Method for synthesizing linear high molecular weight polyphenylene sulfide

A technology of polyphenylene sulfide and high molecular weight, which is applied in the field of chemical materials, can solve the problems of difficult sulfur purification, industrialization, and technical difficulty, and achieve the effect of easy washing of metal ions, easy separation, and friendly operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

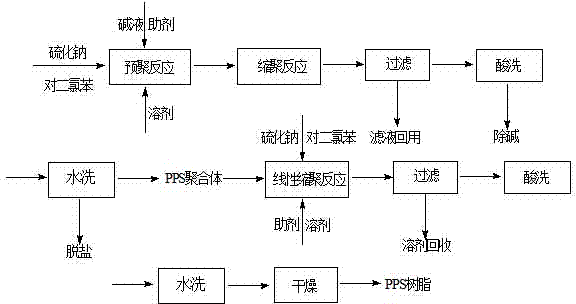

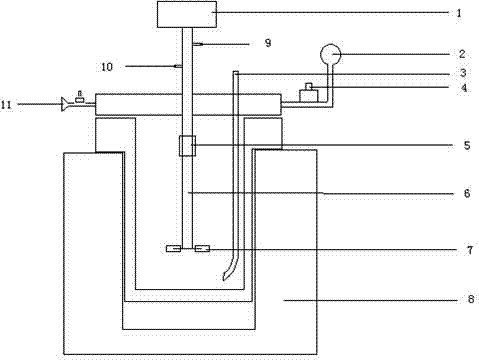

Method used

Image

Examples

Embodiment 1

[0026] Add 1.02mol sodium sulfide, 1mol p-dichlorobenzene, 1mol sodium hydroxide, 5mol solvent (N-methylpyrrolidone, N,N- Dimethylacetamide) and 0.005mol lithium chloride, under the protection of nitrogen, turn on the electricity to heat up the temperature, and carry out the prepolymerization reaction at 160°C for 1h, when the temperature rises to 220°C, stop heating, and use the reaction heat to reduce the temperature in the reactor Continue to rise, and at the same time turn on the cooling water to adjust and control the temperature in the reactor. Under the conditions of temperature 240 ° C and pressure 1 MPa, the polycondensation reaction is carried out for 1 hour and then ends. After the reaction kettle was cooled down and the pressure was relieved, the reaction slurry was cooled to 100°C, filtered, and the filter cake was washed once with hydrochloric acid and deionized water once, and the obtained polyphenylene sulfide polymer was mixed with 1mol sodium sulfide, 1mol Ch...

Embodiment 2

[0028]Add 1.02mol sodium sulfide, 1mol p-dichlorobenzene, 1.1mol potassium hydroxide, 6mol solvent (N-methylpyrrolidone, hexamethyl Phosphoric triamide) and 0.006mol calcium chloride, under the protection of nitrogen, turn on the electricity to heat up, and carry out the prepolymerization reaction at 170°C for 1.5h. When the temperature rises to 220°C, stop heating, and use the heat of reaction to reduce the temperature in the reactor Continue to rise, and at the same time turn on the cooling water to adjust and control the temperature in the reactor. Under the conditions of temperature 250°C and pressure 1.2MPa, the polycondensation reaction is carried out for 1.5h and then ends. After the reaction kettle was cooled down and the pressure was relieved, the reaction slurry was cooled to 105°C, filtered, the filter cake was washed twice with hydrochloric acid and once with deionized water, and the obtained polyphenylene sulfide polymer was mixed with 1mol sodium sulfide, 1mol p ...

Embodiment 3

[0030] Add 1.03mol sodium sulfide, 1mol p-dichlorobenzene, 1.2mol calcium hydroxide, 7mol solvents (N-methylpyrrolidone, pyridine) and 0.006mol Potassium Chloride, under the protection of nitrogen, turn on the electricity to heat up the temperature, and carry out the prepolymerization reaction at 180°C for 2 hours. When the temperature rises to 220°C, stop heating, use the heat of reaction to continue to rise the temperature in the reactor, and turn on the cooling water at the same time In order to adjust and control the temperature in the reactor, under the conditions of temperature 260° C. and pressure 1.3 MPa, the polycondensation reaction was carried out for 2 hours and then ended. After the reaction kettle was cooled and the pressure was relieved, the reaction slurry was cooled to 110°C, filtered, the filter cake was washed twice with hydrochloric acid and twice with deionized water, and the obtained polyphenylene sulfide polymer was mixed with 1mol sodium sulfide, 1mol C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com