Method for preparing carbon-coated lithium titanate negative electrode material for lithium battery

A carbon-coated lithium titanate and negative electrode material technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of uncontrollable molecular chain length, high equipment and environmental requirements, and different lengths, and achieve carbon chain length Uniform and controllable, uniform carbon chain length distribution, and small molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

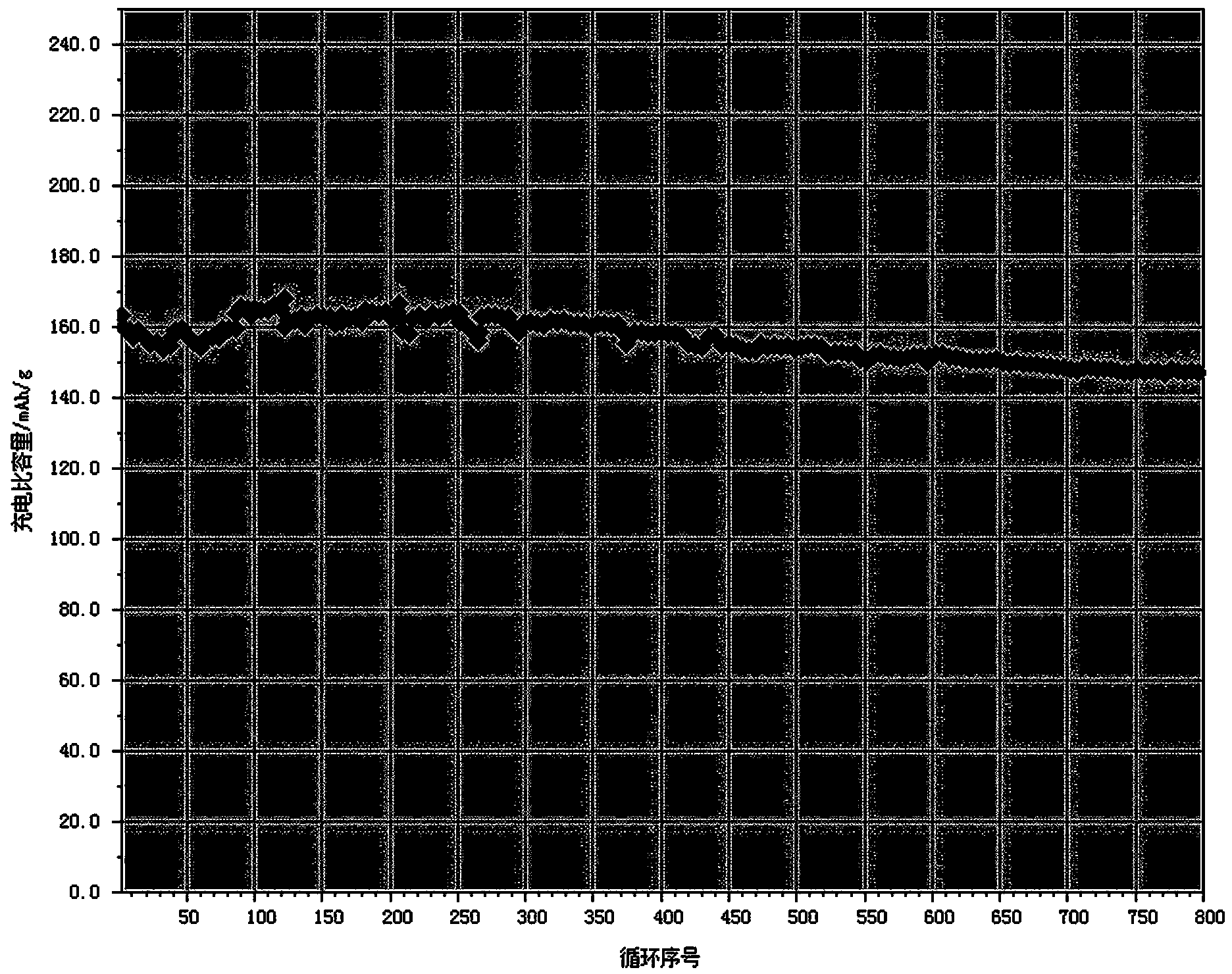

Embodiment 1

[0033] A method for preparing a carbon-coated lithium titanate negative electrode material for a lithium battery, which is prepared by the following steps:

[0034] 1) Dissolve the polymer monomer methacrylic acid, azo-type initiator azobisisobutylcyanide and trithiocarbonate in tetrahydrofuran to prepare a mixed solution, and prepare a mixed solution in a nitrogen atmosphere at 70-90 o The reaction is carried out at a temperature of C for 5-10 hours, and the reaction process is carried out in a closed reaction kettle. Wherein the molar ratio of each mixture is, methacrylic acid: azobisisobutylcyanide: trithiocarbonate=100:0.5-1: 0.01-1, the volume ratio of polymer monomer and solvent is, polymer monomer : Tetrahydrofuran=1: 1-2; Polymerization rate described in this step increases with reaction temperature and accelerates; Prepared polymer molecular weight decreases with the content increase of trithiocarbonate in the reaction raw material, increases with the reaction time a...

Embodiment 2

[0040] A method for preparing a carbon-coated lithium titanate negative electrode material for a lithium battery, which is prepared by the following steps:

[0041] 1) The polymer monomer methacrylic acid, the azo initiator azobisisoheptanonitrile and trithiocarbonate were dissolved in tetrahydrofuran to prepare a mixed solution, and the mixed solution was prepared in a nitrogen atmosphere at 80 o C temperature was reacted for 5 hours, and the reaction process was carried out in a closed reactor. Wherein the molar ratio of each mixture is, methacrylic acid: azobisisobutylcyanide: trithiocarbonate=100: 1: 0.5, the volume ratio of polymer monomer and solvent is, polymer monomer: THF=1 : 2;

[0042] 2) The solution obtained in step 1) was precipitated in methanol, and then filtered and dried to obtain a polymer.

[0043] 3) According to the molar ratio of lithium ions to titanium ions Li + : Ti + =0.8:1 Weigh lithium-containing compound lithium carbonate and titanium-containi...

Embodiment 3

[0047] A method for preparing a carbon-coated lithium titanate negative electrode material for a lithium battery, which is prepared by the following steps:

[0048] 1) The polymer monomer methyl methacrylate, the initiator azobisisobutylcyanide and trithiocarbonate were dissolved in tetrahydrofuran to prepare a solution, and the solution was prepared in a nitrogen atmosphere for 70 o C temperature for 10 hours. Wherein the molar ratio is, methyl methacrylate: azobisisobutylcyanide: trithiocarbonate=100: 0.5: 0.1, methyl methacrylate: tetrahydrofuran=1: 1.5;

[0049] 2) Precipitate the solution obtained in step 1) in methanol, then filter and dry to obtain the polymer;

[0050] 3) According to the molar ratio of lithium ions to titanium ions Li + : Ti + =0.8:1 Weigh lithium-containing compound lithium hydroxide and titanium-containing oxide rutile titanium dioxide, and weigh the polymer obtained (step 2) according to 10% of the total weight of lithium-containing compound and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com