Metal porous plate and preparation method thereof

A production method and technology of metal holes, applied to printing plates, printing plate preparation, rotary printing machines, etc., can solve the problems of long auxiliary work time, depending on the printing durability, and difficult to achieve, so as to improve printing quality and printing durability Higher rate, higher printing durability, beneficial to the effect of flattening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

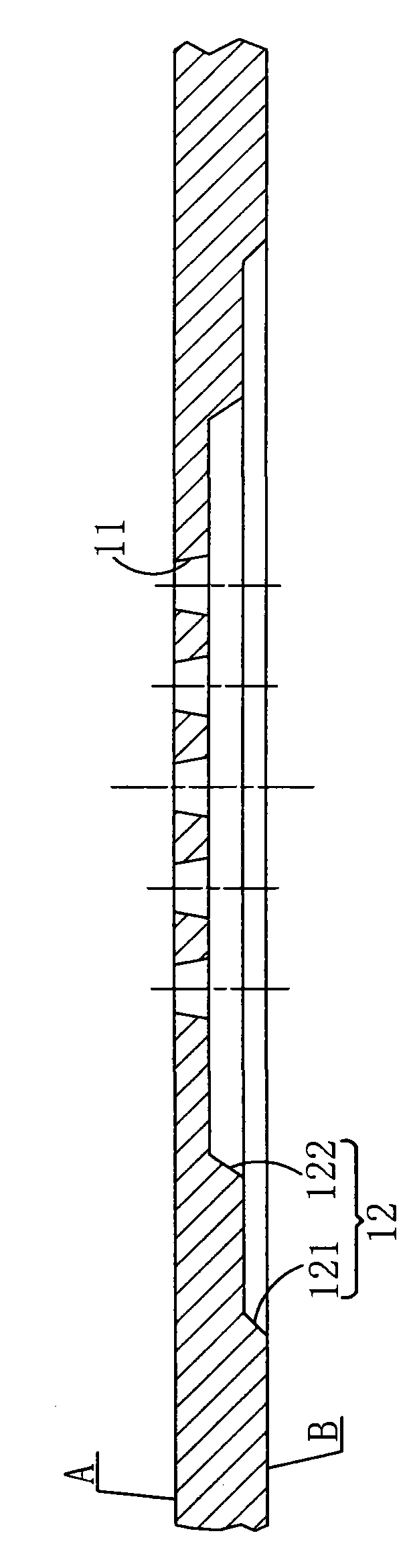

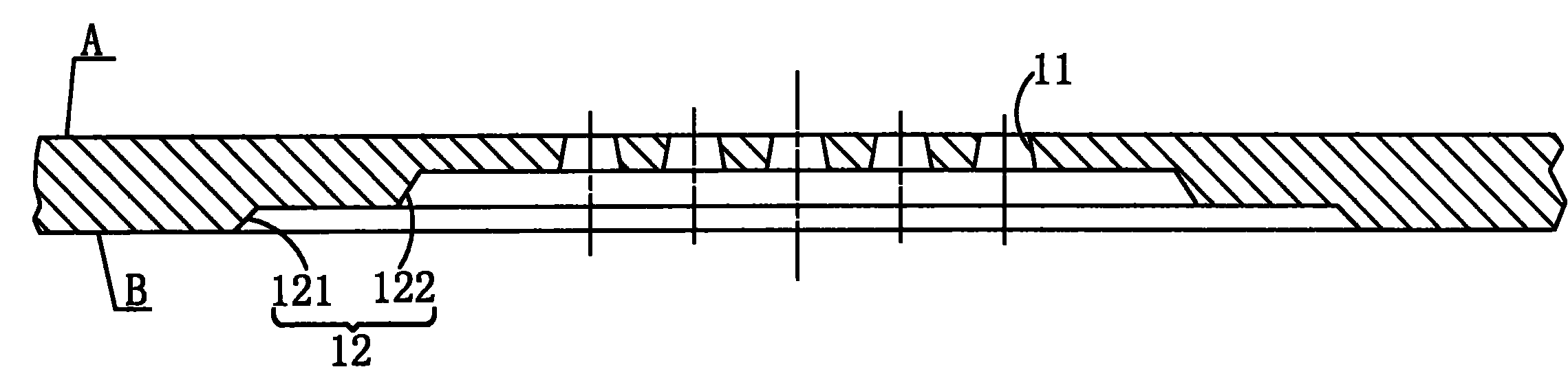

[0030] Such as figure 1 As shown, the metal stencil proposed by the present invention includes a metal plate 1, on which an ink penetration hole 11 is provided, on the metal plate 1 and outside the area of the ink penetration hole 11, a lining area 12 is opened, and the lining The area of the plate area 12 is larger than the area of the ink penetration hole 11, and the lining area 12 and the ink penetration hole 11 are distributed in steps.

[0031] Because the stencil of the present invention uses metal as the plate material, the printing durability of the stencil is greatly improved; due to the stress around the ink penetration hole, the stencil is prone to deformation during printing, so the present invention is still in the region of the ink penetration hole 11 A lining area 12 is set outside to increase the support for the ink penetration hole 11, and at the same time facilitate the flattening of the stencil to avoid deformation of the stencil, thereby improving the...

Embodiment approach 2

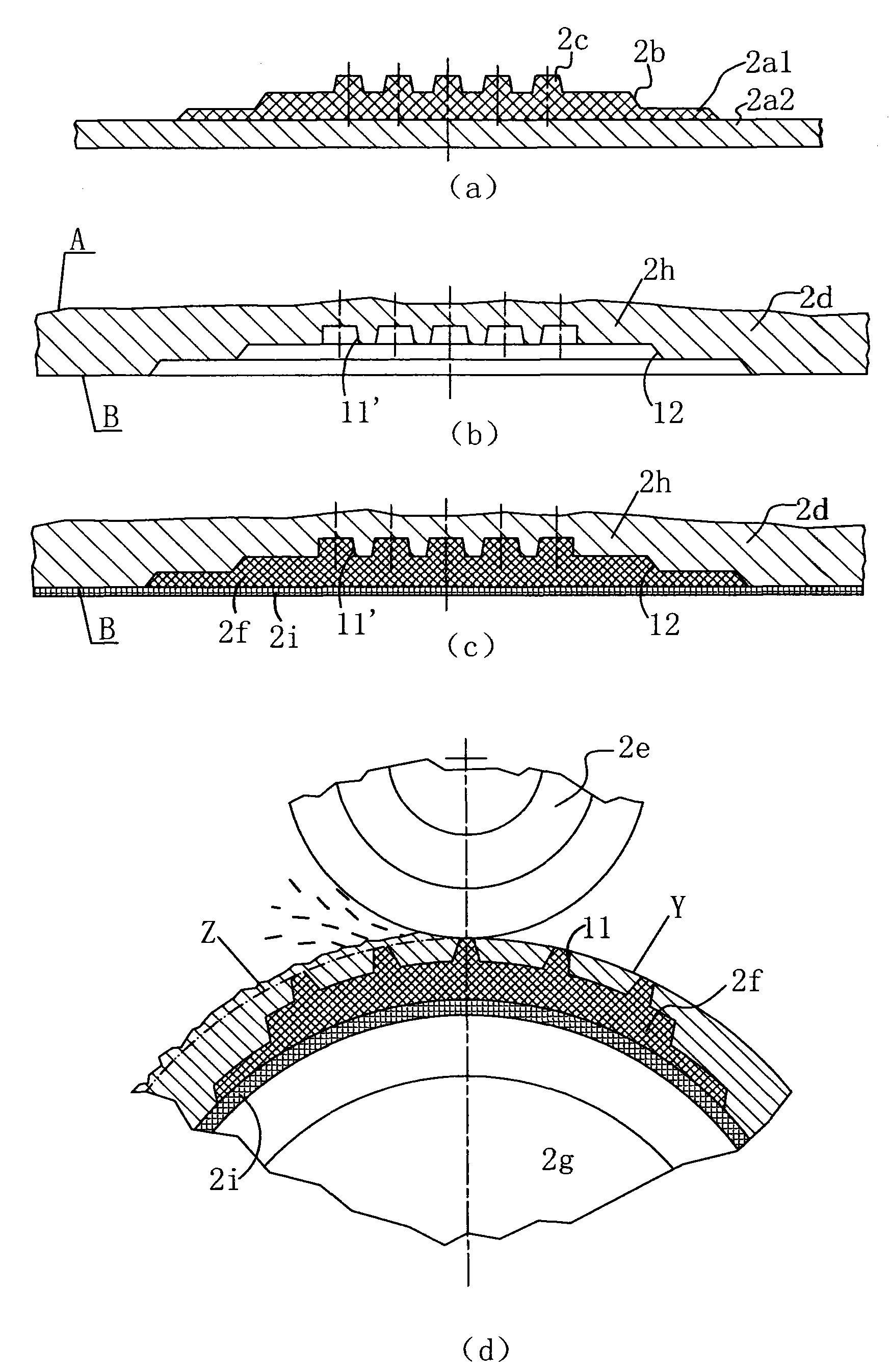

[0036] Such as figure 2 As shown, the manufacturing method of the metal stencil that the embodiment of the present invention proposes, it comprises the following steps:

[0037] Such as figure 2 As shown in (a), a stencil punch 2a1 is provided, and the punch 2a1 has more than one step 2b, here there are two steps 2b, and a plurality of bumps 2c are provided on the top of the step 2b; wherein, the punch 2a1 can be placed on the bottom support 2a2, and the convex mold 2a1 can be a nylon convex mold, such as alcohol-displaying nylon convex mold.

[0038] Such as figure 2 As shown in (b), the metal intaglio body 2d is turned over by the punch 2a1, and the metal intaglio body 2d forms a step-like lining area 12 corresponding to the above-mentioned step 2b, and forms a non-penetrating ink penetrating area corresponding to the above-mentioned bump 2c. Blind hole 11', that is, the ink-through blind hole 11' at this time is not a through hole, but a blind hole. The area of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com