Flexible conductive composite fabric, and preparation and application thereof

A composite fabric, flexible and conductive technology, applied in the field of flexible conductive composite fabric and its preparation and application, can solve the problems of increasing the thickness and hardness of the fabric, increasing the difficulty of the weaving process, and poor washing resistance, so as to achieve enhanced conductivity and improved electrical properties. Good safety, durability, and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Material:

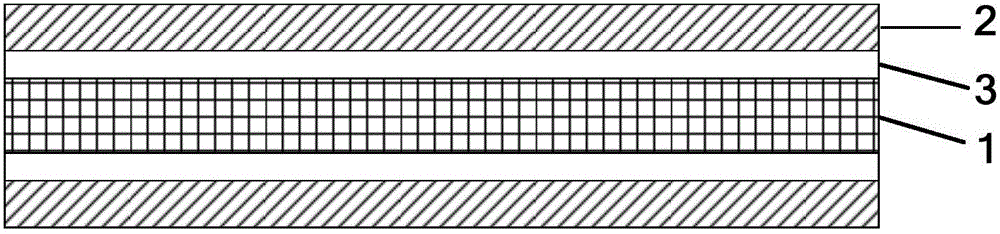

[0031] (1) The selected size is 40×40cm 2 The carbon nanotube membrane 1 (Suzhou Institute of Nanotechnology and Nanobionics, Chinese Academy of Sciences), the thickness of the membrane is 20 μm, the porosity is 75%, the tensile strength is about 200MPa, and the electrical conductivity is about 1*10 5 S / m;

[0032] (2) select the graphene suspension of 2mg / ml (New Material Co., Ltd.);

[0033] (3) The selected aniline monomer (Aldrich Chemical Reagent Company) for polyaniline in-situ polymerization was purified by distillation before use; perchloric acid (HClO 4 ), ammonium persulfate (APS, (NH 4 ) 2 S 2 o 8 ) are products of Sinopharm Chemical Reagent Co., Ltd., and are analytically pure;

[0034] (4) Use ultra-fine and ultra-thin Lycra cloth 2, weight: 110g / m 2 , yarn count: 20D, composition and content: nylon: 80%, spandex: 20%, size 40×40cm 2 .

[0035] (5) Mix PDMS (polydimethylsiloxane) liquid (Dow Corning DC184) and curing agent at a ratio o...

Embodiment 2

[0042] Material:

[0043] (1) The selected size is 40×40cm 2The carbon nanotube membrane 1 (Suzhou Institute of Nanotechnology and Nanobionics, Chinese Academy of Sciences), the thickness of the membrane is 20 μm, the porosity is 75%, the tensile strength is about 200MPa, and the electrical conductivity is about 1*10 5 S / m;

[0044] (2) select the graphene suspension of 2mg / ml (New Material Co., Ltd.);

[0045] (3) The selected aniline monomer (Aldrich Chemical Reagent Company) for polyaniline in-situ polymerization was purified by distillation before use; perchloric acid (HClO 4 ), ammonium persulfate (APS, (NH 4 ) 2 S 2 o 8 ) are products of Sinopharm Chemical Reagent Co., Ltd., and are analytically pure;

[0046] (4) Use 100D polyester four-sided elastic fabric 2, weight: 125g / m 2 , composition and content: polyester: 90%, spandex: 10%, size is 40×40cm 2 .

[0047] (5) Water-soluble polyurethane (Bayer Technology Co., Ltd.) is selected as the adhesive 3, which is ...

Embodiment 3

[0054] (1) The selected size is 40×40cm 2 The carbon nanotube membrane 1 (Suzhou Institute of Nanotechnology and Nanobionics, Chinese Academy of Sciences), the thickness of the membrane is 20 μm, the porosity is 75%, the tensile strength is about 200MPa, and the electrical conductivity is about 1*10 5 S / m;

[0055] (2) select the graphene suspension of 2mg / ml (New Material Co., Ltd.);

[0056] (3) The selected aniline monomer (Aldrich Chemical Reagent Company) for polyaniline in-situ polymerization was purified by distillation before use; perchloric acid (HClO 4 ), ammonium persulfate (APS, (NH 4 ) 2 S 2 o 8 ) are products of Sinopharm Chemical Reagent Co., Ltd., and are analytically pure;

[0057] (4) Select high-density nylon four-sided elastic fabric 2, weight: 168g / m 2 , Composition and content: nylon: 84%, spandex: 16%, size 40×40cm 2 .

[0058] (5) Water-soluble polyurethane (Bayer Technology Co., Ltd.) was selected as the adhesive 3 .

[0059] Preparation step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com