Polyvinyl alcohol ester sulfonate, synthetic method thereof, hydrophilic plate for printing and application thereof, and printing plate

A technology of polyvinyl alcohol ester sulfonate and polyvinyl alcohol, which is applied in printing, printing plates, printing processes, etc., to achieve high printing durability, good hydrophilic effect, and clean and flawless surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

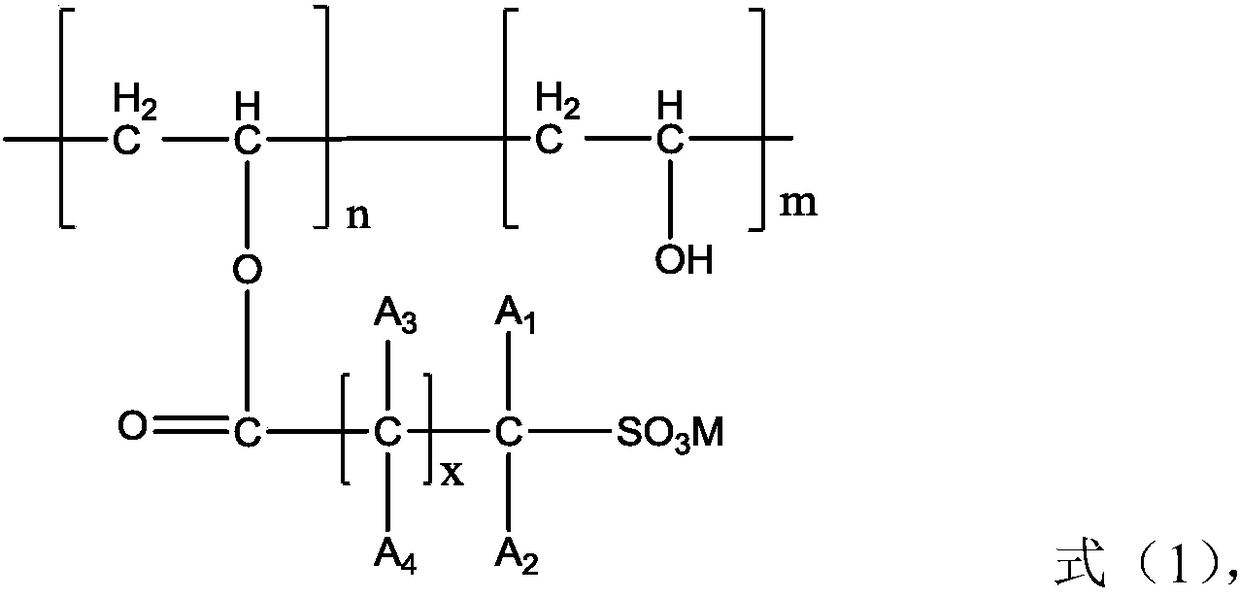

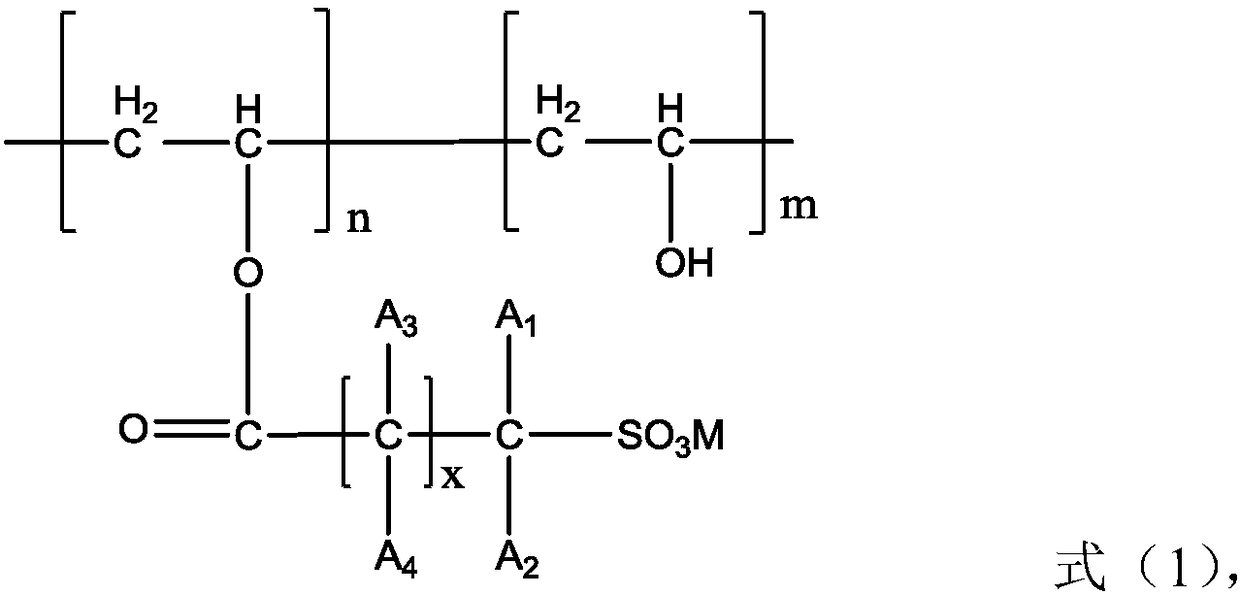

[0030] According to a preferred embodiment of the present invention, the polyvinyl alcohol ester sulfonate can be synthesized by the following method: the polyvinyl alcohol ester sulfonate is an esterification product of polyvinyl alcohol and sulfopropionic anhydride.

[0031] Preferably, the sulfopropionic anhydride is selected from 3-sulfopropionic anhydride, 4-methyl-3-sulfopropionic anhydride, 5-methyl-3-sulfopropionic anhydride, 4,4-dimethyl- 3-sulfopropionic anhydride, 5,5-dimethyl-3-sulfopropionic anhydride, 4,5-dimethyl-3-sulfopropionic anhydride, 4-propyl-3-sulfopropionic anhydride and 5 - at least one of isopropyl-3-sulfopropionic anhydride.

[0032] In the present invention, polyvinyl alcohol and sulfopropionic anhydride undergo esterification reaction in the presence of activator and solvent. The activator is preferably an alkaline compound, for example, the activator can be selected from tetramethylammonium hydroxide, lithium hydroxide, sodium hydroxide, potassiu...

Embodiment 1

[0094] This example illustrates the preparation of polyvinyl alcohol ester sulfonates of the present invention.

[0095] Dissolve 22g of polyvinyl alcohol (Ningxia Dadi Chemical Co., Ltd. 1799) in 200mL of dimethylformamide (DMF), add 5.7g of sodium metal after chopping, and mix at room temperature for 0.5h;

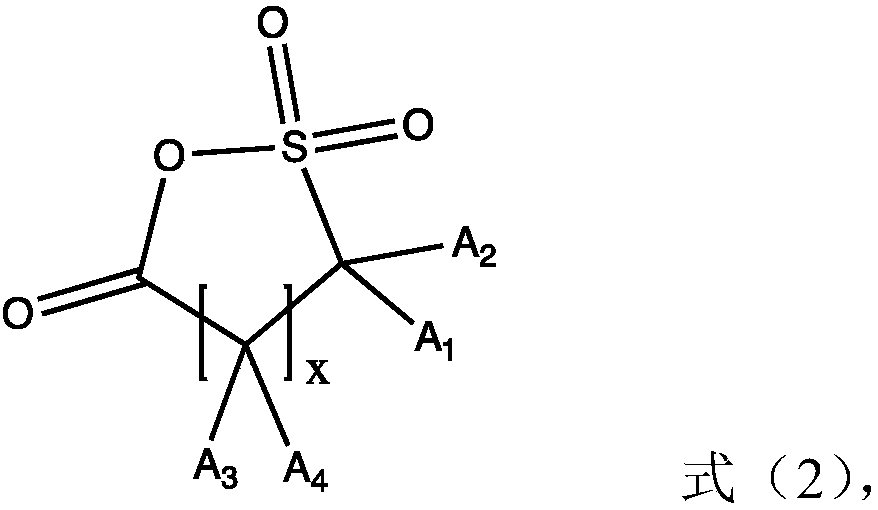

[0096] Then drop 3-sulfopropionic anhydride (structural formula such as formula (2), wherein A 1 、A 2 、A 3 and A 4 Both are H, x=1; purchased from Shanghai Sanmu Chemical Technology Co., Ltd.), dimethylformamide solution (3-sulfopropionic anhydride 34.03g, dimethylformamide 300mL), polyvinyl alcohol: 3-sulfo The weight ratio of propionic anhydride is 0.65:1, after about 1h, the reaction mixture is obtained;

[0097] The reaction mixture was pre-reacted at room temperature for 1 hour, and then heated to 70°C for etherification reaction for 3 hours;

[0098] The product obtained after the etherification reaction is completed is spray-dried to obtain a solid powder.

...

Embodiment 2

[0102] This example illustrates the preparation of polyvinyl alcohol ester sulfonates of the present invention.

[0103] 11g of polyvinyl alcohol (Ningxia Dadi Chemical Co., Ltd. 1899) was dissolved in 100mL of dioxane, and a total of 3.6g of sodium hydride (dispersed in mineral oil, wherein the concentration of sodium hydride was 60% by weight) was slowly added in three batches. ), mixed at room temperature for 1h;

[0104] Then drop 4-methyl-3-sulfopropionic anhydride (structural formula such as formula (2), wherein A 1 is methyl, A 2 、A 3 and A 4 Both are H, x=1; purchased from Bailingwei Company) dioxane solution (4-methyl-3-sulfopropionic anhydride 22.52g, dioxane 20mL), polyvinyl alcohol: 4-methyl- The weight ratio of 3-sulfopropionic anhydride is 0.49:1, after about 1 hour, the reaction mixture is obtained;

[0105] The reaction mixture was pre-reacted at room temperature for 1.2 hours, and then heated to 75°C for etherification reaction for 2 hours;

[0106] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com