Water soluble carbon nano tube of grafting phosphorylcholine and preparing method

A technology of grafting phosphorylcholine and carbon nanotubes, which is applied in the field of nanometers, can solve the problems of difficult application and poor biocompatibility of azo dyes, and achieve the effects of stable water solubility, obvious water solubility, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

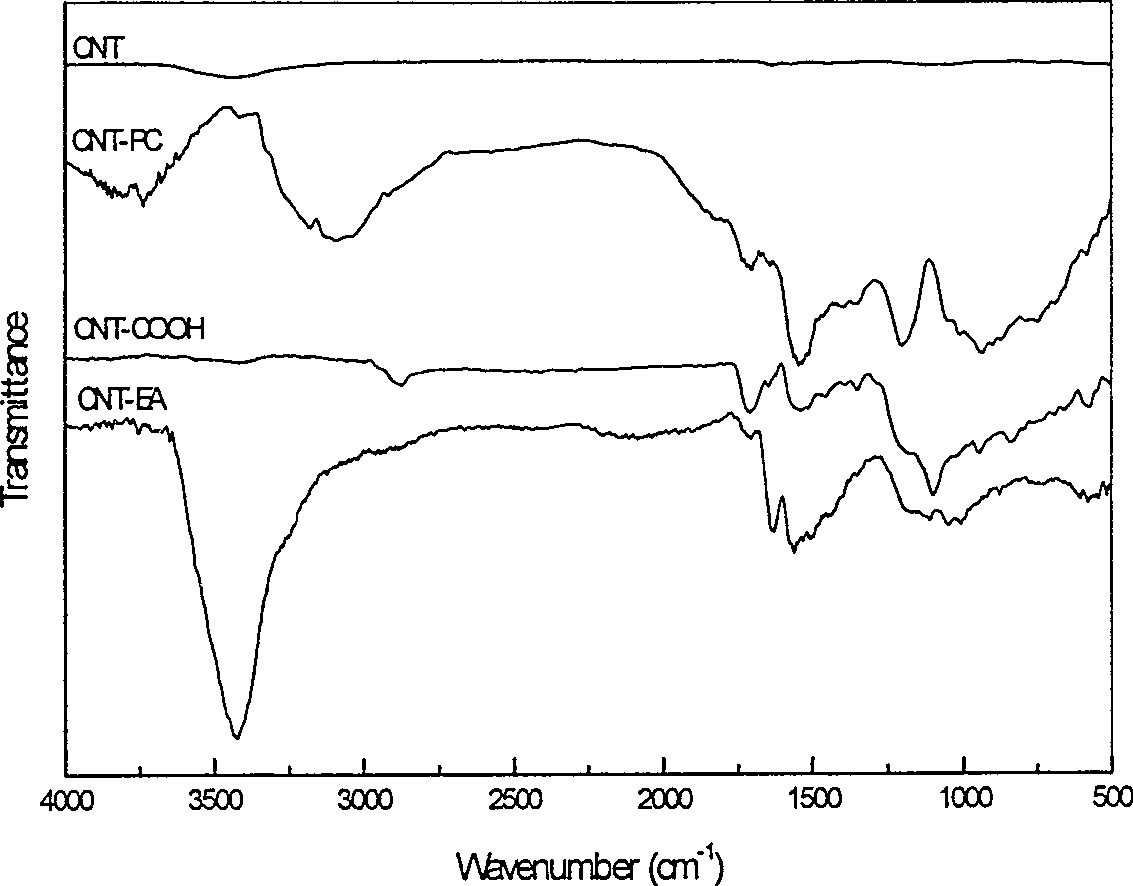

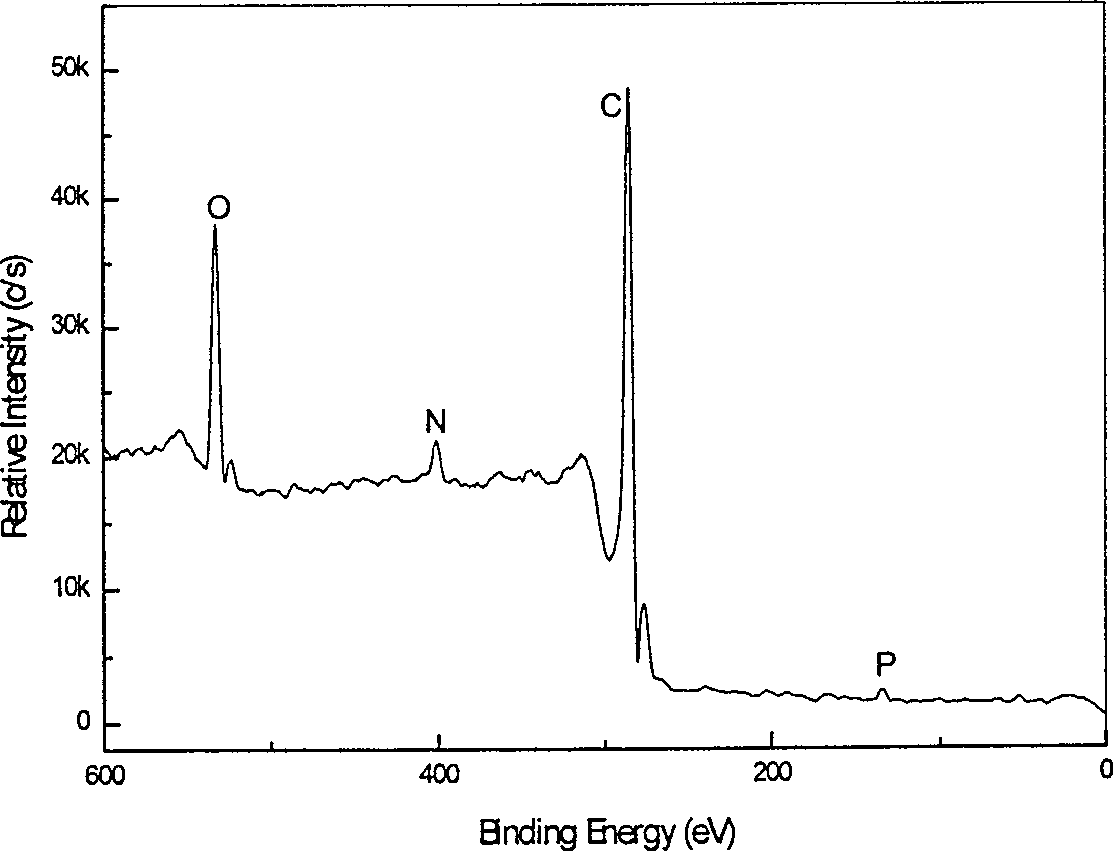

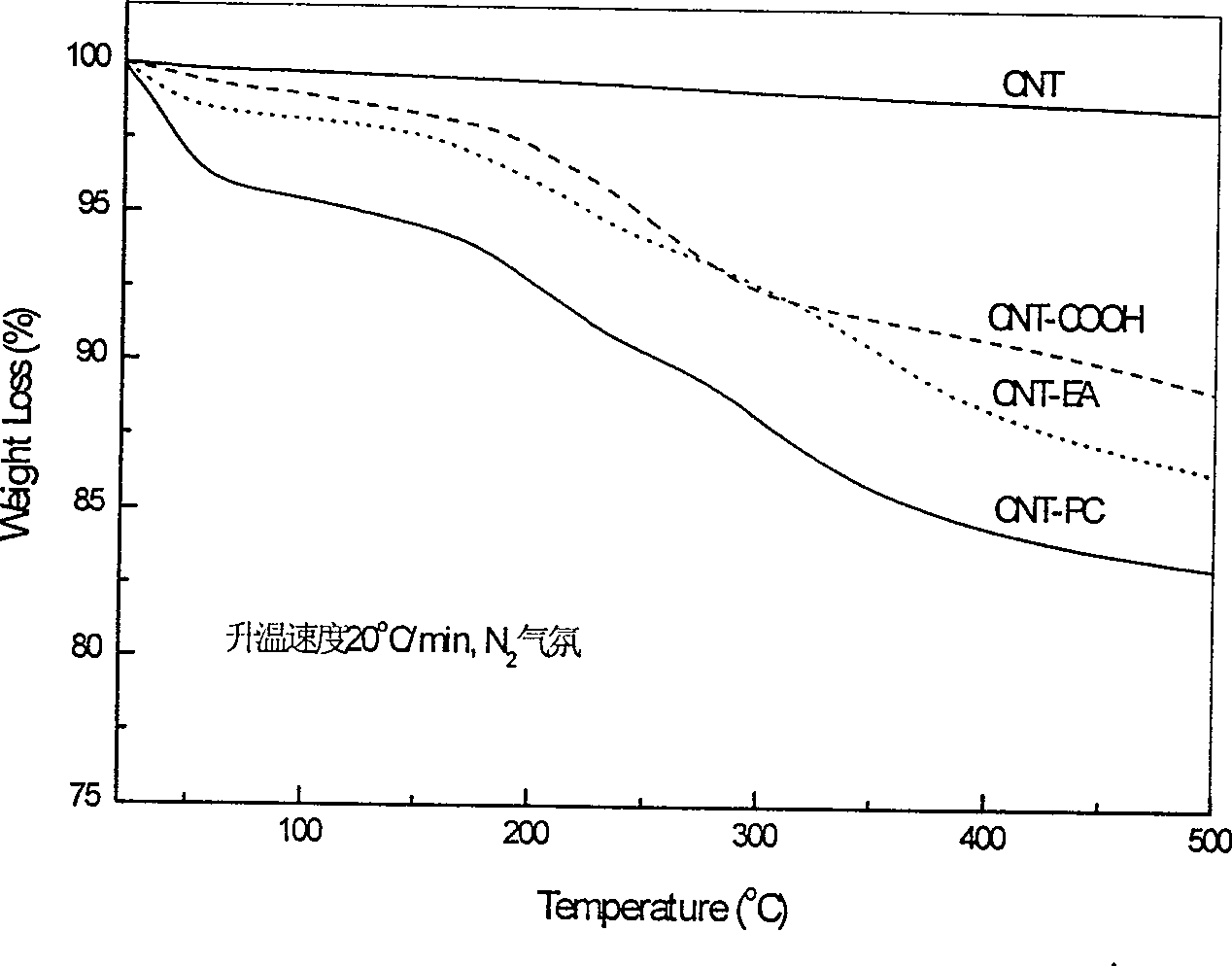

Embodiment 1

[0030] The first step, acidification of carbon nanotubes: take 2 g of multi-walled carbon nanotubes and put them in a flask, add 75 mL of concentrated sulfuric acid and 25 mL of concentrated nitric acid, and use an ultrasonic cleaner (power 50W to 1000W is acceptable) for 24 hours after ultrasonic treatment at room temperature Centrifuge, pour off the upper layer of acid solution, add 50mL of distilled water, centrifugal separation after ultrasonic dispersion, pour off the supernatant liquid, repeat this process until the pH value of the clear liquid is neutral, centrifuge to obtain a solid, and vacuum dry to obtain acidified Carbon nanotube CNT-COOH 1.9g.

[0031] The second step, the acid halide of acidified carbon nanotubes: take the acidified carbon nanotubes CNT-COOH in the first step and put them in a flask, add 30mL of thionyl chloride dropwise, ultrasonically disperse for 3 hours, then raise the temperature to 70°C under stirring and reflux React for 24 hours. After t...

Embodiment 2

[0037] The same process as in Example 1, except that the multi-walled carbon nanotubes were replaced with single-walled carbon nanotubes, obtained water-soluble single-walled carbon nanotubes grafted with phosphorylcholine.

Embodiment 3

[0039] Same as Example 1, except that the acidification of carbon nanotubes in the first step does not require ultrasonic treatment, but adopts the method of heating and refluxing at 70° C. (50-120° C.) for 24 hours to obtain grafted phosphorylcholine Water-soluble carbon nanotubes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com