Lithographic printing method and presensitized plate

A pre-sensitized plate and compound technology, used in printing, plate preparation, photoplate making process of pattern surface, etc., can solve the problems of printing life and polymerization efficiency that are not suitable for practical application and have not been commercialized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0424] An image-recording layer-forming coating liquid A having the composition described below was prepared below. Coat the newly prepared coating solution on the previously obtained support with a wire-wound bar, and then dry it at 115° C. for 45 seconds with a hot air dryer to form an image recording layer and complete the negative presensitization Production of version P-1. Coating amount after drying is 1.0g / m 2 . Composition of coating solution A for forming image-recording layer:

[0425] Infrared absorber (IR-2 in the first aspect) 0.05g

[0426] Free radical generator (formerly OS-7) 0.2g

[0427] Monomer compound of formula 1.3g

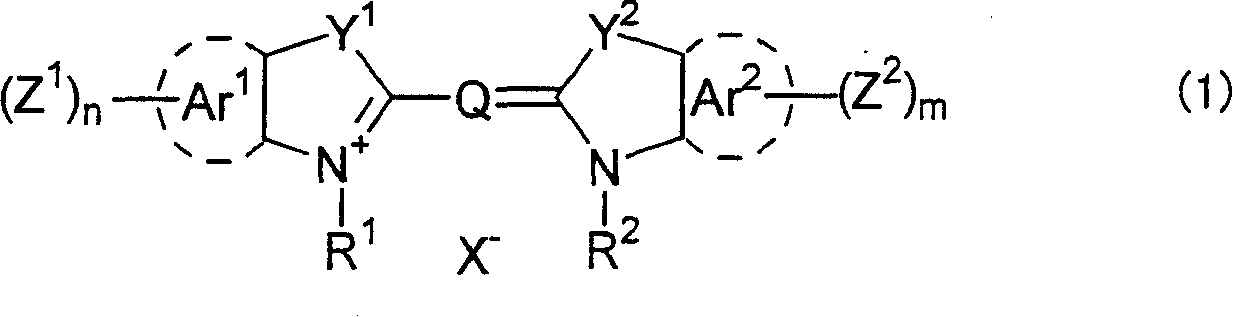

[0428]

[0429] Poly(allyl methacrylate) (weight average molecular weight is 120000) 0.5g

[0430] Victoria Pure Blue, Naphthalene Sulfonate 0.02g

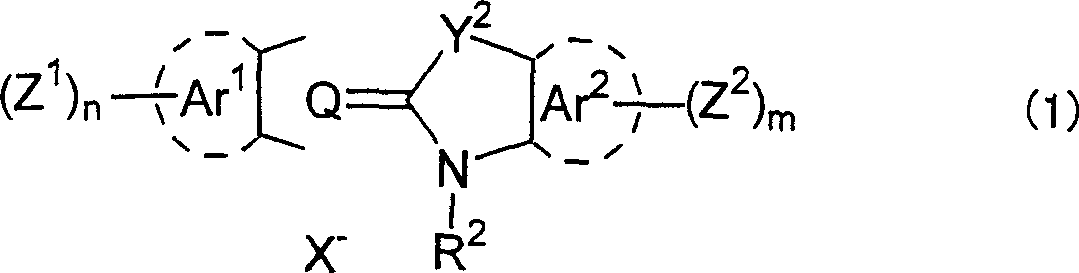

[0431] Fluorosurfactant of the following formula 0.1g

[0432]

[0433] Methyl ethyl ketone 18.0g

Embodiment 1-2 to 1-7

[0435] Except changing the kind of infrared absorber and free radical generating agent used in each embodiment as shown in Table 1, obtain the negative presensitization plate P-2 to P-7 with the method identical with embodiment 1-1.

Embodiment 1-8

[0437] Except that the copolymer of allyl methacrylate and sodium methacrylate (80:20 in molar ratio) was used instead of poly(allyl methacrylate), the same method as in Example 1-1 was used to obtain a negative-tone prepreg. Sensitized version P-8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com