Patents

Literature

63results about How to "Excellent printing resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Imaging element for producing a lithographic plate therewith

InactiveUS6080523AHigh sensitivityExcellent printing resistancePhotosensitive materialsSemiconductor/solid-state device manufacturingAqueous solutionSpectral sensitivity

According to the present invention there is provided an imaging element comprising on a support having a hydrophilic surface in the order given a photosensitive layer insoluble in an aqueous alkaline solution and capable of becoming soluble in said aqueous alkaline solution upon exposure with actinic light and a thermosensitive layer comprising a masking dye rendering said thermosensitive layer opaque to light for which said photosensitive layer has spectral sensitivity and said imaging element further comprising a compound A capable of converting light into heat comprised in said thermosensitive layer or a layer adjacent thereto, characterized in that said thermosensitive layer further comprises thermoplastic particles of a hydrophobic polymer.

Owner:AGFA NV

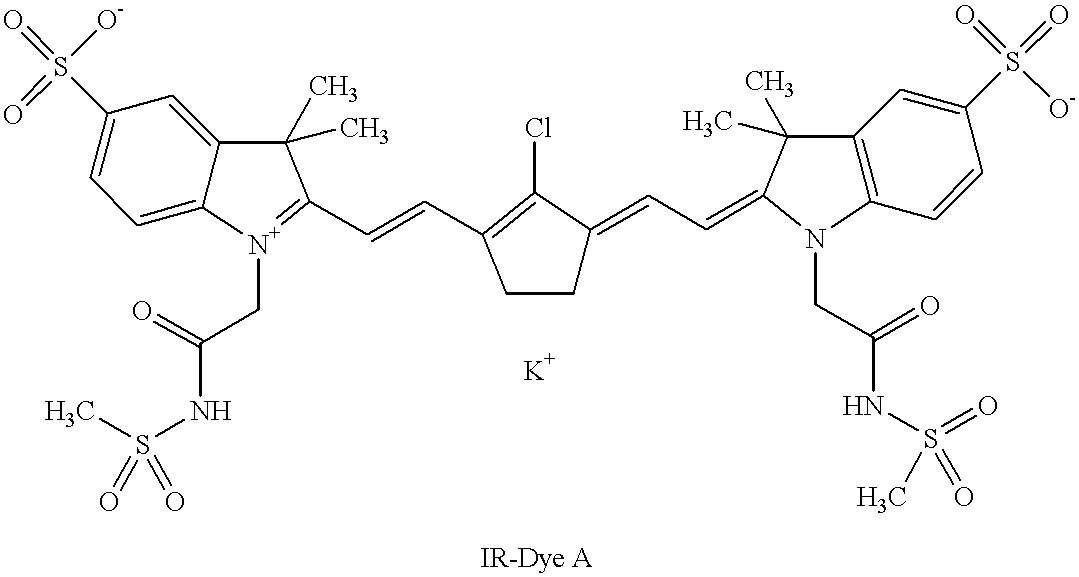

Lithographic printing plate and image forming method

InactiveUS6509133B1Excellent printing resistanceShow resistanceX-ray/infra-red processesPhotosensitive materialsWater dispersibleComputer to plate

In order to provide a computer-to-plate (CTP) plate in which an image can be inscribed by a laser beam having Ithe maximum strength in a near infrared or infrared region, and heat processing is not necessary prior to developing a latent image, and which allows the use of a conventional printing apparatus as it is upon printing, (I) a lithographic printing plate is provided which has on a substrate, a photosensitive layer comprising a photosensitive composition containing a crosslinking agent, an aqueous dispersion of resin fine particles made of a resin which is self water-dispersible having a carboxylic group and a functional group capable of performing cross-linking reactions with the crosslinking agent, and an infrared absorption agent; and (II) an image forming method is provided which is characterized in that after an image has been formed on a photosensitive layer of the lithographic printing plate set forth in the above (I) by using a laser beam, the image is subjected to wet development.

Owner:DAINIPPON INK & CHEM INC

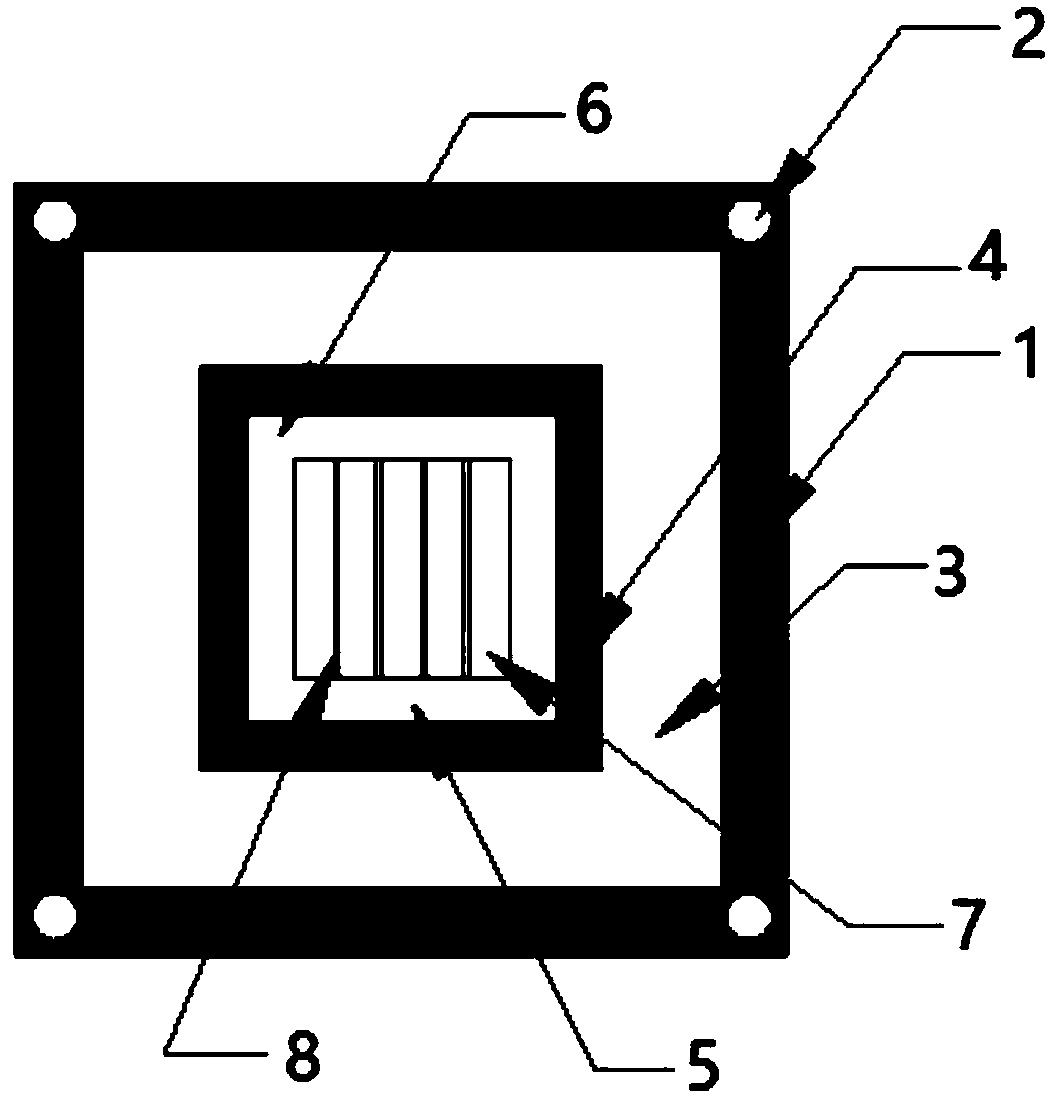

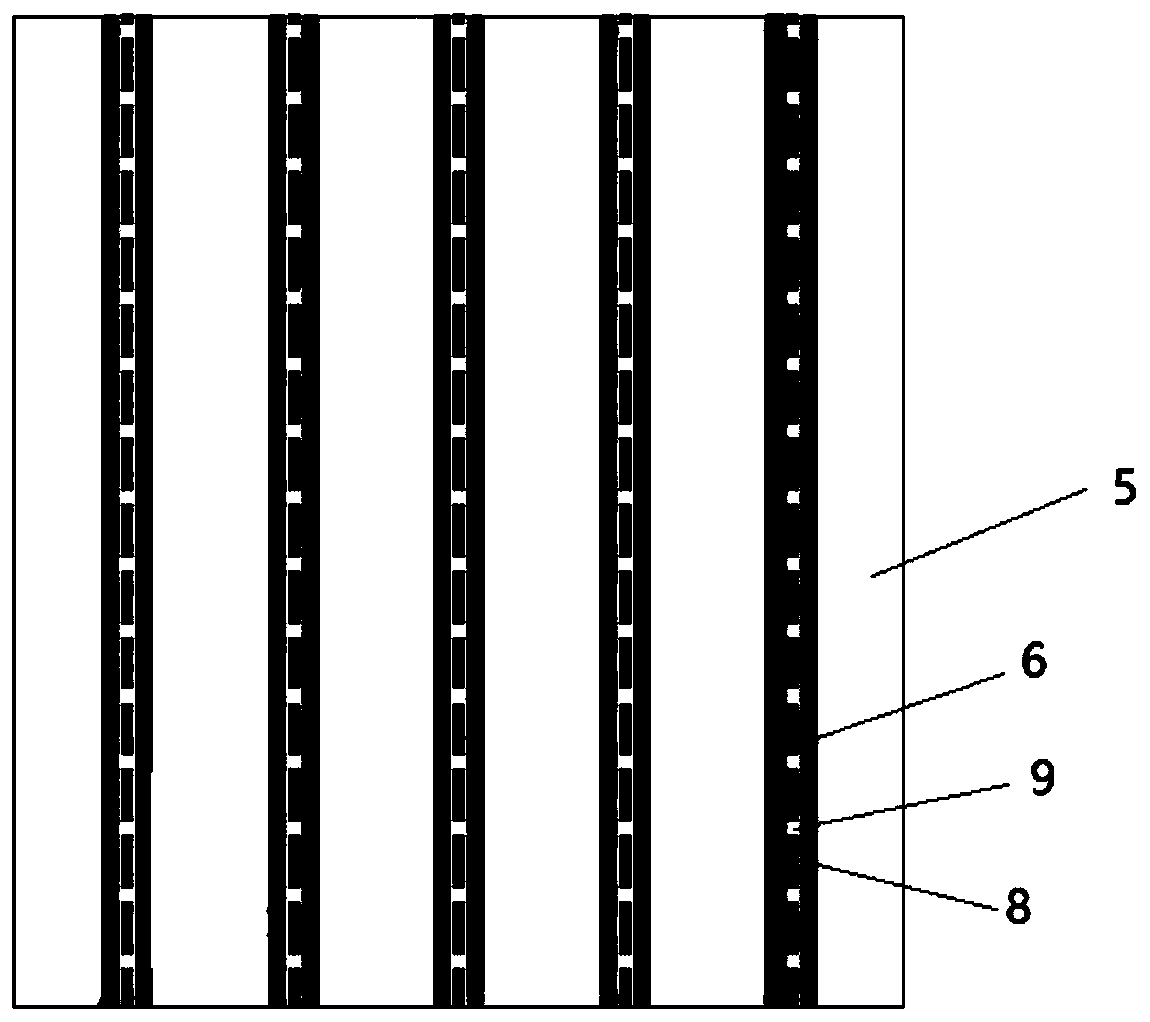

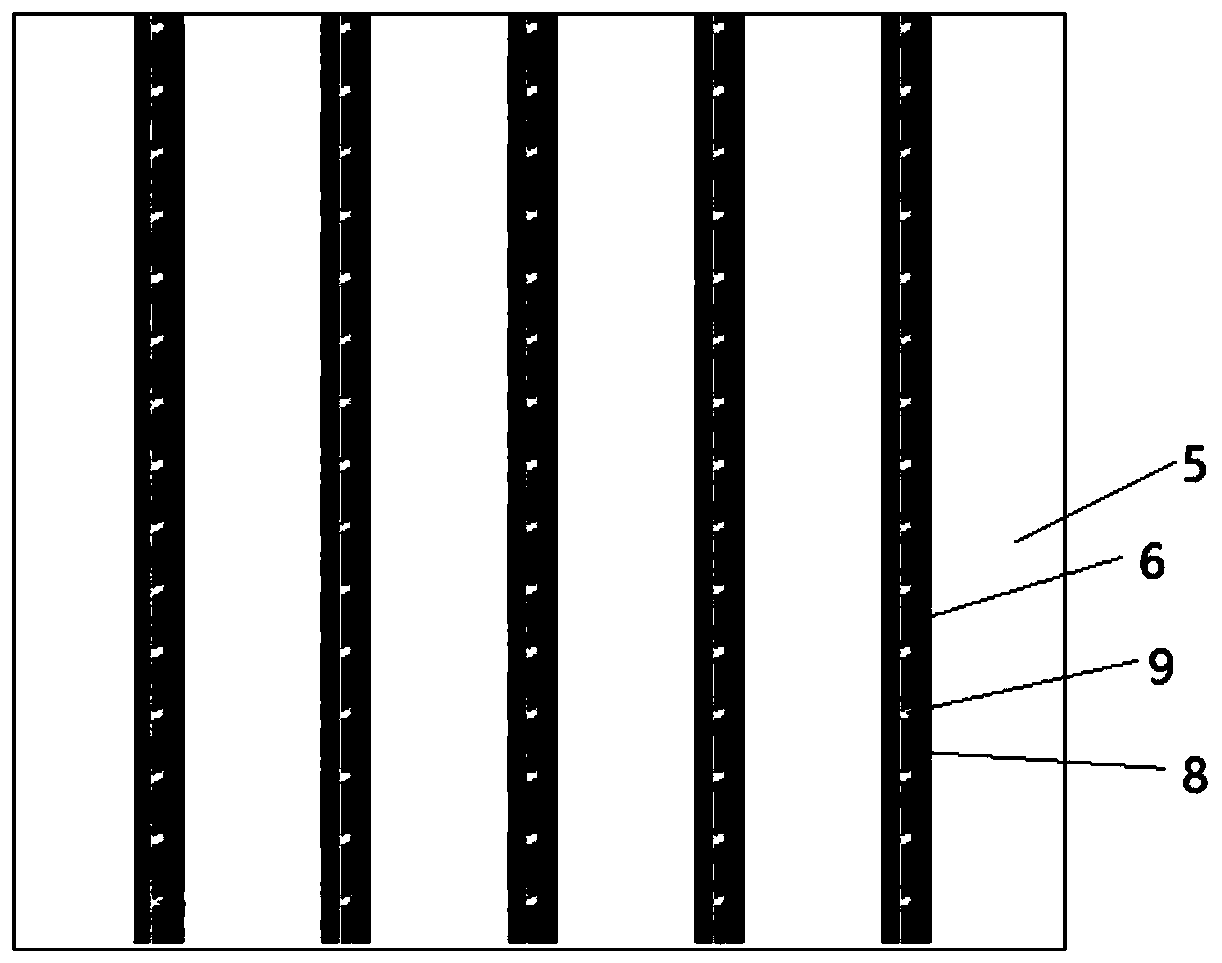

Manufacturing method of metal alloy composite screen plate

InactiveCN110039883ALow elongationGood dimensional stabilityPlate printingFoil printingDouble supportPuncture resistance

The invention discloses a manufacturing method of a metal alloy composite screen plate. The manufacturing method comprises the following specific steps of 1) carrying out net pulling compounding; 2) manufacturing an alloy sheet pattern outer contour; 3) preparing a film layer; 4) coating an adhesive layer; 5) coating a film; 6) drying; 7) laser; 8) cleaning; and 9) detecting and packaging. In thisway, according to the manufacturing method of the metal alloy composite screen plate, a metal alloy sheet is adopted to replace traditional mesh cloth, and the manufacturing method has low elongationrate, better dimensional stability, printing resistance, puncture resistance, double supports of the metal alloy sheet and the film layer are adopted, the service life of the bonding strength far beyond a silk-screen and the film layer can be improved by 30% or above, and under the action of a high-molecular adhesive, the adhesion force of the high-molecular composite layer is extremely high, theplate making yield is greatly improved, the production cost is saved, the printing is good, the line type is good, and the efficiency of a battery piece is obviously improved.

Owner:SUZHOU WOSUTE ELECTRONICS MATERIALS CO LTD

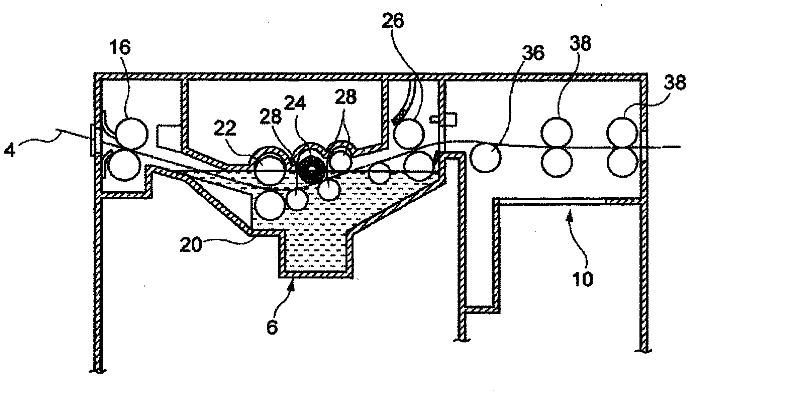

Heat sensitive imaging element for providing a lithographic printing plate

InactiveUS6210857B1Improve photolithography qualityLabor intensiveSemiconductor/solid-state device manufacturingPhotosensitive material auxillary/base layersHydrophilic polymersEngineering

According to the present invention there is provided a heat-sensitive imaging element for providing a lithographic printing late, comprising a lithographic base with a hydrophobic oleophilic surface and a top layer comprising a compound capable of converting light into heat and a hydrophilic polymer, characterized in that said hydrophilic polymer is crosslinked.

Owner:AGFA NV

Original edition of lithographic printing plate

ActiveCN1511712AGood plate durabilityExcellent printing resistancePlate printingPhotosensitive material processingImage recordingEngineering

To provide an original plate for a planographic printing plate, which is excellent in any of sensitivity, and printing resistance, scumming resistance and easy viewability of a water rise in the use of the original plate as the planographic printing plate. In this original plate for the planographic printing plate, an image recording layer, where an image can be formed by heat, is provided on a substrate for the planographic printing plate, which is obtained by applying electrochemical surface roughing using an aqueous solution containing at least hydrochloric acid, anodic oxidation and alkaline-metal silicate treatment to an aluminum plate. The substrate for the planographic printing plate has a grained surface with a structure wherein a large pit with an average opening diameter of 2-10 [mu]m and a small pit with an average opening diameter of 0.05-0.8 [mu]m are superposed on each other, and the average ratio of the depth of the small pit to the opening diameter thereof is in a range of 0.2-0.6. In terms of the substrate for the planographic printing plate, a surface area difference [Delta]S50, which is obtained by means of an atomic force microscope, is in a range of 20-40%, and the coating weight of Si atoms on the surface of the substrate for the planographic printing plate is in a range of 1.0-12.0 mg / m2. (C)2004,JPO&NCIPI.

Owner:FUJIFILM CORP

Imaging element for different imaging systems

InactiveUS6367383B1High acceptanceExcellent printing resistanceDuplicating/marking methodsPlate printingPolymer chemistryThermoplastic polymer

According to the present invention there is provided a method for preparing a lithographic printing plate, comprising the step of dispensing in a predetermined pattern a hydrophobic or hydrophobizing composition onto a receiving element comprising on a support a layer comprising hydrophobic thermoplastic polymer particles dispersed in a hardened hydrophilic binder.

Owner:AGFA NV

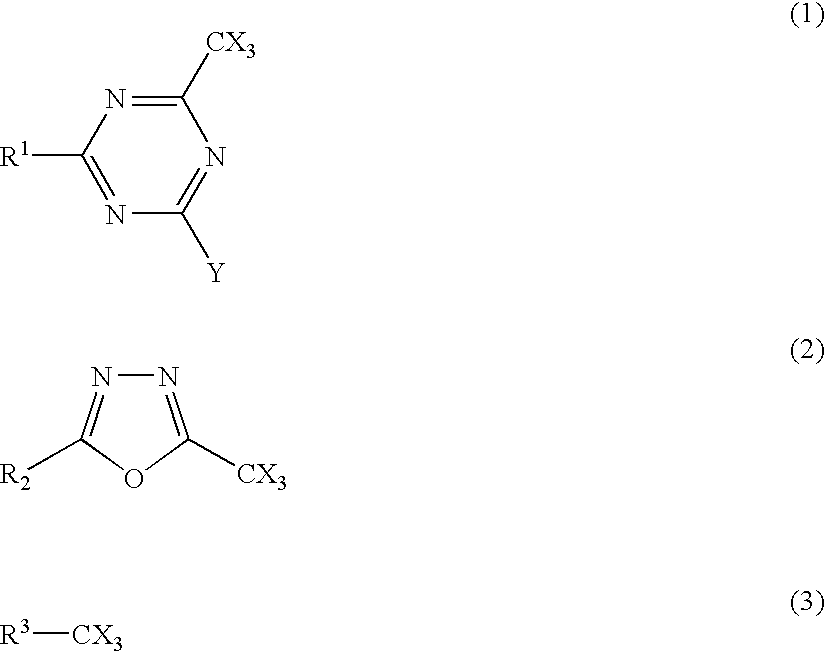

Aluminum alloy sheet for lithographic printing plate

InactiveCN1572533AImprove compactnessImprove water retentionPlate printingFoil printingAlloySoftening

The present invention provides an aluminum alloy sheet for a lithographic printing plate which allows pits to be uniformly formed by electrochemical roughening, and excels in strength and heat softening resistance. The aluminum alloy sheet for a lithographic printing plate includes 0.1-0.3% of Mg, more than 0.05%, but 0.5% or less of Zn, 0.2-0.6% of Fe, 0.03-0.15% of Si, 0.02% or less of Cu, and 0.003-0.05% of Ti, the remainder being Al and impurities. The aluminum alloy sheet may include more than 0.05%, but 0.3% or less of Mn.

Owner:SUMITOMO LIGHT METAL INDS LTD +1

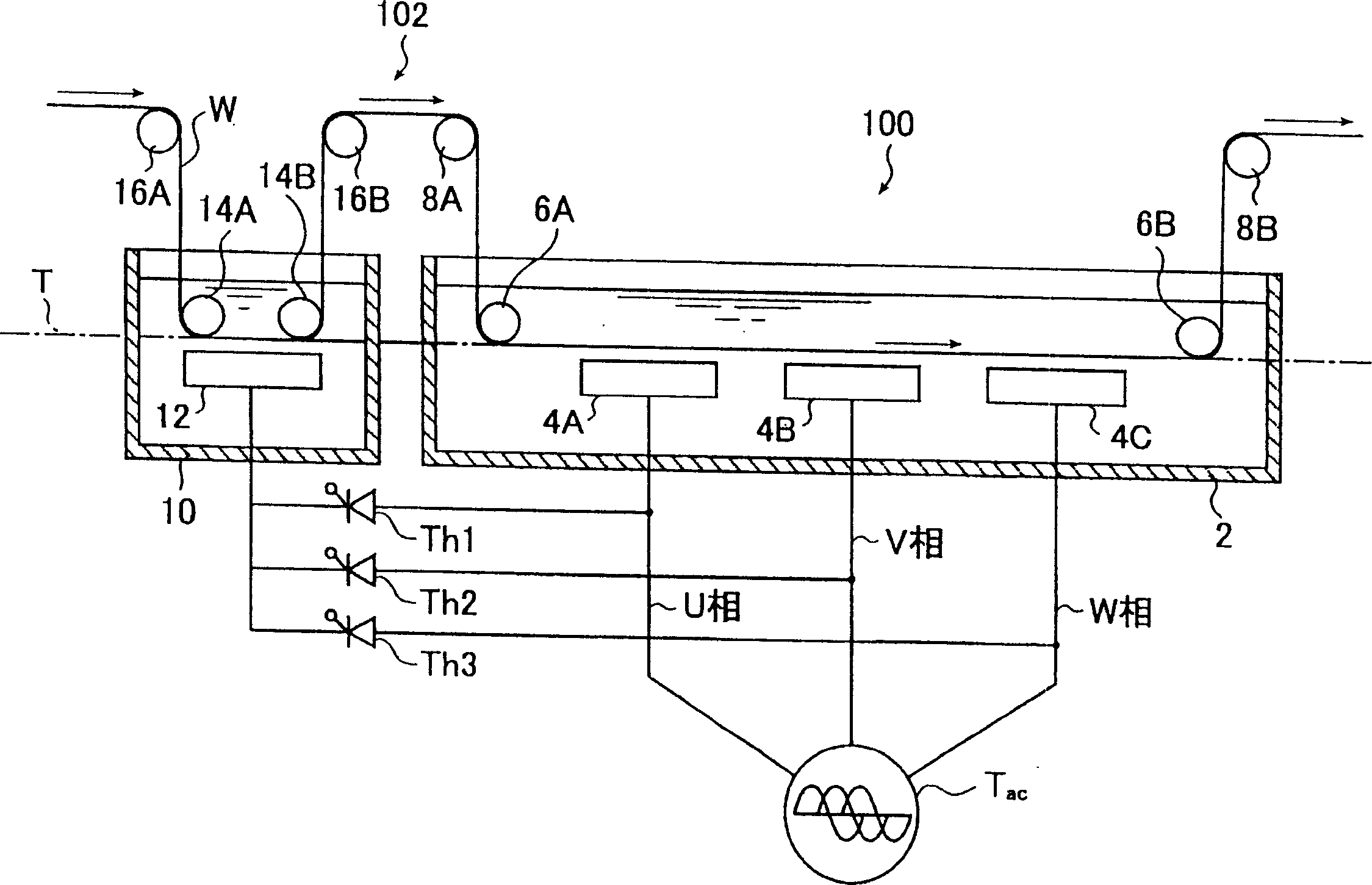

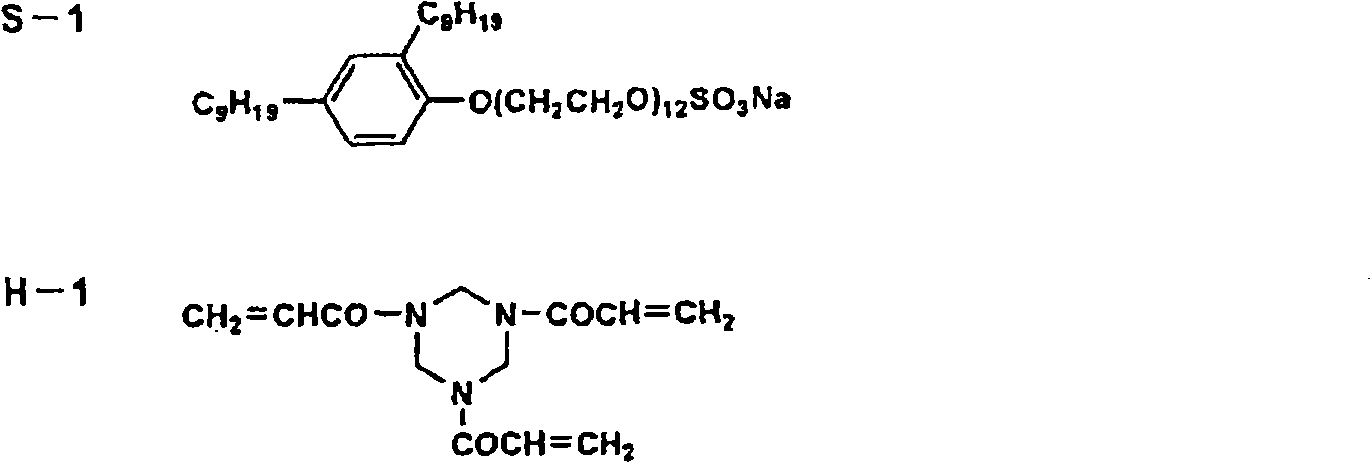

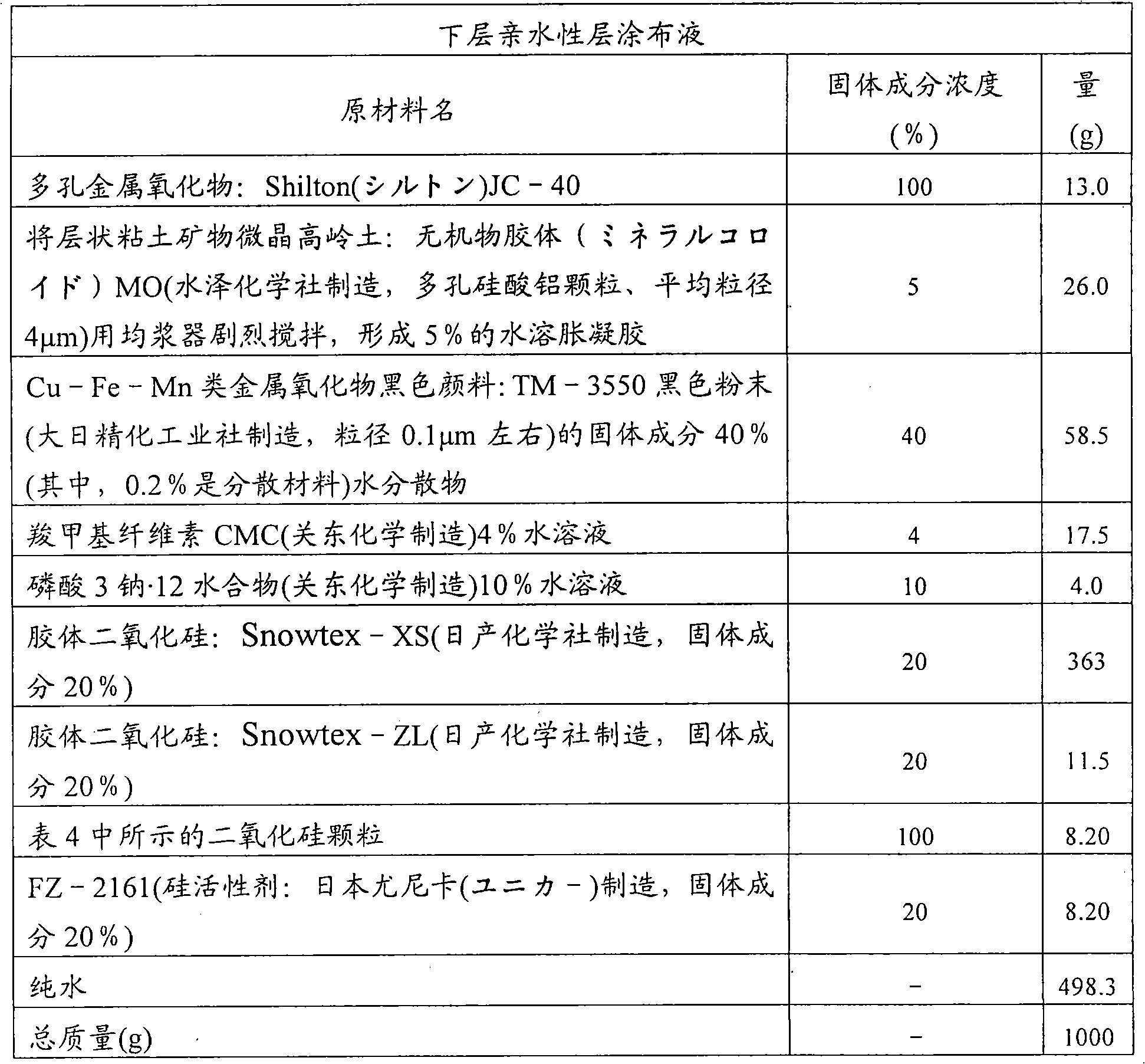

Lithographic printing plate material and printing method

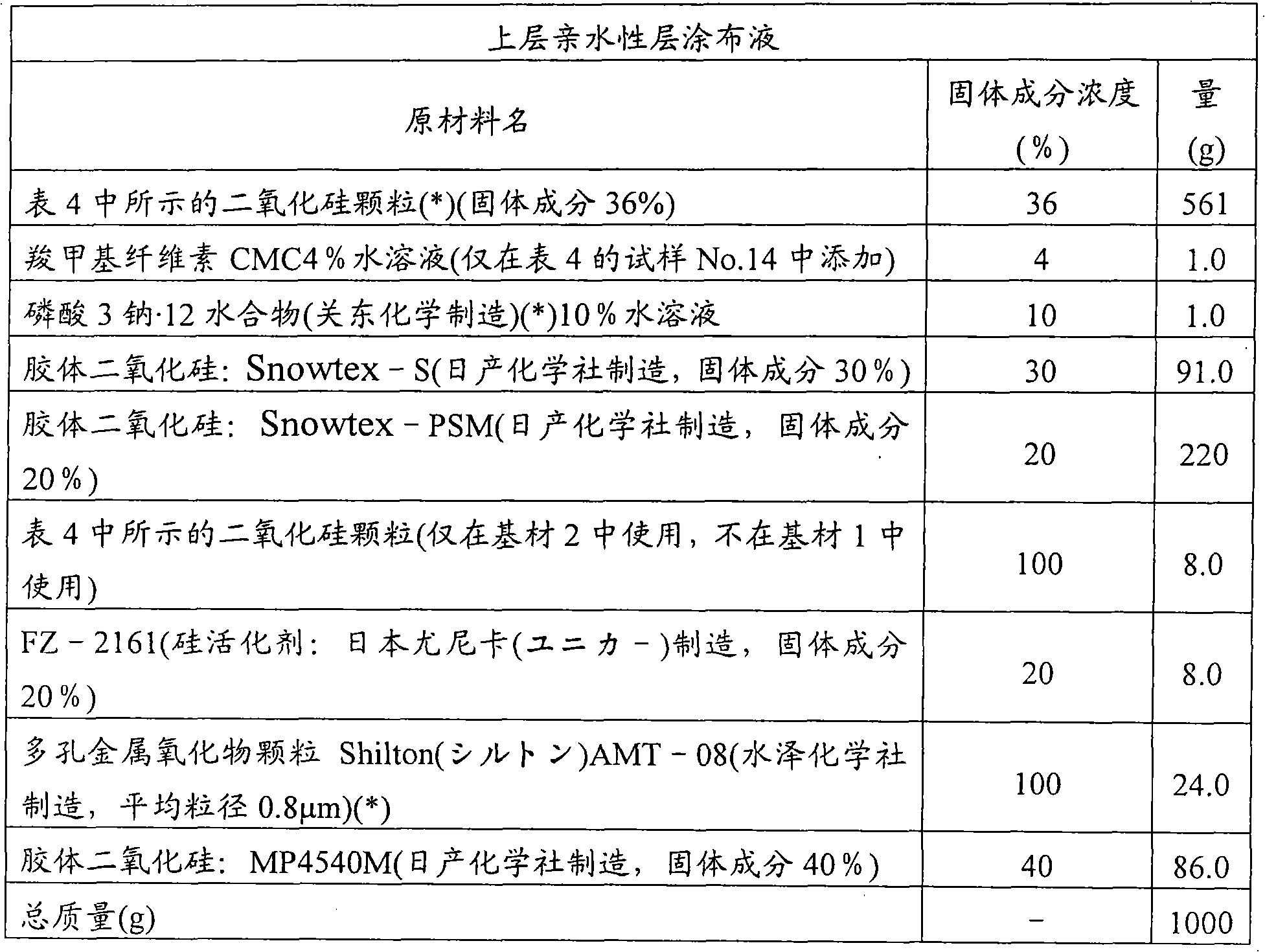

InactiveCN101316720AGood adhesionGood staining performancePlate printingFoil printingSilica particleMohs scale of mineral hardness

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

Offset printing plate, offset printing plate material, support for offset printing plate and offset printing method

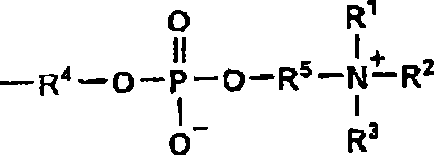

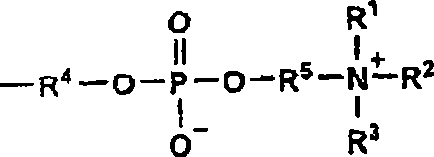

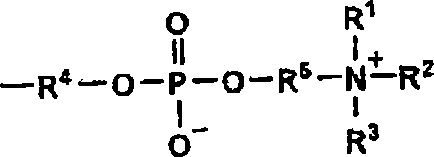

InactiveCN101466554AExcellent printing resistanceExcellent chemical resistancePlate printingFoil printingWater solubleEngineering

An objective is to provide a planographic printing plate material exhibiting excellent properties such as printing durability, resistance to chemicals and anti-stain at the beginning of printing via restart of printing, and also a planographic printing plate exhibiting excellent properties such as printing durability, resistance to chemicals and anti-stain at the beginning of printing via restart of printing. Disclosed is a planographic printing plate comprising a support and provided thereon, an image portion and a non-image portion, wherein the non-image portion comprises a water-soluble phosphobetaine compound.

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

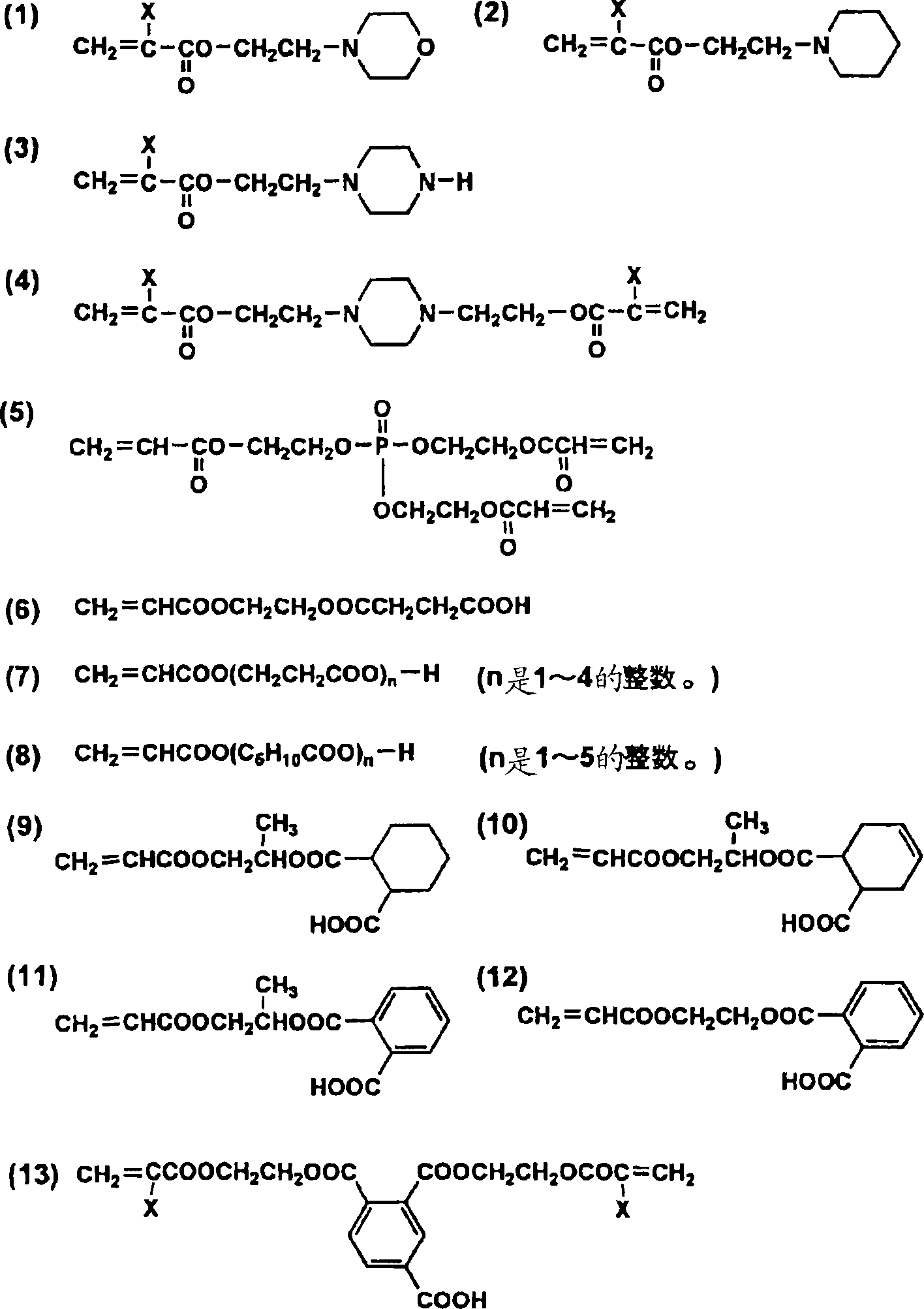

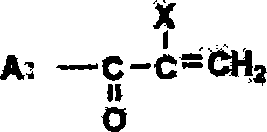

Photosensitive composition

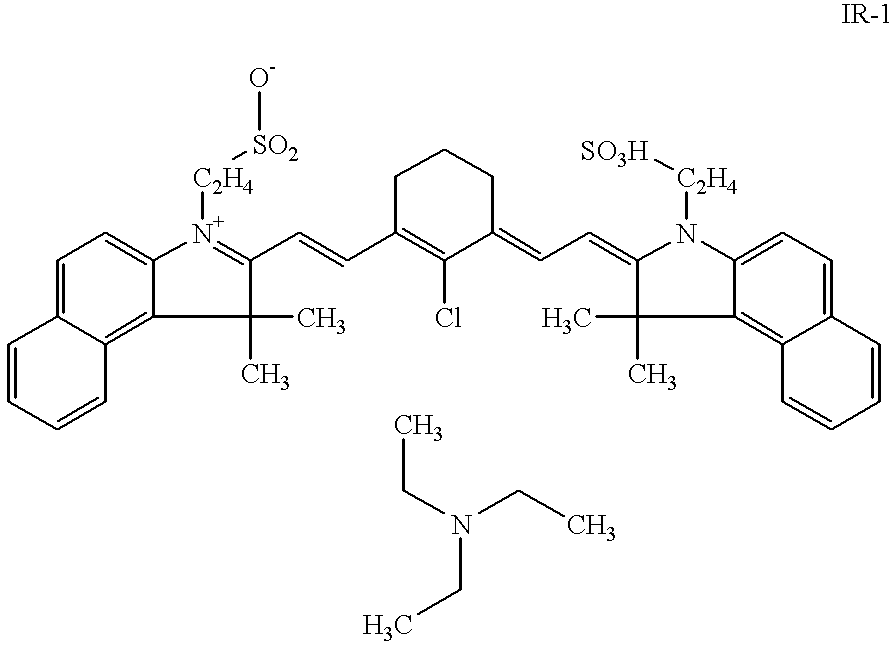

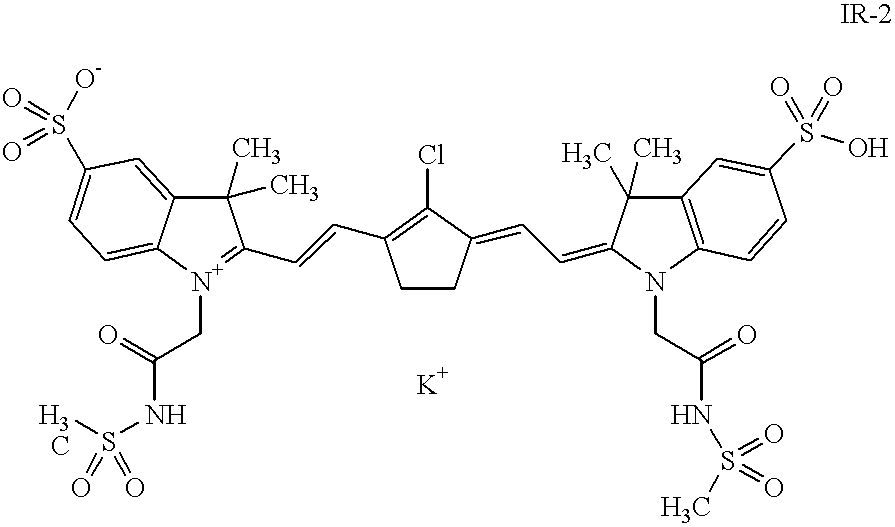

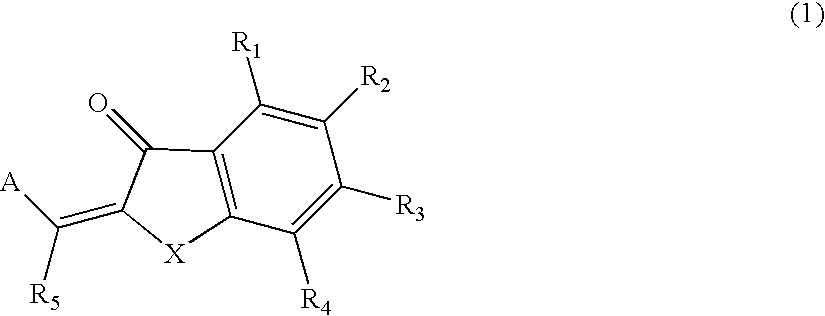

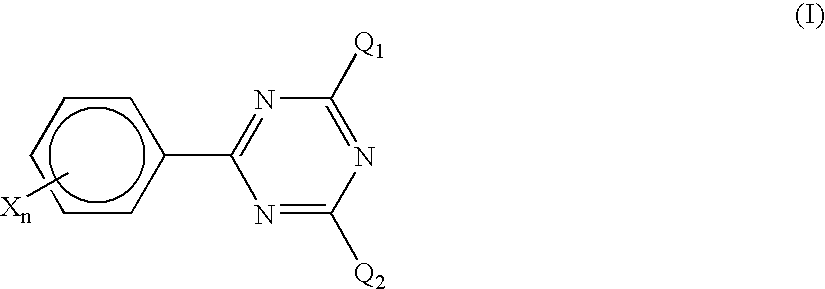

InactiveUS20060073410A1High sensitivityExcellent printing resistanceRadiation applicationsSemiconductor/solid-state device manufacturingHydrogen atomAtomic group

A photosensitive composition comprising: a sensitizing dye represented by the following formula (I): in which A represents an optionally substituted aromatic ring or an optionally substituted hetero ring; X represents an oxygen atoms a sulfur atom, or —N(R6)—; and R1, R2, R3, R4, R5, and R6 each independently represents a hydrogen atom or a monovalent non-metal atomic group; an activator compound being capable of causing a chemical change due to a mutual action with light absorption of the sensitizing dye represented by the formula (1) so as to generate at least one of a radical, an acid and a base; and a compound being capable of reacting with at least one of a radical and an acid so that physical or chemical characteristics thereof change irreversibly.

Owner:FUJIFILM CORP +1

Coextrusion casting polyester film and preparation method thereof

ActiveCN102848676AExcellent printing resistanceSolve the problem of long-term brittlenessSynthetic resin layered productsCoatingsPolyesterPolyethylene terephthalate glycol

The invention provides a coextrusion casting polyester film and a preparation method thereof. The polyester film is made by a coextrusion casting technique, wherein the inner and outer layers are isophthalic acid modified PET (Polyethylene Terephthalate) resin and the middle layer is maleic anhydride graft modified by PP (Propene Polymer) resin. The invention further provides a preparation method of the coextrusion casting polyester film. According to the technical scheme of the invention, the polyester film provided by the invention is high in elongation at break, difficult to become fragile after being stored for long time and capable of being adhered to the surface of a metal plate, so that the problem that the single layer of casting polyester film is easy to become fragile after being stored for long time in the prior art is solved.

Owner:ORG TECH CO LTD

Lithographic Printing Original Plate, Method For Producing Lithographic Printing Plate Using Same, And Method For Producing Printed Matter

InactiveCN107430342AGood reproducibilityNo rejectionPlaten pressesPlate printingEngineeringPlanographic printing

Owner:TORAY IND INC

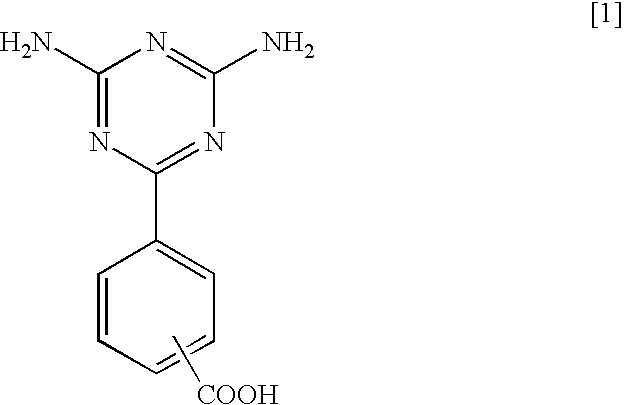

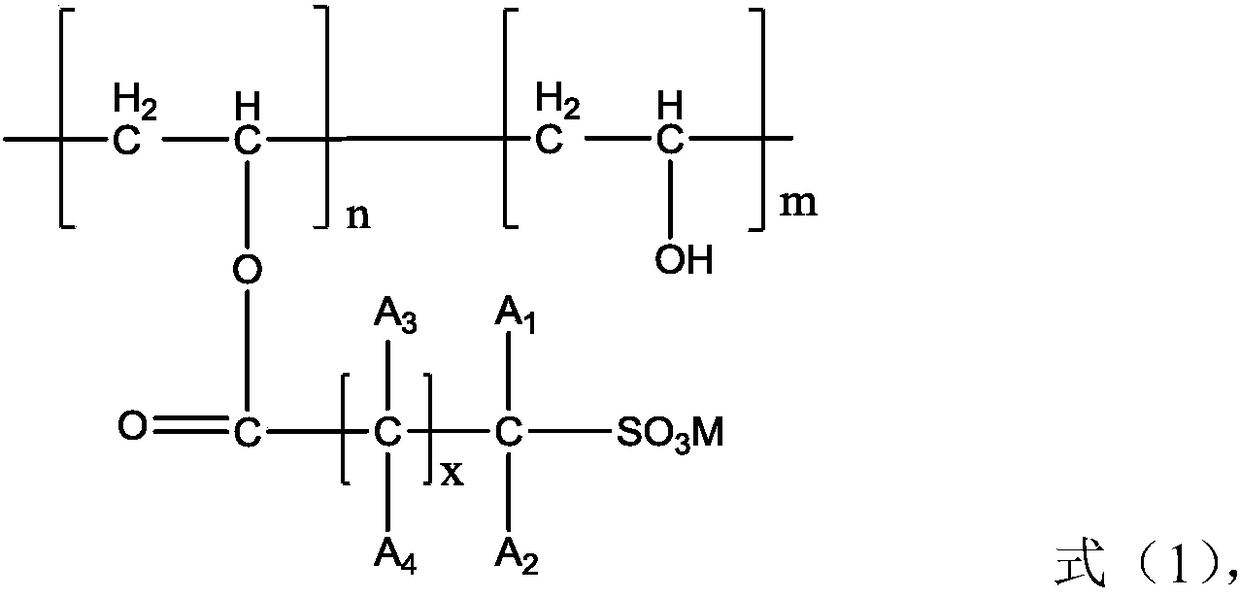

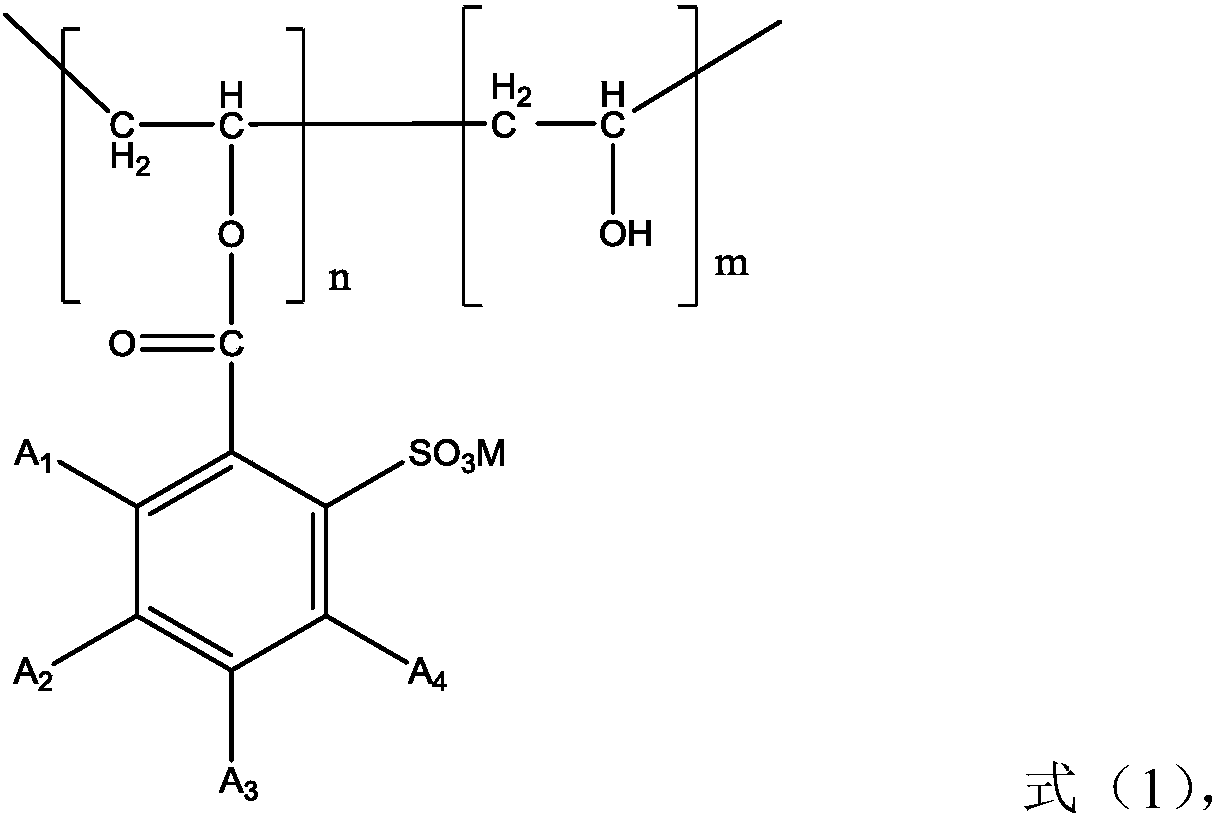

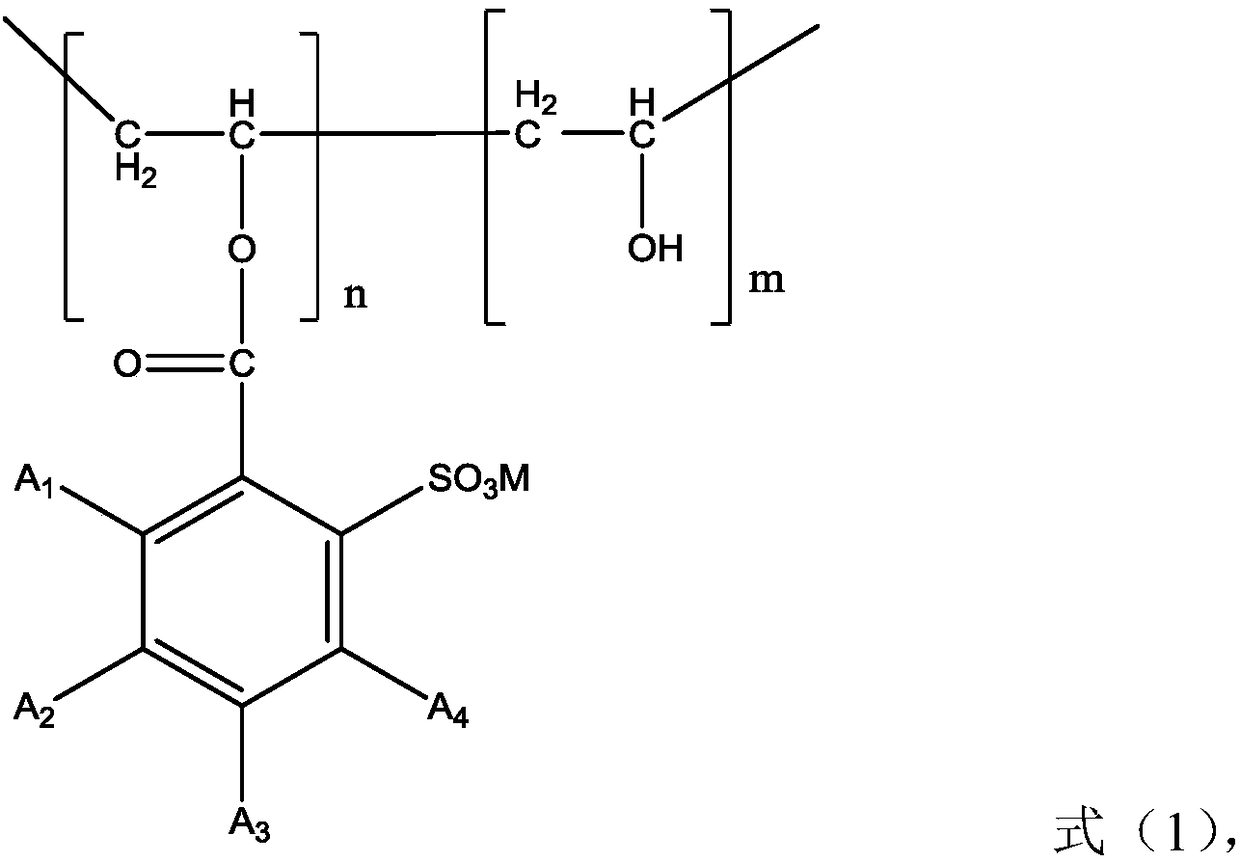

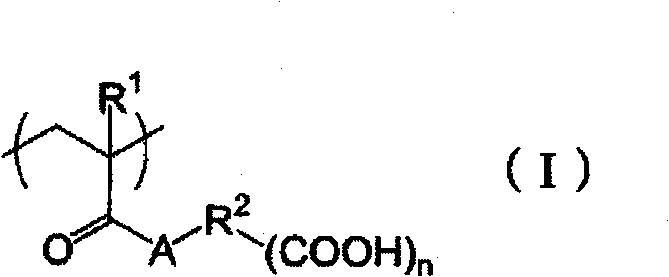

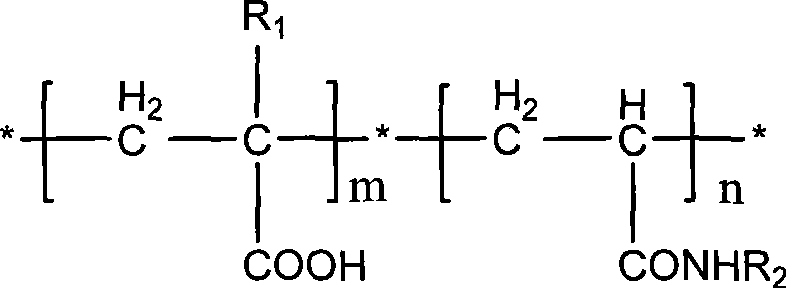

Polyvinyl alcohol ester sulfonate, synthetic method thereof, hydrophilic plate for printing and application thereof, and printing plate

ActiveCN108329409AHigh printing durabilityImprove hydrophilicityPlate printingCoatingsSulfonatePolymer science

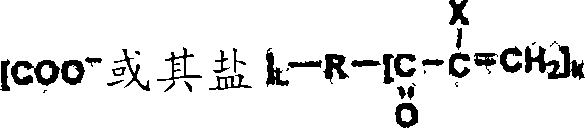

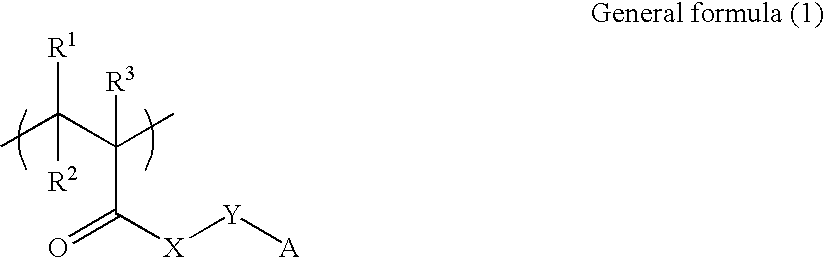

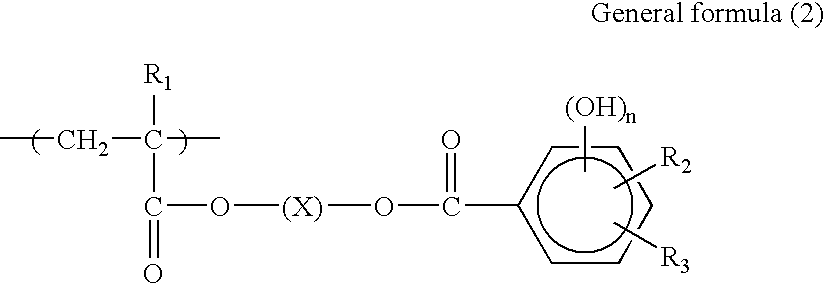

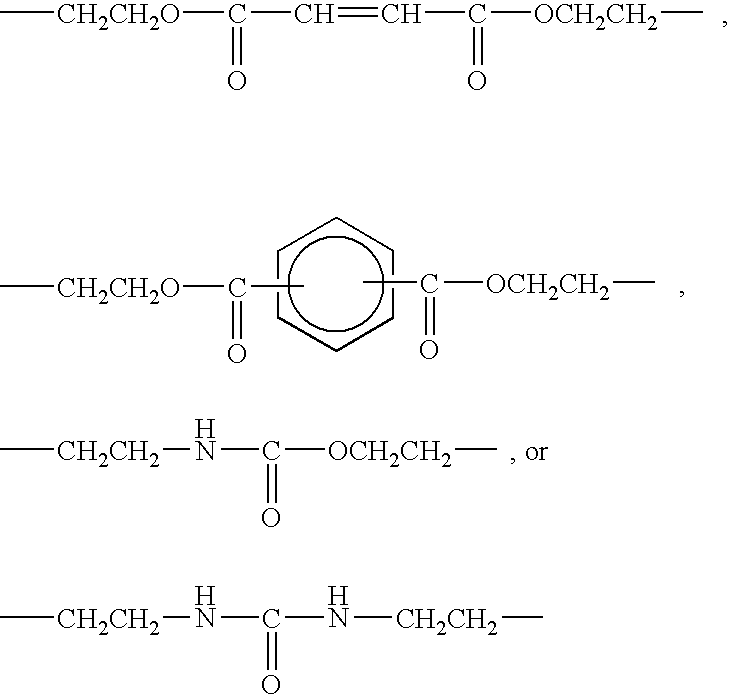

The invention relates to the field of ink jet printing, and discloses polyvinyl alcohol ester sulfonate, a synthetic method thereof, a hydrophilic plate for printing and application thereof, and a printing plate. The polyvinyl alcohol ester sulfonate contains a chemical structure represented as the formula (1), wherein the sum of m and n is a positive integer of 400 to 5000; n / (m+n) is 0.05 to 1;x is a positive integer of 1 to 3; A1-A4 are independently hydrogen or C1-C6 alkyl groups; M is Li, Na, K or NH4. The hydrophilic high-molecular compound can greatly improve hydrophilicity of a coating layer and improve printability of the hydrophilic plate.

Owner:INST OF CHEM CHINESE ACAD OF SCI

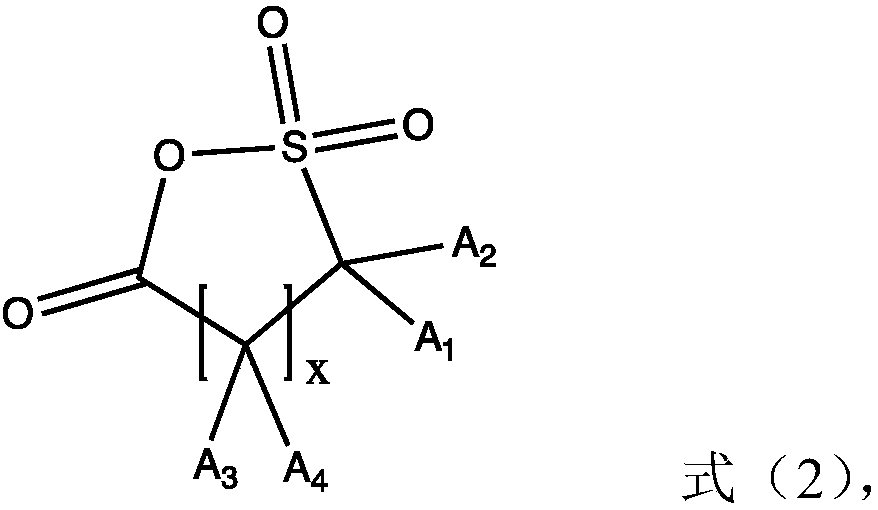

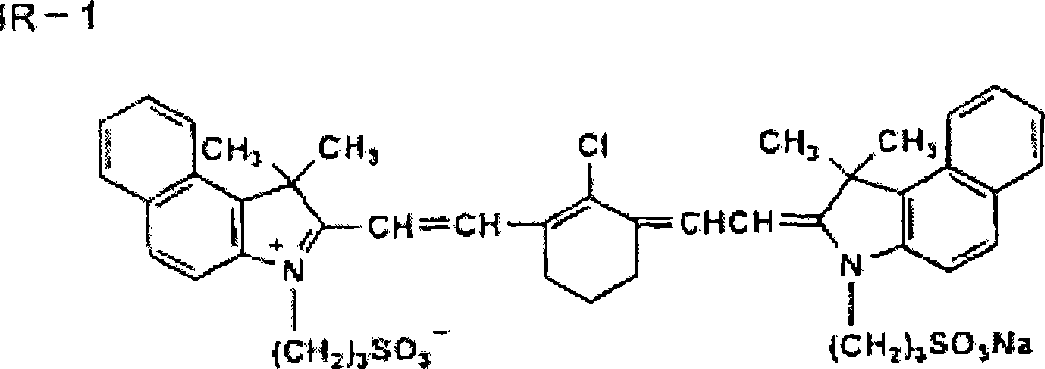

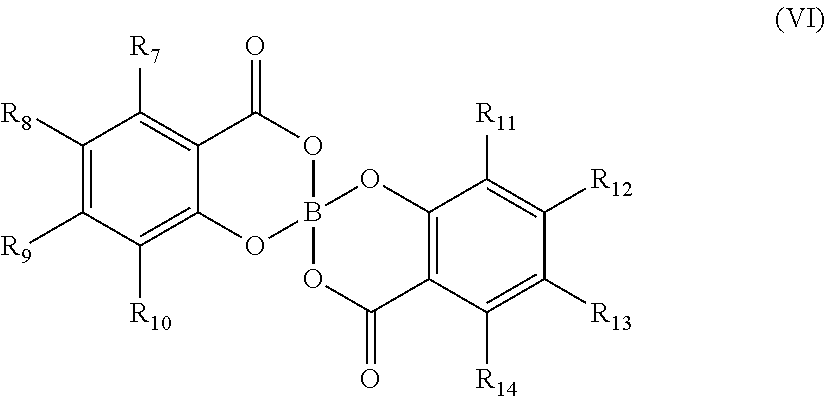

Negative photosensitive composition and negative photosensitive lithographic printing plate

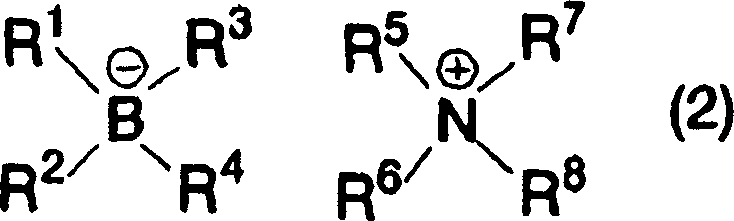

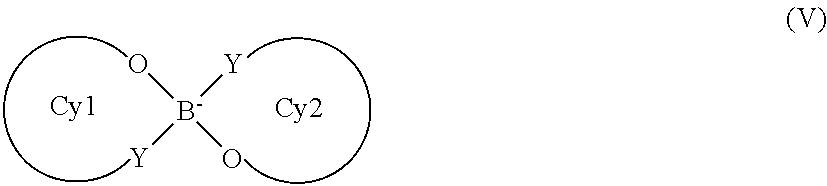

ActiveCN1898604AInhibition of polymerizationImprove stabilityThermographyPhotosensitive materials for photomechanical apparatusInfraredOrganic Boron Compounds

The present invention relates to a negative photosensitive composition comprising (A) an infrared absorber, (B) an organoboron compound that functions as a polymerization initiator by using in combination with (A) the infrared absorber, (C) an onium salt , and (D) a compound having a polymerizable unsaturated group. By using the negative photosensitive composition of the present invention, it is possible to provide a negative photosensitive composition that can be cured by infrared rays, is less likely to be inhibited by oxygen during radical polymerization, and has excellent storage stability, and provides a The negative photosensitive lithographic printing plate directly forms an image by irradiating infrared rays irradiated from a solid-state laser or a semiconductor laser based on a digital signal without preheating, has high sensitivity, and has excellent printing resistance and storage stability.

Owner:柯达彩色绘图日本株式会社

Printing plate material and process for producing printing plate

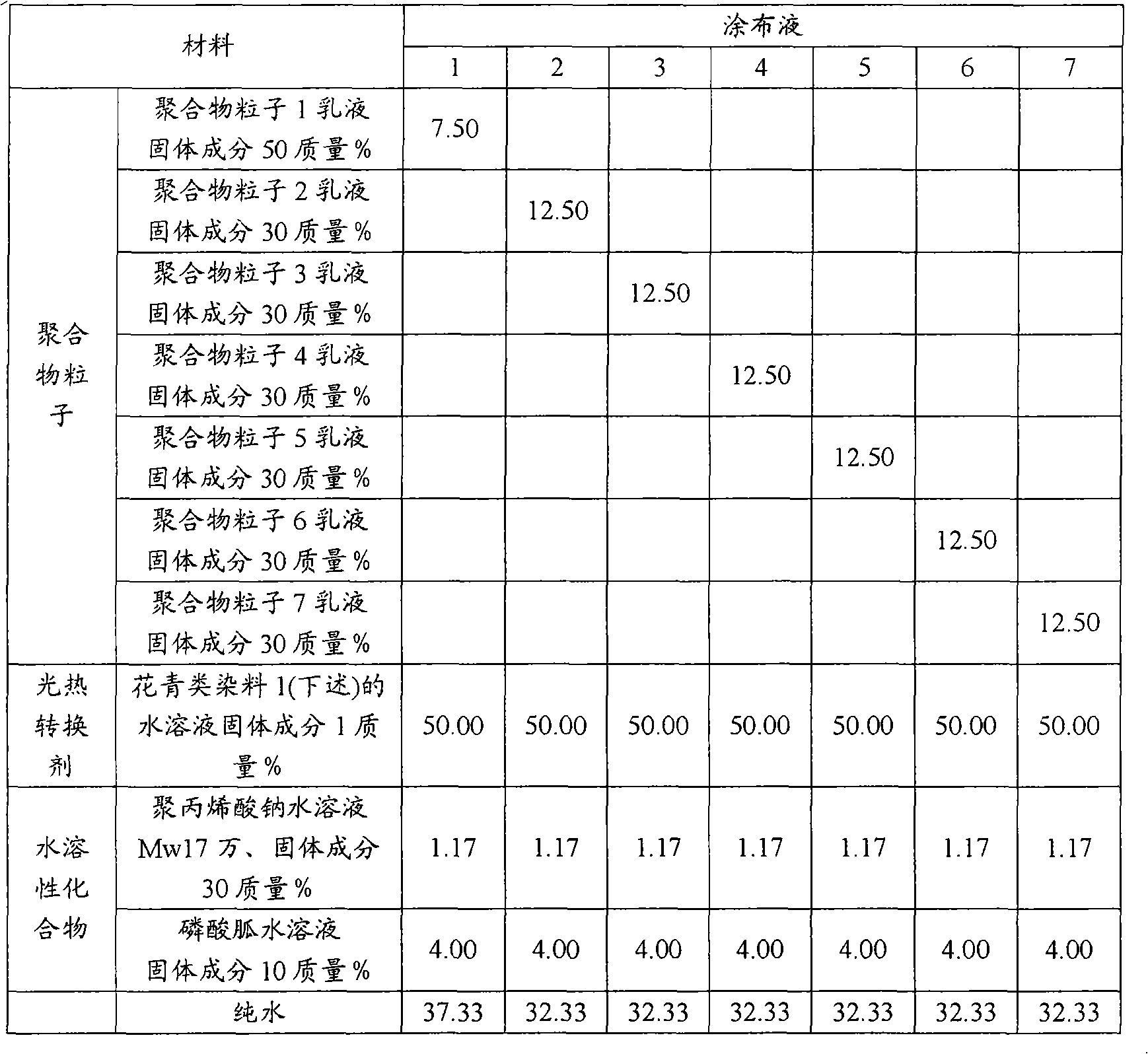

InactiveCN101253054AGood printabilityExcellent printing resistancePlate printingFoil printingPhotothermal conversionEngineering

The present invention provides a printing plate material comprising a base material and a thermal image forming layer and a constituent layer provided on the base material. The printing plate material is characterized in that the thermal image forming layer contains a silicate and a carbonate, the constituent layer is provided between the base material and the thermal image forming layer, and at least one of the constituent layer and the thermal image forming layer contains a photothermal conversion agent. The printing plate material has excellent print starting properties, printing durability, and scratch mark fouling preventive properties. The present invention also provided a process for producing a printing plate.

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

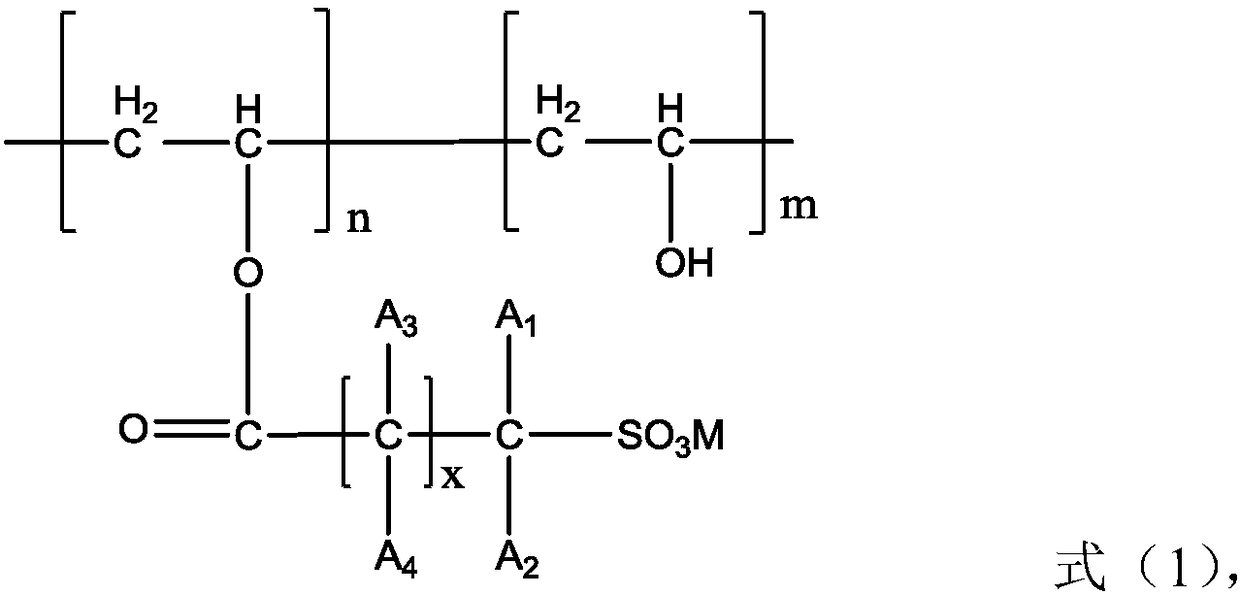

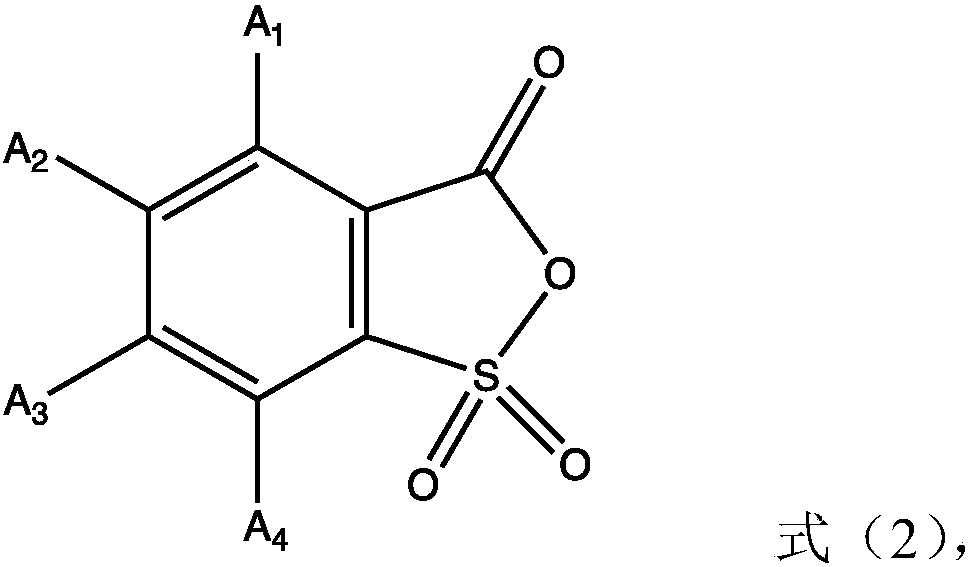

Polyvinyl alcohol ester benzene sulfonate and synthesis method thereof, hydrophilic plate used for printing, applications, and printing plate

ActiveCN108329412AGood hydrophilic effectClean surface without blemishesPlate printingCoatingsHalogenChemical structure

The invention relates to the field of ink jet printing, and discloses a polyvinyl alcohol ester benzene sulfonate and a synthesis method thereof, a hydrophilic plate used for printing, applications, and a printing plate. The polyvinyl alcohol ester benzene sulfonate contains the chemical structure represented as the formula (I), wherein the sum of m and n is a positive integer of 400 to 5000, n / (m+ n) is 0.05-1, A1-A4 are independently hydrogen, C1-C6 alkoxyl groups or halogen elements, M is Li, Na, K or NH4. The hydrophilic high-molecular compound can greatly improve hydrophilicity of the coating layer and improves printability of the hydrophilic plate.

Owner:INST OF CHEM CHINESE ACAD OF SCI

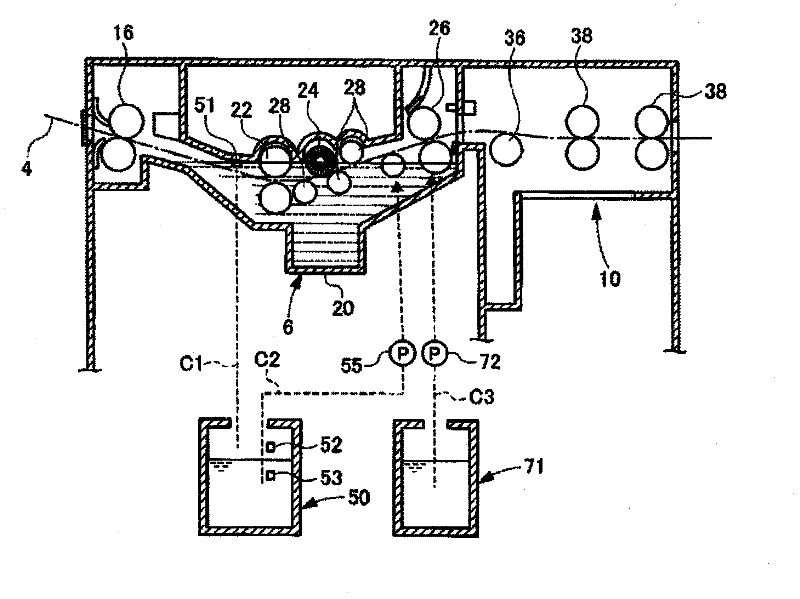

Material of lithographic printing plate, process for producing material of lithographic printing plate, and method of printing

InactiveCN101137513AExcellent developabilityExcellent printing resistancePlate printingFoil printingEngineeringPlanographic printing

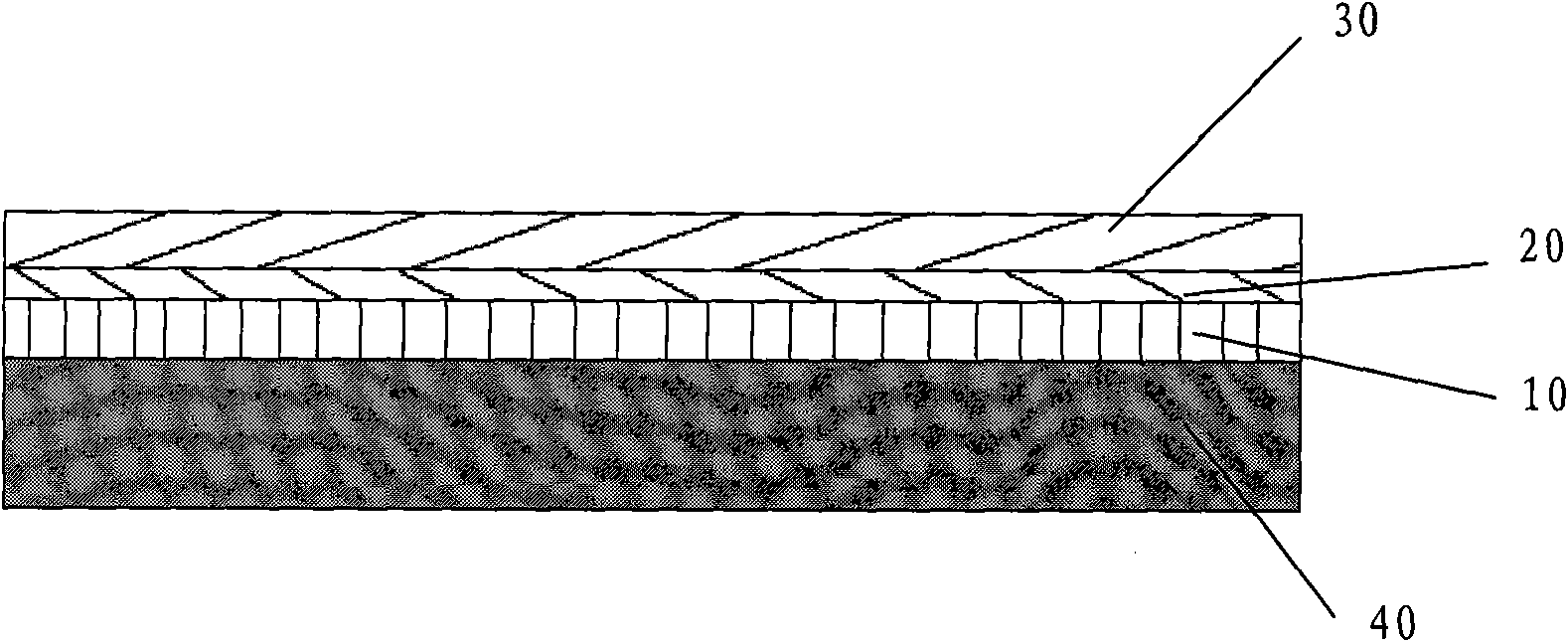

A material of lithographic printing plate excelling in on-press developability, printing plate life and pressure fogging resistance; a process for producing the material of lithographic printing plate; and a method of printing with the use of the material of lithographic printing plate. There is provided an on-press developable lithographic printing plate material including a support and, superimposed thereon, a hydrophilic layer and a thermosensitive image forming layer, characterized in that the hydrophilic layer is one produced by coating the support with a coating material containing a compound having an unsaturated bond capable of addition polymerization and a polymerization initiator and effecting polymerization of the compound having an unsaturated bond capable of addition polymerization.

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

Heat shrinkable multilayer film

ActiveCN101541533AImprove reusabilityImprove adhesionFlexible coversWrappersElastomerPolymer chemistry

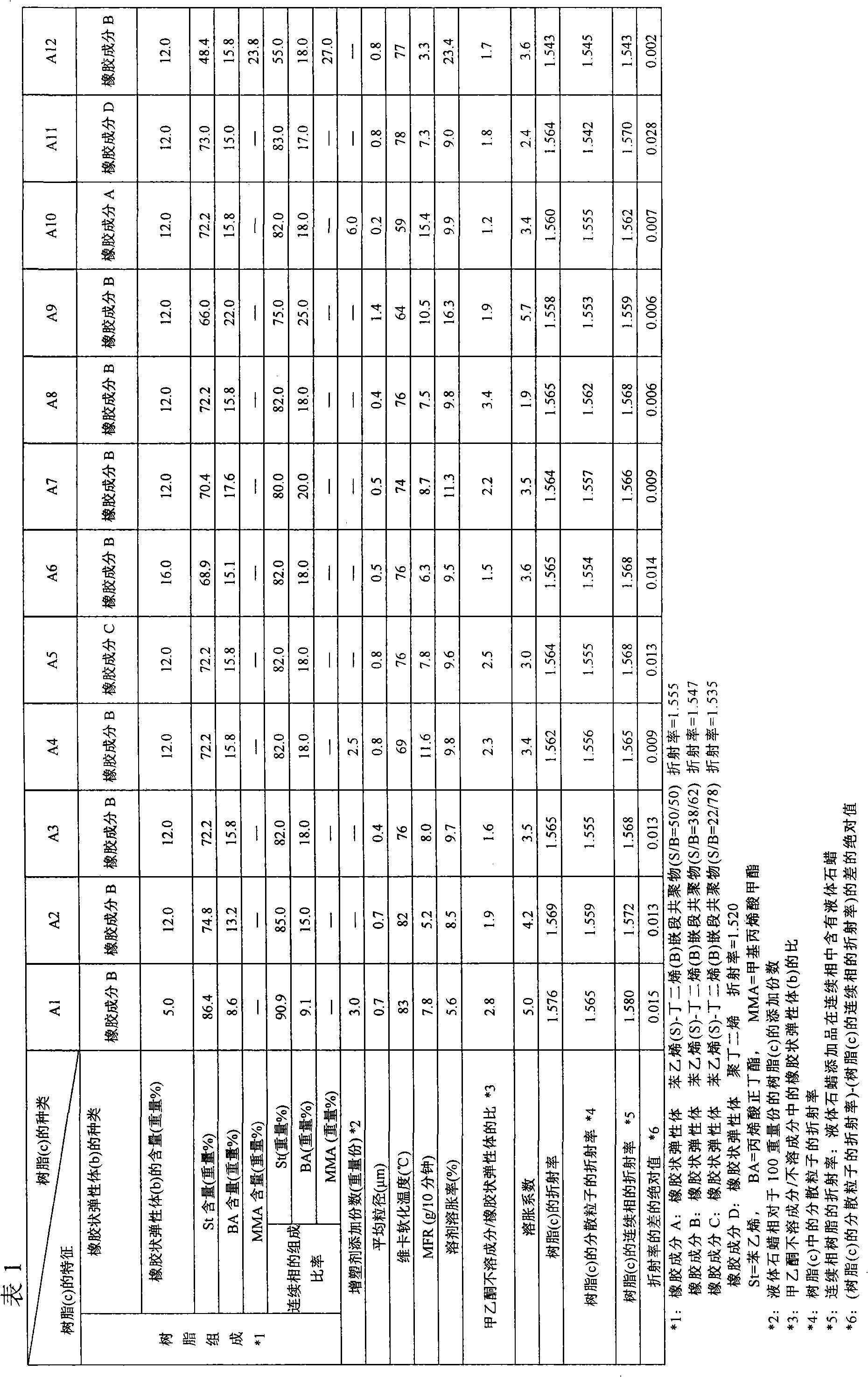

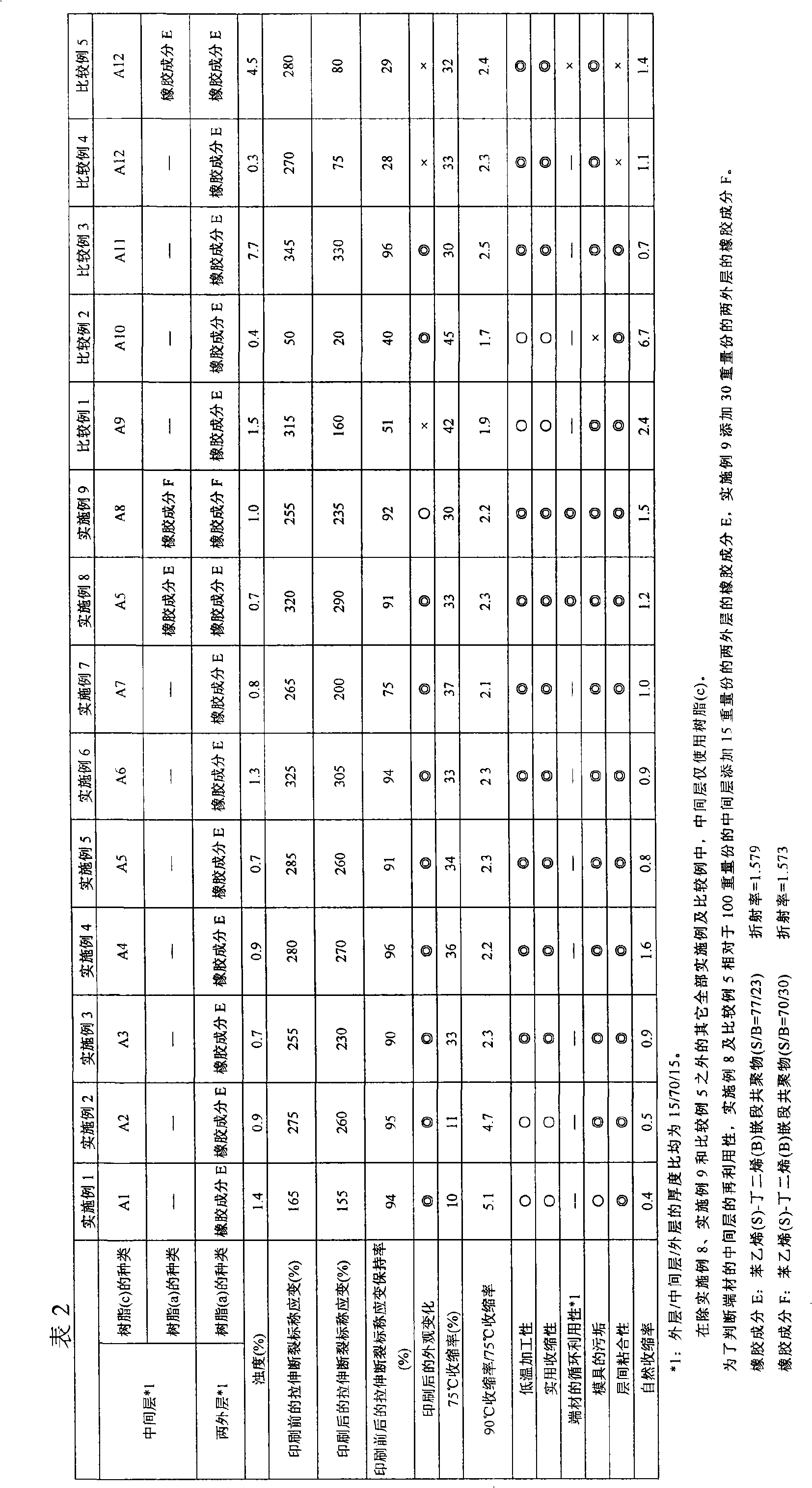

Disclosed is a heat shrinkable multilayer film obtained by at least uniaxially stretching a multilayer film which comprises outer layers mainly composed of a block copolymer resin (a) composed of a styrene monomer and a conjugated diene monomer, and an intermediate layer mainly composed of a resin (c) wherein a component made from a rubber elastic body (b) is contained in the form of dispersed particles in a continuous phase of a styrene polymer which is composed of a styrene monomer and an n-butyl acrylate. The rubber elastic body (b) is a block copolymer composed of 20-45% by weight of a styrene monomer and 80-55% by weight of a conjugated diene monomer, and the rubber elastic body (b) content in the resin (c) is 3-20% by weight. The resin composition of the continuous phase of the resin (c) is composed of 78-93% by weight of a styrene monomer and 22-7% by weight of an n-butyl acrylate, and the resin (c) has a Vicat softening temperature of 60-85 DEG C.

Owner:PS JAPAN CORP

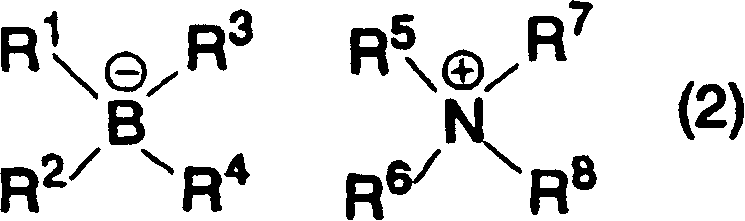

Curable composition, lithographic printing plate precursor, method for producing lithographic printing plate, and compound

ActiveUS20190369495A1Excellent on-machine developabilityFavorable temporal stabilityOrganic chemistryPhotomechanical apparatusSolubilityImage recording

Provided are a curable composition including a sail compound having a) an organic anion in which, in Hansen, solubility parameter, δd is 16 or more, δp is 16 or more and 32 or less, and δH is 60% or less of δp and b) a counter cation, a lithographic printing plate precursor having an image-recording layer containing the curable composition, a method for producing a lithographic printing plate using the lithographic printing plate precursor, and a compound that is used in the image-recording layer in the lithographic printing plate precursor.

Owner:FUJIFILM CORP

Method for manufacturing lithographic printing plate, developer for original lithographic printing plate, and replenisher for developing original lithographic printing plate

ActiveCN102227684AExcellent developabilityExcellent printing resistancePhotosensitive material processingEngineeringPlanographic printing

Provided are a method for manufacturing a lithographic printing plate, a developer for the original lithographic printing plate, and a replenisher for developing the original lithographic printing plate, whereby a lithographic printing plate with excellent developability and good printing performance, including printing durability and stain resistance, can be manufactured, and the occurrence of development residue attributable to ethylenic unsaturated compounds can be prevented while achieving excellent processing capability. The method for manufacturing a lithographic printing plate has a step (A) in which a lithographic printing plate having a photosensitive layer containing (i) a binder polymer, (ii) an ethylenic unsaturated compound, and (iii) a radical polymerization initiator is produced on a substrate, an exposure step (B) in which the aforementioned lithographic printing plate is exposed to light, and a development step (C) in which the photosensitive layer in unexposed portions of the aforementioned lithographic printing plate is removed. The aforementioned development step (C) is carried out using a developer containing an enzyme.

Owner:FUJIFILM CORP

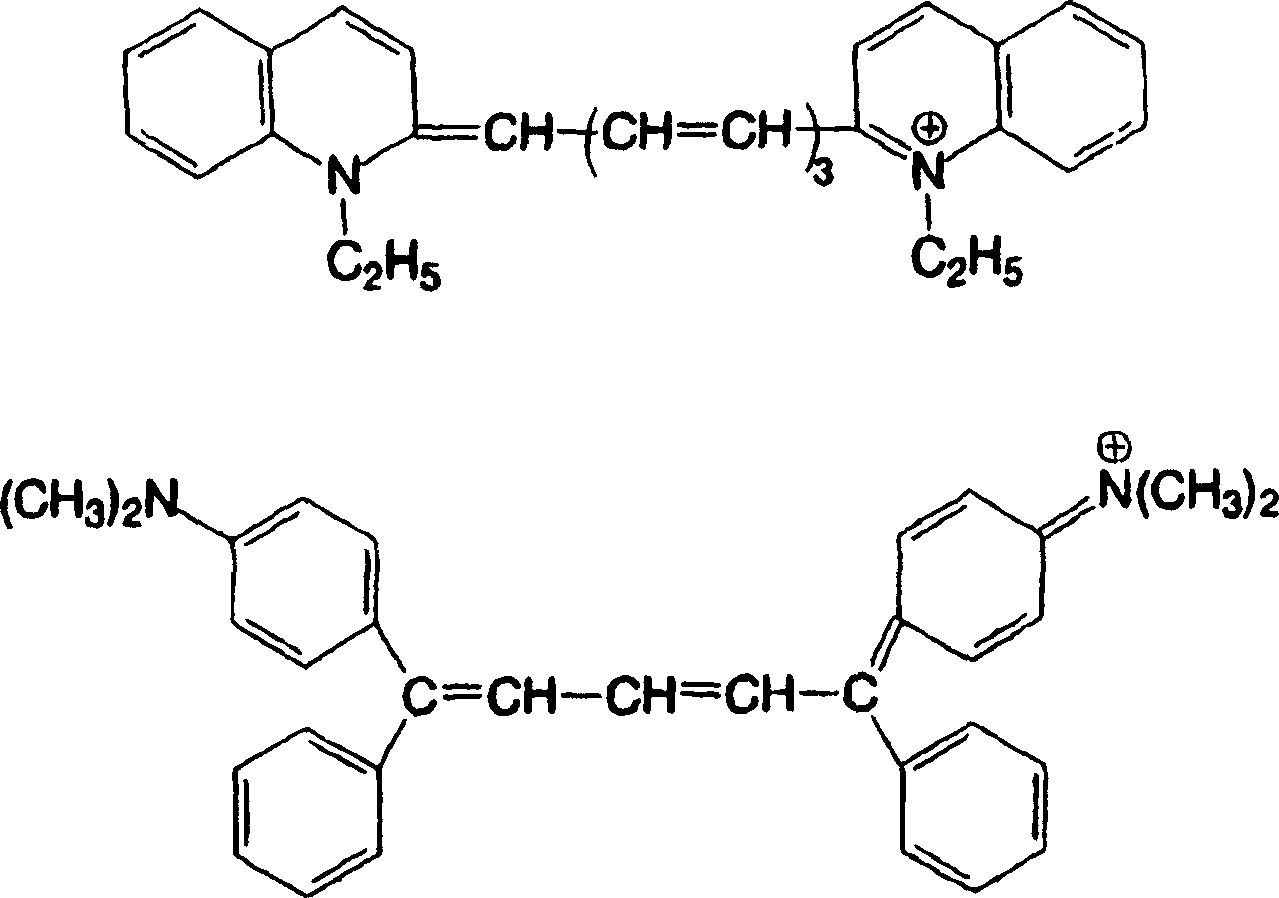

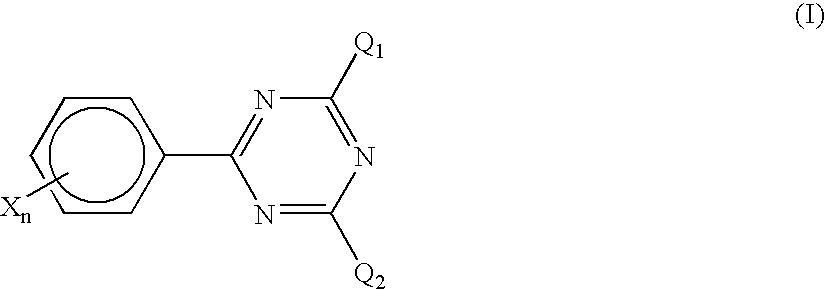

Photopolymerizable composition and image recording material

InactiveUS20050053862A1High sensitivityImprove stabilityPhotomechanical apparatusPhotosensitive material auxillary/base layersImage recordingDouble bond

Owner:FUJIFILM CORP +1

Support for lithographic printing plate material, process for producing the same and lithographic printing plate material therefrom

InactiveCN101341031AExcellent printing resistanceExcellent pollution preventionPlate printingFoil printingTone reproductionEngineering

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

Composite hydrophillic printing substrate and manufacturing and regenerating methods thereof

InactiveCN101673054ALow priceFlexible and convenient choicePlate printingFoil printingAdhesive glueEmulsion

The invention discloses a composite hydrophillic printing substrate and manufacturing and regenerating methods thereof. The composite hydrophilic printing substrate comprises an aluminium foil, a substrate layer arranged on a side surface of the aluminium foil, a hydrophillic layer arranged on the side of the substrate layer far from the aluminium foil and an organic plate connected to the side ofthe aluminium foil which is not provided with the hydrophillic layer. The manufacturing method comprises the following steps: coating the substrate layer on at least one side surface of the selectedaluminium foil; coating the hydrophillic layer on the side surface of the substrate layer far from the aluminium foil; coating photosensitive emulsion on a side surface of the hydrophillic layer far from the aluminium foil, and coating adhesive glue on a side surface of the aluminium foil far from the substrate layer; and adhering the organic plate to the surface of the aluminium foil coated withthe adhesive glue and pressing through lamination. The regenerating method comprises the following steps: cleaning to remove ink on the printing substrate; soaking the printing substrate with solutionof a treating agent to remove a picture and text part; and coating hydrophillic dispersion on the prior hydrophillic layer to form a new hydrophillic layer. The composite hydrophillic printing substrate has simple process and low cost.

Owner:GUANGZHOU HUMAN CHEM

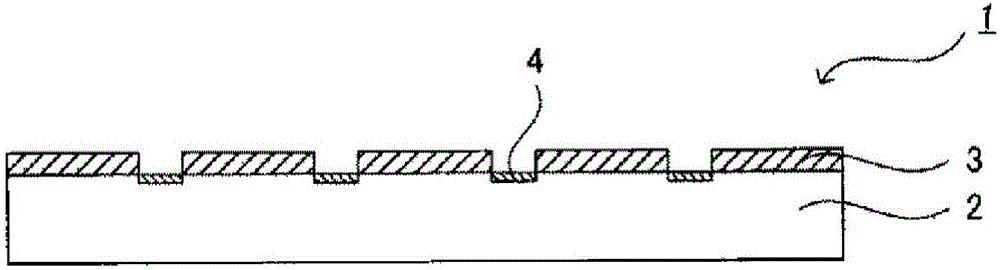

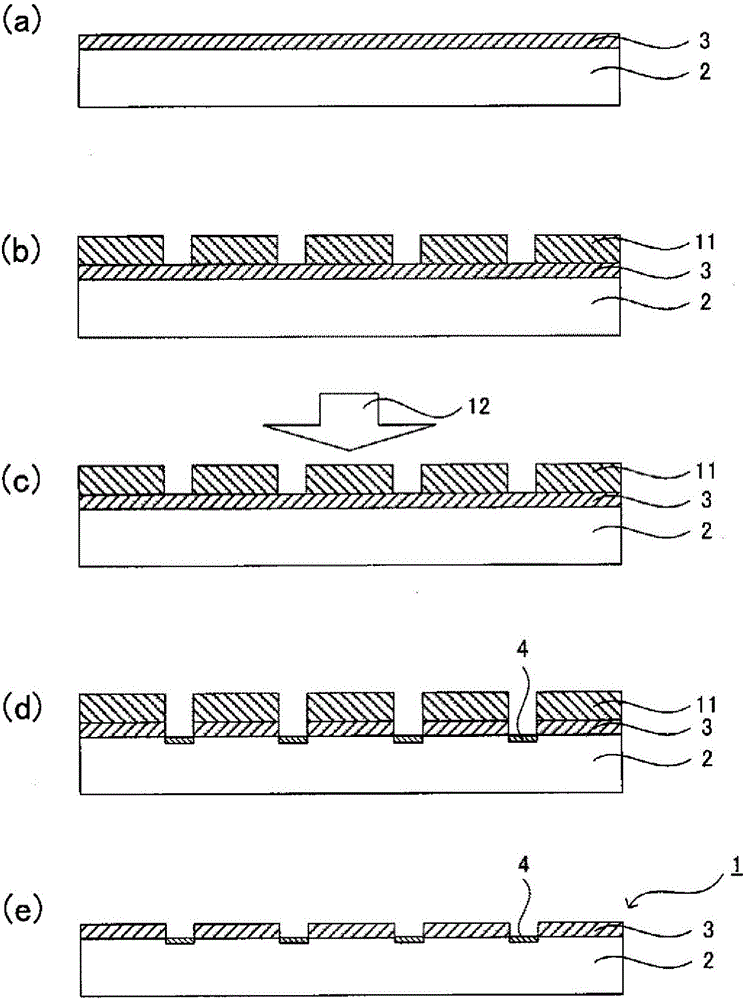

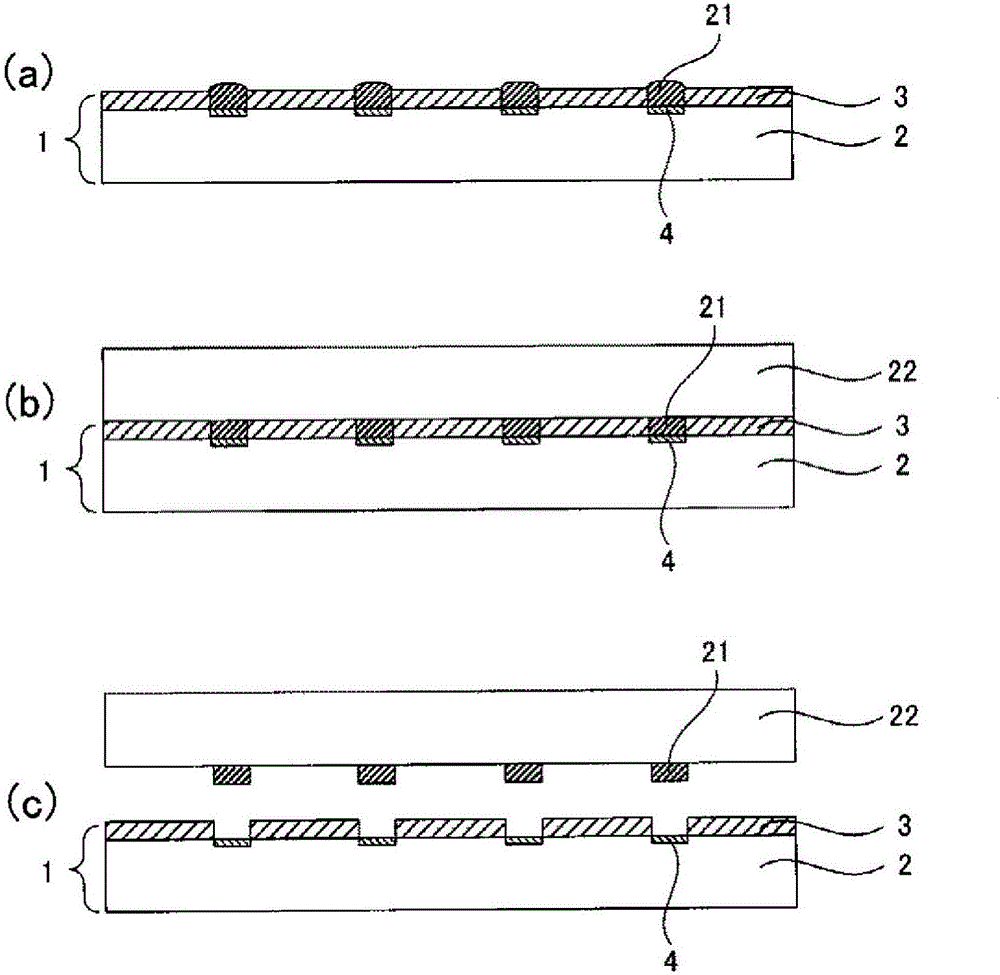

Printing plate, method for producing printing plate, method for manufacturing functional element and printing apparatus

InactiveCN106457868AGood transferabilityExcellent printing resistanceCylinder pressesPhotomechanical apparatusImage resolutionEngineering

The main purpose of the present invention is to provide: a printing plate that has excellent transferability, printing durability and resolution; a method for producing a printing plate; a method for manufacturing a functional element using the printing plate; and a printing apparatus using the printing plate. The present invention achieves the above-mentioned purpose by providing a printing plate which is characterized by comprising: a base that contains an elastic body that is swellable in a solvent; a hydrophobic solvent permeation prevention layer that is formed as a pattern on the base; and a hydrophilic part that is formed on the base surface in an opening part of the hydrophobic solvent permeation prevention layer and has higher hydrophilicity than the hydrophobic solvent permeation prevention layer.

Owner:DAI NIPPON PRINTING CO LTD

Positive type infrared light responsive composition, positive type printing plate and method of use thereof

ActiveCN101439609AOvercome the disadvantage of unstable qualityIncreased sensitivityThermographyLithographyPositive typeEngineering

The invention discloses a male pattern infrared light sensitizing composition and a printing plate made of the composition and an application method of the printing plate. The composition mainly contains (1) 45-74 parts by weight of hydrophilic polymer, (2) 5-30 parts by weight of etherified amino resin, and (3) 5-25 parts by weight of infrared absorption agent. The male pattern infrared light sensitizing composition has the advantages of high light sensitivity, good preservation property, good printing resistance and good chemical resistance. The provided photolithography plate has the advantages of high light sensitivity and good mesh point reducibility, and can be directly mounted on a photolithography machine for printing after exposure.

Owner:LUCKY HUAGUANG GRAPHICS +1

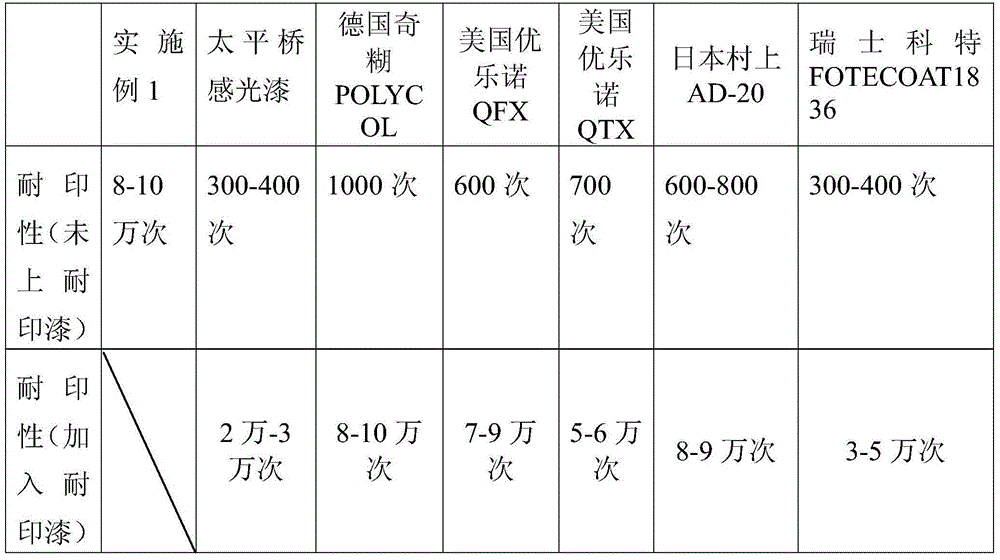

Long-pressrun photosensitiser for printing of blanket and towel

ActiveCN104911926AExcellent printing resistanceReduce usageDyeing processPhotosensitive materials for photomechanical apparatusOrganic solventEmulsion

The invention brings forward a long-pressrun photosensitiser for printing of blanket and towel. The long-pressrun photosensitiser is prepared by mainly using a modified polyvinylalcohol aqueous solution, modified vinyl acetate, acrylate, an organosilicone monomer copolymer emulsion and modified photosensitive urethane acrylate. The photosensitiser provided by the invention has good long-pressrun performance. Without a long-pressrun paint, pressrun number can meet actual use requirements, platemaking process is minimized, and platemaking efficiency is raised. During production, use of the long-pressrun paint is reduced, and the damage of an organic solvent in the long-pressrun paint to workers and the environment is avoided.

Owner:JIASHAN MINGXIAN NEW MATERIAL TECH

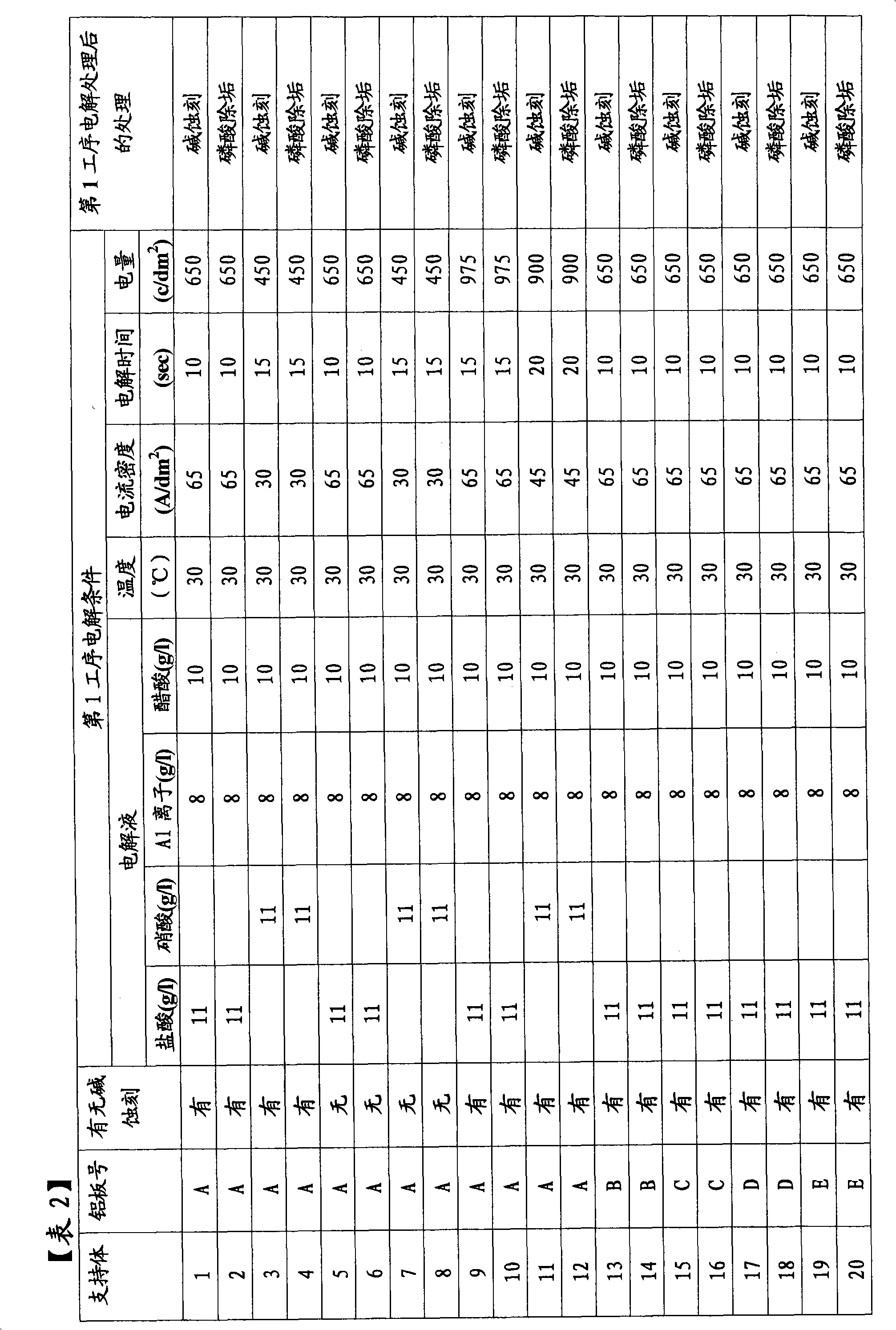

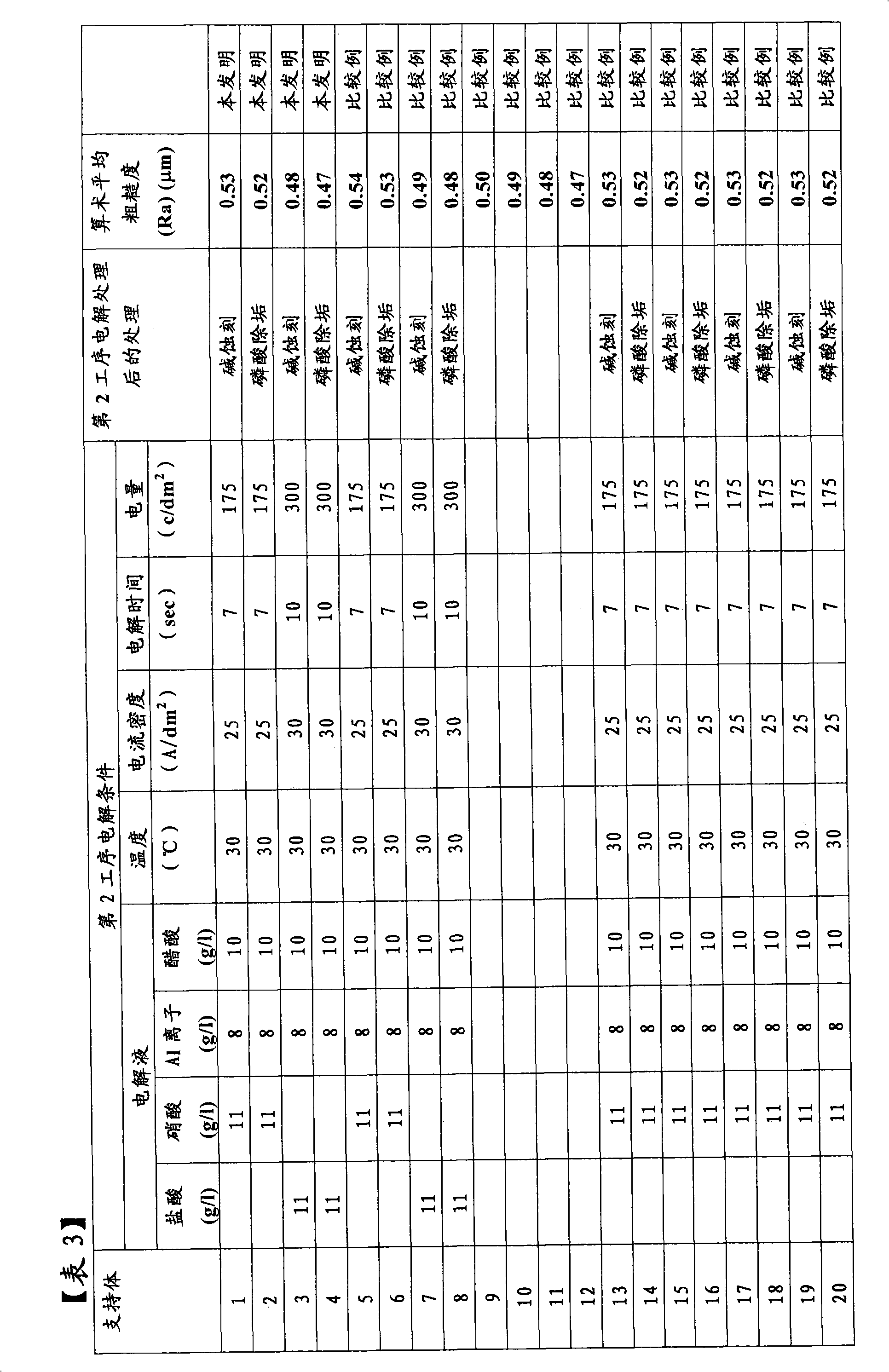

Process for producing aluminum support for material for lithographic printing plate, aluminum support for material for lithographic printing plate, and material for lithographic printing plate

InactiveCN101111393AExcellent pollution preventionExcellent printing resistancePlate printingFoil printingElectrolysisPhosphoric acid

The present invention provides a lithographic printing plate material excellent in printing durability, blanket stain prevention, and post-stand stain prevention; an aluminum support for a lithographic printing plate material and an aluminum support for a lithographic printing plate material imparted to the lithographic printing plate material The production method is characterized in that, for the aluminum support body, sequentially implement in the electrolytic solution with hydrochloric acid as the main body at a current density of 35A / dm 2 ~150A / dm 2 , Current capacity 600A×sec / dm 2 ~1500A×sec / dm 2 Perform AC electrolysis rough surface treatment; make the aluminum plate dissolve in 3~5g / m 2 Etching treatment; in the electrolyte with hydrochloric acid as the main body, at a current density of 15-30A / dm 2 , Electricity 100~400A×sec / dm 2 Perform AC electrolysis for rough surface treatment; the amount of undissolved dirt remaining on the dirt in an acidic solution mainly composed of phosphoric acid is 0.05-0.3g / m 2 treatment; anodizing treatment to form a rough surface.

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

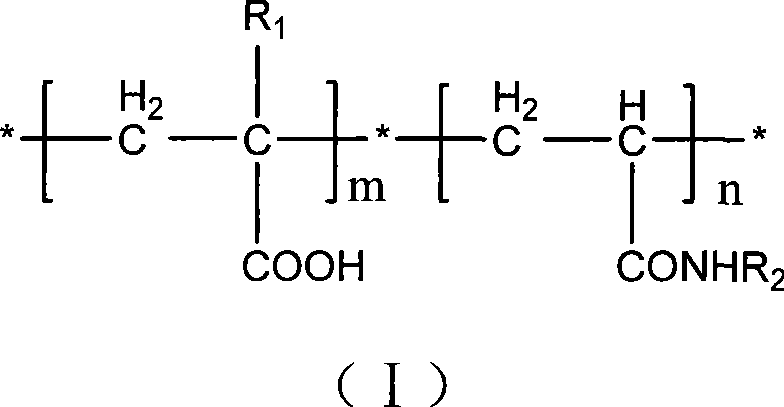

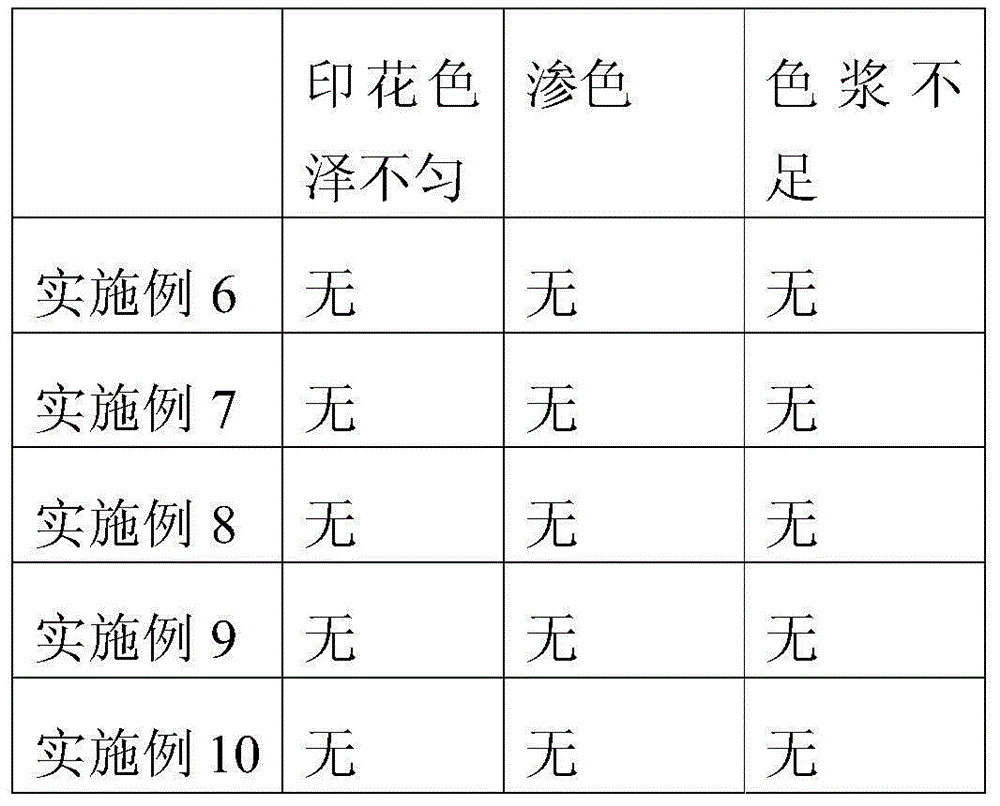

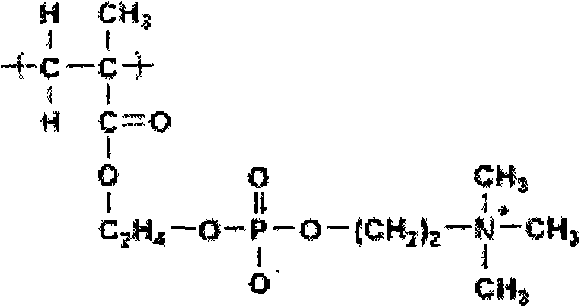

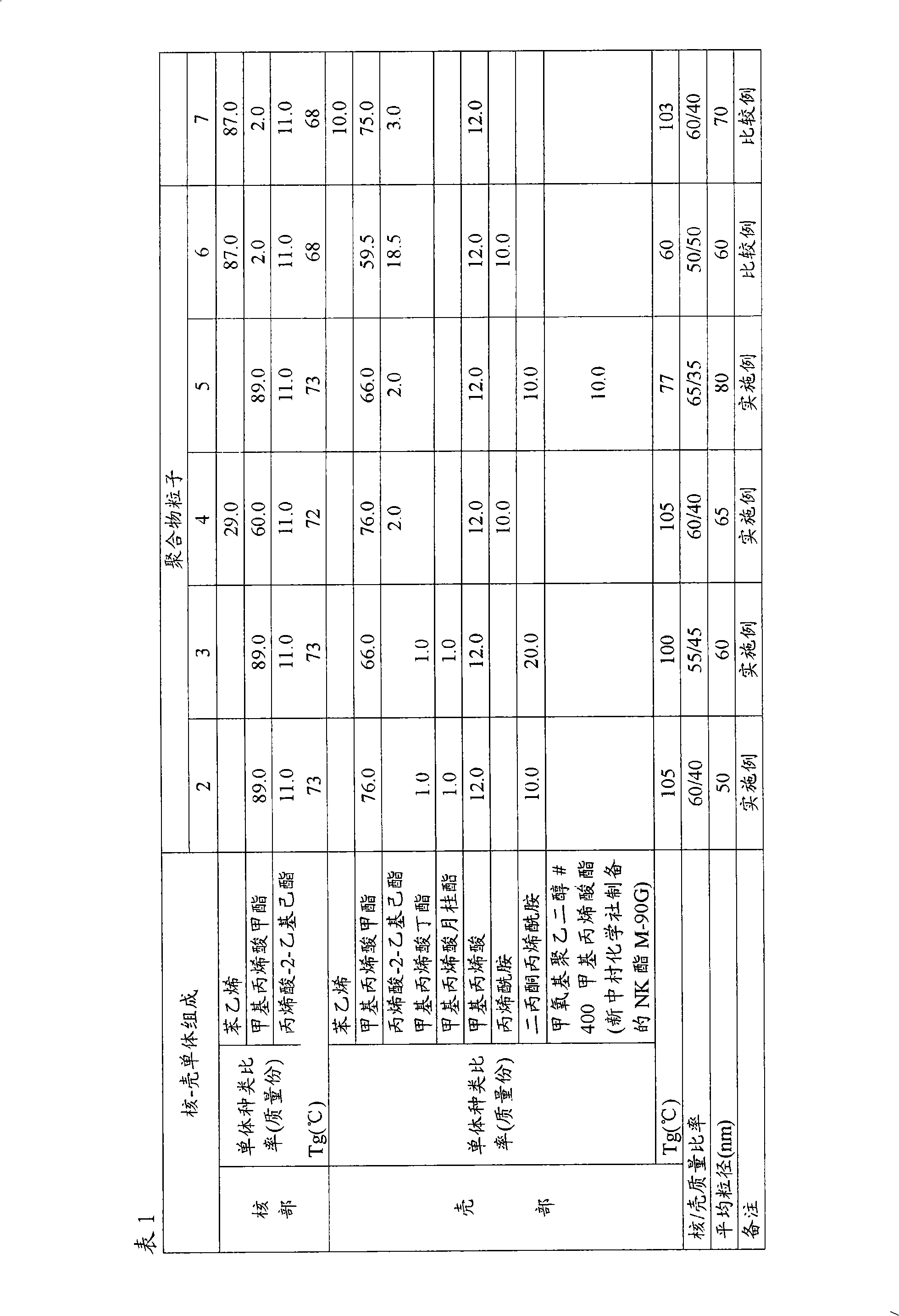

Printing plate material

InactiveCN101573241AExcellent printing resistanceStorage stabilityPlate printingFoil printingVitrificationPolymer science

A printing plate material for use in CTP systems which has high sensitivity and is excellent in printing resistance and storage stability while retaining satisfactory on-press developability. This printing plate material comprises a base and an image-forming layer formed thereon, and is characterized in that the image-forming layer contains the following (A1) or (A2). (A1) Polymer particles having a glass transition temperature (Tg) of 70 DEG C or higher formed by the emulsion polymerization of a polymerizable carboxylated monomer and a polymerizable amidated monomer; (A2) polymer particles having a core / shell structure formed by emulsion polymerization in which the shells of the polymer particles are made of a polymer having a glass transition temperature (Tg) of 70 DEG C or higher obtained by the polymerization of a polymerizable carboxylated monomer and a polymerizable amidated monomer.

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

Polymerizable composition and negative-working planographic printing plate precursor using the same

InactiveUS7232644B2High molecular weightGood effectPhotosensitive materialsRadiation applicationsHigh intensityRecording layer

The invention provides a polymerizable composition comprising: a binder polymer containing at least an acid group having an acid dissociation constant (pKa) of 5.5 or more and a radical addition polymerizable group, and a radical-generating compound capable of generating a radical with light or heat. Further, the invention provides a negative-working planographic printing plate precursor which has a recording layer containing the polymerizable composition. Use of the polymerizable composition of the invention provides a planographic printing plate precursor that is capable of forming high-quality images free from stains in non-image portions, and further has high strength in formed image portions and excellent printing endurance.

Owner:FUJIFILM CORP +1

Image recording material and image formation process thereof

InactiveCN101184631AExcellent exposure visibility and image qualityExcellent on-press developabilityRadiation applicationsPlate printingImage recordingImage formation

An objective is to provide an image recording material exhibiting an excellent exposure visualization property as well as an image formation process employing the image recording material, and further to provide not only a printing plate material exhibiting excellent on-press developability and printing durability, but also an image formation process employing the printing plate material, accompanied with an excellent exposure visualization property. Also disclosed is an image recording material possessing a support and provided thereon, a thermosensitive image formation layer, wherein the thermosensitive image formation layer contains thermoplastic spherical particles having an average particle diameter of 100 - 500 nm, and exhibits a structural color originated with the thermoplastic spherical particles.

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com