Modified waterborne polyester resin dispersion for waterborne stoving varnish and preparation method of dispersion

A technology of water-based polyester resin and polyester resin, which is applied in the field of modified water-based polyester resin dispersion for baking varnish and its preparation, which can solve the problems of poor storage stability, poor water resistance, unfavorable application and storage of baking varnish, and achieve stable storage Improved water resistance, excellent water resistance, and improved water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 Modified aqueous polyester resin dispersion preparation embodiment

preparation example 1

[0026] Preparation of Modified Waterborne Polyester Resin Dispersion

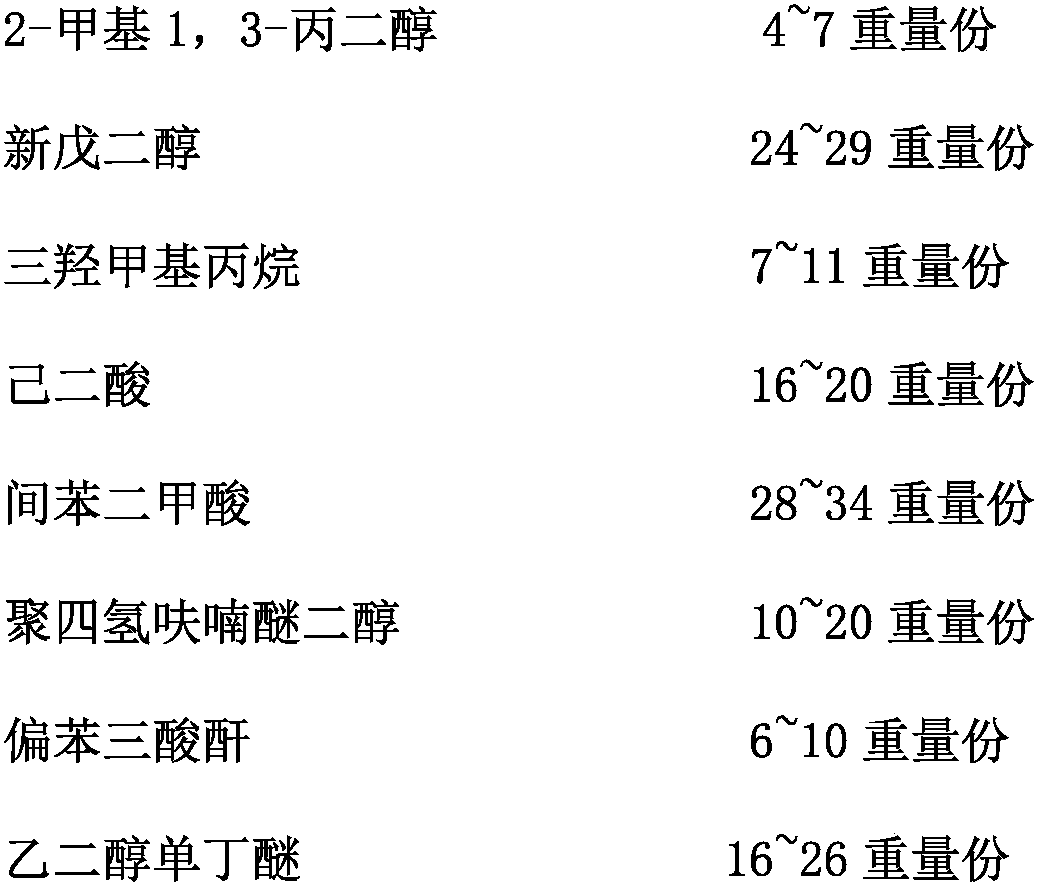

[0027] 4 parts by weight of 2-methyl 1,3-propanediol, 24 parts by weight of neopentyl glycol, 7 parts by weight of trimethylolpropane, 16 parts by weight of adipic acid, 28 parts by weight of isophthalic acid , 10 parts by weight of polytetrahydrofuran ether glycol, 6 parts by weight of trimellitic anhydride, 16 parts by weight of ethylene glycol monobutyl ether, and dimethylethanolamine of 6 parts by weight are mixed, incubated at 140°C for 0.5 hours, and then heated up to 150 ℃ for 1 hour, continue to heat up to 180 ℃ for 2 to 3 hours, then raise the temperature to 220 ℃ for esterification reaction, until the reaction reaches an acid value of 20, stop the reaction; after the esterification reaction, add 110 parts by weight of Purified water, adjusted to solid content: 40-44%, VIS: 500-5000mpa.s (25°C), to obtain a modified water-based polyester resin dispersion.

[0028] Preparation of modified water-bas...

preparation example 2

[0031] Preparation of Modified Waterborne Polyester Resin Dispersion

[0032] 7 parts by weight of 2-methyl 1,3-propanediol, 29 parts by weight of neopentyl glycol, 11 parts by weight of trimethylolpropane, 20 parts by weight of adipic acid, 34 parts by weight of isophthalic acid , 20 parts by weight of polytetrahydrofuran ether glycol, 10 parts by weight of trimellitic anhydride, 26 parts by weight of ethylene glycol monobutyl ether, and 10 parts by weight of dimethylethanolamine are mixed at 140 ° C for 0.5 hours, and then heated to 160 Keep warm at 190°C for 1 hour, continue to heat up to 190°C for 2 to 3 hours, then raise the temperature to 230°C for esterification until the acid value is 30, stop the reaction; add 130 parts by weight after the esterification pure water, adjusted to solid content: 40-44%, VIS: 500-5000mPa.s (25°C), to obtain a modified water-based polyester resin dispersion.

[0033] Preparation of modified water-based baking varnish

[0034] Mix the obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com