Negative light-sensitive lithographic printing plate

A lithographic printing plate, negative photosensitive technology, applied in lithographic printing equipment, printing, printing process and other directions, can solve the problems of damaged developing ability, difficult to long printing life and high developing ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 21~30 and comparative example 5~7

[0236] In the same manner as in Examples 1 to 20, the properties of the negative-working photosensitive lithographic printing plates listed in Table 3 were evaluated.

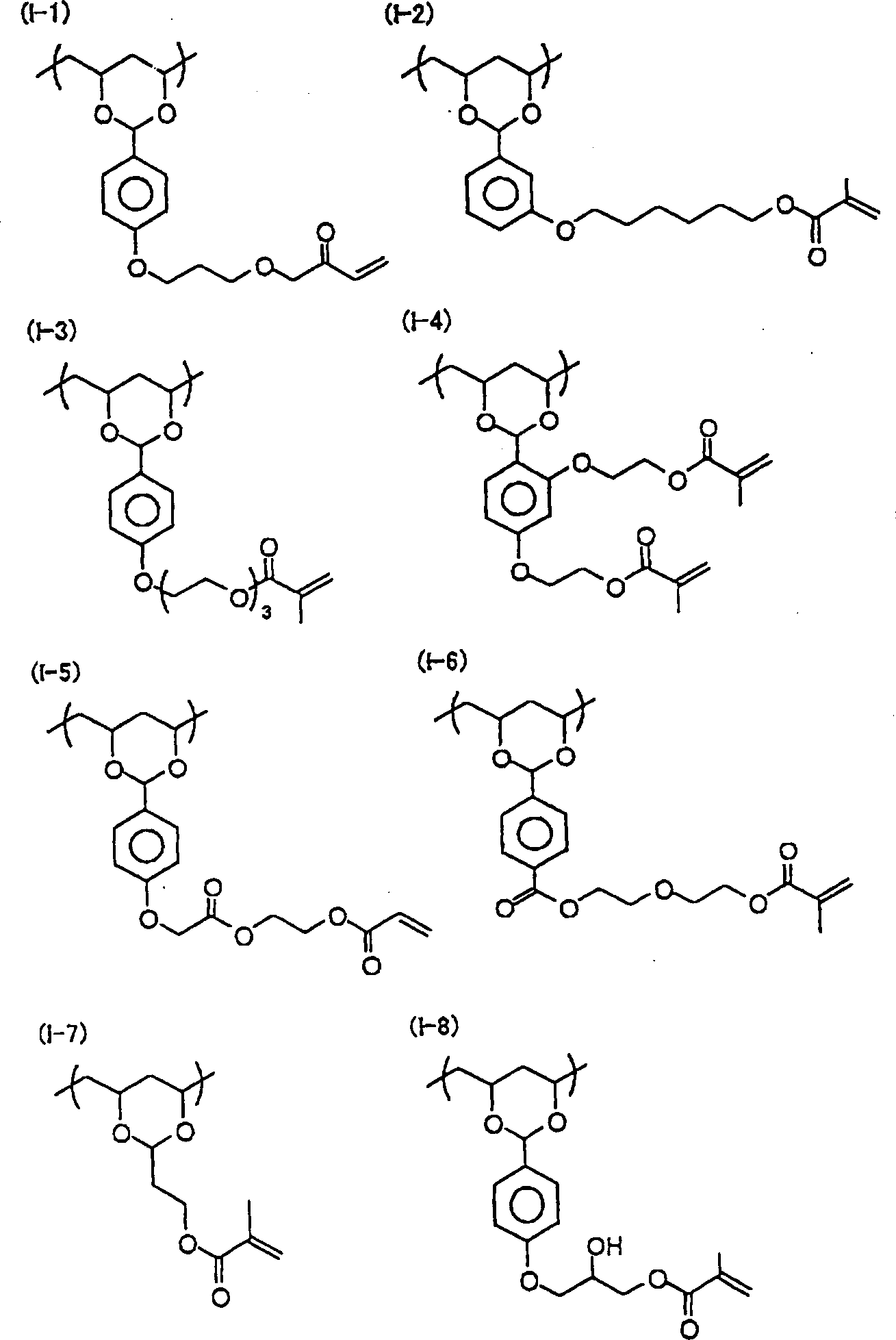

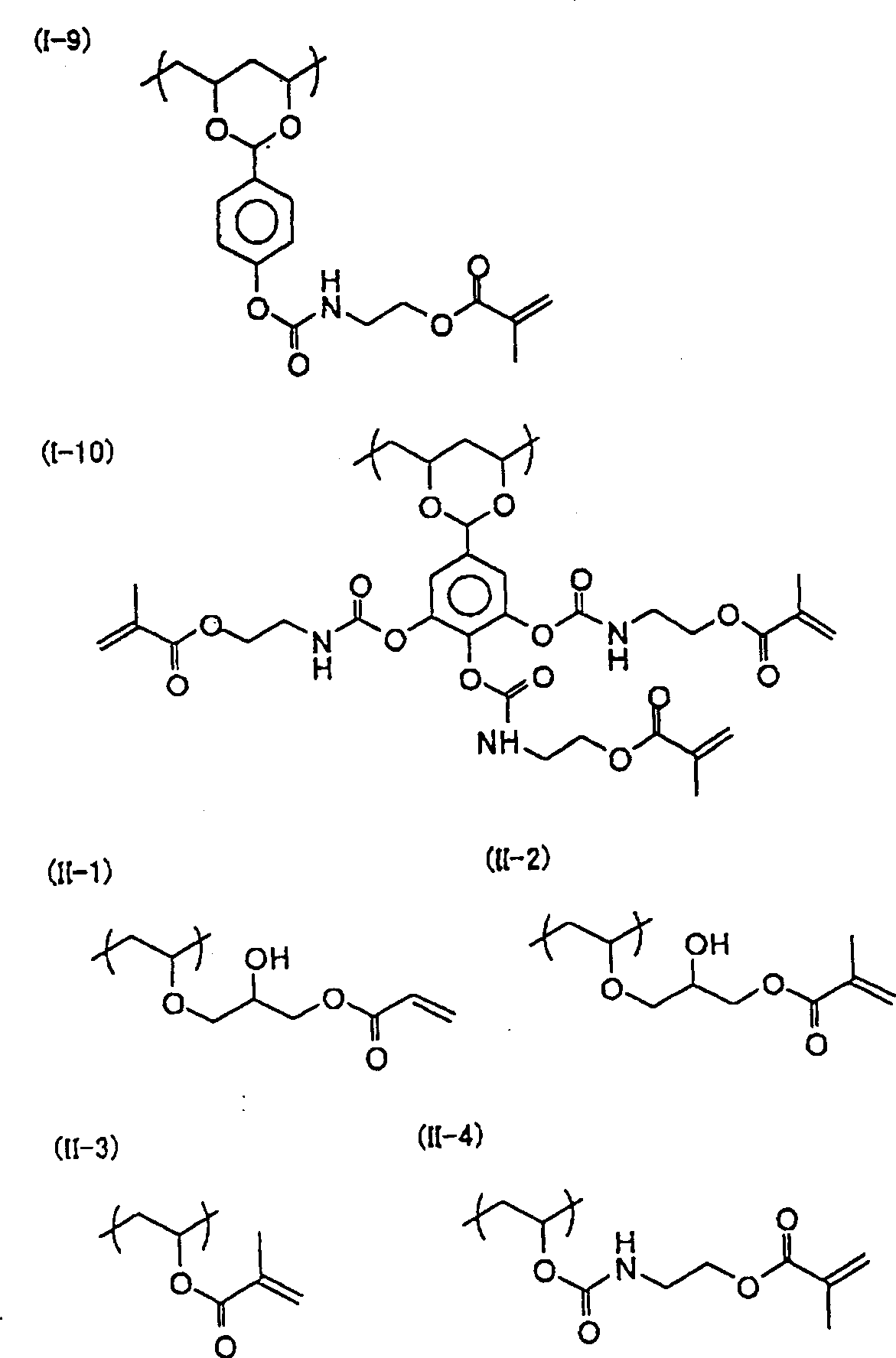

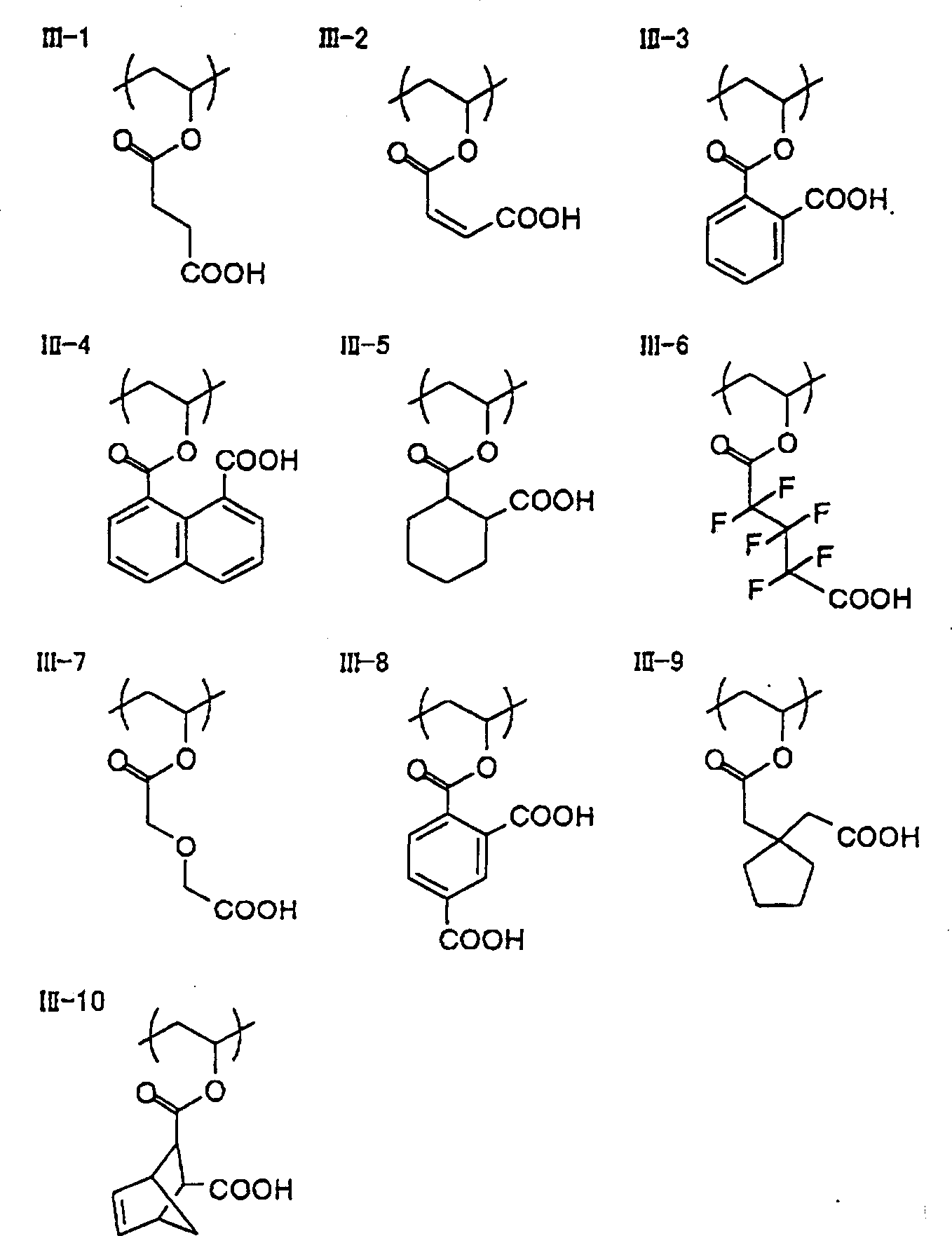

[0237] The following are the compounds listed in Tables 2 and 3. [Addition-polymerizable compound] M-1: Pentaerythritol tetraacrylate (NK Ester A-TMMT, manufactured by Shin-Nakamura Chemical Co., Ltd.) M-2: Glyceryl dimethacrylate / hexamethylene diisocyanate Polyurethane prepolymer (UA101H, manufactured by Kyoeisha Chemical Co., Ltd.) M-3: Dipentaerythritol acrylate (NK Ester A-9530, manufactured by Shin-Nakamura Chemical Co., Ltd.) [Light in Tables 2 and 3 Poly-initiator material] [Binder polymers in Tables 2 and 3] PA-1:

[0238] Allyl methacrylate / methacrylic acid copolymer (molar ratio of copolymerization is 80:20)

[0239] The acid value measured by NaOH titration is 1.70 meq / g

[0240] The weight average molecular weight measured by GPC method is 48000PA-2:

[0241] Methyl methacrylate / acrylonitrile / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com