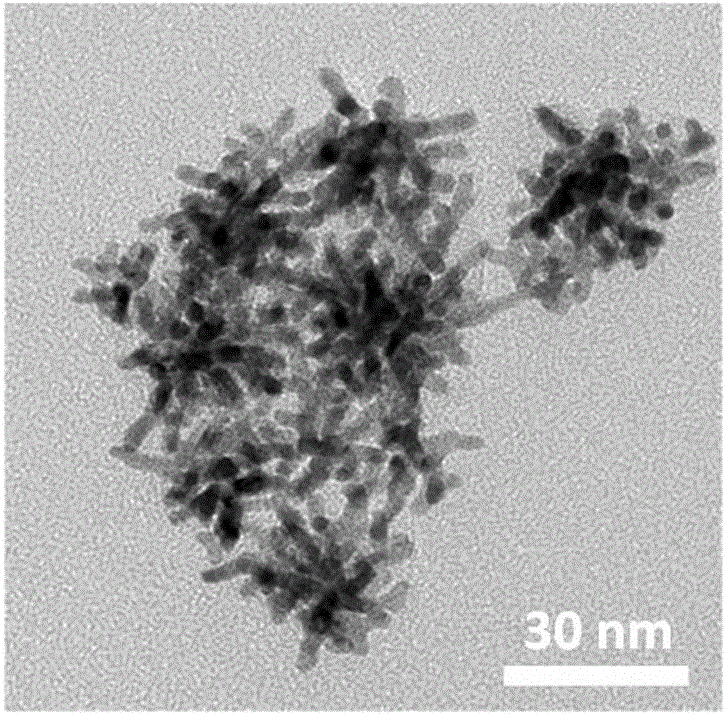

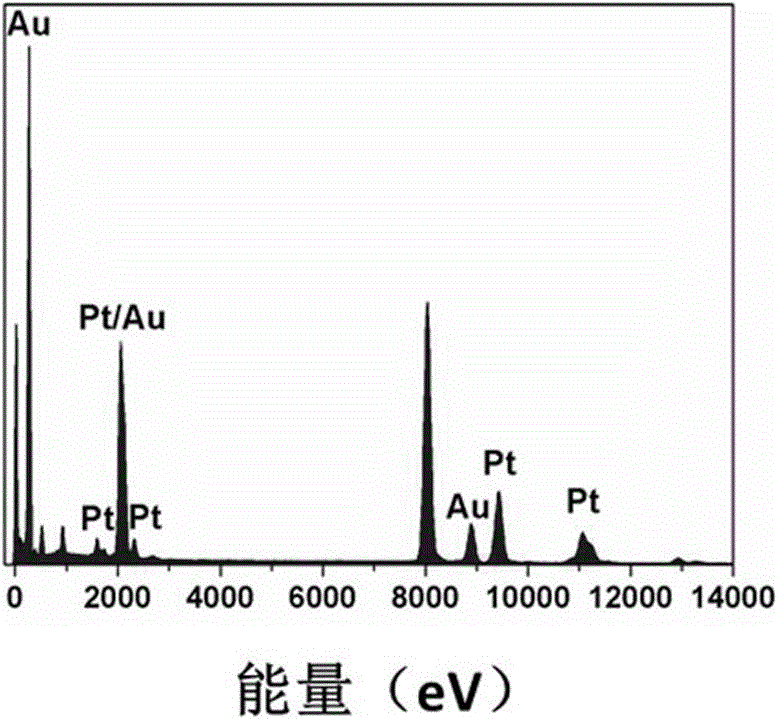

Branched gold-platinum dual-metal nanoparticle as well as preparation method and application thereof

ActiveCN106729738AAbsorb moreIncreased radiotherapy deposition volumePowder deliveryHeavy metal active ingredientsPolyethylene glycolRadio sensitization

The invention discloses a branched gold-platinum dual-metal nanoparticle as well as a preparation method and application thereof. The gold-platinum dual-metal nanoparticle has photo-thermal / radio-sensitization combined treatment performance and structurally contains gold-platinum nanoparticles and polyethylene glycol, wherein the gold-platinum nanoparticles are used for photo-thermal / radio-sensitization combined treatment, and polyethylene glycol is used for the surface modification of a thioctic acid terminal of a hydrophilic polymer. The gold-platinum dual-metal nanoparticle can be applied to the photo-thermal / radio-sensitization combined treatment and has the advantages of simplicity in preparation, low cost and remarkable treatment effect.

Owner:SUN YAT SEN MEMORIAL HOSPITAL SUN YAT SEN UNIV

Additive for ink jet ink

InactiveUS6030438AExtended drying timeImprove colloidal stabilityDuplicating/marking methodsInksAlcoholPolyol

An ink jet ink composition comprising from about 30 to about 90% by weight of water, from about 0.5 to about 30% by weight of a pigment, from about 0.1 to about 10% by weight of a swelling clay, and from about 10 to about 50% by weight of a humectant comprising a polyhydric alcohol or a nitrogen-containing cyclic compound.

Owner:EASTMAN KODAK CO

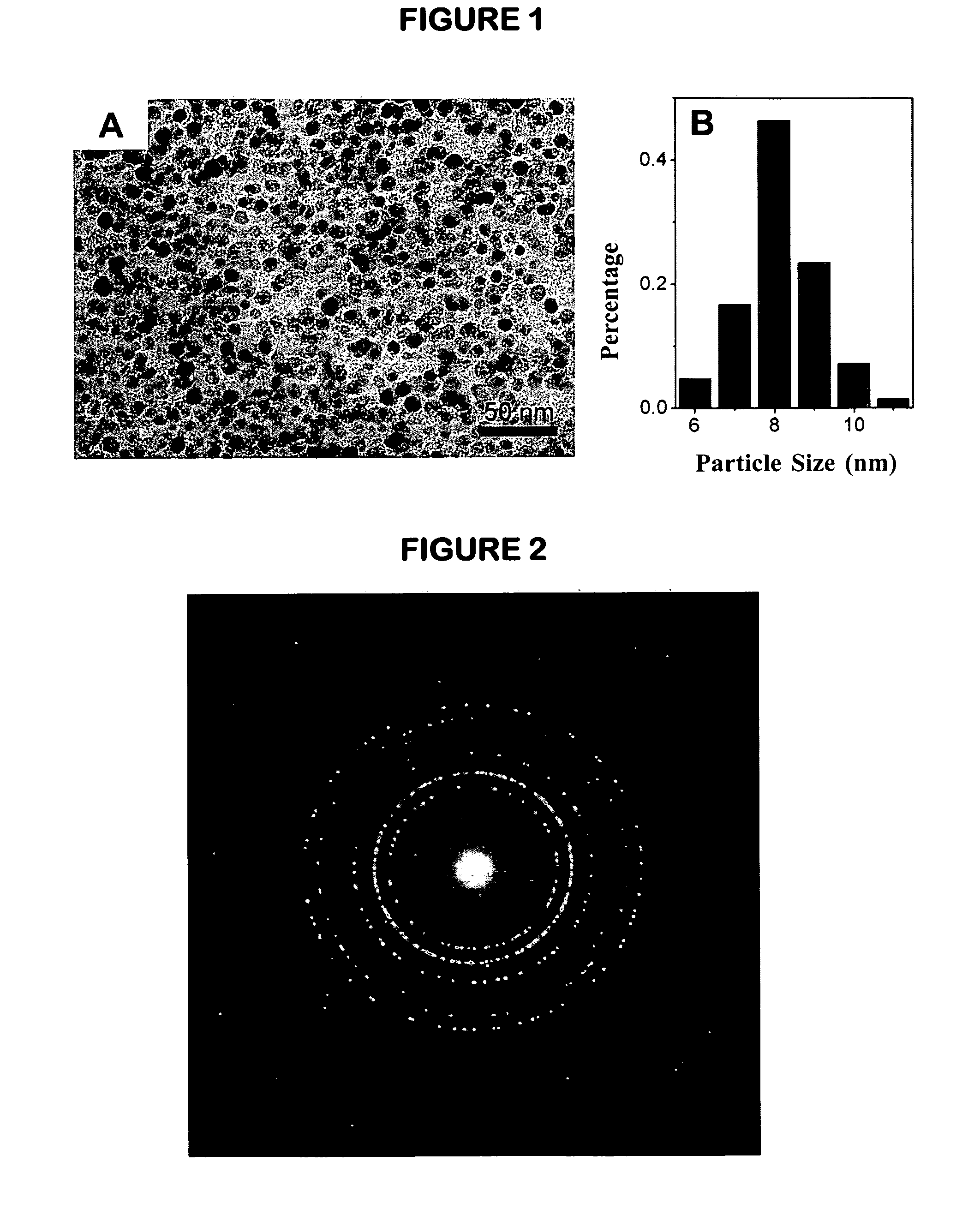

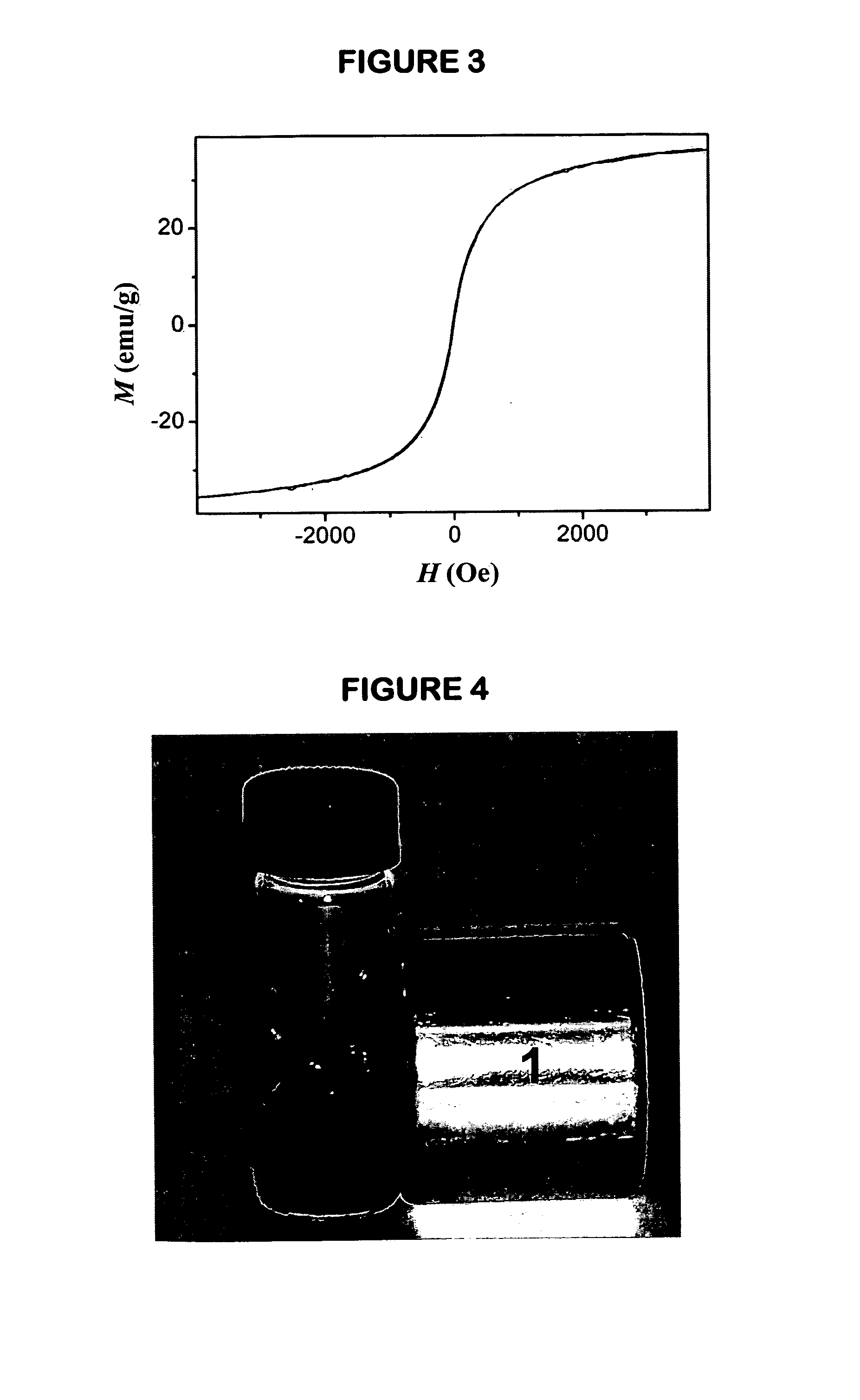

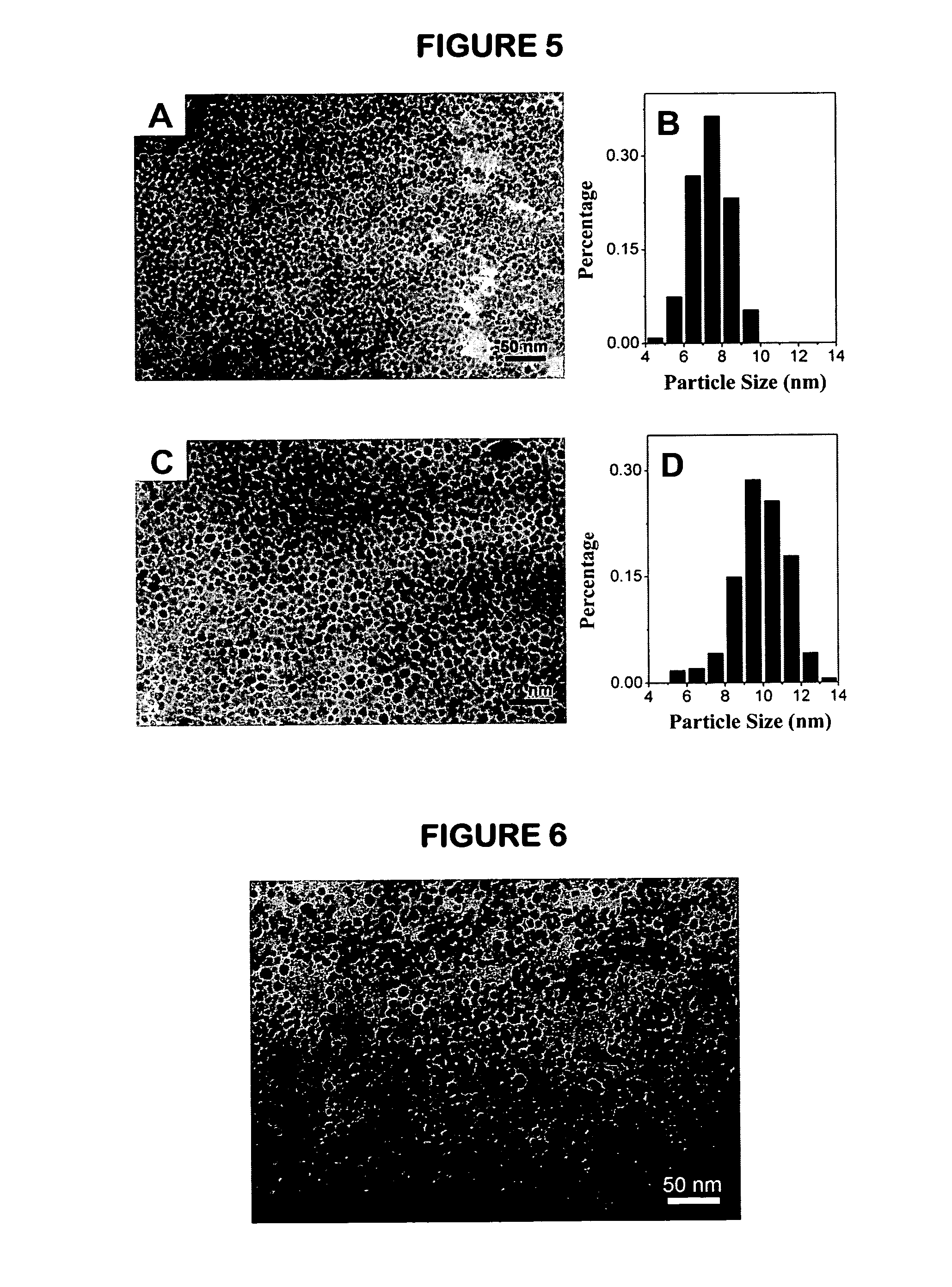

Biocompatible magnetic nanocrystal, powder of a biocompatible magnetic nanocrystal bearing a surface reactive group and preparations thereof

ActiveUS20080203351A1Improve colloidal stabilityHigh crystallinityMaterial nanotechnologyNanomagnetismOrganic solventN-Hydroxysuccinimide

This invention is concerned with biocompatible magnetic nanocrystals highly soluble and dispersible in a physiological buffer, powder of biocompatible magnetic nanocrystals and nanocrystals bearing surface reactive N-hydroxysuccinimide ester moiety, and preparations thereof. The magnetic nanocrystals in powder form are highly soluble in a physiological buffer. The resultant aqueous colloidal solution presents long term stability in ambient conditions. Moreover, the carboxyl group on the surface of the magnetic nanocrystals can be converted to N-hydroxysuccinimide ester moiety in an organic solvent. The resultant powder of the magnetic nanocrystals carrying surface N-hydroxysuccinimide ester moiety is soluble and dispersible in an aqueous solution. Different types of biomolecules bearing amino group can covalently be attached to the magnetic nanocrystal simply by mixing them in aqueous solutions. Moreover, the powder of the magnetic nanocrystals bearing surface N-hydroxysuccinimide ester moiety retain reaction activity with biomolecule after long-term storage.

Owner:INST OF CHEM

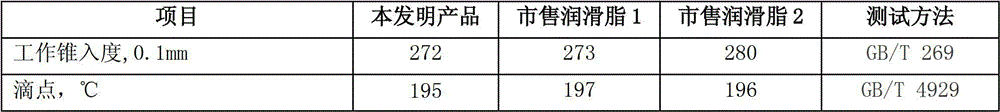

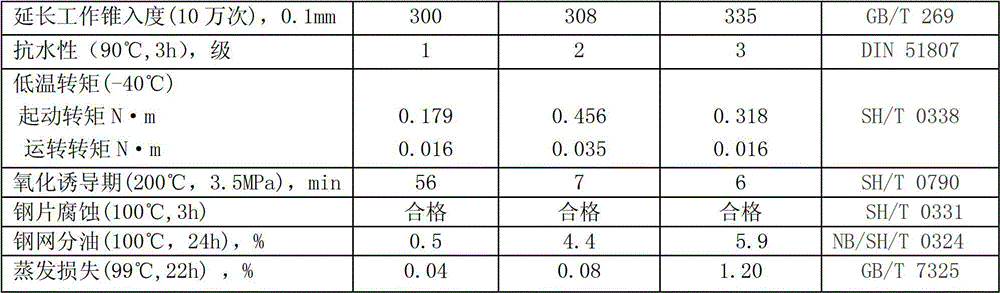

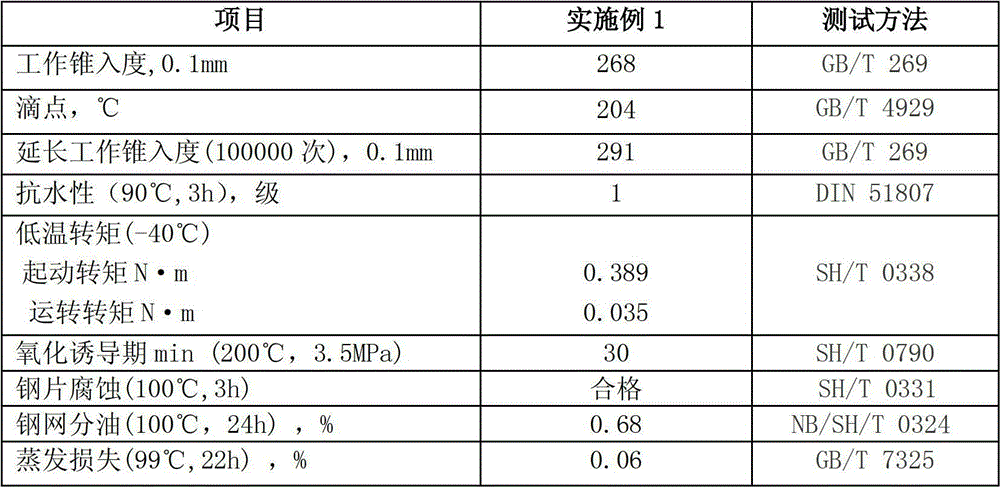

Lubricating grease composition for automobile glass lifter and preparation method of lubricating grease composition

ActiveCN102876434AOutstanding water resistanceOutstanding shear performanceLubricant compositionAntioxidantEvaporation

The invention provides a lubricating grease composition for an automobile glass lifter and a preparation method of the lubricating grease composition. The lubricating grease for the automobile glass lifter comprises the following ingredients in percentage by weight: 87 to 91.5 percent of basic oil, 7.5 to 12 percent of thickening agents, 0.5 percent of antioxidants, 0.03 percent of anti-rust agents and 0.5 percent of structure improving agents. The unique mixed thickening agent type is adopted, so the water-resistance and shearing performance of the lubricating grease are excellent, good low-temperature and viscosity-temperature performance is given to the lubricating agent through the proper basic oil type and mixture ratio, and the wide temperature use requirement being minus 40 DEG C to 70 DEG C of the automobile glass lifter accessories can be perfectly met. The prepared lubricating grease has the characteristics that the water resistance and the oxidation resistance are excellent, the oil rate is low, the evaporation loss is small, the shearing stability is high, the high-low temperature performance and the anti-corrosion protection effect are good, and the like, the use requirements of the automobile glass lifter can be perfectly met, and the use temperature range of the lubricating grease is minus 40 DEG C to 130 DEG C.

Owner:CHINA PETROLEUM & CHEM CORP

Heat sensitive imaging element for providing a lithographic printing plate

InactiveUS6210857B1Improve photolithography qualityLabor intensiveSemiconductor/solid-state device manufacturingPhotosensitive material auxillary/base layersHydrophilic polymersEngineering

According to the present invention there is provided a heat-sensitive imaging element for providing a lithographic printing late, comprising a lithographic base with a hydrophobic oleophilic surface and a top layer comprising a compound capable of converting light into heat and a hydrophilic polymer, characterized in that said hydrophilic polymer is crosslinked.

Owner:AGFA NV

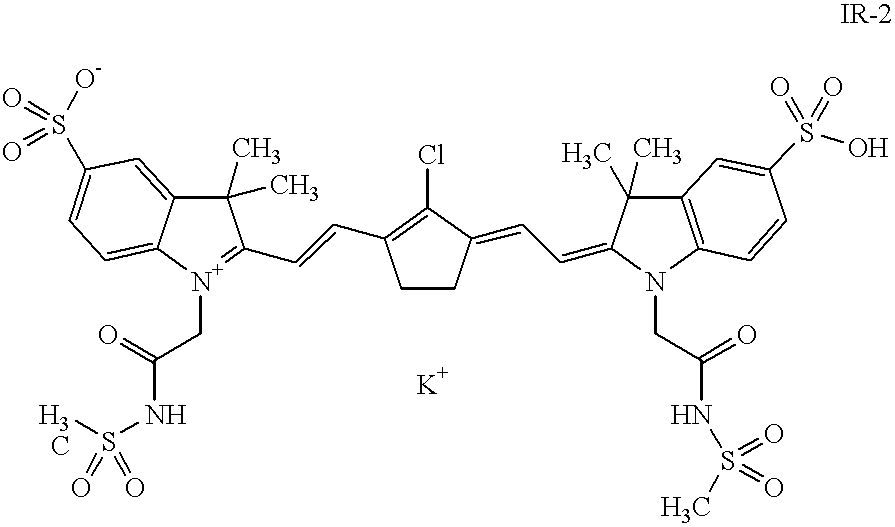

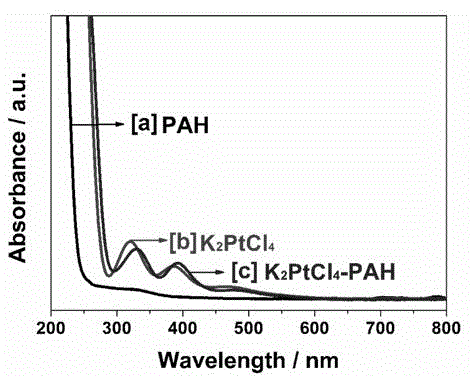

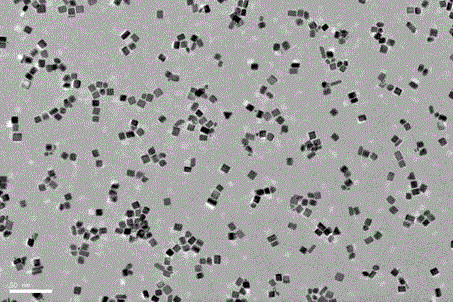

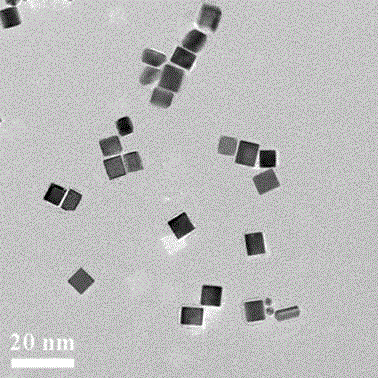

Poly-allylamine oriented platinum nano cube preparation method

InactiveCN102873337AThe mechanism of the preparation process is clearThe mechanism of the preparation process is reliableNanotechnologyPlatinumAqueous solution

The invention discloses a poly-allylamine oriented platinum nano cube preparation method. A hydrothermal reduction method is used for reducing K2PtCl4 into cubic platinum nano particles regular in shape and uniform in size by taking PAH (poly-allylamine hydrochloride) as complexing agent, stabilizing agent and morphological guide agent and taking HCHO as reducing agent. The platinum nano particles are in a cubic structure consisting of six {100} crystal faces and have excellent dispersibility and stability in aqueous solution and is high in catalytic activity and stability to electrochemical oxygen reduction reaction (ORR). The preparation method is simple, economical and suitable for industrial massive production.

Owner:NANJING NORMAL UNIVERSITY

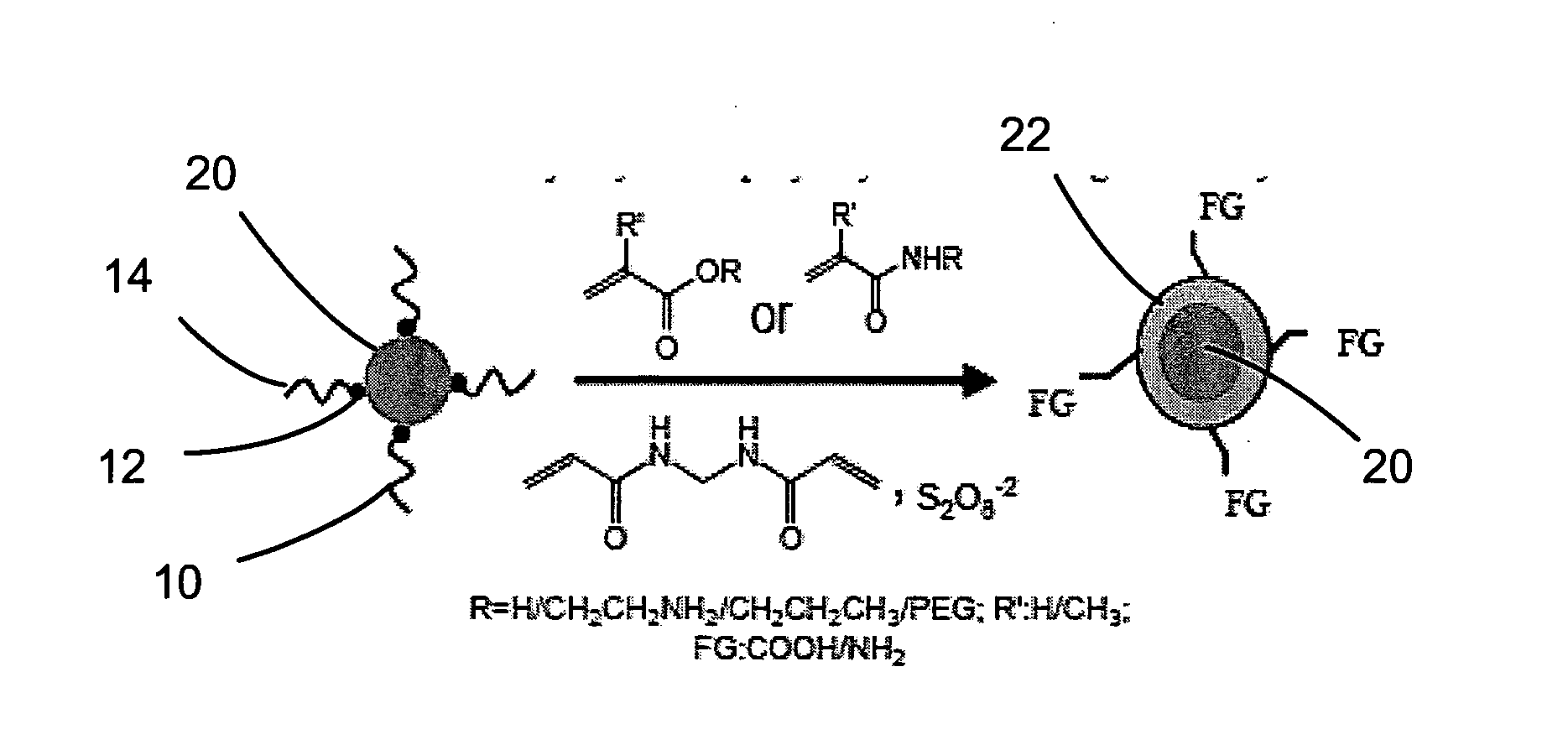

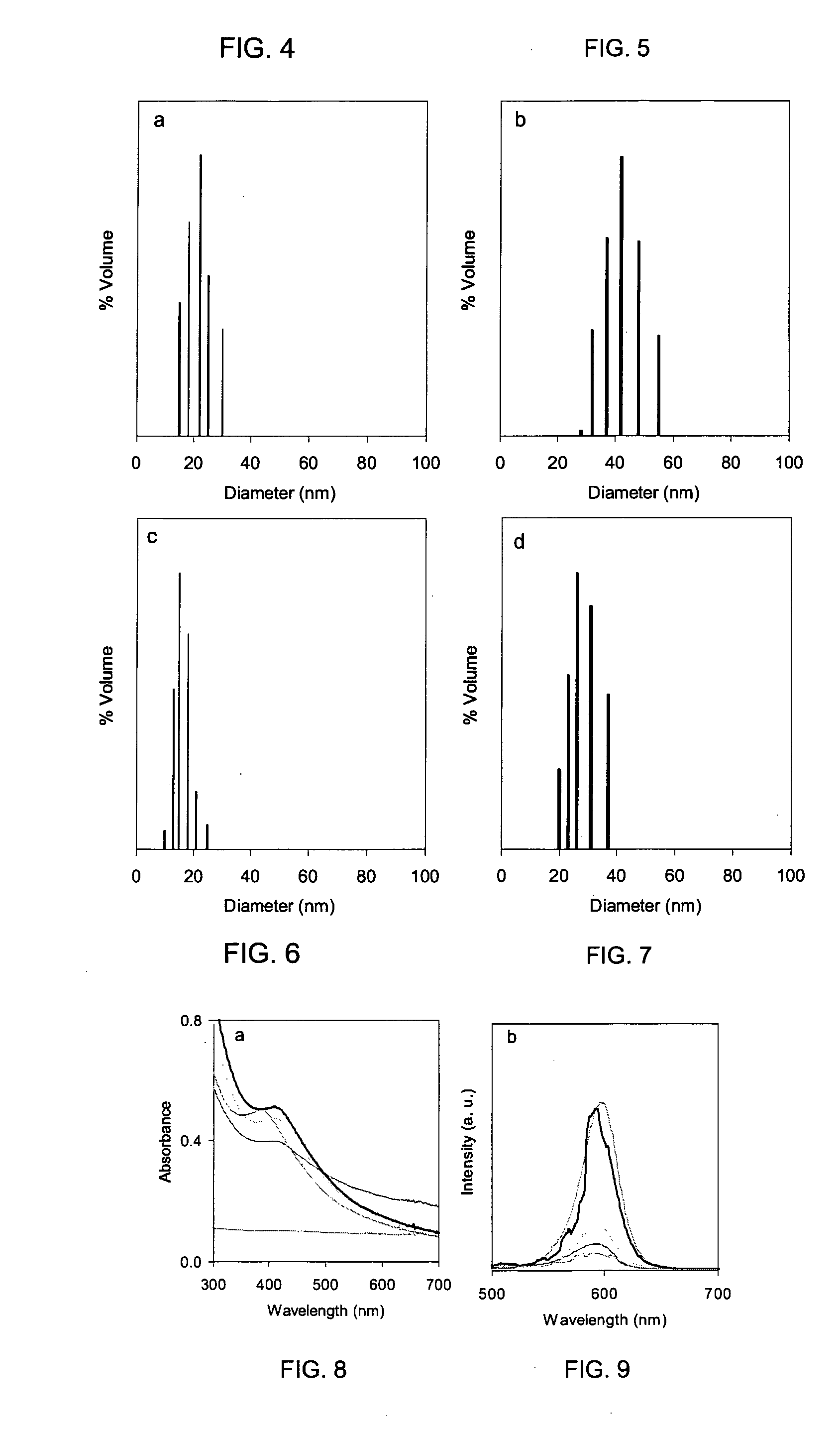

Polymerization on particle surface with reverse micelle

InactiveUS20120135141A1Simple processImprove colloidal stabilityLiquid surface applicatorsNanotechnologyCross-linkNanoparticle

A method of coating particles comprises providing a solution comprising reverse micelles. The reverse micelles define discrete aqueous regions in the solution. Hydrophobic nanoparticles are dispersed in the solution. Amphiphilic monomers are added to the solution to attach the amphiphilic monomers to individual ones of the nanoparticles and to dissolve the individual nanoparticles attached with amphiphilic monomers in the discrete aqueous regions. The monomers attached to the nanoparticles are polymerized to form a polymer layer on the individual nanoparticles within the discrete aqueous regions. The polymerization comprises adding a cross-linker to the solution to cross-link the monomers attached to the individual nanoparticles. The solution for coating individual nanoparticles may comprise a microemulsion comprising a continuous phase and a discrete aqueous region defined by reverse micelles; hydrophobic nanoparticles dispersed in the microemulsion; amphiphilic polymerizable monomers attachable to the hydrophobic nanoparticles; and a cross-linker for polymerizing the monomers.

Owner:AGENCY FOR SCI TECH & RES

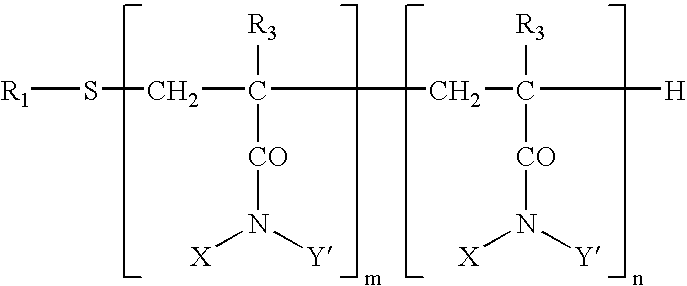

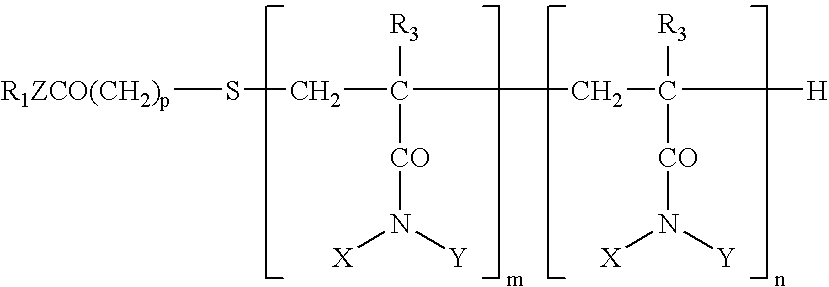

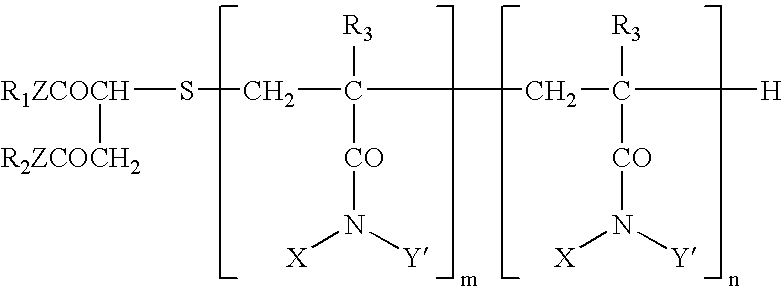

Dispersant for ink jet ink

InactiveUS6046253AIncrease surface tensionImprove colloidal stabilityInksPolyester coatingsPolyesterPigment

Owner:EASTMAN KODAK CO

Stabilized redispersible polymer powder compositions

ActiveUS20110160347A1Improve colloidal stabilityLow viscosityLayered productsWater/sewage treatment by flocculation/precipitationPolymer scienceWater insoluble

A water redispersible polymer powder may be produced by drying an aqueous mixture of a water insoluble film-forming polymer and a colloidal stabilizer comprising a chelating agent to obtain a water redispersible polymer powder, where the amount of chelating agent is at least 0.1% by weight, preferably at least 1% by weight, most preferably at least 3% by weight, based upon the weight of the water insoluble film-forming polymer. Dispersions or polymer compositions containing a chelating agent as a colloidal stabilizer exhibit an unexpectedly low viscosity which facilitates spray drying and permits use of high solids content dispersions with low pressure spray drying to increase production efficiency. The chelating agents are stable at high pH and so high pH spray dryable compositions containing them as a colloidal stabilizer may sit or be stored for prolonged periods of time prior to spray drying without loss of effectiveness of the colloidal stabilizer.

Owner:DOW GLOBAL TECH LLC

Polymer particle stabilized by dispersant and method of preparation

InactiveUS6906157B2Improve colloidal stabilityReduce needPhotosensitive materialsCoatingsWater dispersiblePolymer chemistry

A water dispersible polymer particle stabilized by a hydrophobically capped oligomeric acrylamide dispersant or a heterogeneous method for forming polymer particles comprising providing a water immiscible organic phase comprising at least one monomer dispersed in a continuous water phase and a hydrophobically capped oligomeric acrylamide, and polymerizing the organic phase to yield polymer particles stabilized with hydrophobically capped oligomeric acrylamide. Also, a heterogeneous method for forming polymer particles comprising providing a water immiscible organic dispersed in a continuous water phase, polymerizing the organic phase, and adding hydrophobically capped oligomeric acrylamide to yield polymer particles stabilized with hydrophobically capped oligomeric acrylamide.

Owner:EASTMAN KODAK CO

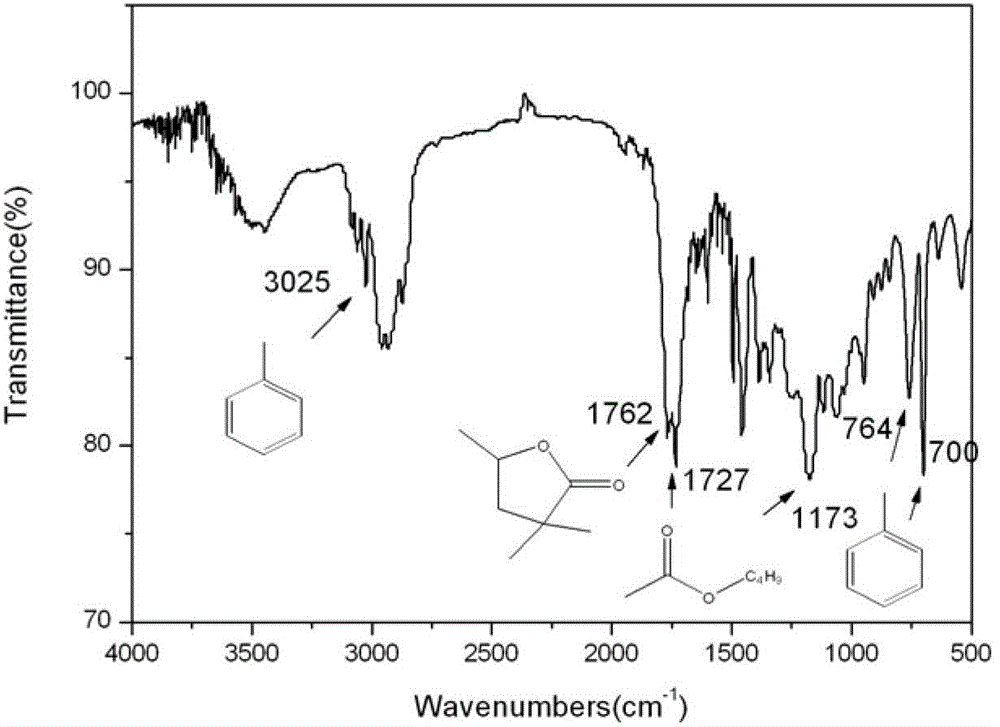

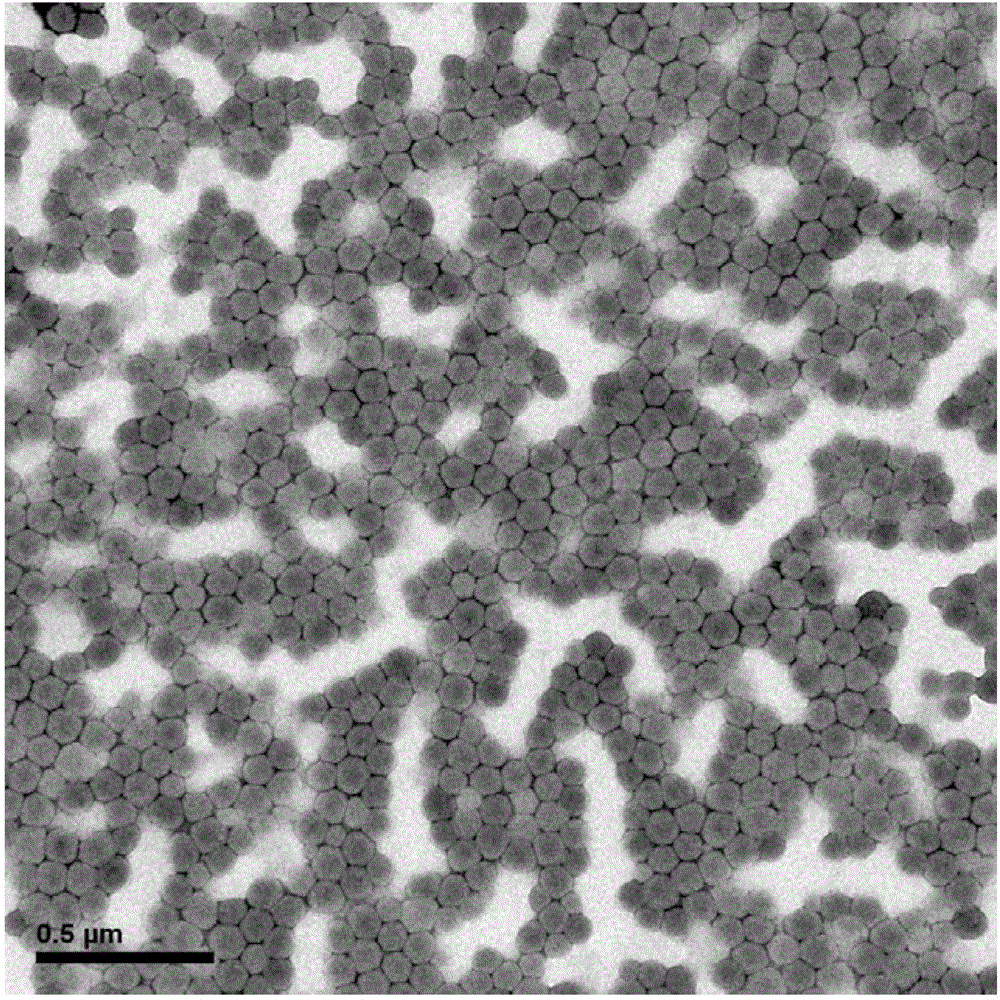

Block copolymer containing block with glass transition temperature higher than 100 DEG C and method for preparing block copolymer

The invention discloses a block copolymer containing a block with the glass transition temperature higher than 100 DEG C and a method for preparing the block copolymer. In the method, the block copolymer latex is prepared by taking n-butyl acrylate as a soft segment and the random copolymer of styrene and gamma-methyl-alpha-methylene-gamma-butyrolactone as a hard segment, adopting an emulsion polymerization system and applying a reversible addition-fragmentation chain transfer free radical polymerization technology. The method adopts simple processes and equipment, and the processes are environmental-friendly and energy-saving; an amphipathic macromolecule reversible addition-fragmentation chain transfer reagent is adopted, has the dual functions of both a chain transfer reagent and an emulsifier, not only is the good monomer polymerization control realized, but also the traditional emulsifier is prevented from being used; the reaction has no inhibition period, the reaction speed is high and the final conversion rate is high; the colloidal particles are stably increased during the process; and the glass transition temperature of the hard segment of the product can reach 155 DEG C, and the block copolymer has a good application prospect in the field of high-heat-resistance thermoplastic elastomers.

Owner:ZHEJIANG UNIV

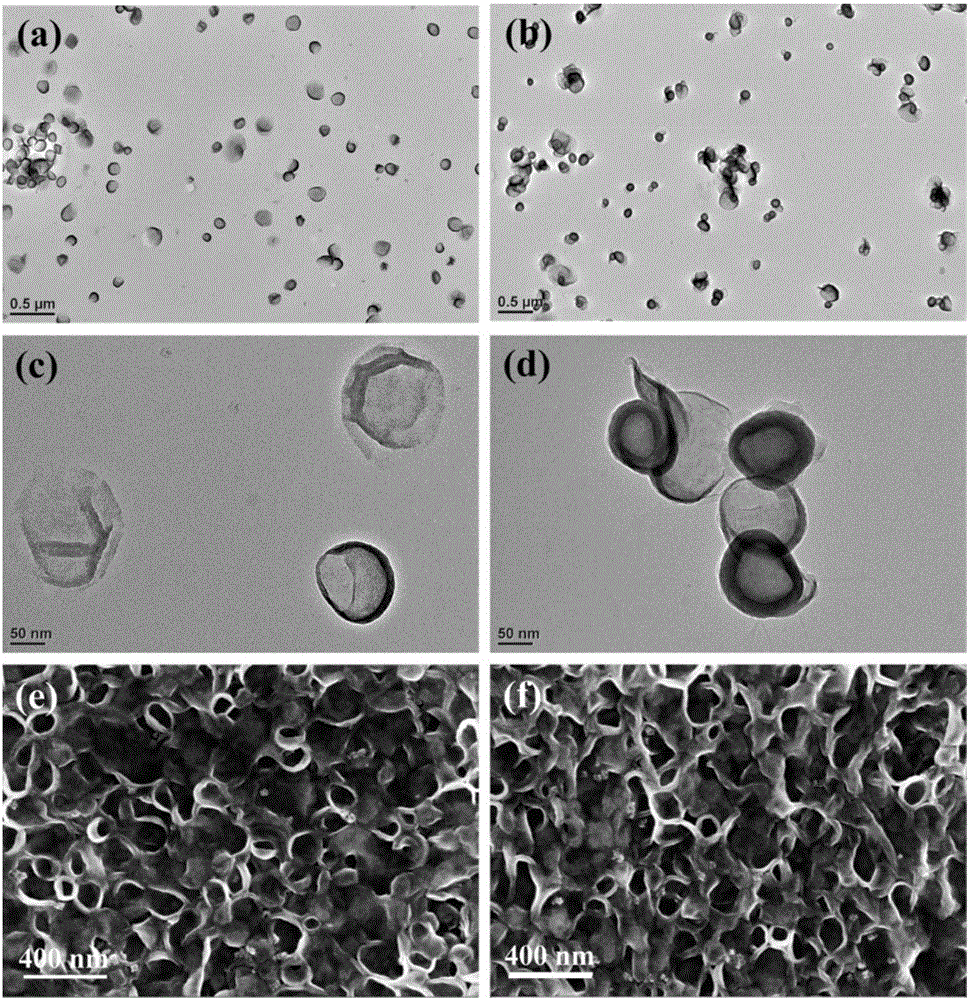

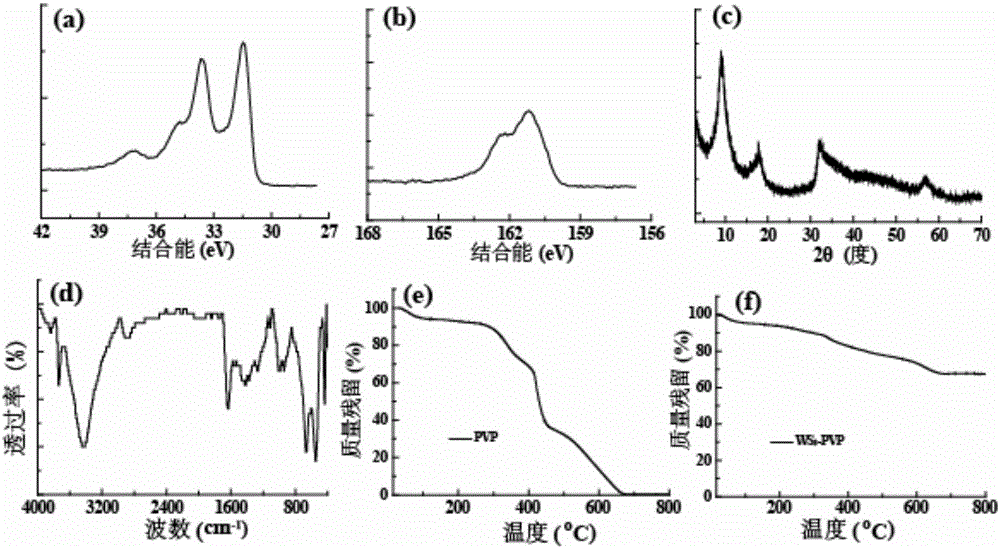

A WS2-PVP nanometer sheet, a preparing method thereof and applications of the nanometer sheet

InactiveCN106075439AConstrained growthControl shapeEnergy modified materialsGeneral/multifunctional contrast agentsPolymer dissolutionSolvent

A WS2-PVP nanometer sheet is provided. The surface of a WS2 nanometer sheet is modified with polyvinylpyrrolidone. The invention also provides a preparing method of the WS2-PVP nanometer sheet. The method includes dissolving a sulfur source and a tungsten source into a solvent, stirring to fully dissolve the sources, dissolving a polymer into the solution of the sulfur source and the tungsten source under stirring to obtain a mixed solution of the sulfur source, the tungsten source and the polymer, transferring the prepared solution to a stainless steel reaction kettle having a poly(p-phenylene) liner, reacting under a sealed condition for a certain period of time, centrifuging for separation, and cleaning the prepared product the is the two-dimensional WS2-PVP nanometer sheet the surface of which is modified with the polymer and which has good colloid stability. The invention also provides applications of the WS2-PVP nanometer sheet as a photo-thermal conversion material. The nanometer sheet has excellent photo-thermal conversion, computed tomography and photoacoustic imaging capabilities, and is expected to be used for efficient cooperative diagnosis and treatment for tumor.

Owner:UNIV OF SHANGHAI FOR SCI & TECH +1

Polymer particle stabilized by dispersant and method of preparation

Owner:EASTMAN KODAK CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com