Patents

Literature

178results about How to "Not easy to wear and tear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

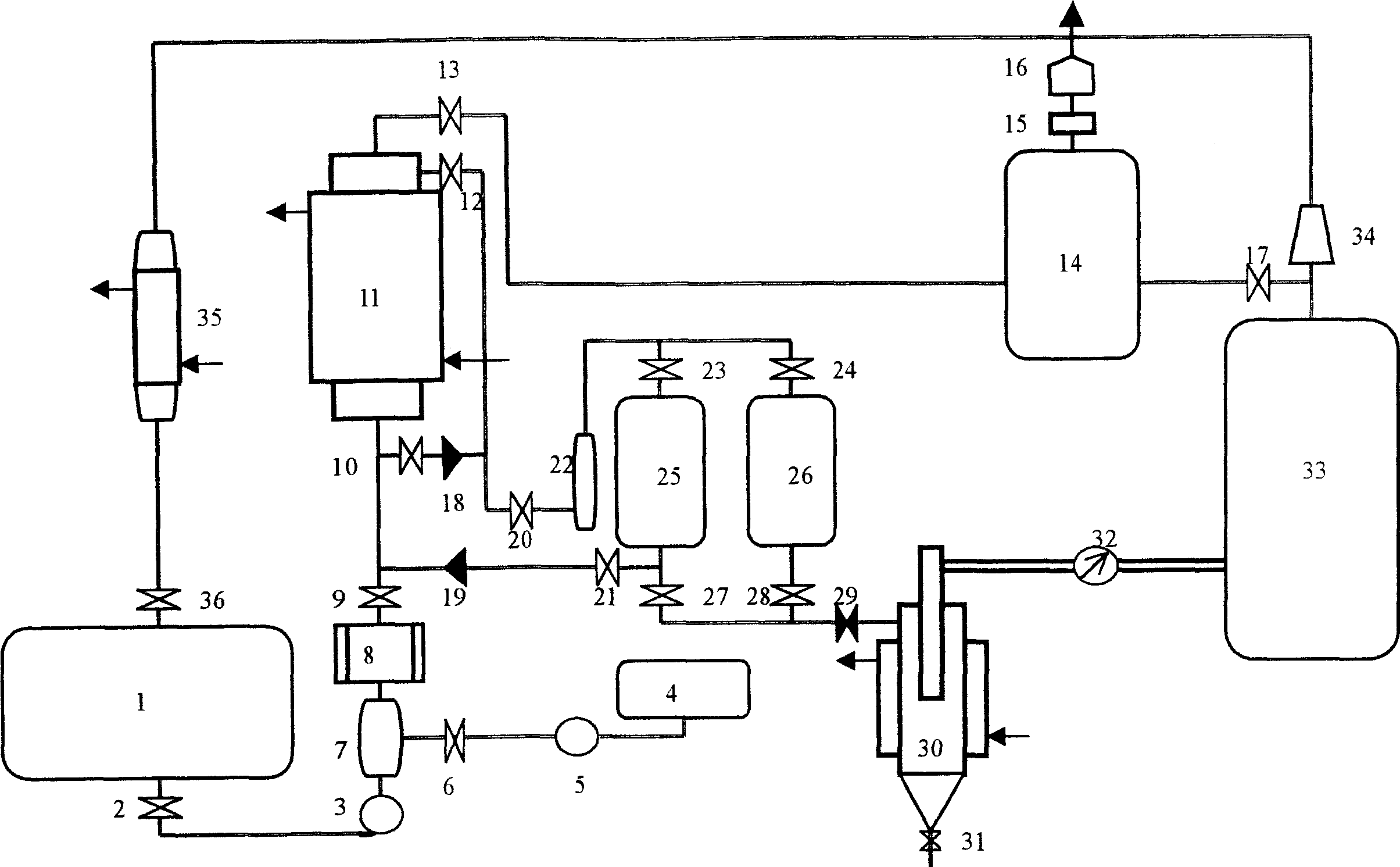

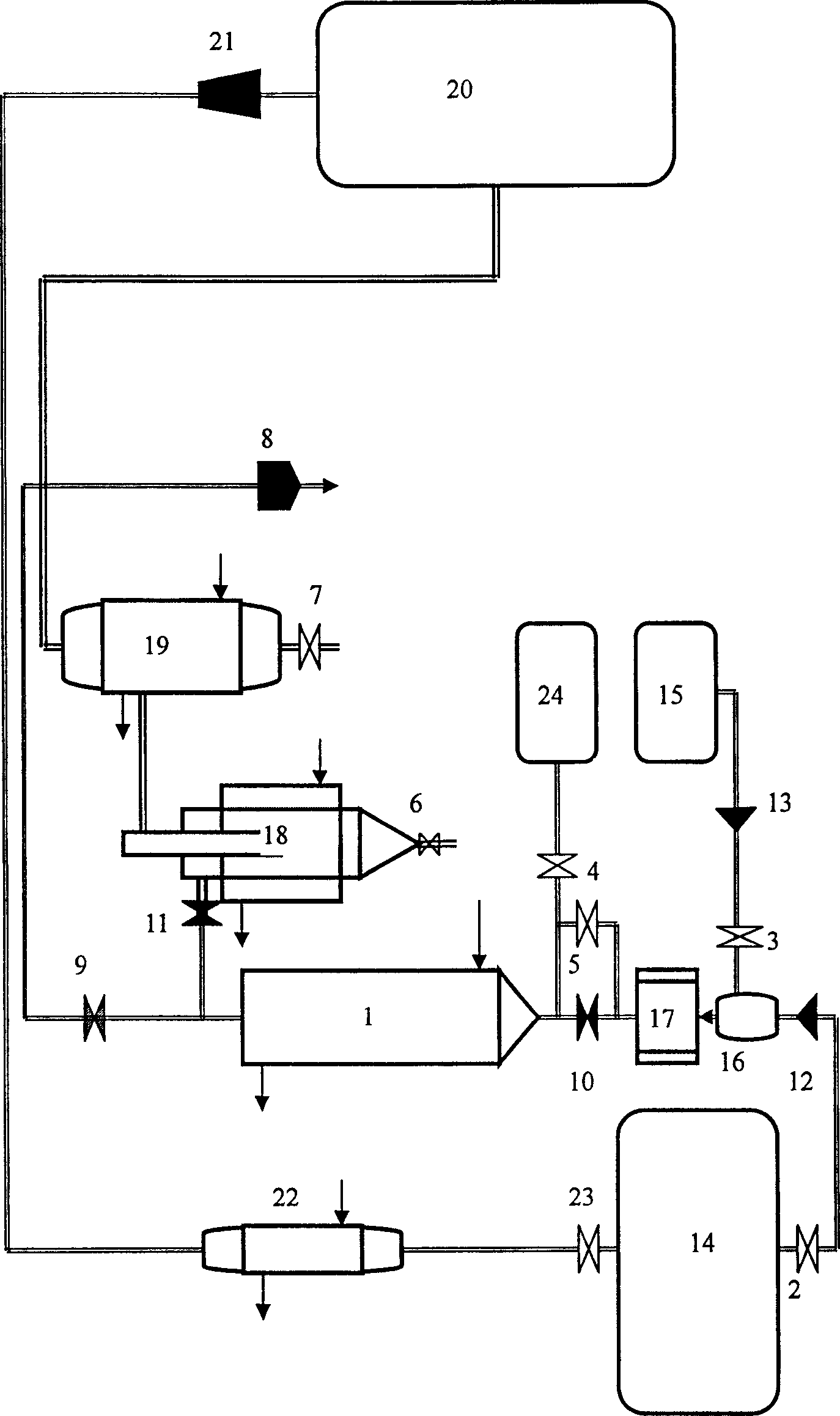

Method extracting waste tobacco at subcritical DMC

InactiveCN1682613AIncrease profitReduce economic riskTobacco treatmentSolid solvent extractionNicotineDimethyl ether

The present invention discloses subcritical dimethyl ether (DME) method of extracting waste tobacco. The technology adopts DME at subcritical state as main solvent in extracting waste tobacco, and through altering the temperature and pressure of the main solvent and adding different kinds of co-solvent in different amount, tobacco extractum, coarse solanesol extractum and coarse nicotine are extracted selectively.

Owner:侯金荣 +1

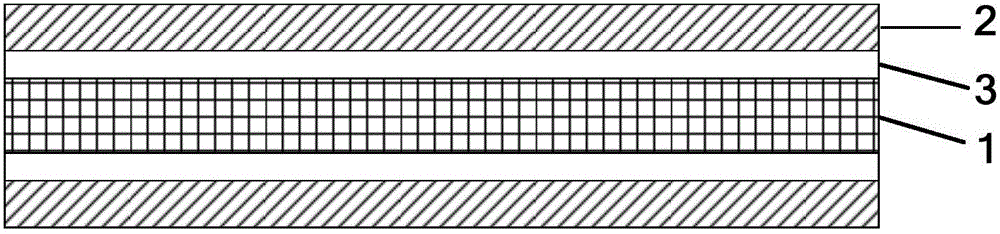

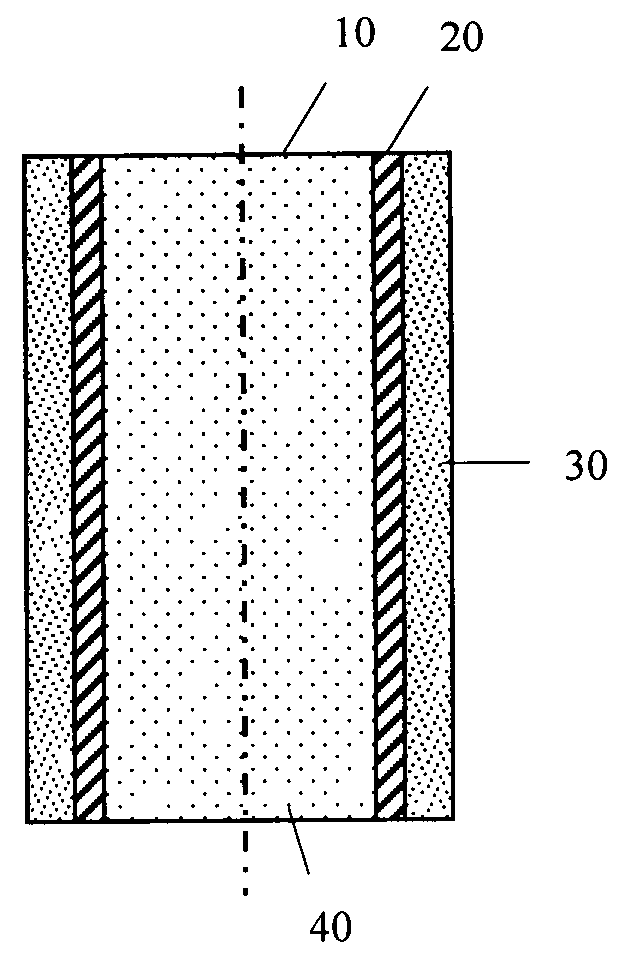

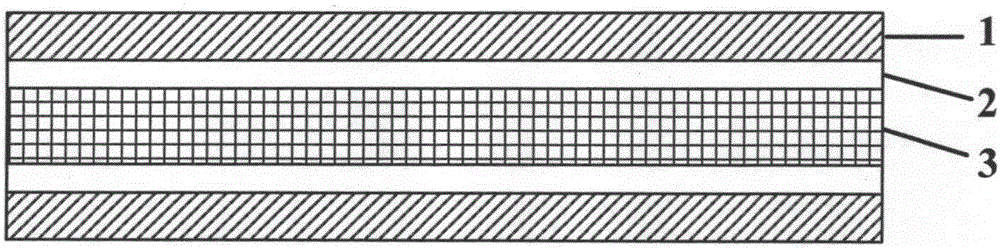

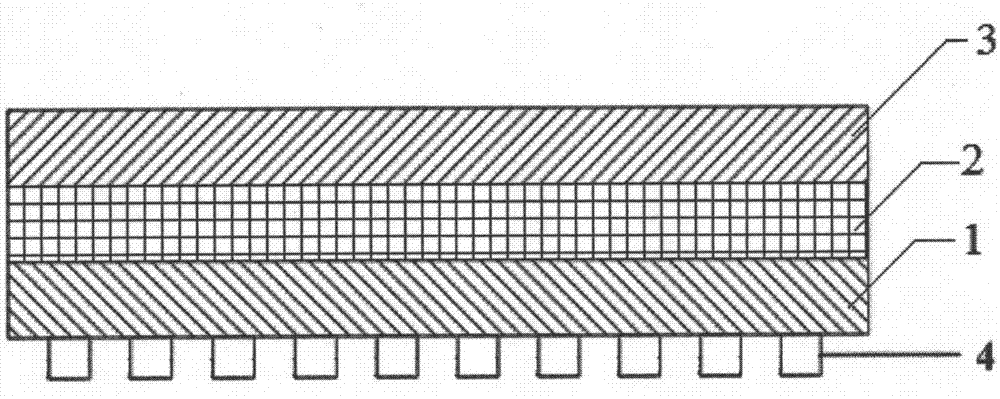

Flexible conductive composite fabric, and preparation and application thereof

InactiveCN106183316AGood flexibilityImprove electrical performanceFibre treatmentSynthetic resin layered productsComposite filmAdhesive

The invention relates to a flexible conductive composite fabric, and preparation and application thereof. The flexible conductive composite fabric comprises a conductive composite film (1), a base fabric (2) and an adhesive (3), wherein the base fabric (2) is adhered on the upper and lower surfaces of the conductive composite film through the adhesive (3); and two ends of the conductive composite film (1) are respectively adhered with an electrode. The flexible conductive composite fabric is prepared through the following steps: impregnating a carbon nanotube thin film in a graphene suspension, then taking the carbon nanotube thin film out of the graphene suspension, and carrying out drying in the air so as to obtain a carbon nanotube / graphene composite film; allowing a polyaniline nanowire array to grow in situ on the surface of the carbon nanotube / graphene composite film so as to obtain a carbon nanotube / graphene / polyaniline composite film; and respectively adhering an electrode at two ends of the composite film, coating the base fabric on the upper and lower surfaces of the composite film through the adhesive, and carrying out curing so as to obtain the flexible conductive composite fabric. The prepared conductive fabric provided by the invention has good conductivity, can reach 103 S / m to 105 S / m, can bear a certain degree of bending and compressive deformation, and is extensively applied in the fields of intelligent textile structures and intelligent materials.

Owner:DONGHUA UNIV

Biological carbon energy water-soluble fertilizer

ActiveCN103964924ANot easy to wear and tearNo need to worry about lossFertilizer mixturesPhosphateMonopotassium phosphate

The invention discloses a biological carbon energy water-soluble fertilizer, relating to the technical field of fruit and vegetable planting cultivation. The fertilizer comprises the following raw materials by weight percent: 30%-60% of potassium fulvate, 5%-25% of biological organic carbon, 5%-25% of potassium dihydrogen phosphate, 4%-15% of potassium sulfate and 5%-25% of urea. A preparation method of the fertilizer comprises the steps of preparing the raw materials, grinding the urea, grinding potassium fulvate into powder, extracting biological organic carbon, uniformly mixing the materials, metering, packaging, and detecting to obtain a finished product of the fertilizer. Potassium fulvate and biological organic carbon are rich in carbon, hydrogen and oxygen and have strong adsorption functions, and carbon, hydrogen and oxygen are organically combined with nitrogen, phosphorus and potassium to form six nutritional elements required by plants, so that the utilization rate of various nutrients is greatly increased, the usage amount is low, and the effect is good. The fertilizer can be quickly adhered to soil when meeting water and is organically fused together with the soil, holes do not need to be dug and the fertilizer is applied along with the water when the base fertilizer is applied to fruits and vegetables, the nutrient loss is not easily caused, and the labor and effort are saved.

Owner:山西奥德福生物科技有限公司

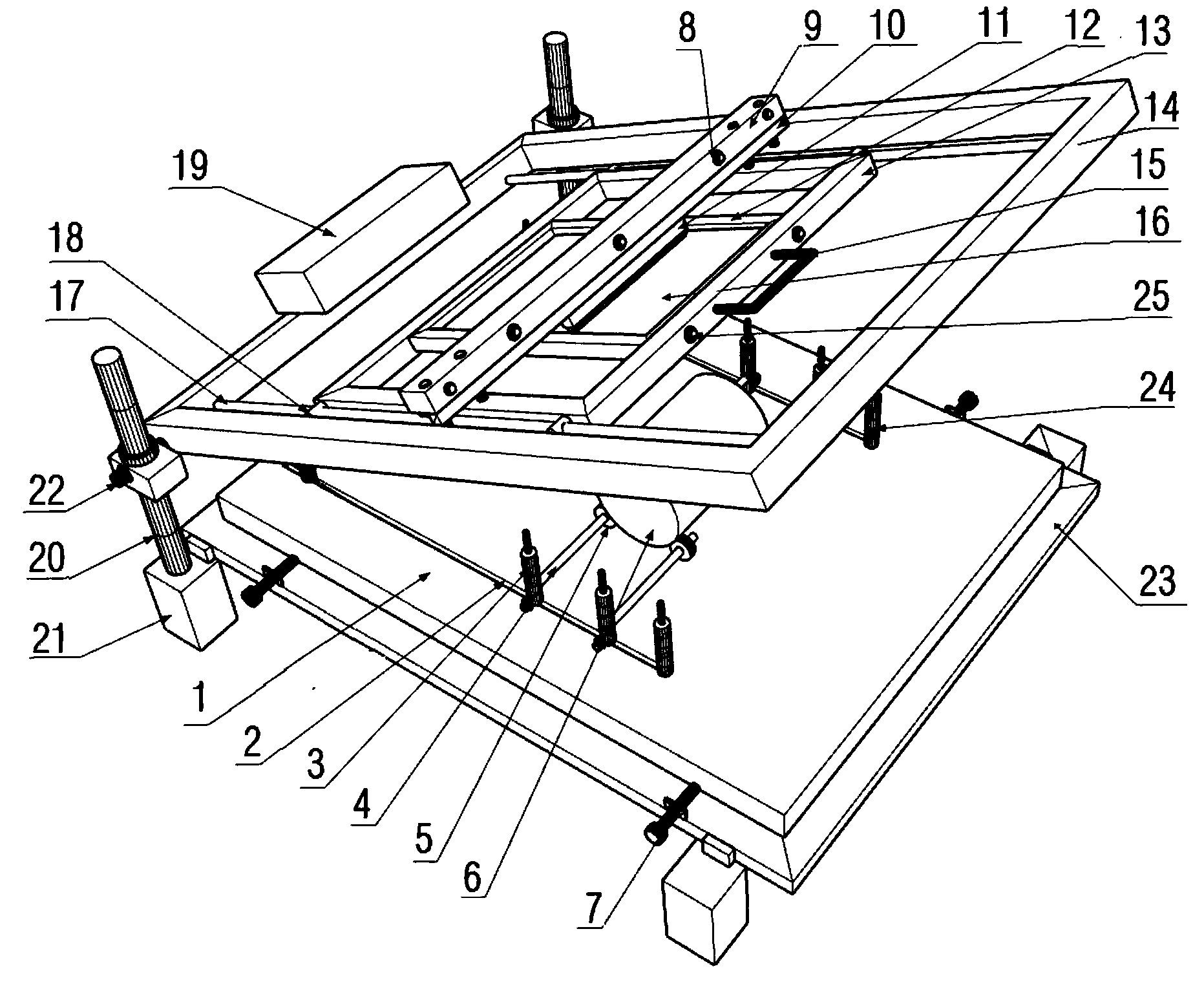

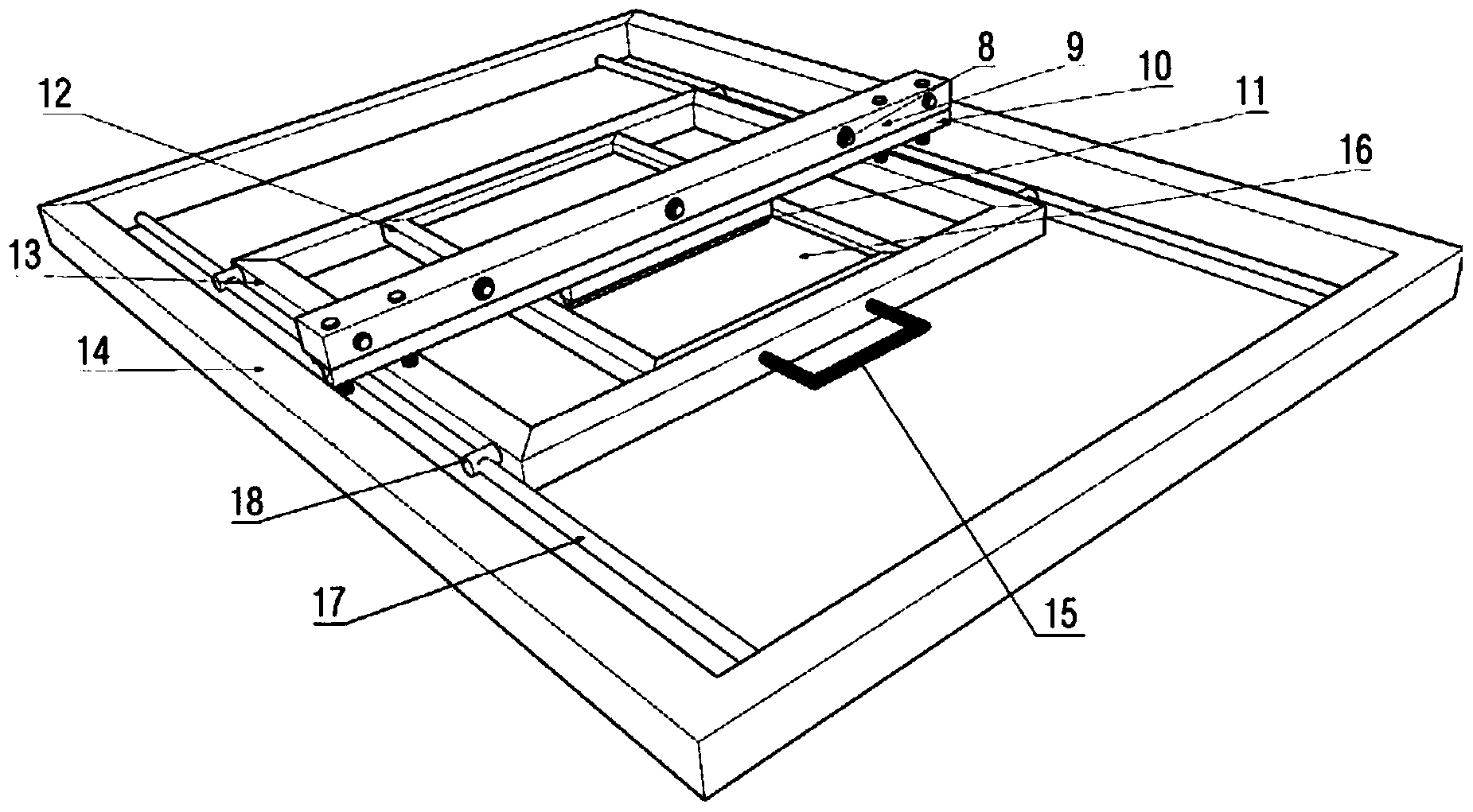

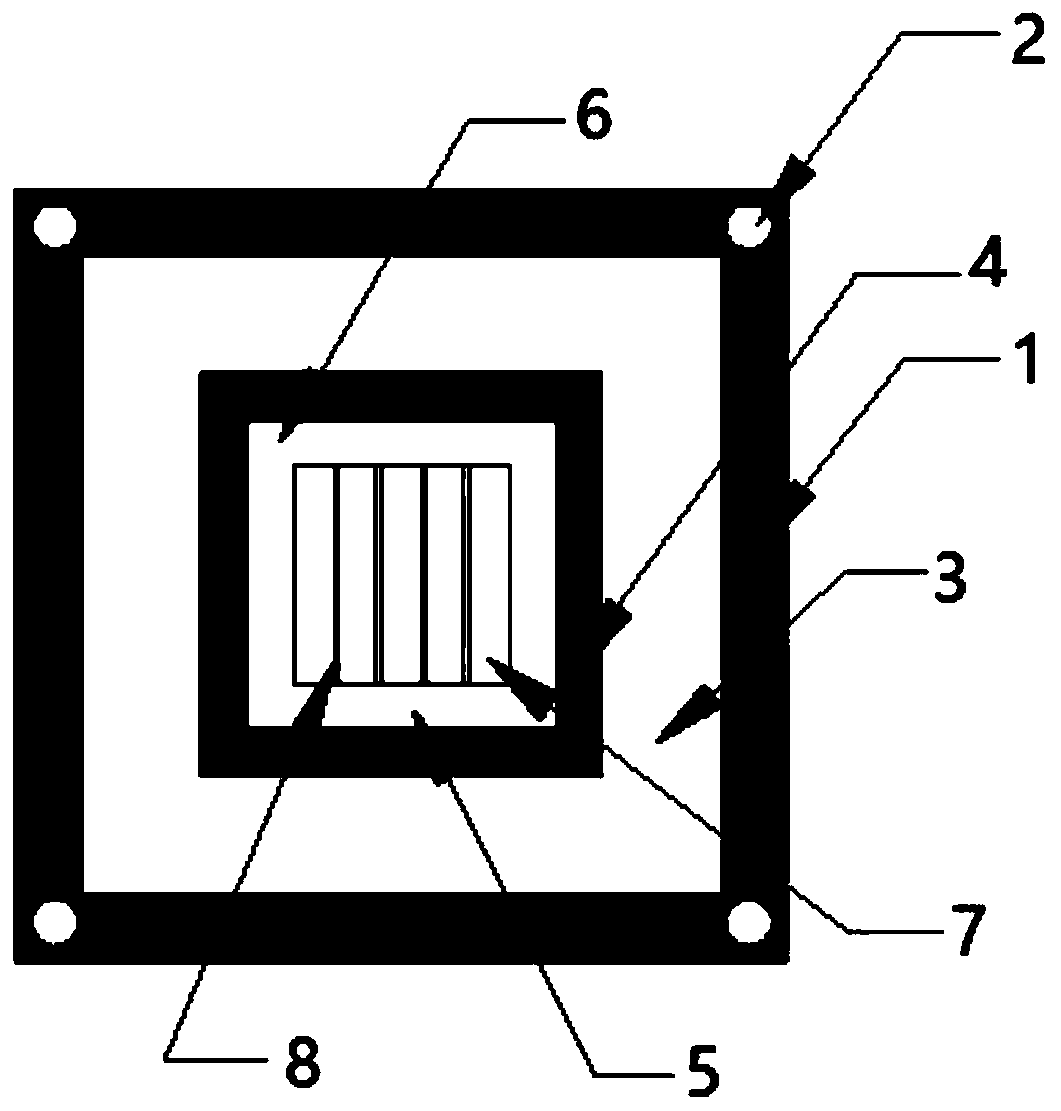

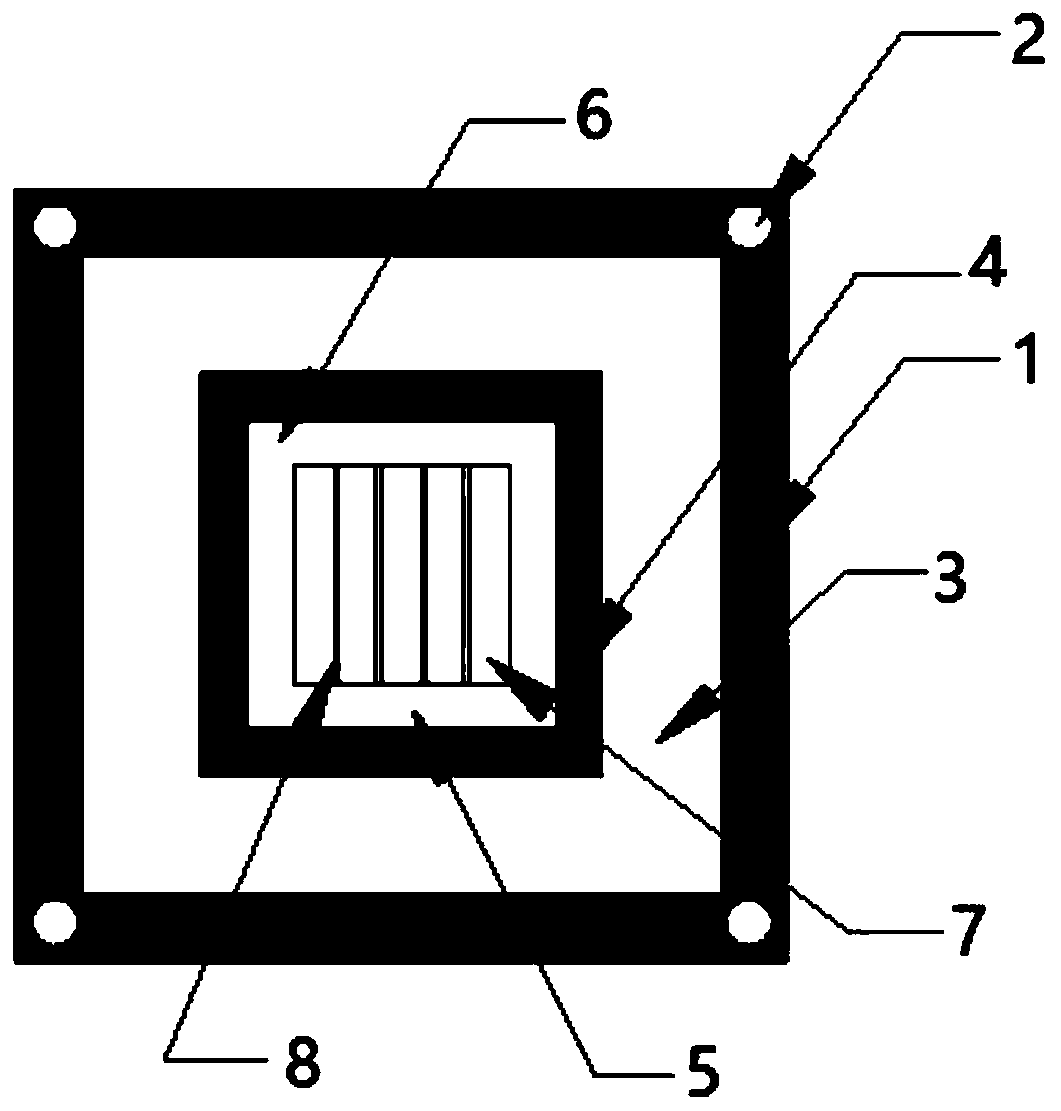

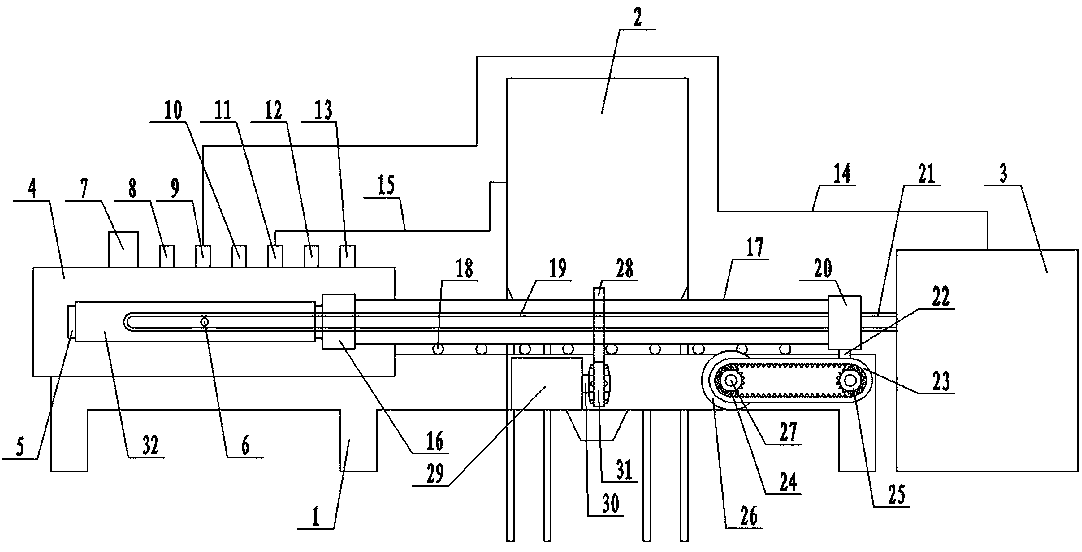

Three-dimensional manual curve surface screen printing machine

The invention relates to a three-dimensional manual curve surface screen printing machine which comprises a base plate, base plate supports and a space three-dimensional moving device. The base plate supports are disposed at four corners of the base plate. Lifting screws are disposed on the two base plate supports on the rear side. The space three-dimensional moving device is divided into an upper part and a lower part, the upper part is a liftable printing frame, and the lower part is a to-be-printed object three-dimensional moving mechanism. The lower mechanism is provided with a operation platform mounted on the base plate. Two slide rod station grooves are formed in the surface of the platform, four slidable longitudinal slide rods are mounted on the grooves, a transverses slide rod with a support bearing is mounted on each longitudinal slide rod, and the to-be-printed object is placed on the four support bearings. The upper printing frame is provided with an outer frame and a screen plate moving frame connected to the inside of the printing frame. A printing screen plate frame with a silk screen plate is connected into the screen plate moving frame. A scraper rack and a scraper are disposed on the screen plate moving frame. A balance iron square is disposed at the rear end of the outer frame. The printing machine is simple in structure, convenient to use, high in practicality and capable of printing cone frustums and cones with two ends of different diameters and irregular columns with handles.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Method for preparing composite ceramic graphite electrode

The invention relates to a method for preparing a composite ceramic graphite electrode. The method is characterized by comprising the following steps: (1) carrying out hot-pressing on a graphite rod: calcining, blending, kneading, pressing, baking and graphitizing petroleum coke, needle-shaped coke and anthracite serving as raw materials, wherein coal pitch is taken as a binder; (2) depositing a silicon carbide nanometer layer by virtue of a chemical vapor deposition method; and (3) depositing a hafnium carbide nanometer layer by virtue of a chemical vapor deposition method. The method has the advantages of mature shaping process and simple device; the composite ceramic graphite electrode has the advantages of compact structure, excellent oxidation resistance and high emission properties; an anti-oxidative layer on the surface of the composite ceramic graphite electrode and an electrode substrate are bonded by virtue of chemical bonds, the bonding force is strong and the anti-oxidative layer does not easily fall off.

Owner:SUZHOU HONGJIU AVIATION THERMAL MATERIALS TECH CO LTD

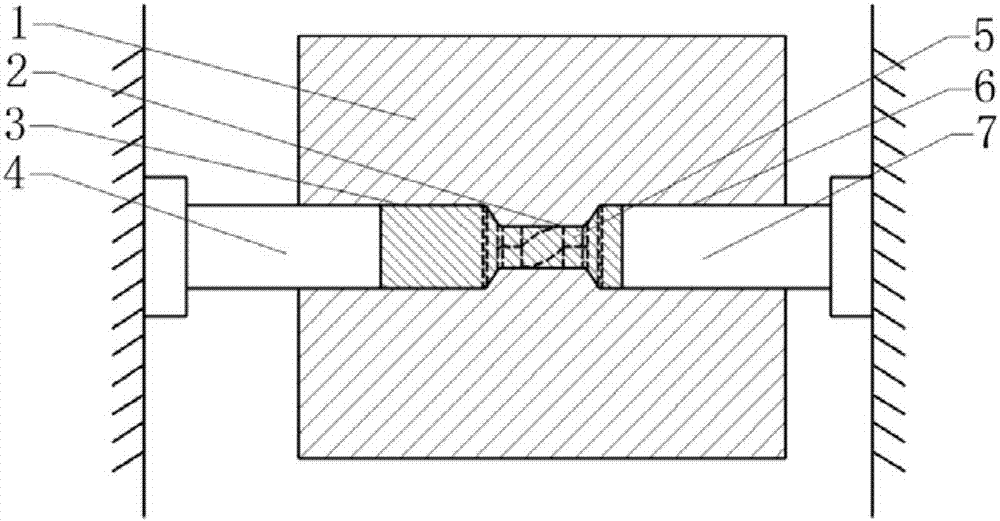

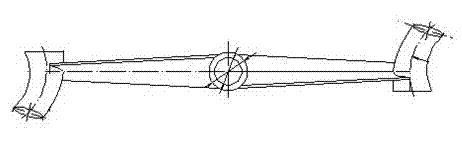

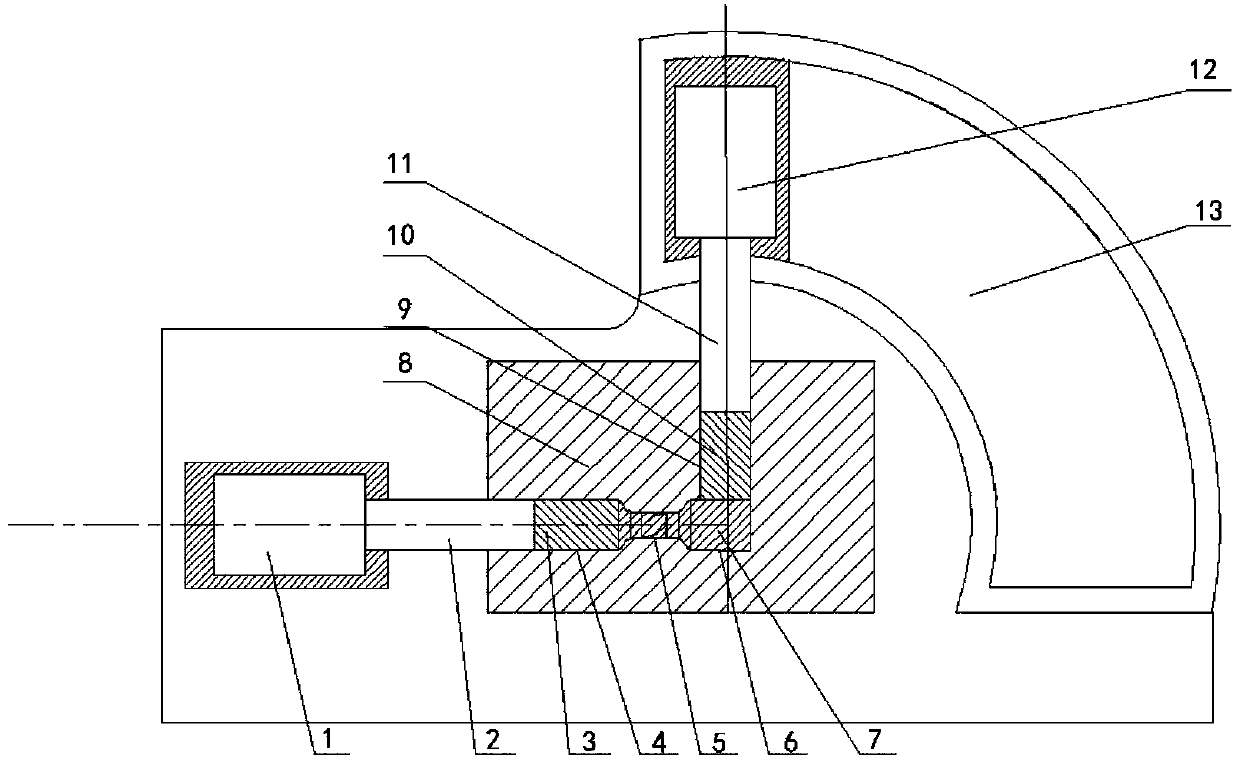

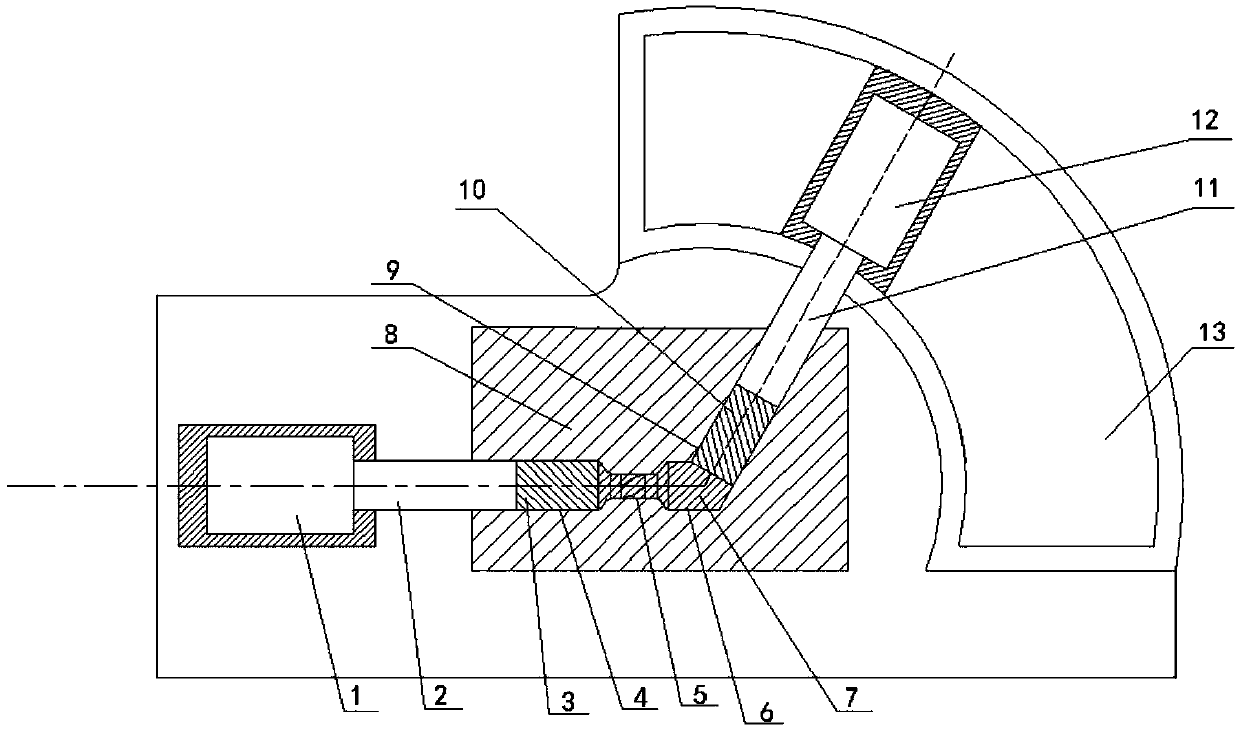

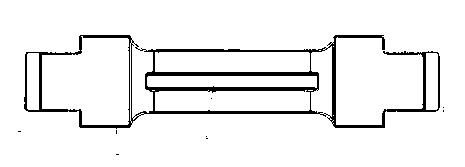

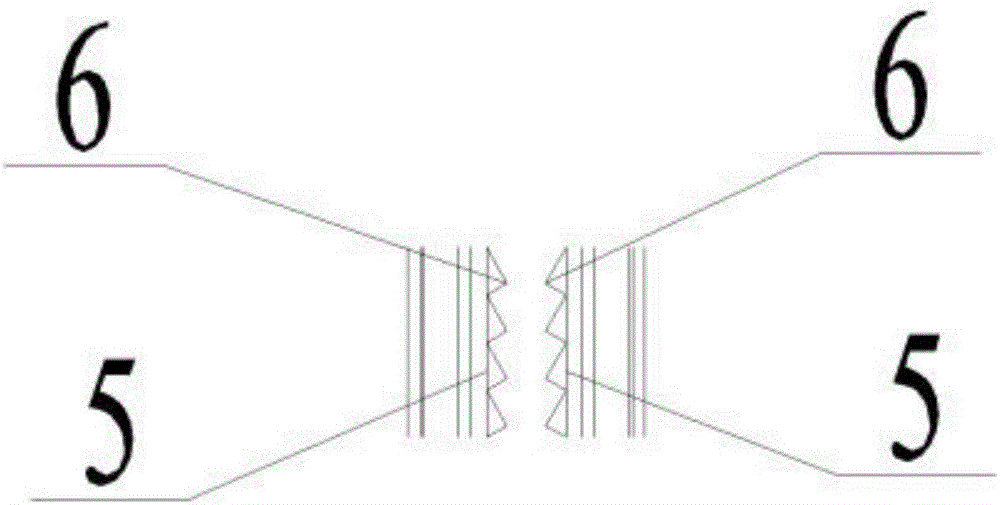

Blocked type variable cross-section reciprocating squeezing, twisting and upsetting forming method for ultra-fine grain bars

InactiveCN107282671ASolve uneven stressImprove uniformityMetal-working apparatusUltra fineEngineering

The invention discloses a blocked type variable cross-section reciprocating squeezing, twisting and upsetting forming method for ultra-fine grain bars. On the basis of a three-way hydraulic forming machine, the die assembly force is provided through an upper slide block, and pressure required for forming of punches at the two ends is provided through a left slide block and a right slide block. A die inner cavity is a linear channel formed by sequentially connecting a first squeezing channel, a middle twisting channel and a second squeezing channel on the same straight line. The section area of the middle twisting channel is smaller than the section area of the first squeezing channel and the section area of the second squeezing channel. The punches at the two ends are located at the two ends of the linear channel in a one-to-one correspondence manner, and a blocked variable section cavity is formed through the reciprocating punches at the two ends. By means of reciprocating of the punches at the two ends, the reciprocating squeezing, twisting and upsetting process of a to-be-processed blank in the linear channel is achieved, and preparation of the ultra-fine grain bars is completed through multi-pass forming. By means of the blocked type variable cross-section reciprocating squeezing, twisting and upsetting forming method, bar grains can be effectively refined, the forming limit of the bars is improved, and the blocked type variable cross-section reciprocating squeezing, twisting and upsetting forming method is easy to operate, high in applicability and capable of being easily applied in an engineered manner.

Owner:HEFEI UNIV OF TECH

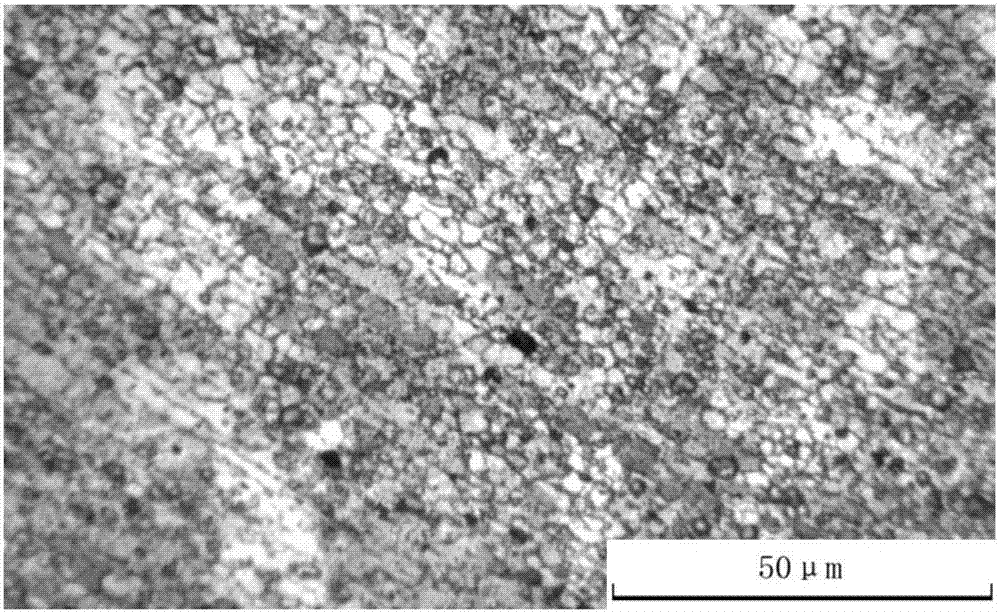

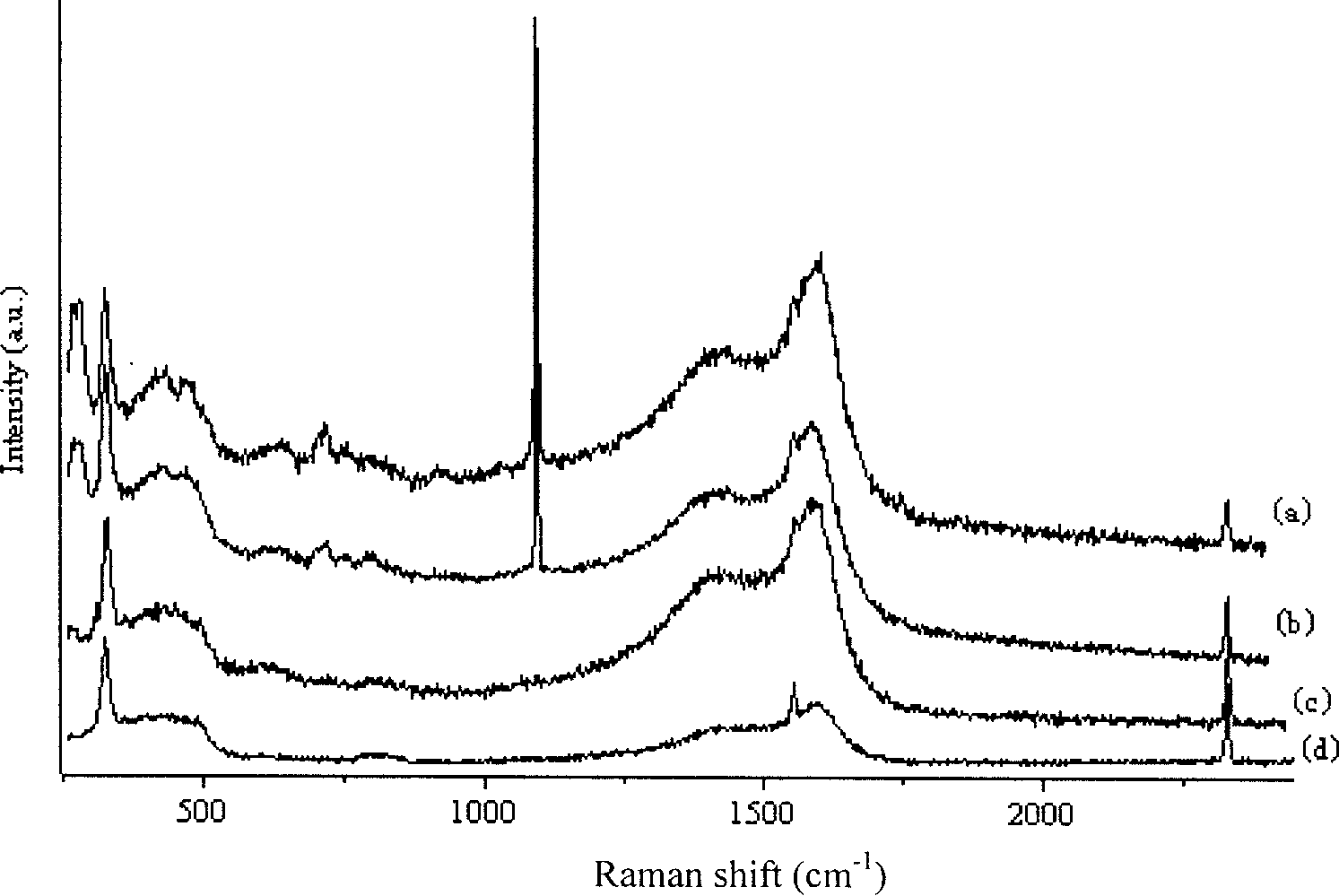

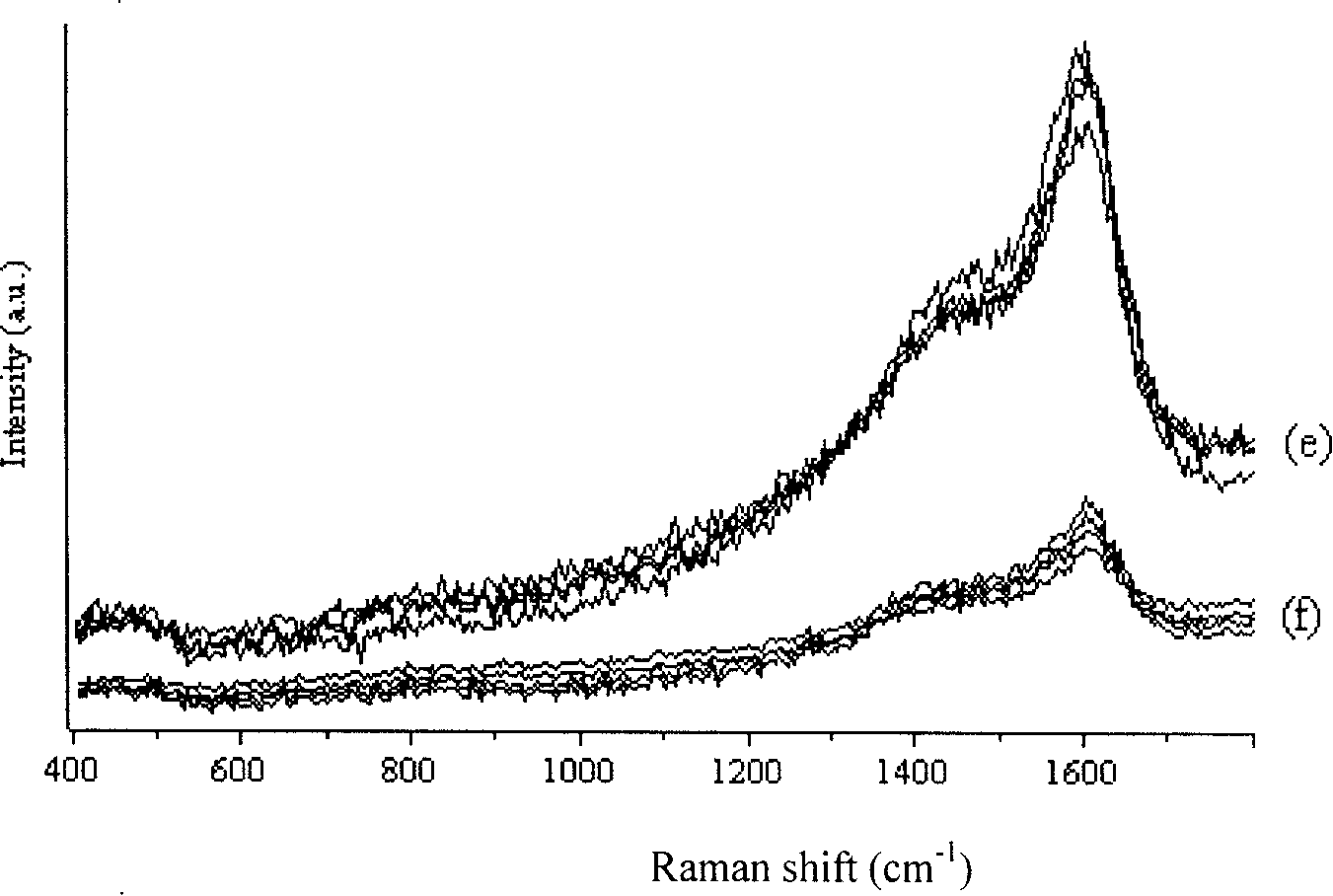

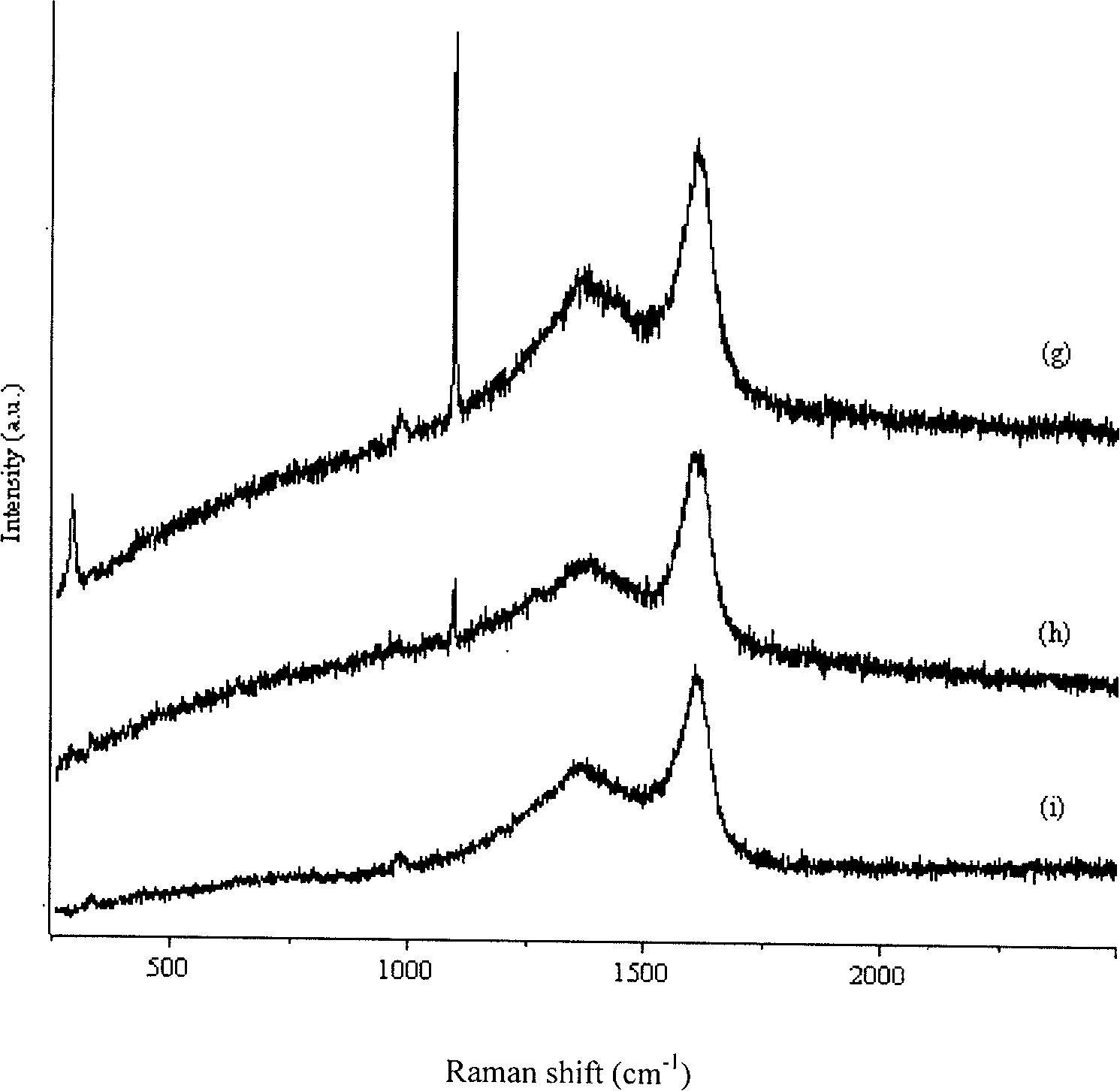

Raman optical spectrum method for identifying blackness handwriting

InactiveCN101162508ANot easy to wear and tearCharacter and pattern recognitionHandwritingRelative variation

The invention provides a Raman spectrum method for identifying black handwriting, wherein, the method adopts ultraviolet laser light as an excitation light source; fluorescence is avoided through adopting ultraviolet laser light which directly irradiates handwriting; the Raman spectrum signals of corresponding handwritings on a detected material and a sample are respectively collected; whether the ink compositions of the handwritings are different or not can be identified from the difference of Raman peaks through comparison; moreover, the different written times of the handwritings can be identified through the relative variation of corresponding Raman peak strength. As for black handwriting containing carbon black, the forming time can be judged according to the ratio of the integral area of the Raman characteristic peak at 1600cm<-1> and the integral area of newly written handwriting at the same position. The method which is of great convenience realizes objective and actual identification without any damage on identified handwriting.

Owner:柯惟中 +2

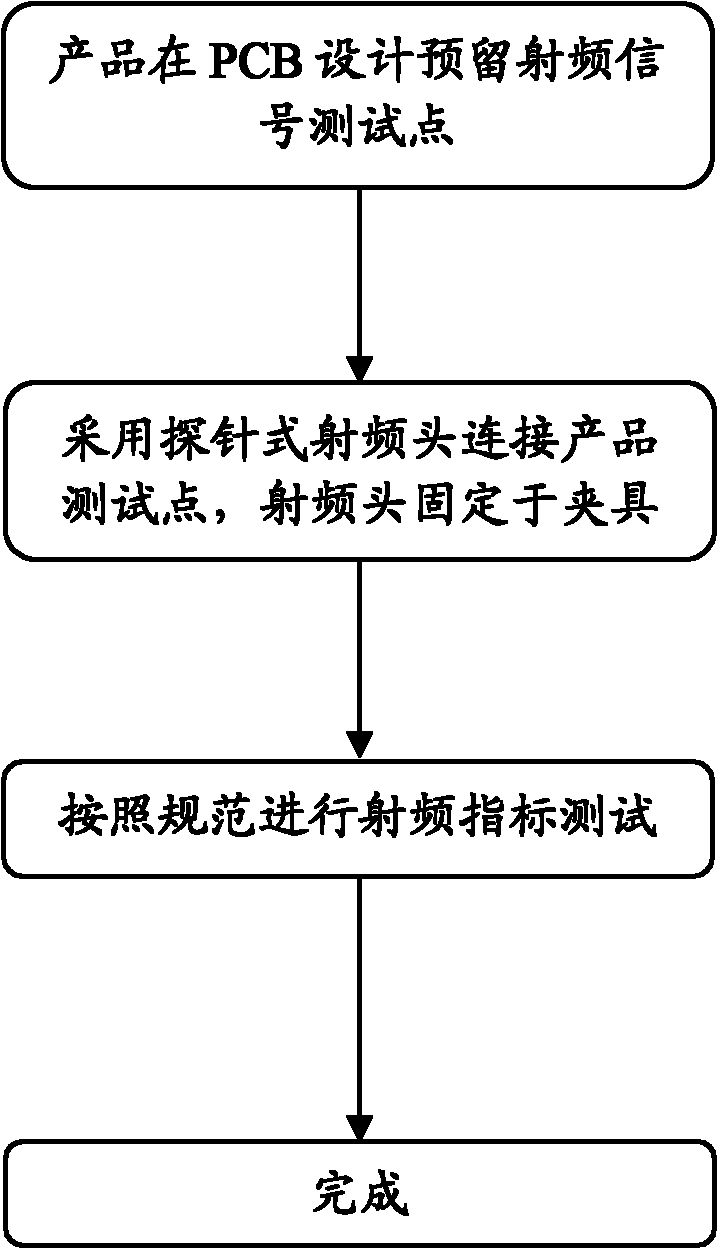

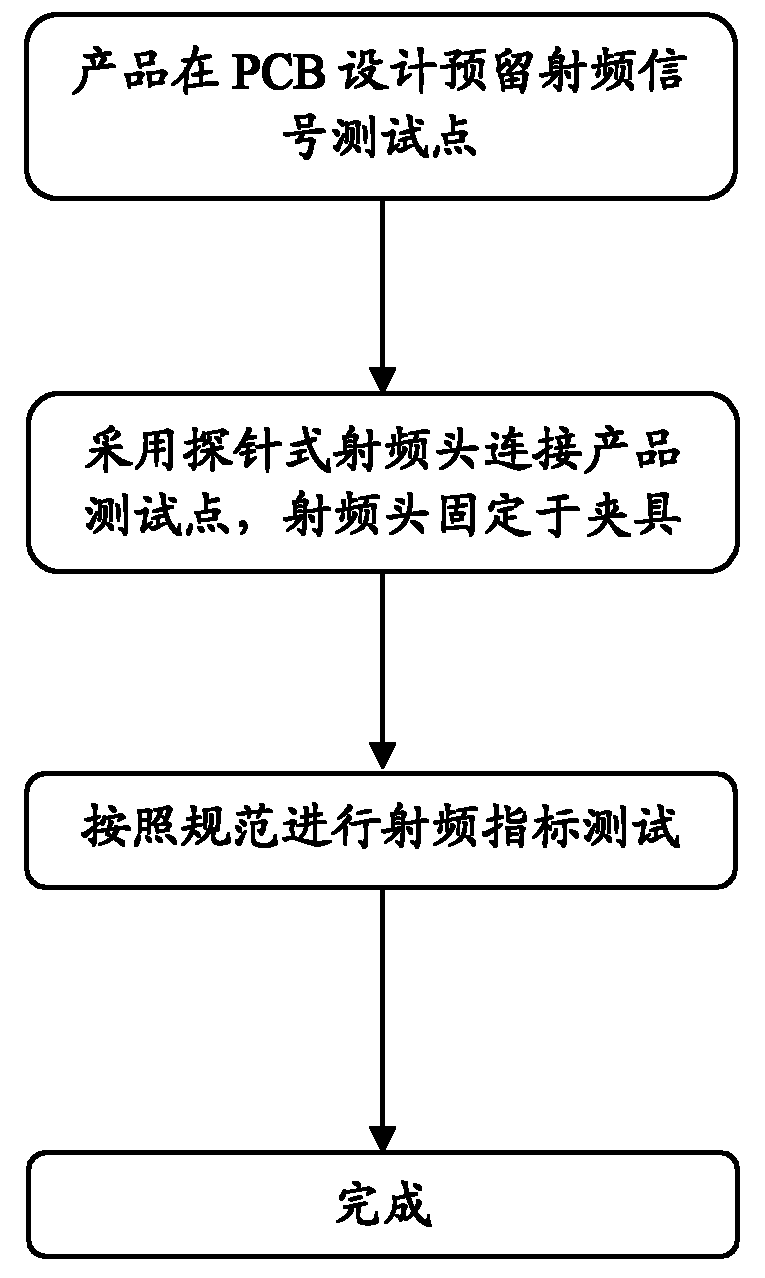

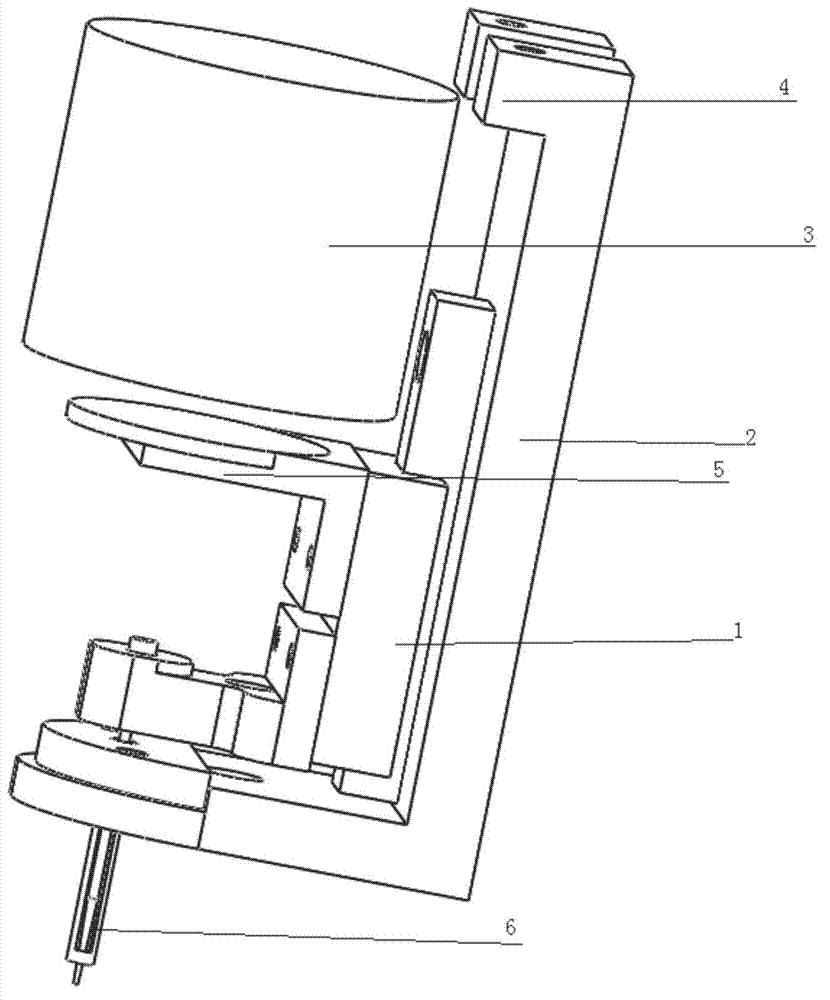

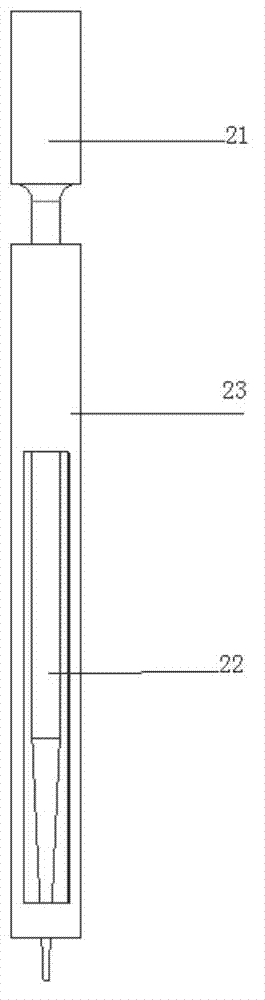

Radio-frequency (RF) signal test connection structure and radio-frequency signal test optimization method

InactiveCN102013930ASolve the costSolve efficiency problemsElectrical testingTransmission monitoringTest efficiencyProbe type

The invention relates to a radio-frequency (RF) signal test connection structure, which comprises a radio-frequency tester, a tested product is provided with a radio-frequency signal test point, the radio-frequency tester is connected with a probe-type radio-frequency head by a radio-frequency cable, and a probe at the end part of the probe-type radio-frequency head is contacted and connected with the radio-frequency signal test point. The invention also relates to a method for realizing radio-frequency signal test optimization based on the radio-frequency signal test connection structure. The radio-frequency signal test connection structure and the radio-frequency signal test optimization method of the invention have the advantages that: the size of the test point is matched with the used probe-type radio-frequency head; the hardware test connection mode is as follows: an RF output port of the tester, the radio-frequency cable, the probe type radio-frequency head, and the radio-frequency signal test point of the tested product are sequentially connected, therefore, the cost for an antenna connector in a BOM of the tested product is saved; the probe-type radio-frequency head is not easy to be damaged, thereby reducing the test cost; the probe-type radio-frequency head is fixed on a clamp for testing, thereby improving the first pass yield of the tested product; meanwhile, the radio-frequency signal test connection structure and the radio-frequency signal test optimization method of the invention are high in test efficiency, simple in structure, fast and convenient to operate, stable and reliable in operating performance, and wide in application scope.

Owner:SHANGHAI GONGJIN COMM TECH

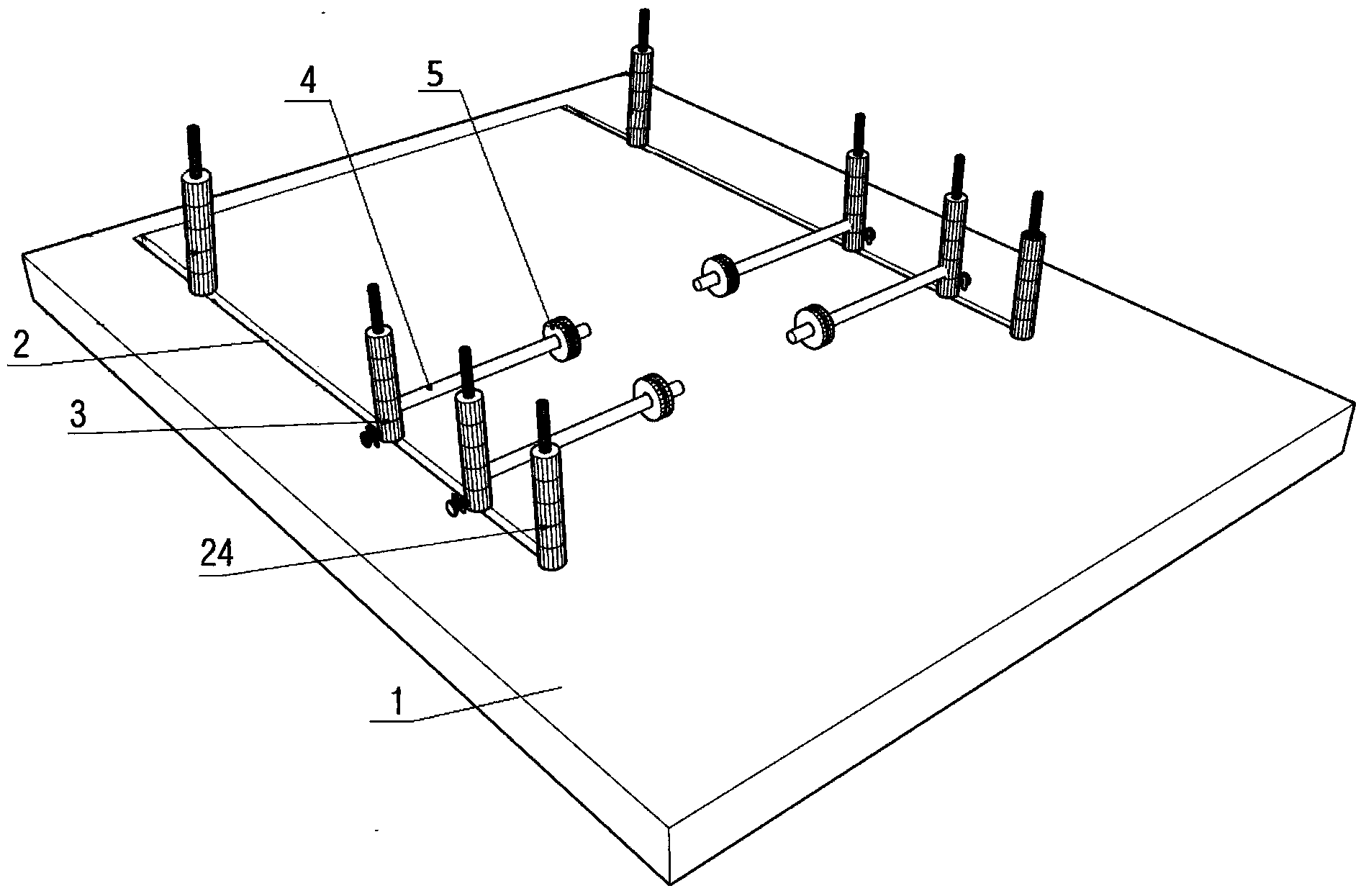

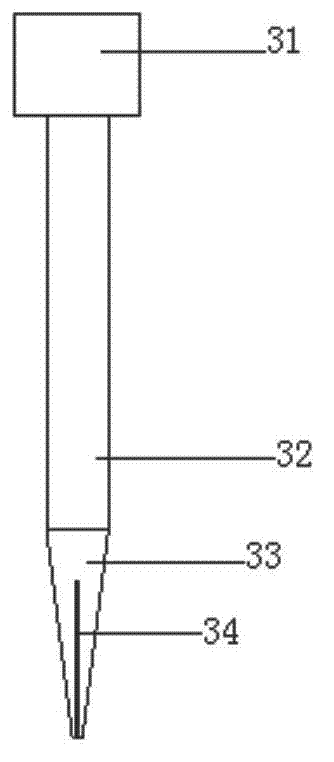

Biochip sample application instrument

InactiveCN103115807AHigh spotting frequencyNot easy to wear and tearPreparing sample for investigationControl systemFerromagnetism

The invention discloses a biochip sample application instrument. The biochip sample application instrument comprises a sample application platform, a three-dimensional motion device, a biochip sample application device, a power circuit and a control system, wherein the sample application platform comprises a sample placing platform and a sample fixing device; the biochip sample application device comprises a lengthways extending tack and a linear guide rail formed by a sliding block which is clamped and sleeved on the track; one end of the track is provided with an electromagnet, and the other end of the track is provided with a sliding block limiting part; one end of the sliding block is fixedly provided with a ferromagnetism suction piece, and the other end of the sliding block is fixedly provided with a sample application needle component; the three-dimensional motion device comprises X, Y and Z-direction motion shafts, the Z shaft is connected with the biochip sample application device and drives the biochip sample application device to move along the X, Y and Z three-dimensional directions; the power circuit is connected with the biochip sample application device and the three-dimensional motion device to supply electric power; and the control system is connected with the biochip sample application device and the three-dimensional motion device to control the automatic sample application. The biochip sample application instrument provided by the invention is a high-efficiency and low-cost product which is high in precision, quick in speed, high in efficiency and wide in applicability.

Owner:上海聚阵生物科技有限公司

Method for treating tobacco leaves through subscritical liquid

InactiveCN1759769AReduce harmful ingredientsImprove inner qualityTobacco preparationChemistryFluid handling

A process for treating tobacco leaves by subcritical fluid includes such steps as regulating such parameters of subcritical fluid as 0.4-4 kg / min for flow, 20-90 deg.C and 20-60 deg.C for extracting temp and separating temp, 0.5-3 MPa and 0.1-0.5 MPa for extracting pressure and separating pressure, and pH=9-11, selectively removing harmful components, vacuum recovery of medium while refrigerating to -20¿D-60 deg.C, and puffing by filling saturated steam. Its advantage is less loss of flavouring components and reducing sugar.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

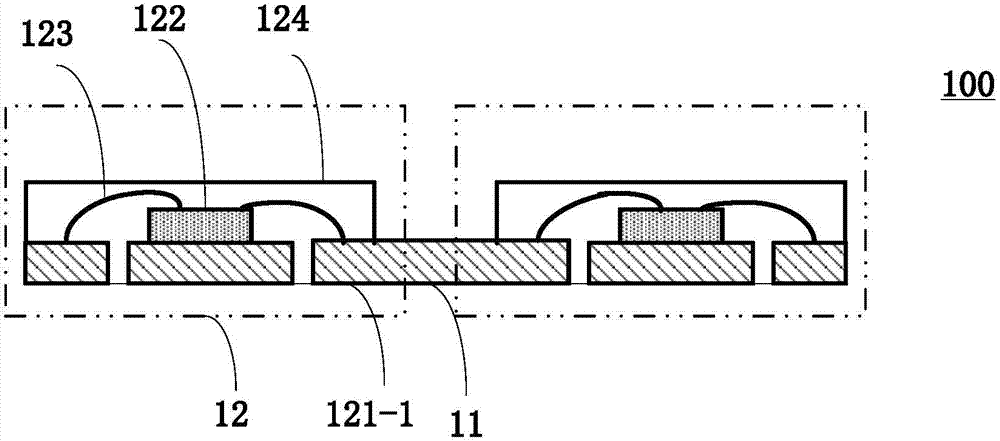

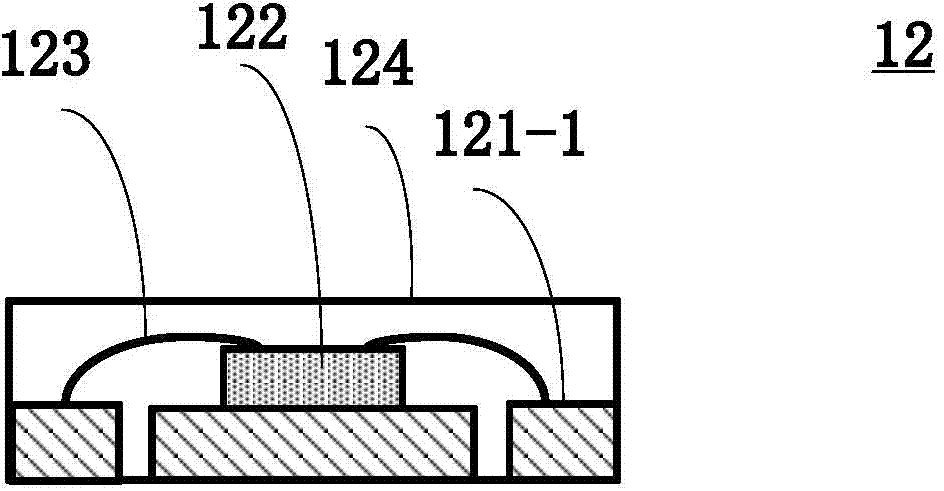

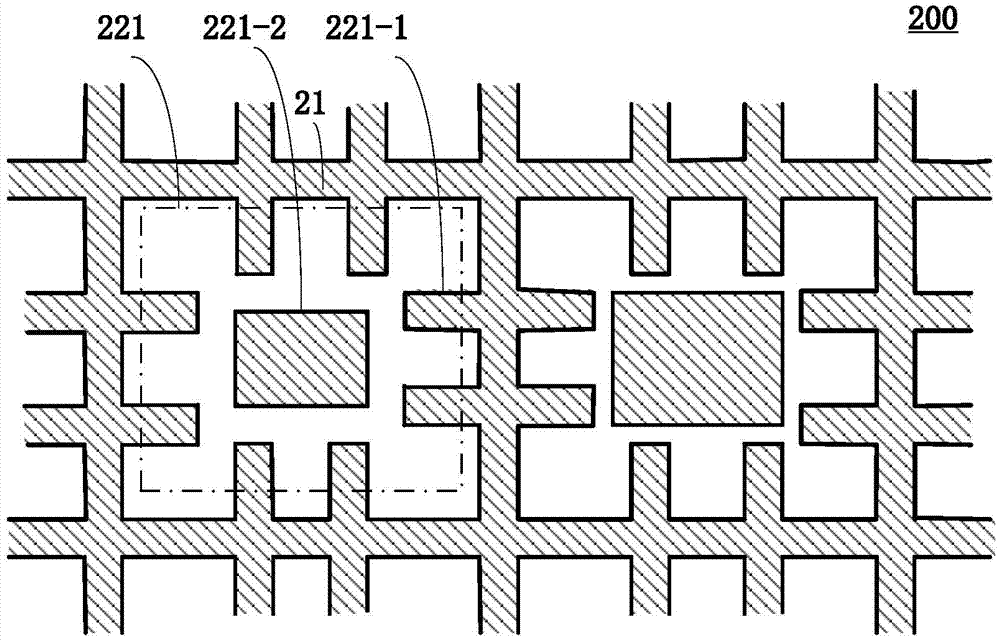

Non-outer-pin packaging structure and manufacturing method and wire frame of non-outer-pin packaging structure

InactiveCN103928353AReduce thicknessReduce frictionSemiconductor/solid-state device detailsSolid-state devicesPlastic packagingMetal

The invention provides a non-outer-pin packaging structure and a manufacturing method and a wire frame of the non-outer-pin packaging structure. The non-outer-pin packaging structure comprises the wire frame, a chip, a plurality of electric connection elements and a plastic packaging body. The wire frame comprises a wire frame unit and a connecting support. The wire frame unit comprises a plurality of pins connected with the connecting support, and the thickness of the ends, away from the wire frame unit, of the pins is smaller than the thickness of the pins. The chip is electrically connected to the pins through the electric connection elements. The plastic packaging body packages the chip and the electric connection elements and encapsulates the pins. The ends, away from the center of the wire frame unit, of the pins can have first parts with the thickness smaller than that of the pins, one side of each first part is a cutting channel, the metal thickness at the cutting positions is reduced, the loss of a cutter can be reduced, the cutting efficiency can be improved, the contact area between the pins and plastic packaging materials is increased, and the packaging reliability of the chip can be improved.

Owner:SILERGY SEMICON TECH (HANGZHOU) CO LTD

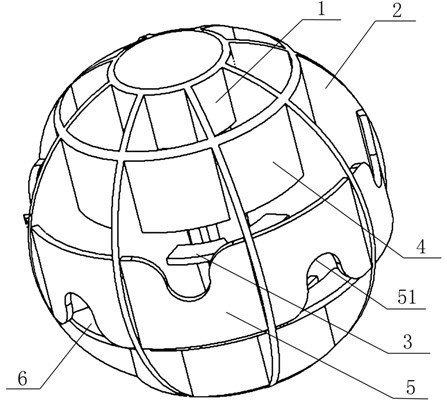

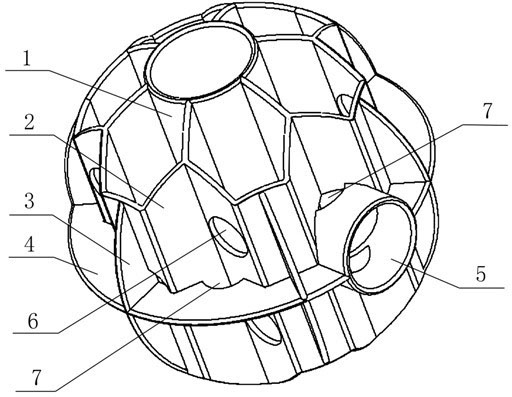

Labyrinth-shaped spherical hollow filler

InactiveCN102614606AEliminate explosion pointsFlame suppression effectContainer filling methodsFire rescueEngineeringSpherical shaped

The invention discloses a labyrinth-shaped spherical hollow filler which is characterized in that coaxial tubular bodies are arranged at the two ends of the filler respectively, and a plurality of fan-shaped bodies are uniformly connected to the circumference of the two tubular bodies; a ring-shaped body is arranged at the middle parts of the two tubular bodies respectively and connected with each fan-shaped body; two large tubular bodies are arranged on the outer side of each tubular body and have a larger radius than that of the tubular bodies; and a ring-shaped belt is arranged in the position close to the vertex of each fan-shaped body. The internal structure of the labyrinth-shaped spherical hollow filler is spatially divided into a plurality of cells. Compared with the prior art, the cells are communicated to ensure the movability of liquid in the internal space, so as to, on one hand, suppress the spread of fire, and on the other hand, rapidly dissipate the local heat by virtue of the excellent heat absorptivity and extended surface area of the porous filler. Therefore, the labyrinth-shaped spherical hollow filler achieves the purpose of eliminating explosion points and suitable conditions for explosion of the explosion points.

Owner:常熟市新港农产品产销有限公司

Manufacturing method of composite screen printing plate

InactiveCN110039882ANot easy to wear and tearIncreased printing lifePlate printingFoil printingLine widthEngineering

The invention discloses a manufacturing method of a composite screen printing plate. The manufacturing method comprises the following steps of 1) screen pulling and compounding; 2) film layer manufacturing; 3) coating an adhesive layer; 4) coating a film; 5) drying; 6) laser; 7) cleaning; and 8) detection and packaging. By means of the mode, the manufacturing method of the composite screen plate has the advantages that when the screen printing plate is used, the film layer is not easy to wear and break, the printing life is prolonged by one time or more, the printing life of a conventional plate-making screen printing plate is averagely increased by about 50 thousand, the average energy of the screen printing life prepared by the method can reach 100 thousand or above and even higher, theprinting line at the later stage is not expanded, and the efficiency of the battery piece is obvious; and the manufactured screen printing plate is better in ink permeability, so that the limitation of the high-precision narrow line width can be greatly reduced, on the basis of the same type of ink printing, the width of the designed line can be compressed by 2-5 microns, the printing is good, theline type is good, and therefore the efficiency of the battery piece is obviously improved.

Owner:SUZHOU WOSUTE ELECTRONICS MATERIALS CO LTD

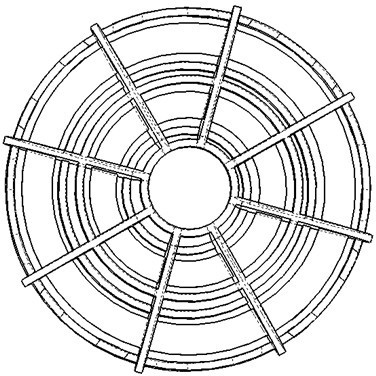

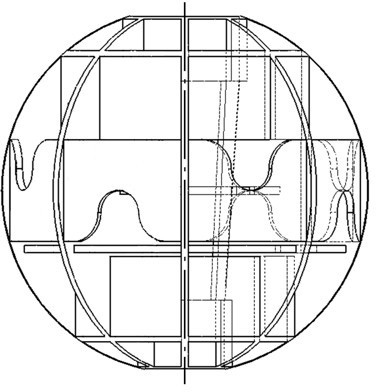

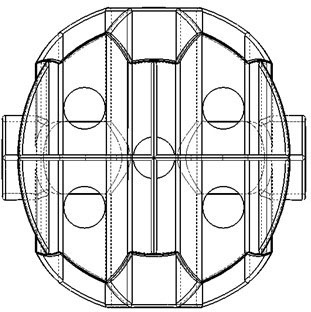

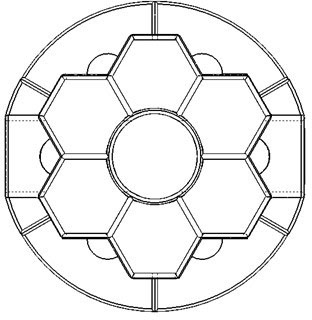

Honeycombed spherical hollow filler

InactiveCN102614604AEliminate explosion pointsFlame suppression effectContainer filling methodsFire rescueEngineeringSpherical form

The invention discloses a honeycombed spherical hollow filler which is characterized in that a central pipe is arranged at the center of the filler in a penetrating manner, six honeycombed hexagonal parts are arranged on the circumference of the central pipe in a way that each two of the six honeycombed hexagonal parts are connected, a longitudinal fan-shaped wing is connected to the outer side face of each honeycombed hexagonal part, a round fin is arranged on the middle cross section of the central pipe and connected with the outer side face of each honeycombed hexagonal part, and one or two honeycombed hexagonal through-pipes are arranged on the middle cross section of the central pipe and communicated with the central pipe and the outside of the central pipe. The internal structure of the honeycombed spherical hollow filler is spatially divided into a plurality of cells. The cells are communicated to ensure the movability of liquid in the internal space, so as to, one the one hand, suppress the spread of fire, and on the other hand, rapidly dissipate the local heat by virtue of the excellent heat absorptivity and extended surface area of the porous filler. Therefore, the honeycombed spherical hollow filler achieves the purpose of eliminating explosion points and suitable conditions for explosion of the explosion points.

Owner:常熟市新港农产品产销有限公司

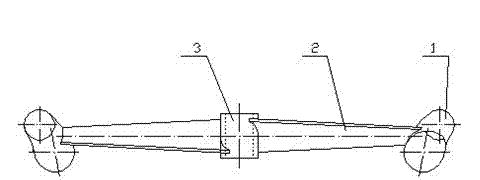

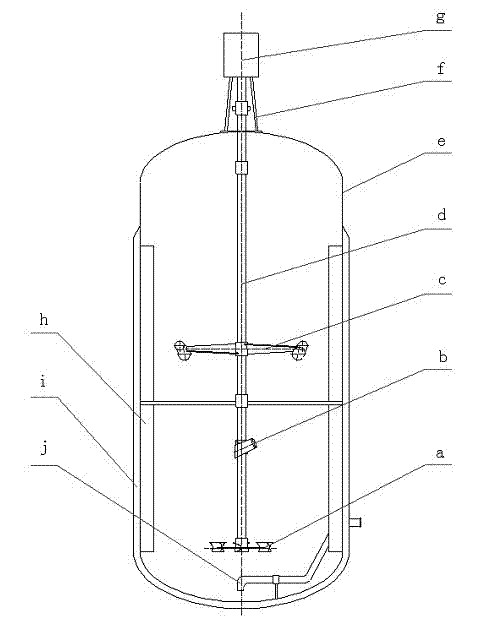

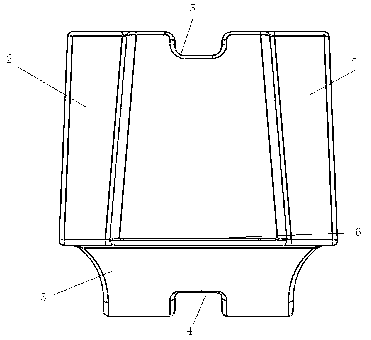

Cross flow guide type stirring paddle applied to fermentation tank

ActiveCN103566797AReduced shear damageNot easy to wear and tearBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringFermentation

A cross flow guide type stirring paddle applied to a fermentation tank belongs to the technical field of chemical machinery. The stirring paddle comprises a hub 3, a cambered surface inclined-blade paddle 2 and a cross flow guide pipe 1, wherein the hub 3 is a hollow cylinder, the cross section of the cambered surface inclined-blade paddle 2 is an arc bulged upwards, two to four blades of the cambered surface inclined-blade paddle are symmetrically distributed on the hub, and the cross flow guide pipe 1 is arranged at the tail end of the cambered surface inclined-blade paddle. The stirring paddle is mounted on a stirring shaft in the tank, is an axial flow stirring paddle and is applicable to the occasions like liquid-liquid blending, gas-liquid dispersion and forced heat transfer. The fluid in the fermentation tank moves axially under the action of the cambered surface inclined-blade paddle, meanwhile, part of the flow is guided to the rear upper part of the outer side of the blade, shocks on the wall of the tank and forms cross flow with the downward axial flow formed by the cambered surface inclined-blade paddle under the action of the cross flow guide pipe at the tail end of the stirring paddle, so that the fluid blending, gas-liquid dispersion and heat transfer are facilitated. The stirring paddle is relatively simple in blade structure, different specifications and sizes can be made according to the requirements, and the manufacturing cost is low.

Owner:JIANGNAN UNIV +1

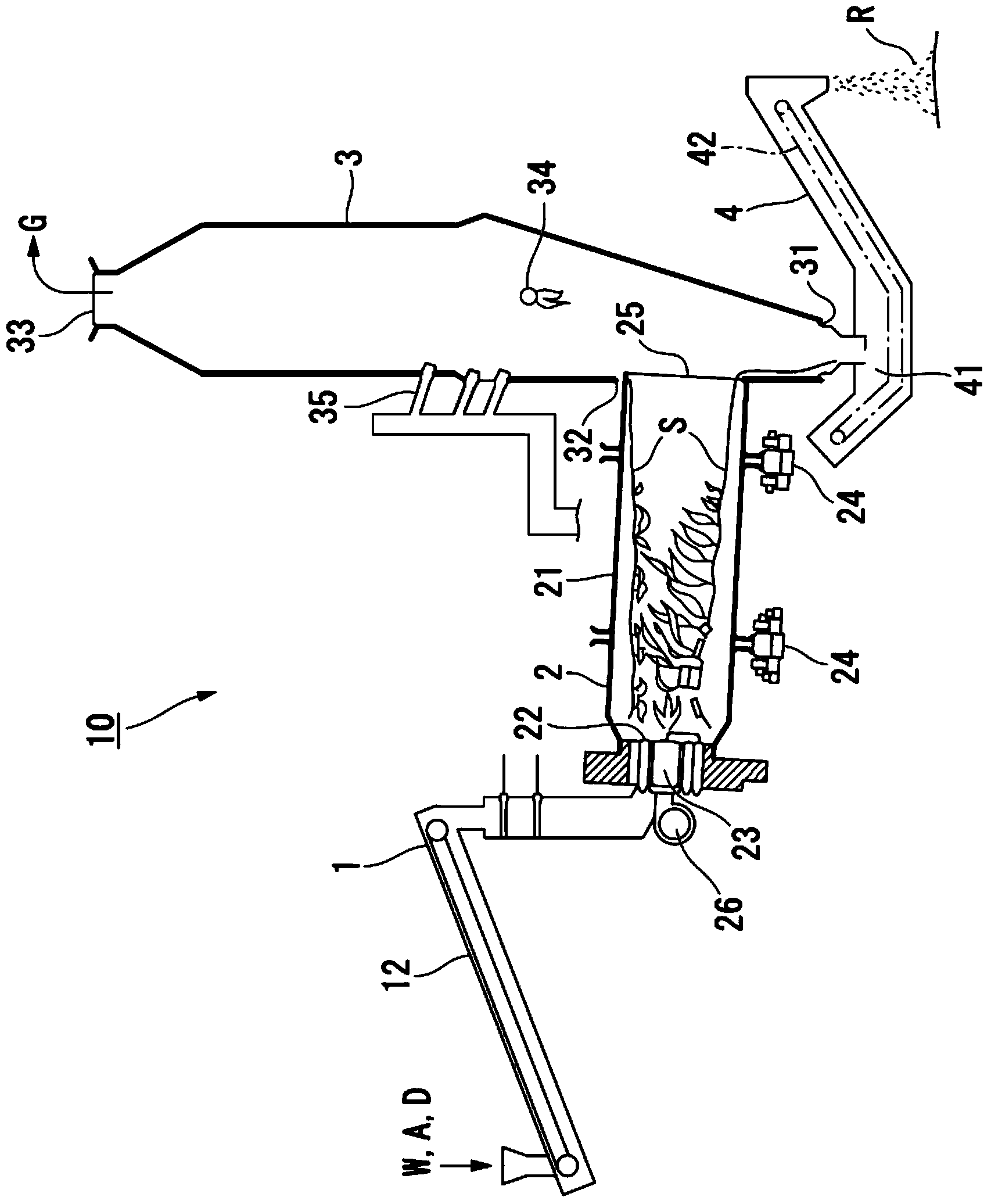

Method for processing starting materials for recycling

ActiveCN104395485AStable processing efficiencySuppress local lossSolid waste disposalTransportation and packagingSlagRotary kiln

A method of treating recyclable raw materials containing valuable metals is provided, the method including the steps of: feeding recyclable raw materials (W) containing valuable metals into a rotary kiln furnace (2) in which a refractory product having an Al 2 O 3 -Cr 2 O 3 content of 70% or greater is used for an inner wall; feeding an additive (A) containing SiO 2 as a major component into the rotary kiln furnace (2) so as to increase a viscosity of a slag (S) flowing along the inner wall, thereby the recyclable raw materials (W) are attached on the slag (S) having a high viscosity such that at least part of the recyclable raw materials (W) is exposed to the inside of the rotary kiln furnace; and burning / melting the recyclable raw materials (W) attached on the slag (S) in the rotary kiln furnace (2).

Owner:MITSUBISHI MATERIALS CORP

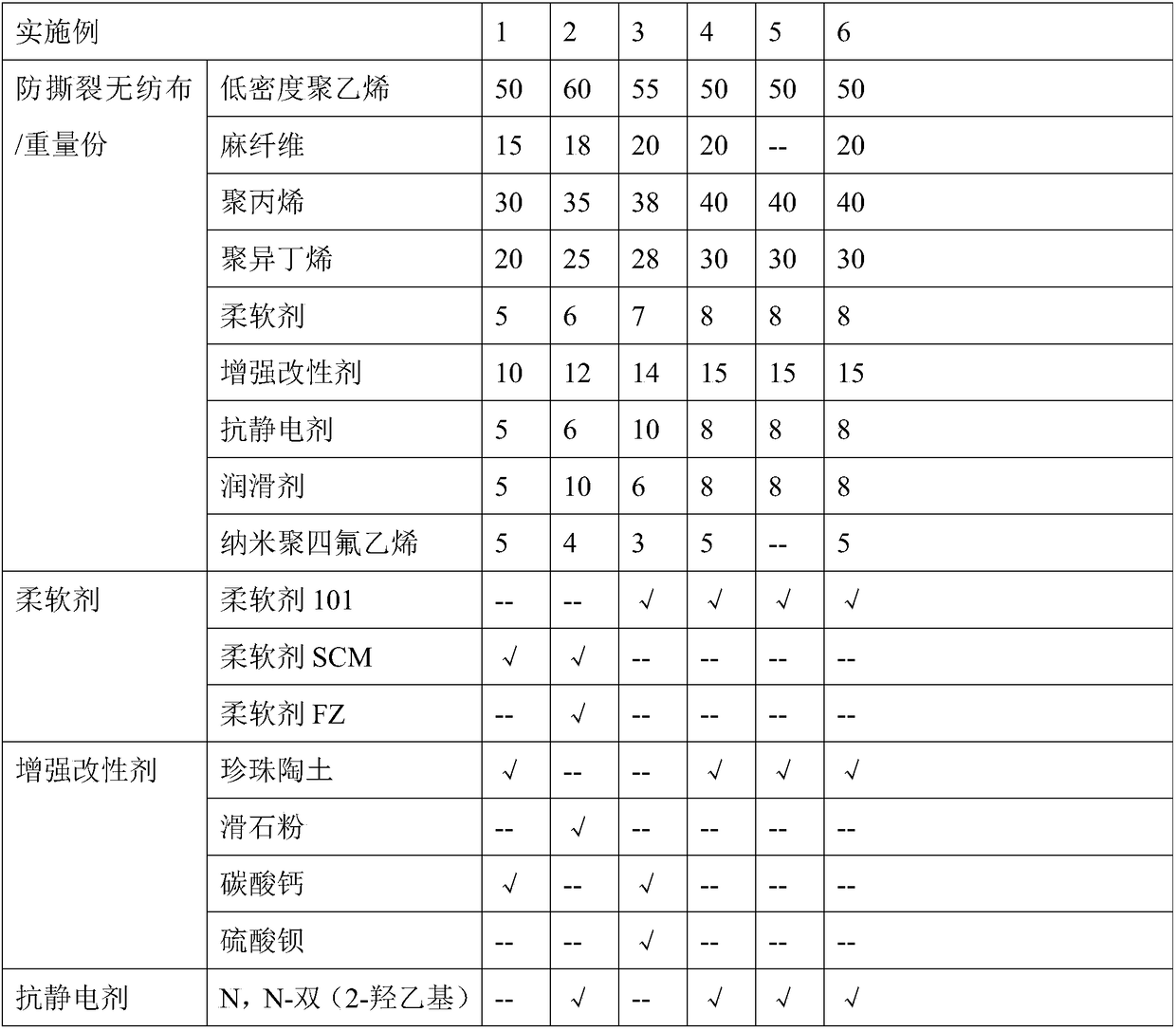

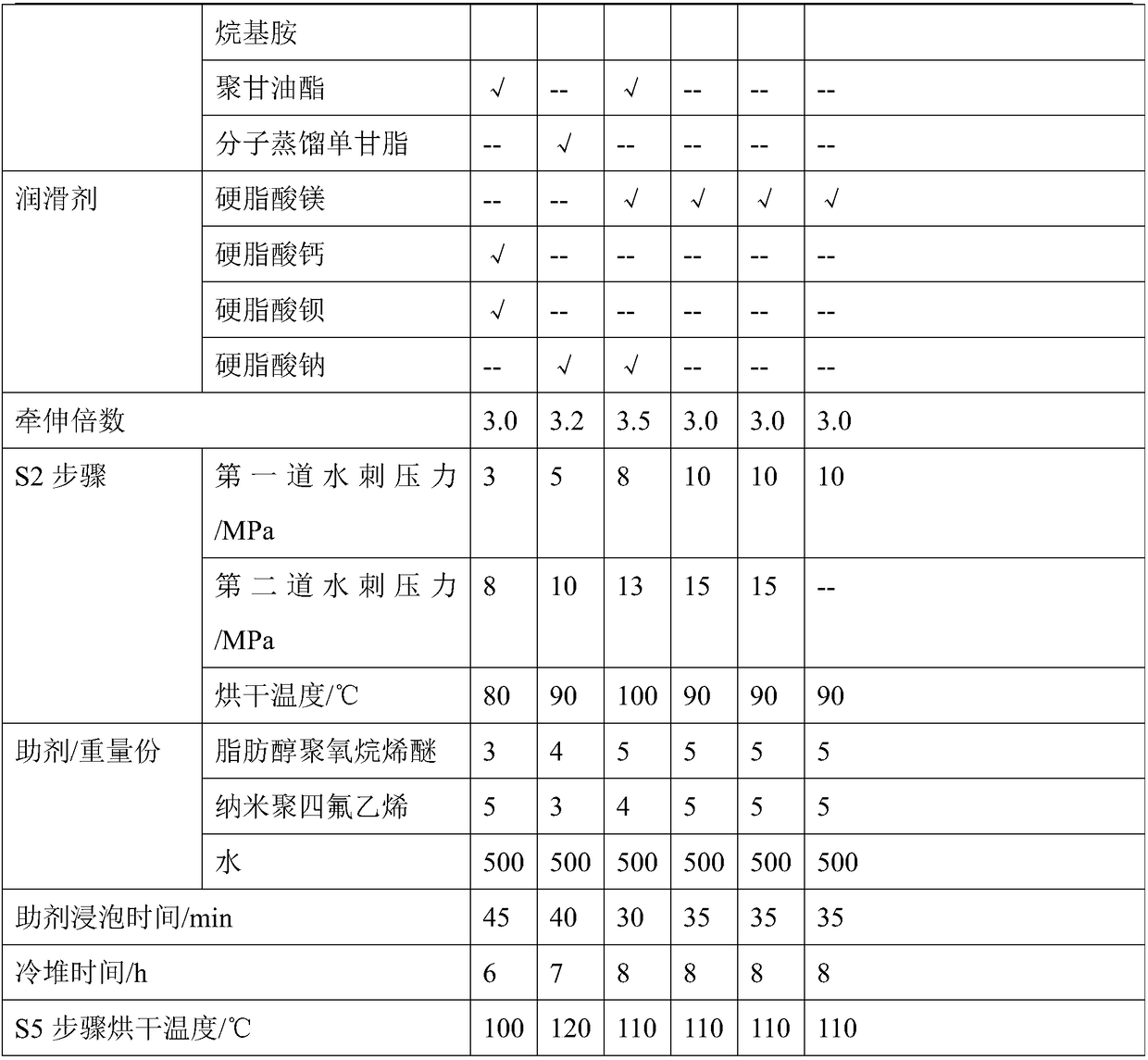

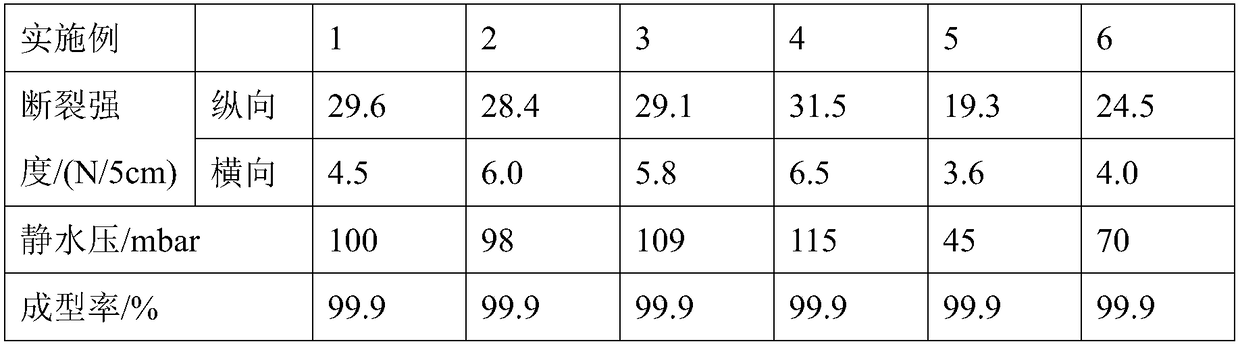

Anti-tearing non-woven fabric and preparation method thereof

ActiveCN108950866AReduce breakage rateGood touchNon-woven fabricsVegetal fibresLow-density polyethyleneNonwoven fabric

The invention relates to anti-tearing non-woven fabric and a preparation method thereof, and belongs to the technical field of non-woven fabric and preparation thereof. The anti-tearing non-woven fabric is prepared from, by weight, 50-60 parts of low-density polyethylene, 15-20 parts of fibrilia, 30-40 parts of polypropylene, 20-30 parts of polyisobutene, 5-8 parts of softening agent, 10-15 partsof reinforced modifier, 5-10 parts of antistatic agent, 5-10 parts of lubricating agent and 3-5 parts of nano polytetrafluoroethylene. The preparation method comprises the following steps of fiber webpreparation, wherein raw materials are subjected to fusion, mixing and opening and then are carded by a carding machine to form a web to obtain a fiber web, and a drafting machine carries out drafting on the fiber web; spunlacing, wherein the drafted fiber web is fed into a spunlacing area for primary spunlacing and secondary spunlacing to form the non-woven fabric; drying, cold bleaching, washing and drying. The anti-tearing non-woven fabric and the preparation method thereof have the advantages that the breaking strength is high, the hydrostatic pressure is high, and the molding rate is high.

Owner:FUJIAN GUAN HONG IND

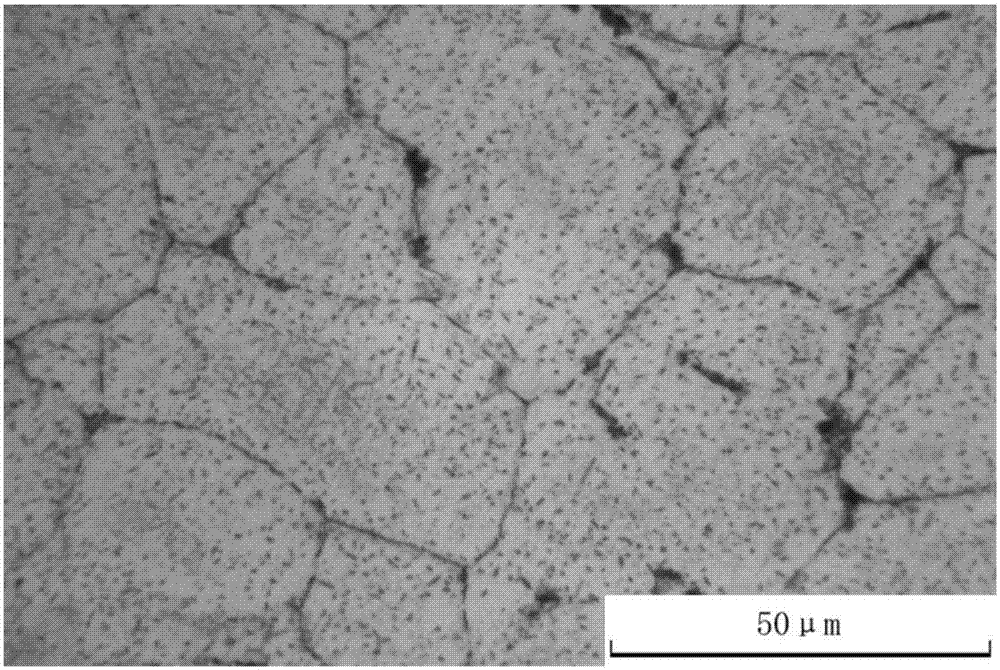

High silicon ball iron injection molding machine template casting preparing method

InactiveCN107513658AImprove mechanical propertiesSolve the shrinkage cavityProcess efficiency improvementSlagMolding machine

Disclosed is a high silicon ball iron injection molding machine template casting preparing method. The method comprises the steps that raw materials comprises, by weight, 40-50% of pig iron, 20-30% of scrap steel, 20-30% of foundry returns, 1-1.4% of silicon iron and 0.004-0.005% of Sb, and are configured; melting is conducted, sampling analysis and blending composition are conducted; firstly, a rare earth magnesium nodularizer and Sb are correspondingly placed on the two sides of a bottom transverse blocking of a nodulizing bag, scrap steel sheets covers the surface of the rare earth magnesium nodularizer, and molten iron is poured into the nodulizing bag with Sb on one side, after the nodulizing reaction begins, a ladle-to-ladle inoculant is added into the nodulizing bag for inoculation, meanwhile, the molten iron is stirred, and melting of the ladle-to-ladle inoculant is promoted; and slag removal and pouring are conducted. The high silicon ball iron injection molding machine template casting preparing method has the advantages that the defects such as shrinkage and shrinkage cavity of a casting can be effectively solved, and the brittleness of the casting can be reduced, thus the scrap rate of during high silicon ball iron injection molding machine template casting manufacturing can be greatly reduced.

Owner:RIYUE HEAVY IND

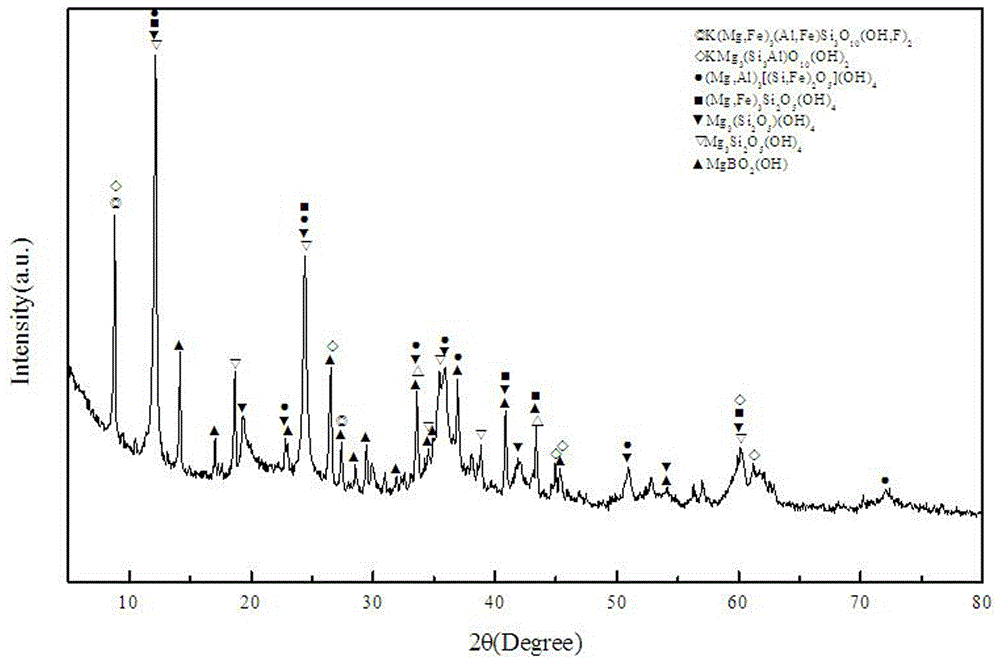

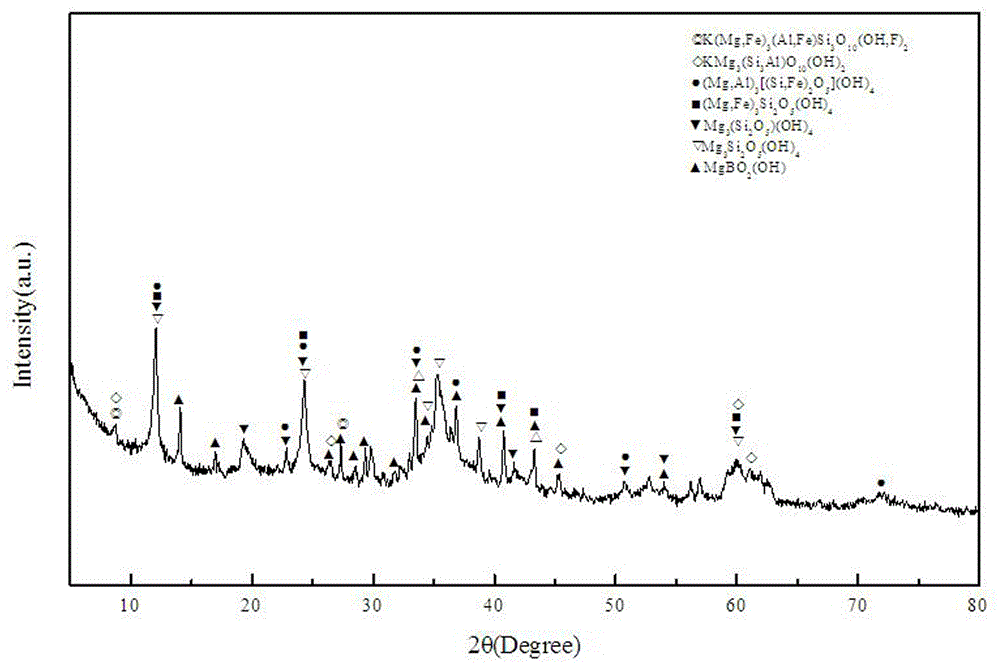

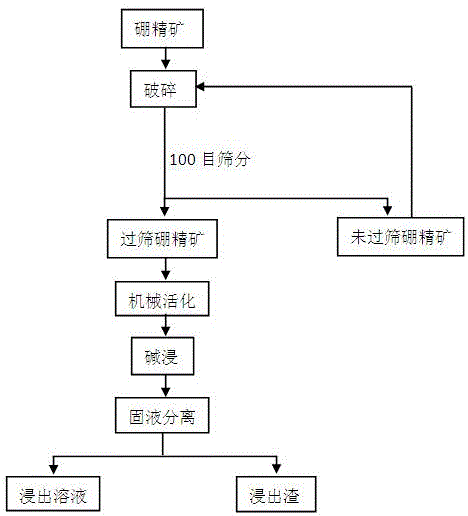

A process of increasing the boron leaching rate of a boron concentrate through mechanical activation

ActiveCN106492940AImprove leaching rateReduce dependenceGrain treatmentsBoron compoundsResource utilizationHigh energy

The invention belongs to the field of boron ore resource utilization, and particularly relates to a process of increasing the boron leaching rate of a boron concentrate through mechanical activation. The process includes firstly mechanically crushing the boron concentrate, keeping the crushed boron concentrate as a raw material for later use, adding the crushed boron concentrate raw material into a high-energy ball mill, performing mechanical activation to obtain a mechanically activated boron concentrate with the mass ratio of grinding balls to the boron concentrate raw material being (4-16):1, the diameter of the grinding balls being 3-10 mm, the filing ratio of the grinding balls and the boron concentrate in a ball milling tank is 30-70%, a ball milling rotary speed being 100-300 r / min and ball milling time being 10-120 min, stirring with a sodium hydroxide solution, heating the mixture, and leaching the mechanically activated boron concentrate to obtain a boron-containing leachate and leaching slag. The boron leaching rate is 73.1% or above. The process in which mechanical activation and alkali soaking are combined for enhancing boron leaching from the boron concentrate is a simple, safe, economical, environment friendly, efficient and novel process. The process can improve activity of the boron concentrate, and therefore the high boron leaching rate at a low alkalinity and temperature is expected to be acquired.

Owner:NORTHEASTERN UNIV

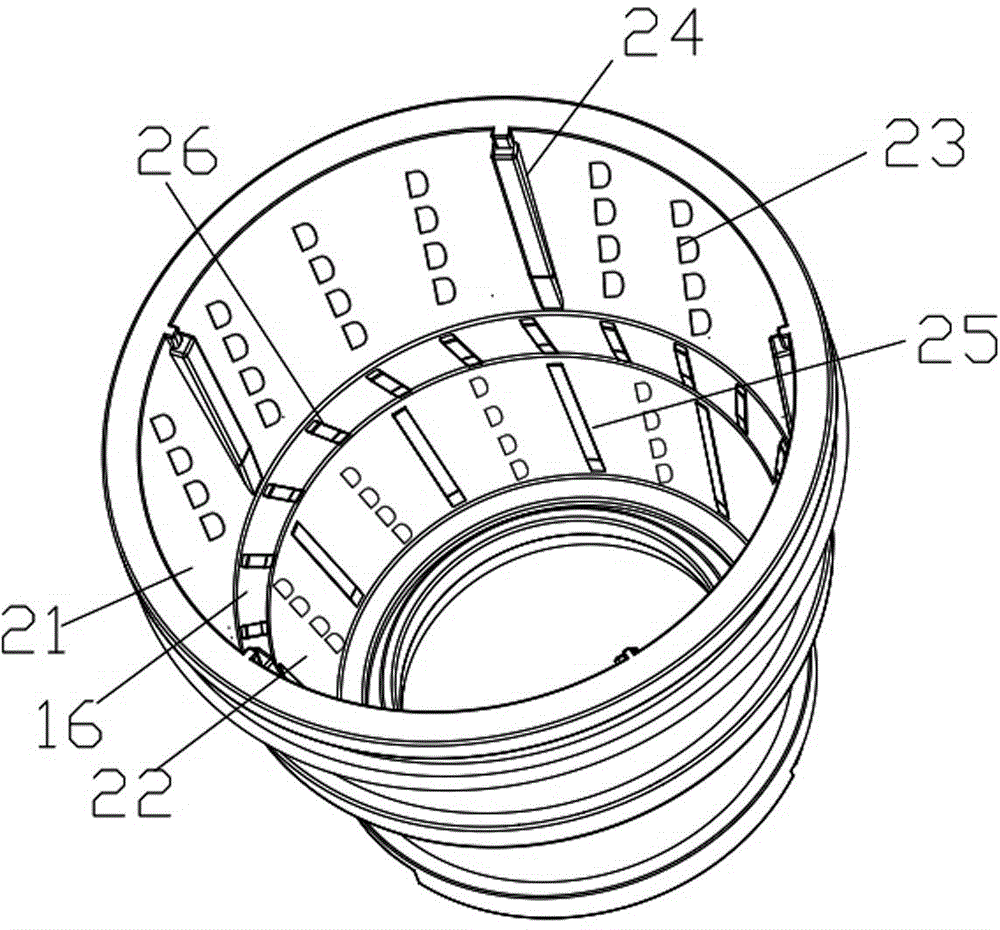

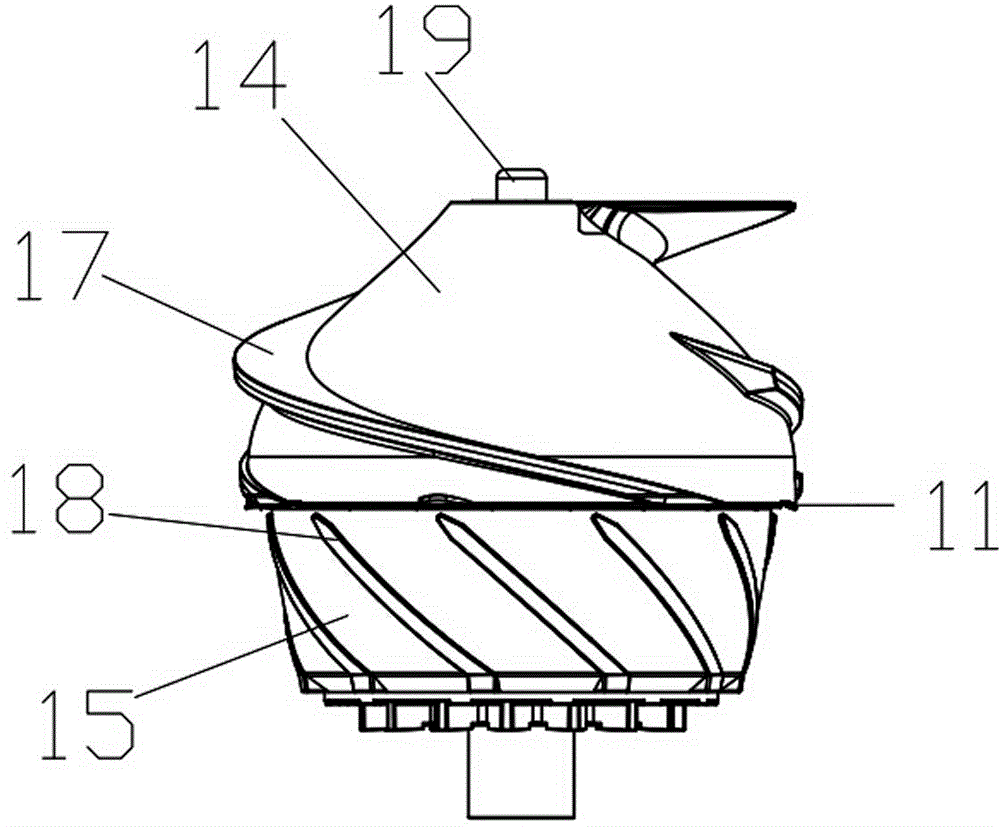

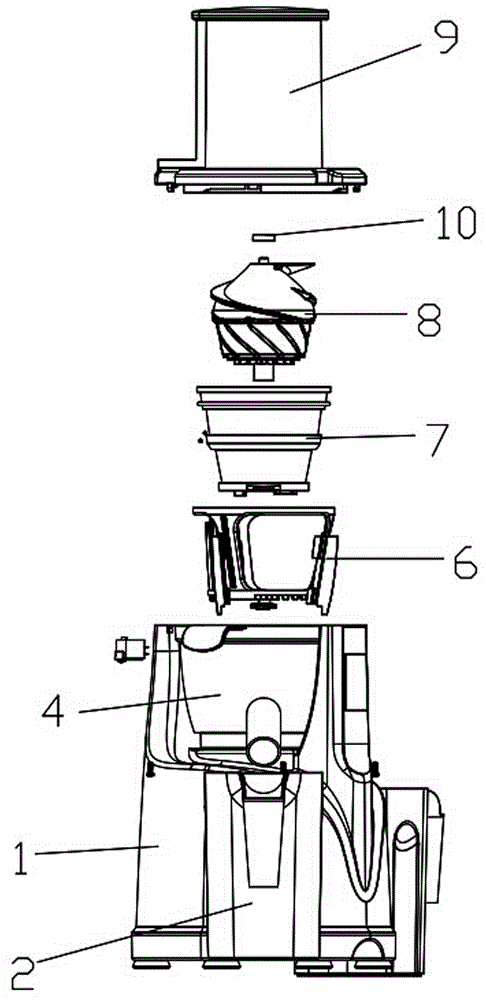

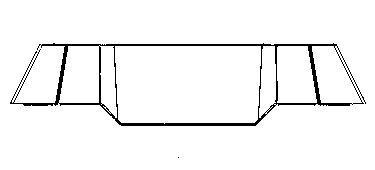

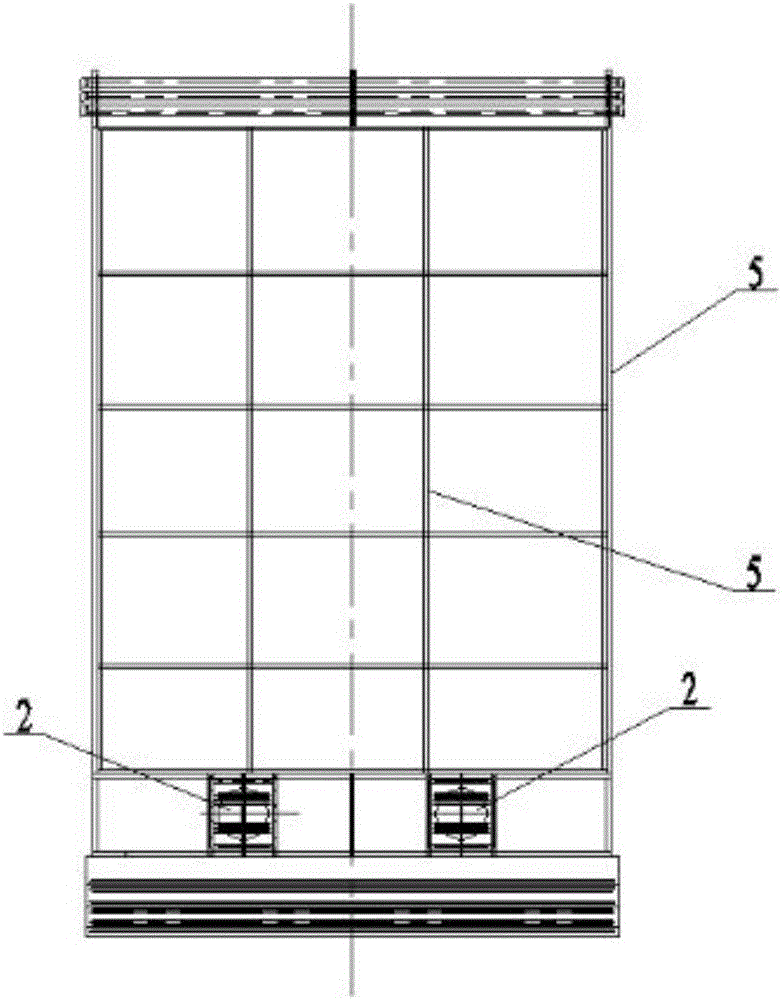

Double-layer net grinding pressing mechanism and double-layer net grinding pressing juice extractor

The invention relates to the technical field of domestic electrical appliance products, in particular to a double-layer net grinding pressing mechanism and a double-layer net grinding pressing juice extractor. The juice extractor comprises a motor box, a motor, a middle cover, a grinding pressing mechanism and an upper cover, wherein the grinding pressing mechanism is composed of a filter screen and a rotor; the filter screen is of a double-layer filter screen structure, and comprises an upper filter screen and a lower filter screen; the rotor comprises an upper coarse grinding part and a lower coarse grinding part; the motor is mounted in the motor box; the middle cover is fixed on the motor box; the filter screen is mounted in the middle cover; the rotor is positioned in the filter screen; the middle cover is covered with the upper cover, and the upper cover is used for hooding the filter screen and the rotor; the rotor is connected to the motor through a rotor shaft. The filter screen and the rotor are designed to form a structure with an upper part and a lower part corresponding to each other, and a grinding pressing structure is newly added through combination; compared with a traditional structure, fruit residues inside the double-layer net grinding pressing mechanism is great in stress, high in juice extraction speed and high in juice yield, the content of fibers is also improved, and the juice extractor has a more obvious juice extraction effect for raw materials with hard shells such as beans.

Owner:东莞溢丰电器有限公司

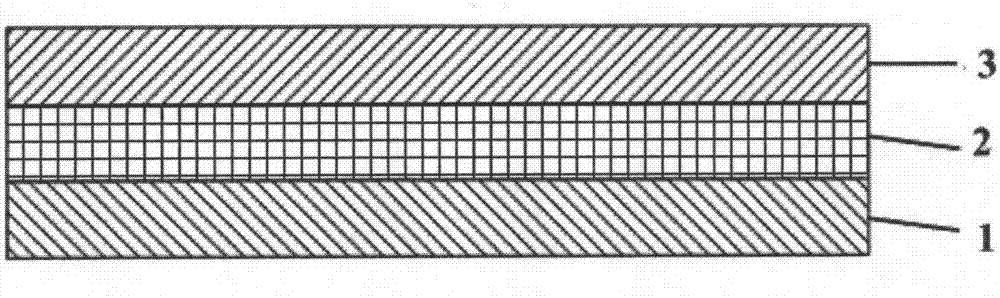

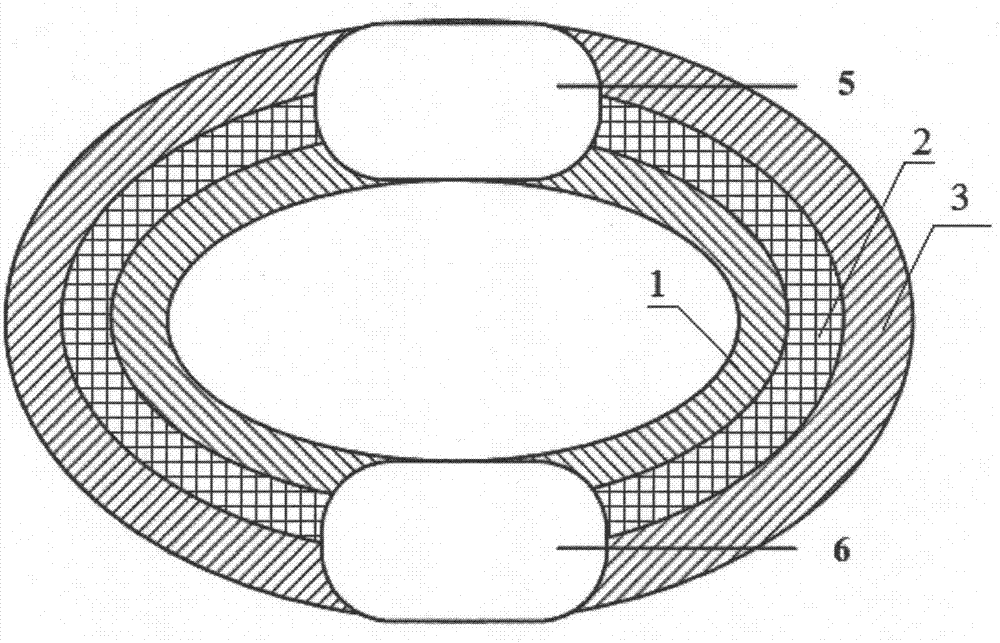

Elastic conductive composite fabric and preparation method thereof

ActiveCN106003875AIncrease elasticityImprove conductivitySynthetic resin layered productsClothingsEngineeringSmart material

The invention provides an elastic conductive composite fabric and a preparation method thereof. The elastic conductive composite fabric is characterized by comprising spandex elastic fabric, an adhesive layer, a flexible nano-conductive film, another adhesive layer and spandex elastic fabric from the top to the bottom in sequence. The conductive composite fabric prepared according to the preparation method of the invention has good electrical conductivity (10<3>S / m to 10<5>S / m), good elasticity and high elongation (20% to 50%), and can bear bending and compression deformation. The elastic conductive composite fabric can be used in the production of intelligent wearable clothing, and has wide application in the fields of intelligent textile structures and intelligent materials.

Owner:DONGHUA UNIV

A kind of elastic conductive film material and preparation method thereof

InactiveCN105869720BGood flexibilityIncrease elasticityConductive layers on insulating-supportsCarbon-silicon compound conductorsPolymer scienceAdhesive

The invention provides an elastic conducting film material and a preparation method thereof. The preparation method of the elastic conducting film material comprises steps as follows: an elastic film is selected as an elastic attaching base body, certain pull force is applied to two ends of the elastic film, the elastic film is stretched to certain elongation and then fixed, the surface of the elastic film is coated with a liquid elastomeric adhesive, and an adhesive layer is formed; a flexible nano conducting film is pressed on the adhesive layer; the upper side of the flexible nano conducting film is coated with resin with a protection function, so that the adhesive and the resin are cured; the pull force applied to the elastic attaching base body is released, the flexible nano conducting film is driven to retract, and the elastic conducting film material can be prepared. The prepared conducting film material has the characteristics of certain elasticity, good flexibility, stable electrical property and the like; a carbon nanotube film is protected in a resin coating manner, wearing and electric leakage are not easily caused, and the electric safety and the durability of the material are improved.

Owner:DONGHUA UNIV

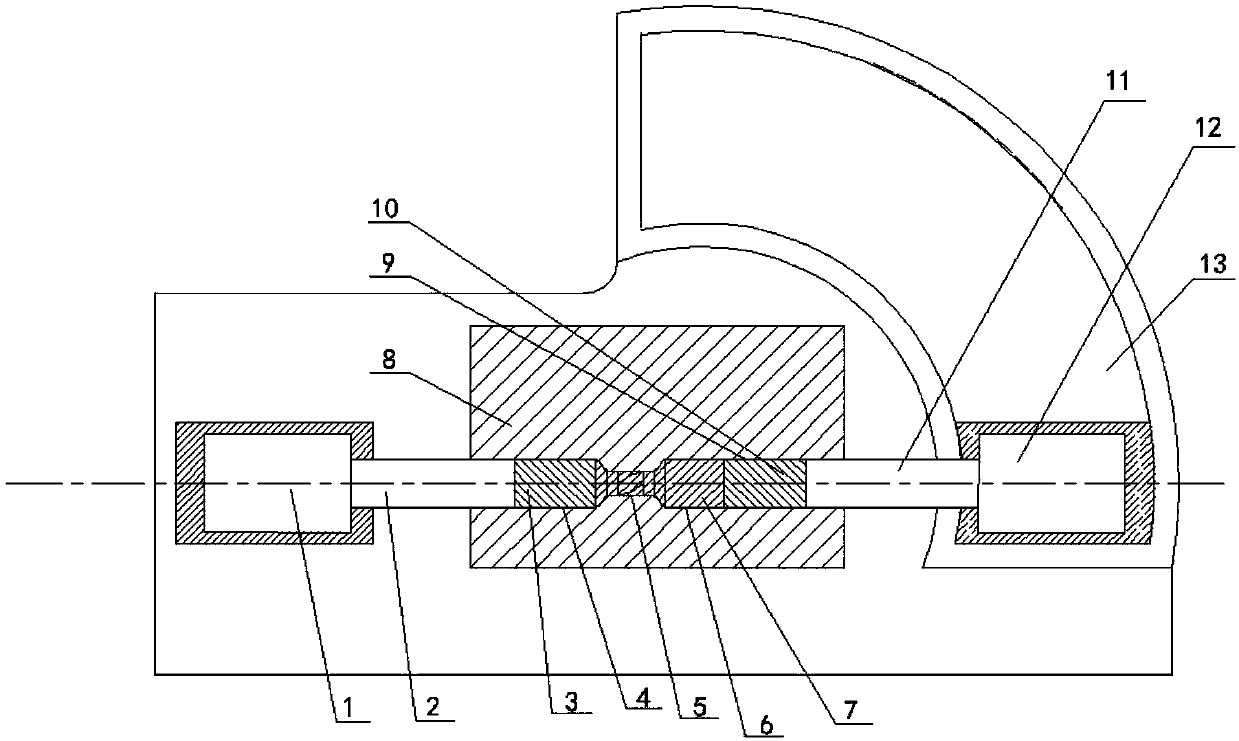

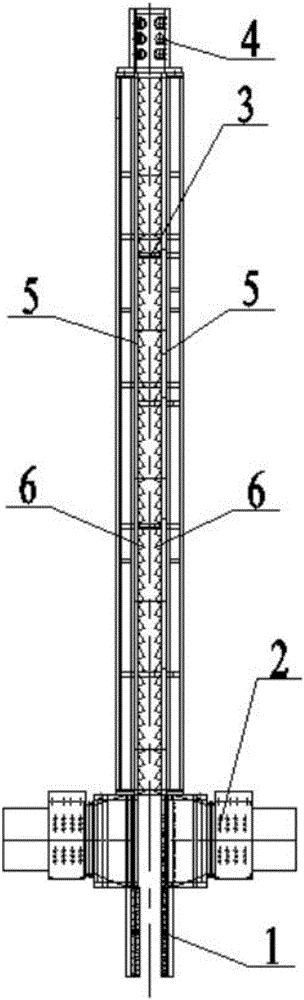

Reciprocating twisting and upsetting isometric angle forming method for preparing ultra-fine grain material

ActiveCN107893201ASolve the problem of uneven strainSolve the problem of limited sample sizeHydraulic cylinderUltra fine

The invention discloses a reciprocating twisting and upsetting isometric angle forming method for preparing an ultra-fine grain material. Based on a multi-station forming hydraulic machine, a combinedfemale die is adopted as the die, wherein an upper die and a lower die of the combined female die are split. An upper sliding block in the multi-station forming hydraulic machine is used for providing die combining force needed by the combined female die, and a die inner cavity of the combined female die is formed by sequentially connecting a left-side extruding channel, a twisting channel, a right-side extruding channel and an isometric angle extruding channel. Due to the fact that a left-side hydraulic cylinder located at the inlet end of the left-side extruding channel and a right-side hydraulic cylinder located at the inlet end of the isometric angle extruding channel are used for providing extruding force and back pressure force in turns. The right-side hydraulic cylinder is arrangedon an arc sliding rail, the position of the right-side hydraulic cylinder in the arc sliding rail is adjusted so that the set angle of the isometric angle extruding channel can be obtained. By meansof the reciprocating twisting and upsetting isometric angle forming method, the grain structure of the material can be refined to the ultra-fine grain level, the material strength and plasticity are obviously improved, the application range is wide, operation is easy and convenient, and industrial application is easy to achieve.

Owner:HEFEI UNIV OF TECH

Vacuum spraying target production equipment

ActiveCN104174544APrevent surface oxidationStable physical propertiesPretreated surfacesCoatingsNumerical controlSurface cooling

The invention discloses vacuum spraying target production equipment with a good spraying effect. The vacuum spraying target production equipment comprises a stander, a dust removal recycling device and a numerical control water cooling device, wherein a vacuum pipe is arranged on the stander; a target base material and a plasma spraying gun are arranged in the vacuum pipe; a coating layer thickness measurer, a coating layer temperature measurer, a spraying bin cooling water inlet, a nitrogen protection gas inlet, a negative pressure gas opening, a target surface cooling liquid nitrogen inlet and a vision monitoring opening are arranged on and formed in the vacuum pipe in sequence; the spraying bin cooling water inlet is connected with the numerical control water cooling device through a connection water pipe; the negative pressure gas opening is connected with the dust removal recycling device through a negative pressure pipe; one end of the target base material is connected with one end of a rotating shaft through a joint; the rotating shaft is supported on the stander through a plurality of supporting wheels.

Owner:FAKETE TECH JIANGSU

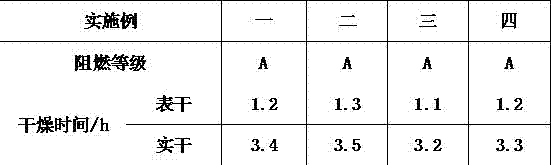

Environment-friendly flame-retardant paint for interior wall and preparation method thereof

The invention discloses environment-friendly flame-retardant paint for an interior wall. The environment-friendly flame-retardant paint is prepared from the following raw materials including water-borne epoxy resin, water-borne acrylic resin, xanthan gum, gelatin, ultrafine silicon dioxide, sodium dodecyl benzene sulfonate, ammonium sulphonate, ammonium polyphosphate, melamine phosphate, coloring agents, ultraviolet absorbers, anti-sedimentation agents, stabilizing agents, ethyl alcohol and water. A preparation method of the paint comprises the following steps of preparing a resin mixed solution; mixing sodium dodecyl benzene sulfonate and melamine phosphate; dissolving and mixing ammonium sulphonate and ammonium polyphosphate; dissolving and mixing xanthan gum and gelatin; mixing auxiliary agents; dispersing ultrafine silicon dioxide. The paint provided by the invention has the advantages of safety, environment-friendly performance, high drying speed, strong impact capability, good flame-retardant performance and excellent anti-aging performance; the operation process is simple; all raw materials are uniformly mixed; the preparation process achieves the pollution-free effect; the production efficiency is high; the paint is applicable to home interior walls.

Owner:六安三创建筑材料有限公司

Grooving blade

InactiveCN102837048ANot easy to wear and tearImprove machining accuracyMilling cuttersMilling equipment detailsIsosceles trapezoidMilling cutter

The invention relates to a grooving blade, characterized in that: the grooving blade is manufactured by integral molding, the blade body (1) is a quadrangular prism that has a side surface which is an isosceles trapezoid, the front and back surfaces of the blade body are respectively provided with a concave-shaped boss (2), the bottom of the blade body is provided with a boss (3) that has a side surface which is a trapezoid, the bottom of the trapezoid boss is provided with a bottom locating slot (4), the top surface of the blade body is provided with a top locating slot (5), and the cutting edge (6) of the blade is arranged at the bottom edges of the side surfaces of the two side trapezoid of the blade body. When the grooving blade works, the grooving blade is fixed on a facing cutter, the locating slot fits a locating key arranged on the base of the facing cutter to locate the cutter; when one side of the cutting edge is worn down, just the turning of the blade is needed, and the other side of the cutting edge is used. According to the invention, the cutting blade has a centrally symmetric structure, continuous work can be conducted without need for presetting the cutter again after turning, and the processing precision is high.

Owner:WUXI YUTIAN PRECISION TOOL

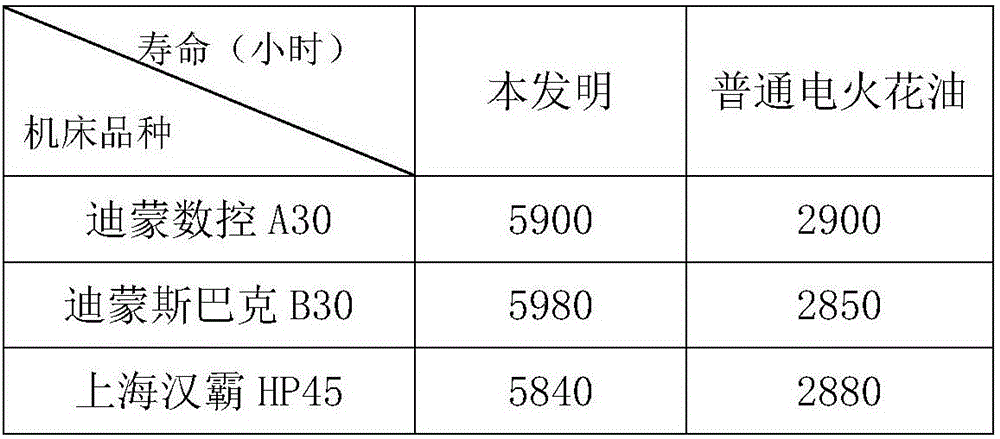

EDM oil for mirror EDM and preparation method therefor

The invention discloses an electric discharge machining (EDM) oil for mirror EDM. The oil comprises the following raw materials in parts by weight: 6 to 10 parts of solvent oil D110 (Nanjing Beautychem Co.Ltd), 0.7 to 1 parts of poly epoxy succinic acid, 2 to 3 parts of dodecyl phenyl succinic acid, 0.1 to 0.14 parts of triallyl isocyanurate, 0.02 to 0.04 parts of 1,2,3 - benzotriazole, 0.1 to 0.2 parts of polyimide, 1 to 2 parts of polyacrylamide, 75 to 85 parts of n-alkanes solvent oil, 0.6 to 1 parts of isopropyl oleate, 1.5 to 2 parts of corrosion inhibitor, 0.05 to 0.06 parts of zinc acetylacetonate, 0.01 to 0.02 parts of polyglycerol fatty acid ester, 2 to 4 parts of N - vinyl pyrrolidone, 0.3 to 0.4 parts of ethyl orthosilicate and 0.1 to 0.2 parts of simethicone. The finished product produced by the invention is high in chemical stability, relatively long in service life, good in environmental protection and outstanding in comprehensive performance.

Owner:浙江模德科技有限公司

Thin film multistage energy-saving drying method and system

InactiveCN106216199AShorten drying timeWon't hurtPretreated surfacesCoatingsEngineeringDirect heating

The invention discloses a thin film multistage energy-saving drying method and system. The thin film multistage energy-saving drying method comprises the steps that a thin film is made to operate in the fixed direction; and the thin film in the operating process is sequentially subjected to double-surface electric heating and drying, double-surface hot air drying and double-surface common air drying. The thin film multistage energy-saving drying system comprises a direct heating type part, an indirect heating and blowing part, a drying box part and an auxiliary blowing part and can conduct double-surface electric heating and drying, double-surface hot air drying and double-surface common air drying on the thin film in sequence. According to the thin film multistage energy-saving drying method and system, double-surface multi-mode drying can be conducted on the thin film, heat is not prone to being lost in the drying process, the drying effect can be improved, the thin film drying time is shortened, and energy sources are saved; and meanwhile, the thin film cannot be damaged.

Owner:山东莱芜新甫冠龙塑料机械有限公司

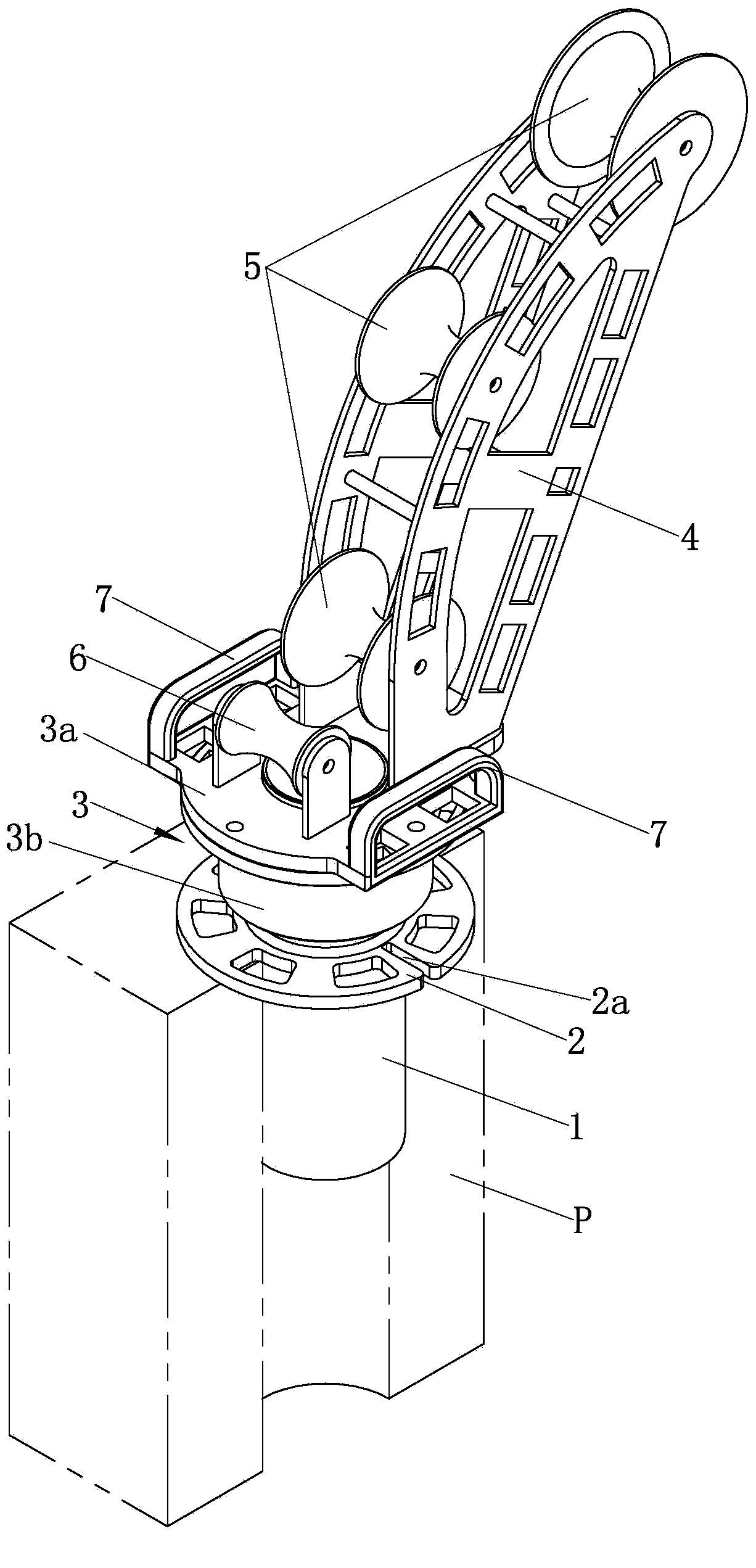

Tube drawing auxiliary device applied to on-site mixed emulsion explosive loading procedure

The invention discloses a tube drawing auxiliary device applied to an on-site mixed emulsion explosive loading procedure. A supporting disc is fixedly arranged at the upper end of a positioning tube in a sleeved mode, a rotary support is composed of an upper round disc part and a lower sleeve-shaped part, central holes of the two parts are concentric, and the rotary support is installed at the upper end of the positioning tube in a sleeved mode through a bearing. A supporting frame is fixedly arranged on the top surface of the round disc part of the rotary support, at least one guide wheel is horizontally arranged on the supporting frame, and the two ends of a supporting shaft of the guide wheel are inserted into corresponding installation holes in the supporting frame. The axis of the guide wheel is perpendicular to the axis of the positioning tube, and an arc-shaped guide groove is formed in the outer circumferential surface of the guide wheel in the circumferential direction. The auxiliary device is matched with a coiling disc on an explosive loading cart to achieve automatic tube drawing, manpower is basically not needed in the tube drawing process, an explosive conveying tube has no friction with the rock at the opening of a blasthole, the explosive conveying tube is not prone to loss, and the use cost is lowered. The coiling disc can pull the explosive conveying tube only with small input power, and the energy consumption is low.

Owner:CHINA GEZHOUBA GRP YIPULI CO LTD

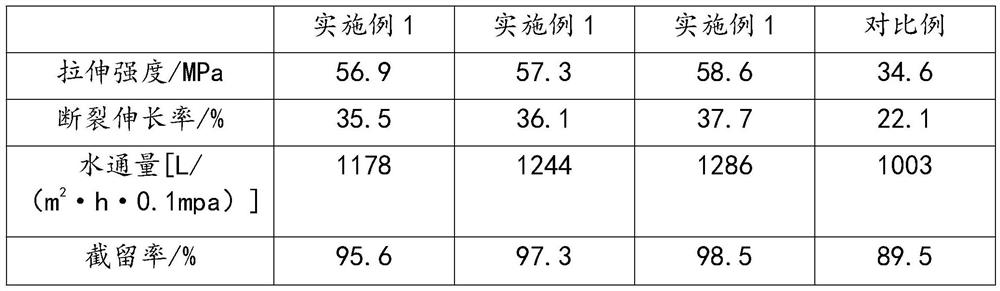

Ultrafiltration membrane for wastewater treatment and preparation method thereof

InactiveCN112108002AIncrease water fluxHigh retention rateMembranesUltrafiltrationUltrafiltrationPolythylene glycol

The invention discloses an ultrafiltration membrane for wastewater treatment and a preparation method of the ultrafiltration membrane. The ultrafiltration membrane is prepared from the following components: chlorinated polyvinyl chloride, modified polyacrylonitrile, polyethylene glycol, polyoxyethylene fatty alcohol ether and dimethylformamide. The ultrafiltration membrane is subjected to hydrophilic modification, so that the infiltration rate of the ultrafiltration membrane is high, the water flux of the ultrafiltration membrane is increased, and the rejection rate of the ultrafiltration membrane is increased; after the polyvinyl chloride is subjected to chlorination modification, the chlorine content of the material is improved, so that the molecular bond polarity of the material is increased, the intermolecular force is enhanced, the chemical stability is improved, and the mechanical property, the chemical corrosion resistance and the heat resistance of the material are greatly improved; polyacrylonitrile is modified, so that precious metal ions and rare metal ions have high adsorption capacity; and the ultrafiltration membrane is good in wastewater treatment effect, good in physical property and mechanical property and not prone to loss, and the wastewater treatment cost is reduced.

Owner:广德华东电子电路发展有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com