Block copolymer containing block with glass transition temperature higher than 100 DEG C and method for preparing block copolymer

A technology of block copolymer and glass transition temperature, which is applied in the field of block copolymer materials, can solve problems such as limiting the application of materials, and achieve the effects of improving production efficiency, high conversion rate, and good control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

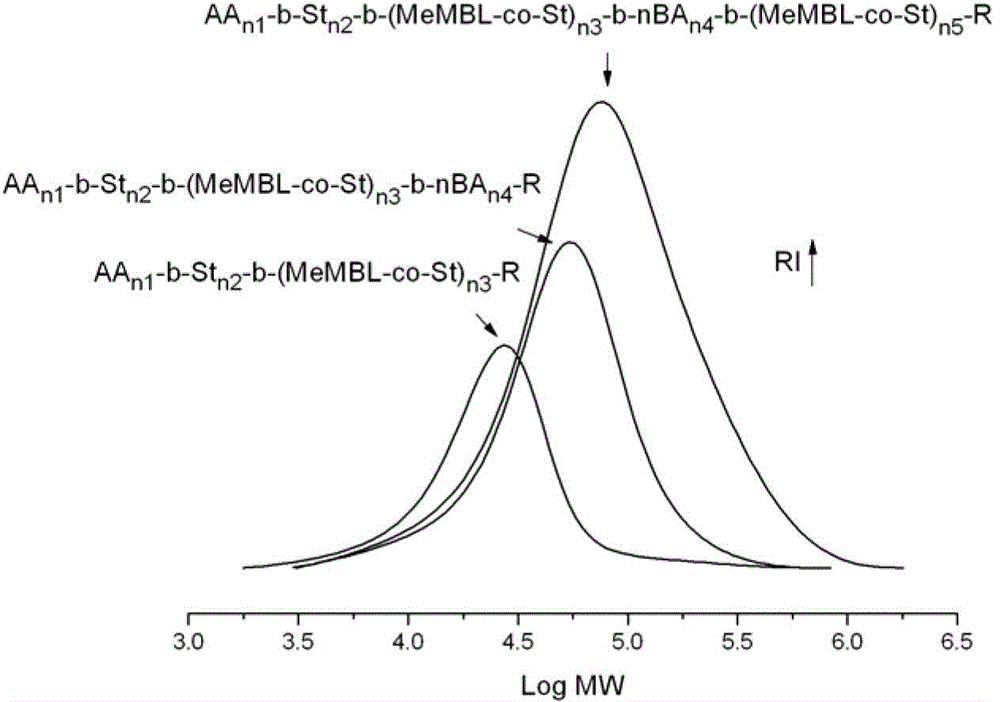

[0049] Embodiment 1 ((MeMBL-co-St) n3 -b-nBA n4 -b-(MeMBL-co-St) n5 The molecular weight of the three-block design is 30K-25K-30K, and the ratio of the number of units of MeMBL to St is 1:2):

[0050] The first step: 1.9 parts by weight of amphiphilic macromolecular reversible addition fragmentation chain transfer reagent (1) was stirred and dissolved in 85 parts by weight of water to form a uniform water phase, and then mixed with 11 parts by weight of St and 6 parts by weight of MeMBL Pour the oil phase together into the reactor and stir to mix. Raise the temperature of the reactor to 70°C, keep stirring, add 0.03 parts by weight of potassium persulfate after passing nitrogen gas for 30 minutes, add an aqueous solution containing 0.2 parts by weight of sodium hydroxide when the polymerization is initiated for 20 minutes, and continue the reaction for 20 minutes to obtain AA n1 -b-St n2 -b-(MeMBL-co-St) n3 -R polymer.

[0051] The second step: After the first step of th...

Embodiment 2

[0054] Embodiment 2 ((MeMBL-co-St) n3 -b-nBA n4 -b-(MeMBL-co-St) n5 The molecular weight of the three-block design is 30K-70K-30K, and the ratio of the number of units of MeMBL to St is 1:2):

[0055]The first step: 1.3 parts by weight of amphiphilic macromolecular reversible addition fragmentation chain transfer reagent (1) was stirred and dissolved in 62 parts by weight of water to form a uniform aqueous phase, and then mixed with 7.5 parts by weight of St and 4 parts by weight of MeMBL Pour the oil phase together into the reactor and stir to mix. Raise the temperature of the reactor to 70°C, keep stirring, add 0.02 parts by weight of potassium persulfate after passing nitrogen gas for 40 minutes, add an aqueous solution containing 0.17 parts by weight of sodium hydroxide when the polymerization is initiated for 20 minutes, and continue the reaction for 20 minutes to obtain AA n1 -b-St n2 -b-(MeMBL-co-St) n3 -R polymer.

[0056] The second step: after the first step of...

Embodiment 3

[0060] Embodiment 3 ((MeMBL-co-St) n3 -b-nBA n4 -b-(MeMBL-co-St) n5 The molecular weight of the three-block design is 30K-90K-30K, and the ratio of the number of units of MeMBL to St is 1:2):

[0061] The first step: 1.3 parts by weight of amphiphilic macromolecular reversible addition fragmentation chain transfer reagent (1) was stirred and dissolved in 62 parts by weight of water to form a uniform aqueous phase, and then mixed with 7.5 parts by weight of St and 4 parts by weight of MeMBL Pour the oil phase together into the reactor and stir to mix. Raise the temperature of the reactor to 70°C, keep stirring, add 0.02 parts by weight of potassium persulfate after passing nitrogen gas for 30 minutes, add an aqueous solution containing 0.16 parts by weight of sodium hydroxide when the polymerization is initiated for 20 minutes, and continue the reaction for 20 minutes to obtain AA n1 -b-St n2 -b-(MeMBL-co-St) n3 -R polymer.

[0062] Step 2: After the first step of reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com