Honeycombed spherical hollow filler

A honeycomb-shaped, filled body technology, applied in container filling methods, gas/liquid distribution and storage, fire rescue, etc., to achieve the effects of inhibiting diffusion, eliminating explosion points, and reducing economic property and loss of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

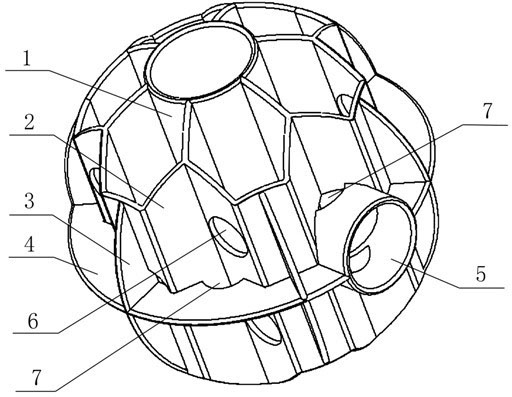

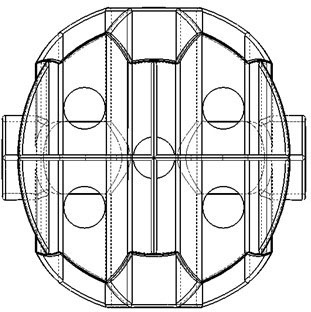

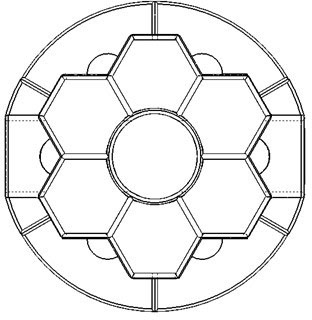

[0082] Such as Figure 1-4 As shown, the honeycomb-shaped spherical hollow filling body has a central tube body 1 that runs through the center, and six honeycomb-shaped hexagons 2 connected in pairs are arranged on the circumference of the center tube body 1, and the center tube body 1 is in the shape of a circle. shape or regular hexagon, the whole honeycomb spherical hollow filling body is supported by the central tube body 1 and the honeycomb hexagon 2;

[0083] The outer surface of each honeycomb hexagon 2 is connected with a longitudinal fan-shaped fin 3, and the fan-shaped fin 3 acts as a reinforcing rib for the honeycomb hexagon 2, and the middle cross section of the central tube body 1 is provided with Circular fins 4 are connected to the outer surfaces of each of the honeycomb hexagons 2 , and the circular fins 4 can strengthen the transverse strength of the central tube body 1 and the honeycomb hexagons 2 .

[0084] One or two penetrating pipe bodies 5 are arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com