Method extracting waste tobacco at subcritical DMC

A subcritical and extraction technology, applied in the fields of tobacco, solvent extraction, and tobacco treatment, can solve the problems of easy thermal denaturation, large one-time investment in fixed assets, and high production costs, so as to solve the technical bottleneck problem, improve the comprehensive utilization rate, The effect of low production running costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

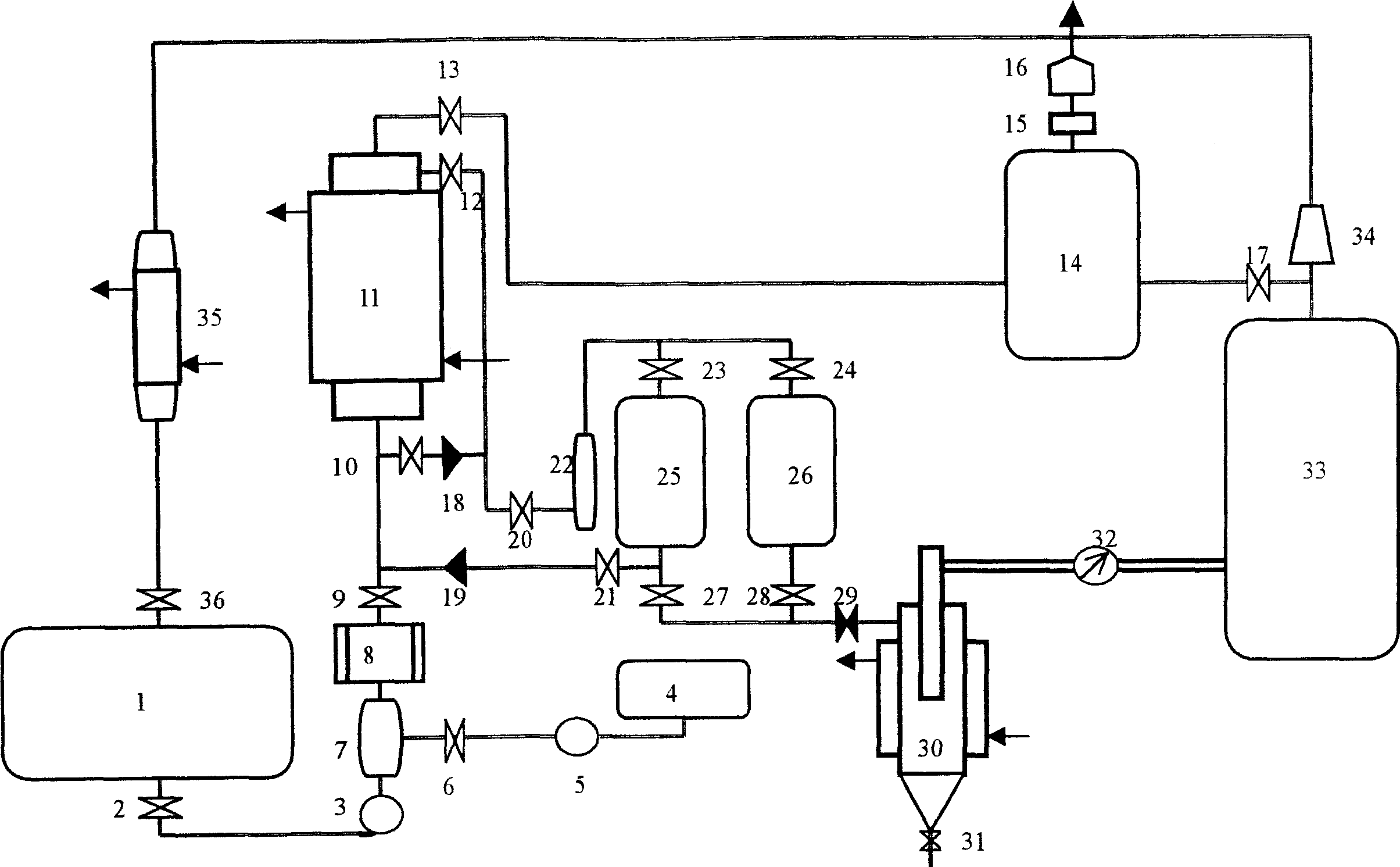

Method used

Image

Examples

example 1

[0043] 100kg tobacco leaves are packed in the extraction kettle, start the vacuum pump to remove the air in the extraction kettle, the main solvent is added in the tobacco leaves by the weight ratio of tobacco leaf: main solvent=1: 6, add and account for 1% ethanol by weight, at a temperature of Under the technological conditions of 30°C and pressure of 0.5Mpa, extract three times continuously, each extraction time is 30 minutes, and the first two extracts are separated in the separation tank under the technological conditions of temperature of 30°C and pressure of 0.1Mpa 3kg, then add the above third extraction solution by tobacco leaf: extraction solution=1:2 weight ratio, add water that accounts for 1% by weight, at a temperature of 30 ° C, a pressure of 0.5Mpa process conditions, extract 30 Minutes, at a temperature of 30°C and a pressure of 0.1Mpa, 3.2kg of crude nicotine was separated.

example 2

[0045] 100kg tobacco leaves are packed in the extraction kettle, start the vacuum pump to remove the air in the extraction kettle, the main solvent is added in the tobacco leaves by the weight ratio of tobacco leaves: main solvent=1: 15, add and account for 5% ethanol by weight, at a temperature of Under the technological conditions of 60°C and pressure of 1.75Mpa, extract three times continuously, each extraction time is 60 minutes, and the first two extracts are separated in the separation tank under the technological conditions of temperature of 60°C and pressure of 0.25Mpa 4.3kg, then add the above third extract by tobacco leaves: extract = 1:5 weight ratio, add water that accounts for 5% by weight, at a temperature of 60 ° C, a pressure of 1.25Mpa process conditions, extraction After 60 minutes, 4.3kg of crude nicotine was separated under the process conditions of a temperature of 60°C and a pressure of 0.25Mpa.

example 3

[0047] 100kg tobacco leaves are packed in the extraction kettle, start the vacuum pump to remove the air in the extraction kettle, the main solvent is added in the tobacco leaves by the weight ratio of tobacco leaves: main solvent=1: 24, add and account for 10% ethanol by weight, at a temperature of Under the technological conditions of 90°C and pressure of 3Mpa, extract three times continuously, each extraction time is 90 minutes, and the first two extracts are separated in the separation tank under the technological conditions of temperature of 90°C and pressure of 0.5Mpa. kg, then add the above third extraction solution by tobacco leaf: extraction solution=1:8 weight ratio, add water that accounts for 10% by weight, at a temperature of 90 ° C, under the pressure of 2Mpa process conditions, extract for 90 minutes , at a temperature of 90°C and a pressure of 0.5Mpa, 4.9kg of crude nicotine was separated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com