Vacuum spraying target production equipment

A production equipment, a technology of vacuum spraying, applied in coatings, devices for coating liquids on surfaces, pretreatment surfaces, etc., can solve the problems of uncontrollable trace element content, long production cycle, and non-recycling of raw materials, and achieve trace elements. The content is controllable, the product quality is improved, and the effect of ensuring good health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

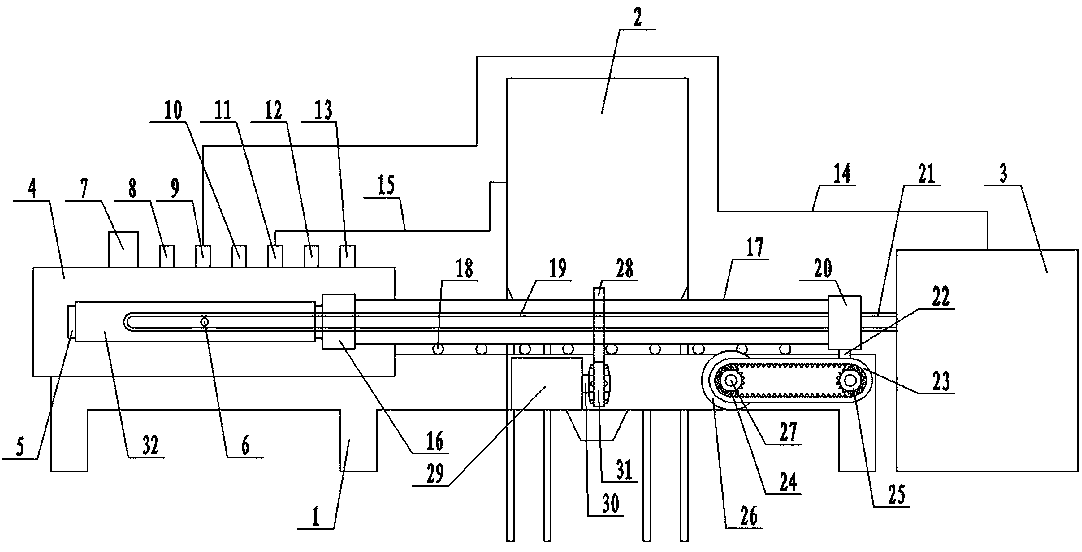

[0009] Such as figure 1 As shown, the target material vacuum spraying production equipment includes: a frame 1, a dust removal recovery device 2 and a numerically controlled water cooling device 3, a vacuum tube 4 is arranged on the frame 1, and a target substrate is arranged in the vacuum tube 4. Material 5 and plasma spray gun 6, coating thickness gauge 7, coating temperature gauge 8, spraying chamber cooling water inlet 9, nitrogen protection gas inlet 10, negative pressure gas port 11, target The material surface cooling liquid nitrogen inlet 12 and the visual monitoring port 13, the cooling water inlet 9 of the spraying warehouse is connected with the numerical control water cooling device 3 through the connecting water pipe 14, and the negative pressure air port 11 is connected through the negative pressure pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com