Poly-allylamine oriented platinum nano cube preparation method

A technology of polyallylamine and polyallylamine hydrochloride, which is applied in the field of preparation of platinum nanoparticles, can solve the problems of reducing platinum and the scarcity of platinum reserves, and achieves uniform size, simple preparation method, and simple preparation method easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of polyallylamine-oriented platinum nanocubes, comprising the following steps:

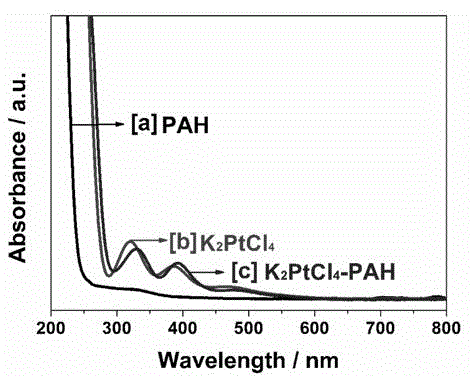

[0027] (1) Pipette 1.0 ml 0.5 M polyallylamine hydrochloride (PAH, molecular weight 150,000) solution (Note: the concentration value is calculated based on monomer concentration) and 2.0 ml 0.025 M K 2 PtCl 4 solution, ultrasonically mixed, adjusted to pH 3.0 with 0.1M NaOH solution under stirring, and left to stand for half an hour to obtain clear PAH-Pt II complex solution.

[0028] (2) To PAH-Pt II Add 0.1ml HCHO (40%wt aqueous solution, the same below) to the complex solution, then put it into a hydrothermal reaction kettle; place the reaction kettle in a drying oven at 140°C to make PAH-Pt II The complex reacts completely with the reducing agent, the metal Pt II After ion reduction, a black suspension was obtained.

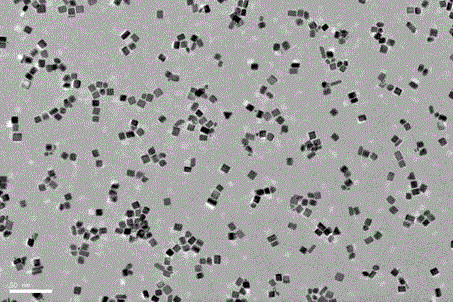

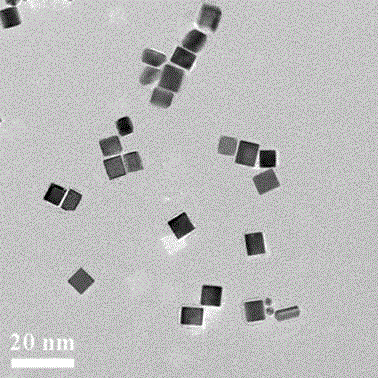

[0029] (3) Then the black suspended matter is centrifuged, washed, and dried in a vacuum oven to obtain the cubic platinum nanoparticles with go...

Embodiment 2

[0031] A preparation method of polyallylamine-oriented platinum nanocubes, comprising the following steps:

[0032] (1) Pipette 1.0 ml 0.5 M polyallylamine hydrochloride (PAH, molecular weight 150,000) solution (Note: the concentration value is calculated based on monomer concentration) and 2.0 ml 0.025 M K 2 PtCl 4 solution, ultrasonically mixed, adjusted to pH 6.0 with 0.1M NaOH solution under stirring, and left to stand for half an hour to obtain clear PAH-Pt II complex solution.

[0033] (2) To PAH-Pt II Add 0.1ml HCHO (40%) to the complex solution, then put it into a hydrothermal reaction kettle; place the reaction kettle in a drying oven at 140°C to make PAH-Pt II The complex reacts completely with the reducing agent, the metal Pt II After ion reduction, a black suspension was obtained.

[0034] (3) Then the black suspended matter is centrifuged, washed, and dried in a vacuum oven to obtain the cubic platinum nanoparticles with good dispersion and stability.

Embodiment 3

[0036] A preparation method of polyallylamine-oriented platinum nanocubes, comprising the following steps:

[0037] (1) Pipette 1.0 ml 0.5 M polyallylamine hydrochloride (PAH, molecular weight 150,000) solution (Note: the concentration value is calculated based on monomer concentration) and 2.0 ml 0.025 M K 2 PtCl 4 solution, ultrasonically mixed, adjusted to pH 9.0 with 0.1M NaOH solution under stirring, and allowed to stand for half an hour to obtain clear PAH-Pt II complex solution.

[0038] (2) To PAH-Pt II Add 0.1ml HCHO (40%) to the complex solution, then put it into a hydrothermal reaction kettle; place the reaction kettle in a drying oven at 140°C to make PAH-Pt II The complex reacts completely with the reducing agent, the metal Pt II After ion reduction, a black suspension was obtained.

[0039] (3) Then the black suspended matter is centrifuged, washed, and dried in a vacuum oven to obtain the cubic platinum nanoparticles with good dispersion and stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com