Novel method for preparing lignosulphonate epoxy resin

A technology of lignosulfonate and epoxy resin, which is applied in the field of biomass material manufacturing adhesive, can solve the problems of complex phenolization process and intermediate products, limited source of raw materials, harsh processing conditions, etc. Complex treatment, the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

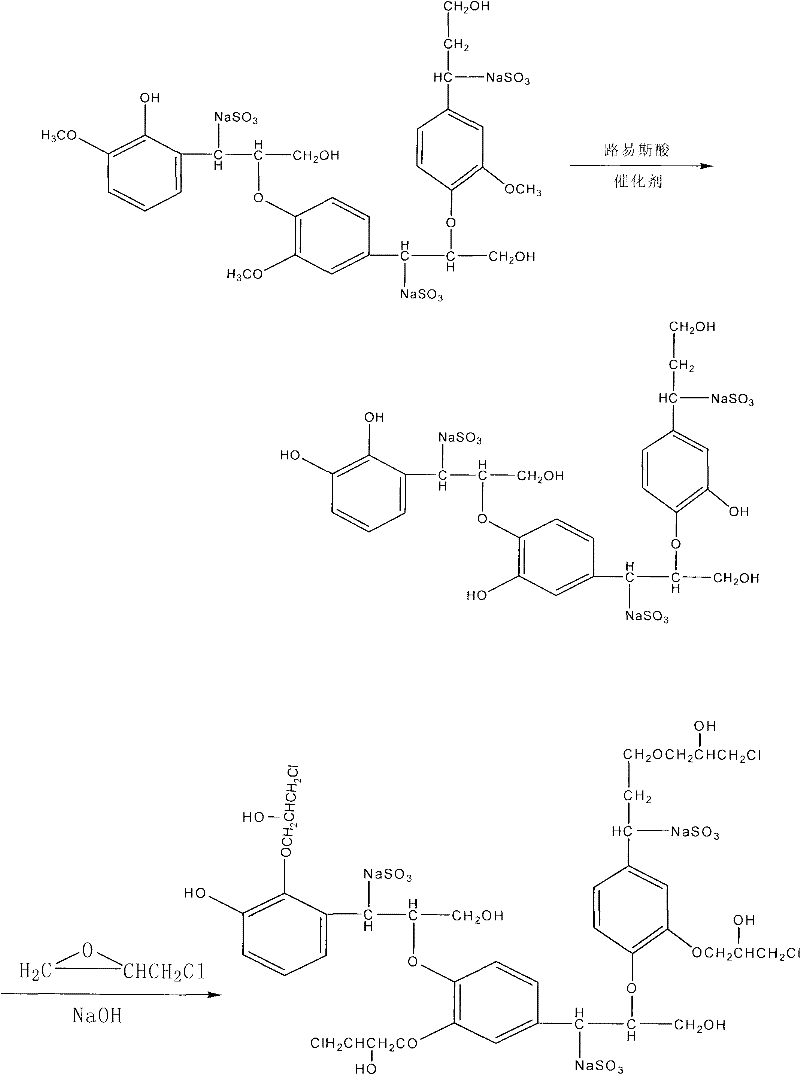

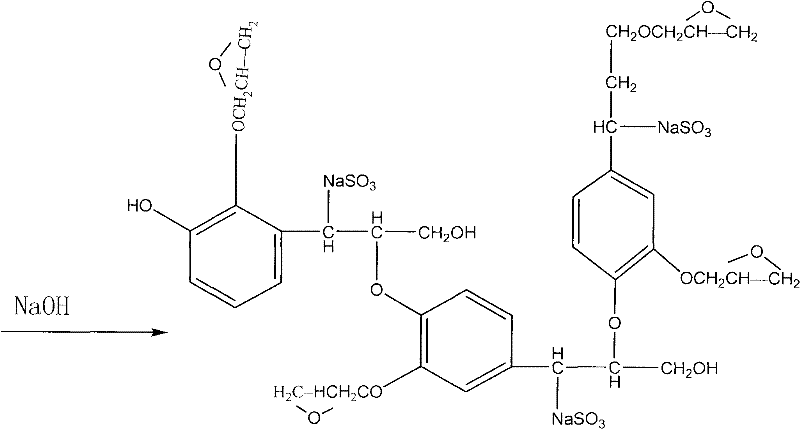

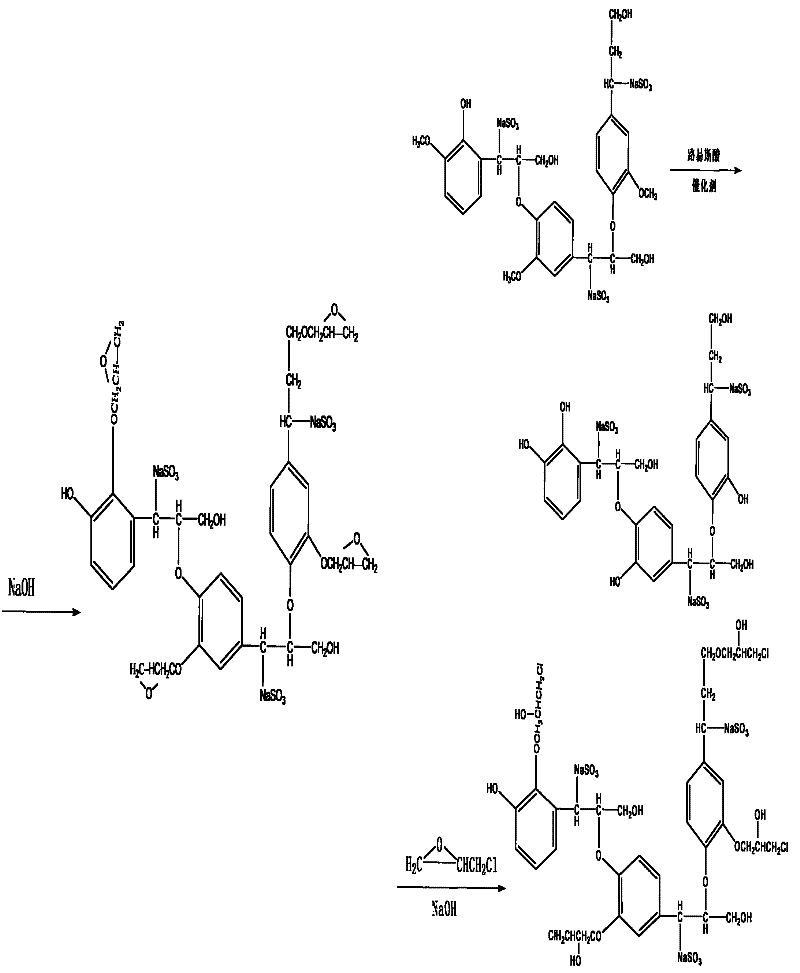

Method used

Image

Examples

Embodiment 1

[0024] Dissolve 16 grams of lignosulfonate in 160ml of water, filter and remove insoluble impurities to obtain lignosulfonate solution; measure 150ml of lignosulfonate solution, add to N 2 In the three-necked flask protected and reflux condensed, add 1.5ml of 50wt% hydrobromic acid and 0.6000g of cetyltributylphosphine bromide catalyst, the temperature is controlled at 60°C, react for 1 hour, use ethyl acetate to extract, water The solvent was removed by washing to obtain 25 g of the phenolated product, which was 2 Add 25g of epichlorohydrin to the obtained phenolated product under protective conditions, control the temperature at 60°C, add 2.5ml of 10wt% sodium hydroxide alkaline solution dropwise, and remove the solvent and unreacted epichlorohydrin after 2h. N 2 Under protective conditions, 20ml of toluene solvent was added to fully dissolve, and 2.5ml of 10wt% sodium hydroxide alkaline solution was added dropwise, and reacted at a temperature of 70° C. for 3 hours to obta...

Embodiment 2

[0026] Dissolve 16 grams of lignosulfonate in 160ml of water, filter and remove insoluble impurities to obtain lignosulfonate solution; measure 150ml of lignosulfonate solution, add to N 2 In the three-necked flask protected and reflux condensed, add 75ml of 50wt% hydrobromic acid and 0.6000g of cetyltrimethylammonium bromide catalyst, the temperature is controlled at 150°C, react for 12 hours, extract with ethyl acetate, wash with water method to remove the solvent to obtain 25g phenolated product, in N 2 Add 75g of epichlorohydrin to the obtained phenolated product under protective conditions, control the temperature at 80°C, add 20ml of 10wt% sodium hydroxide alkaline solution dropwise, and remove the solvent and unreacted epichlorohydrin after 3h. 2 Under protective conditions, 20ml of toluene solvent was added to fully dissolve, and 20ml of 10wt% sodium hydroxide alkaline solution was added dropwise, and reacted at a temperature of 70° C. for 3 hours to obtain a lignosulf...

Embodiment 3

[0028] Dissolve 16 grams of lignosulfonate in 160ml of water, filter and remove insoluble impurities to obtain lignosulfonate solution; measure 150ml of lignosulfonate solution, add to N 2 In the three-necked flask of protection and reflux condensation, add 35ml 45wt% hydroiodic acid and 0.6000g polyethylene glycol-600 catalyst, the temperature is controlled at 100°C, react for 6 hours, use ethyl acetate extraction, water washing method to remove solvent, Obtain 25g phenolated product, in N 2 Add 45g epichlorohydrin to the obtained phenolated product under protective conditions, control the temperature at 70°C, add dropwise 10ml of 10wt% potassium hydroxide alkaline solution, and after 3h, remove the solvent and unreacted epichlorohydrin, N 2 Under protective conditions, 20ml of toluene solvent was added to fully dissolve, and 10ml of 10wt% potassium hydroxide alkaline solution was added dropwise, and reacted at a temperature of 70° C. for 3 hours to obtain a lignosulfonate ep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com