Patents

Literature

131results about How to "High printing durability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Radiation curable inkjet recording ink, and method of producing planographic printing plate using same, and ink composition, inkjet recording method, printed material, method of producing a planographic printing plate, and planographic printing plate

InactiveUS20060128823A1High sensitivityFast curingInksForme preparationRadiation exposureColoring agents

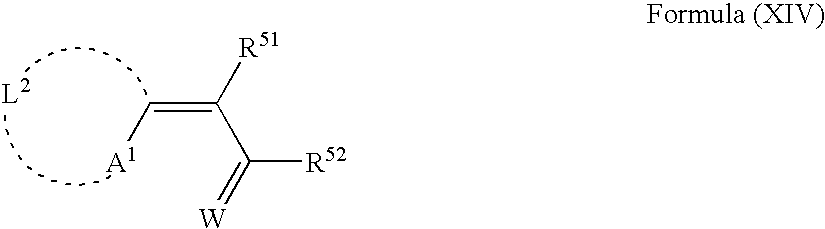

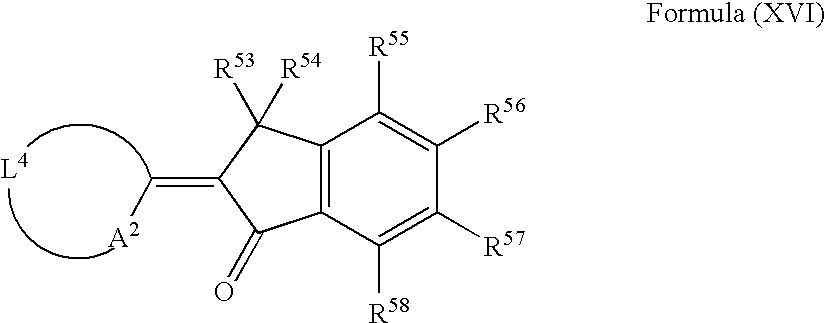

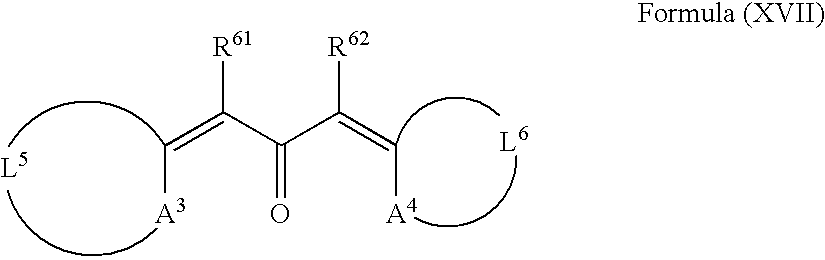

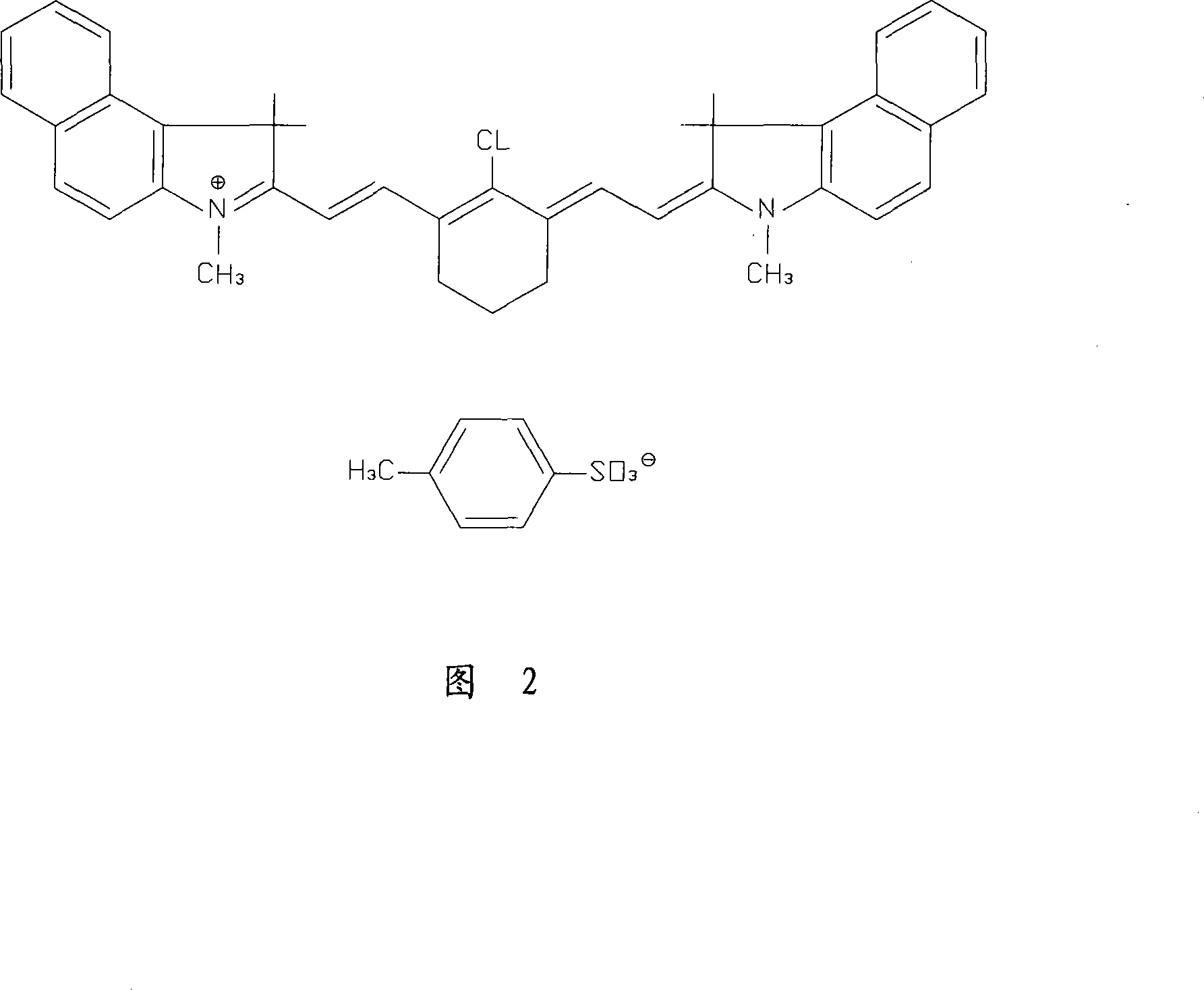

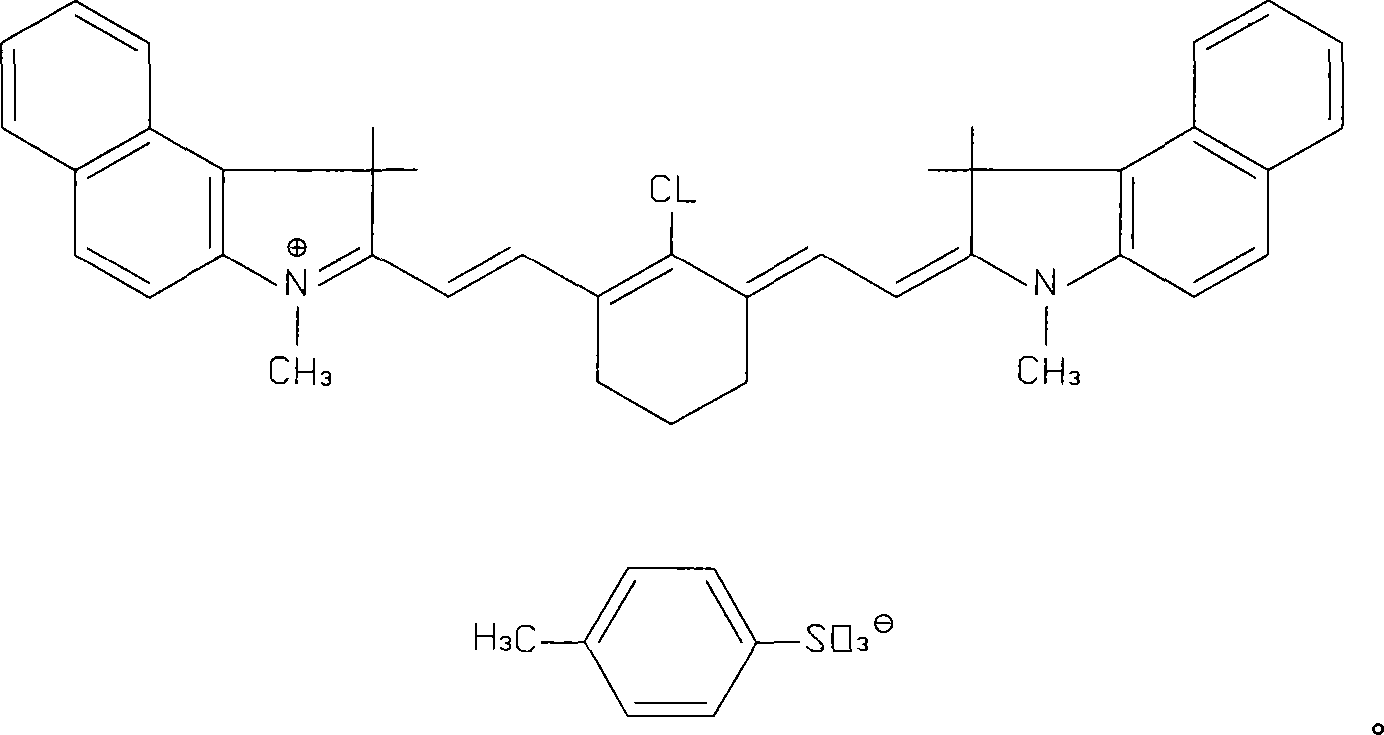

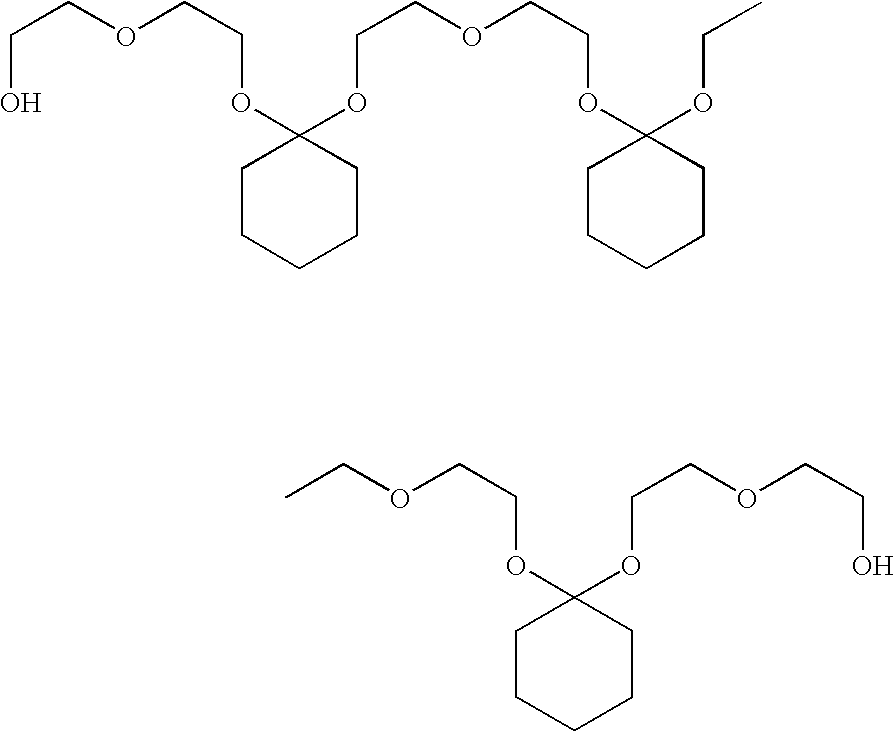

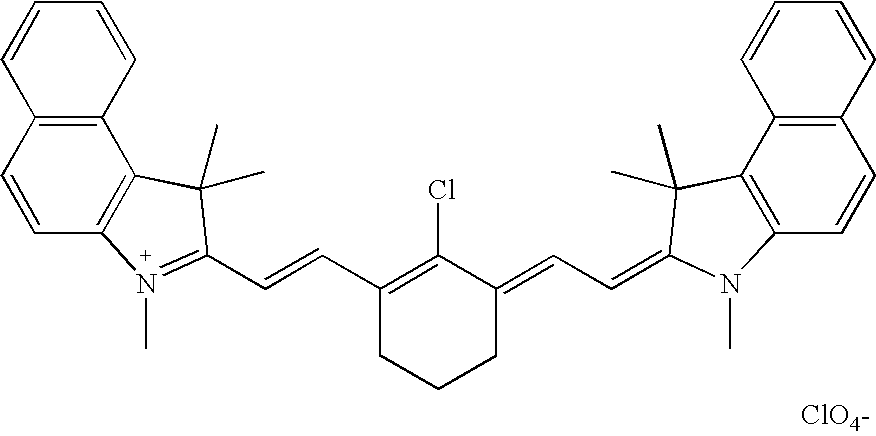

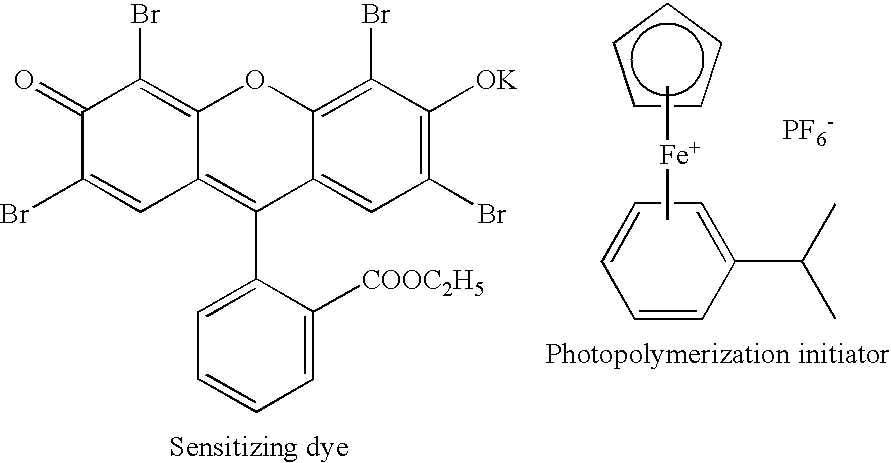

The invention provides an inkjet recording ink which is curable by radiation irradiation containing a colorant, a polymerizable compound, and a polymerization initiation system, wherein the polymerization initiation system contains a sensitizing dye including one or more compounds selected from compounds represented by any one of formula (XIV) and formulae (XVI) to (XXVI) and a polymerization initiator; and a method of producing a planographic printing plate to obtain a hydrophobic image by ejecting the ink onto a hydrophilic support, and by irradiating radiation. Moreover, the invention provides an ink composition containing a sensitizing dye including a specific skeleton or a sensitizing dye represented by formula (1), a polymerizable compound, and a polymerization initiator; an inkjet recording method using the same; a printed material; a planographic printing plate; and a method of producing a planographic printing plate.

Owner:FUJIFILM CORP +1

Method for making positive working printing plates from a lithographic base comprising a flexible support having a hardened hydrophilic substrate

InactiveUS6033740AHigh acceptanceExcellent lithographic printing plateDuplicating/marking methodsPretreated surfacesCross-linkEngineering

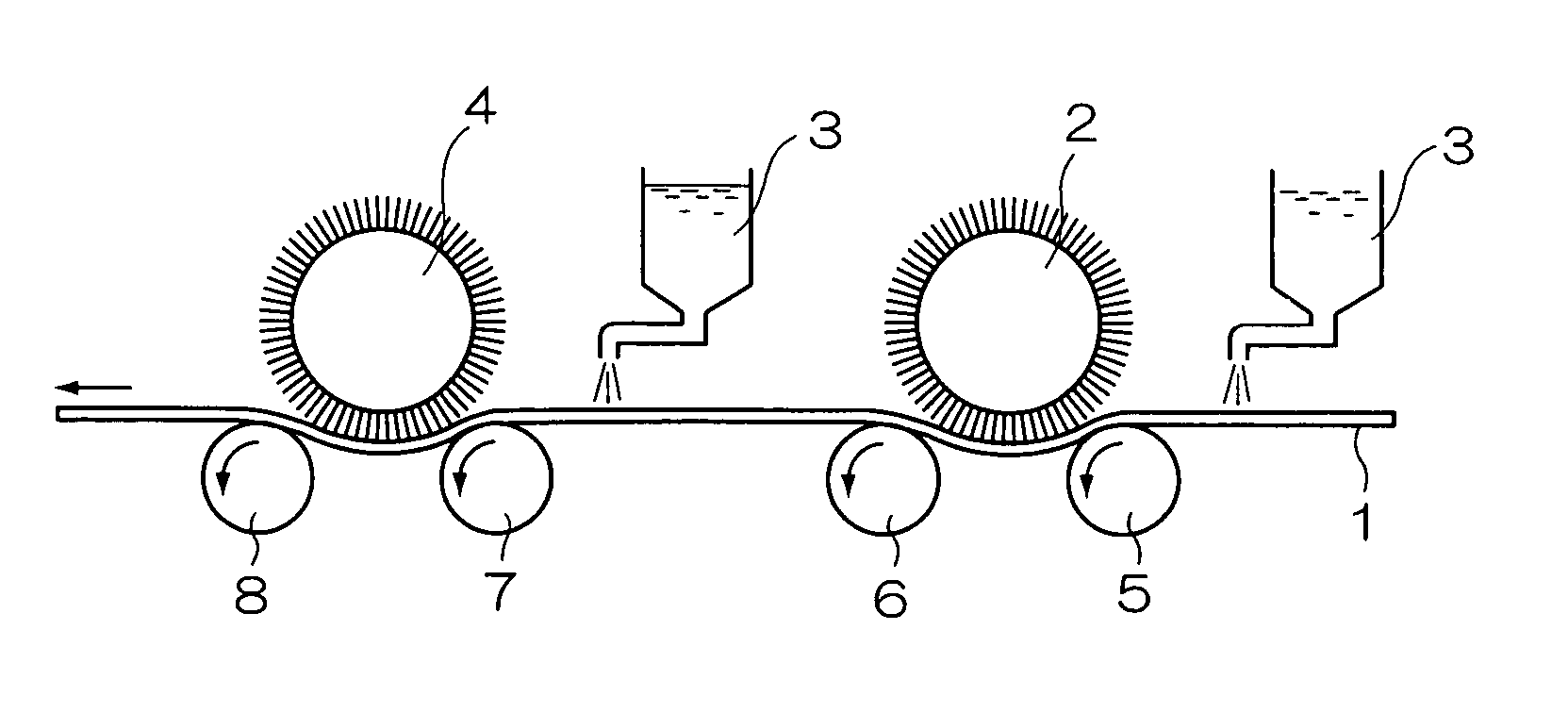

According to the present invention there is provided a method for making lithographic printing plates including the steps of dispensing in a predetermined pattern curable hydrophobic ink from a printhead of a printer onto a lithographic base or polymerizable ink from a printhead of a printer onto a lithographic base which is coated with a polymerization initiator by spraying droplets of the ink onto the lithographic base in the predetermined pattern and curing the sprayed droplets of the ink upon the lithographic base, characterized in that the lithographic base comprises a flexible support having a cross-linked hydrophilic surface.

Owner:AGFA NV

Planographic printing plate precursor

InactiveUS20050069812A1High printing durabilityGood chemical resistanceSilver salt compositionsLithographySolubilityHydrogen

The present invention provides a planographic printing plate precursor including a support, and a recording layer which is formed on the support and includes a water-insoluble and alkali-soluble resin having active hydrogen in a main chain thereof and an infrared absorbent, the solubility of the recording layer in an aqueous alkaline solution being increased by exposure to light; and a planographic printing plate precursor including a support, and a recording layer formed on the support, wherein the recording layer includes a lower layer which is formed on the support and includes a water-insoluble and alkali-soluble resin having active hydrogen in a main chain thereof, and an upper layer which is formed on the lower layer and includes a water-insoluble and alkali-soluble resin and a development inhibitor, the solubility of the upper layer in an aqueous alkaline solution being increased by exposure to light, and at least one of the lower layer and the upper layer of the recording layer includes an infrared absorbent. According to the invention, there is provided is a positive planographic printing plate precursor which can provide a printing plate directly from scanning exposure based on digital signals and is excellent in printing durability and chemical resistance.

Owner:FUJIFILM CORP +1

Lithographic-printing plate precursor and image forming method using the same

InactiveUS20090208869A1High printing durabilityWide development latitudePhotosensitive materialsRadiation applicationsImage recordingAqueous solution

To provide an infrared-sensitive or heat-sensitive lithographic printing plate precursor which has high printing durability and wide development latitude, and also has good developing properties capable of preventing the formation of deposits during the development. In an infrared-sensitive or heat-sensitive lithographic printing plate precursor, comprising a substrate, a first image recording layer formed on the substrate, and a second image recording layer formed on the first image recording layer, the first image recording layer contains a resin which is soluble or dispersible in an aqueous alkali solution, and the second image recording layer contains a polyurethane which has a substituent having an acidic hydrogen atom.

Owner:EASTMAN KODAK CO

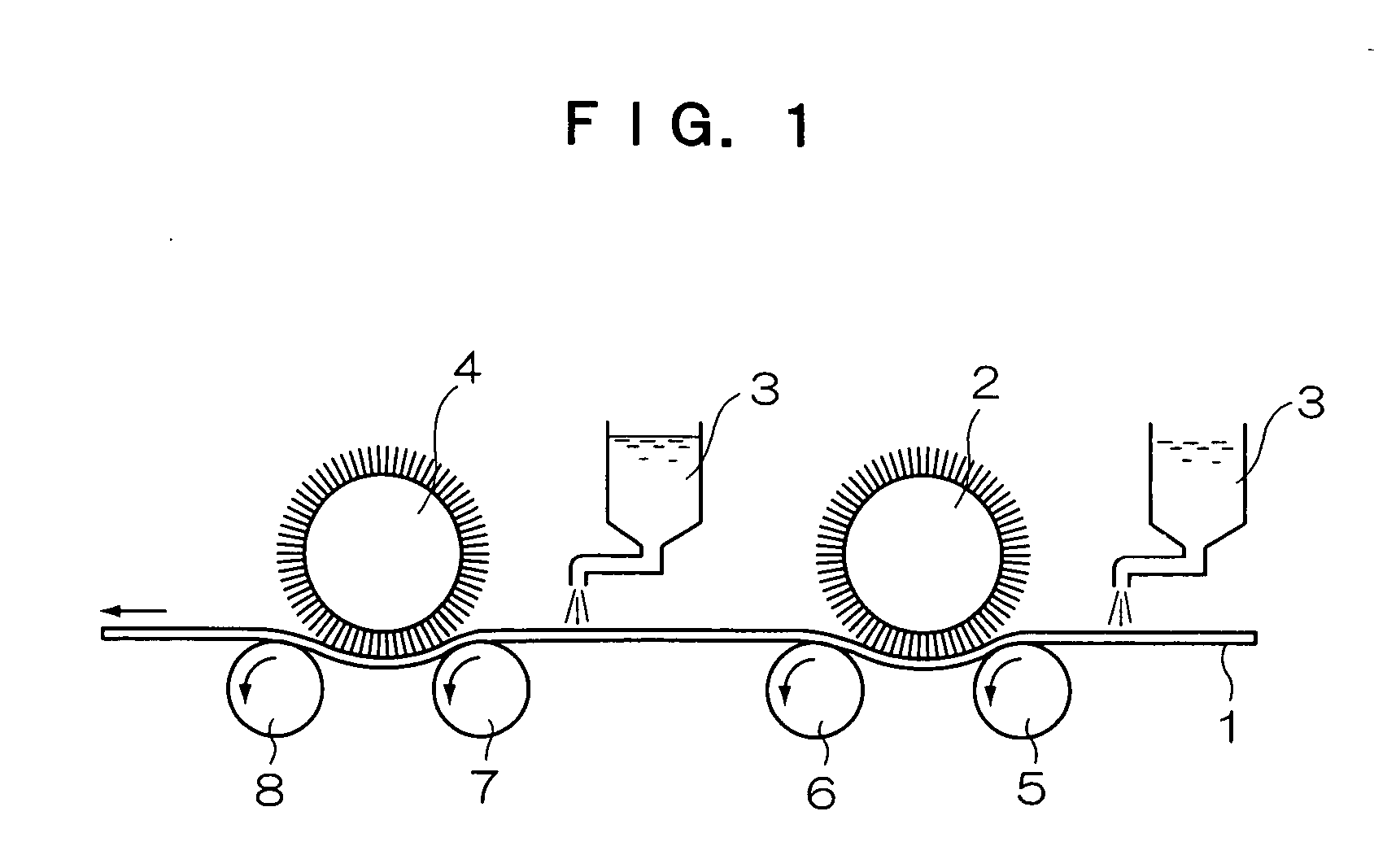

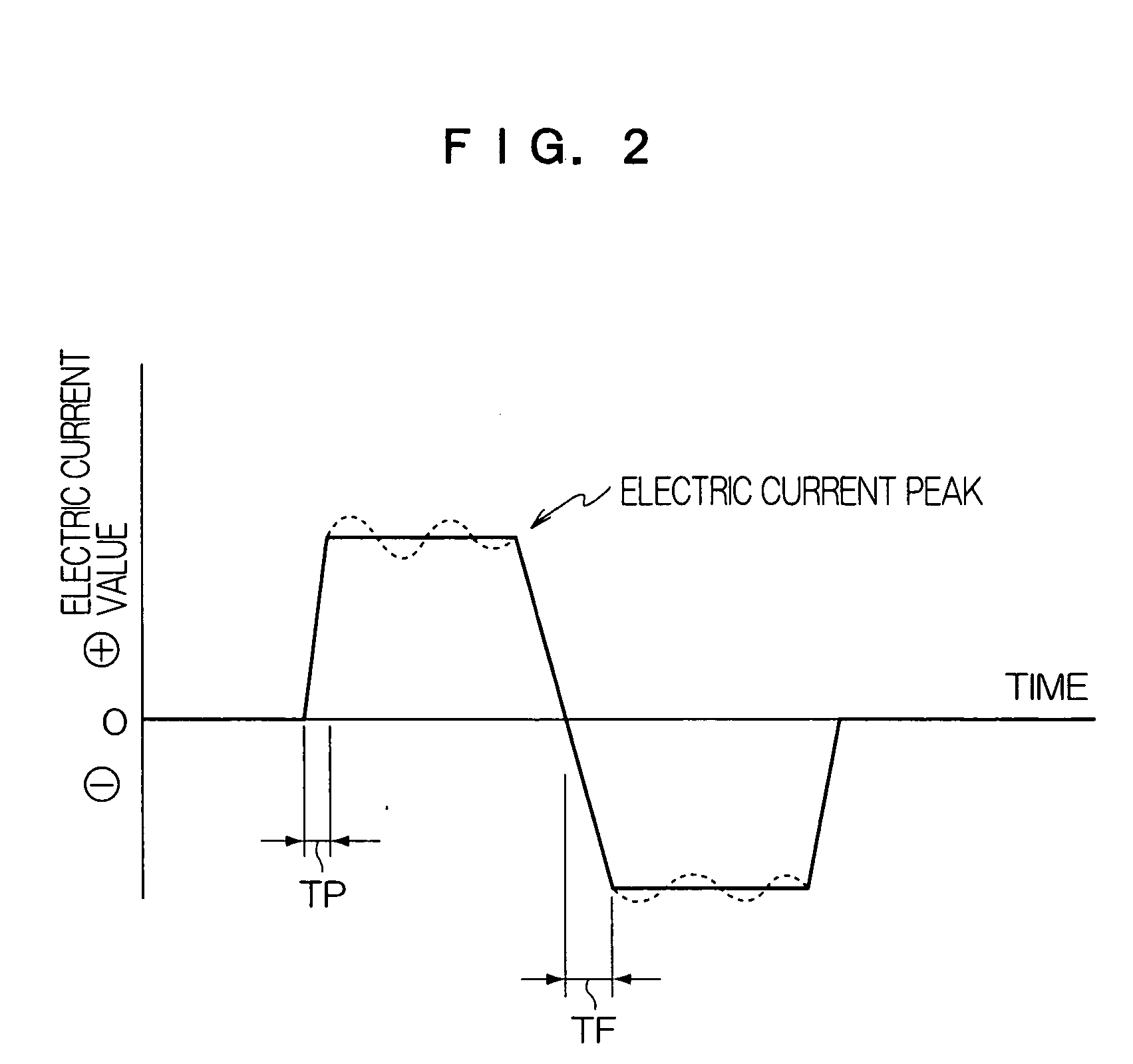

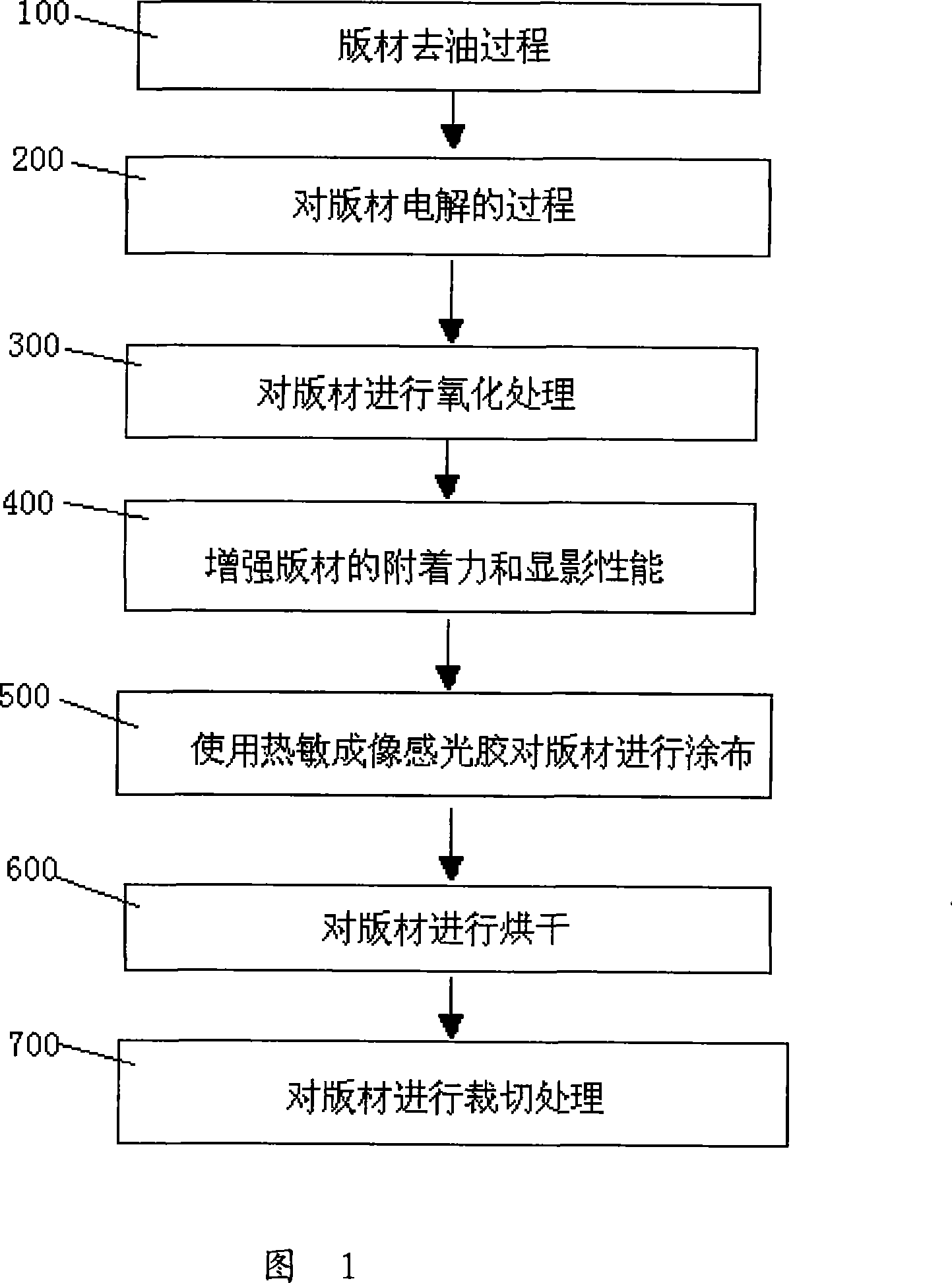

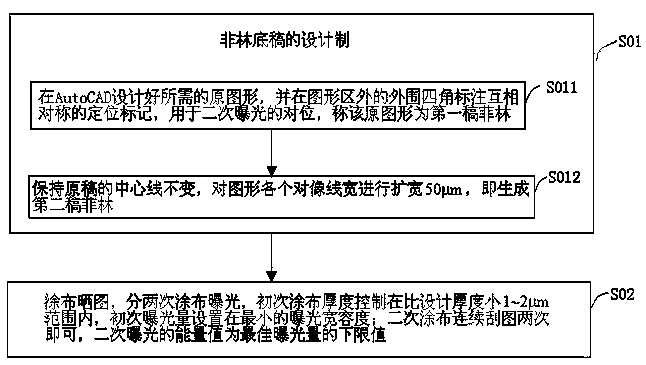

Method for manufacturing printing plate

InactiveCN101168315AGood printabilityStable ink balanceThermographyPrinting pre-treatmentDecompositionMeasuring instrument

The invention discloses a method for manufacturing a printing plate, which includes electrolysis of grains, oxidation, coating with heat-sensitive photoresist and subsequent drying process, wherein the heat-sensitive photoresist is decomposed by alkali after being irradiated, electrolyzed During the process, a substrate surface roughness with a maximum valley depth of 2.5 microns is produced, wherein the maximum valley depth is measured with a surface roughness meter and is called the Rv value. The beneficial technical effects of the present invention are: the produced plates can not only be stored stably for several months under the condition that the maximum temperature exceeds at least 40°C, but also its plate-making time is relatively short, the printing quality is excellent, and the process of the method has great impact on production. There are no other special requirements for the equipment, and the produced plates have excellent printing performance and stable water-ink balance.

Owner:李伟 +3

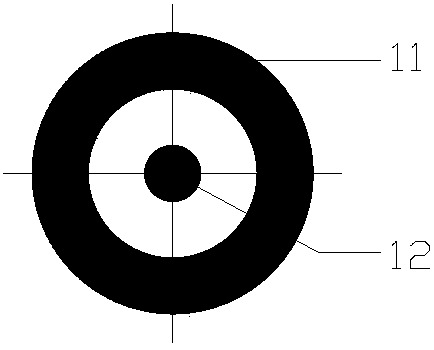

High-precision printing circular screen photographic emulsion and preparation method thereof

ActiveCN102436143AImprove bonding fastnessStrong washing fastnessPhotosensitive materials for photomechanical apparatusSimple Organic CompoundsPolymer science

The invention discloses a high-precision printing circular screen photographic emulsion and a preparation method thereof; the photographic emulsion comprises binder, cross-linking agent, photosensitizer, flexibilizer, catalyst, diluent, stabilizing agent, sensitizer, emulsifying agent, antifoaming agent, fire retardant, buffering material, diluent solution and light sensitive agent; the photographic emulsion is prepared by steps of diluting, stirring, uniformly mixing and standing; the high-precision printing circular screen photographic emulsion has the following advantages that: the granulegrain diameter of the high-precision printing circular screen photographic emulsion is less than 2 microns and the granule has strong bonding force with the printing circular screen, strong chemical corrosion resistance and friction resistance and high printing resistance; the circular screen platemaking is capable of being developed clearly without blocking the screen holes; therefore, the stretching performance of the printing circular screen in printing process is improved; the service life of the printing circular screen is prolonged, the exposing time of the circular screen is shortened and bonding firmness of the emulsion layer and the printing circular screen is improved; in addition, the washing resistance firmness and resolution of the emulsion layer are high; volatilize organic compound is not produced in the preparation process, so the emulsion and the preparation method have less pollution on the environment and low harm on human body.

Owner:山东同大镍网有限公司

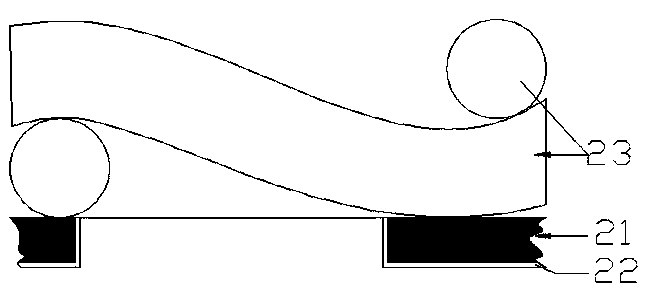

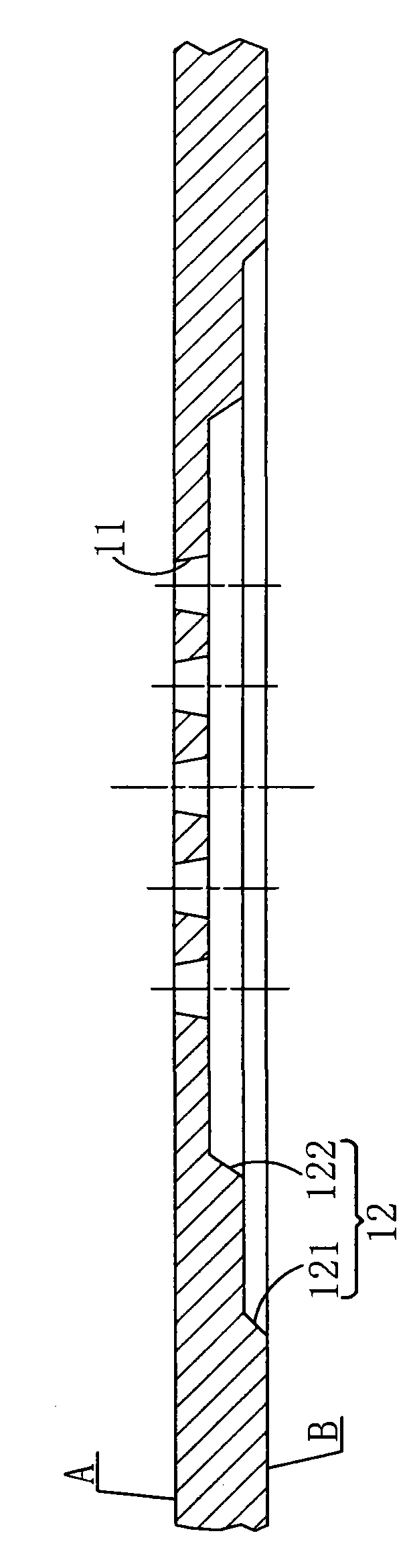

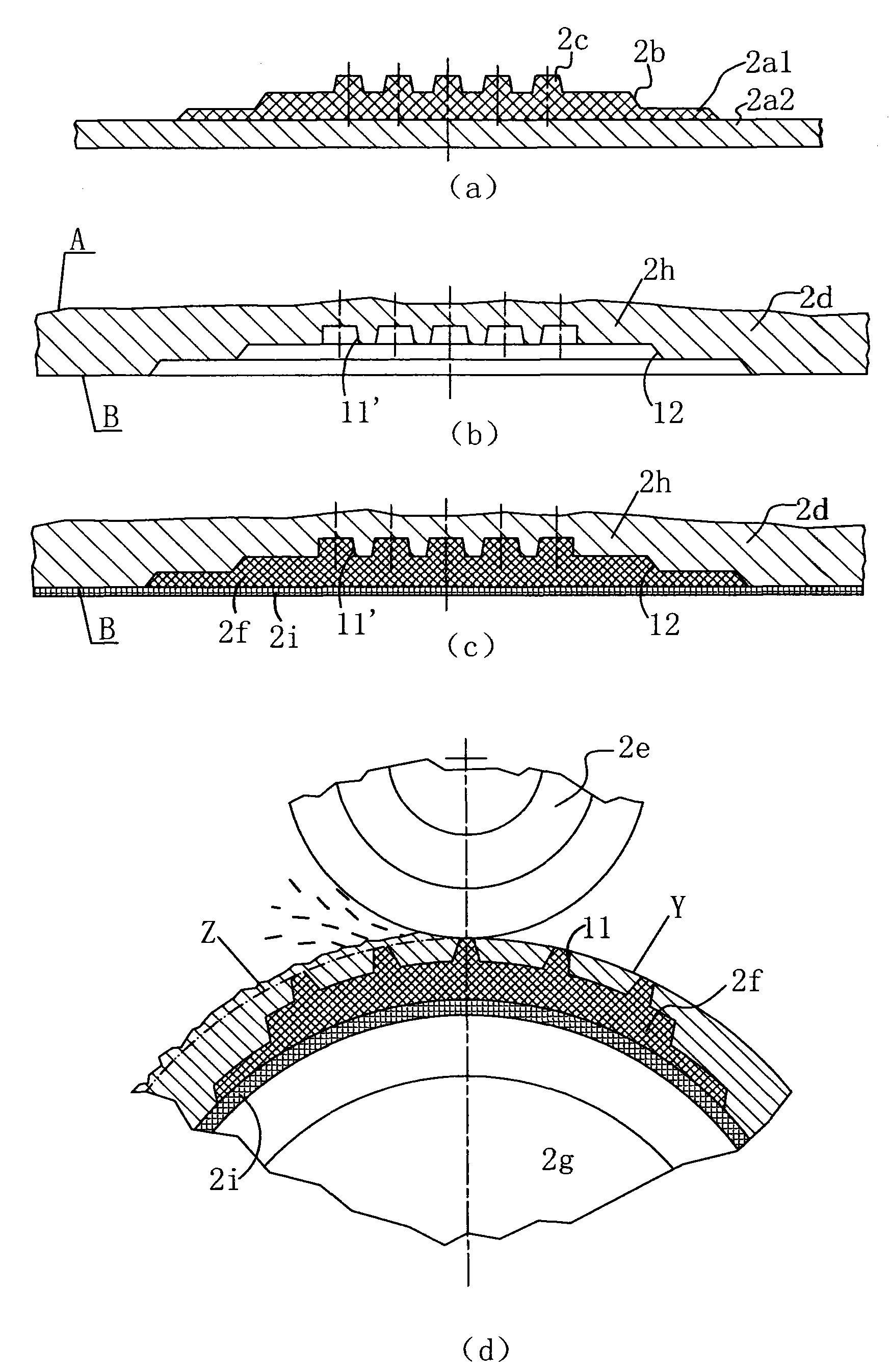

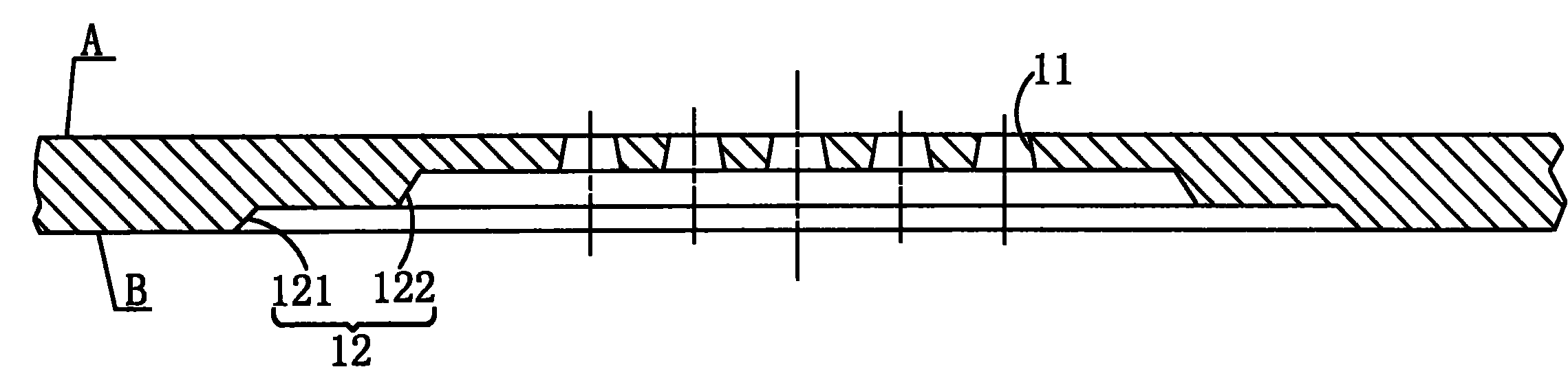

Method for raising light guide plate screen press run and permeability

ActiveCN103777268AImprove performanceHigh printing durabilityPhotomechanical coating apparatusOptical light guidesLine widthEmulsion

The invention provides a method for raising light guide plate screen press run and permeability. The method comprises the following steps that a, the design and production of a film negative comprises the following steps of designing the needed negative pattern firstly, symmetrically marking on the four corners of the periphery of the pattern for the counter point of a second exposure and creating a second draft pattern, remaining the same center line of the negative secondly, broadening 50 Mu m of each object line width of the pattern, creating a second draft pattern and producing two sets of films; b, coating and printing comprises the following steps of coating and exposing twice, using different natures of two photosensitive emulsions in the twice coating. Due to the fact that different natures of the two photosensitive emulsions are used in the coating, the print resistance and the permeability of the screen is improved greatly, production cost is reduced greatly.

Owner:FUZHOU UNIV

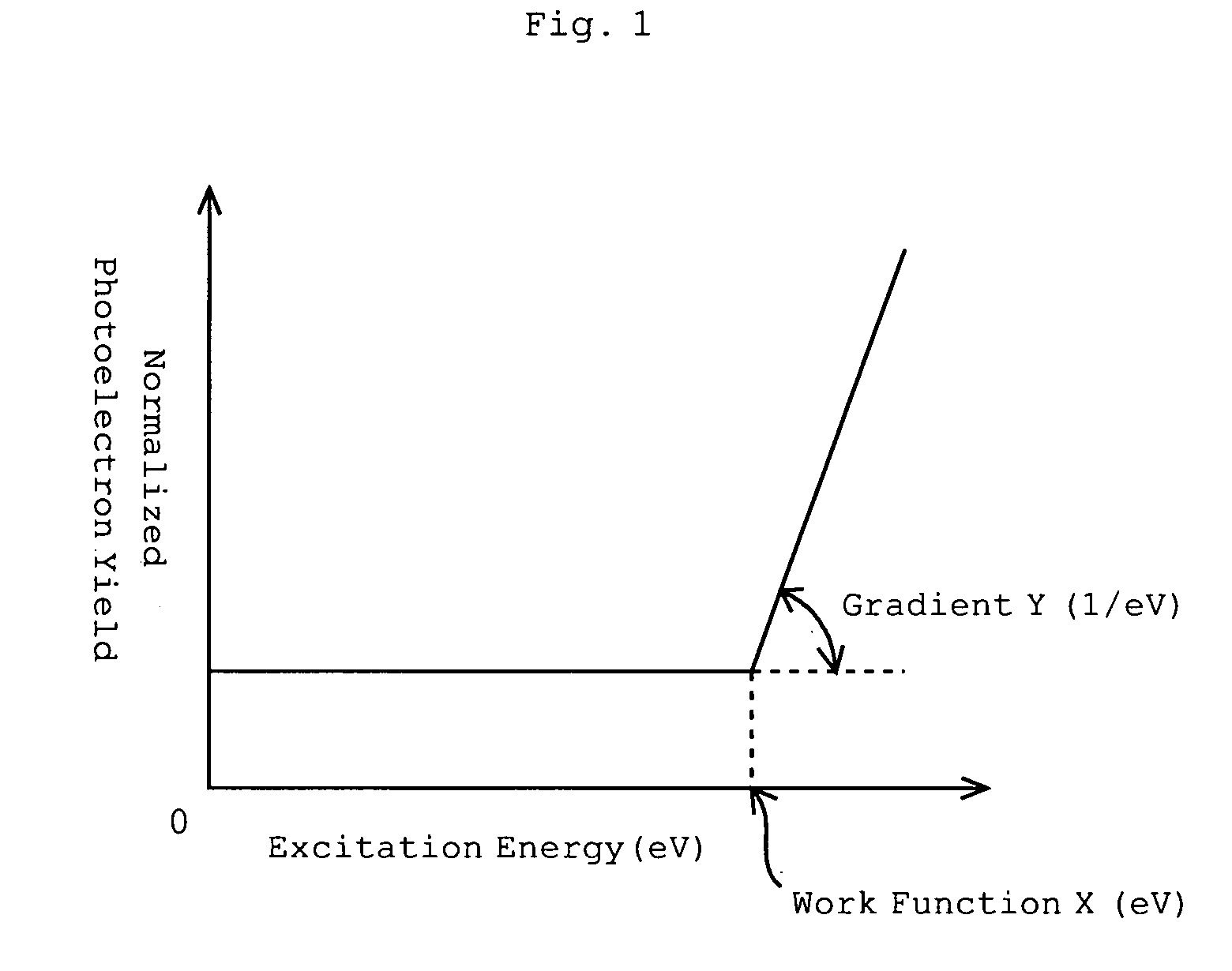

Developer for Development of Electrostatic Image and Production Process Thereof

InactiveUS20080299475A1Easy can be cleaned offGood environmental stabilityDevelopersWork functionEngineering

A developer for development of electrostatic images, comprising colored particles containing a binder resin, a colorant and a parting agent, and an external additive, wherein the developer has properties that a work function is at least 5.70 eV; when excitation energy (eV) in the measurement of the work function is plotted on an axis of abscissa, and a normalized photoelectron yield represented by the 0.5th power of a photoelectron yield per unit photon is plotted on an axis of ordinate, a gradient of the normalized photoelectron yield to the excitation energy is at least 15 / eV; and an extraction quantity with methanol is 5.0% by weight or less, and a production process thereof.

Owner:ZEON CORP

Toner for developing electrostatic image

ActiveUS20090047590A1Excellent low temperature fixabilityIncrease fix rateDevelopersAliphatic hydrocarbonEngineering

Provided is a toner for developing electrostatic image which is excellent in shelf stability, and is further excellent in low-temperature fixability so as to be capable of maintaining a high fixing rate even at a low fixing temperature.A toner for developing electrostatic image is used which comprises colored resin particles containing a binder resin, a colorant, and a parting agent, wherein the parting agent is an aliphatic hydrocarbon polymer obtained by polymerizing an aliphatic hydrocarbon monomer.

Owner:ZEON CORP

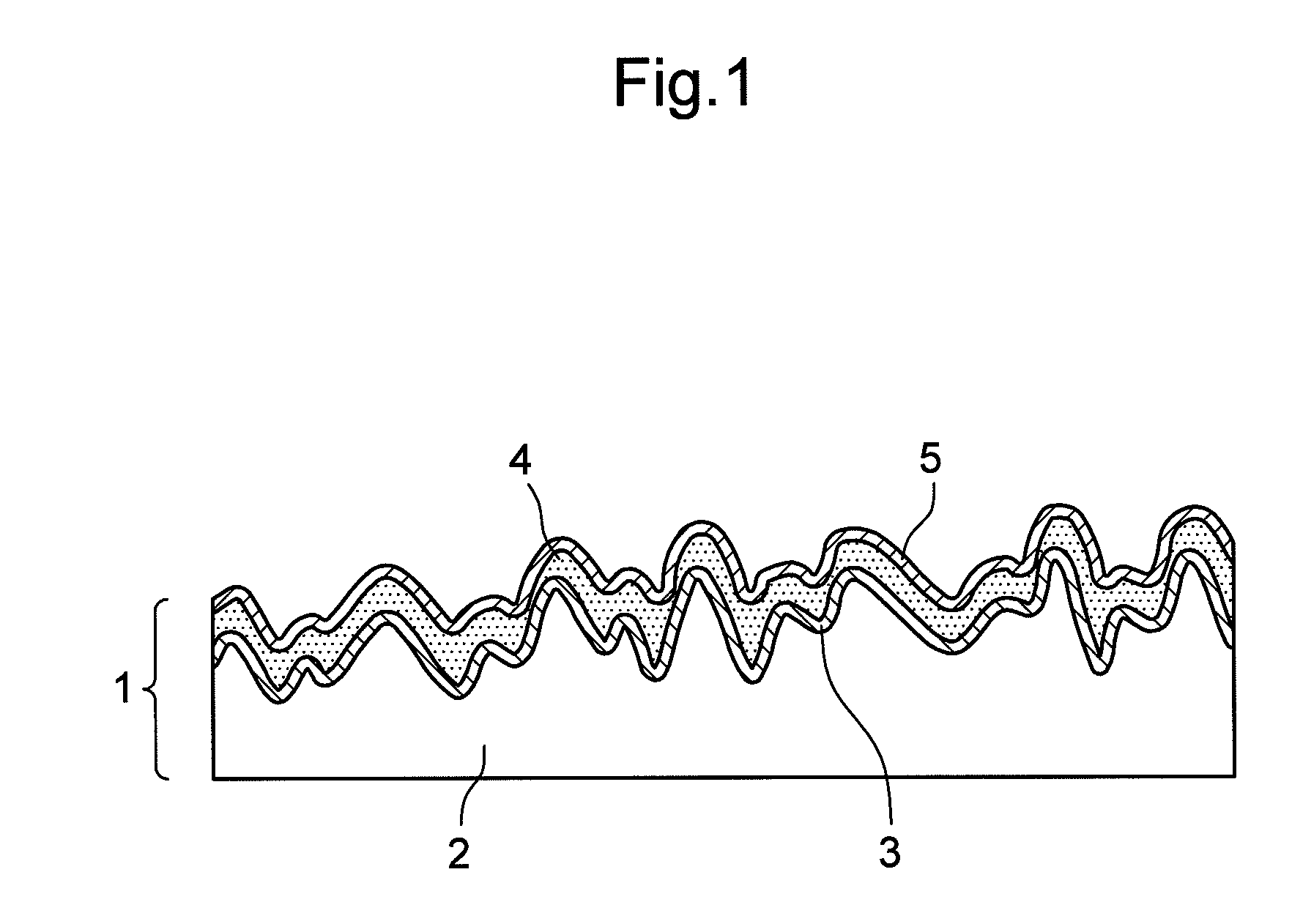

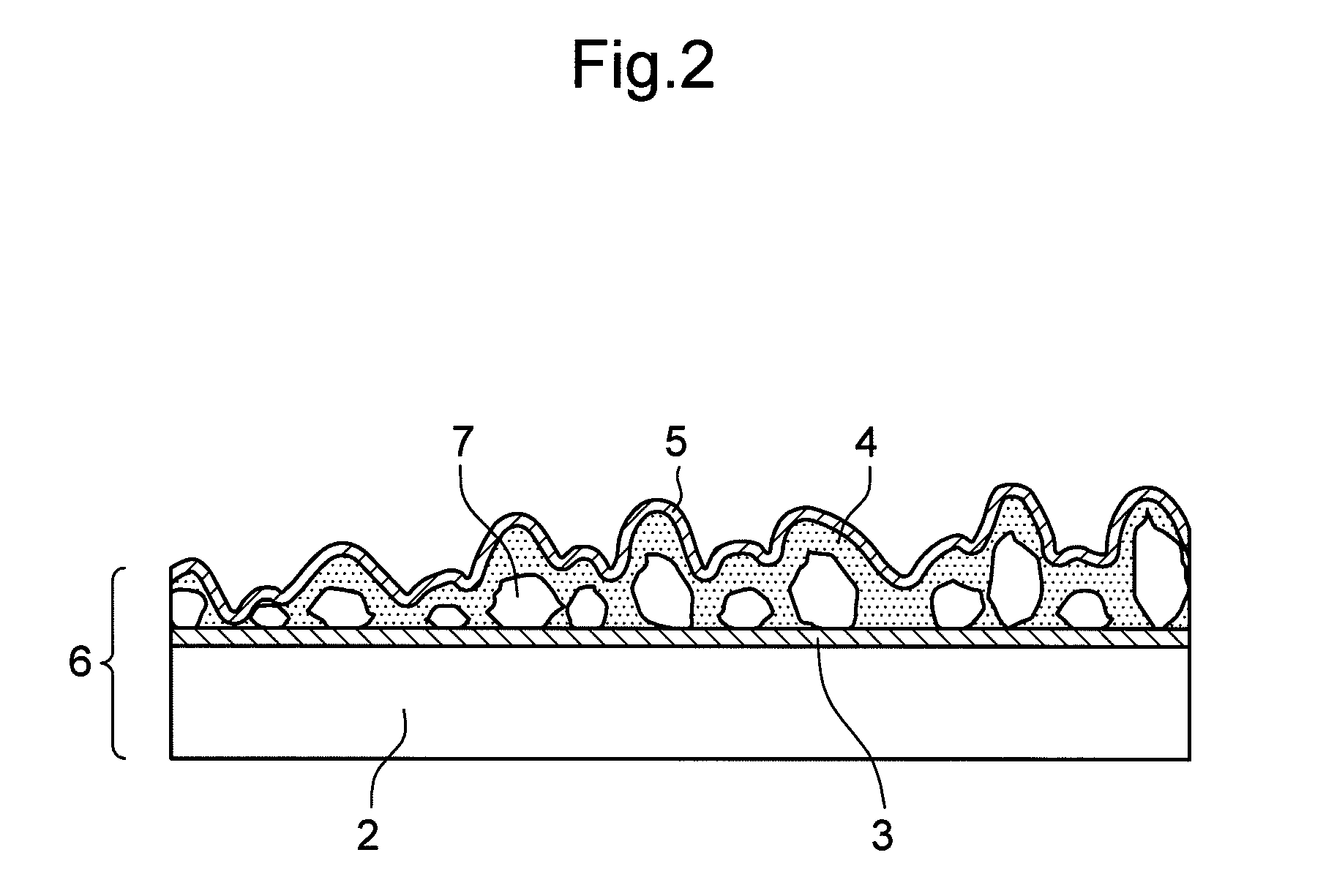

Aluminum support for planographic printing plate, its manufacturing process, and planographic printing plate material

InactiveUS20050233250A1High printing durabilityExcellent anti-stain propertyPhotosensitive materialsSurface reaction electrolytic coatingAnodic oxidationSurface finishing

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

Planographic plate for laser digital scanning and manufacture method thereof

ActiveCN101373333AHigh sensitivityHigh printing durabilityPhotosensitive materials for photomechanical apparatusLithographic artistLaser scanning

The invention relates to printing lithography, in particular to a printing lithographic plate (UV-CTP) for laser digital scanning and the preparation method thereof. The preparation method of the printing lithographic plate (UV-CTP) comprises the following steps: firstly cleaning, neutralizing, electrolyzing and oxidizing aluminum plate strip materials and hole-sealing to obtain the plate base; then, spread-coating the prepared photosensitive coating liquid on the plate base through extruding; and obtaining the UV-CTP after drying. The UV-CTP plate, following the photosensitive CTP plate and the thermosensitive CTP plate, belongs to a novel plate which can be directly imaged through computer digital laser scanning without pretreatment. Compared with the conventional PS plate and CTP plate, the UV-CTP plate has the following characteristics and advantages that the aluminum plate rolling technique with low deformation rate and low surface defect ensures that the plate base of the plate has better physical properties, particularly, the UV-CTP plate is advantageous in manufacturing cost, preservation period and universality over other CTP plates; and the UV-CTP plate has the characteristics of high dot reducibility, high photosensitive speed, great operating latitude and wide application, etc., therefore, the UV-CTP plate is applicable to printing materials, such as metal, plastic, etc., by the UV ink.

Owner:龙马铝业集团有限公司

Printing plate material, manufacturing method of the same, and plate-making method using the same

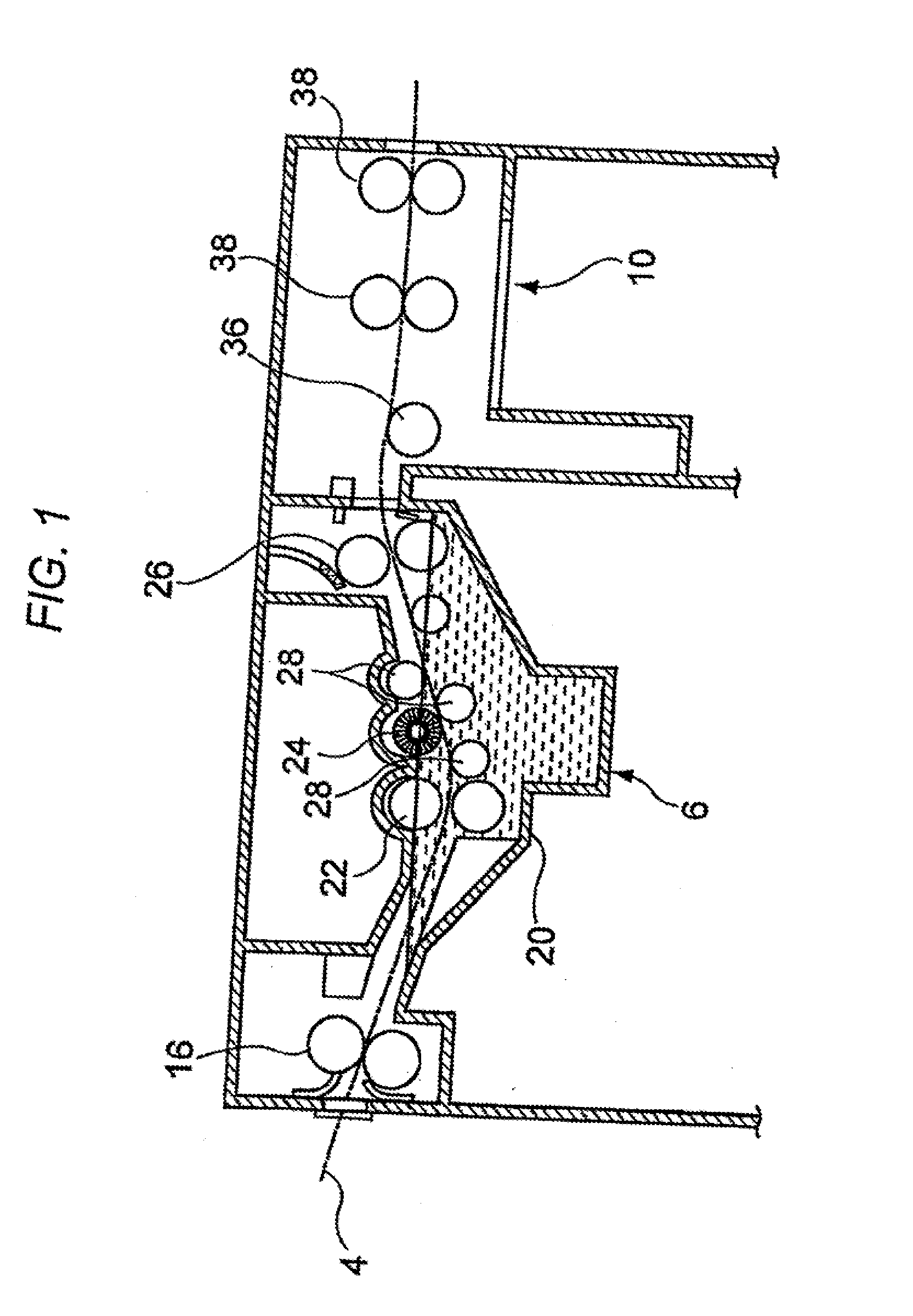

InactiveUS20080011174A1High resolutionSimple structureMounting boardsPlate printingControl layerFilm base

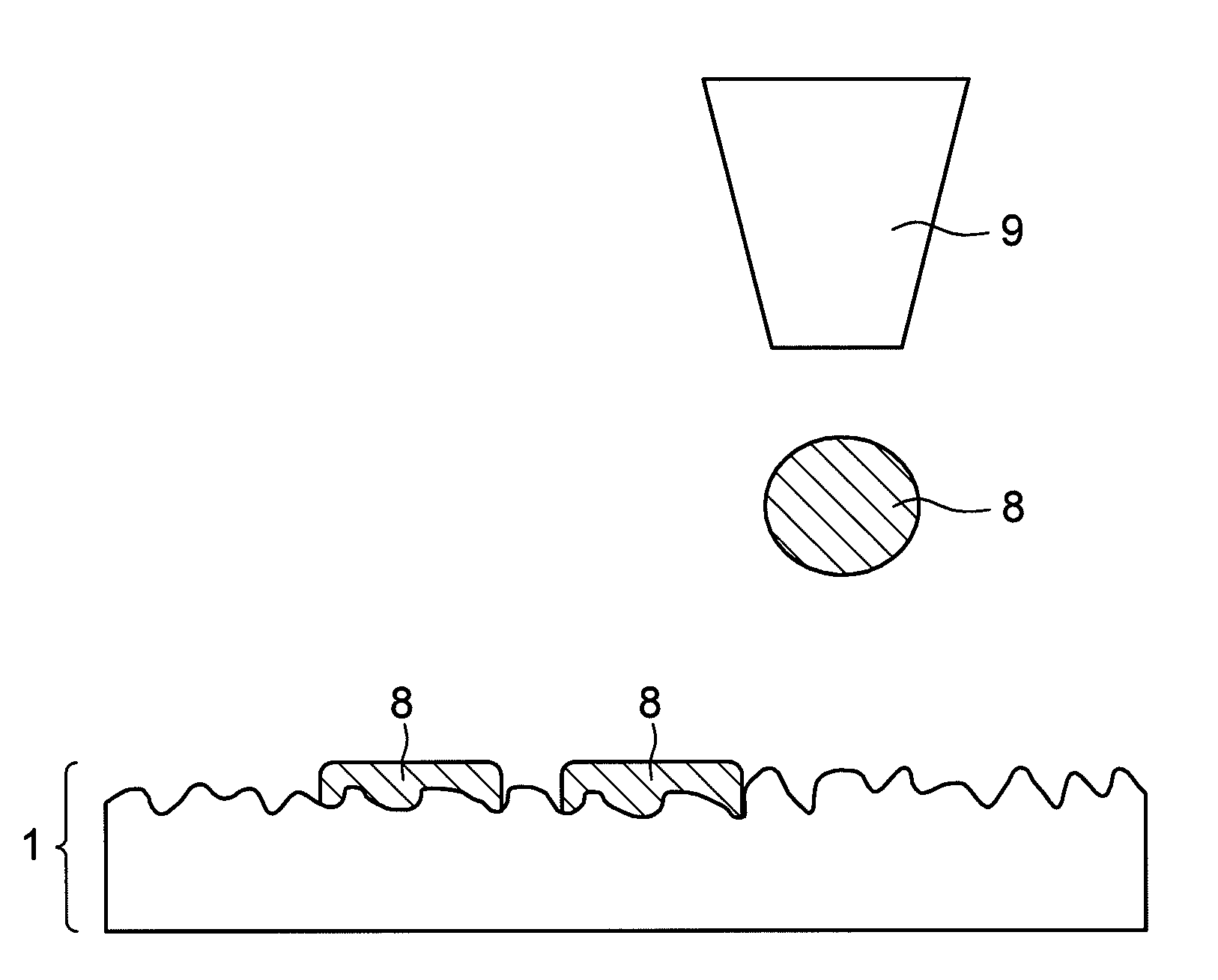

A printing plate material for direct plate-making includes a PET film base material; a protective layer and a photocatalytic hydrophilic layer provided on the base material; and a dot control layer provided on the hydrophilic layer and having a critical surface tension equal to or lower than a surface tension of an image forming liquid. The image forming liquid is discharged from an inkjet recording head onto a surface of the printing plate material for direct plate-making and is hardened. Thereby, a direct-made printing plate is obtained.

Owner:PANASONIC CORP

Printing printmaking method and printing plate thereof

InactiveCN1504326AColor correction is easyAvoid differencesInksForme preparationImage basedColoring agents

The invention provides a process for the manufacture of printing master, and a printing master made thereby, wherein the process comprises, using an ink composition capable of optical polymerization reaction under light illumination, which includes monomer used for optical polymerization reaction, optical polymerization initiator, coloring agent and organic solvent, to print the pattern directly onto the printing image base through high precision ink-jet printers. As the result of light struck, the ink expediting setting on the printing master can be achieved. The advantages of the process according to the invention are, no ink overflow to the periphery, clear image, and simple salting-on procedure.

Owner:王柏枝

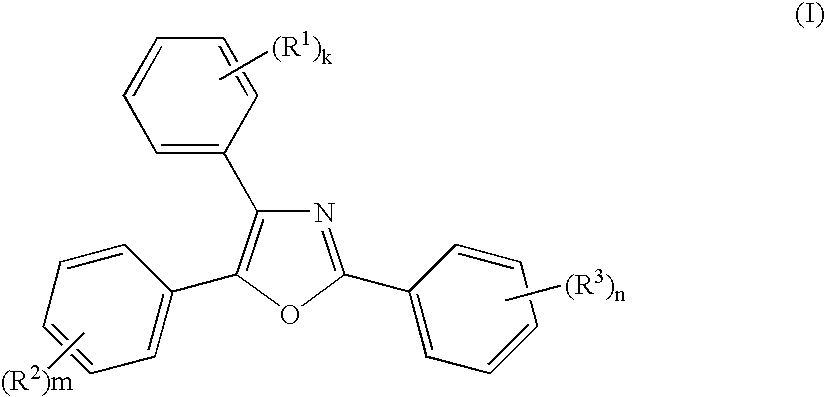

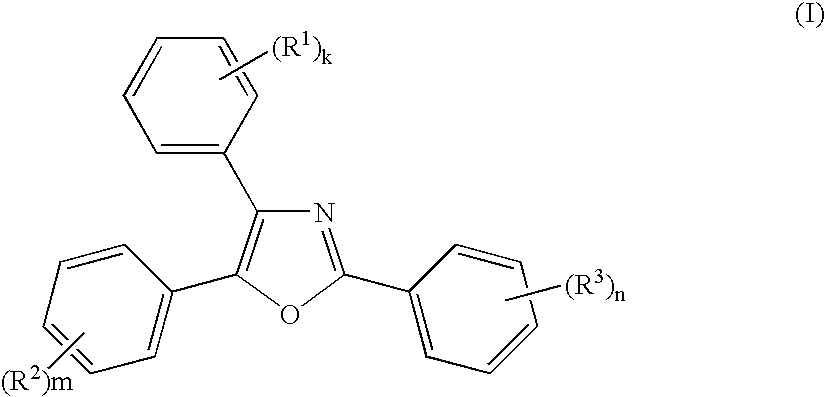

Lithographic printing plate precursor

InactiveUS20060199101A1High printing durabilityExcellent in reproducibility of fine line and printing durabilityPhotomechanical apparatusPhotosensitive material auxillary/base layersCompound (substance)Planographic printing

A lithographic printing plate precursor comprising: a support; and a photosensitive layer containing (A) a sensitizing dye represented by the formula (I) as defined herein, (B) a polymerization initiator, (C) a polymerizable compound, and (D) a binder polymer having a crosslinkable group.

Owner:FUJIFILM HLDG CORP +1

Method for forming images

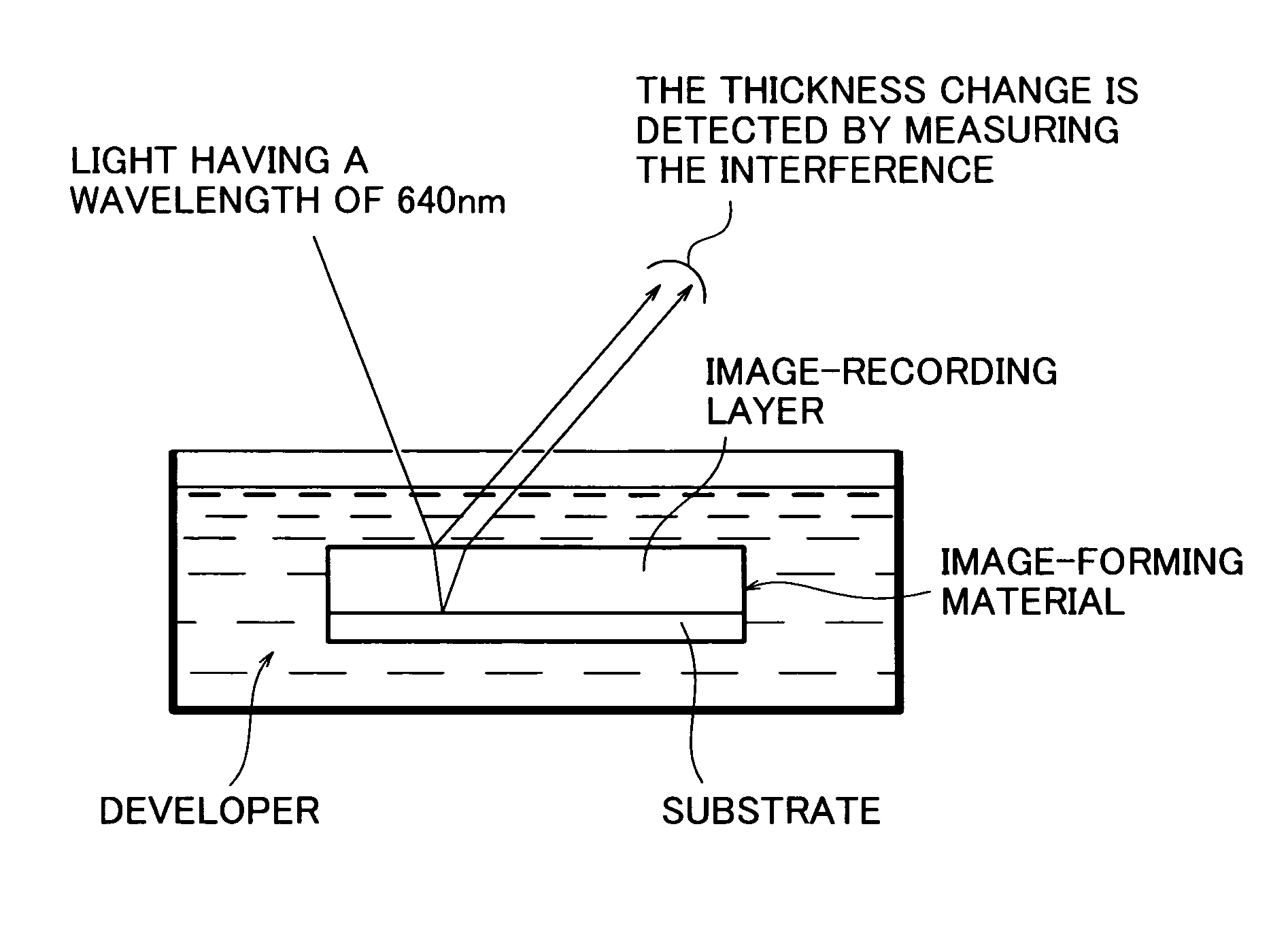

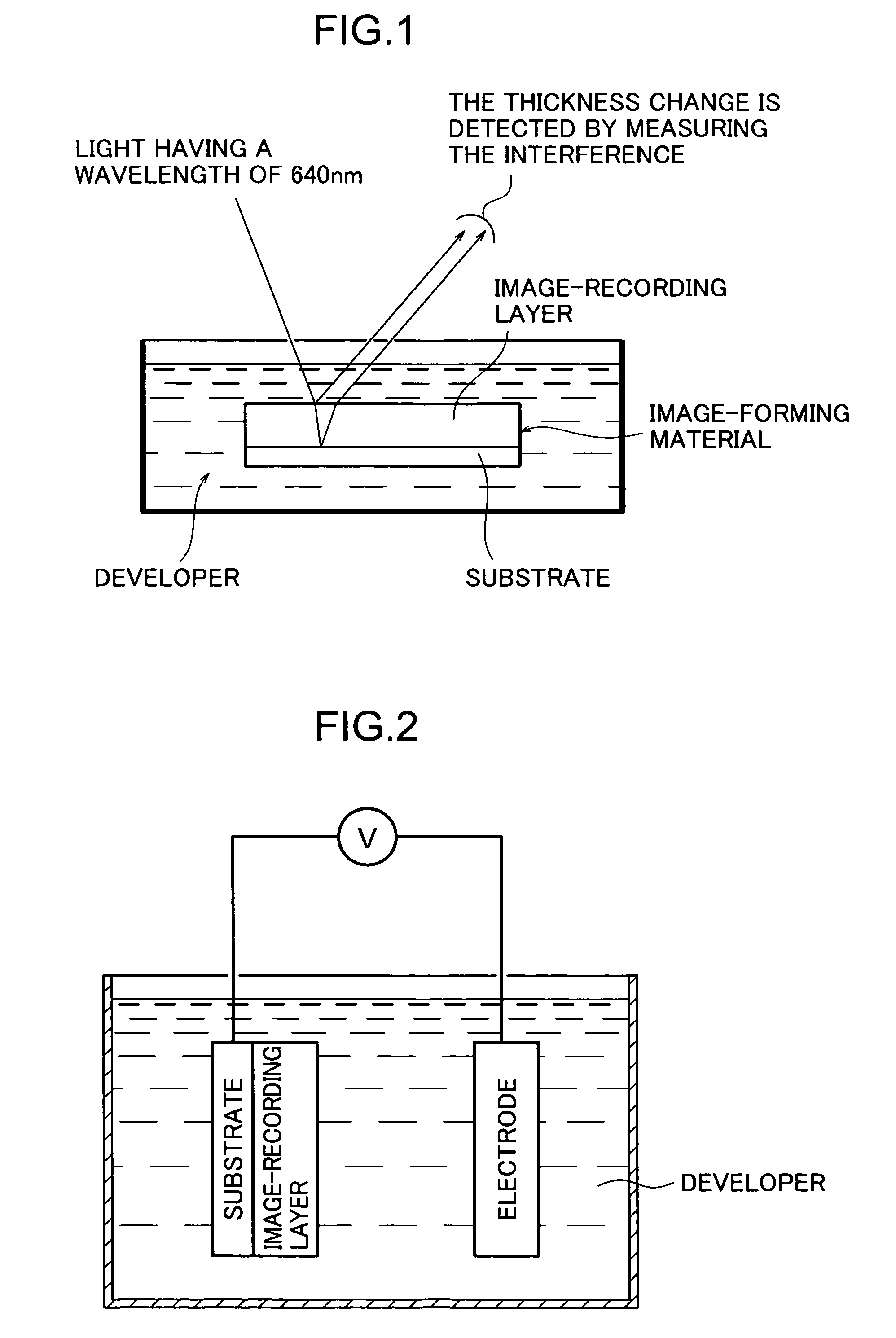

InactiveUS7125648B2Excellent in printing durability and resistance to contaminationStably conductSemiconductor/solid-state device manufacturingPhotosensitive material processingImage formationRecording layer

Owner:FUJIFILM CORP

Lithographic printing plate precursor and plate making method

InactiveUS20150192852A1High sensitivityPrevent curingPrinting pre-treatmentPhotosensitive materials for photomechanical apparatusDigital dataImaging quality

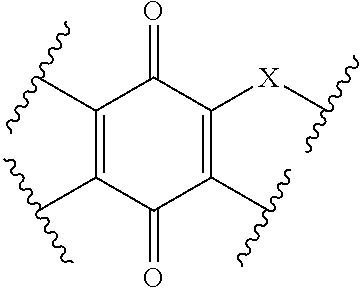

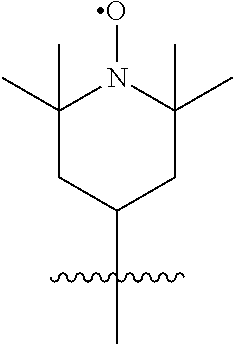

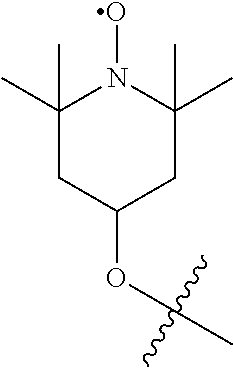

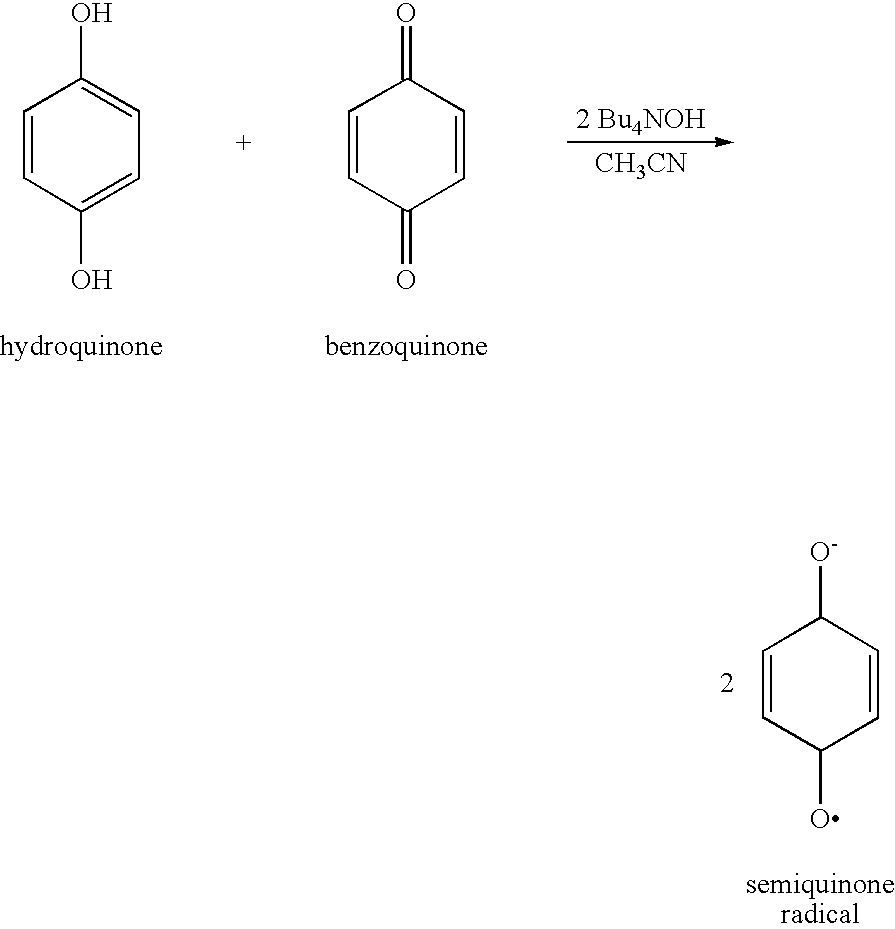

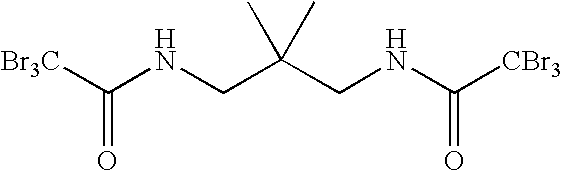

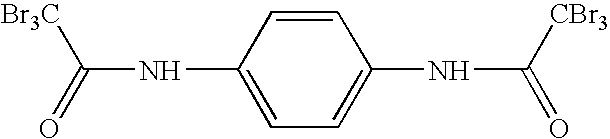

By a lithographic printing plate precursor comprising a support having provided thereon an image-recording layer containing (A) a radical polymerization initiator, (B) a radical polymerizable compound, and (C) a polyfunctional polymerization inhibitor, wherein the polyfunctional polymerization inhibitor has, in a molecule thereof, two or more radical trapping sites to form a covalent bond by directly connecting with a radical, a lithographic printing plate precursor which is capable of being directly recorded from digital data, for example, of a computer, which has high sensitivity, and which can form an image having a high image quality by preventing an undesirable curing reaction in the non-image area from proceeding, wherein the lithographic printing plate precursor can provide a lithographic printing plate having high printing durability, and a plate making method using the same are provided.

Owner:FUJIFILM CORP

Colorful onion powder printing material and printing process thereof

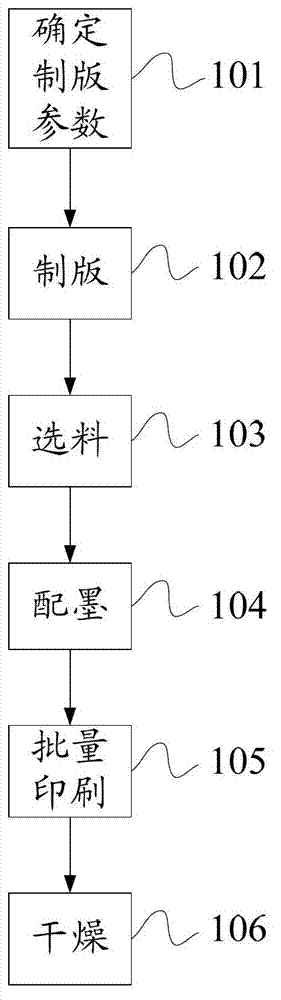

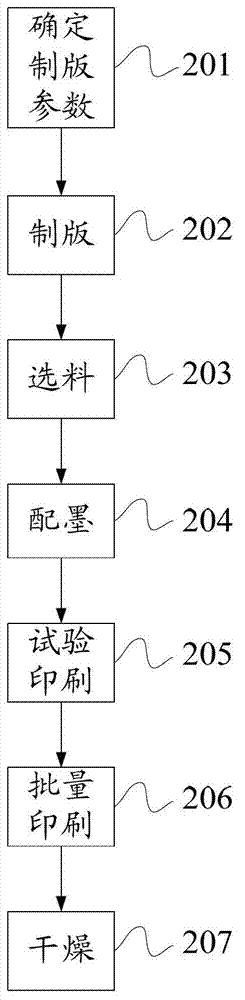

ActiveCN102806790AImprove printing accuracyIncrease printing speedDuplicating/marking methodsPattern printingScreen printingEngineering

The invention discloses a colorful onion powder printing process. The process sequentially comprises the following steps of platemaking parameter determining, plate making, sorting, ink matching, batch printing and drying. An improved gravure printing process is utilized to replace the original screen printing process, so that the printing accuracy of colorful onion powder is effectively increased, the printing speed and the pressrun ratio are higher, and the whole printing efficiency of the colorful onion powder printing process can be correspondingly increased. The invention also discloses a colorful onion powder printing material printed by the colorful onion powder printing process.

Owner:CHANGDE JINPENG PRINTING

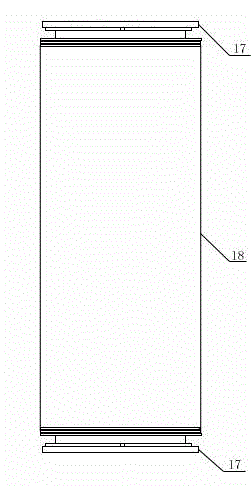

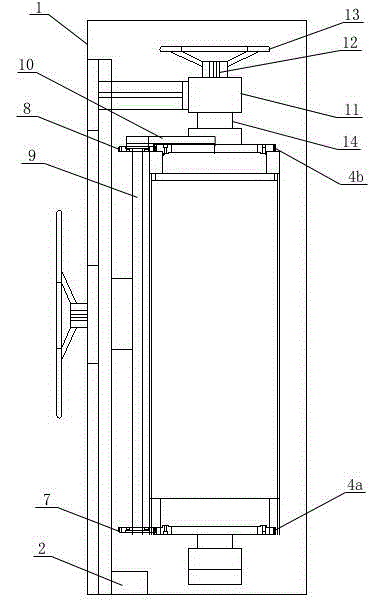

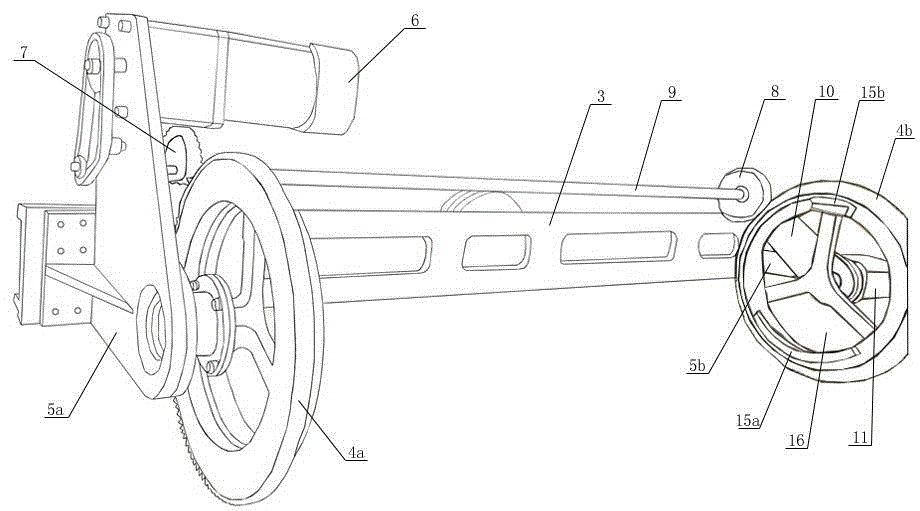

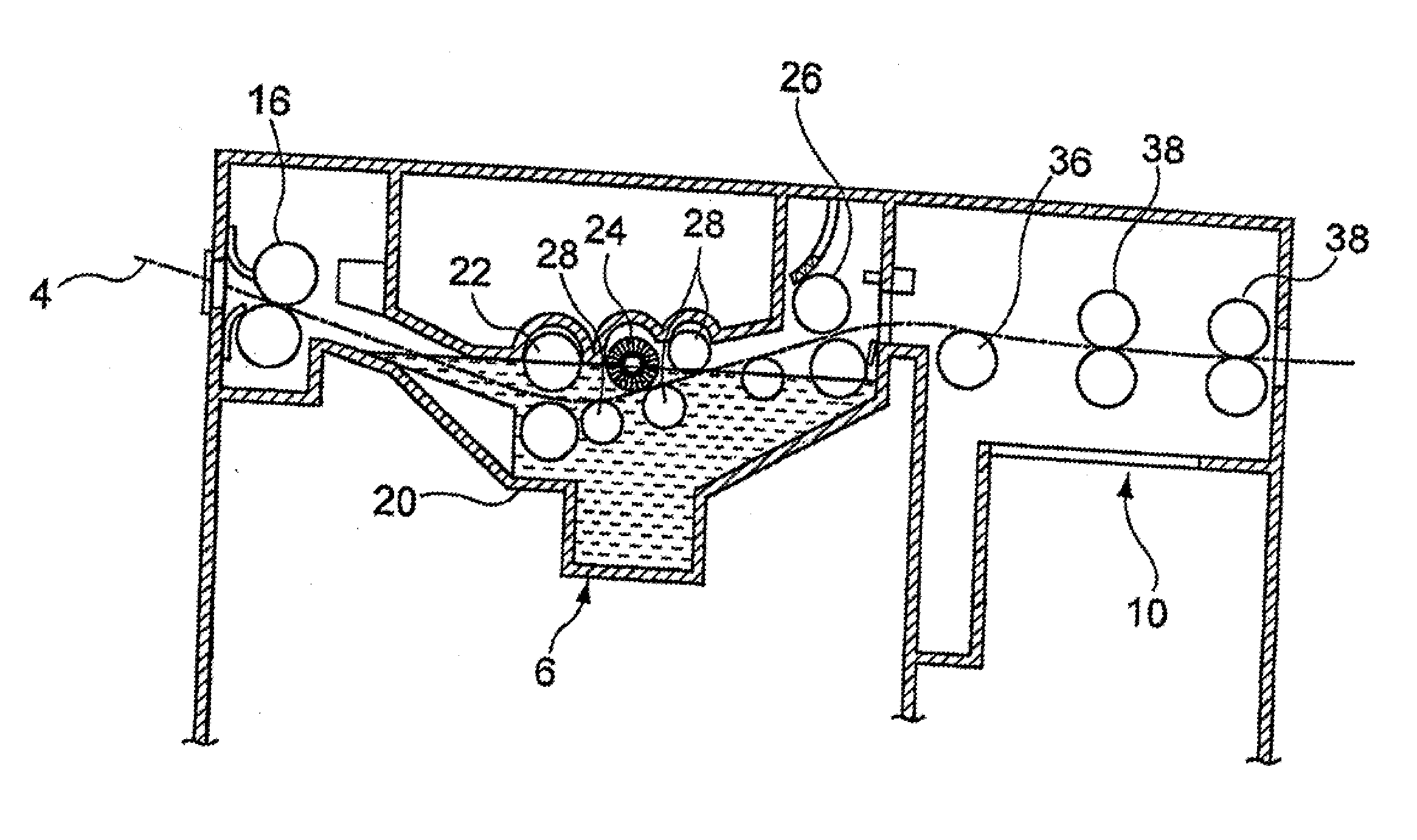

Stencil clamping sizing device and sizing method thereof

The invention discloses a stencil clamping sizing device. The stencil clamping sizing device comprises a sizing cabinet, a stencil clamping unit and a timing heater. The stencil clamping unit comprises a rotating mounting base, a clamping ring assembly and a clamping ring rotation drive mechanism, wherein the rotating mounting base is connected to a rotating mounting base rotation drive mechanism, the clamping ring assembly is composed of a fixed clamping ring and a movable clamping ring which are rotatably connected to a fixed clamping ring mounting base and a movable clamping ring mounting base through rolling bearings respectively, and the clamping ring drive mechanism is used for driving the fixed clamping ring and the movable clamping ring to rotate to the same direction synchronously. A movable clamping ring adjustment mechanism is mounted on the movable clamping ring mounting base. The stencil clamping sizing device uses automatic uniform sizing and sealing heating drying by clamping a money printing stencil, so that an end ring and a stencil cylinder are high in adhesive strength, the deficiency that manual sizing is uneven, low in yield and print run and the like, and the print run rate of the stencil is greatly increased in a printing production process of the stencil.

Owner:CHENGDU BANKNOTE PRINTING

Lithographic printing plate precursor and plate making method thereof

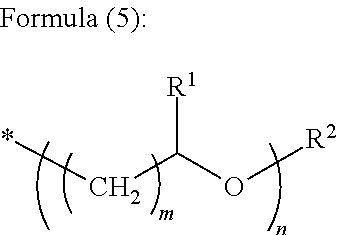

ActiveUS20110076621A1Increased strengthHigh printing durabilityPhotosensitive materialsSemiconductor/solid-state device manufacturingImage recordingSide chain

A lithographic printing plate precursor includes a support, and an image-recording layer, the image-recording layer contains a urethane resin having a polyalkylene oxide chain represented by the formula (1) as defined herein in a side chain, an infrared absorbing agent, a radical polymerizable compound and a radical polymerization initiator, and an unexposed area of the image-recording layer is capable of being removed with at least one of dampening water and ink.

Owner:FUJIFILM CORP

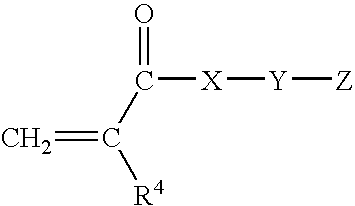

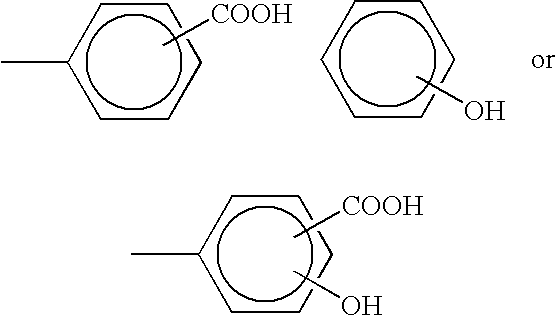

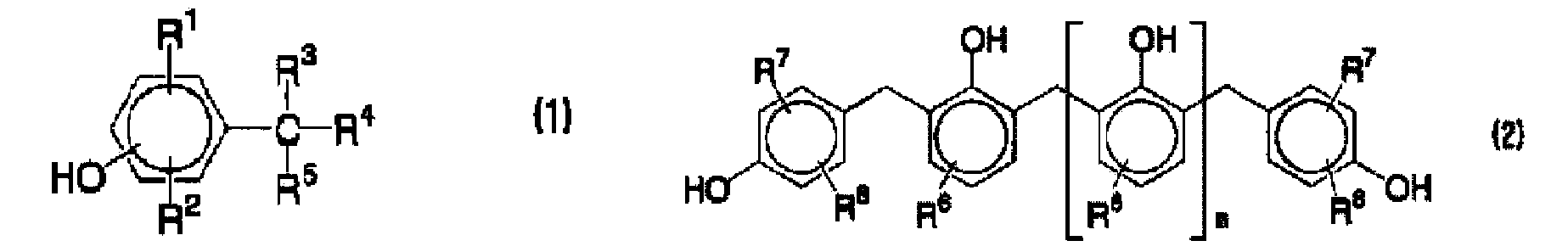

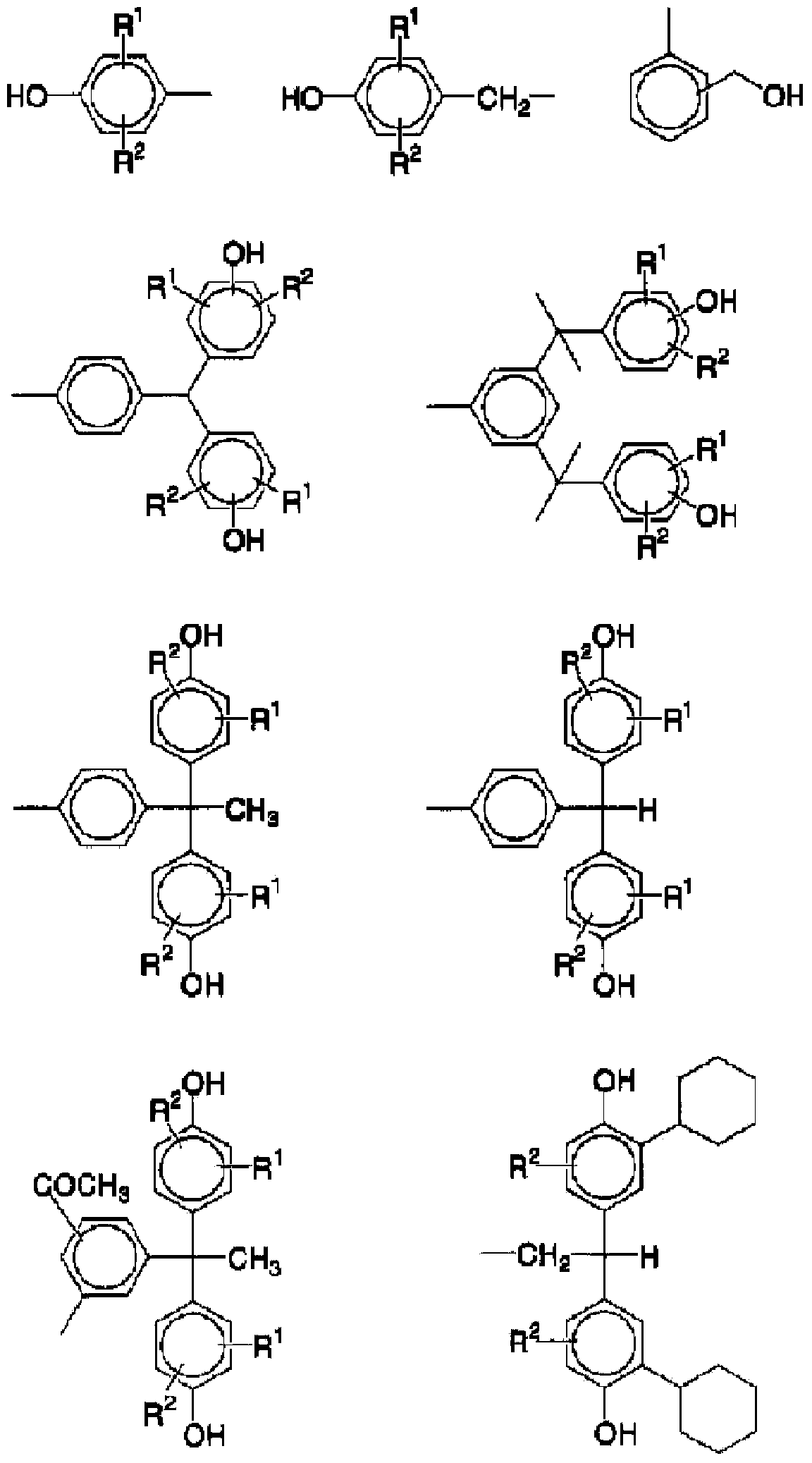

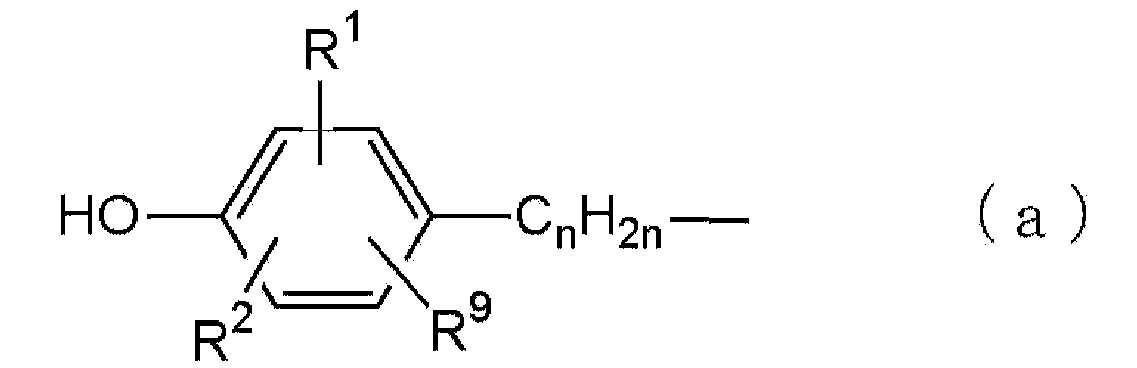

Lithographic printing plate precursor, plate making method thereof and polyvalent isocyanate compound

ActiveCN103430096AHigh organicLow water permeabilityPlate printingFoil printingImage recordingIsocyanate compound

To provide a lithographic printing plate precursor which is capable of undergoing image recording with infrared laser and exhibits high printing durability while maintaining stain resistance and preservation stability, and particularly, to provide a lithographic printing plate precursor capable of undergoing on-press development and a plate making method thereof, the invention is directed to a lithographic printing plate precursor comprising a hydrophilic support having thereon an image-recording layer containing (A) a polymer fine particle, (B) a radical polymerizable compound and (C) an infrared absorbing dye, wherein (A) the polymer fine particle is obtained by a reaction between a polyvalent isocyanate compound which is an adduct of a polyhydric phenol compound having two or more hydroxyl groups in its molecule and isophorone diisocyanate and a compound having an active hydrogen atom.

Owner:FUJIFILM CORP

Metal porous plate and preparation method thereof

InactiveCN102092180AHigh printing durabilityAvoid deformationScreen printersPlate printingStress effectsMetal

The invention discloses a metal porous plate and a preparation method thereof. The metal porous plate comprises a metal plate which is provided with ink through-holes, a plate lining region is arranged on the metal plate outside the ink through-holes, the area of the plate lining region is larger than that of the ink through-holes, and with the plate lining region and the ink through-holes are distributed in a stepped way. Because the metal porous plate is made from metal, the printing rate of the porous plate is greatly improved; because the porous plate is easy to deform in printing under the stress effect around the ink through-holes, the region outside the ink through-holes is further provided with the plate lining region to increase the support to the ink through-holes, be beneficial to stretching of the porous plate, and avoid the deformation, therefore, the printing quality is increased. The invention further discloses a method for making the metal porous plate.

Owner:SECURITY PRINTING INST OF PEOPLES BANK OF CHINA +1

Active agent for lead-free solder paste, preparation method thereof and lead-free solder paste

ActiveCN104191109AHigh printing durabilityExtend storage time at room temperatureWelding/cutting media/materialsSoldering mediaOrganic acidActive agent

The invention discloses an active agent for lead-free solder paste, a preparation method of the active agent for the lead-free solder paste and the lead-free solder paste. The preparation method of the active agent for the lead-free solder paste comprises the steps that organic acid and organic halide particles are smashed into particles with the size smaller than 10 microns, and the particles are added to capsule wall material solutions to be fully emulsified and are made into microcapsule active particles as the active agent for the lead-free solder paste. The active agent for the lead-free solder paste is prepared based on the microcapsulary, the printing durability of the solder paste is greatly improved, and the room temperature storage time of the solder paste is prolonged. Compared with an existing solder paste active agent, through the segmentation activity releasing characteristic of the active agent, the solder paste is made to have better wettability, the use amount of the solder paste can be reduced, and the quantitative control over solder feeding and the solder paste wetting effect is achieved.

Owner:HOERSON ELECTRONICS TECH +1

Engraved intaglio press plate scrapping roller and preparation method

ActiveCN102529342ASmooth runningExtended service lifePrinting press partsPolyvinyl chlorideEngineering

Provided are an engraved intaglio press plate scrapping roller and a preparation method. A cast iron roller core, an elastic layer and a face layer are respectively arranged on a plate scrapping roller from inside to outside, the elastic layer is made of compound rubber, the thickness of the elastic layer is 8-12mm, the hardness of the elastic layer is 30-60 shore A, the face layer is made of polyvinyl chloride (PVC) modified resin, the thickness of the face layer is 1-3mm, and the hardness of the face layer is 90-100 shore A. Raw material proportioning of the face layer and the elastic layer and the preparation method are also provided. The elastic layer and the roller core of the plate scrapping roller are firmly glued, service life can prolong more than one year with separation of two sides of the plate scrapping roller and big pressure during using, printing resisting rate of the face layer is particularly and substantially lifted to two times of the original roller, and roller manufacture work load is greatly reduced. In addition, the engraved intaglio press plate scrapping roller is good in elasticity, a printing press can stably operate under lower printing pressure, and machine loads are reduced.

Owner:石家庄印钞有限公司 +1

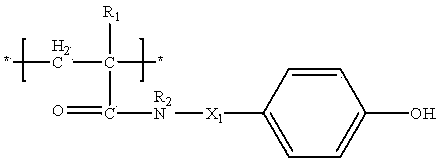

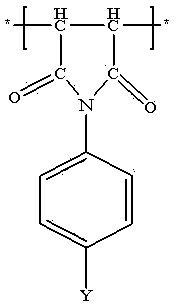

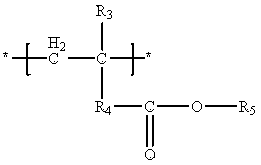

Anti-solvent vinyl polymer with multilayer structure, synthetic method thereof and applications thereof

ActiveCN103881025AChange performanceGood solvent resistancePhotosensitive materials for photomechanical apparatusSolubilityPolymer science

The invention discloses anti-solvent vinyl polymer with a multilayer structure, a synthetic method thereof and applications thereof. The polymer is synthesized by adoption of a method of core-shell emulsion copolymerization. The polymer is vinyl multipolymer having structure units as follows: an amide type structure unit with alkaline solubility, a maleimide type structure unit with alkaline solubility, an acrylate type structure unit, an acrylonitrile type structure unit and an olefin acid type structure unit. The polymer is suitable for manufacturing thermosensitive positive-image CTP plates and can allow the plates to have characteristics of high sensitivity, good storage stability, large latitude of development, good wear resistance and high pressrun. In addition, coatings of the plates are high in resistance to chemicals, and the plates are suitable for UV printing ink printing.

Owner:LUCKY HUAGUANG GRAPHICS

Planographic printing plate material and preparing process of planographic printing plate

ActiveUS20050260524A1High sensitivityHigh printing durabilityRadiation applicationsSemiconductor/solid-state device manufacturingUnsaturated bondsPhotochemistry

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

Lithographic printing plate precursor, plate making method thereof and novel polymer compound

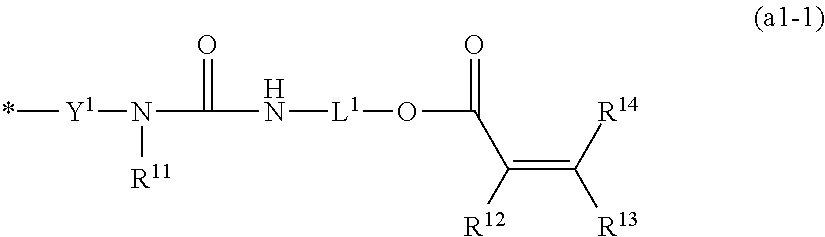

ActiveUS20130089818A1Improve hydrophilicityIncrease resistancePhotosensitive materialsOriginals for photomechanical treatmentCompound aSide chain

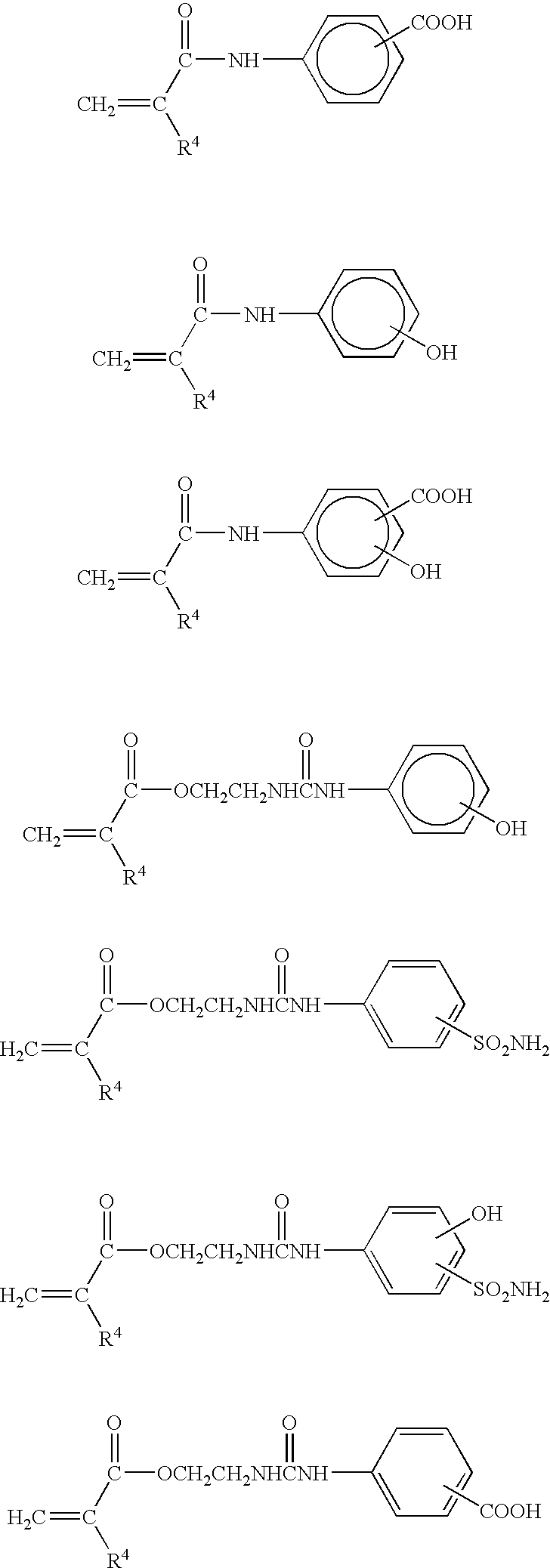

A lithographic printing plate precursor includes: a support; and an image-recording layer containing (A) a polymerization initiator, (B) a sensitizing dye and (C) a polymerizable compound, and the image-recording layer or an undercoat layer which is optionally provided between the support and the image-recording layer comprises (D) a polymer compound comprising (a1) a repeating unit having a side chain having a structure represented by the following formula (a1-1) and (a2) a repeating unit having a side chain having at least one structure of the formulae (a2-1), (a2-2), (a2-3), (a2-4), (a2-5) and (a2-6) as defined herein.

Owner:FUJIFILM CORP

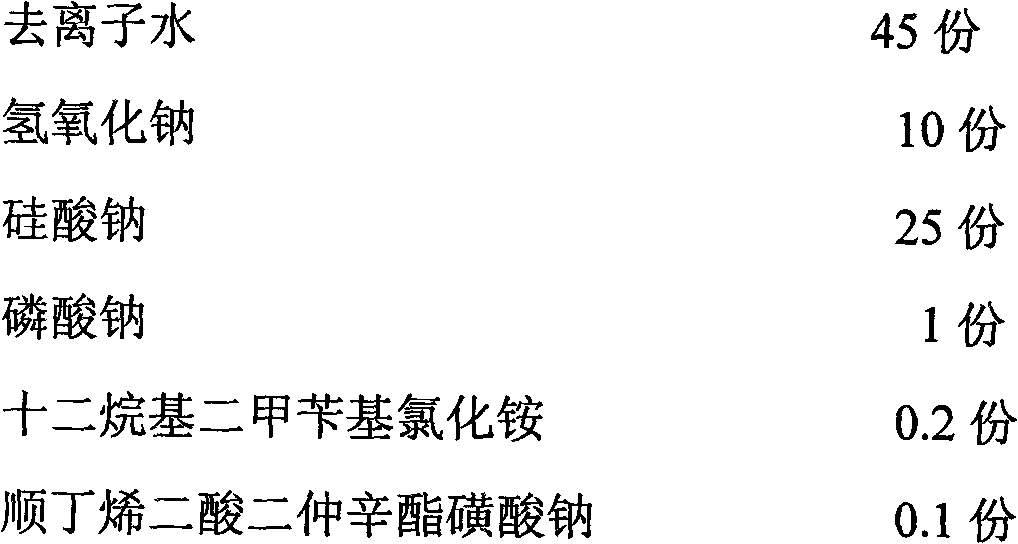

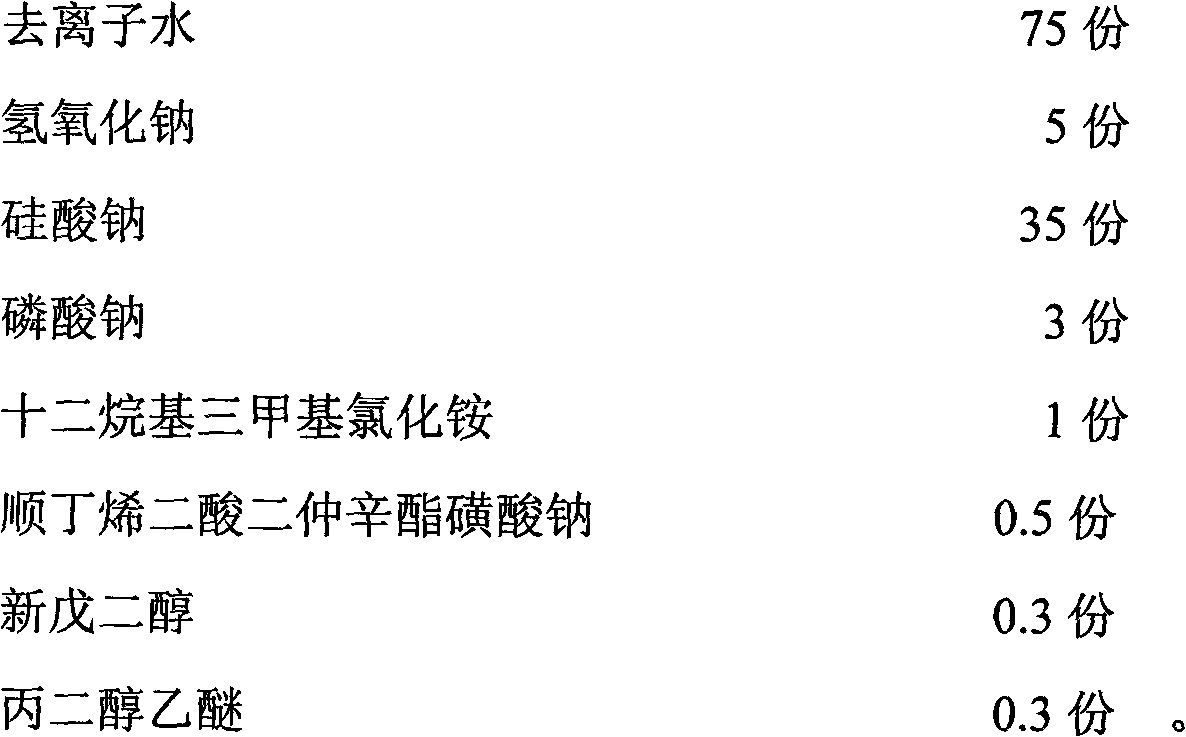

Developer for direct plate-making by using 405nm laser

The invention belongs to the field of inorganic materials, relates to a developer for direct plate-making by using a 405nm laser and particularly discloses a developer for an ultraviolet-computer to plate (UV-CTP) plate with peak sensing wavelength being 405nm. The developer consists of the following components in parts by weight: 40-86 parts of deionized water, 5-18 parts of sodium hydroxide, 25-40 parts of silicate, 1-8 parts of buffering agent, 0.2-2 parts of photosensitive film protecting agent and 1-5 parts of development promoting agent. The developer provided by the invention has the advantages that the developer can rapidly dissolve exposed resin film layers and can well protect unexposed resin layers, the erosion of oxide layers of non-graphic and non-text parts is less, the press run is high, the reproducibility of small dots is good, the dots are fully reproduced and the developer is suitable for high-quality printing.

Owner:胡秋帆

Toner for developing electrostatic images

ActiveUS20180181013A1Improve balanceGood conveyance amount stabilityPigmenting treatmentSilicaHigh humidityEngineering

Provided is a toner for developing electrostatic images that has an excellent balance between low-temperature fixability and heat-resistant shelf stability as well as good conveyance amount stability and printing durability, and causes less occurrence of fog in a high temperature and high humidity environment. The toner for developing electrostatic images of the present invention includes colored resin particles containing a binder resin and a colorant, and an external additive, wherein silica fine particles A having a sodium to silicon ratio of 0.1 to 1.8% by mass, are contained as the external additive.

Owner:ZEON CORP

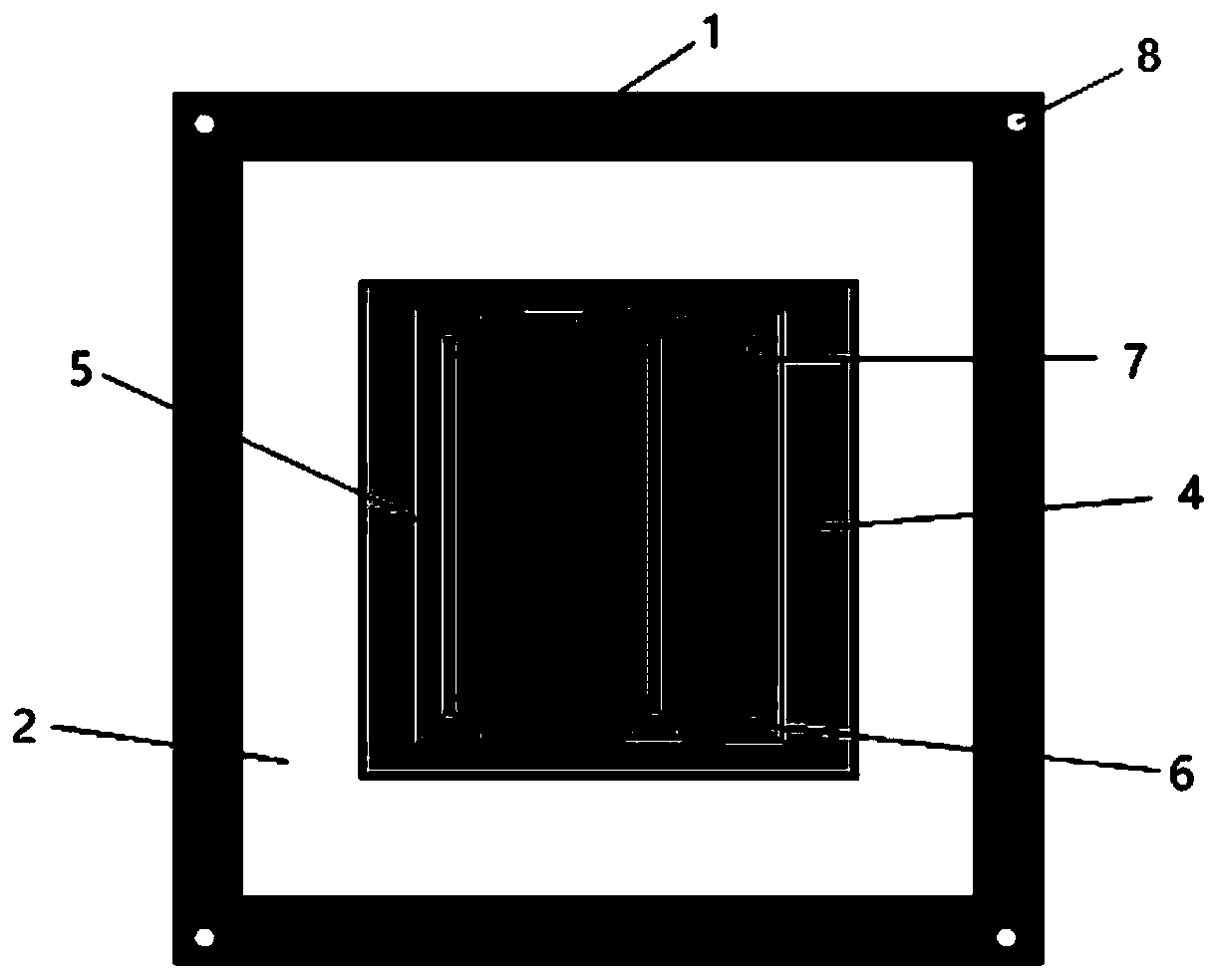

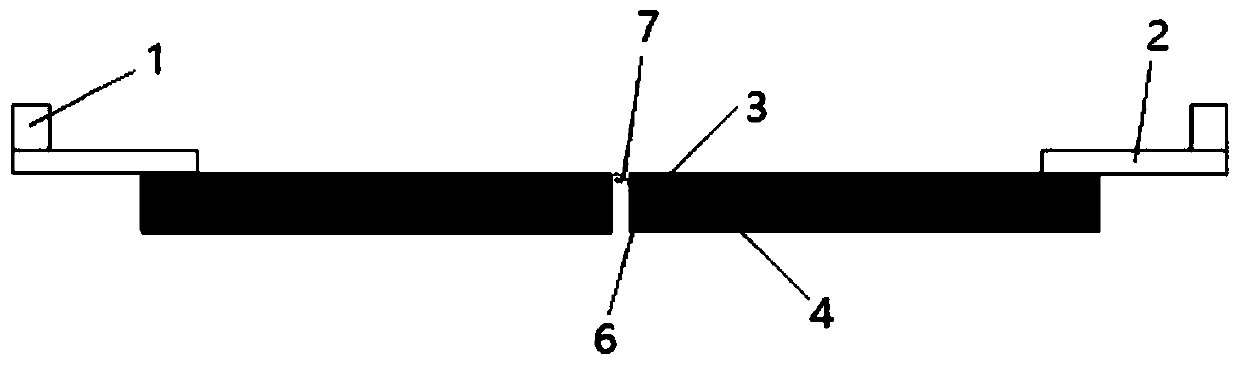

Hyperfine double three-dimensional high molecular material integrated screen printing plate

InactiveCN110271264AHigh printing durabilityImprove wear resistanceFinal product manufactureScreen printersScreen printingPolyester

The invention discloses a hyperfine double three-dimensional high molecular material integrated screen printing plate which comprises a screen frame, a polyester screen, a steel wire gauze, high molecular film layers, high molecular pattern regions, photosensitive glue pattern regions and photosensitive glue lines. The high molecular pattern regions are separately arranged on the high molecular film layers and stretch to the bottom of the steel wire gauze, the photosensitive glue pattern regions fill the high molecular pattern regions, the photosensitive glue lines are arranged in the middle parts of the photosensitive glue pattern regions, and the high molecular pattern regions and the photosensitive glue lines are of hollowed structures. In this way, the high molecular materials in middle non-printed regions of the lines are super high in abrasive resistance and high in printing resistance, the service life of screen printing can be prolonged greatly, the deformation quantities of the silk screen and the patterns are reduced greatly, the printing quality can be improved greatly, high strength of high molecules is combined and high resolution of the photosensitive glue is also available, and meanwhile, new patterns can be re-manufactured after the screen printing plate is recovered and back-washed, so that the cost is saved greatly.

Owner:SUZHOU WOSUTE ELECTRONICS MATERIALS CO LTD

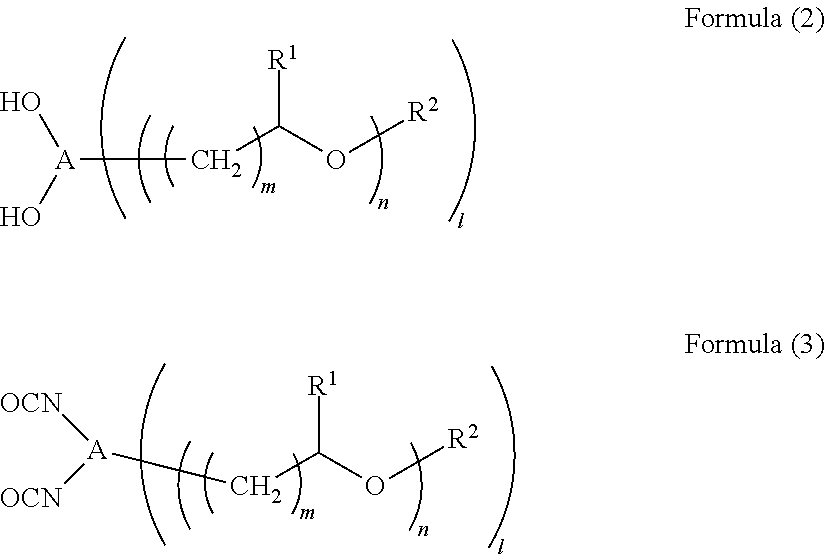

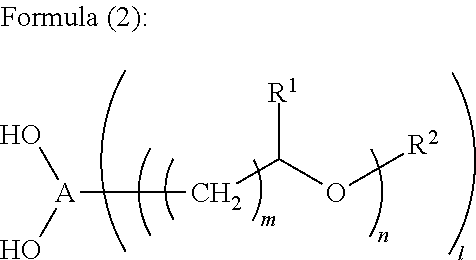

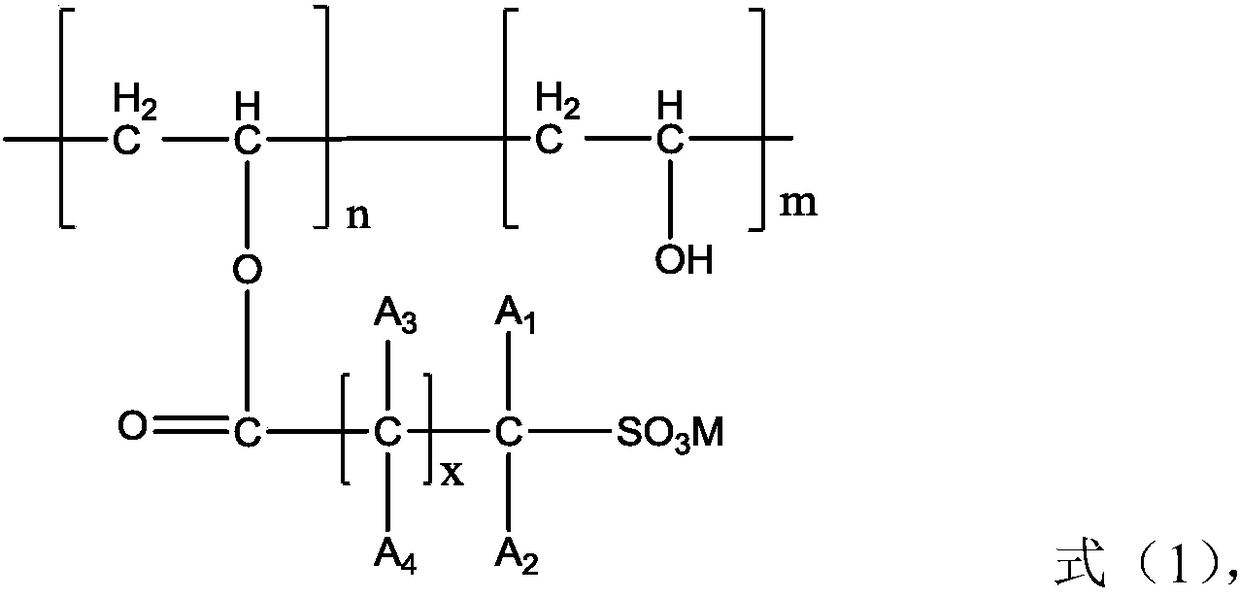

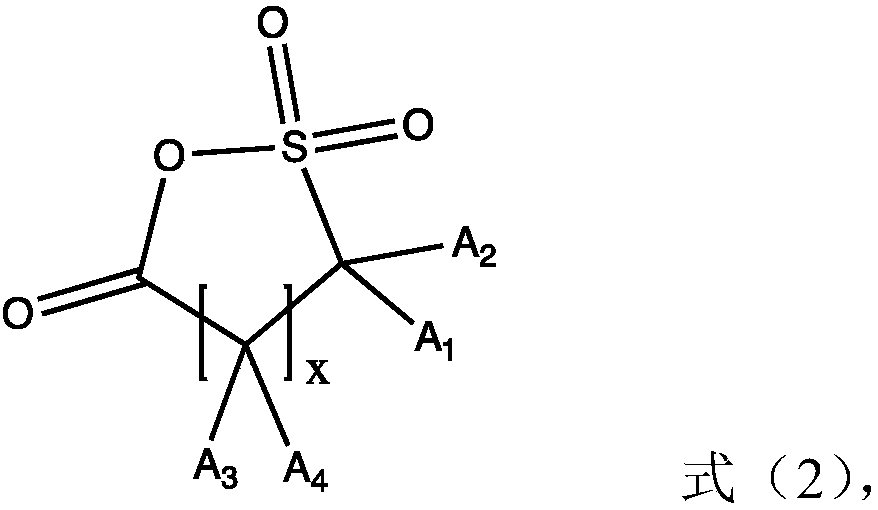

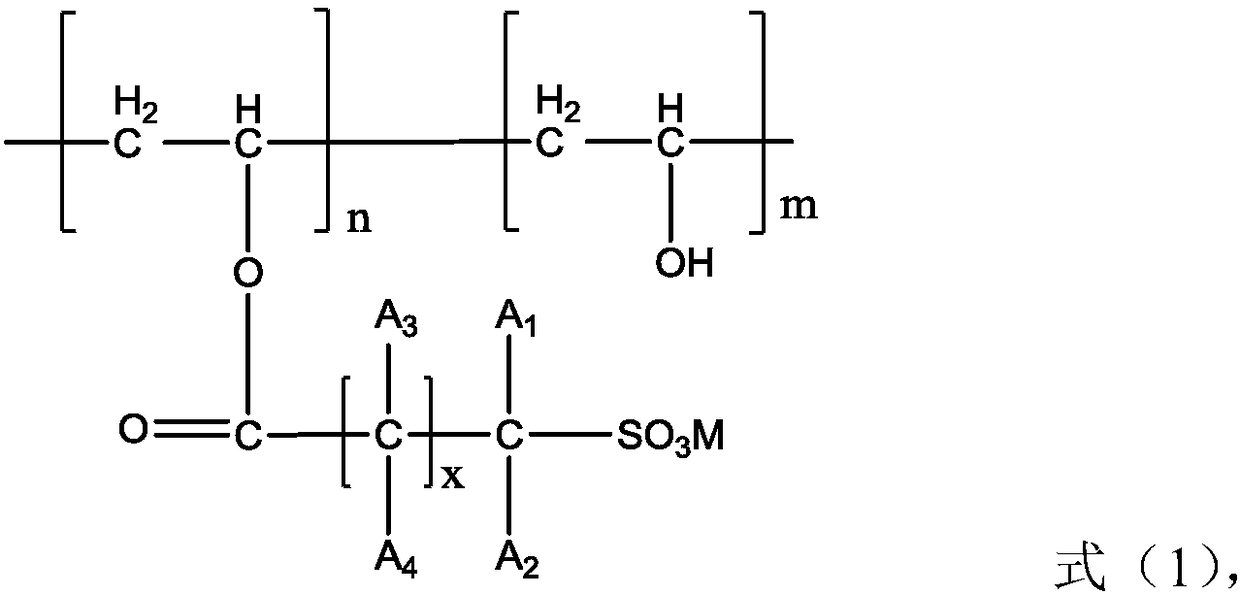

Polyvinyl alcohol ester sulfonate, synthetic method thereof, hydrophilic plate for printing and application thereof, and printing plate

ActiveCN108329409AHigh printing durabilityImprove hydrophilicityPlate printingCoatingsSulfonatePolymer science

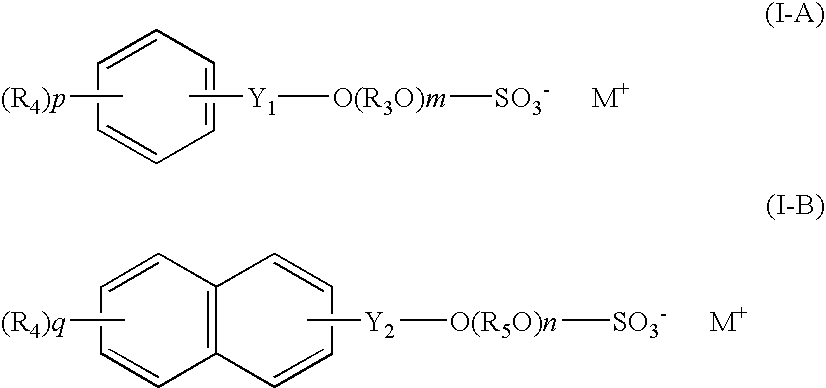

The invention relates to the field of ink jet printing, and discloses polyvinyl alcohol ester sulfonate, a synthetic method thereof, a hydrophilic plate for printing and application thereof, and a printing plate. The polyvinyl alcohol ester sulfonate contains a chemical structure represented as the formula (1), wherein the sum of m and n is a positive integer of 400 to 5000; n / (m+n) is 0.05 to 1;x is a positive integer of 1 to 3; A1-A4 are independently hydrogen or C1-C6 alkyl groups; M is Li, Na, K or NH4. The hydrophilic high-molecular compound can greatly improve hydrophilicity of a coating layer and improve printability of the hydrophilic plate.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com