Patents

Literature

56results about How to "Increased printing life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithographic printing plate precursor

InactiveUS6890700B2Improving residual color residualImproving residual residual filmPhotosensitive materialsRadiation applicationsImage formationLaser exposure

A lithographic printing plate precursor is disclosed, comprising a metal support having formed thereon an anodic oxide film, and an image-forming layer containing a light-to-heat converting agent, or a light-sensitive layer capable of image-forming with infrared laser exposure provided in this order from the support.

Owner:FUJIFILM CORP

On-press developable imageable element comprising a tetraarylborate salt

ActiveUS20060269873A1Increase imaging speedIncreased printing lifePhotosensitive materialsRadiation applicationsPolymerChemistry

The present invention provides an imageable element including a lithographic substrate and an imageable layer disposed on the substrate. The imageable layer includes a radically polymerizable component, an initiator system, and a polymeric binder. The imageable element further includes a tetraarylborate salt. The presence of the tetraarylborate salt may provide improved imaging speed and may enhance press life due to better adhesion between the imageable layer and the substrate. The tetraarylborate salt may be present in the imageable layer, an interlayer, or a separate layer between the substrate and the imageable layer. The imageable element may be imaged and mounted on-press without a separate development step.

Owner:EASTMAN KODAK CO

On-press developable imageable element comprising a tetraarylborate salt

ActiveUS7189494B2Increase speedIncreased printing lifePhotosensitive materialsRadiation applicationsInter layerPolymer

The present invention provides an imageable element including a lithographic substrate and an imageable layer disposed on the substrate. The imageable layer includes a radically polymerizable component, an initiator system, and a polymeric binder. The imageable element further includes a tetraarylborate salt. The presence of the tetraarylborate salt may provide improved imaging speed and may enhance press life due to better adhesion between the imageable layer and the substrate. The tetraarylborate salt may be present in the imageable layer, an interlayer, or a separate layer between the substrate and the imageable layer. The imageable element may be imaged and mounted on-press without a separate development step.

Owner:EASTMAN KODAK CO

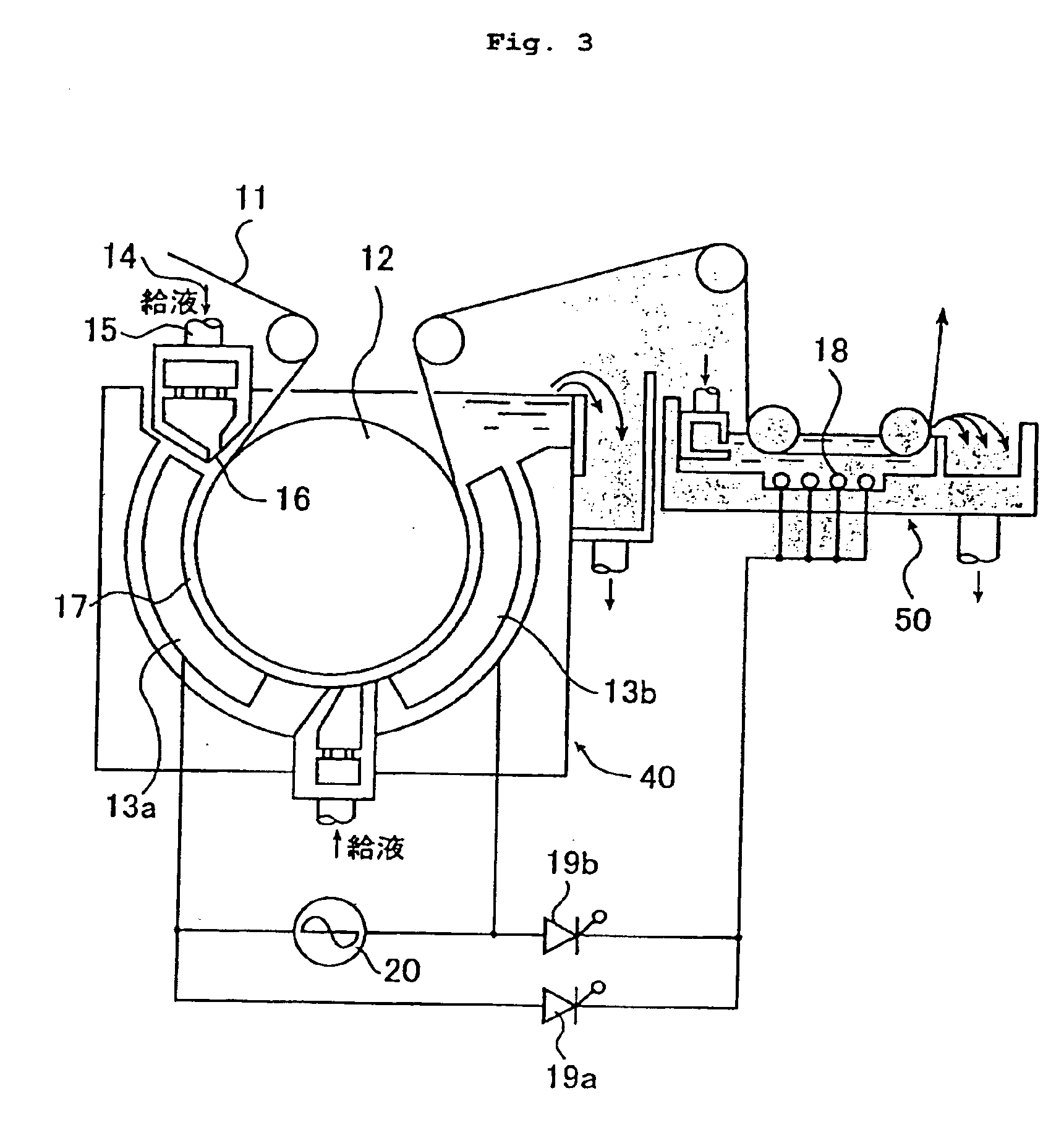

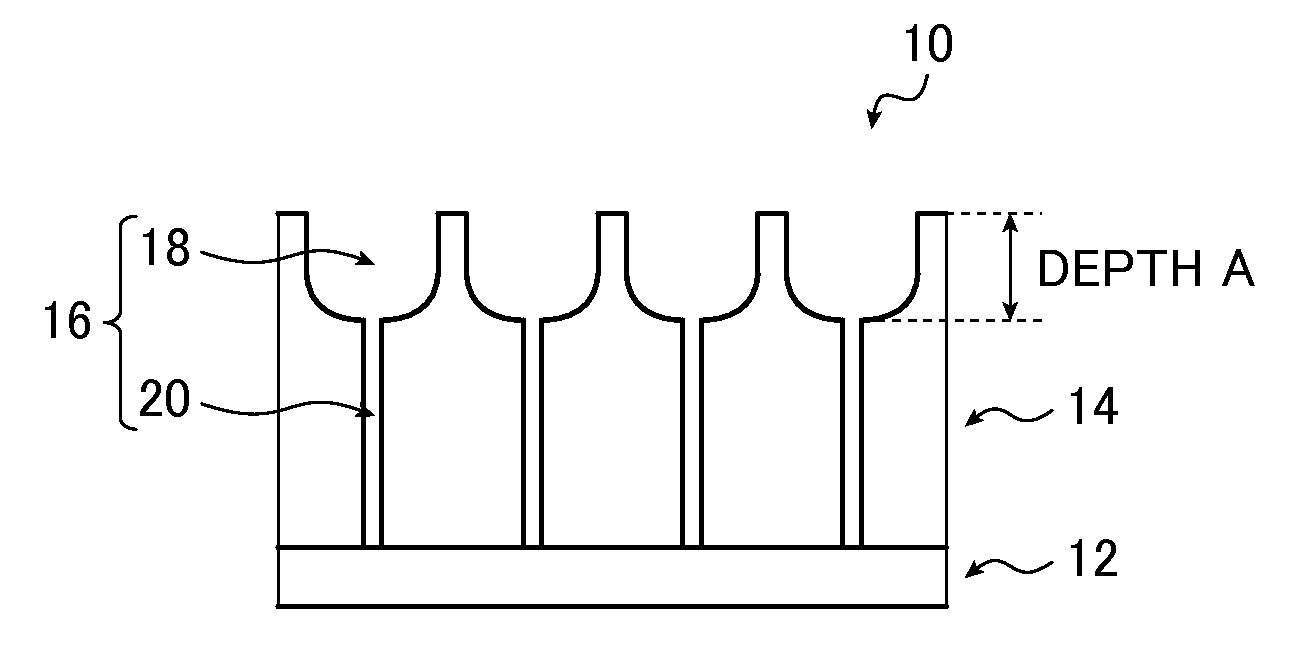

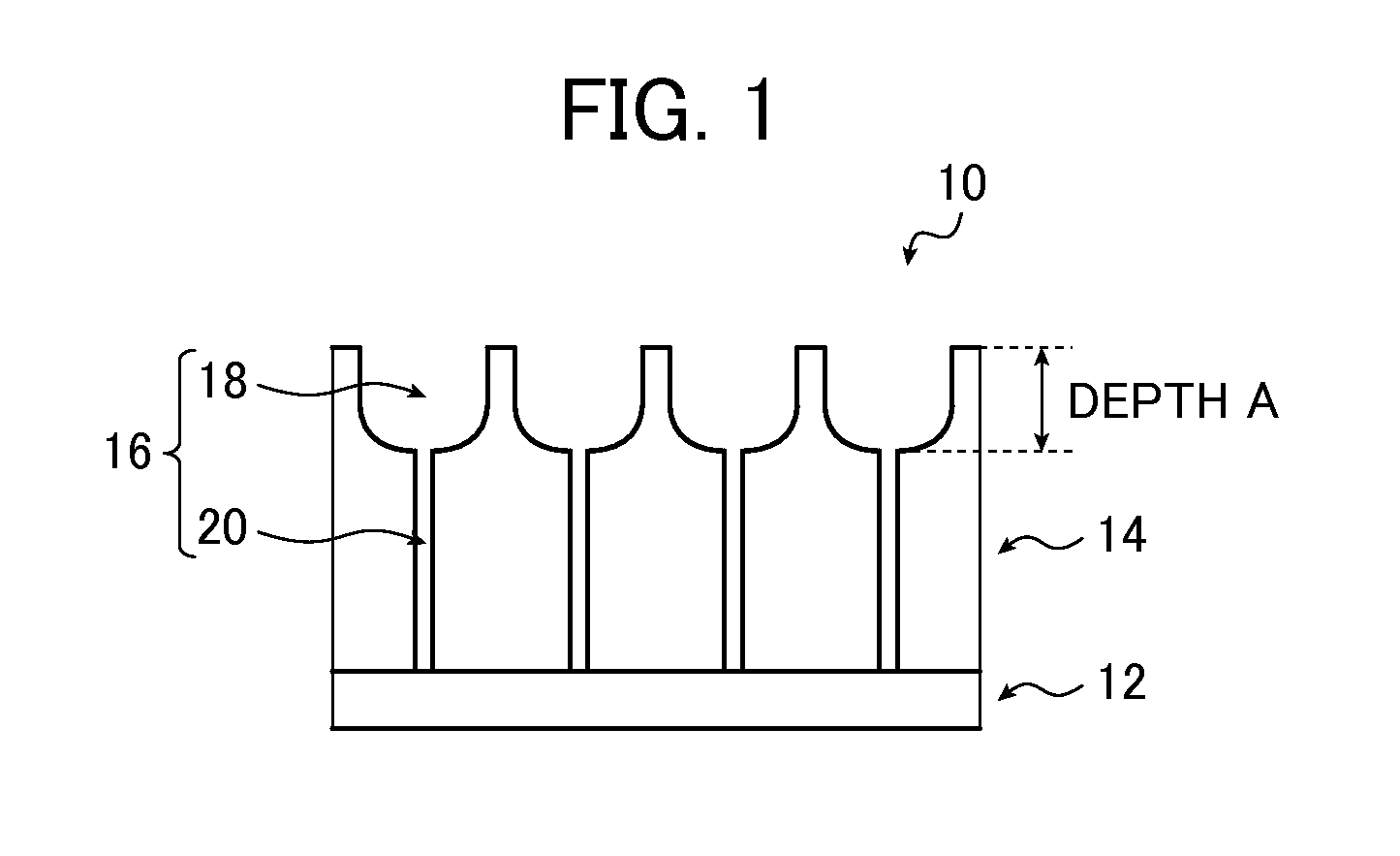

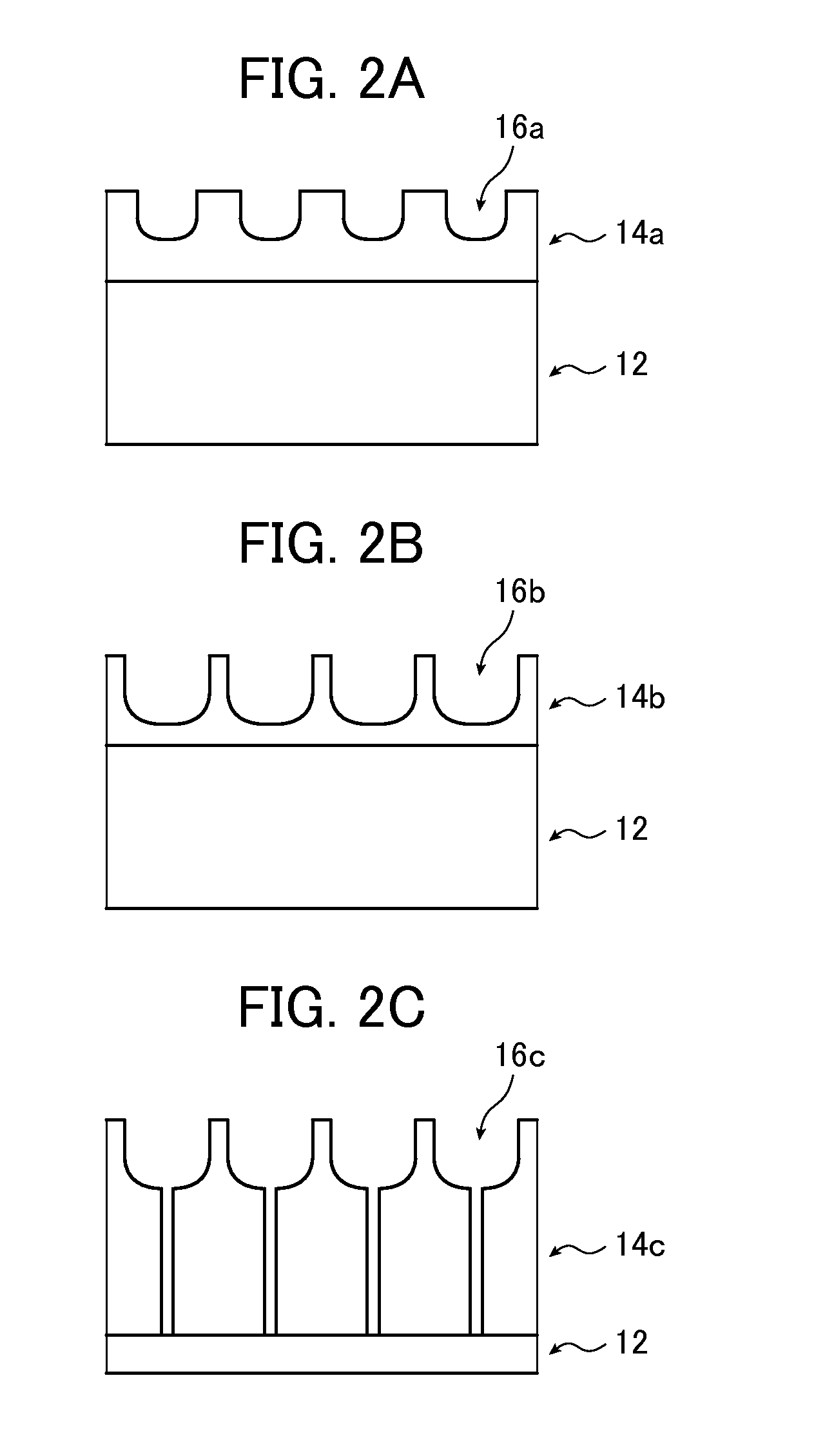

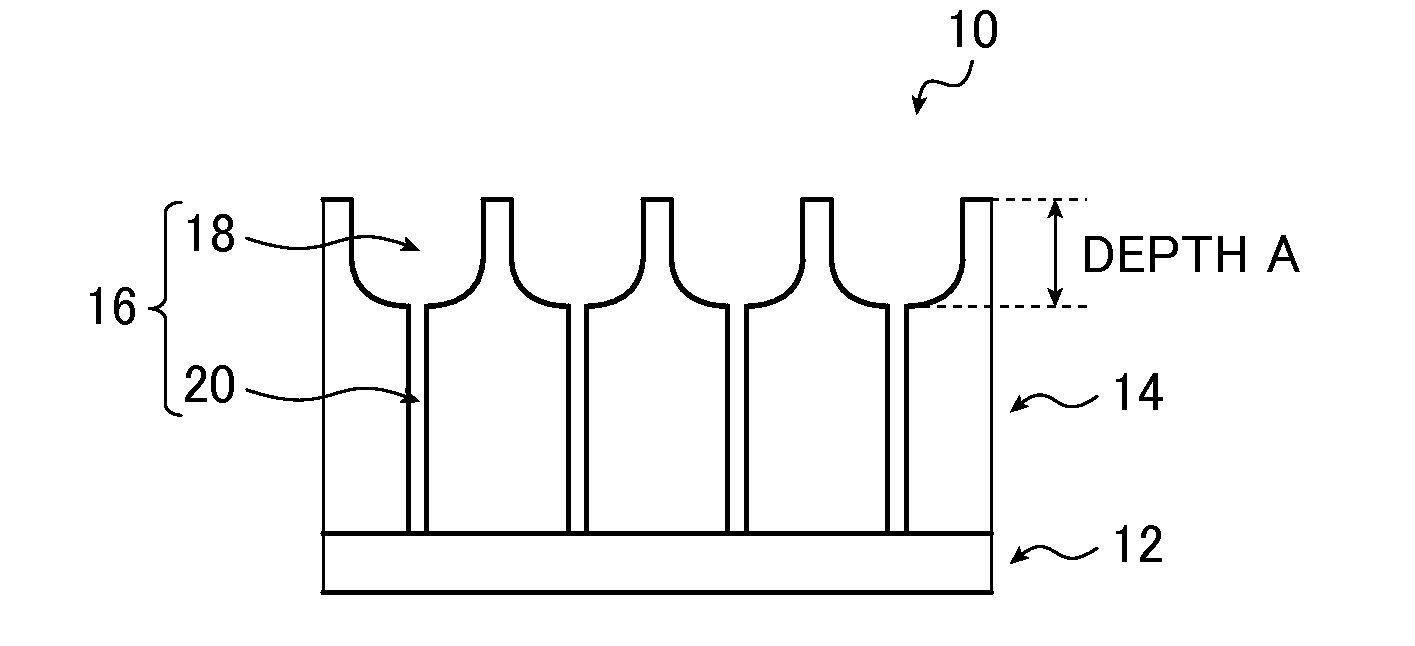

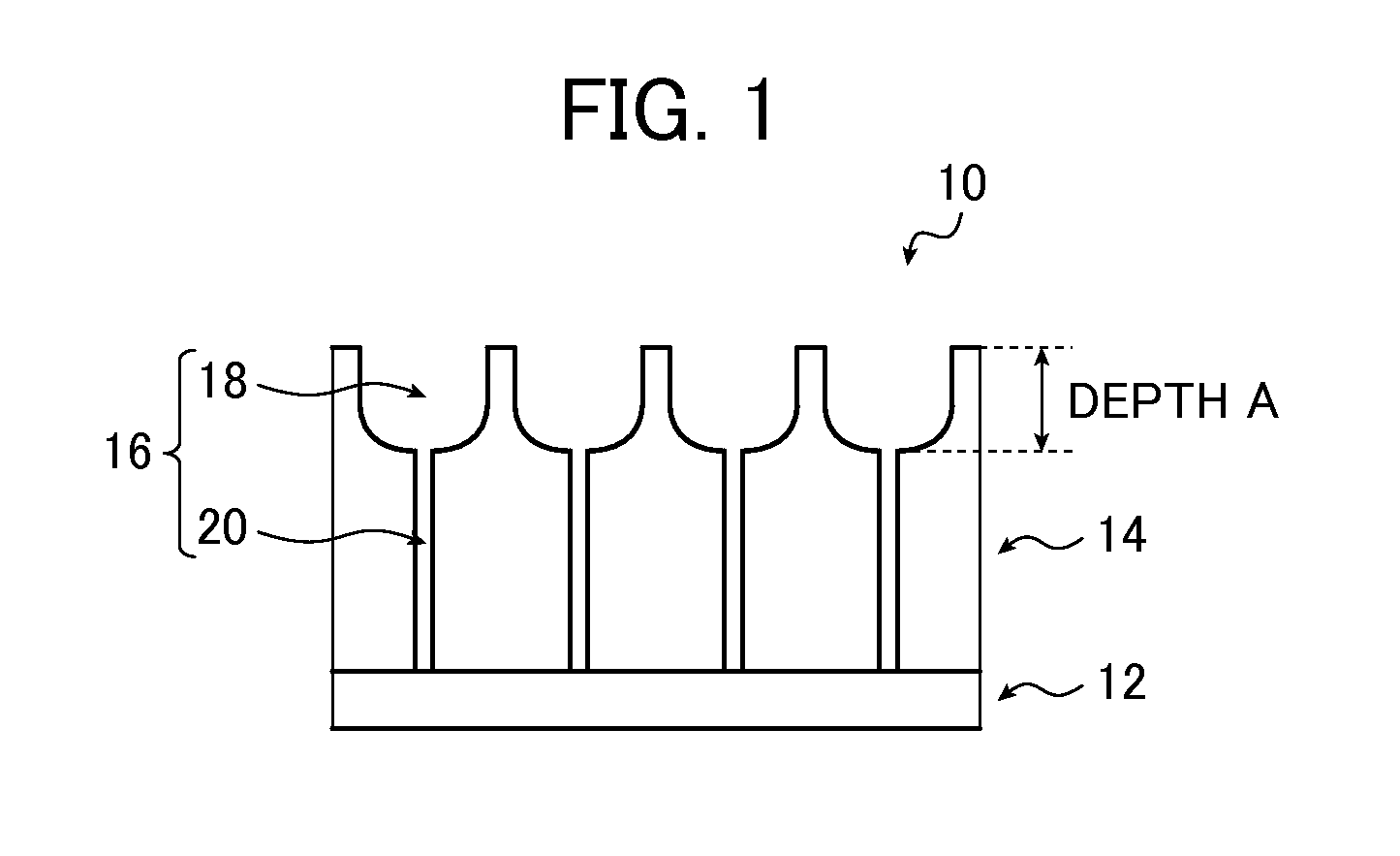

Support for planographic printing plate, method for producing support for planographic printing plate, and planographic printing original plate

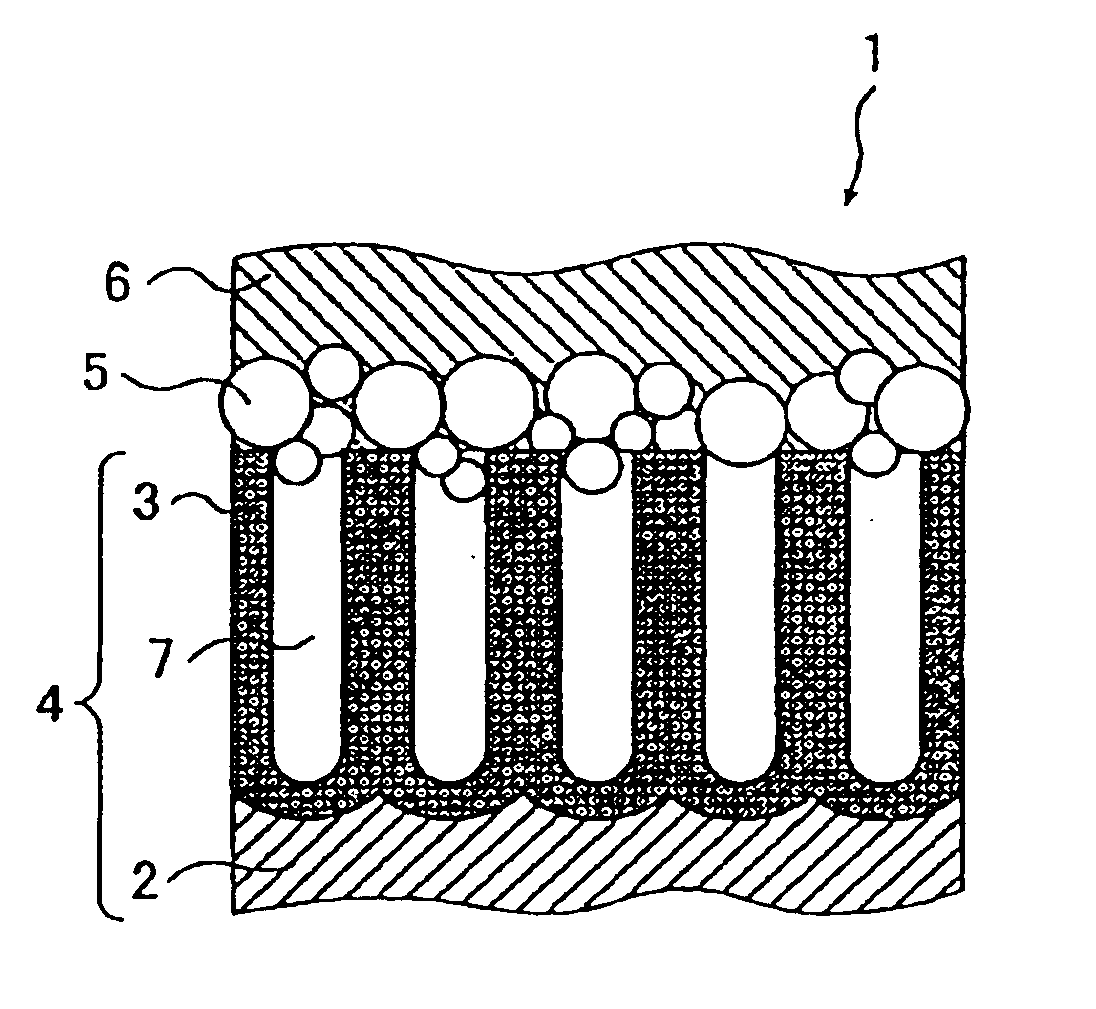

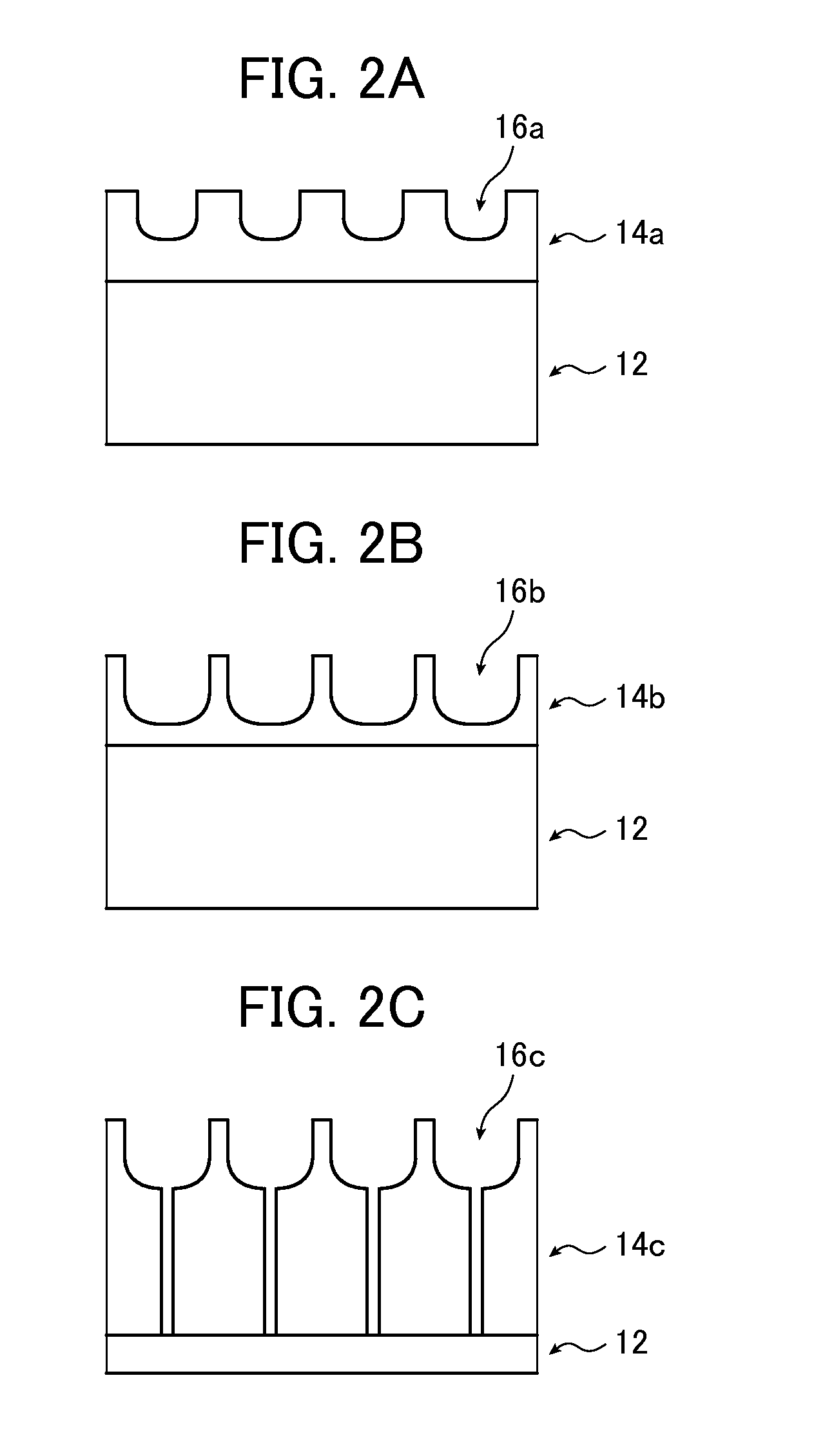

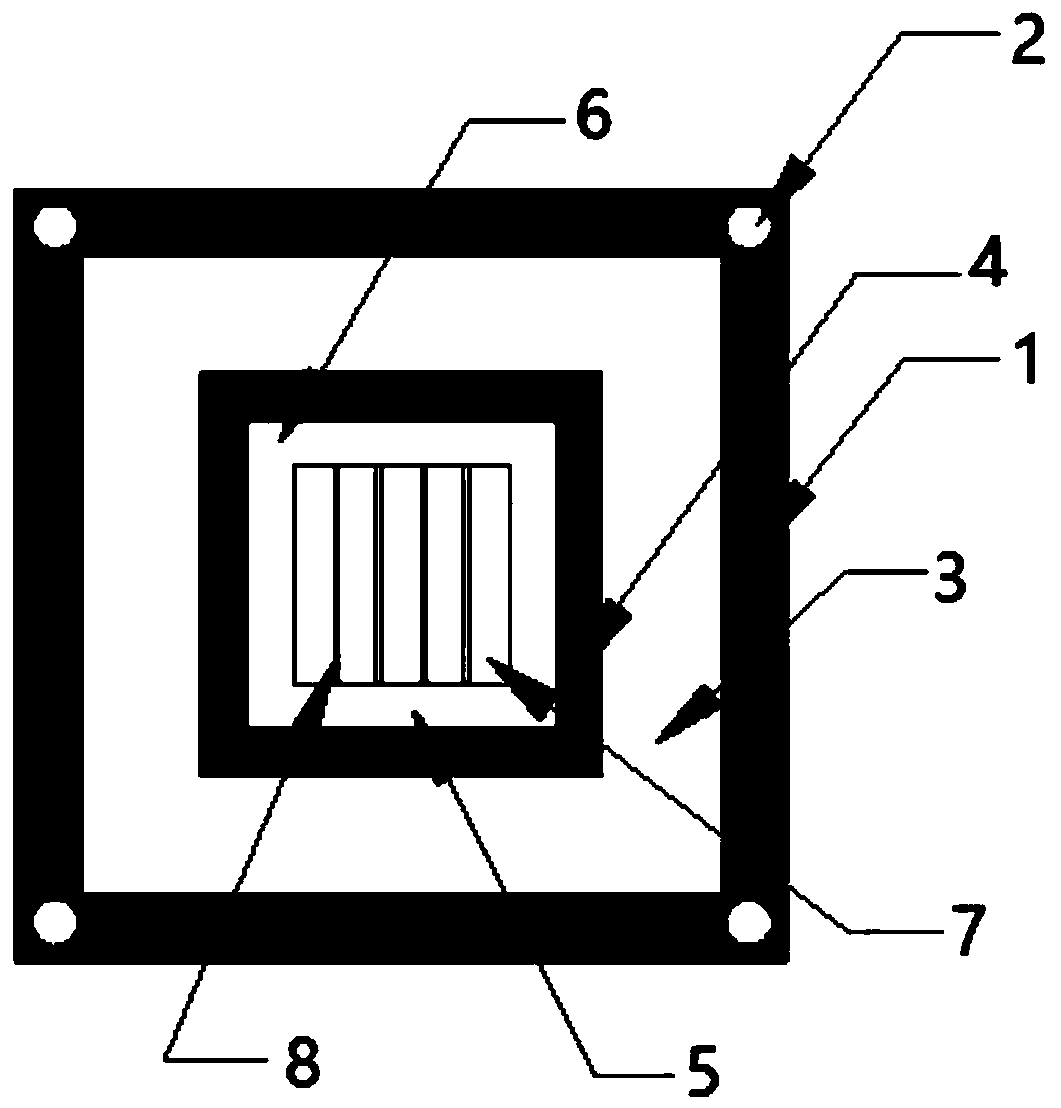

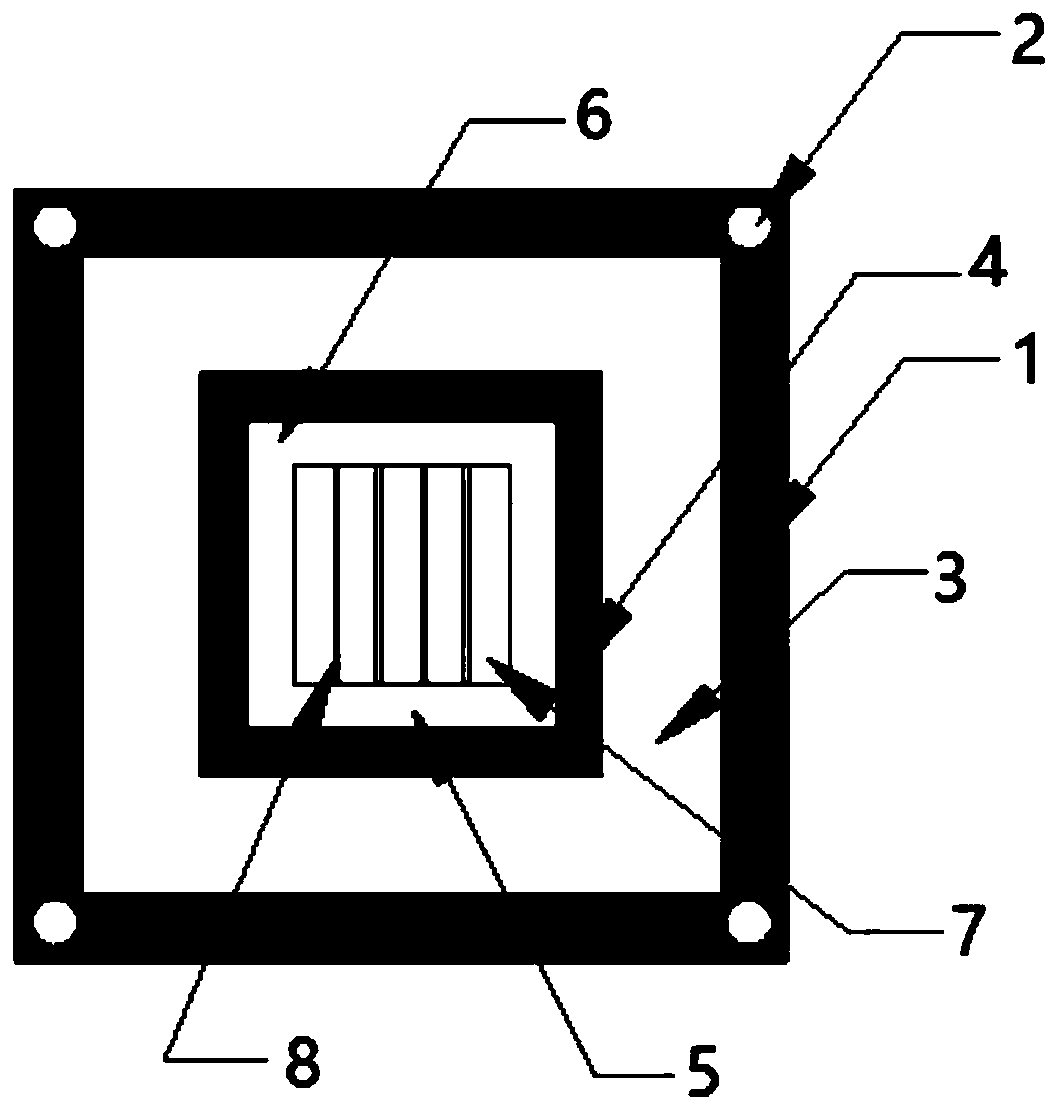

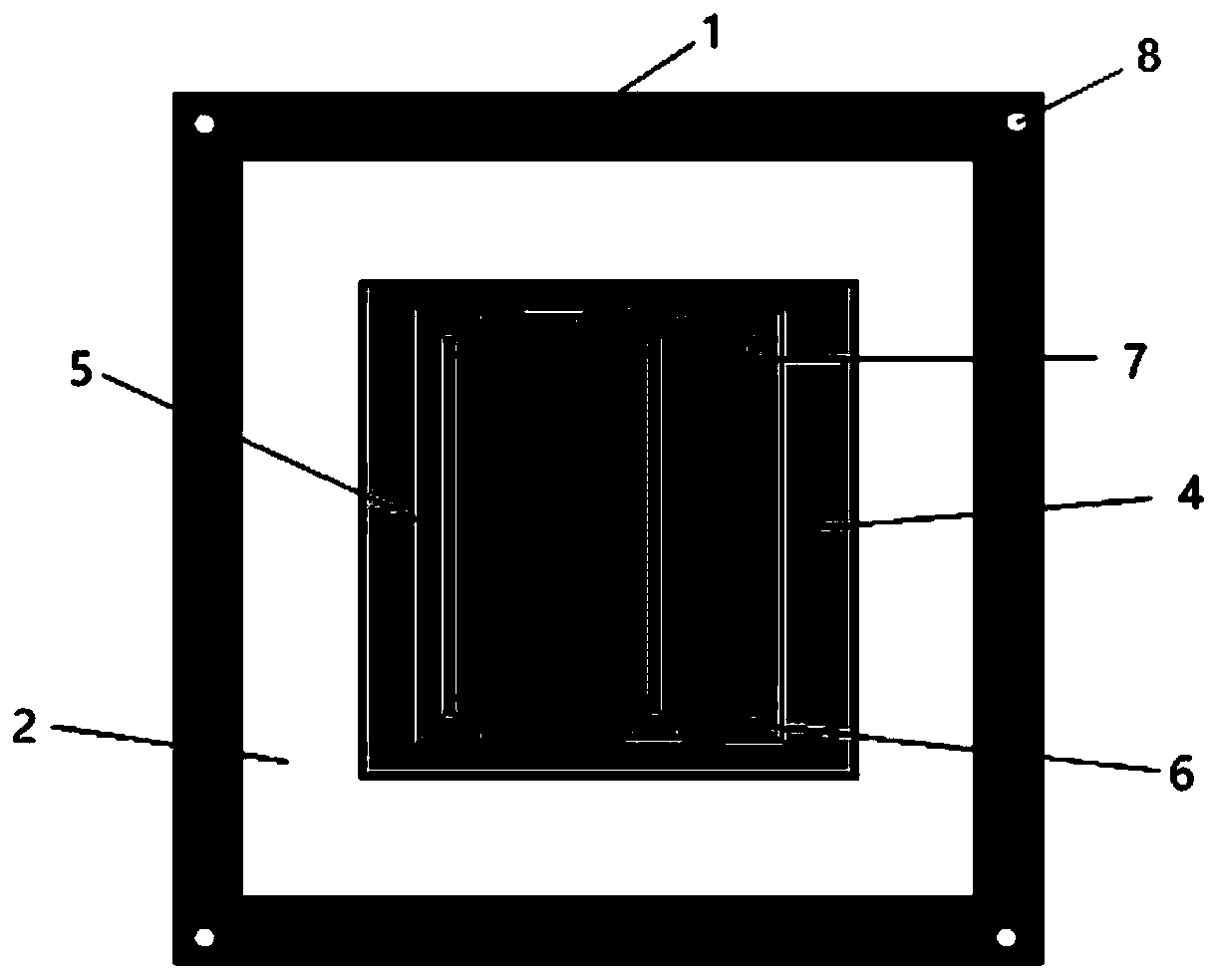

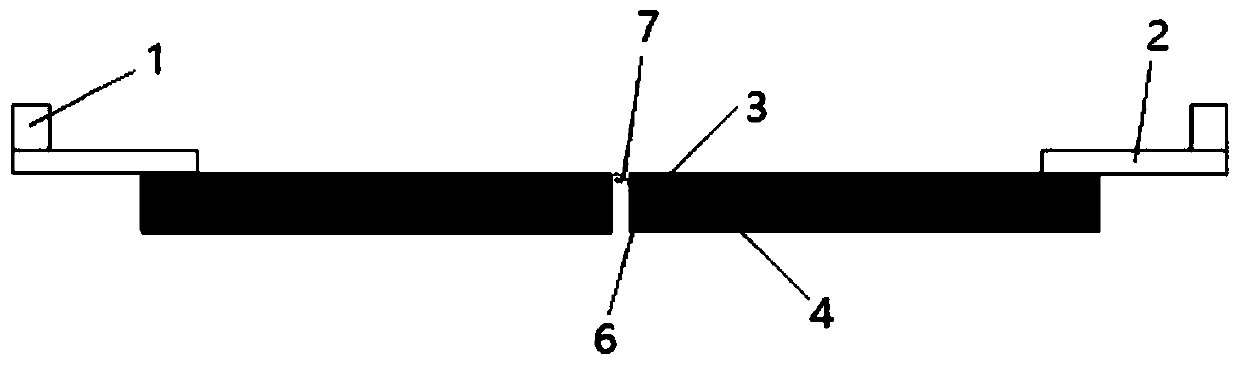

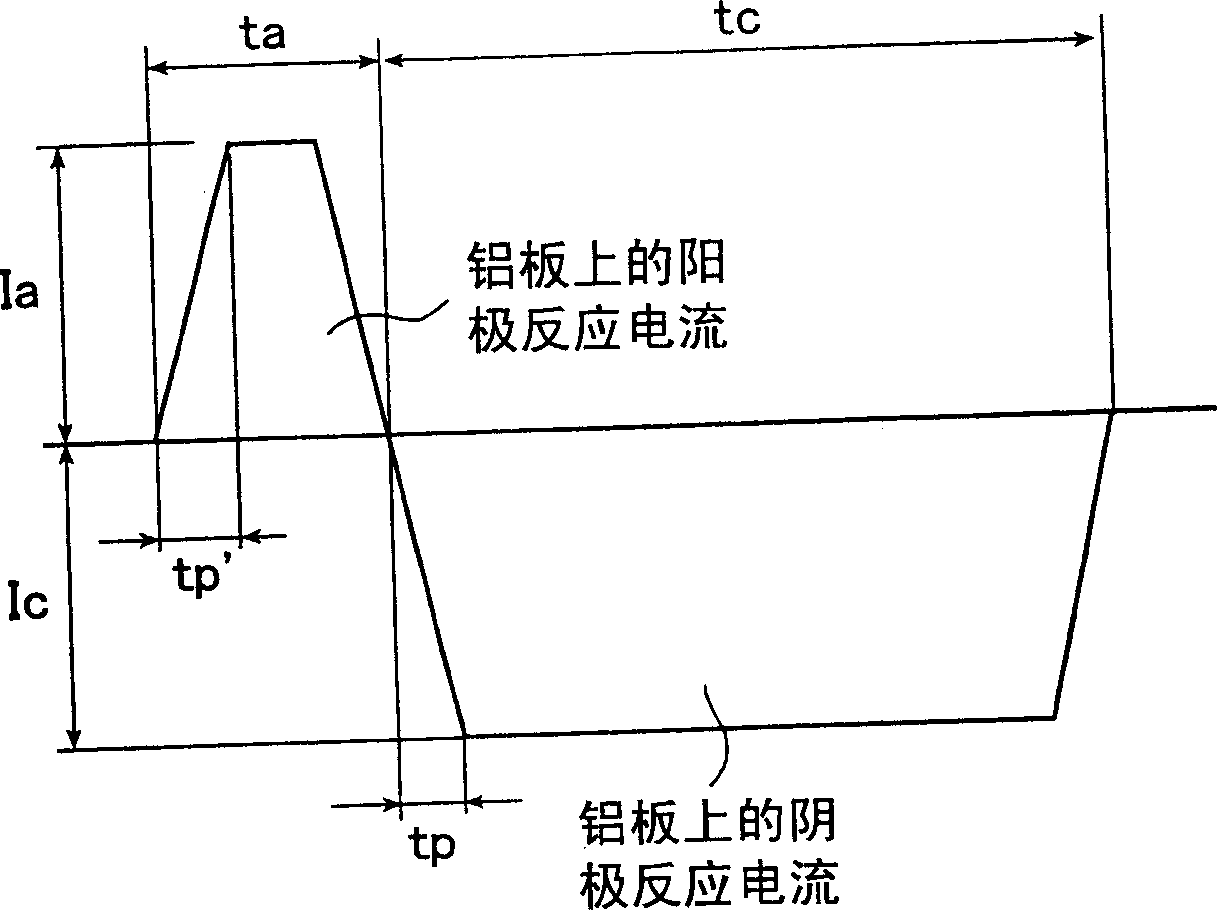

ActiveUS8783179B2Good deinking effectProlong lifeAnodisationDuplicating/marking methodsDepth directionPlanographic printing

Owner:FUJIFILM CORP

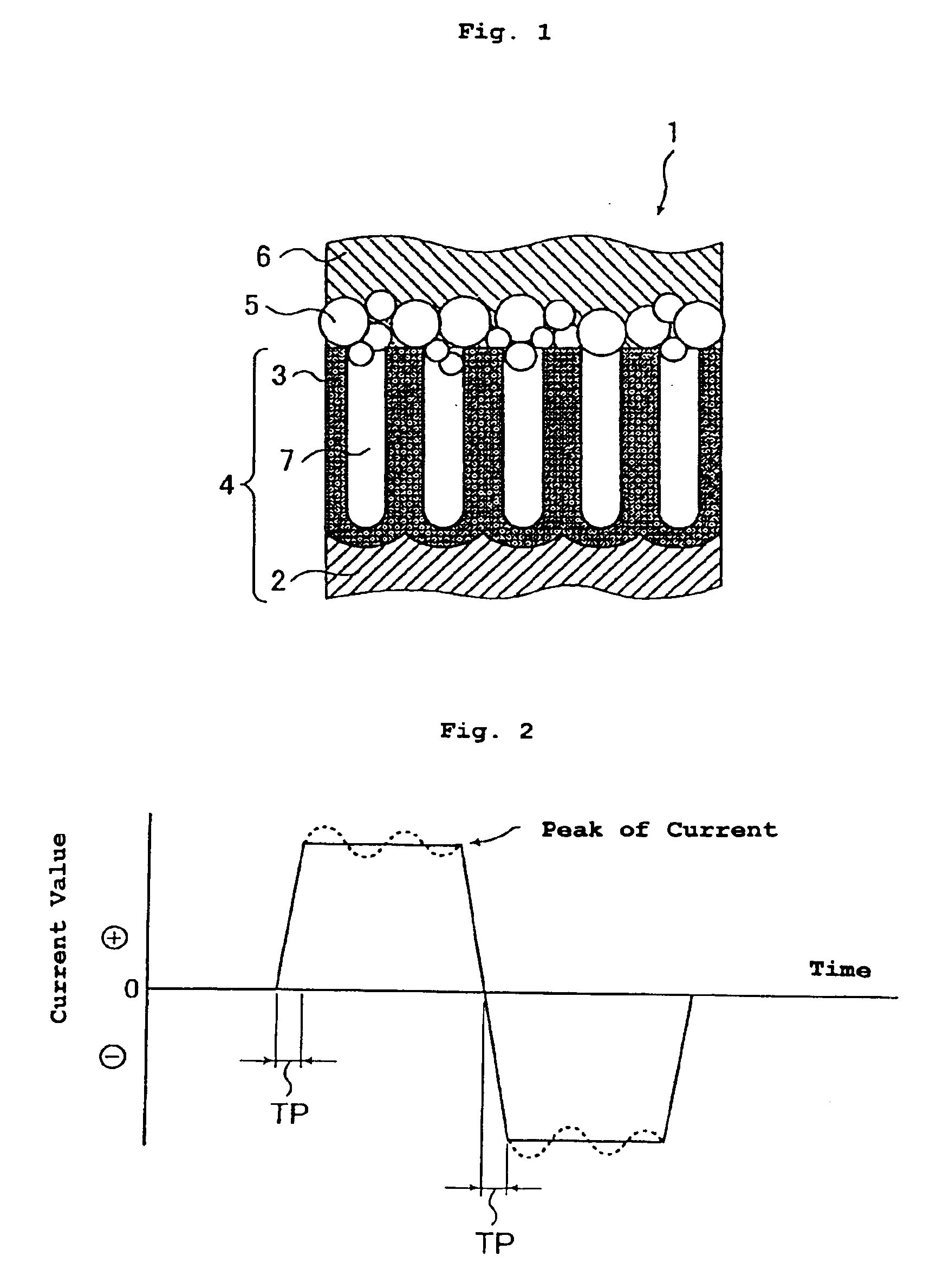

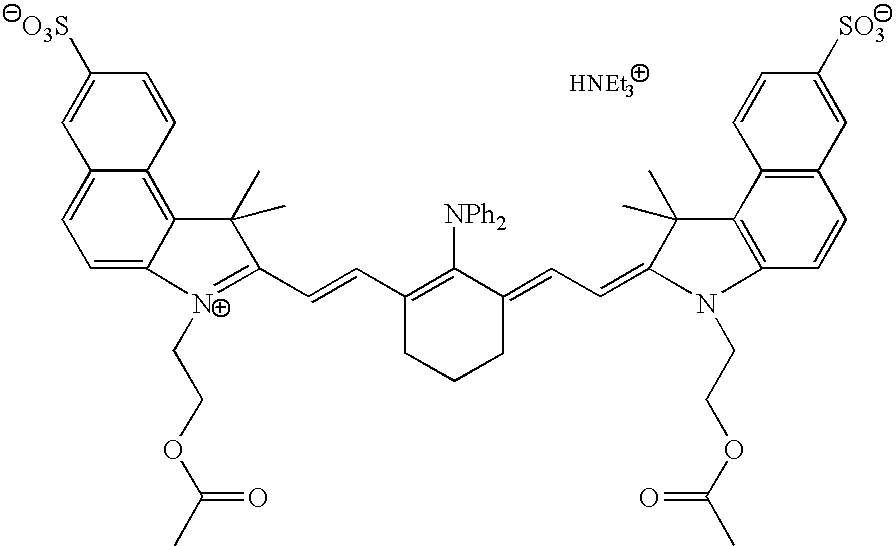

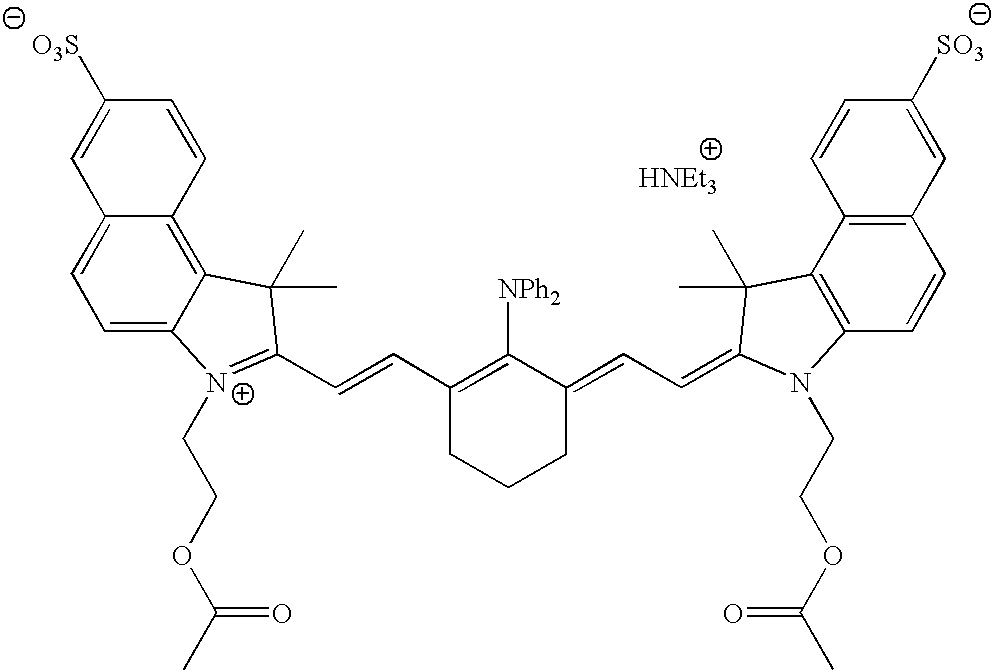

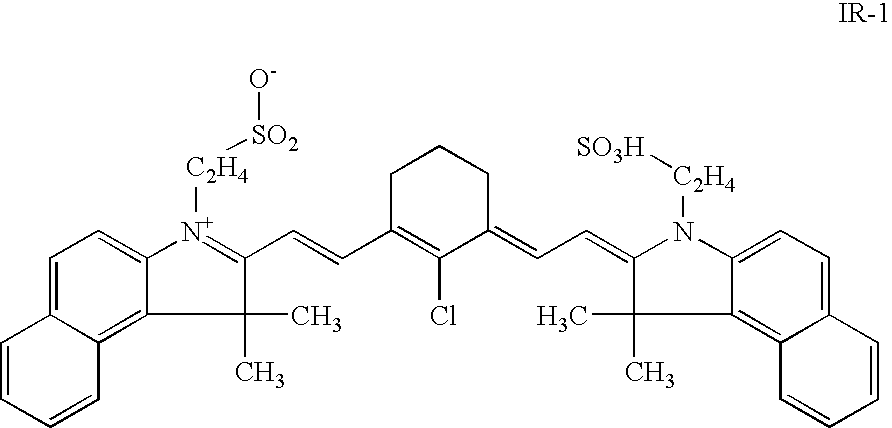

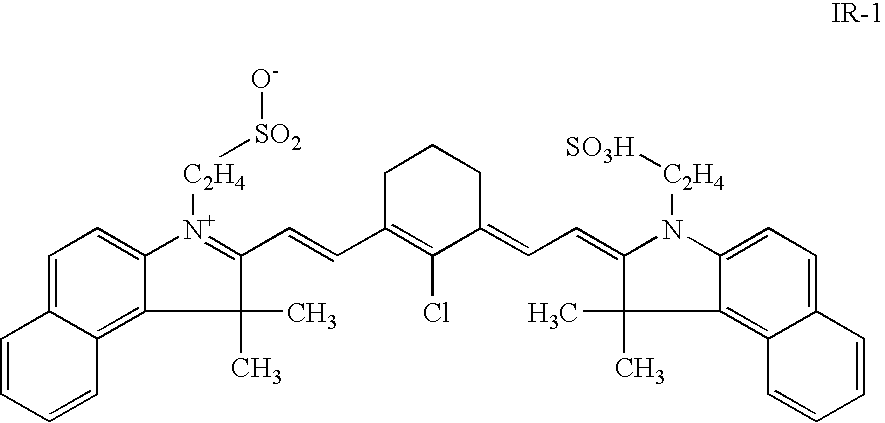

Lithographic printing method and presensitized plate

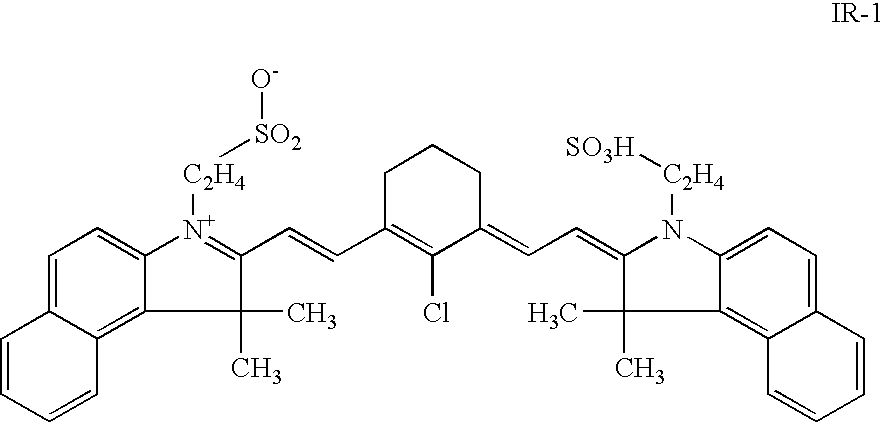

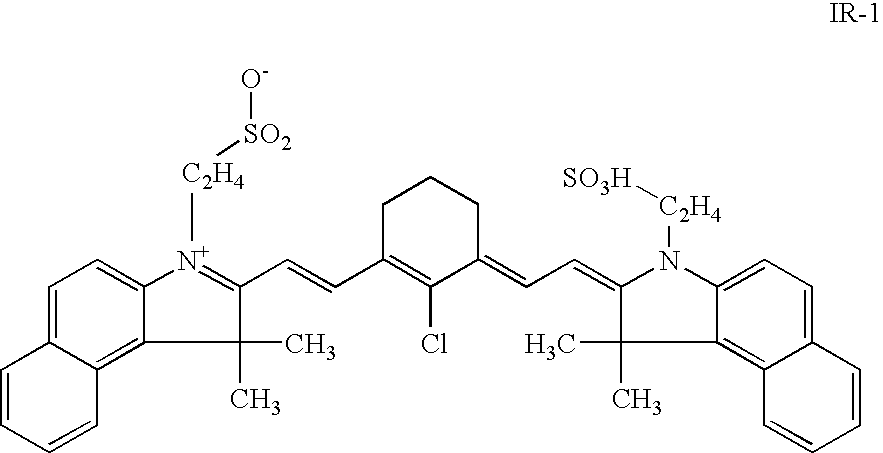

ActiveUS20040197701A1Practical amount of energyIncrease impressionRadiation applicationsPhotomechanical apparatusDigital dataNitrogen

Disclosed is a presensitized plate composed of a support having thereon an image recording layer which includes: an infrared absorber (A) that is a cyanine dye having at least one fused ring composed of a nitrogen-containing heterocycle in combination with an aromatic ring or a second heterocycle, and having on the aromatic ring or second heterocycle an electron-withdrawing group or a heavy atom-containing group, a radical generator (B), and a radical-polymerizable compound (C), and which is removable with printing ink and / or dampening water. The presensitized of the present invention can be imaged with an infrared light-emitting laser to directly record an image from digital data on a computer or the like and is then subjected to on-machine development without carrying out a development step, which is capable of providing a large number of good impressions with a practical amount of energy.

Owner:FUJIFILM CORP

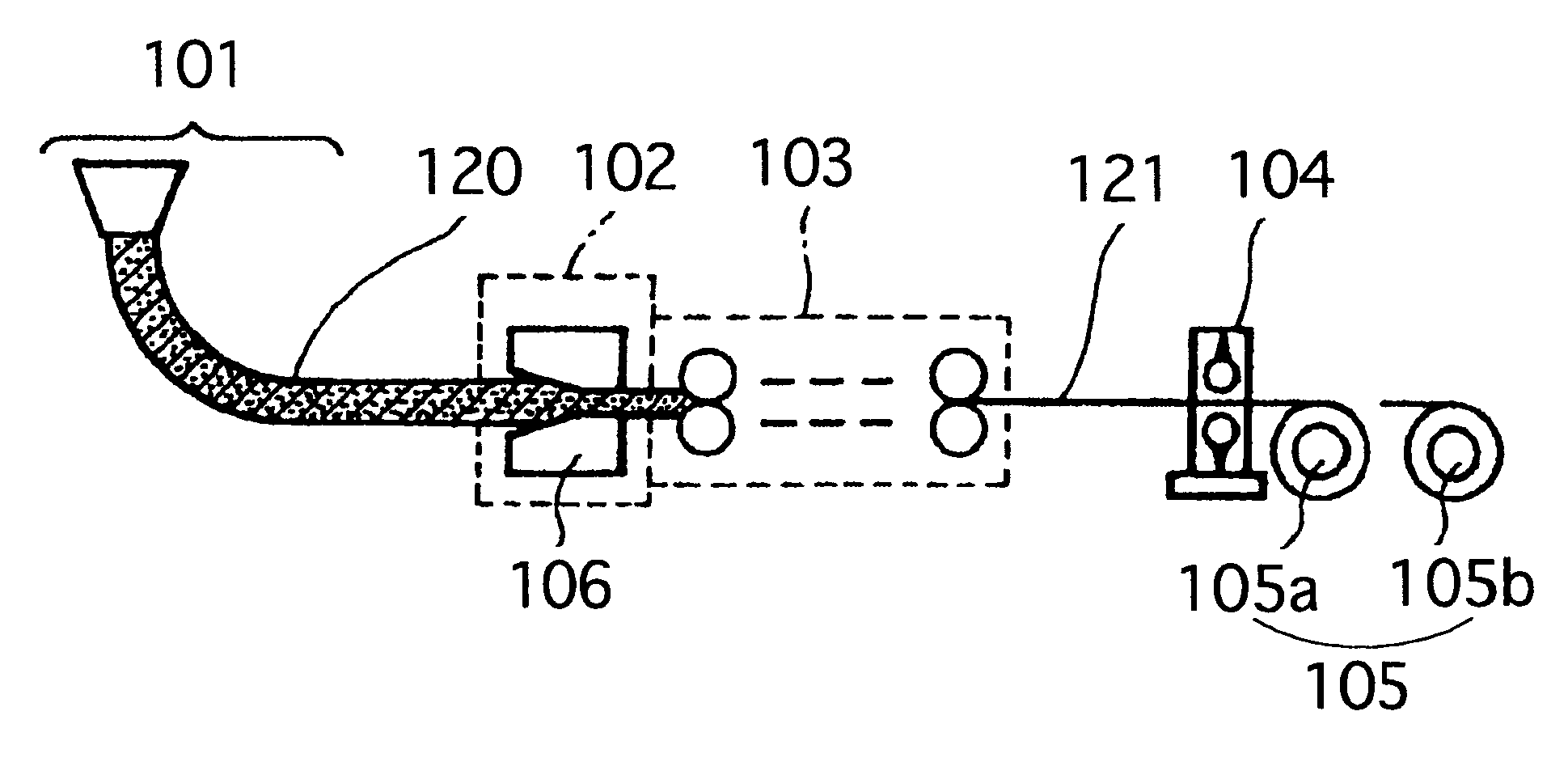

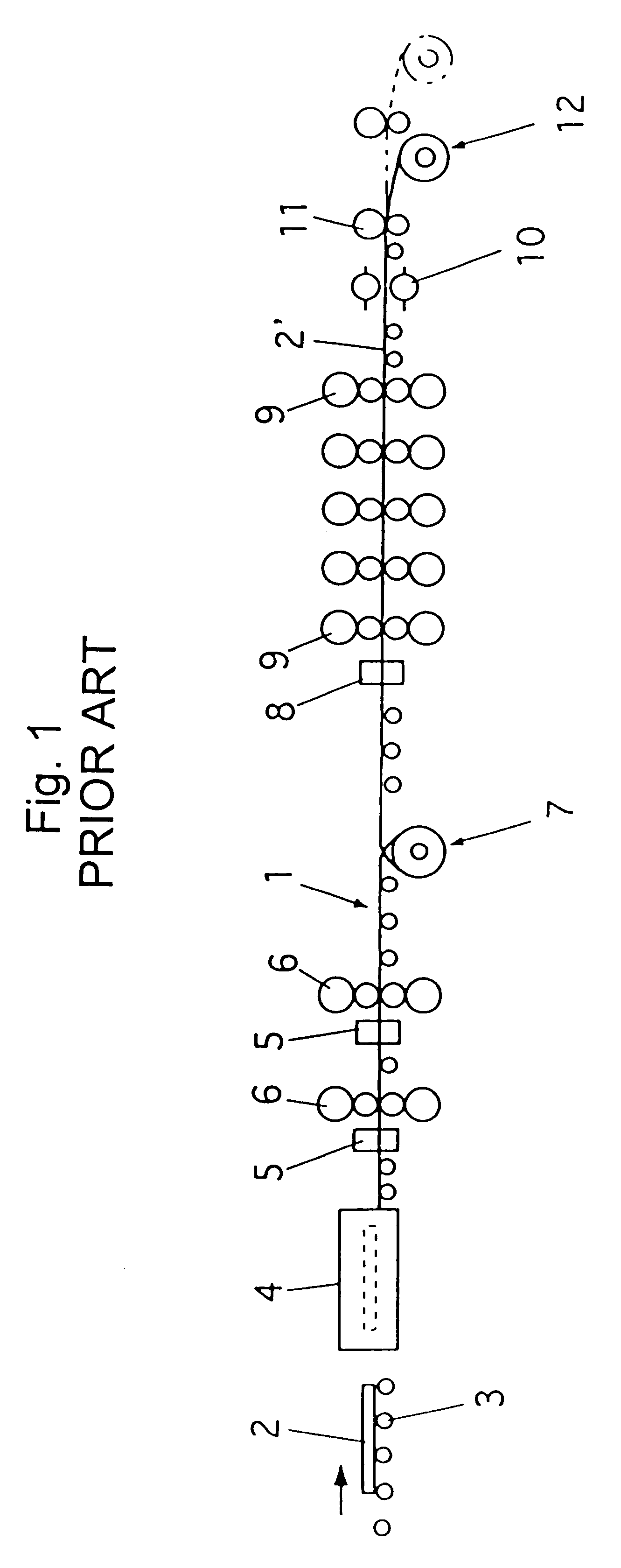

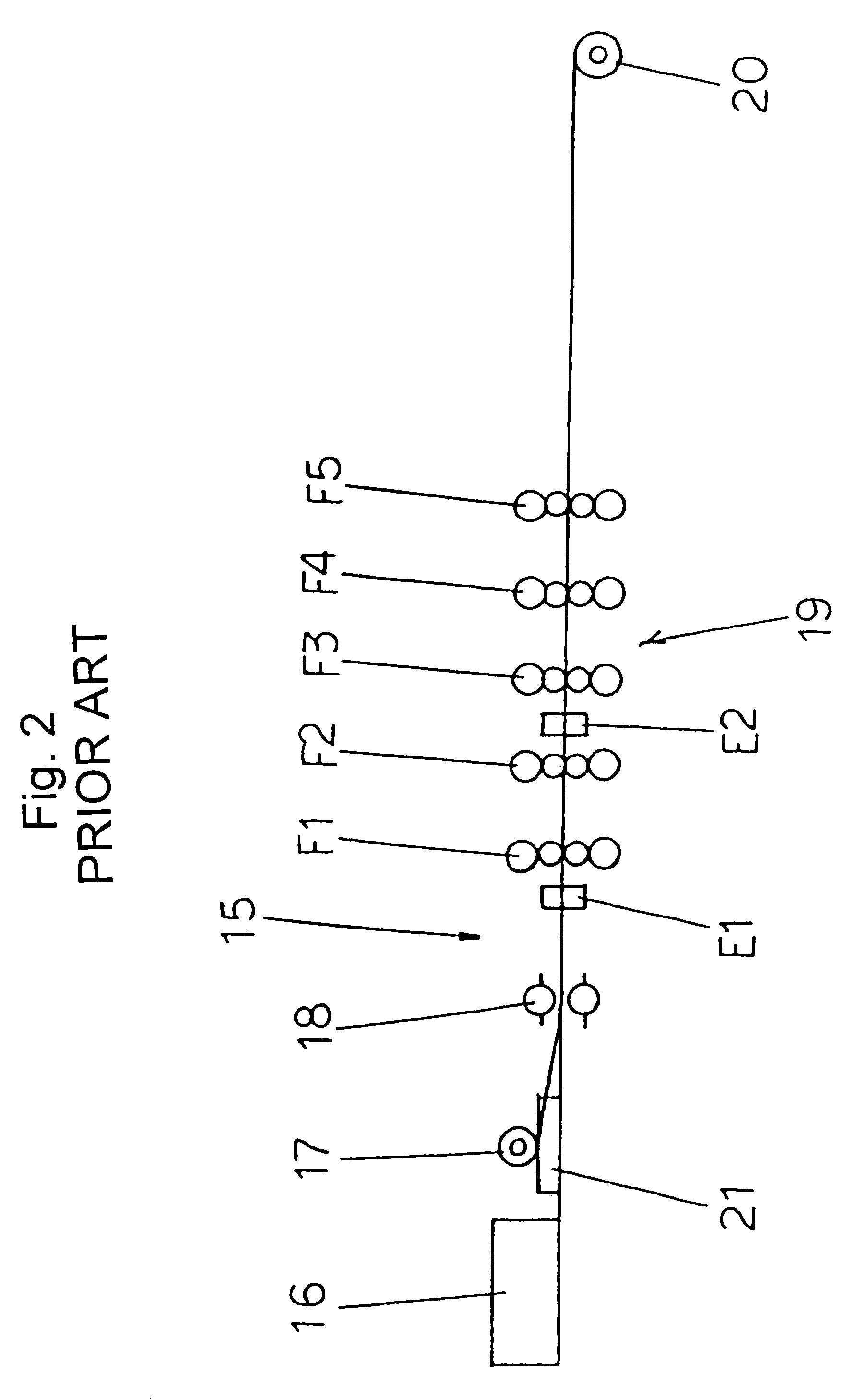

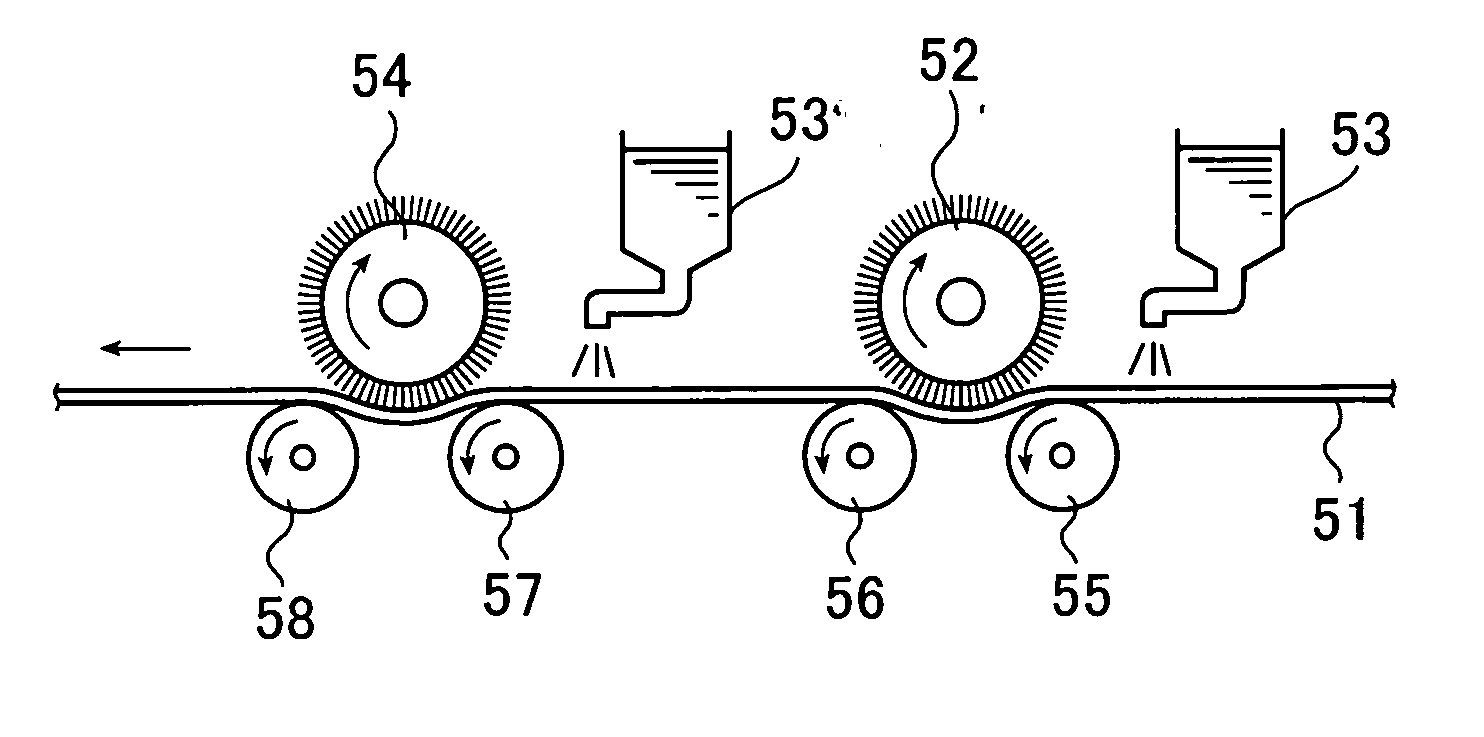

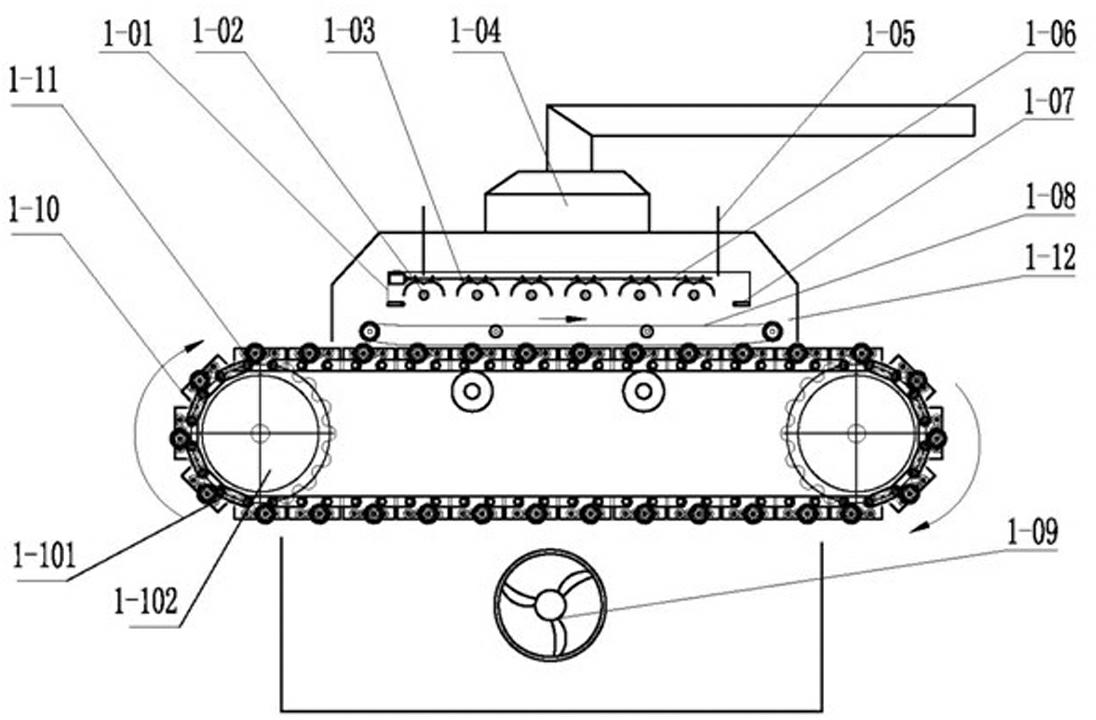

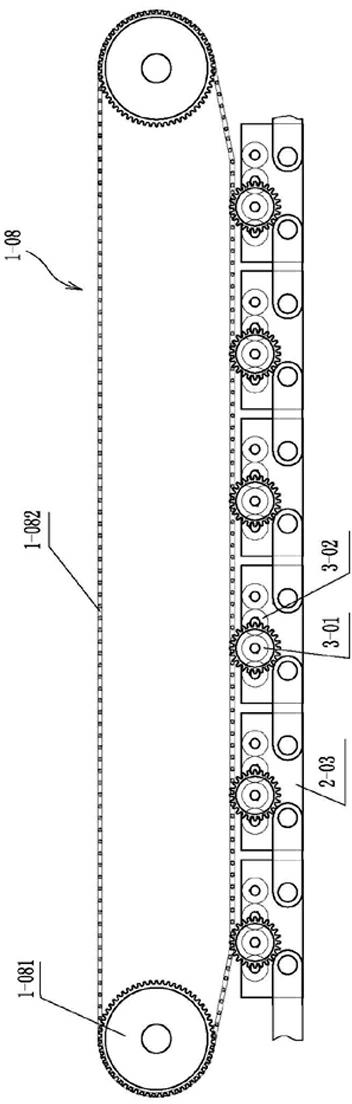

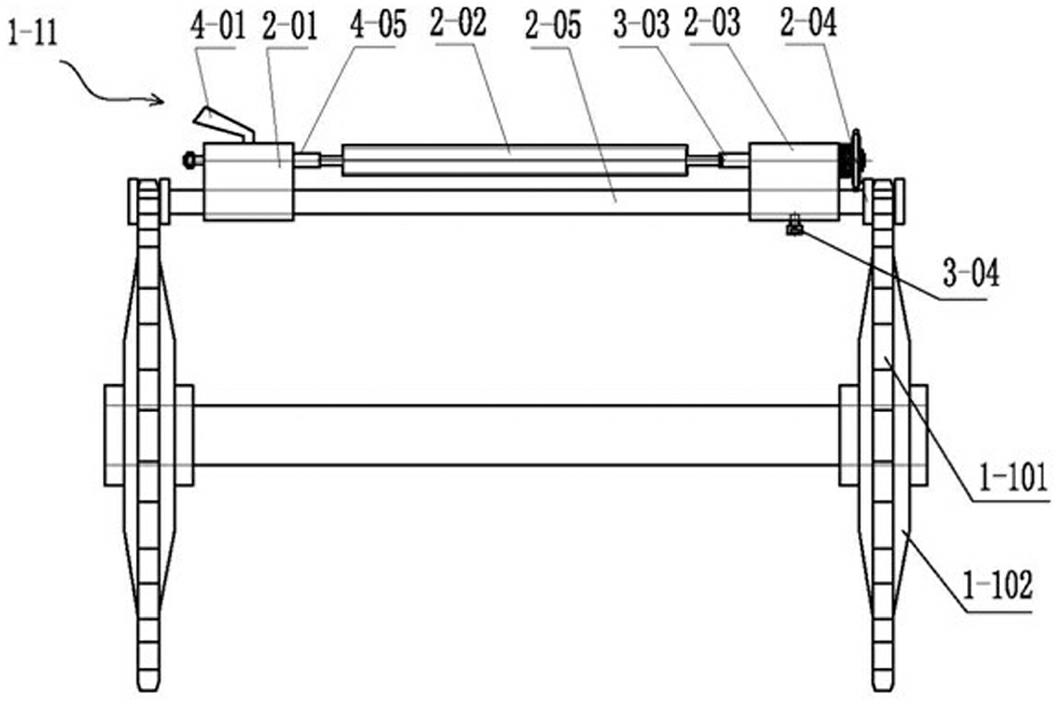

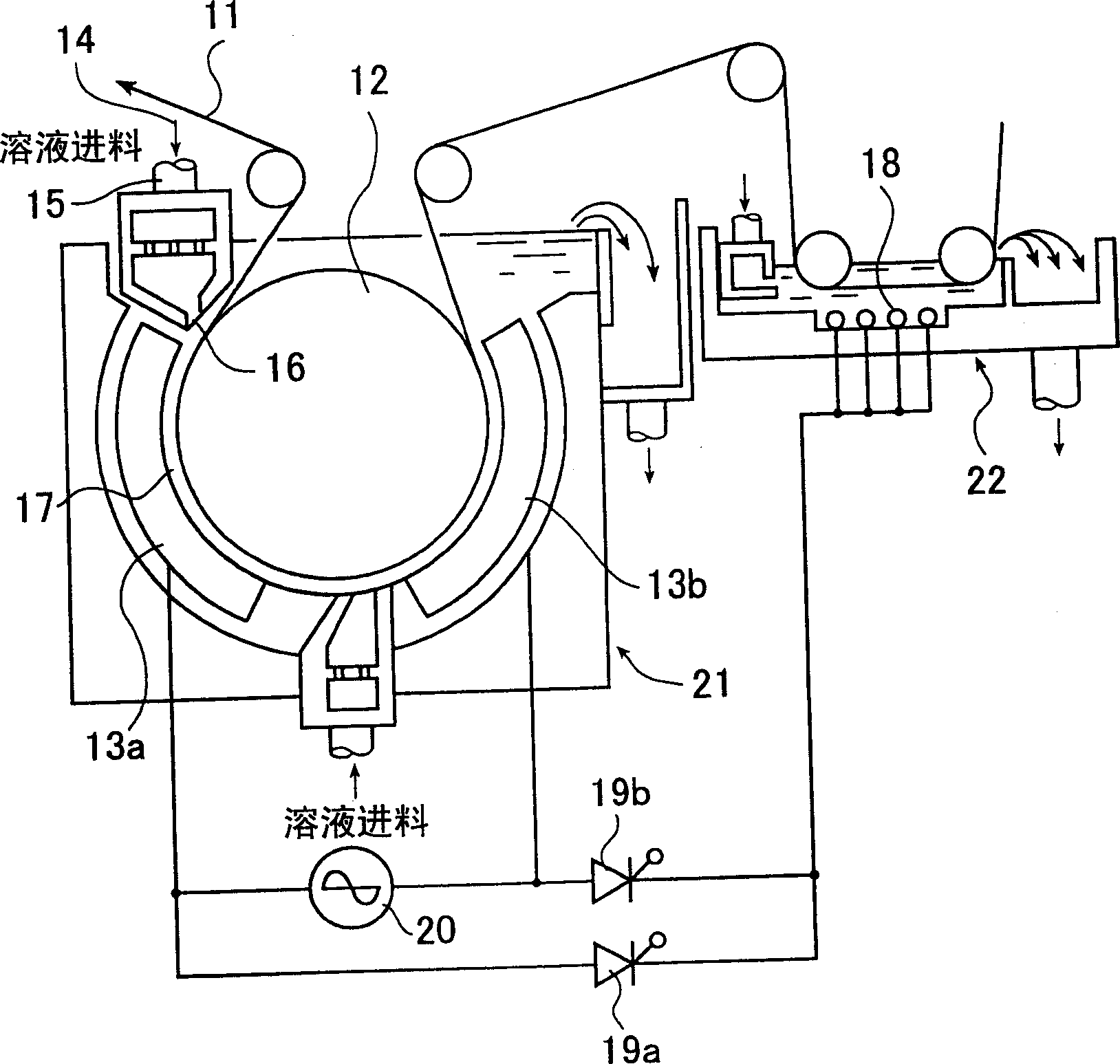

Apparatus and methods for manufacturing hot rolled steel sheets

InactiveUS6463652B1DesignedReduce vibrationForging/pressing devicesMetal rolling stand detailsProduction rateSheet steel

A high-quality hot rolled steel sheet is manufactured with a high production efficiency and a low cost, from a long, hot slab, using a combination of continuous casting facilities and a plate reduction press machine.

Owner:IHI CORP +2

Support for planographic printing plate, method for producing support for planographic printing plate, and planographic printing original plate

ActiveUS20120298001A1Good deinking effectProlong lifeAnodisationDuplicating/marking methodsEngineeringDepth direction

Provided is a lithographic printing plate support that has excellent scratch resistance and is capable of obtaining a presensitized plate which exhibits excellent on-press developability and enables a lithographic printing plate formed therefrom to have a long press life and excellent deinking ability after suspended printing. The lithographic printing plate support includes an aluminum plate, and an aluminum anodized film formed thereon and having micropores which extend in a depth direction of the anodized film from a surface of the anodized film opposite from the aluminum plate. Each micropore has a large-diameter portion which extends to a depth of 5 to 60 nm (depth A) from the anodized film surface, and a small-diameter portion which communicates with the bottom of the large-diameter portion, further extends to a depth of 900 to 2,000 nm from the communication position and has a predetermined average diameter.

Owner:FUJIFILM CORP

Capture member and ink jet printer

InactiveUS20070046722A1Increased printing lifeReduce accumulationMeasurement apparatus componentsOther printing apparatusInk printerEngineering

Owner:SEIKO EPSON CORP

Support for lithographic printing plate and presensitized plate

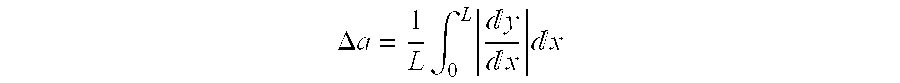

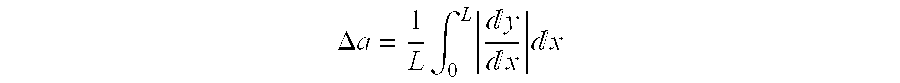

A support for a lithographic printing plate obtained by performing surface graining and anodizing of an aluminum alloy plate, wherein the foregoing aluminum alloy plate contains specific contents of Fe, Si, Cu, Ti, Zn and Mg, with the balance being Al and incidental impurities. The presensitized plate obtained from this support for a lithographic printing plate is excellent in press life and in resistance to dot ink stain when processed into a lithographic printing plate. Preferably, the support for a lithographic printing plate, with regard to the surface of the support, has a center line average roughness Ra in the range of 0.2-0.6 mum, a maximum height Rmax in the range of 3.0-6.0 mum, a ten-point mean roughness Rz in the range of 2.0-5.5 mum, a center line peak height Rp in the range of 1.0-3.0 mum, a center line valley depth Rv in the range of 2.0-3.5 mum, a mean spacing Sm in the range of 40-70 mum, an average inclination DELTAa in the range of 6.0-12.0°, and a peak count Pc in the range of 100-200.

Owner:FUJIFILM CORP

Lithographic printing plate support and presensitized plate

InactiveUS20060223005A1Water visibilityPreventing scummingPhotomechanical apparatusPlate printingEngineeringAlkali metal

Disclosed is a lithographic printing plate support obtainable by subjecting an aluminum plate to an electrochemical graining treatment with an aqueous solution containing hydrochloric acid, anodizing treatment and alkali metal silicate treatment at least, wherein: a surface of the support has a grained shape in which large pits with a mean aperture diameter of 2 to 10 μm and small pits with a mean aperture diameter of 0.05 to 0.8 μm overlap with each other, with the mean ratio of depth to aperture diameter of the small pits being 0.2 to 0.6; a surface area difference ΔS50 defined by equation (1): ΔS50=(Sx50−S050) / S050×100 (%) (1) in which Sx50 is the actual area of a 50 μm square region of the surface as determined by three-point approximation from three-dimensional data obtained by measuring the region with an atomic force microscope at 512×512 points and S050 is the geometrically measured area of the same region, is 20 to 40%; the alkali metal silicate treatment is performed using an aqueous solution of pH 11.5 to 13.0 which contains an alkali metal silicate; and an amount of Si atoms deposited to the surface is 3.0 to 15.0 mg / m2. The presensitized plate according to the present invention allows not only the press life but also the resistance to scumming by ink spreading, resistance to scumming by leaving and resistance to scumming by failed deletion, and the water visibility as well, to be excellent, even if an FM screen is used for halftone.

Owner:FUJIFILM CORP +1

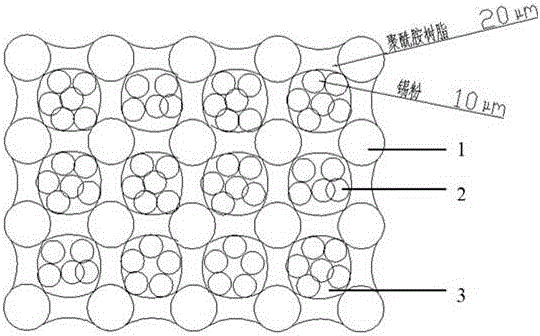

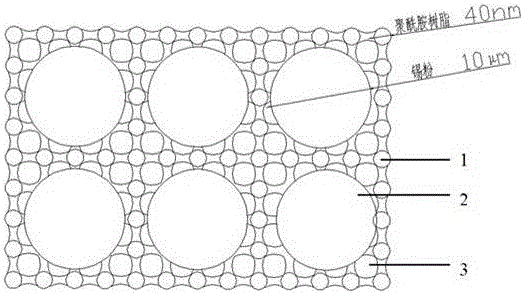

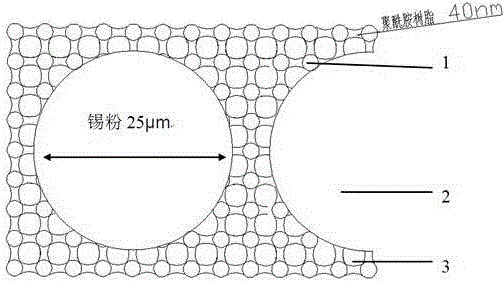

Scaling powder used for high-precision nanometer soldering paste

ActiveCN105345314AReduce frictionIncreased printing lifeWelding/cutting media/materialsSoldering mediaSolventOrganic acid

The invention discloses scaling powder used for high-precision nanometer soldering paste. The raw materials of the scaling powder comprise, by mass, 20%-30% of solvent, 30%-50% of rosin, 3%-8% of surfactant, 2%-5% of thixotropic agents, 5%-10% of organic acid, 2%-5% of organic amine and 2%-5% of inhibiter. Compared with the prior art, the scaling powder used for the high-precision nanometer soldering tin paste has the advantages that 1, each grain of tin powder is wrapped in the scaling powder and makes entire contact with the scaling powder, the tin powder cannot adhere to a net or a scraper in the printing process, and the defects of skipping printing and lessening soldering paste are decreased; 2, the friction among the tin powder is reduced through nanometer particles on the surface of the tin powder, and the printing service life of the soldering paste is prolonged; 3, the thixotropic agents forme a fine anti-setting net-shaped structure, and big crystals cannot be separated out to cause the phenomenon of false thickening; and 4, each grain of the tin powder in the soldering paste keeps in good contact with the scaling powder by adding polyamide resin nanometer powder, and the soldering efficiency of the scaling powder is improved.

Owner:江苏广昇新材料有限公司

Negative light-sensitive lithographic printing plate

InactiveCN1373395AEasy to cross-link and cureGood removal effectPhotomechanical apparatusLithographyPolymer sciencePolyvinyl alcohol

A negative photosensitive lithographic printing plate comprises: a support; and a photosensitive layer containing: i) a modified poly(vinyl alcohol) resin binder having a radical-polymerizable group and an acid group; and ii) at least one of a photo-polymerization initiator and a heat-polymerization initiator.

Owner:FUJIFILM CORP

Manufacturing method of composite screen printing plate

InactiveCN110039882ANot easy to wear and tearIncreased printing lifePlate printingFoil printingLine widthEngineering

The invention discloses a manufacturing method of a composite screen printing plate. The manufacturing method comprises the following steps of 1) screen pulling and compounding; 2) film layer manufacturing; 3) coating an adhesive layer; 4) coating a film; 5) drying; 6) laser; 7) cleaning; and 8) detection and packaging. By means of the mode, the manufacturing method of the composite screen plate has the advantages that when the screen printing plate is used, the film layer is not easy to wear and break, the printing life is prolonged by one time or more, the printing life of a conventional plate-making screen printing plate is averagely increased by about 50 thousand, the average energy of the screen printing life prepared by the method can reach 100 thousand or above and even higher, theprinting line at the later stage is not expanded, and the efficiency of the battery piece is obvious; and the manufactured screen printing plate is better in ink permeability, so that the limitation of the high-precision narrow line width can be greatly reduced, on the basis of the same type of ink printing, the width of the designed line can be compressed by 2-5 microns, the printing is good, theline type is good, and therefore the efficiency of the battery piece is obviously improved.

Owner:SUZHOU WOSUTE ELECTRONICS MATERIALS CO LTD

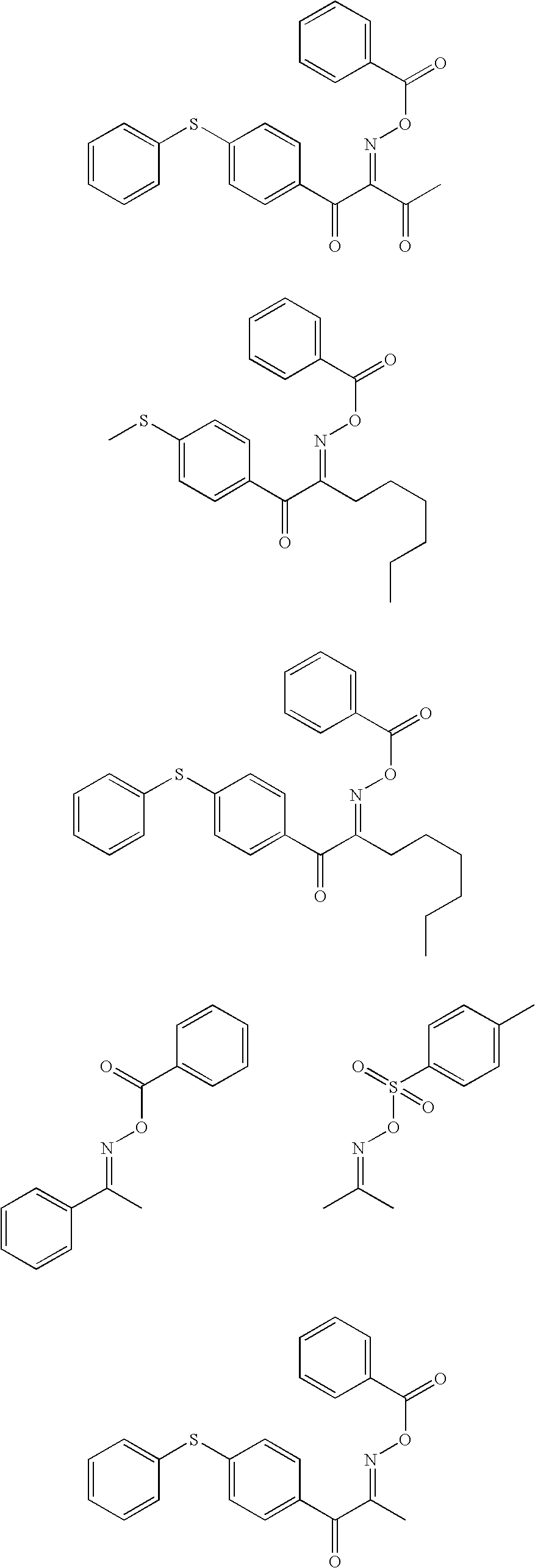

Method for making a lithographic printing plate

ActiveUS20060014104A1Increased printing lifeHigh sensitivityPhoto-taking processesPhotosensitive materialsImage recordingPolymer chemistry

A method for making a lithographic printing plate is disclosed which comprises the steps of: (i) providing a negative-working, heat-sensitive lithographic printing plate precursor comprising a support having a hydrophilic surface or which is provided with a hydrophilic layer and a coating provided thereon, the coating comprising an image-recording layer which comprises hydrophobic thermoplastic polymer particles and a hydrophilic binder, wherein the hydrophobic thermoplastic polymer particles have an average particle size in the range from 45 nm to 63 nm, and wherein the amount of the hydrophobic thermoplastic polymer particles in the image-recording layer is at least 70% by weight relative to the image-recording layer; (ii) exposing the coating to heat or infrared light, thereby inducing coalescence of the thermoplastic polymer particles at exposed areas of the coating; (iii) developing the precursor by applying an aqueous alkaline solution, thereby removing non-exposed areas of the coating from the support, wherein the aqueous alkaline solution has a pH≧10 and comprises a surfactant.

Owner:AGFA OFFSET BV

Lithographic printing method and presensitized plate

ActiveCN1597313AIncreased printing lifePhotomechanical apparatusForme preparationDigital dataInfrared

Disclosed is a presensitized plate composed of a support having thereon an image recording layer which includes: an infrared absorber (A) that is a cyanine dye having at least one fused ring composed of a nitrogen-containing heterocycle in combination with an aromatic ring or a second heterocycle, and having on the aromatic ring or second heterocycle an electron-withdrawing group or a heavy atom-containing group, a radical generator (B), and a radical-polymerizable compound (C), and which is removable with printing ink and / or dampening water. The presensitized of the present invention can be imaged with an infrared light-emitting laser to directly record an image from digital data on a computer or the like and is then subjected to on-machine development without carrying out a development step, which is capable of providing a large number of good impressions with a practical amount of energy.

Owner:FUJIFILM CORP +1

Inkjet recording element comprising aluminosilicate and acetoacetylated poly(vinyl alcohol)

InactiveUS20060044384A1Improve interlayer adhesionImprove image qualityDuplicating/marking methodsPolymer sciencePolyvinyl alcohol

An inkjet recording element comprising a support having thereon, in order over a support, a base layer comprising a synthetic or natural polymer and optionally a polymeric mordant; an inner layer comprising acetoacetylated or carboxylated poly(vinyl alcohol); and an overcoat comprising poly(vinyl alcohol) binder and particles of a synthetic, substantially amorphous aluminosilicate material. Such recording elements exhibit improved adhesion during printing.

Owner:EASTMAN KODAK CO

Manufacture method of multi-angle or zero-angle screen printing plate

InactiveCN110039884AClear and smooth outlineEasy to shapePlate printingFoil printingScreen printingLaser etching

Owner:SUZHOU WOSUTE ELECTRONICS MATERIALS CO LTD

Method for making a lithographic printing plate

ActiveUS20060014103A1Increased printing lifeHigh sensitivityPhotosensitive materialsRadiation applicationsImage recordingHeat sensitive

A method for making a lithographic printing plate is disclosed which comprises the steps of: (i) providing a negative-working, heat-sensitive lithographic printing plate precursor comprising a support having a hydrophilic surface or which is provided with a hydrophilic layer and a coating provided thereon, the coating comprising an image-recording layer which comprises hydrophobic thermoplastic polymer particles and a hydrophilic binder, wherein the hydrophobic thermoplastic polymer particles have an average particle size in the range from 45 nm to 63 nm and wherein the amount of the hydrophobic thermoplastic polymer particles in the image-recording layer is at least 70% by weight relative to the image-recording layer; (ii) exposing the coating to heat or infrared light, thereby inducing coalescence of the thermoplastic polymer particles at exposed areas of the coating; (iii) developing the precursor by applying an aqueous, alkaline solution, thereby removing non-exposed areas of the coating from the support, wherein the aqueous alkaline solution has a pH≧11 and comprises a phosphate buffer or a silicate buffer.

Owner:AGFA OFFSET BV

Lithographic printing plate precursor and lithographic printing method

InactiveUS20060005725A1High film strengthExcellent developabilityPhotomechanical apparatusPlate printingPolymer scienceImage recording

A lithographic printing plate precursor comprising: a support; and an image recording layer comprising a polymerization initiator, a polymerizable compound and a polymer binder and being removable with at least one of a printing ink and a fountain solution, wherein the polymerizable compound and the polymer binder are defined so that a film made by the polymerizable compound and the polymer binder has an elastic modulus of 30 g / mm3 or less.

Owner:FUJIFILM CORP

Method and device capable of obtaining ultraviolet light protection layer on surface of development roller

ActiveCN102253630AReduce material costsReduce energy consumptionElectrographic process apparatusEngineeringPhoto irradiation

The invention discloses a method capable of obtaining an ultraviolet light protection layer on a surface of a development roller. The method comprises the following steps of: irradiating an ultraviolet light having certain wavelength to the surface of the development roller having a high-molecular rubber layer; during the decomposition of an organic matter on the surface of the rubber layer, absorbing the ultraviolet light to cut off a chemical structure of a surface layer of the rubber layer; and cross-linking and vulcanizing high-molecular rubber again to obtain the ultraviolet light protection layer which is 0.1 to 0.3 mm thick on the surface of the rubber layer. The invention also provides a device for implementing the method. The invention has the advantages that: a coating material is not required; material cost is effectively saved; energy consumption is reduced; process time is short; process efficiency is improved by over 200 times; due to no atomization, environmental pollution is reduced; and when the development roller is used for printing, risks of drop-off and abrasion of a coating are avoided, printing quality is effectively improved, and printing service life is prolonged.

Owner:SHENZHEN LEPUTAI TECH CO LTD

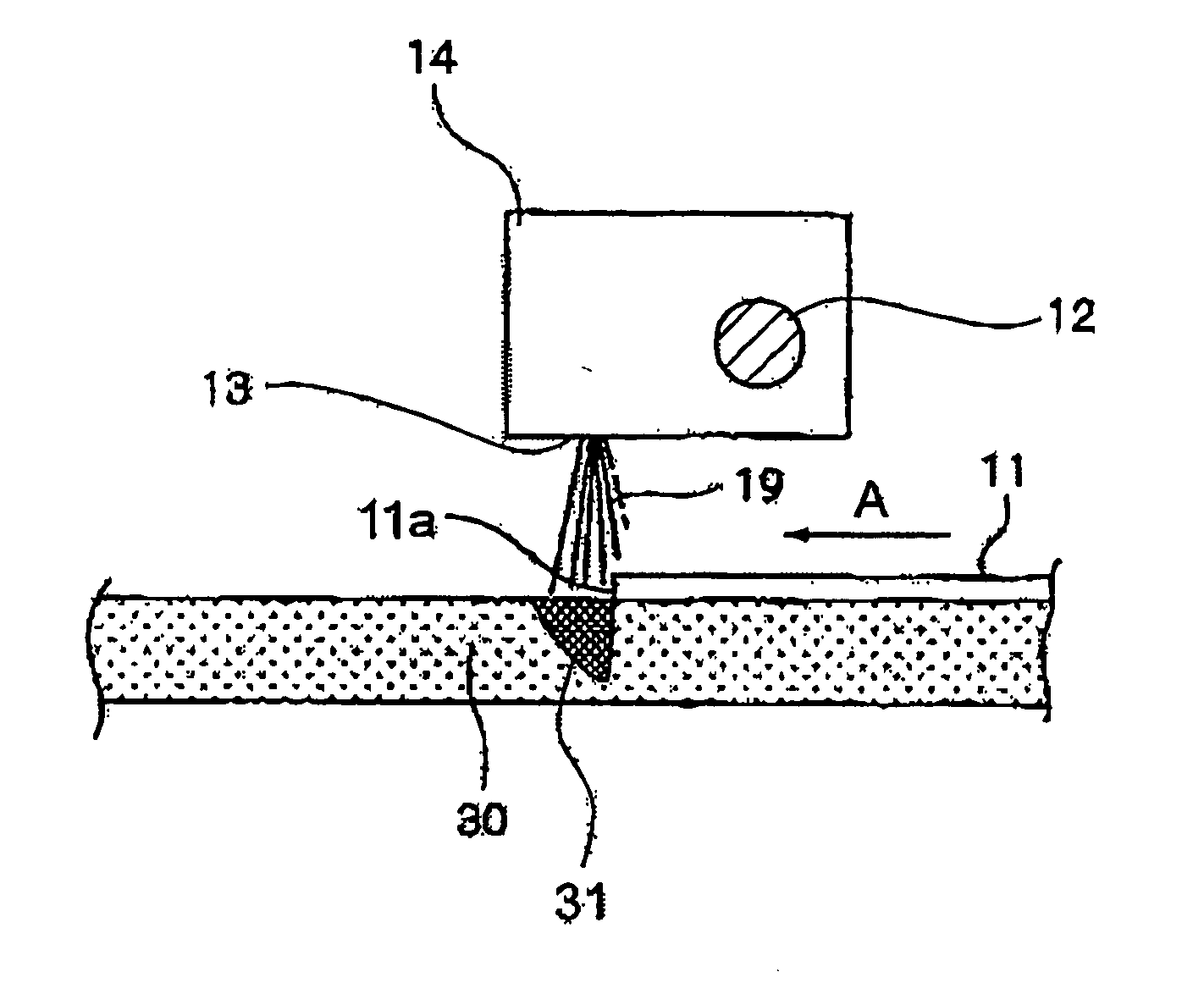

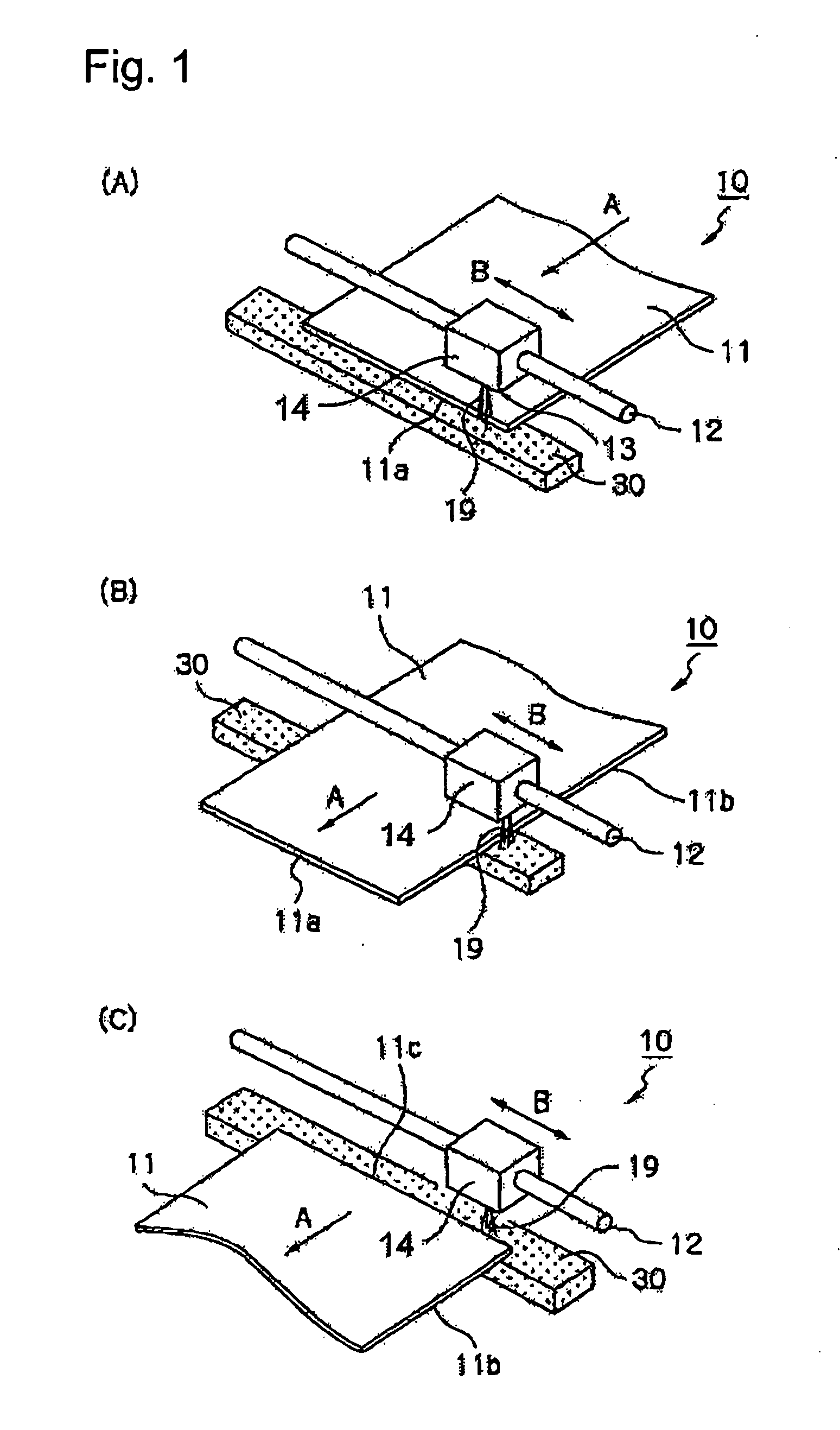

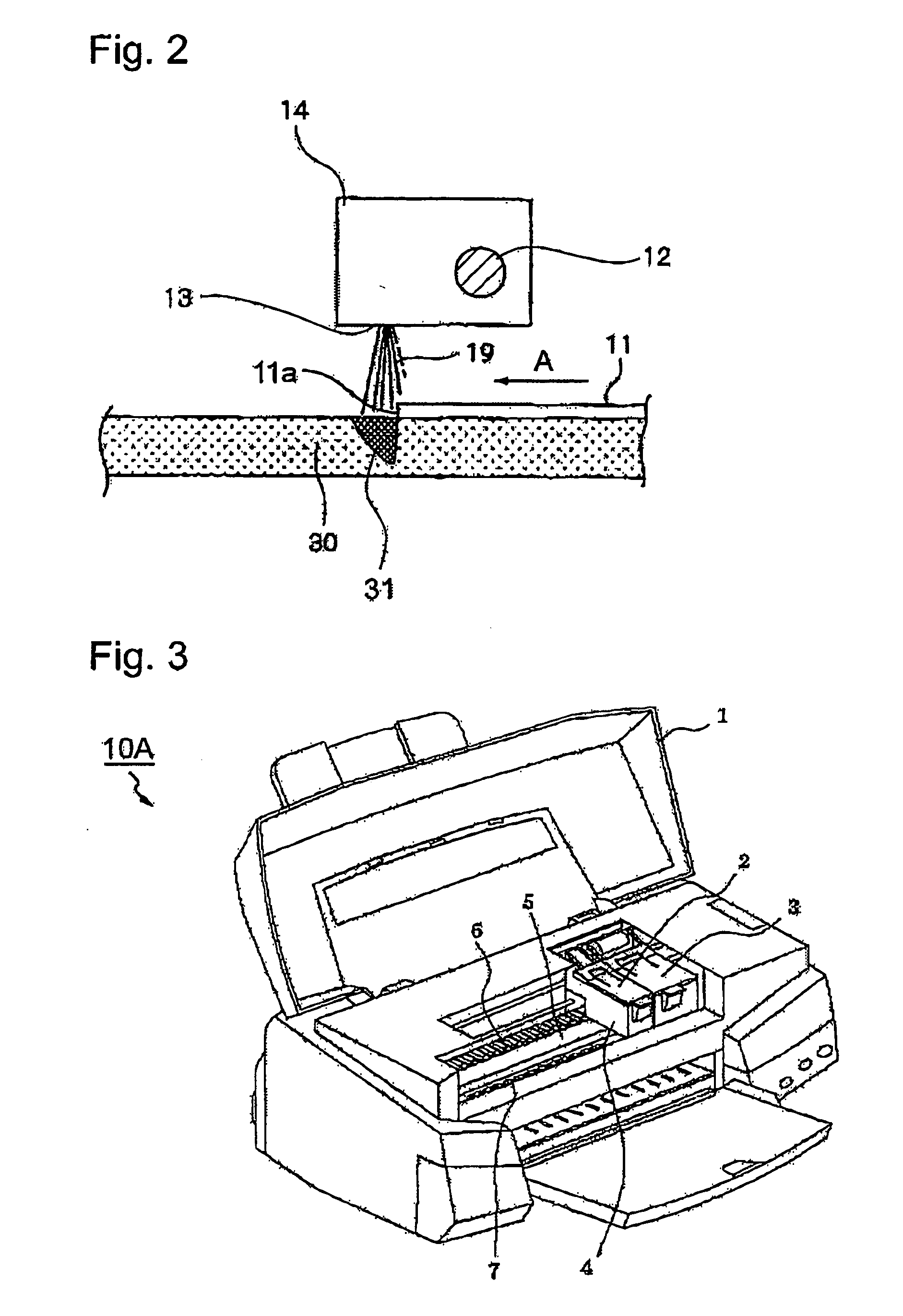

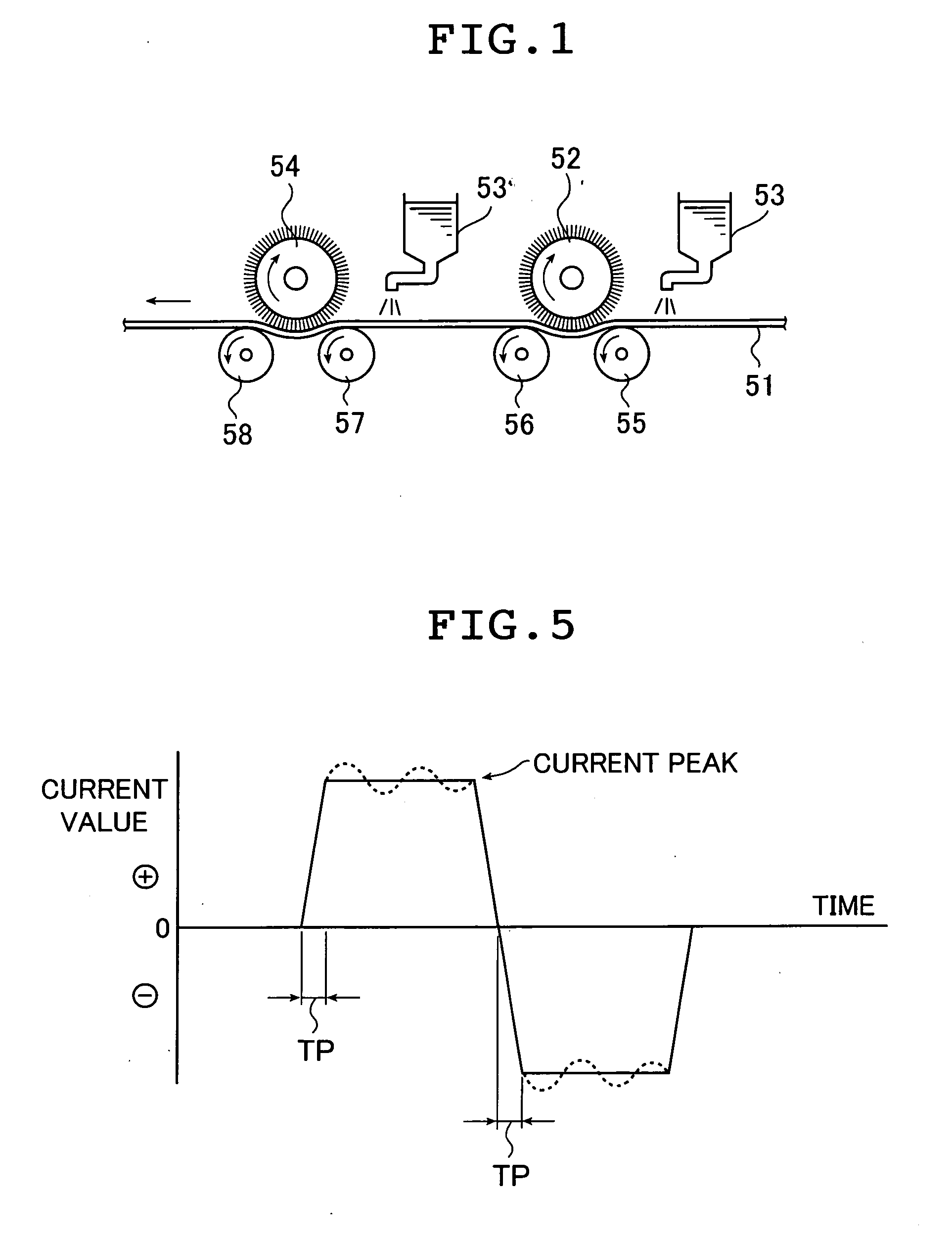

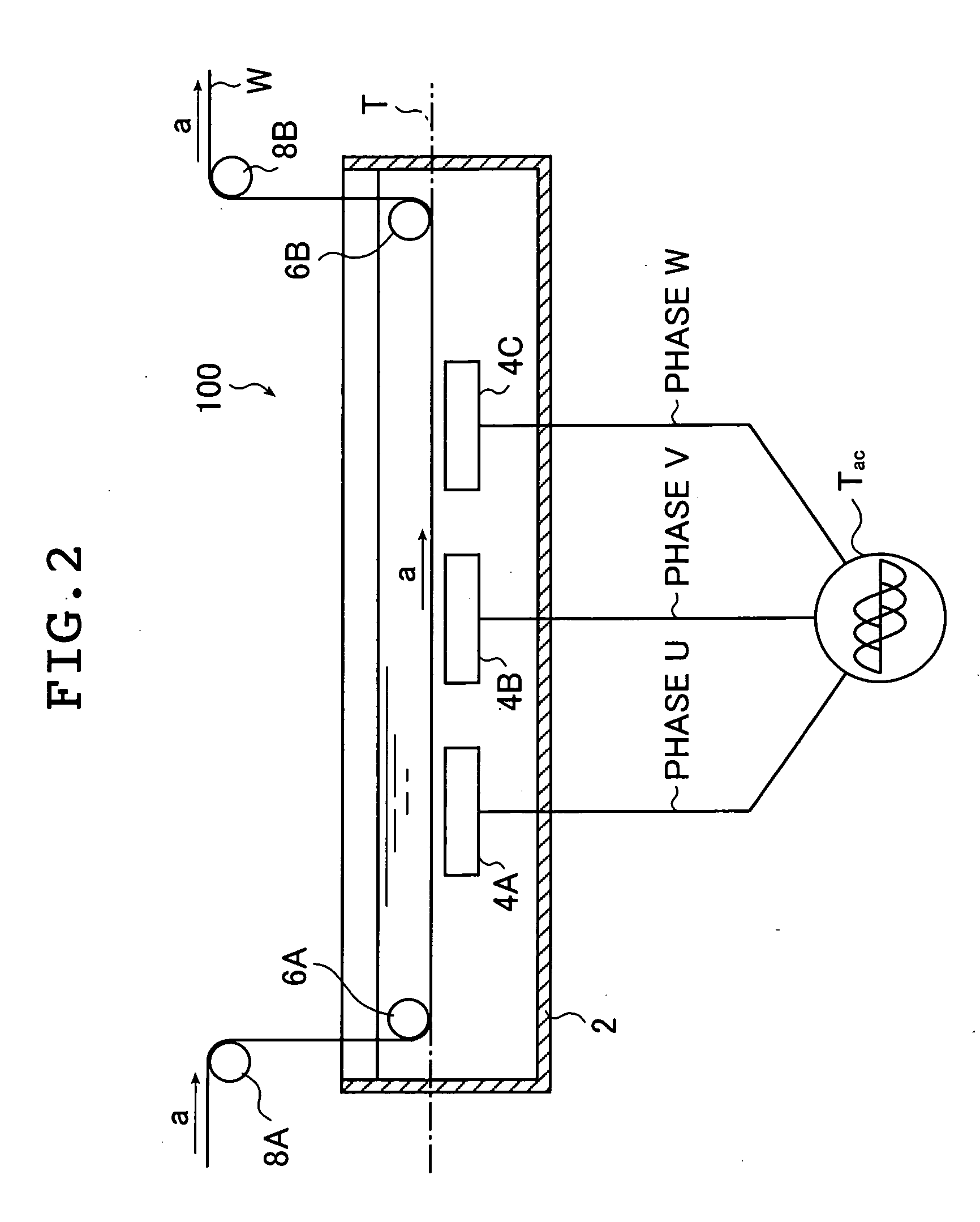

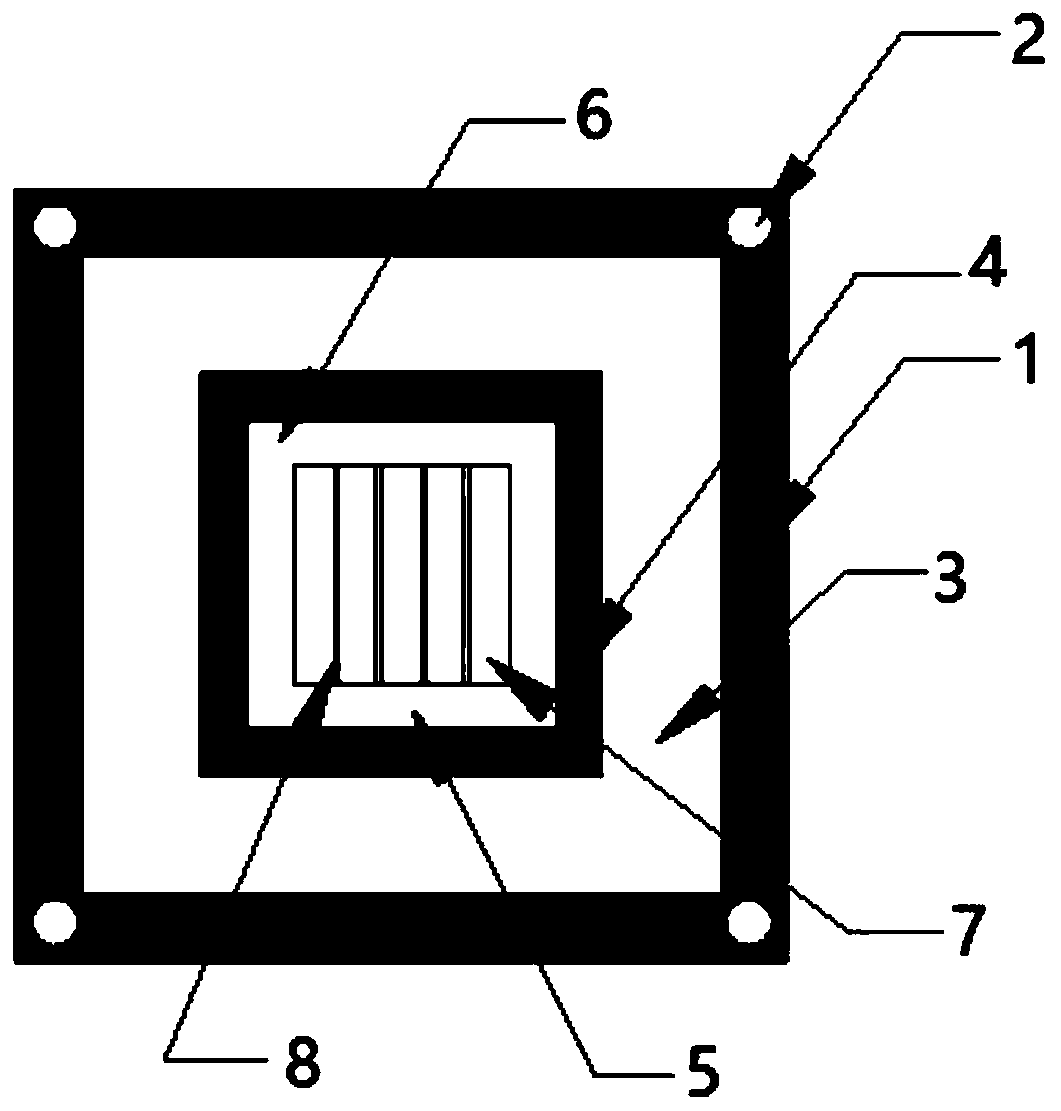

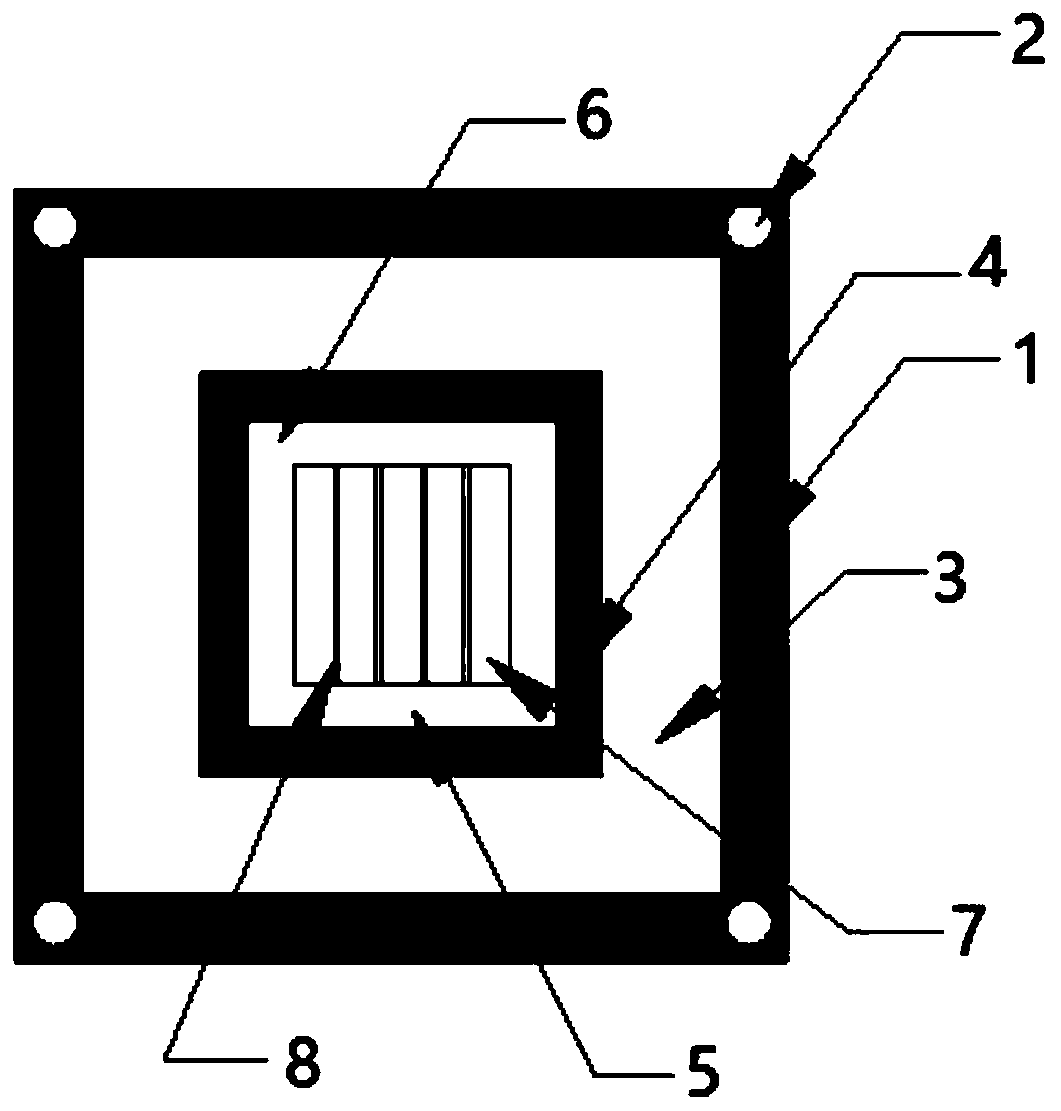

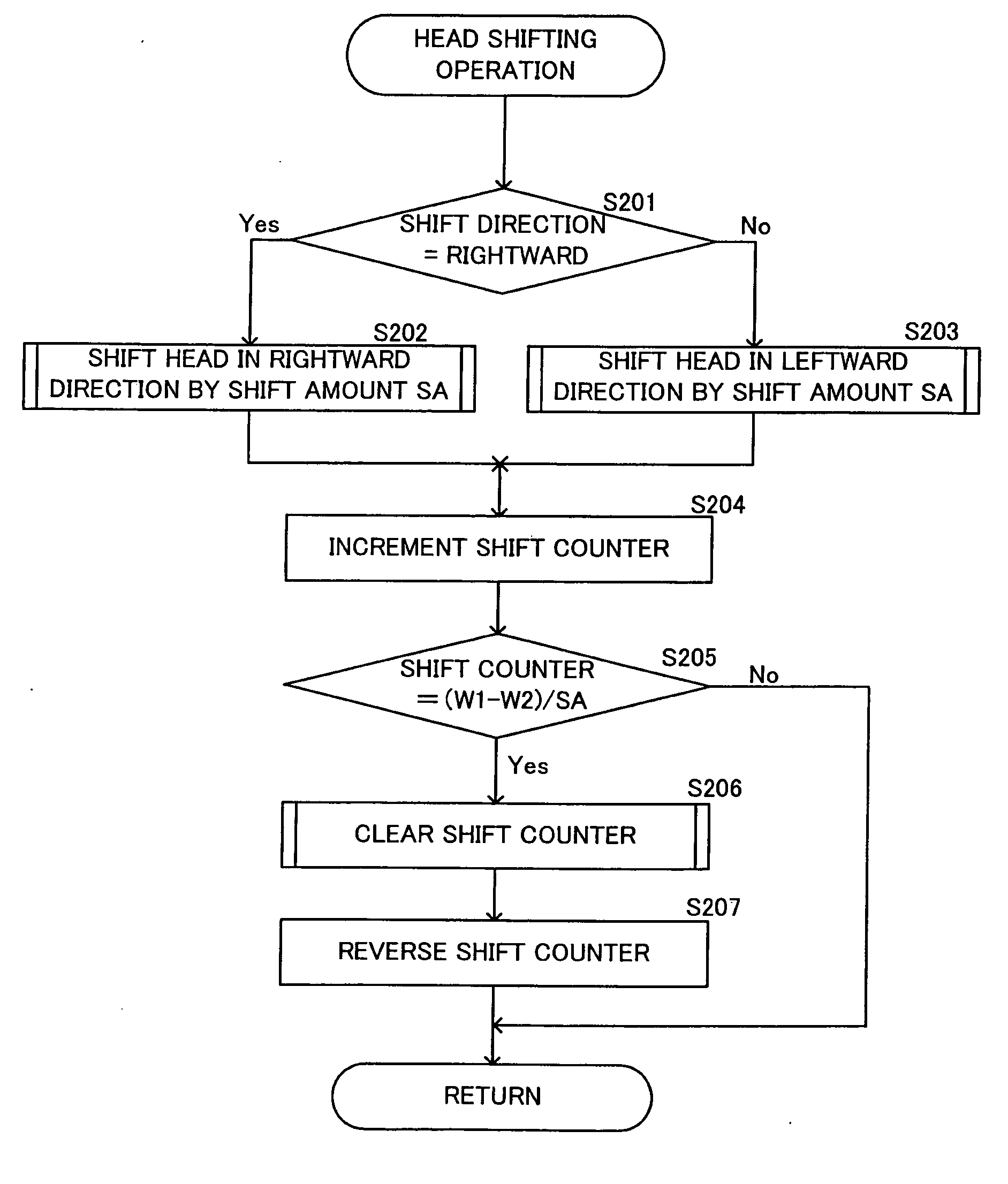

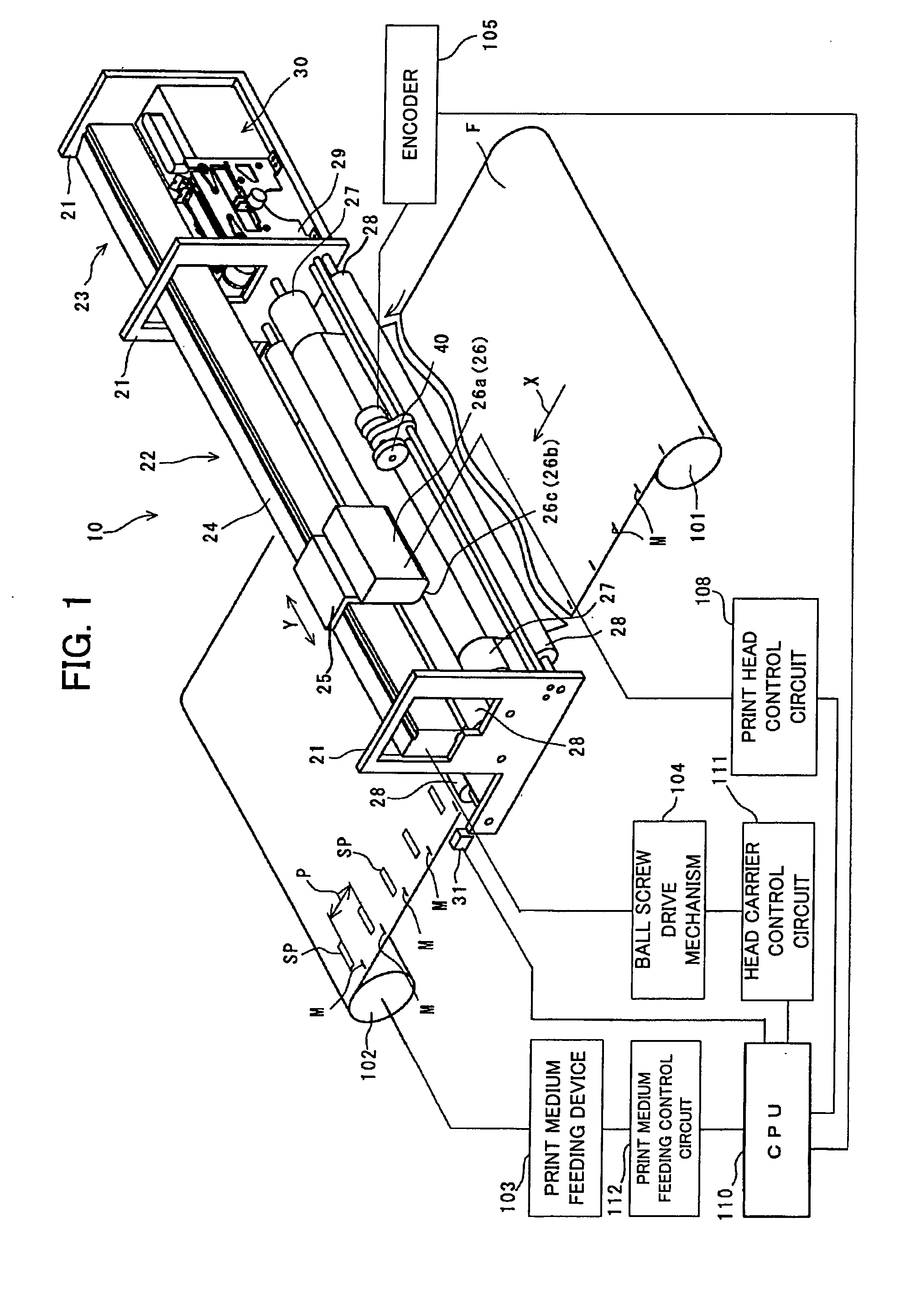

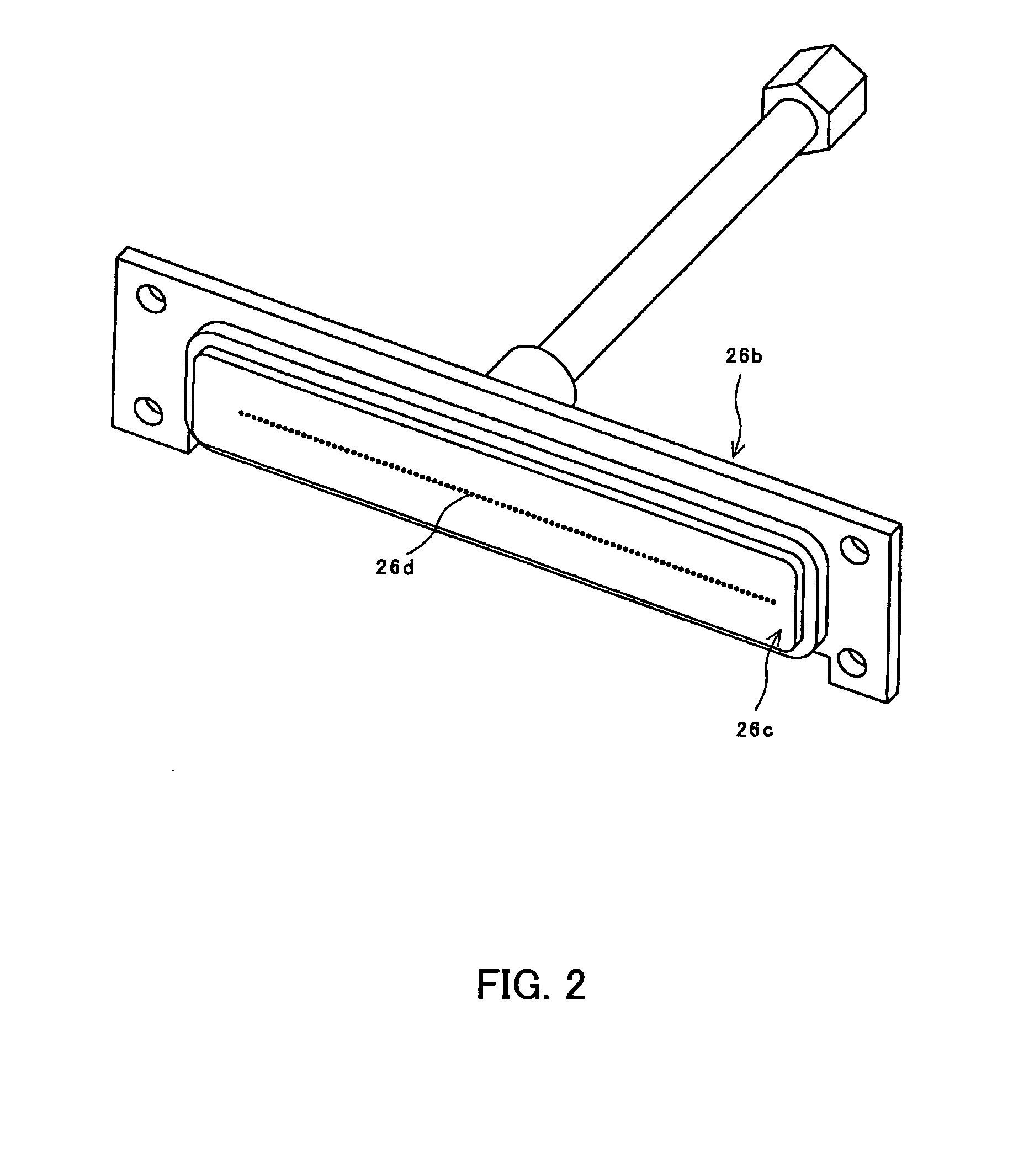

Inkjet Printer and Printing Method

InactiveUS20090002410A1Ejection troubleIncreased printing lifePower drive mechanismsOther printing apparatusEngineeringInkjet printing

Data is printed predetermined number of times on a print area having a width W2 smaller than the maximum print width W1 of a print head (26) by using predetermined ink nozzles (26d) while moving a print medium F relative to the print head (26) in a state that the position of the print head (26) in a direction perpendicular to a feeding direction X of the print medium F is fixed. After that, the print head (26) is moved in the direction perpendicular to the feeding direction X of the print medium F each time printing has been performed the predetermined number of times while the print medium F is moved at a predetermined pitch at a time, and printing is again performed on the print area by using ink nozzles (26d) which are different at least partly from the ink nozzles (26d) which were used before the move, in the state that the print head (26) is fixed.

Owner:SEIKO PRECISION INC

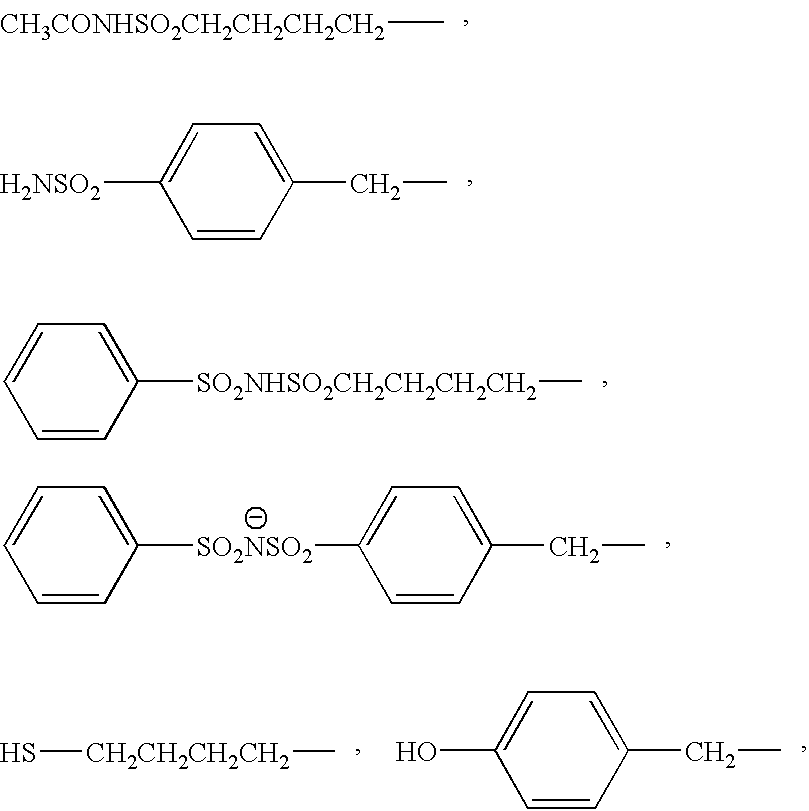

UV-CTP plate imaging coating layer resistant to UV ink

InactiveCN106371290AWon't dissolveStrong resistance to UV inkCoatingsPhotosensitive materials for photomechanical apparatusSolventSulfonyl chloride

The invention relates to a UV-CTP plate imaging coating layer resistant to UV ink. The UV-CTP plate imaging coating layer is characterized by comprising consituents based on percent by mass: 10-60% of solvent resistant resin, 2-12% of solubilizer, 3-25% of dissolution promotion resin, 10-65% of film forming resin, 0-1% of dissolution resistant resin, 6-30% of ester matter of alkylphenol-formaldehyde resin and 2-heavy nitrogen-1-naphthoquinone-4-sulfonyl chloride, 0-30% of ester matter of pyrogallol-acetone resin and 2-heavy nitrogen-1-naphthoquinone-5-sulfonyl chloride, 0-20% of alcohol-resistant dissolution inhibitor and 0.85-2% of dye. With the adoption of the abovementioned technical scheme, the UV-CTP plate imaging coating layer resistant to the UV ink is provided by the invention, is high in UV ink resistance, cannot be dissolved, and has a long printing lifetime.

Owner:温州市行者新材料有限公司

Support for lithographic printing plate and presensitized plate

A support for a lithographic printing plate obtained by performing surface graining and anodizing of an aluminum alloy plate, wherein the foregoing aluminum alloy plate contains specific contents of Fe, Si, Cu, Ti, Zn and Mg, with the balance being Al and incidental impurities. The presensitized plate obtained from this support for a lithographic printing plate is excellent in press life and in resistance to dot ink stain when processed into a lithographic printing plate. Preferably, the support for a lithographic printing plate, with regard to the surface of the support, has a center line average roughness Ra in the range of 0.2-0.6 mum, a maximum height Rmax in the range of 3.0-6.0 mum, a ten-point mean roughness Rz in the range of 2.0-5.5 mum, a center line peak height Rp in the range of 1.0-3.0 mum, a center line valley depth Rv in the range of 2.0-3.5 mum, a mean spacing Sm in the range of 40-70 mum, an average inclination DELTAa in the range of 6.0-12.0°, and a peak count Pc in the range of 100-200.

Owner:FUJIFILM CORP

Hyperfine double three-dimensional high molecular material integrated screen printing plate

InactiveCN110271264AHigh printing durabilityImprove wear resistanceFinal product manufactureScreen printersScreen printingPolyester

The invention discloses a hyperfine double three-dimensional high molecular material integrated screen printing plate which comprises a screen frame, a polyester screen, a steel wire gauze, high molecular film layers, high molecular pattern regions, photosensitive glue pattern regions and photosensitive glue lines. The high molecular pattern regions are separately arranged on the high molecular film layers and stretch to the bottom of the steel wire gauze, the photosensitive glue pattern regions fill the high molecular pattern regions, the photosensitive glue lines are arranged in the middle parts of the photosensitive glue pattern regions, and the high molecular pattern regions and the photosensitive glue lines are of hollowed structures. In this way, the high molecular materials in middle non-printed regions of the lines are super high in abrasive resistance and high in printing resistance, the service life of screen printing can be prolonged greatly, the deformation quantities of the silk screen and the patterns are reduced greatly, the printing quality can be improved greatly, high strength of high molecules is combined and high resolution of the photosensitive glue is also available, and meanwhile, new patterns can be re-manufactured after the screen printing plate is recovered and back-washed, so that the cost is saved greatly.

Owner:SUZHOU WOSUTE ELECTRONICS MATERIALS CO LTD

Support for lithographic printing plate and presensitized plate

InactiveCN1601382AIncreased printing lifeGood scum resistancePlate printingFoil printingPhosphateImage formation

A support for a lithographic printing plate is composed of a metal base that has been grained and anodized then subjected to treatment with an aqueous solution containing an inorganic fluorine compound and a phosphate compound, followed or preceded by treatment with a silicate compound-containing aqueous solution, and an intermediate layer which lies on the treated metal base and contains an acid group-bearing polymeric compound. Presensitized plates composed in part of the support, when used as on-machine development type plates, have a good on-machine developability, high sensitivity, long press life and good resistance to scumming. When used as positive or negative-working thermal plates, such presensitized plates efficiently utilize heat in image formation, have a high sensitivity and a long press life, and minimize scumming in non-image areas.

Owner:FUJIFILM CORP

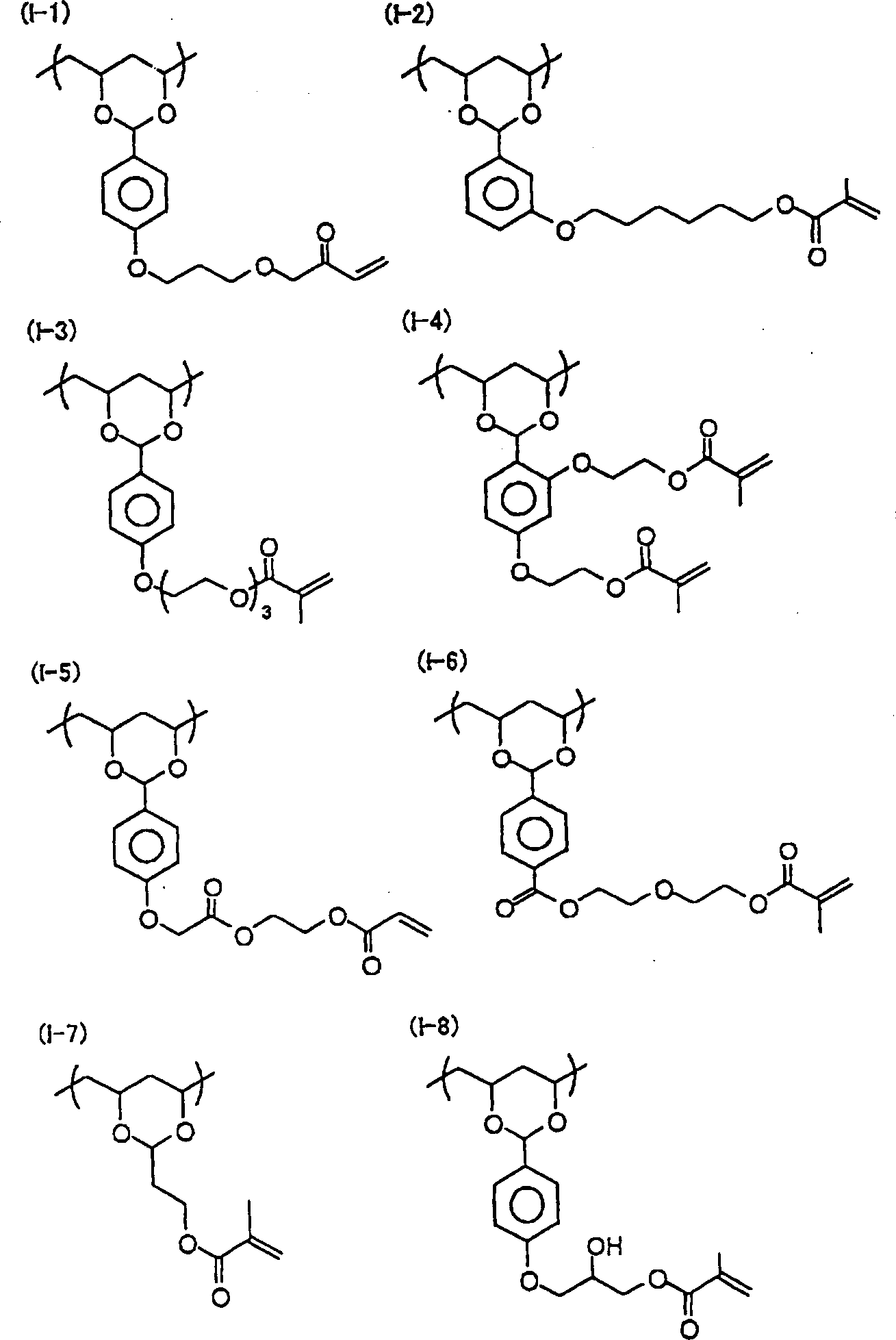

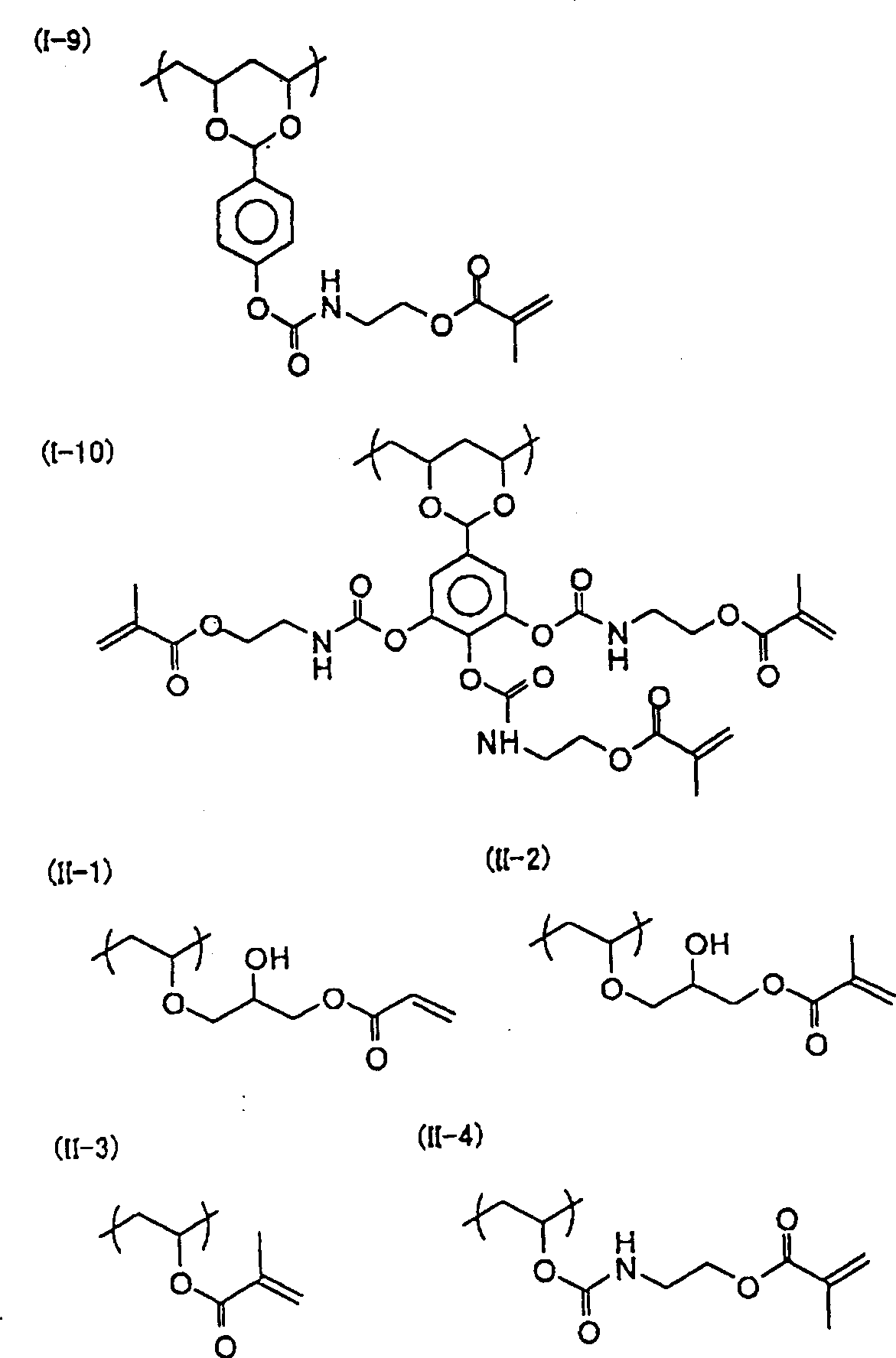

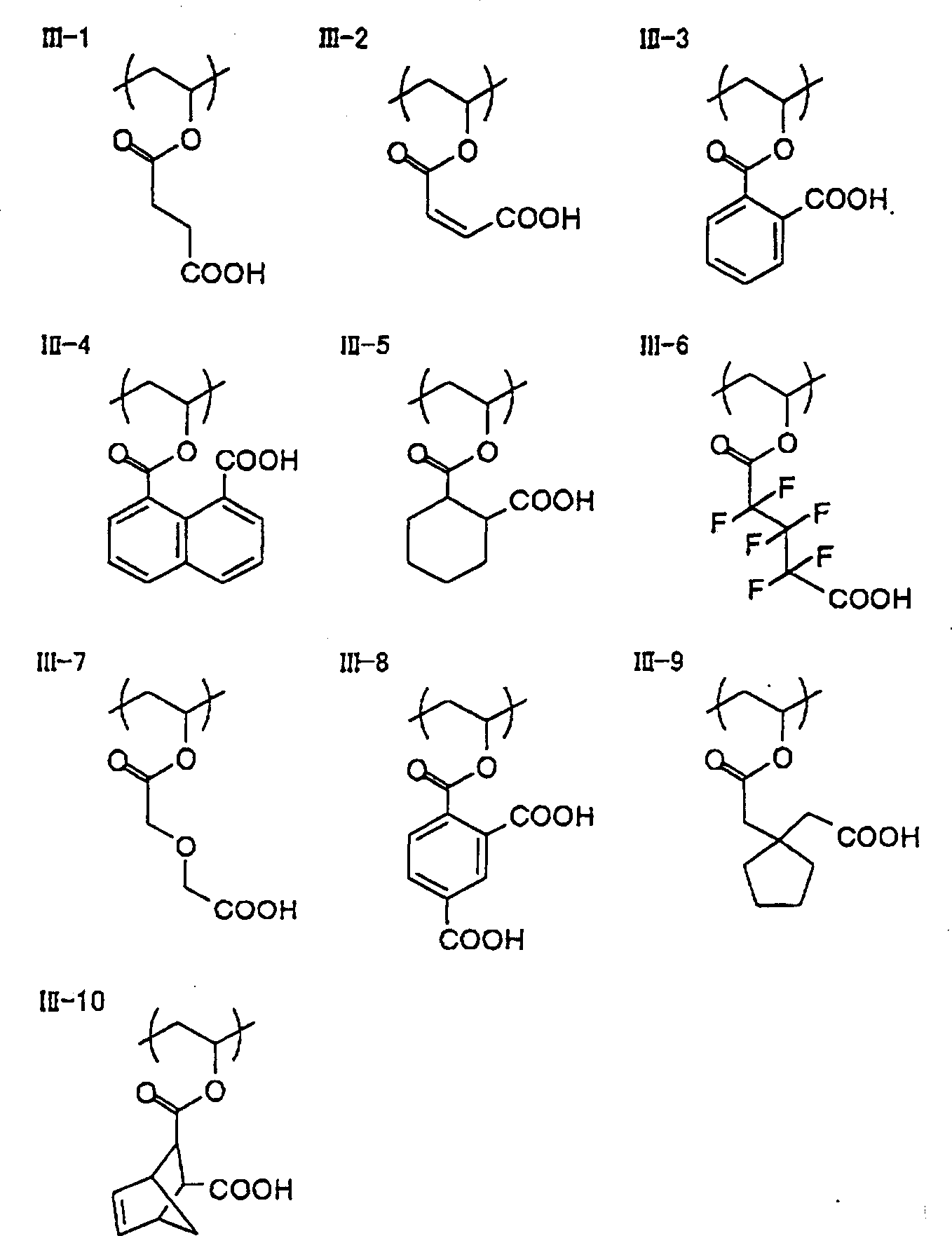

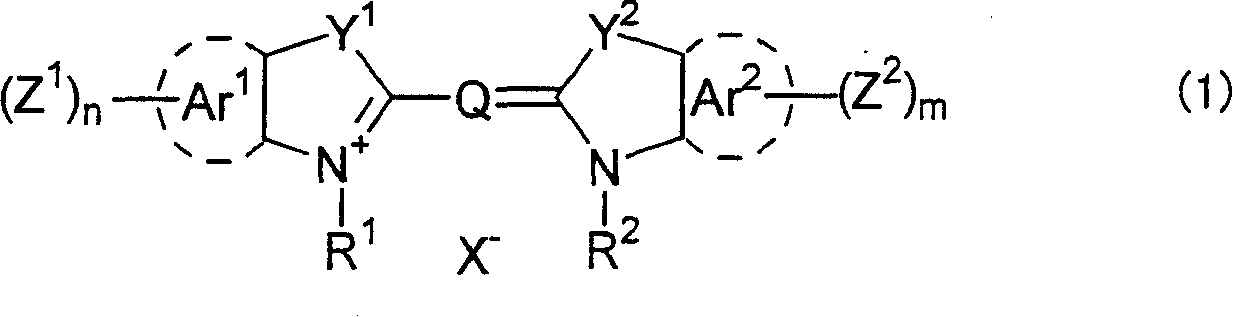

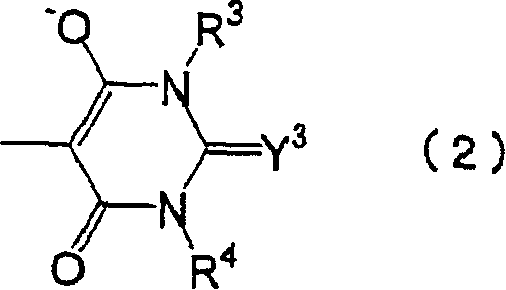

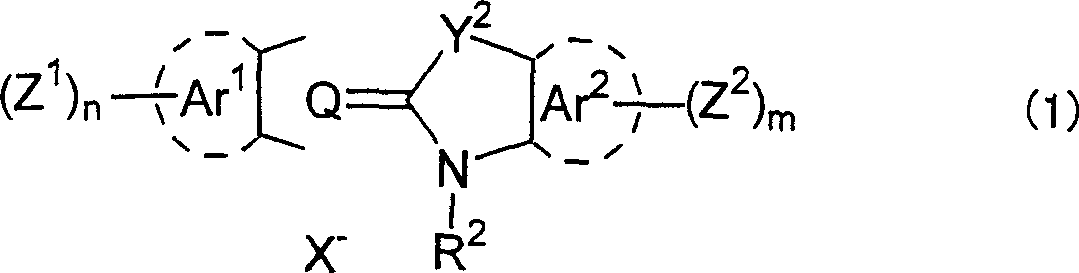

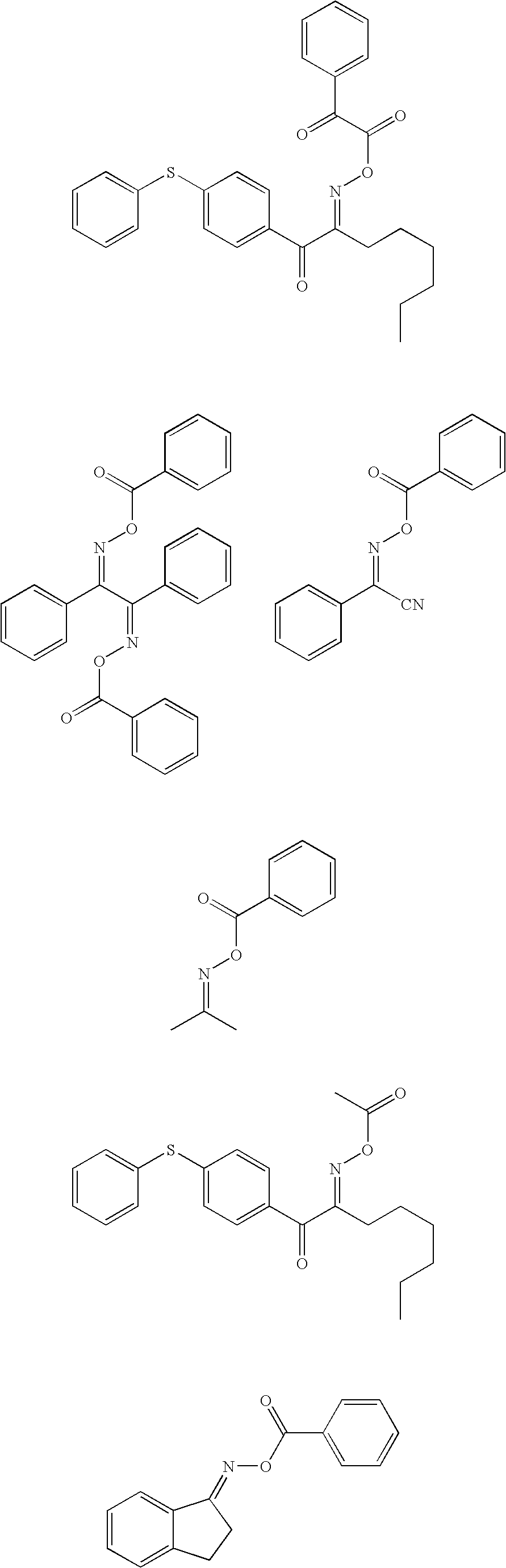

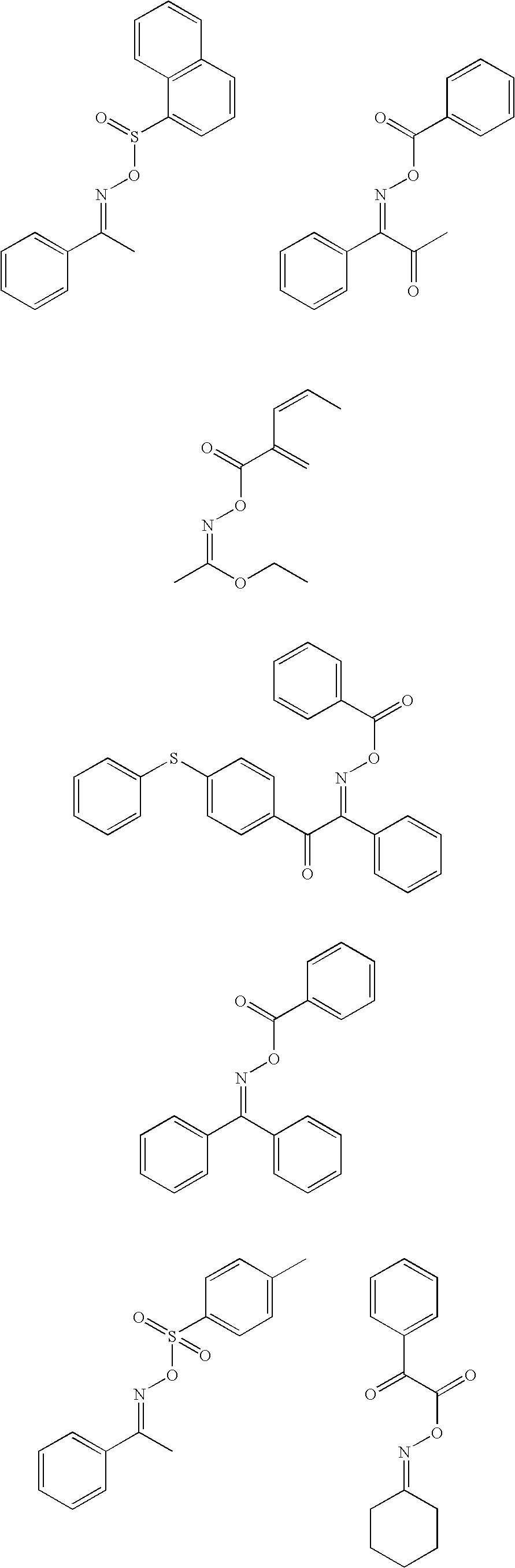

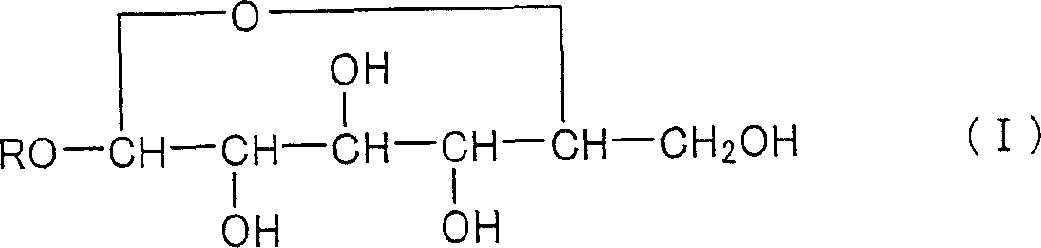

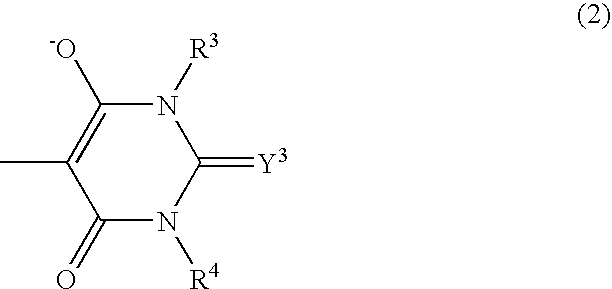

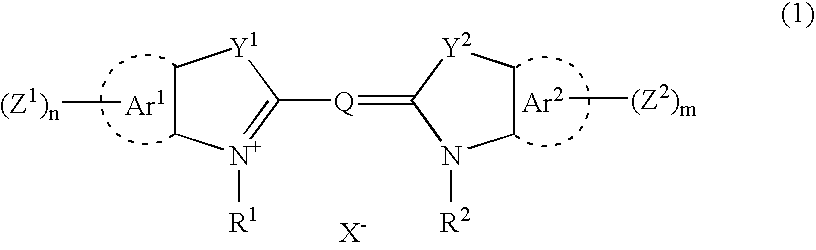

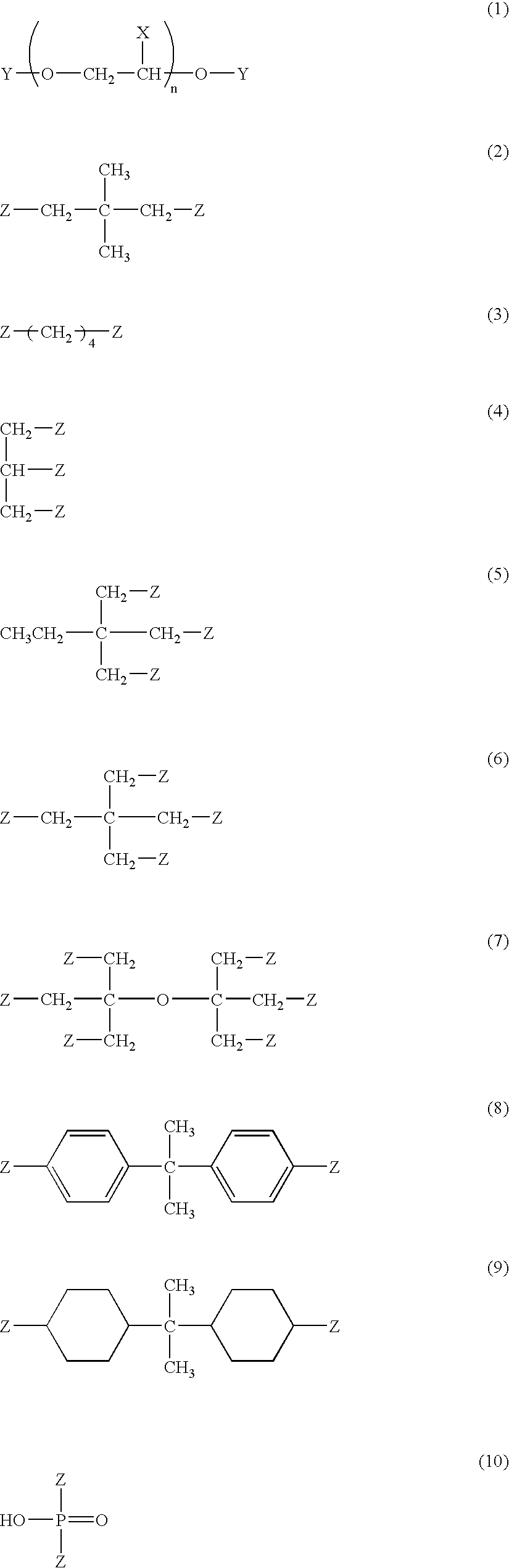

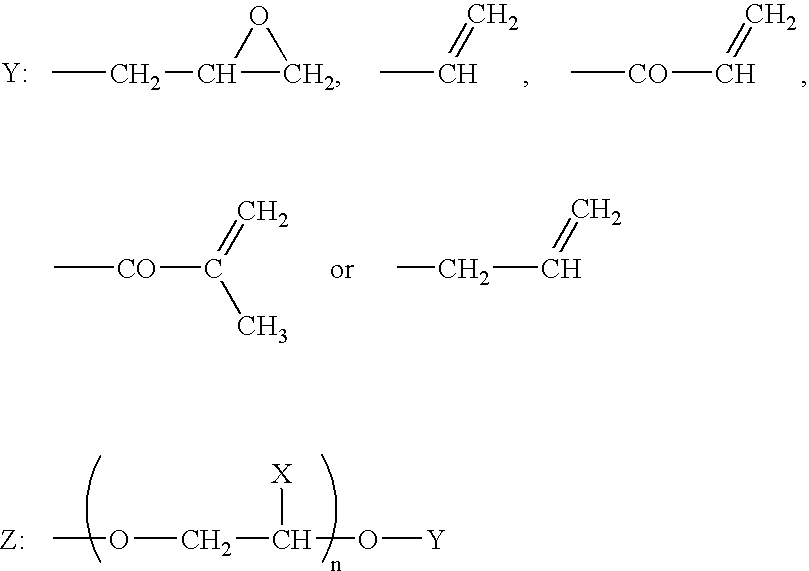

Photopolymerizable composition

ActiveUS7108952B2High sensitivityEnhanced interactionPhotosensitive materialsSemiconductor/solid-state device manufacturingPolymerInorganic chemistry

A photopolymerizable composition comprising a polymer having a radical polymerizable group and a unit represented by the following formula (I):wherein Q1 represents a cyano group or COX2; X1 and X2 each independently represent —R— or a halogen atom, R represents a hetero atom; Ra and Rb each independently represent a hydrogen atom, a halogen atom, a cyano group or an organic residual group; X1 and X2 may be taken together to form a cyclic structure; Ra and Rb may be taken together to form a cyclic structure; and X1 and Ra or Rb may be taken together to form a cyclic structure.

Owner:FUJIFILM CORP +1

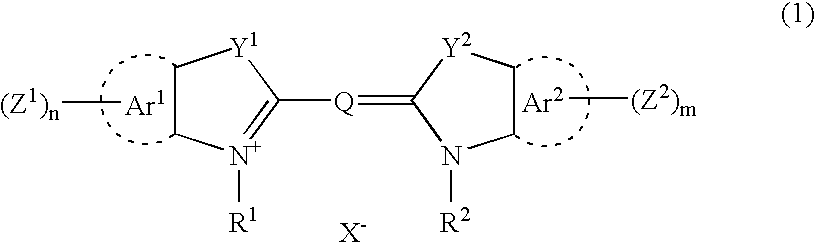

Lithographic printing method and presensitized plate

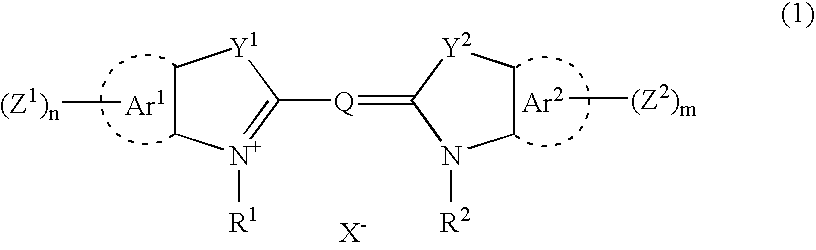

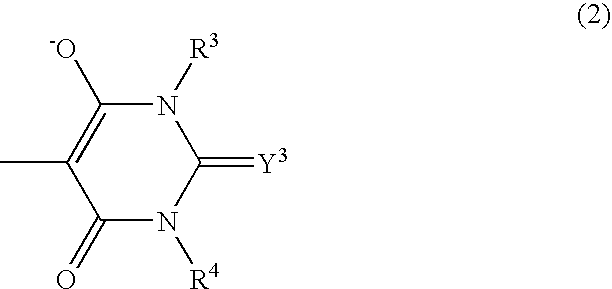

ActiveUS7282321B2Increase impressionIncreased printing lifeRadiation applicationsSemiconductor/solid-state device manufacturingDigital dataChemical compound

Disclosed is a presensitized plate composed of a support having thereon an image recording layer which includes:an infrared absorber (A) that is a cyanine dye having at least one fused ring composed of a nitrogen-containing heterocycle in combination with an aromatic ring or a second heterocycle, and having on the aromatic ring or second heterocycle an electron-withdrawing group or a heavy atom-containing group,a radical generator (B), anda radical-polymerizable compound (C),and which is removable with printing ink and / or dampening water.The presensitized of the present invention can be imaged with an infrared light-emitting laser to directly record an image from digital data on a computer or the like and is then subjected to on-machine development without carrying out a development step, which is capable of providing a large number of good impressions with a practical amount of energy.

Owner:FUJIFILM CORP

Method for making a negative working, heat-sensitive lithographic printing plate precursor

ActiveUS7195861B2High sensitivityIncrease run lengthPhotosensitive materialsSemiconductor/solid-state device manufacturingImage recordingHeat sensitive

A method for making a heat-sensitive negative-working lithographic printing plate precursor is disclosed comprising the steps of(i) preparing a coating solution comprising hydrophobic thermoplastic polymer particles and a hydrophilic binder;(ii) applying said coating solution on a support having a hydrophilic surface or which is provided with a hydrophilic layer, thereby obtaining an image-recording layer;(iii) drying said image-recording layer;characterized in that said hydrophobic thermoplastic polymer particles have an average particle size in the range from 45 nm to 63 nm,and that the amount of said hydrophobic thermoplastic polymer particles in the image-recording layer is at least 70% by weight relative to the dried image-recording layer.

Owner:AGFA OFFSET BV

Method for making a lithographic printing plate

ActiveUS7425405B2Increased printing lifeHigh sensitivityPhoto-taking processesPhotosensitive materialsCeriumImage recording

Owner:AGFA OFFSET BV

Heat-sensitive lithographic printing plate

InactiveUS7101649B2Excellent developabilityIncrease resistancePhotosensitive materialsRadiation applicationsInfraredDigital data

A heat-sensitive lithographic printing plate of the present invention, which enables image recording by infrared-ray scanning exposure based on digital data and has excellent on-press developability, high resistance to scumming and a long press life, the heat-sensitive lithographic printing plate having on a support with a hydrophilic surface an image-forming layer made up of microcapsules in which a reactive group-containing hydrophobic compound is enclosed, a light-to-heat converting agent and a water-soluble compound which has a reactive group capable of reacting with the hydrophobic compound and is situated outside the microcapsules.

Owner:FUJIFILM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com