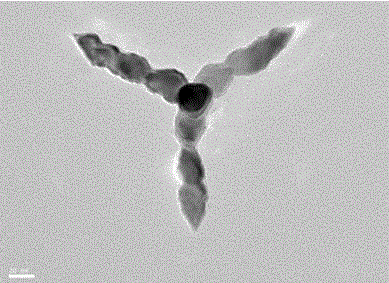

Method for preparing three-legged snail-shaped nano-palladium

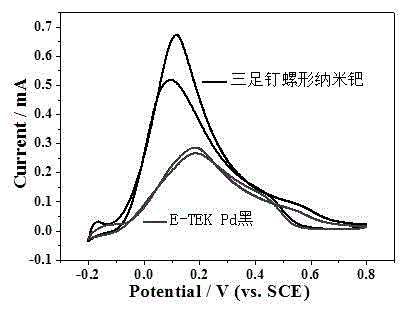

A technology of nano-palladium and snails, which is applied in the field of preparation of palladium nanoparticles, can solve the problems of reducing the scarcity of palladium and palladium reserves, and achieve the effects of simple preparation method, excellent electrocatalytic activity and stability, and simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method for tripod screw-shaped nano-palladium, comprising the following steps:

[0029] (1) Pipette 0.2 mL of 0.05 M ethylenediaminetetramethylenephosphonic acid (EDTMPA) solution and 0.12 mL of 0.05 M PdCl 2 solution, ultrasonically mixed to obtain EDTMPA-Pd II complex solution.

[0030] (2) To EDTMPA-Pd II 0.01 g of PVP and 0.5 mL of HCHO (40% wt aqueous solution, the same below) were added to the complex solution, and 7 mL of deionized water was added.

[0031] (3) Adjust the pH to 7 with 0.1 M NaOH solution under stirring, and then move it into a hydrothermal reaction kettle; place the reaction kettle in a drying oven at 140°C to make EDTMPA-Pd II The complex reacts completely with the reducing agent HCHO, and the metal Pd II After ion reduction, a black suspension was obtained, which was the target product.

[0032] (4) The product is then centrifuged, washed, and then dried in a vacuum oven to obtain the tripod helical nano-palladium.

Embodiment 2

[0034] A preparation method for tripod screw-shaped nano-palladium, comprising the following steps:

[0035] (1) Pipette 1.0 mL 0.05 M ethylenediaminetetramethylenephosphonic acid (EDTMPA) and 0.6 mL 0.05 M PdCl 2 solution, ultrasonically mixed to obtain EDTMPA-Pd II complex solution.

[0036] (2) To EDTMPA-Pd II Add 0.01 g PVP and 0.5 mL HCHO (40%) to the complex solution, and add 7 mL deionized water.

[0037] (3) Adjust the pH to 7 with 0.1 M NaOH solution under stirring, and then move it into a hydrothermal reactor; place the reactor in a drying oven at 140°C to make EDTMPA-Pd II The complex reacts completely with the reducing agent HCHO, and the metal Pd II After ion reduction, a black suspension was obtained, which was the target product.

[0038] (4) The product is then centrifuged, washed, and then dried in a vacuum oven to obtain the tripod helical nano-palladium.

Embodiment 3

[0040] A preparation method for tripod screw-shaped nano-palladium, comprising the following steps:

[0041] (1) Pipette 2.0 mL 0.05 M ethylenediaminetetramethylenephosphonic acid (EDTMPA) and 1.2 mL 0.05 M PdCl 2 solution, ultrasonically mixed to obtain EDTMPA-Pd II complex solution.

[0042] (2) To EDTMPA-Pd II Add 0.01 g PVP and 0.5 mL HCHO (40%) to the complex solution, and add 7 mL deionized water.

[0043] (3) Adjust the pH to 7 with 0.1 M NaOH solution under stirring, and then move it into a hydrothermal reactor; place the reactor in a drying oven at 140°C to make EDTMPA-Pd II The complex reacts completely with the reducing agent HCHO, and the metal Pd II After ion reduction, a black suspension was obtained, which was the target product.

[0044] (4) The product is then centrifuged, washed, and then dried in a vacuum oven to obtain the tripod helical nano-palladium.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com