Negative light-sensitive lithographic printing plate

A lithographic printing plate, negative photosensitive technology, applied in lithographic printing equipment, printing, printing process and other directions, can solve the problems of difficult to long printing life and high developing ability, developing ability damage and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~20 and comparative example 1~4

[0243] Negative working photosensitive lithographic printing plates were prepared and their printing properties were evaluated according to the method described below. The results are shown in Table 2.

[0244] [Preparation of carrier]

[0245] A JIS A 1050 aluminum plate having a thickness of 0.24 mm and a width of 1030 mm was continuously subjected to the following treatments.

[0246] (a) Using the existing mechanical surface roughening device, while supplying abrasive material suspension (pumice) (abrasive slurry with a specific gravity in water of 1.12) to the surface of the aluminum plate, mechanically roughen the surface of the aluminum plate with a rotating nylon brush roller . The average particle size of the abrasive material is 40-45 μm, and the maximum particle size is 200 μm. The nylon brush is made of nylon-6,10, the bristles are 50mm long and the bristle diameter is 0.3mm. Three rotating brush rolls were used, each of which consisted of a perforated cylinder...

Embodiment 21~30 and comparative example 5~7

[0312] In the same manner as in Examples 1 to 20, the properties of the negative-working photosensitive planographic printing plates listed in Table 3 were evaluated.

[0313] The following are the compounds listed in Tables 2 and 3.

[0314] [addition polymerizable compound]

[0315] M-1: pentaerythritol tetraacrylate (NK Ester A-TMMT, manufactured by Shin-Nakamura Chemical Co., Ltd.)

[0316] M-2: Polyurethane prepolymer of glyceryl dimethacrylate / hexamethylene diisocyanate (UA101H, manufactured by Kyoeisha Chemical Co., Ltd.)

[0317] M-3: dipentaerythritol acrylate (NK Ester A-9530, manufactured by Shin-Nakamura Chemical Co., Ltd.)

[0318] [Photopolymerization initiator materials in Tables 2 and 3]

[0319]

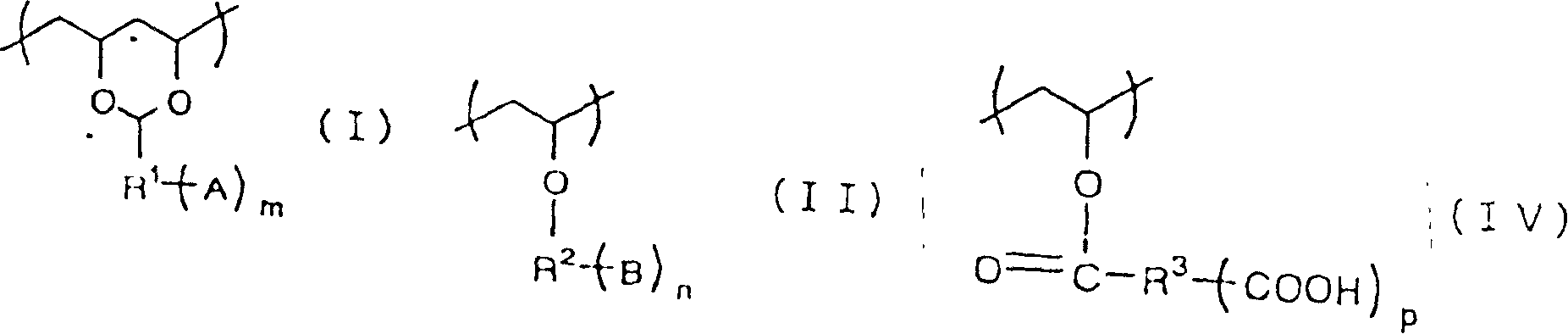

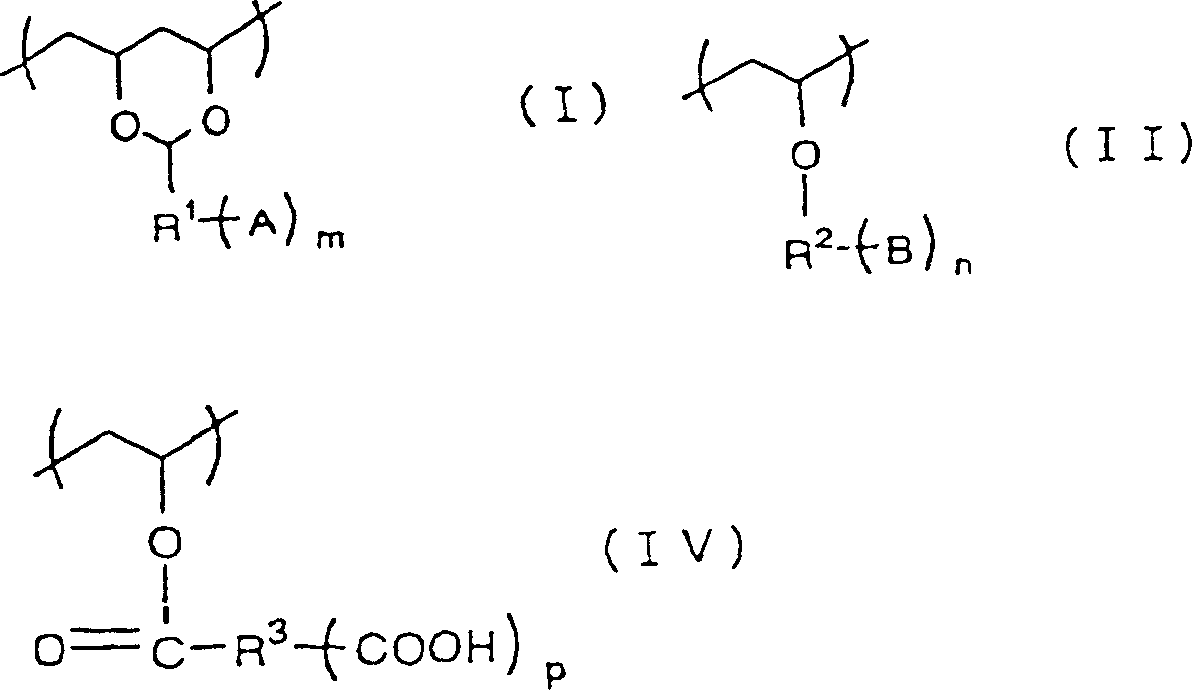

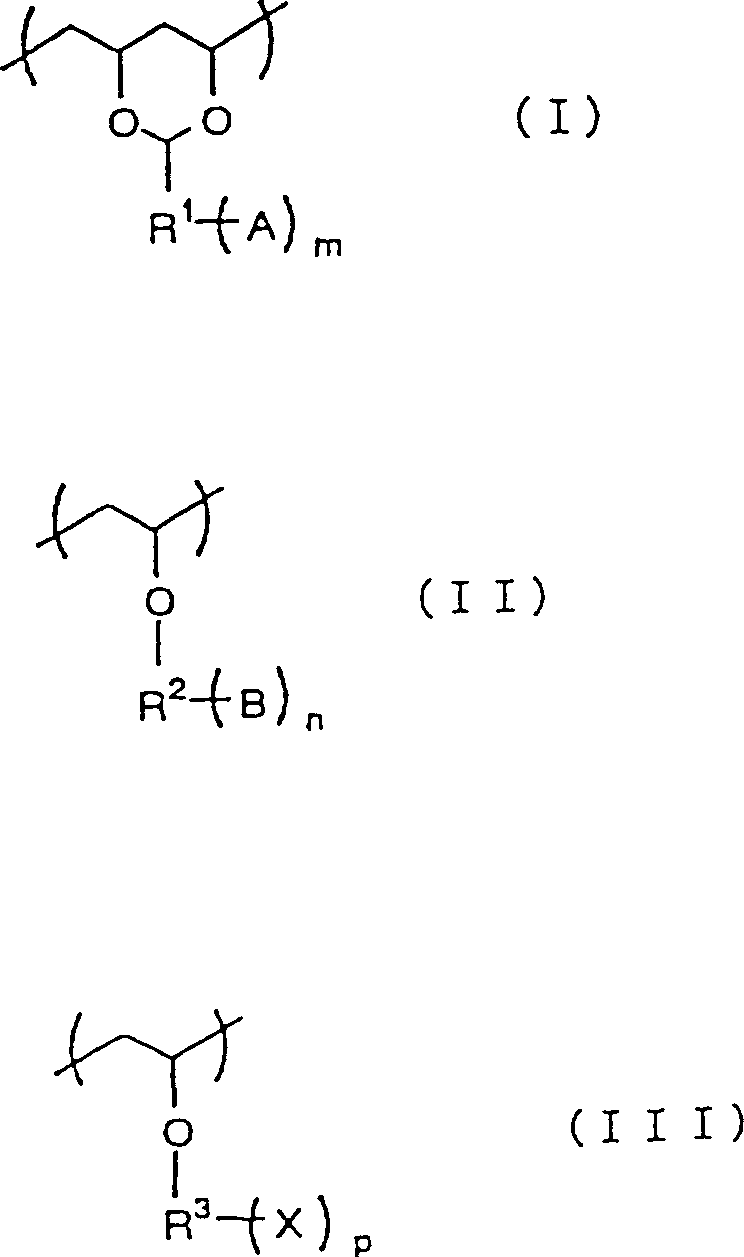

[0320][Binder polymers in Tables 2 and 3]

[0321] PA-1:

[0322] Allyl methacrylate / methacrylic acid copolymer (copolymerization molar ratio is 80:20)

[0323] The acid value measured by NaOH titration is 1.70meq / g

[0324] The weight average molecular wei...

Embodiment 41~60 and comparative example 11~14

[0363] [Formation of photosensitive layer]

[0364] The following photosensitive layer-forming coating solutions were prepared and coated onto the aluminum support [AS-4] in an amount to obtain the dry coating amount shown in Table 5 using a wire bar. Dry the coating at 115° C. for 45 seconds with a hot air drying oven to form a photosensitive layer. Coating solution for forming a photosensitive layer:

[0365] Addition polymerizable compound (compound shown in Table 5) 1.0g

[0366] Adhesive polymer (compound shown in Table 5) 1.0g

[0367] Infrared absorber (IR-1) 0.08g

[0368] Thermal polymerization initiator (compound shown in table 5) 0.3g

[0369] Fluorinated nonionic surfactant (Megafac F-176,

[0370] Dai-nippon Ink & Chemicals, Inc.) 0.01g

[0371] Victoria Pure Blue Naphthalene Sulfonate 0.04g

[0372] Methyl ethyl ketone 9.0g

[0373] Propylene glycol monomethyl ether 8.0g

[0374] Methanol 10.0g

[0375] [Form a protective layer]

[0376] 3% by weight p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com