Patents

Literature

57results about How to "Solve printing problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

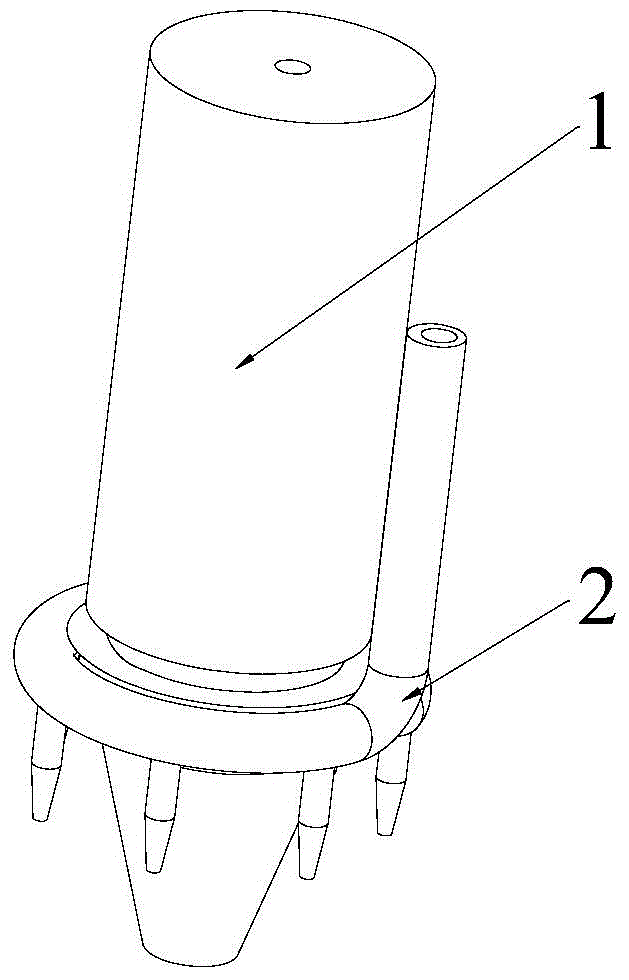

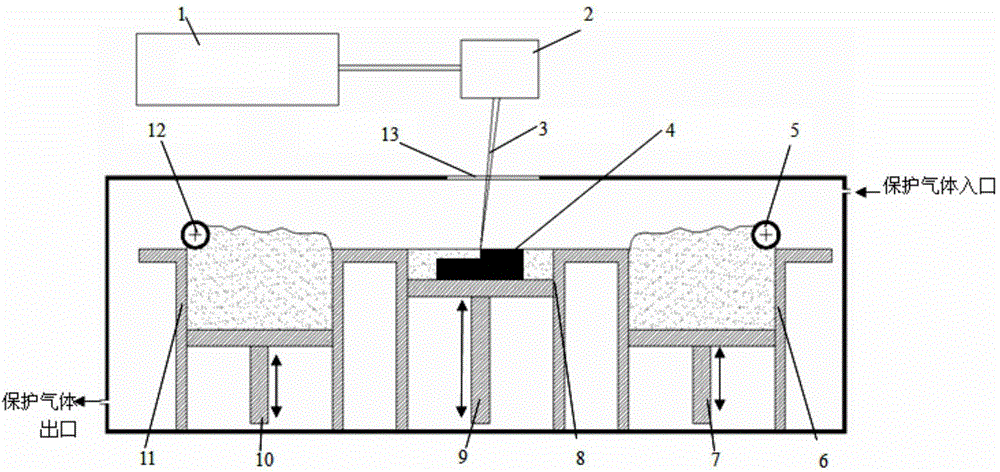

Multi-material multi-scale 3D (3-dimensional) printing device provided with single spray nozzle as well as working method of 3D printing device

ActiveCN105196550ARealize printingReasonable control of macro geometryManufacturing platforms/substratesTransportation and packagingMulti materialSpray nozzle

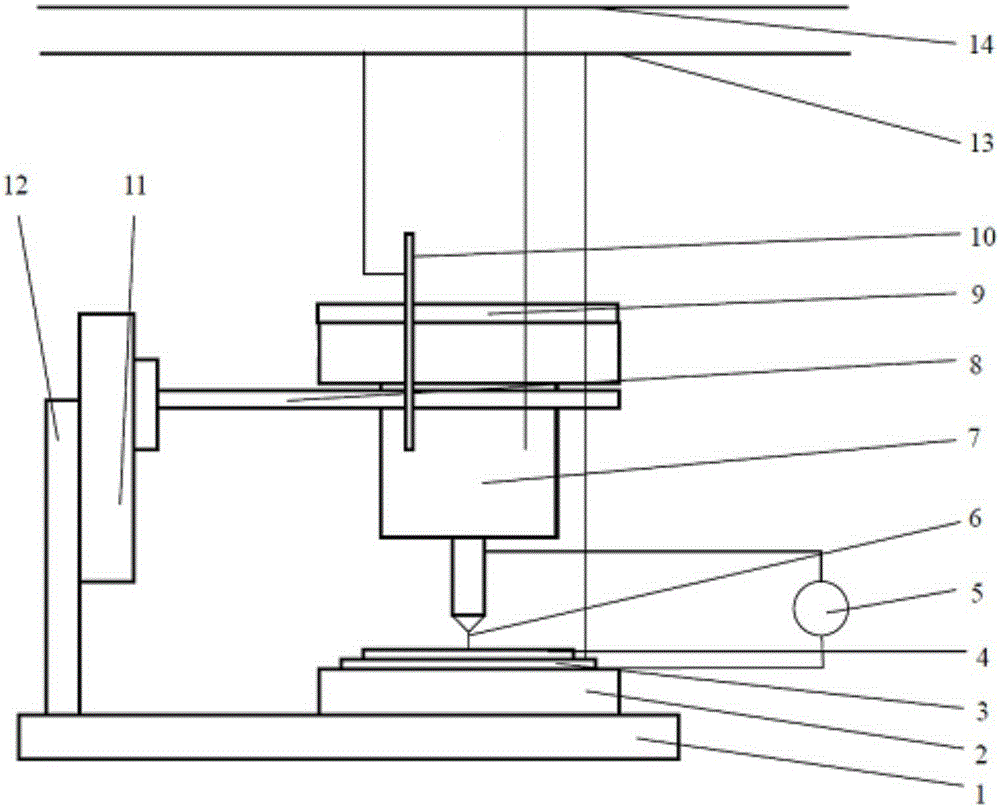

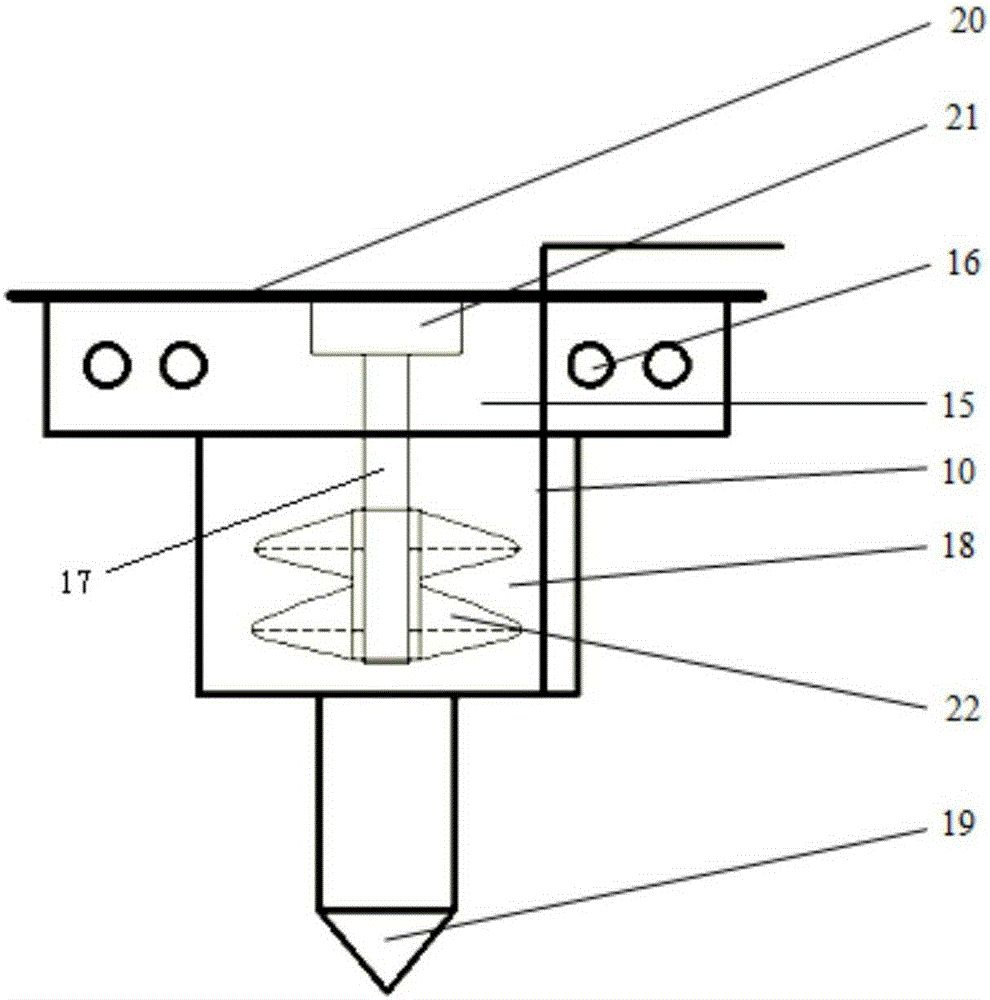

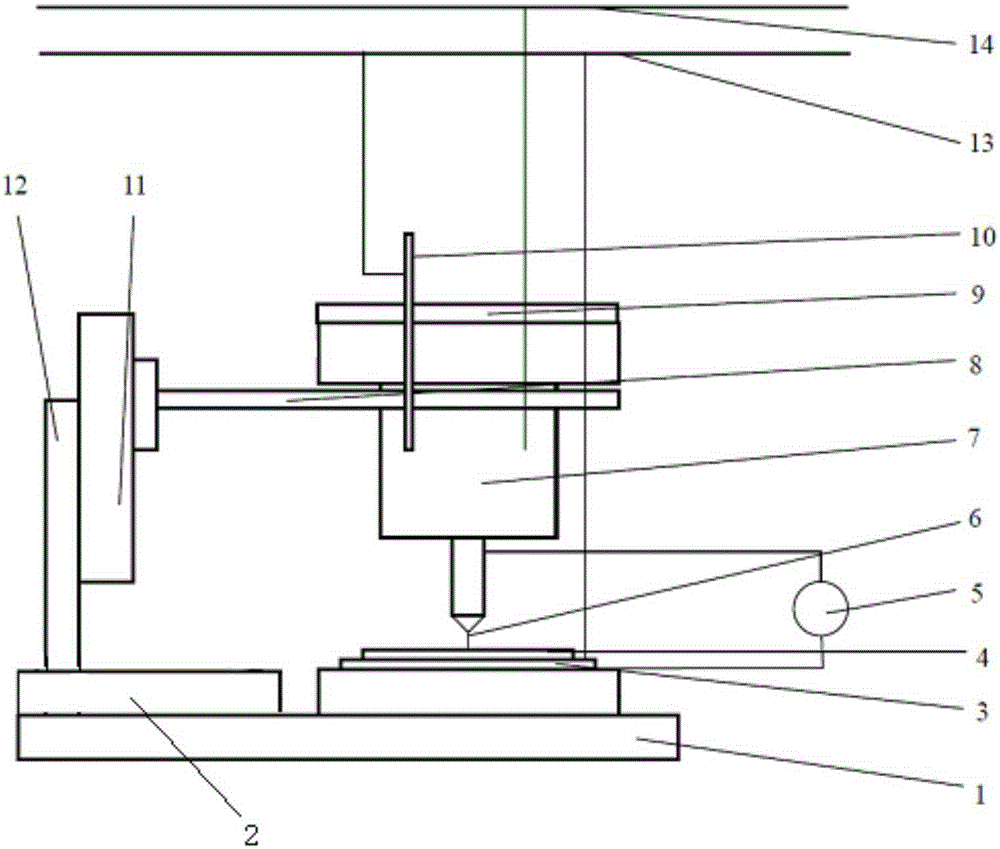

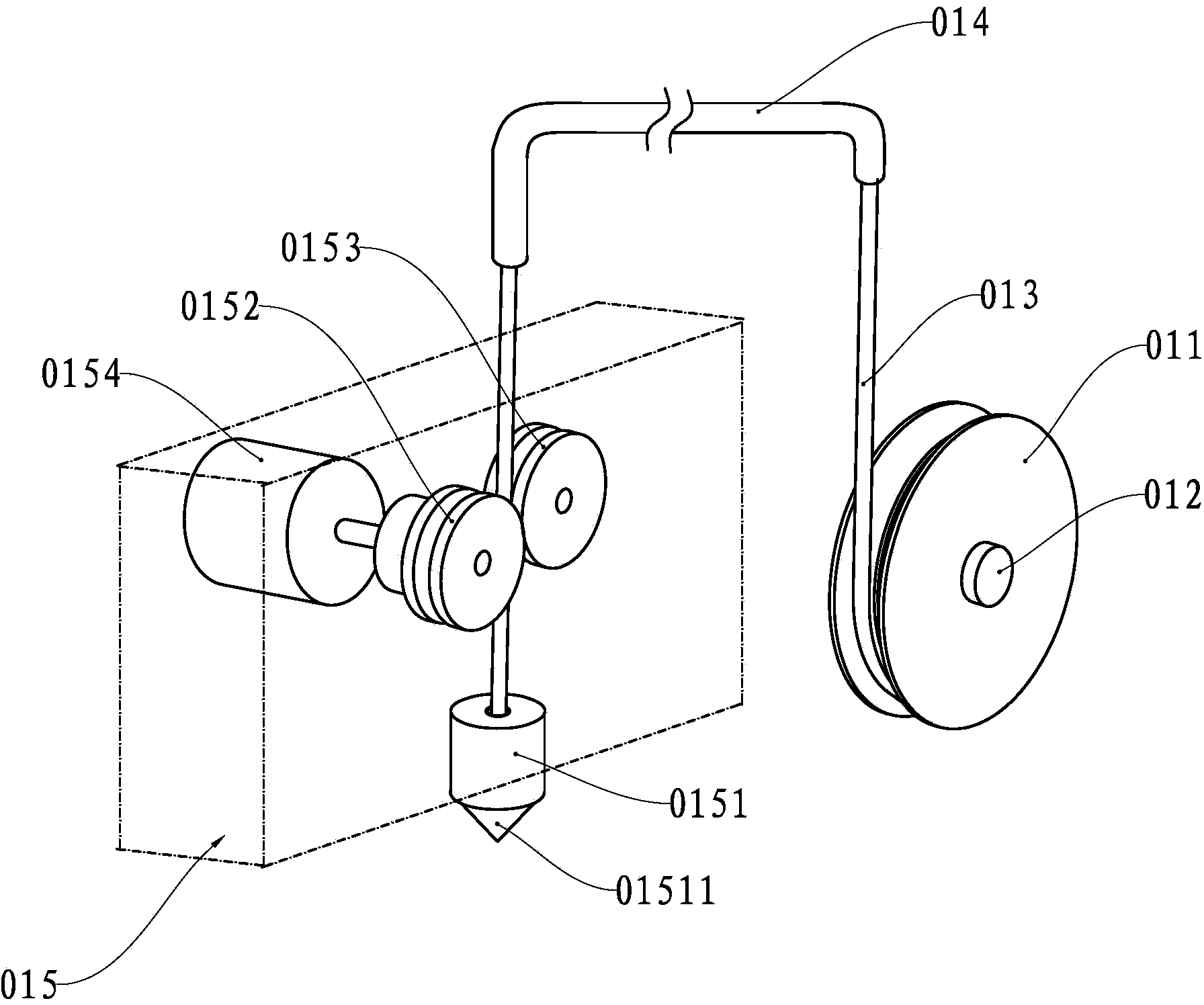

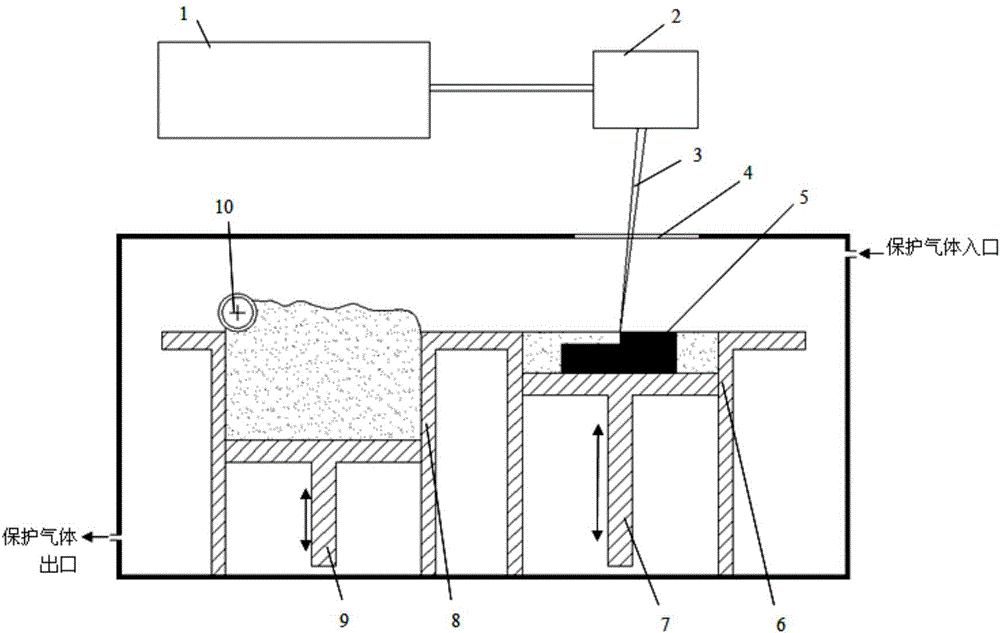

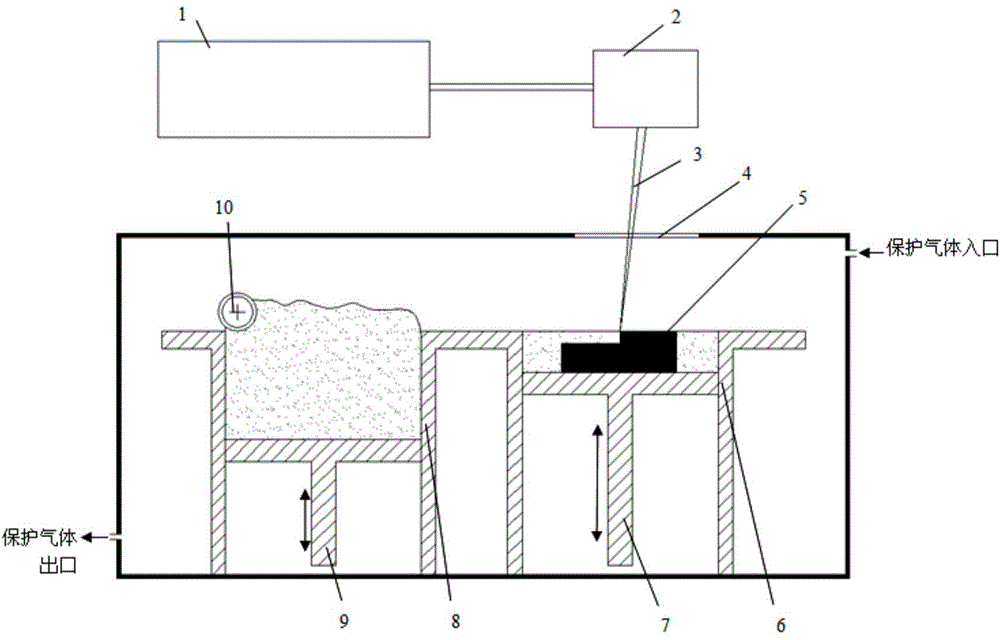

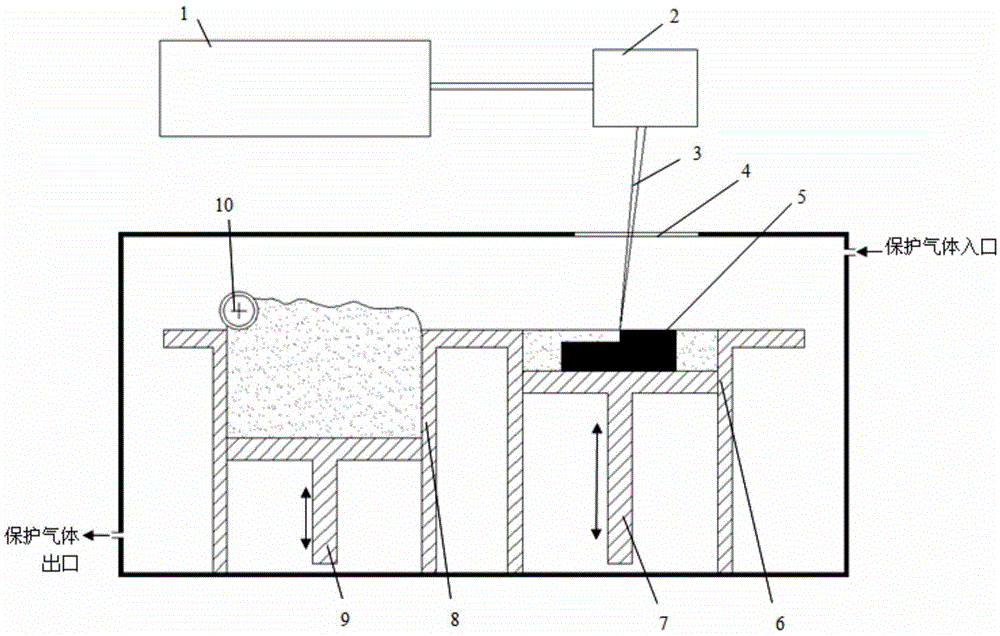

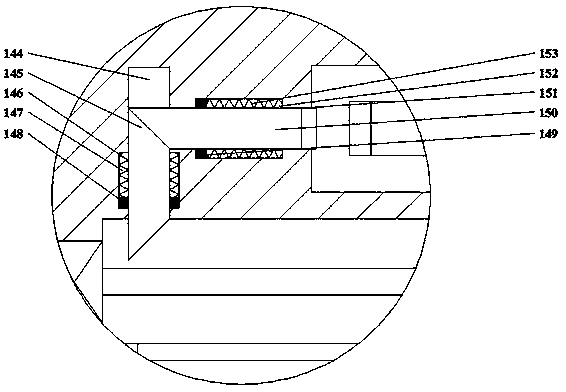

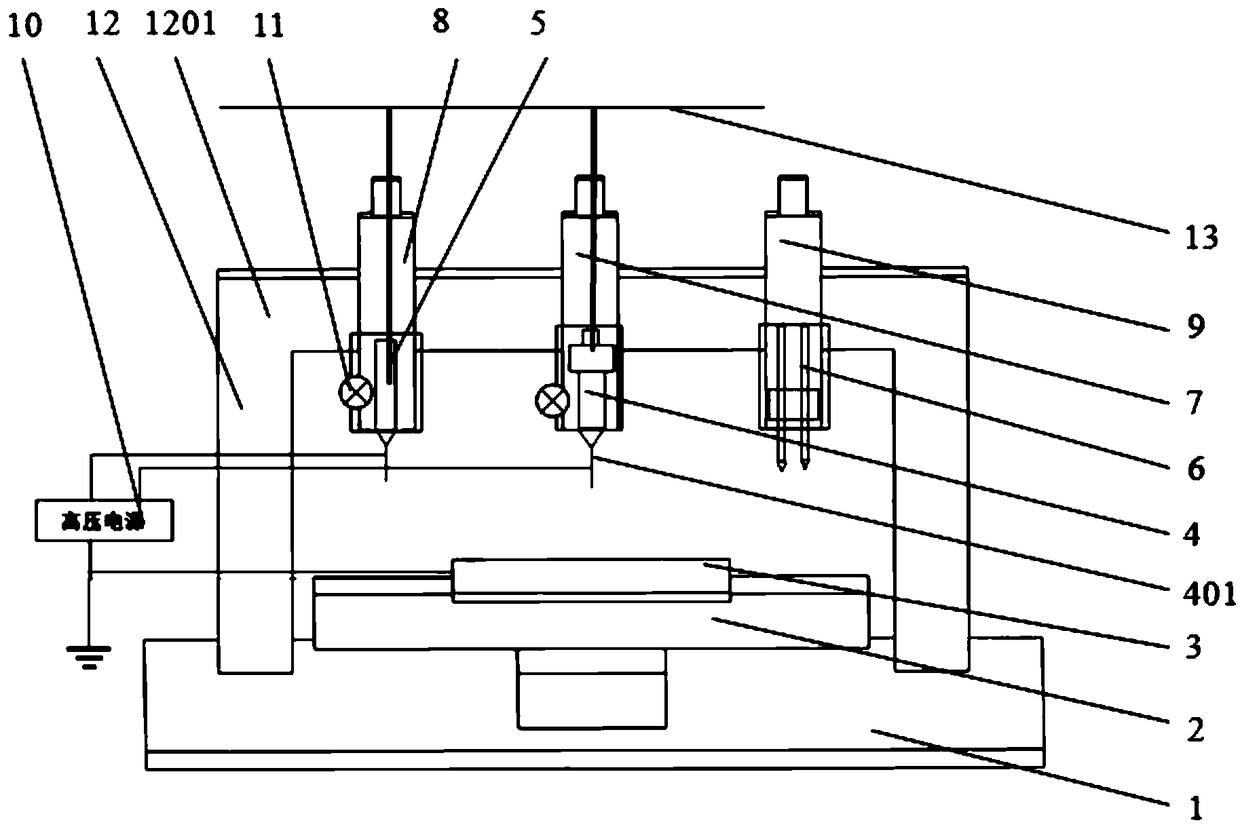

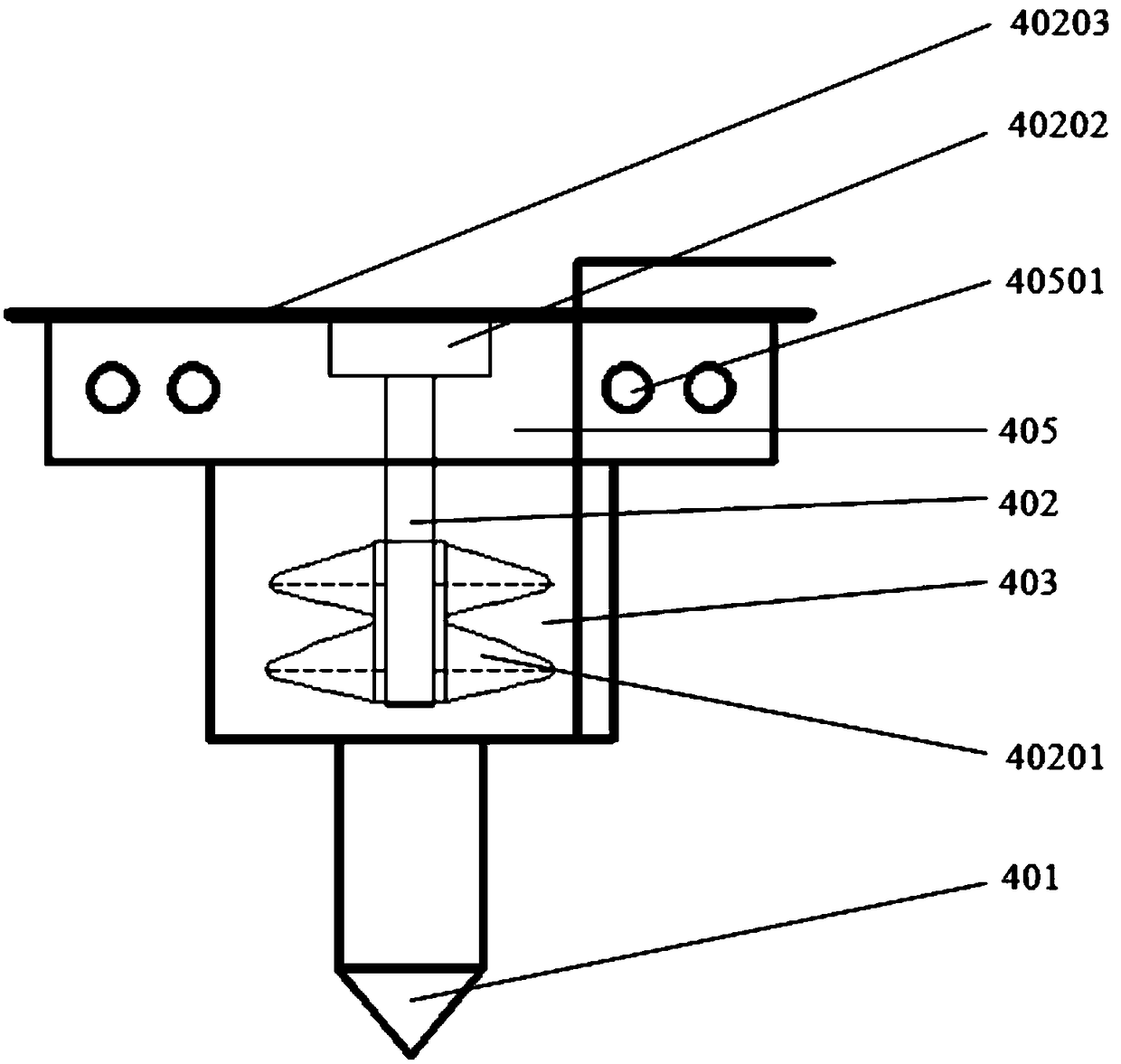

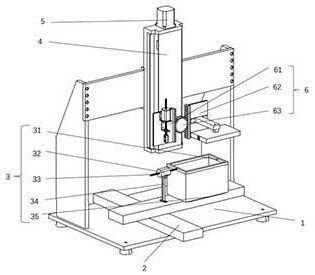

The invention discloses a multi-material multi-scale 3D (3-dimensional) printing device provided with a single spray nozzle as well as a working method of the 3D printing device. The 3D printing device comprises a base, a work table, a bearing table, a substrate, a power supply, the spray nozzle and a bracket, wherein the base is mounted at the bottommost part, the bracket and the work table are mounted above the base, the spray nozzle is mounted on the bracket, the bearing table is fixed on the work table, and the substrate is fixed above the bearing table; an anode and a cathode of the power supply are connected with a nozzle body of the spray nozzle and the bearing table respectively; relative motion between the spray nozzle and the substrate in x, y and z directions is realized by the aid of relative motion between the work table and the bracket. The spray nozzle is provided with a plurality of feed openings connected with different trace feeding pumps, multiple materials are thoroughly mixed under the action of a stirrer after entering the spray nozzle, and multi-material printing is realized. The macroscopic geometrical shape as well as microstructures in an object and on the surface of the object is controlled reasonably, and multi-scale structural integrated manufacture is realized.

Owner:兰红波

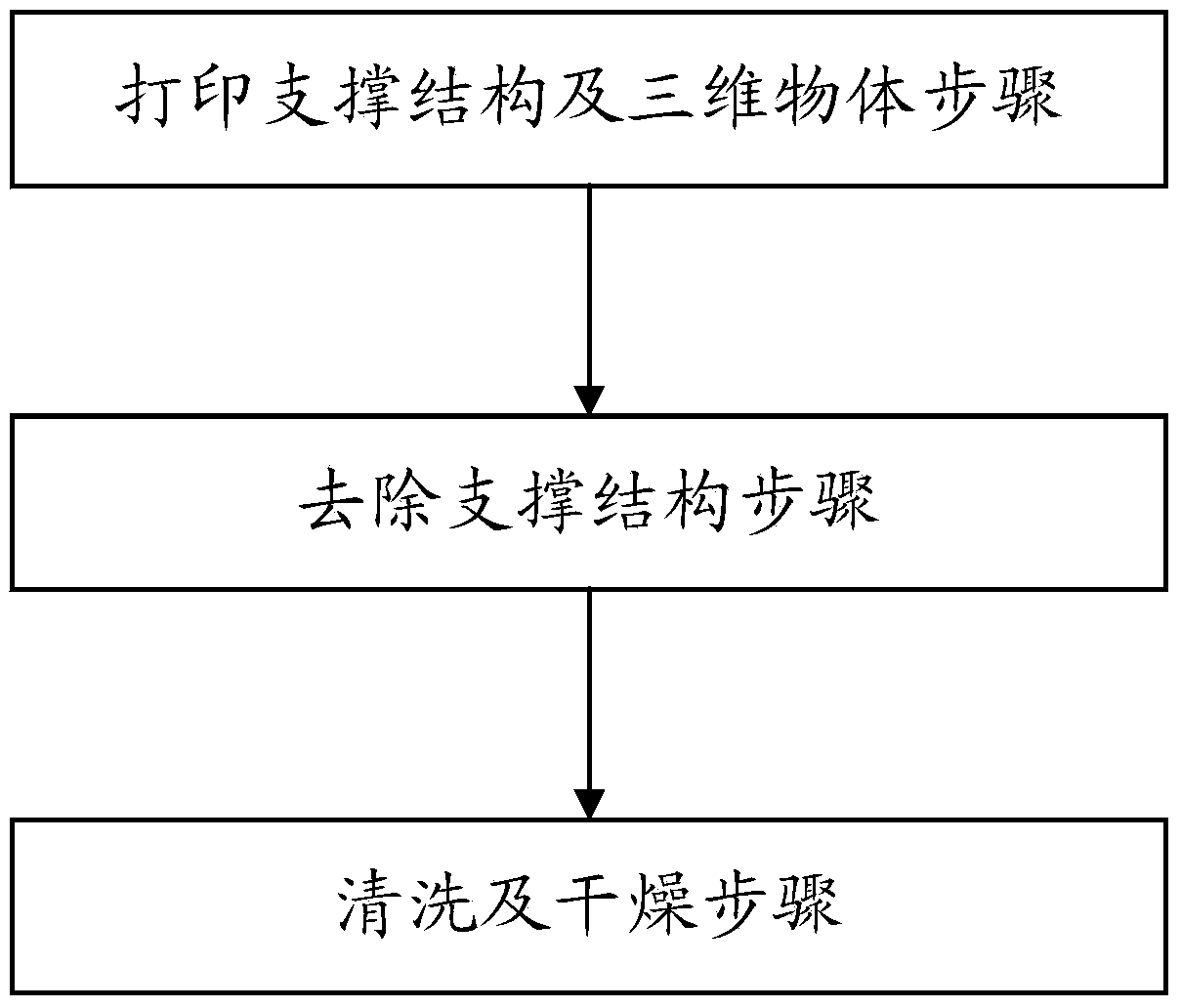

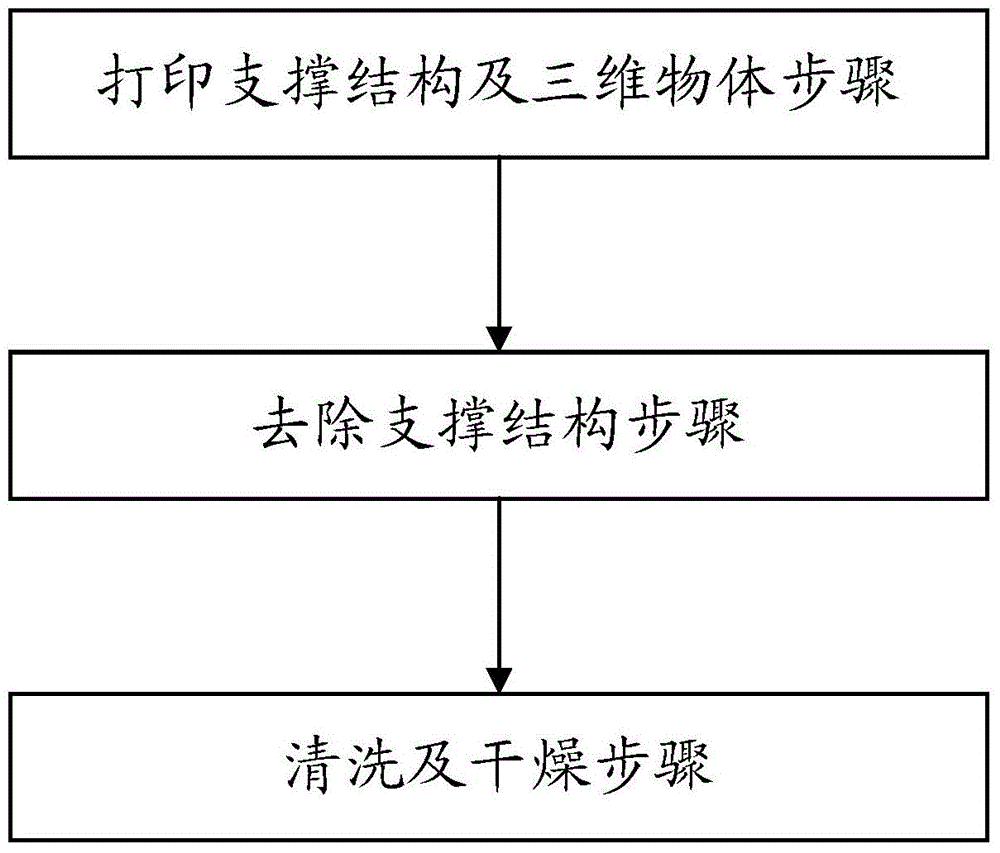

Three-dimensional printing method and machine

The invention relates to a three-dimensional printing method which comprises the steps that a supporting structure and a three-dimensional object are printed, wherein according to a set printing scheme, the supporting structure and the three-dimensional object are printed through a printing head; and the supporting structure is removed, wherein during printing of the supporting structure and the three-dimensional object, when the distance between the printing head and an object carrying table reaches a set value, a solution which can dissolve supporting materials and cannot dissolve forming materials is used for carrying out ultrasonic cleaning on the three-dimensional object and the supporting structure with the distance from a printing face larger than the set value. During a printing process, the supporting structure is removed, and the printing cycle is effectively shortened. In addition, the invention provides a three-dimensional printing machine suitable for the three-dimensional printing method.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

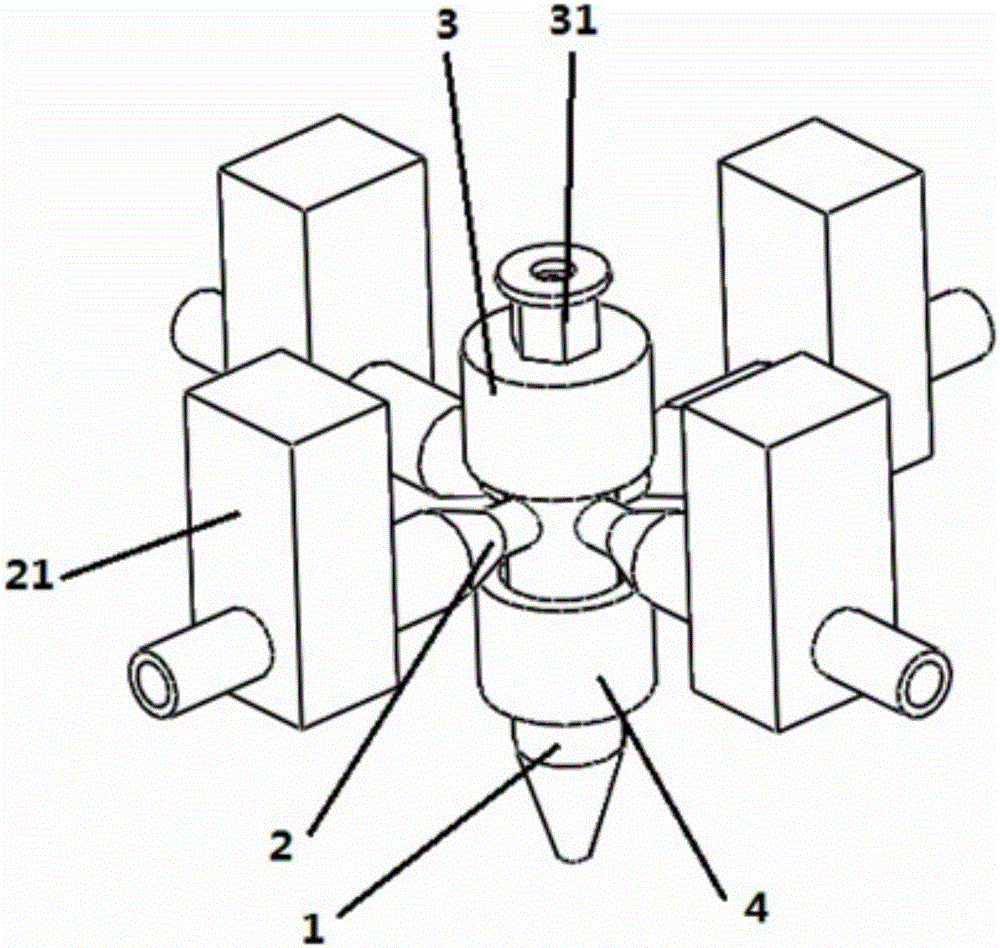

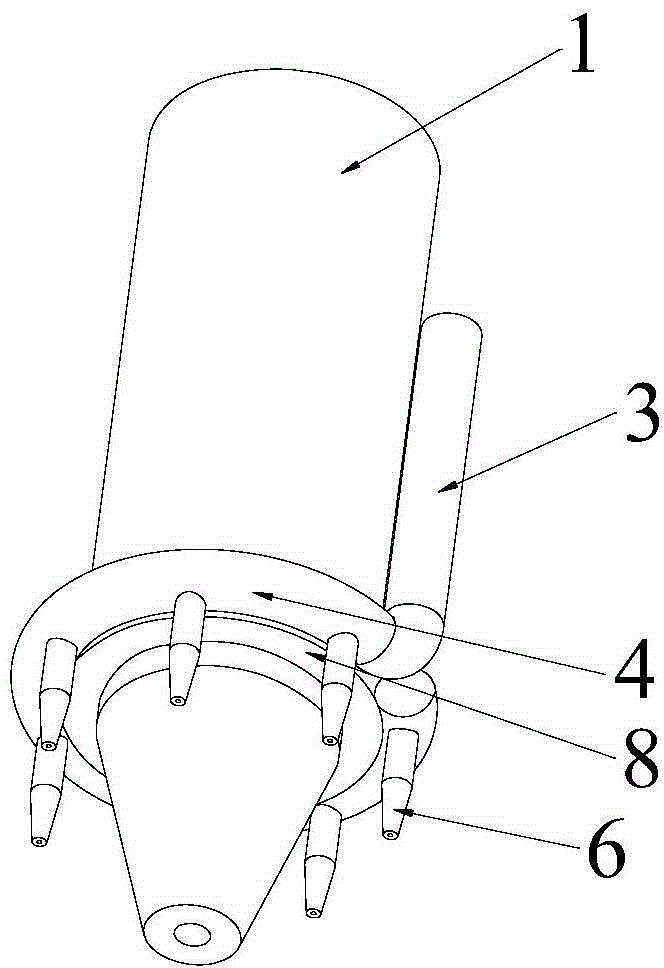

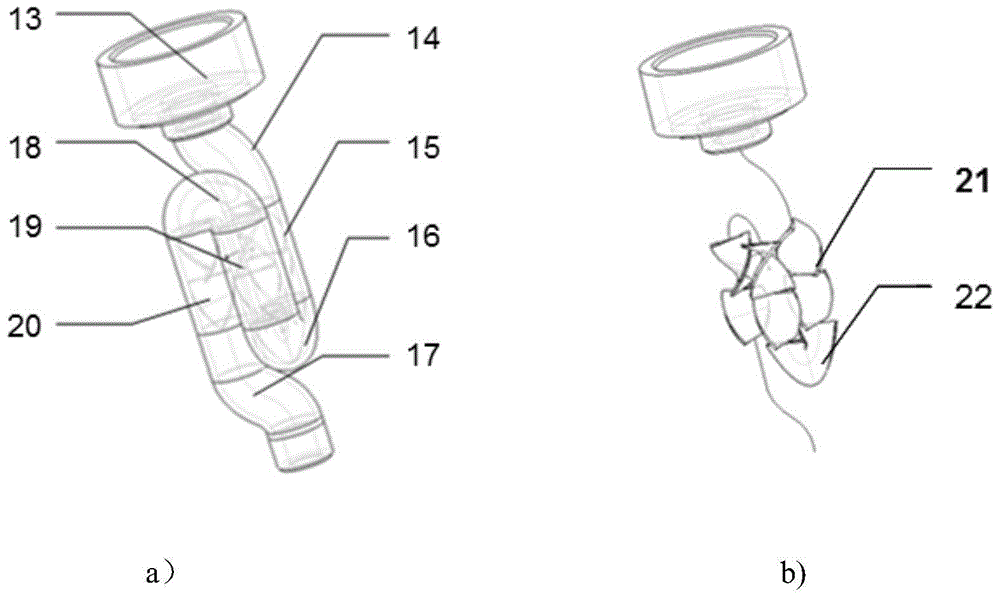

Multi-material 3D printing sprayer and operating method thereof

InactiveCN106393679ASolve printing problemsSimple structure3D object support structuresApplying layer meansState of artMulti material

The invention discloses a multi-material 3D printing sprayer and an operating method thereof. The multi-material 3D printing sprayer comprises a sprayer body, a plurality of feeding channels, a sprayer cover and an ultrasonic oscillating ring, wherein the sprayer cover is mounted on the sprayer body; the feeding channels are arranged on a cylindrical surface above the sprayer body in a surrounding mode in the circumferential direction, communicate with an inner cavity of the sprayer body, and are located below the sprayer cover and above the ultrasonic oscillating ring; and the upper portion of a discharging port of the sprayer body is sleeved with the ultrasonic oscillating ring. According to the multi-material 3D printing sprayer and the operating method thereof, the single sprayer body connected with the multiple feeding channels is arranged, and the ultrasonic oscillating ring is mounted on the upper portion of the discharging port for uniform mixing so that mixed printing or separated printing of various materials can be achieved, printing of gradient material products can be completed, and the purpose for printing the gradient material products in the prior art is effectively achieved; the multi-material 3D printing sprayer and the operating method thereof have the advantages that the structure is simple, and the cost is low; and proportional valves are used for controlling the feeding quantities of the feeding channels so that components can be controlled for multi-material printing.

Owner:GUIZHOU AEROSPACE INST OF MEASURING & TESTING TECH

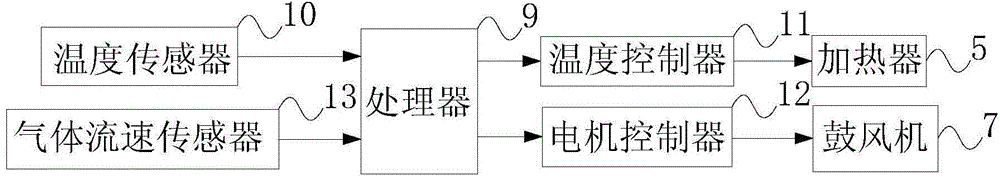

Print head assembly, 3D printer and printing method

The invention discloses a print head assembly, a 3D printer and a 3D printing method. The print head assembly comprises a print head body and a heating device, wherein the heating device is arranged on the heat head of the print head body and used for heating a base material which is printed to be formed at last pass. The print head assembly disclosed by the invention is capable of heating the uppermost layer of a printed model and heating the base material to a surface micro-melting state through the heating device to preferably fuse a subsequently printed material and the base material, thereby effectively solving the problem of edge warping of 3D printing of a plastic material with high contraction ratio in a 3D printing process and solving the problem of printing of a raw material with high cooling speed; the print head assembly disclosed by the invention can be used for outstandingly improving the forming quality of 3D printing and forming the filaments of raw materials of a PP type, a PE type and the like and the material modified through the addition of other substances, achieves preferable forming quality and can be applied to the 3D printing of a similar material.

Owner:董一航

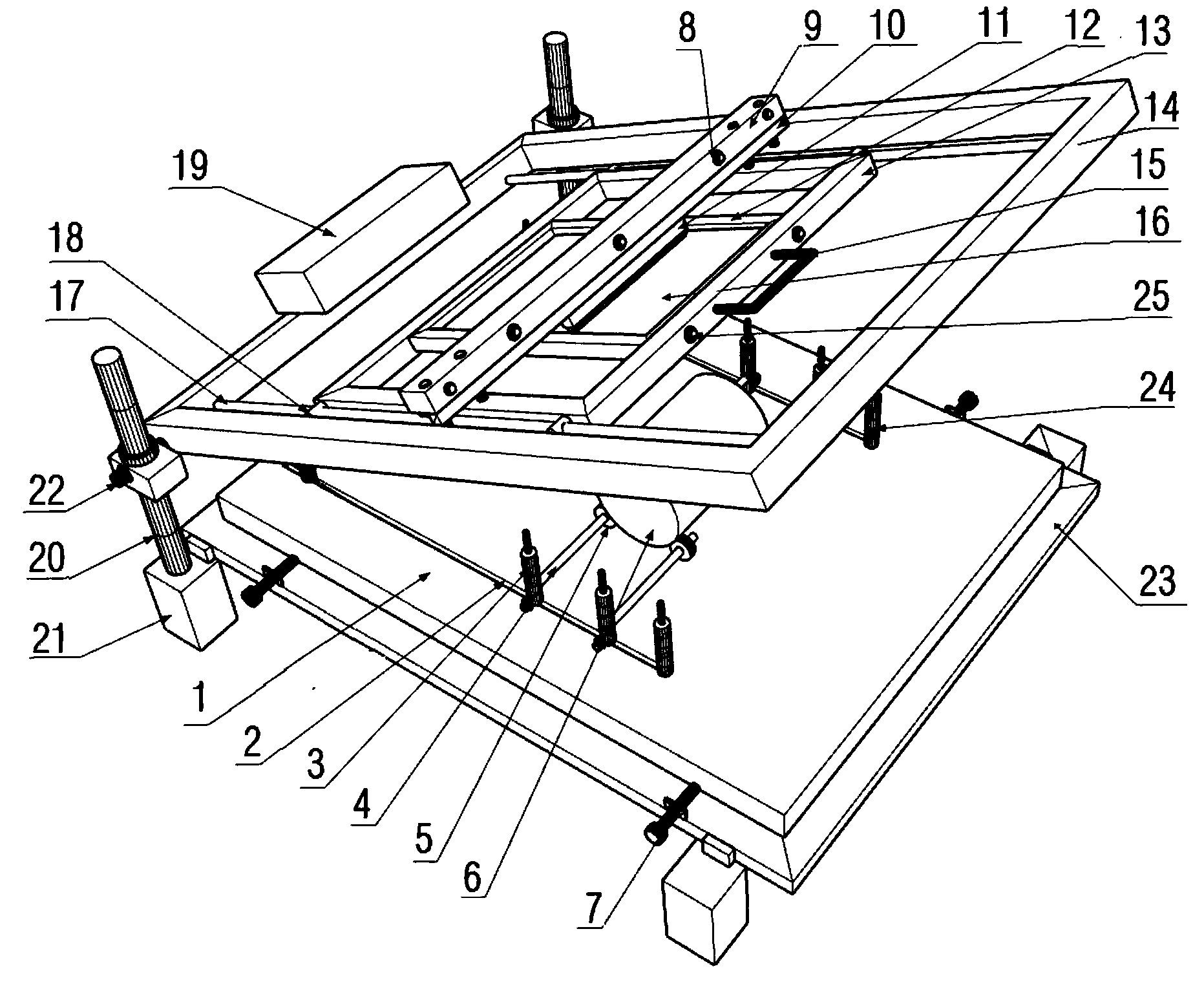

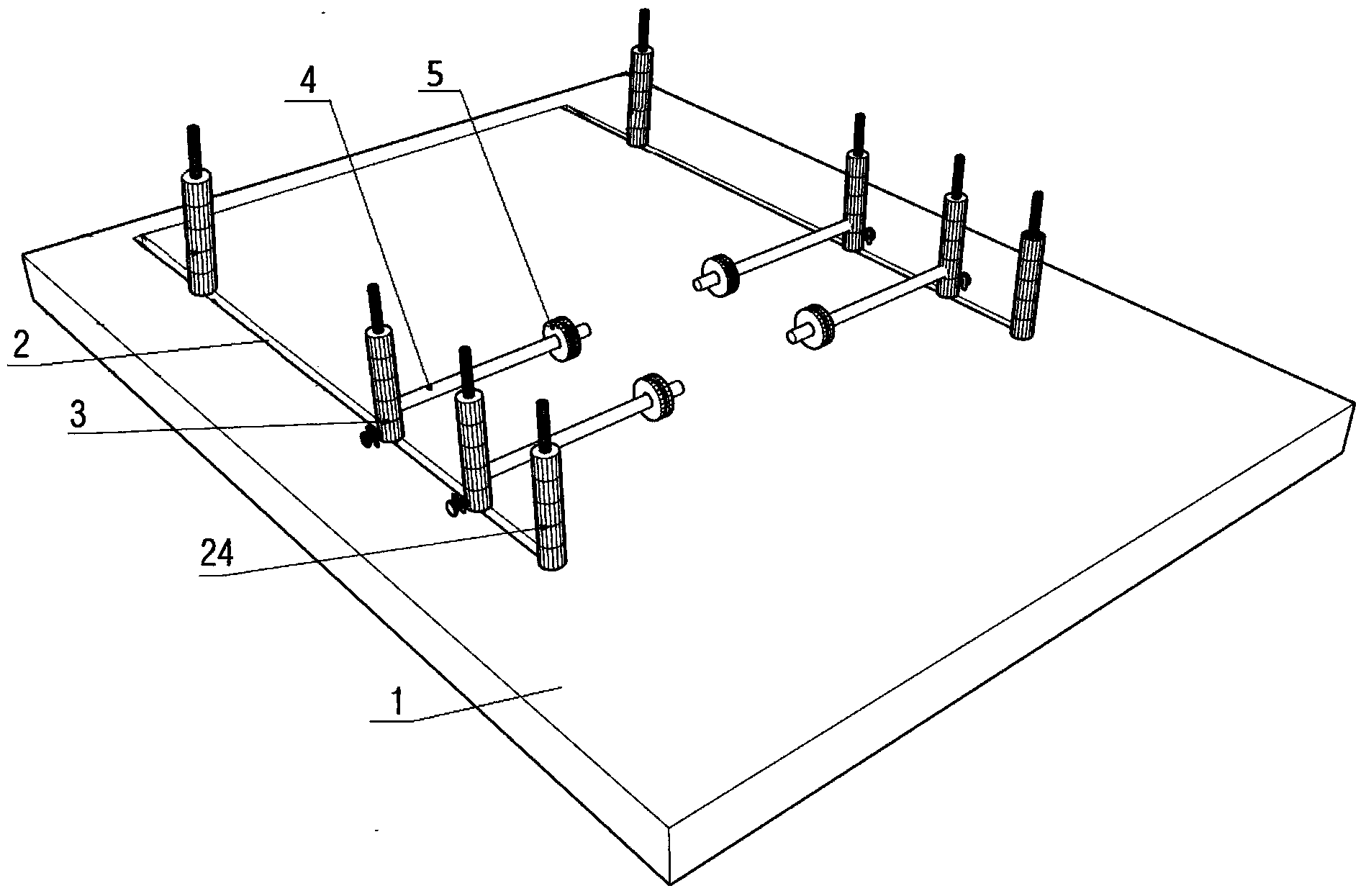

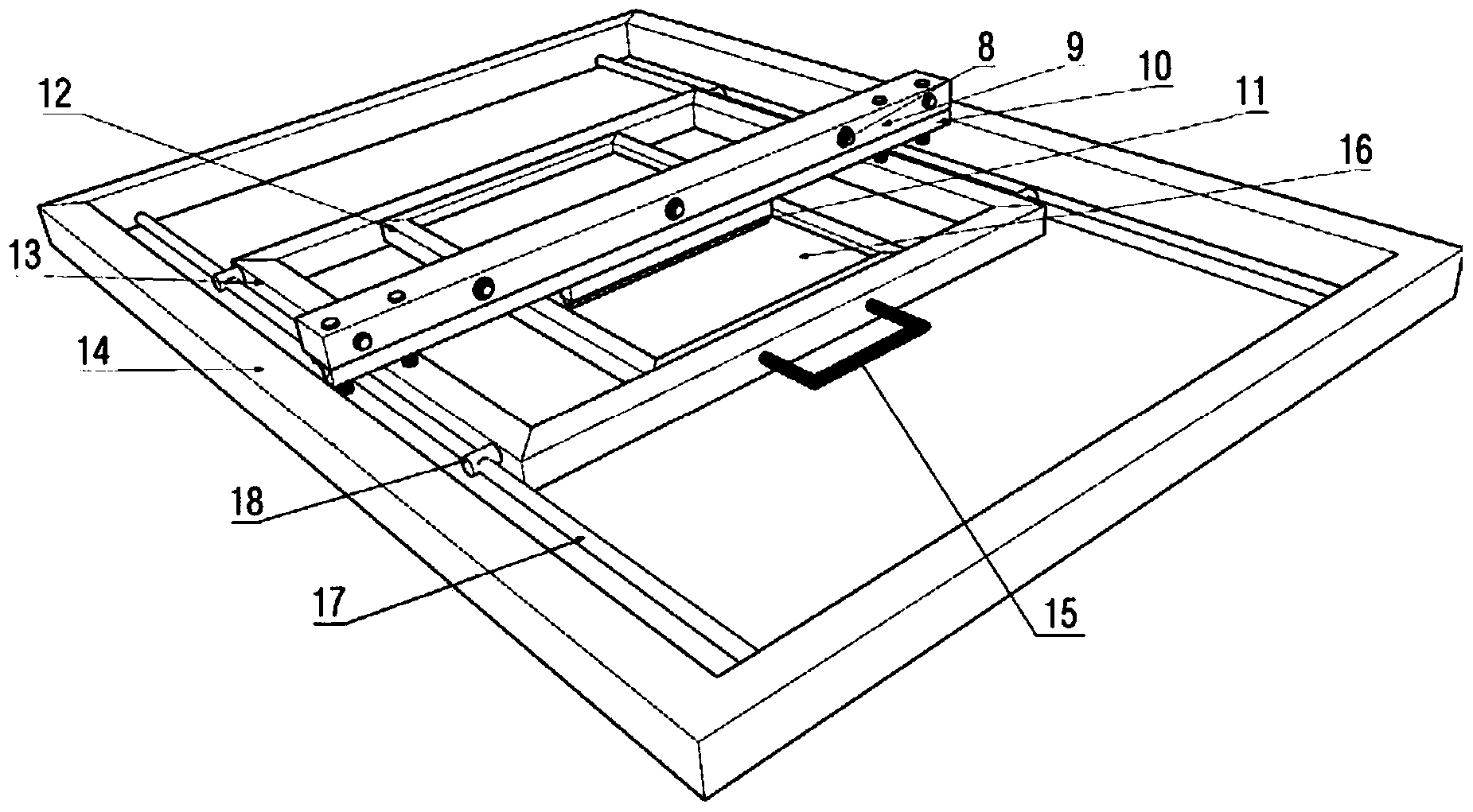

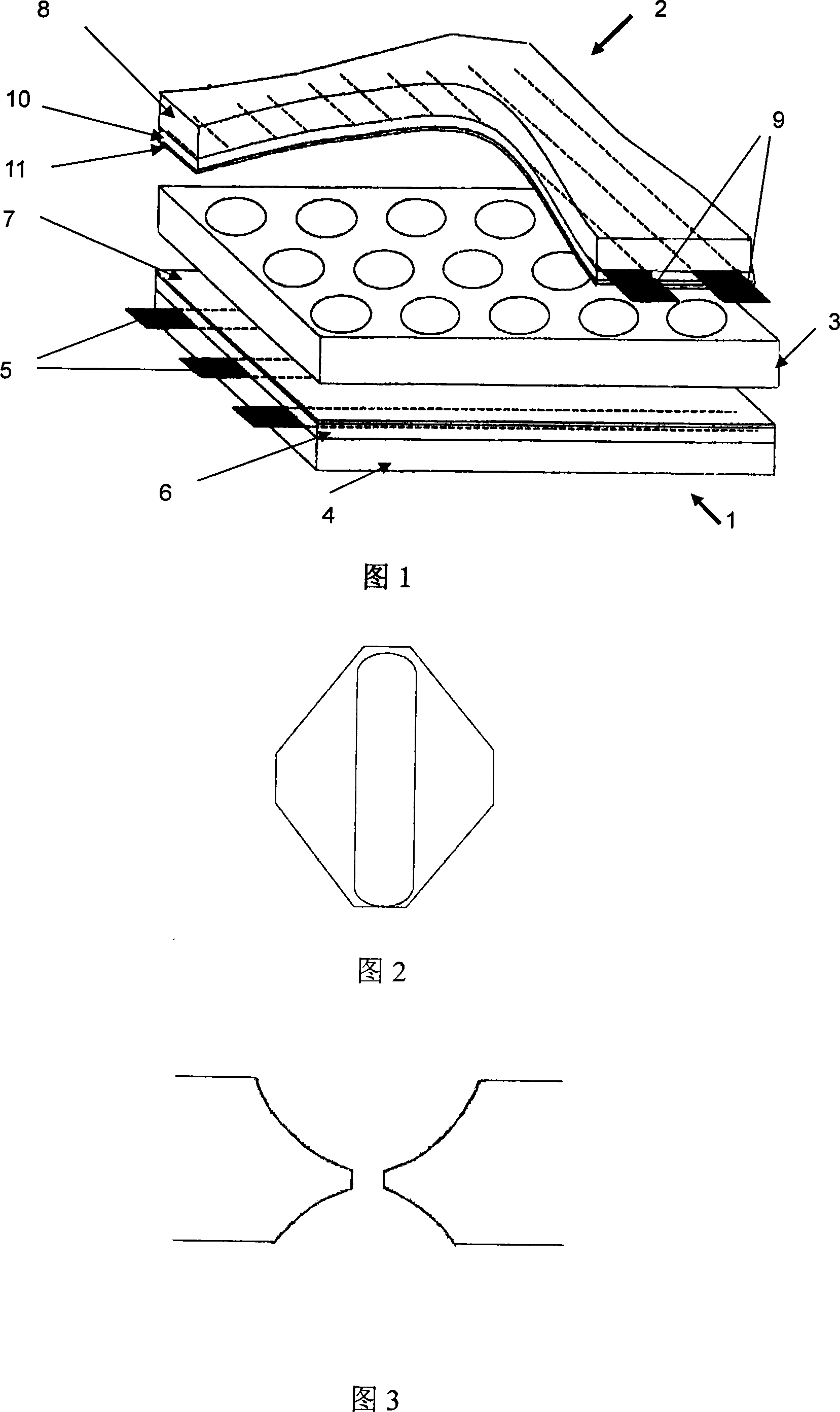

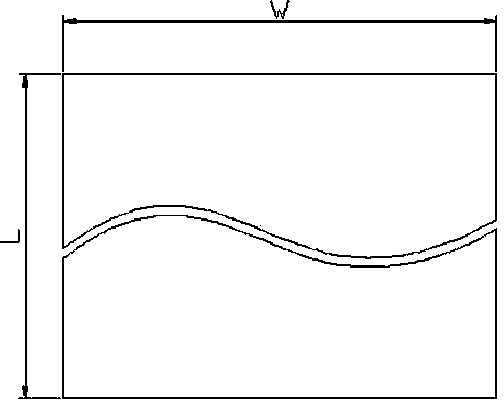

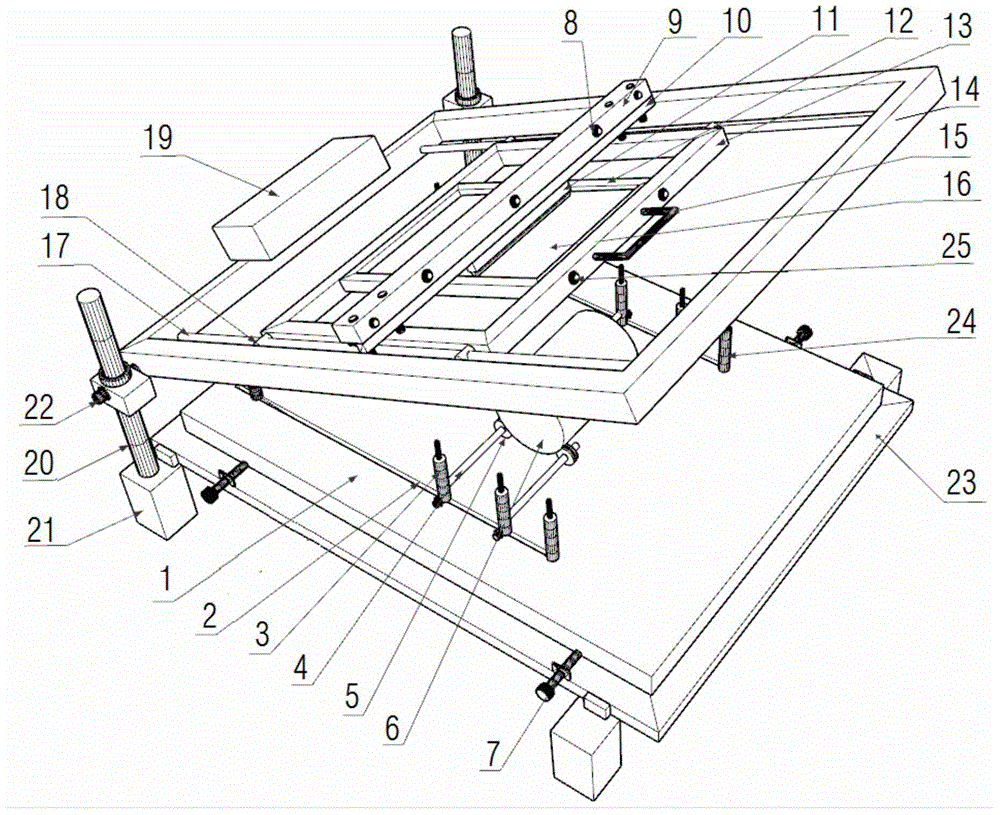

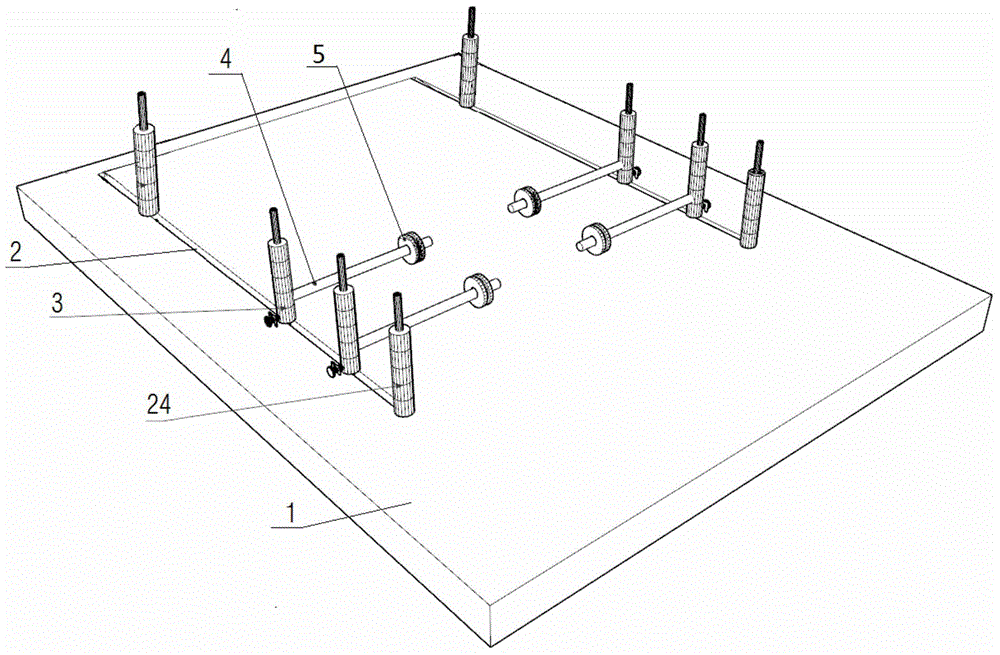

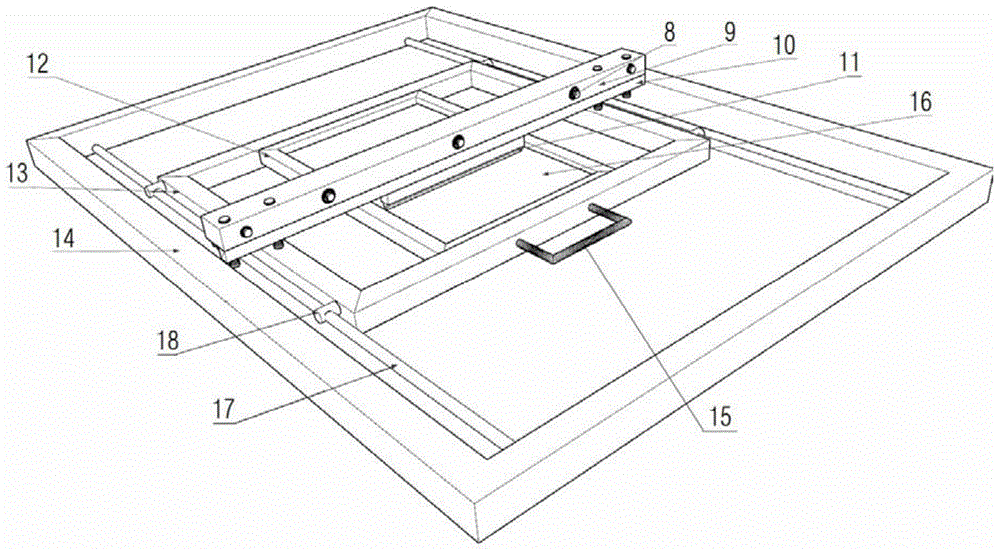

Three-dimensional manual curve surface screen printing machine

The invention relates to a three-dimensional manual curve surface screen printing machine which comprises a base plate, base plate supports and a space three-dimensional moving device. The base plate supports are disposed at four corners of the base plate. Lifting screws are disposed on the two base plate supports on the rear side. The space three-dimensional moving device is divided into an upper part and a lower part, the upper part is a liftable printing frame, and the lower part is a to-be-printed object three-dimensional moving mechanism. The lower mechanism is provided with a operation platform mounted on the base plate. Two slide rod station grooves are formed in the surface of the platform, four slidable longitudinal slide rods are mounted on the grooves, a transverses slide rod with a support bearing is mounted on each longitudinal slide rod, and the to-be-printed object is placed on the four support bearings. The upper printing frame is provided with an outer frame and a screen plate moving frame connected to the inside of the printing frame. A printing screen plate frame with a silk screen plate is connected into the screen plate moving frame. A scraper rack and a scraper are disposed on the screen plate moving frame. A balance iron square is disposed at the rear end of the outer frame. The printing machine is simple in structure, convenient to use, high in practicality and capable of printing cone frustums and cones with two ends of different diameters and irregular columns with handles.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

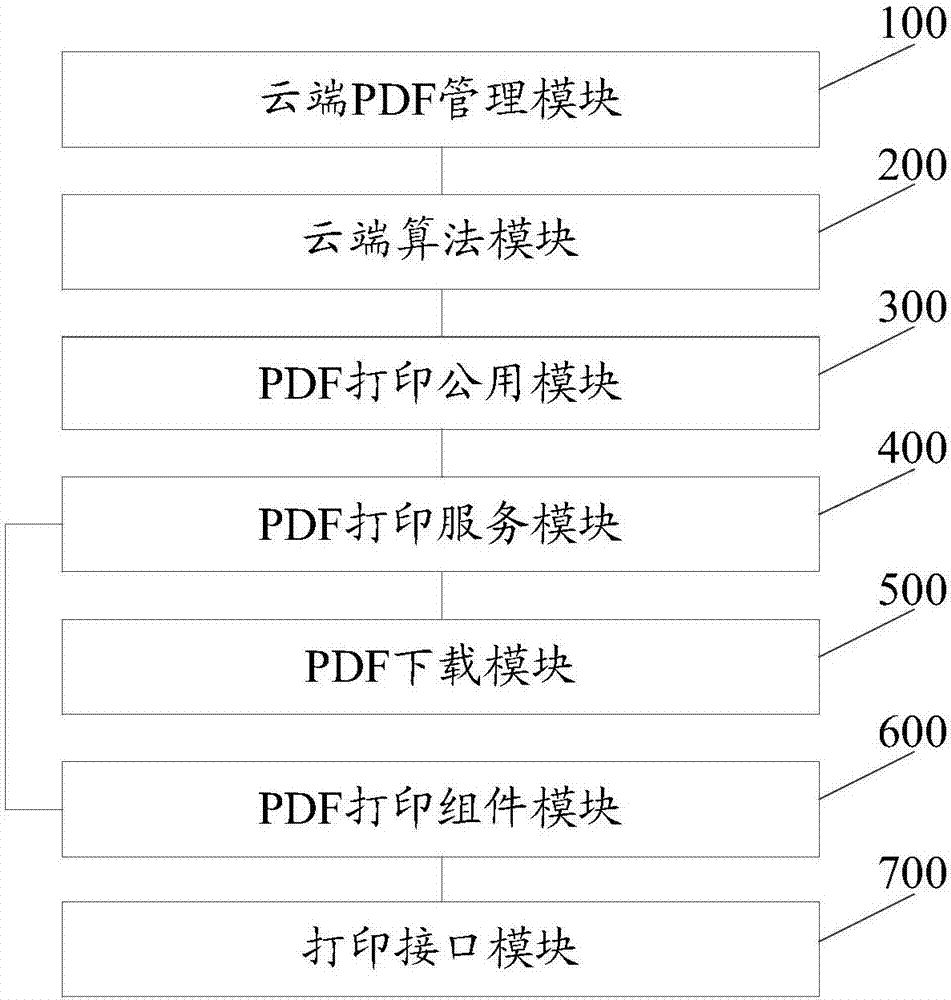

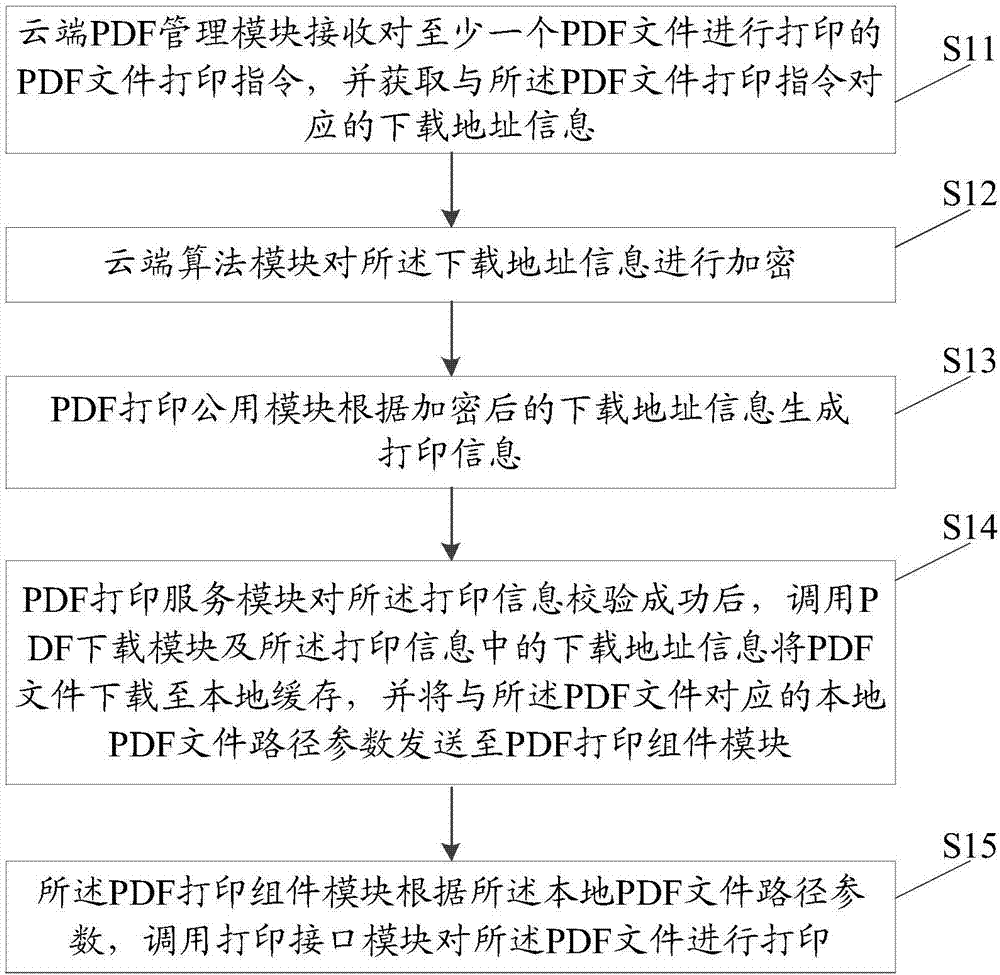

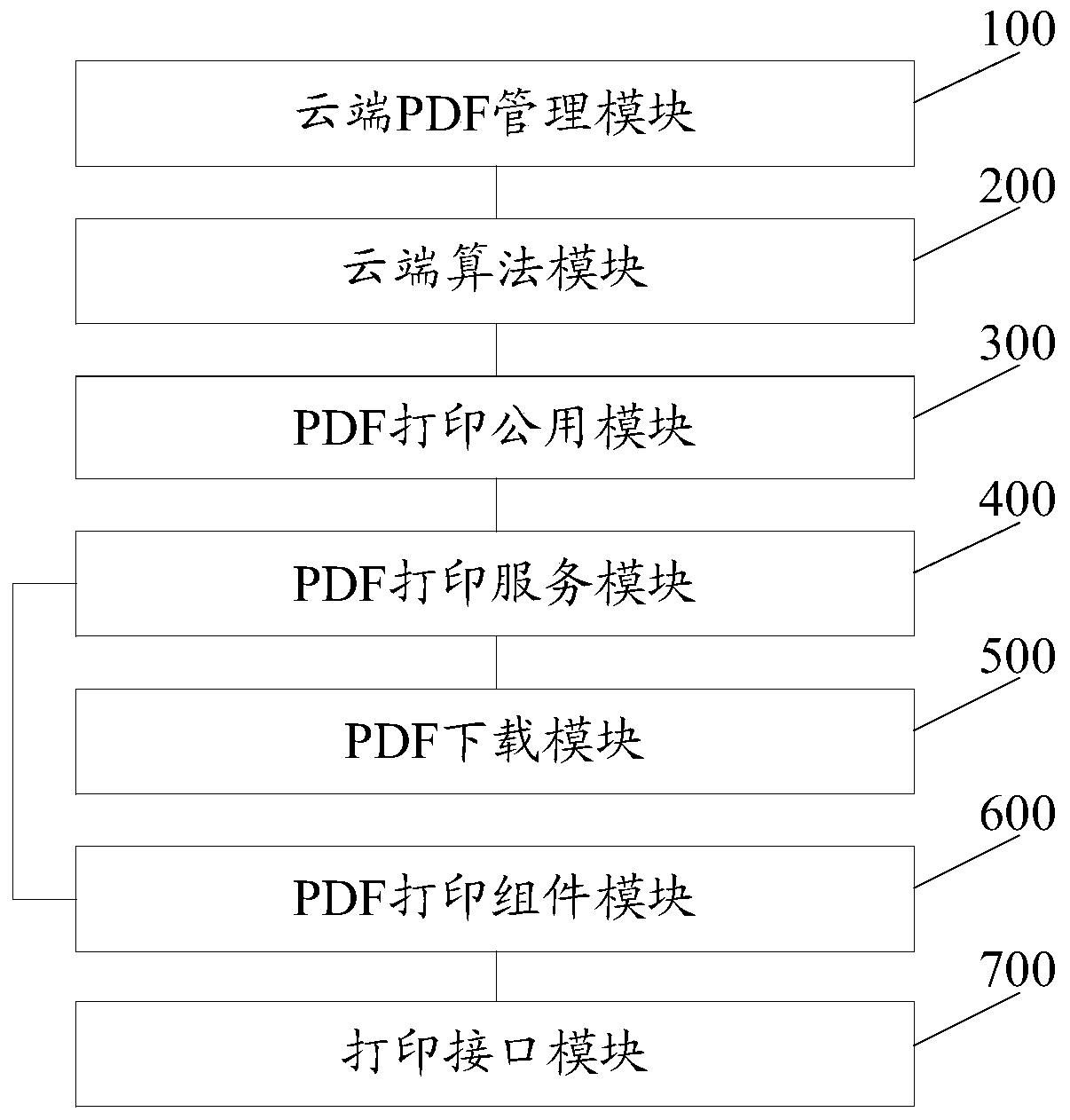

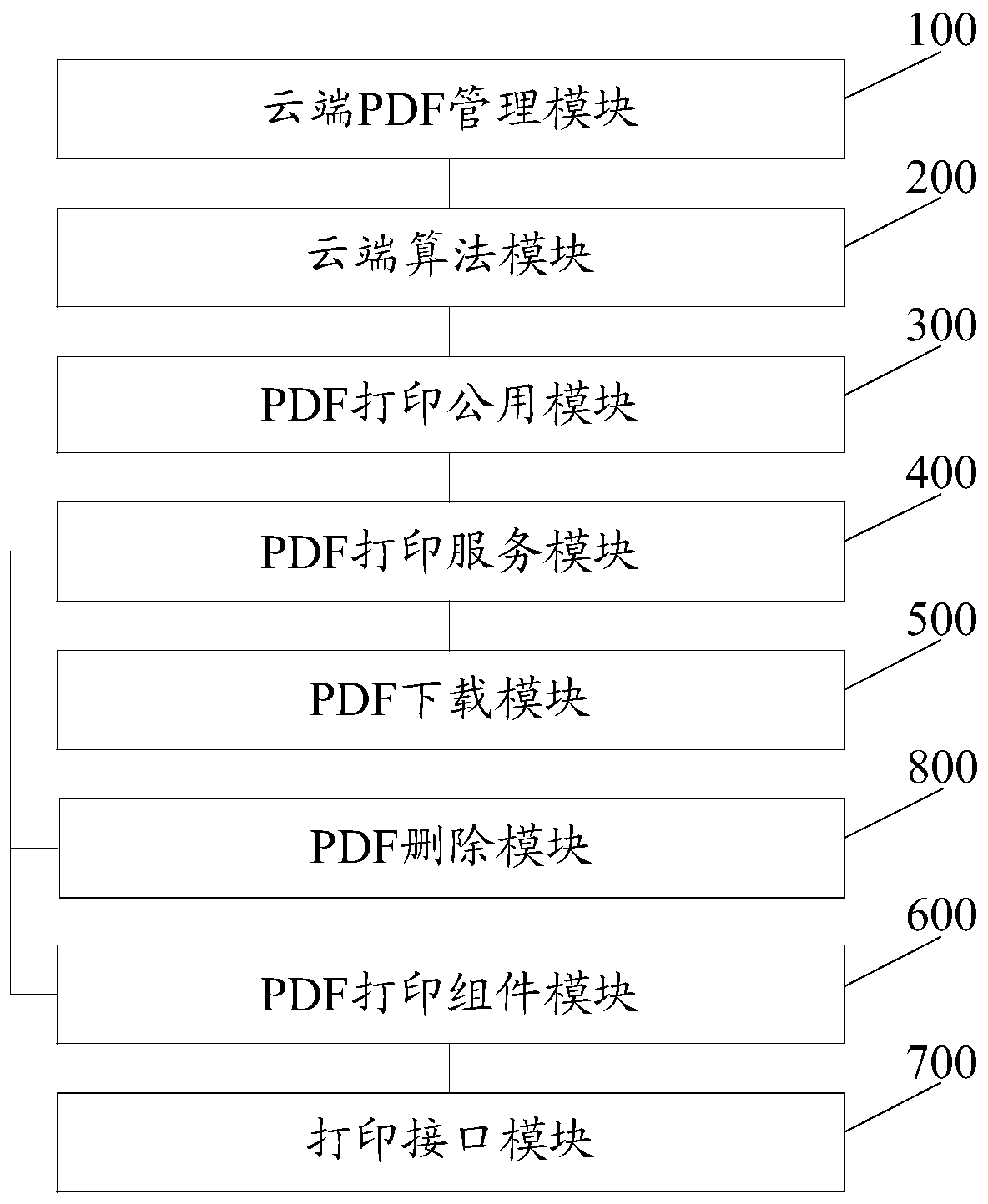

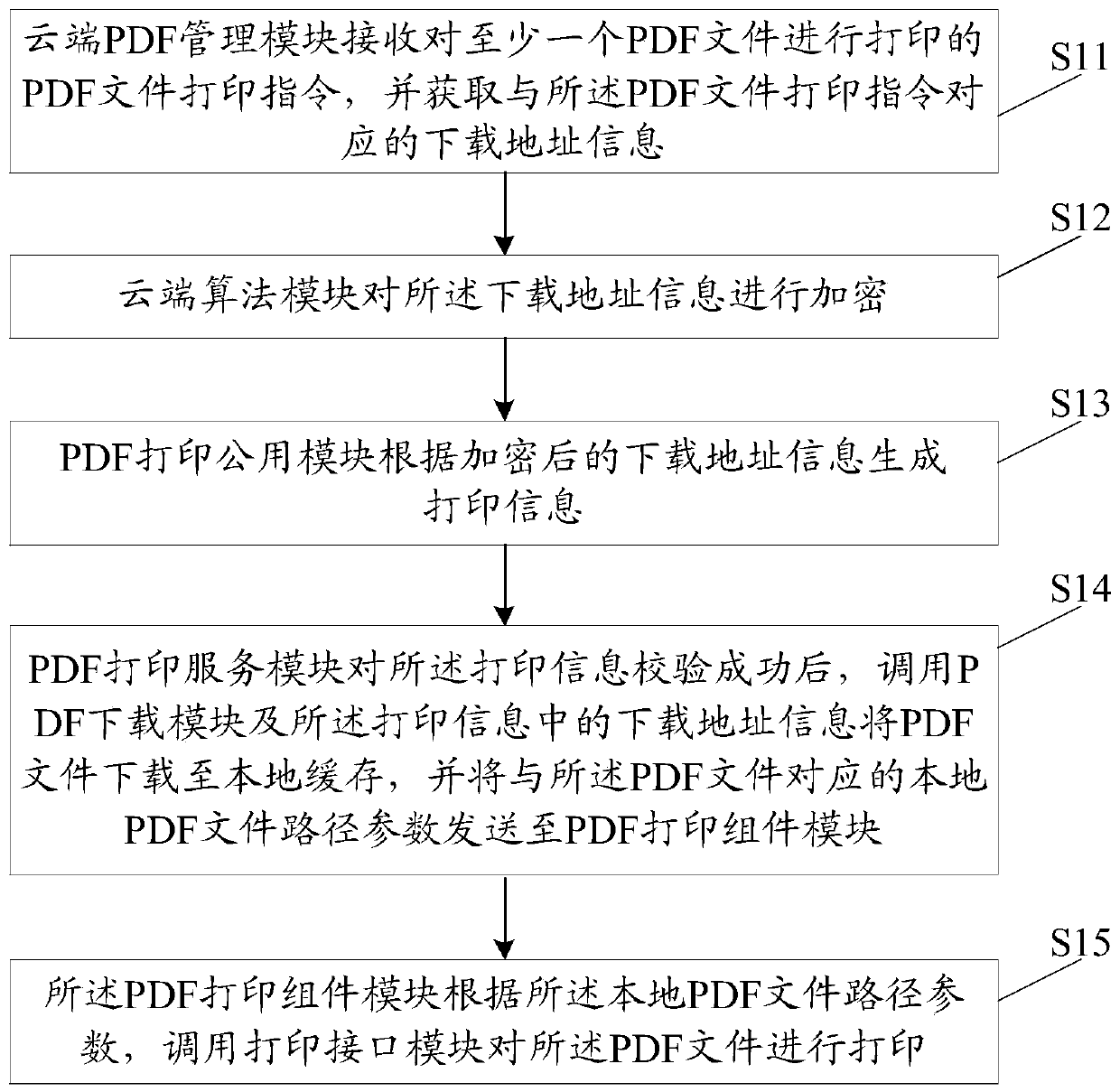

Online printing system and method of PDF (portable document format) electronic invoice format file

ActiveCN107450869ARealize online printingFast and efficient online printingDigital output to print unitsInvoicePortable document format

The invention discloses an online printing system and method of a PDF (portable document format) electronic invoice format file. In the scheme, it is possible to print a PDF file online so that when using an electronic invoice business system, a customer may print PDF files efficiently online directly by the aid of the business system, manually downloading the PDF file to the locale and importing and printing the file via a PDF reader is not required, and directly opening the PDF file through a browser prior to printing single sheets through the printing function of the browser is not required either. By using the system and method of the invention, both the single sheet printing problem and the batch printing problem are solved, and time and labor are economized. In addition, it is possible to make calling across browser through a PDF printing service module and a PDF printing component module, and developing plugins for different browsers is not required.

Owner:国信电子票据平台信息服务有限公司

Manufacturing method for AgC electrical contact and integrated assembly thereof

ActiveCN104821248AImprove conductivityNo wasteAdditive manufacturing apparatusElectric switchesCarbon compositesElectricity

The invention relates to a manufacturing method for an AgC electrical contact and an integrated assembly thereof. The manufacturing method comprises the steps of firstly preparing coated silver-carbon composite powder and loading in a powder cylinder of a 3D printer, then establishing a three-dimensional model of the AgC electrical contact and the integrated assembly thereof, and finishing 3D printing molding of the AgC electrical contact and the integrated assembly thereof. According to the manufacturing method, direct and quick molding of the AgC electrical contact and the integrated assembly thereof from raw material to finished product is realized, and raw material and production cost are saved. Furthermore zero stock and zero time delivery are realized. The manufacturing method is a novel method for manufacturing the AgC electrical contact and the integrated assembly thereof.

Owner:SHANGHAI HIWAVE COMPOSITE MATERIALS CO LTD

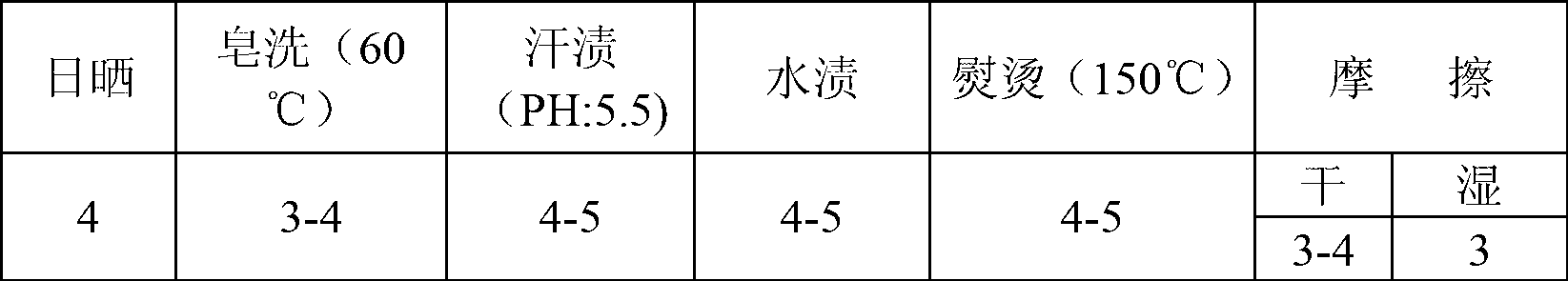

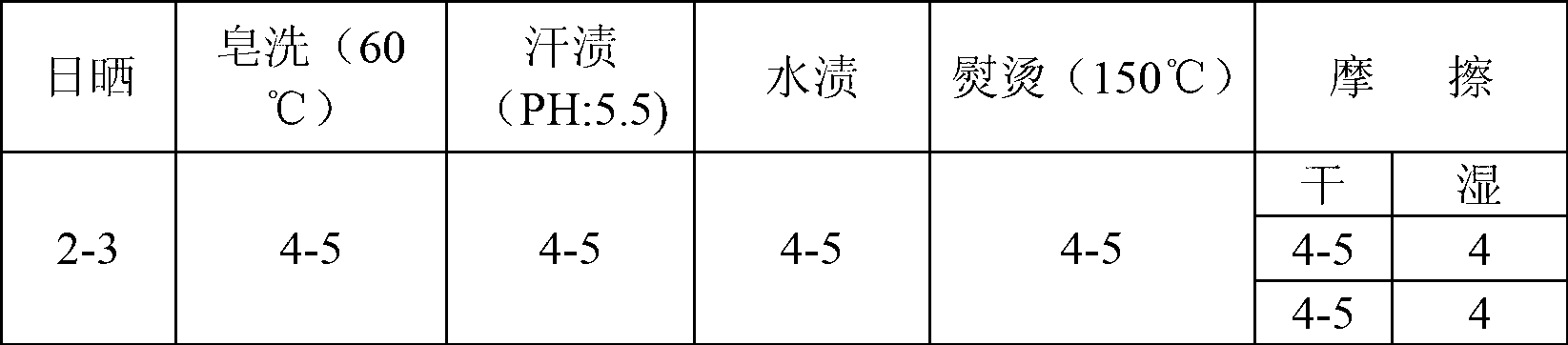

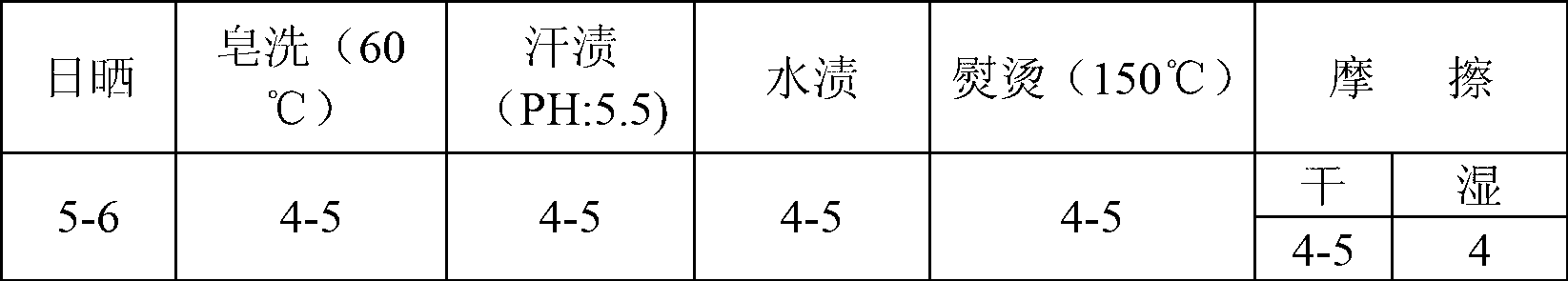

Digital printing method for wool-polyester roughly spun fabric

InactiveCN103015226ASolve printing problemsImprove developmentTransfer printing processDyeing processDigital printingPolyester

The invention discloses a digital printing method for a wool-polyester roughly spun fabric. The method comprises the following steps of: respectively and simultaneously filling acidic dye or active dye ink-jetting ink and dispersion dye ink-jetting ink into ink boxes for controlling different sprayers by selecting a double-sprayer or multi-sprayer digital printing machine; selecting patterns, and performing color separation and color toning; simultaneously spraying the acidic dye or active dye ink-jetting ink and the dispersion dye ink-jetting ink to an ink-jetting carrier with an ink absorption layer by different sprayers, and after the ink is dried, rolling the carrier to make a digital printing transferring carrier; uniformly wetting the wool-polyester roughly spun fabric by wetting liquid; attaching the spraying surface of the transferring printing carrier and the wetting surface of the wool-polyester roughly spun fabric, and putting into a transferring printing machine; after transferring is finished, drying; fixing the color of a dispersion dye by a thermal baking or saturated steam evaporating mode; fixing the color of the acidic dye or the active dye by a saturated steam color fixing mode; and washing and sizing to form the digitally printed wool-polyester roughly spun fabric.

Owner:张家港市普坤羊绒制品有限公司

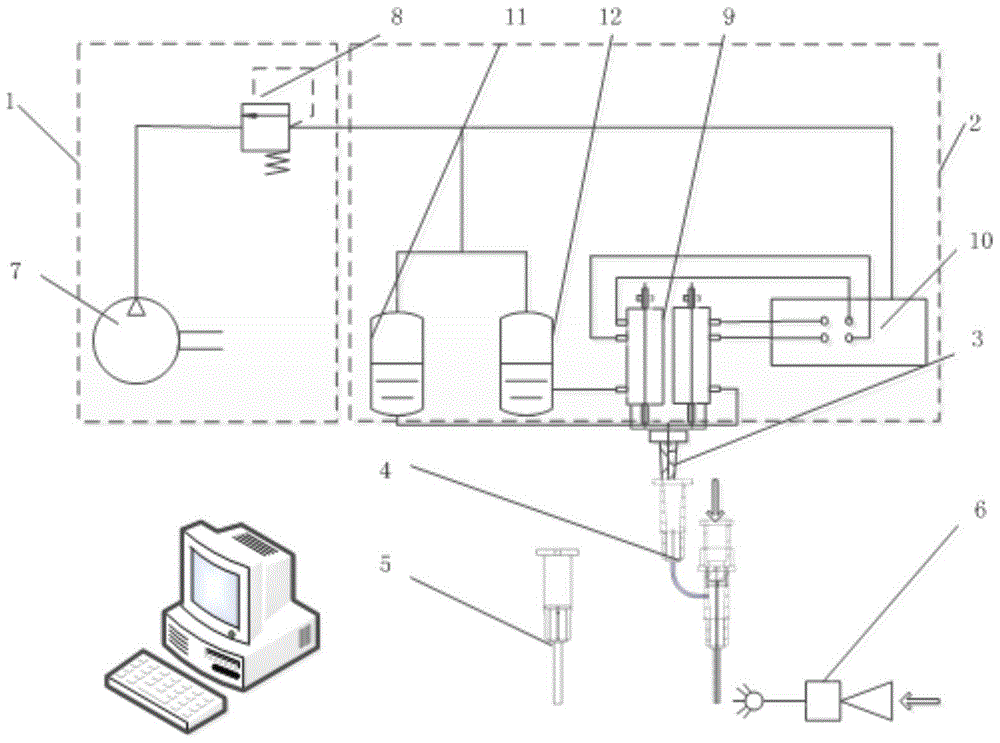

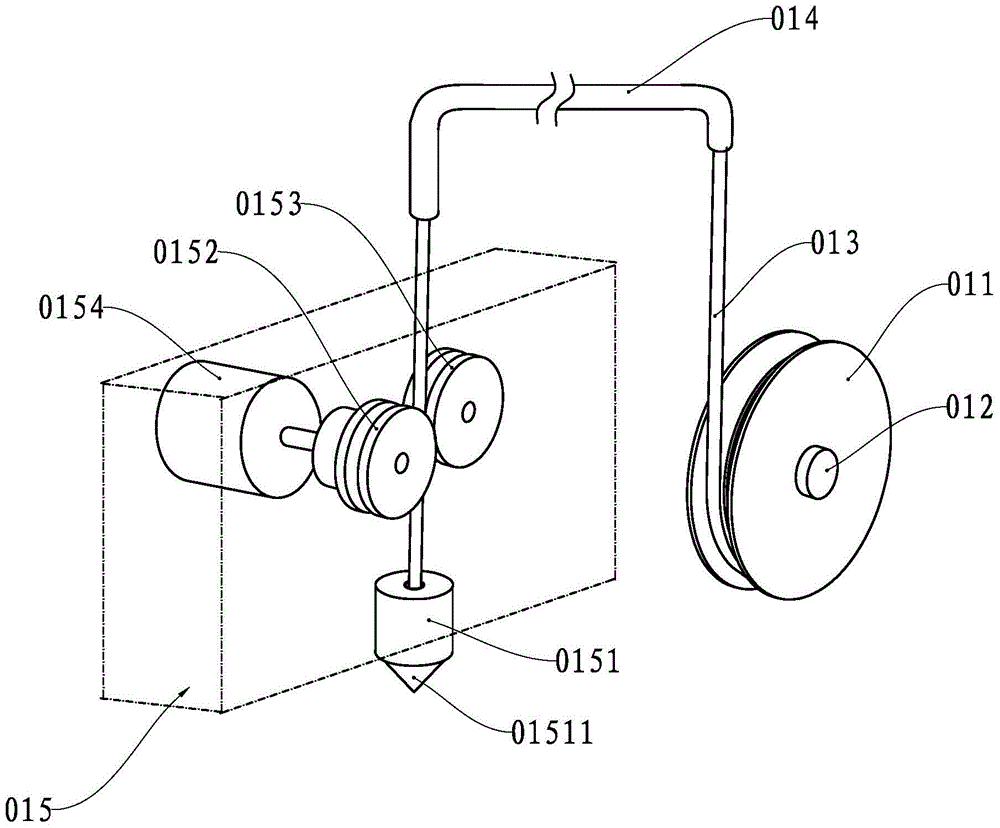

Print nozzle system and mixed spraying printing technology of adjustable soft hollow tube support

The invention provides a print nozzle system and mixed spraying printing technology of an adjustable soft hollow tube support.The print nozzle system comprises five functional parts including a pneumatic power source, a feeding device, a mixing device, sprayers and a spraying device. A hollow circular pipe is formed in such a manner that a solution A is subjected to dispensing, mixing and spraying technology under effects of a solution B, a solution C and a solution D via the sprayers. A two-layer or multi-layer structure is constructed. Under the spraying effect, connection strength between / among layers can be increased. The print nozzle system and mixed spraying printing technology of the adjustable soft hollow tube have following beneficial effects: two solutions can be completely mixed; continuous structures of hollow or solid circular pipes can be printed and accumulated in order to form different structures in order to print and manufacture hollow circular pipes similar to blood vessels; a micro-channel structure in the interior of the support can be constructed in order to transfer nutrition and other substance in tissue engineering by repair of large tissue; and the print nozzle system and mixed spraying printing technology of the adjustable soft hollow tube can be extensively applied to construction of biological tissues in all kinds.

Owner:XI AN JIAOTONG UNIV

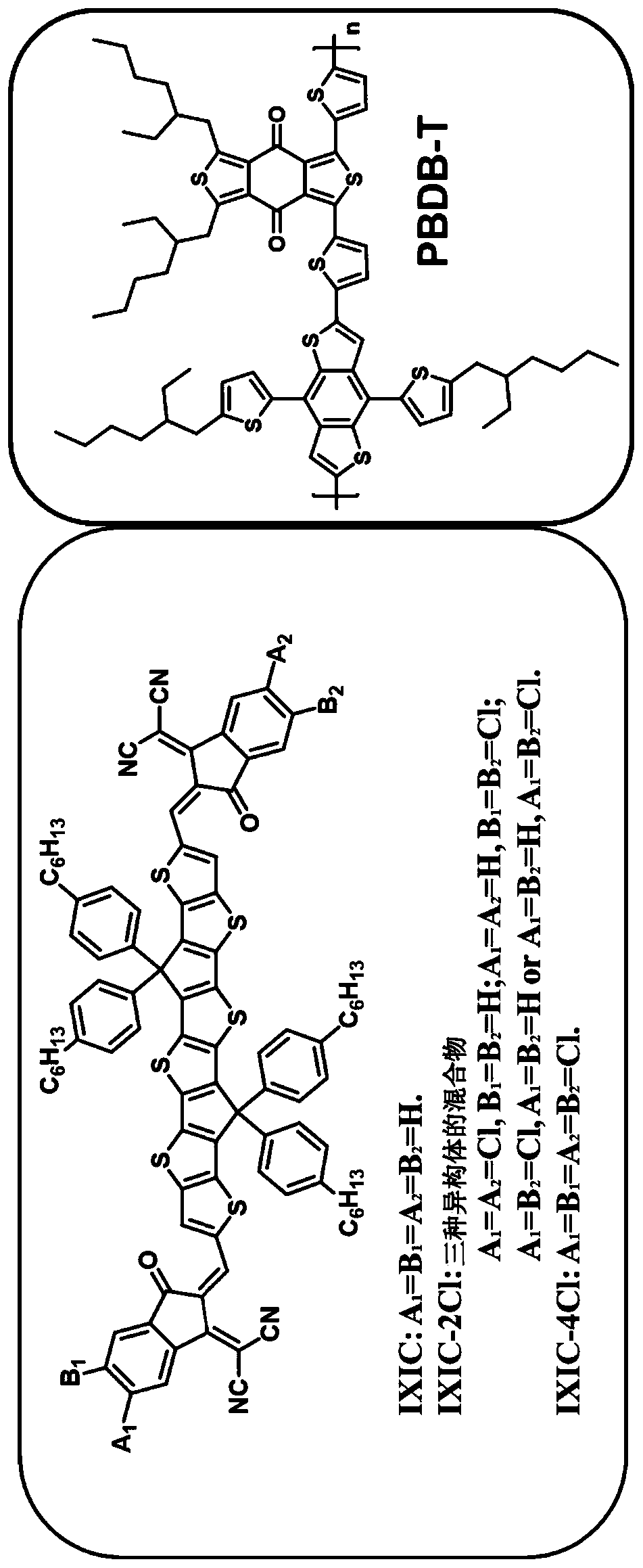

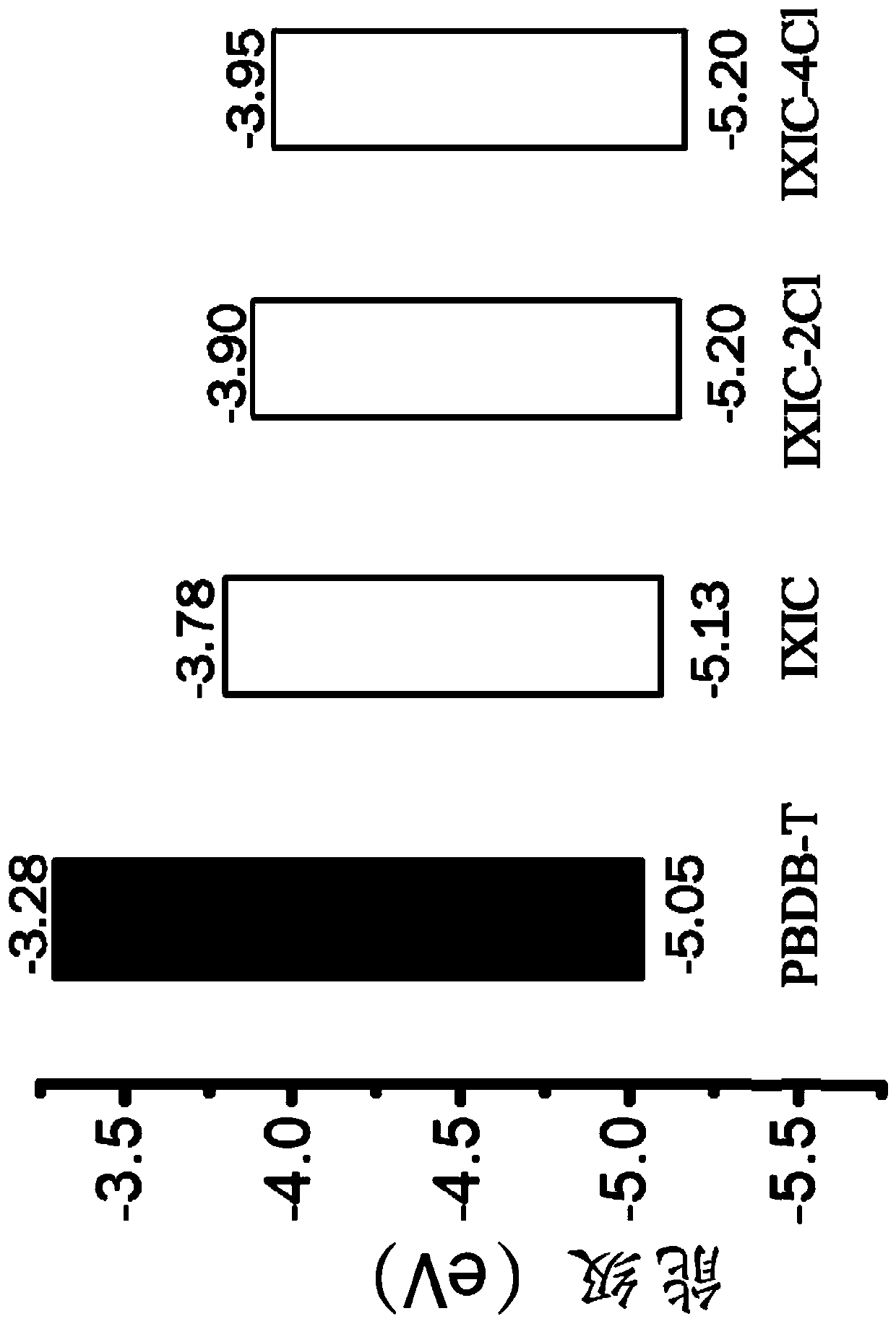

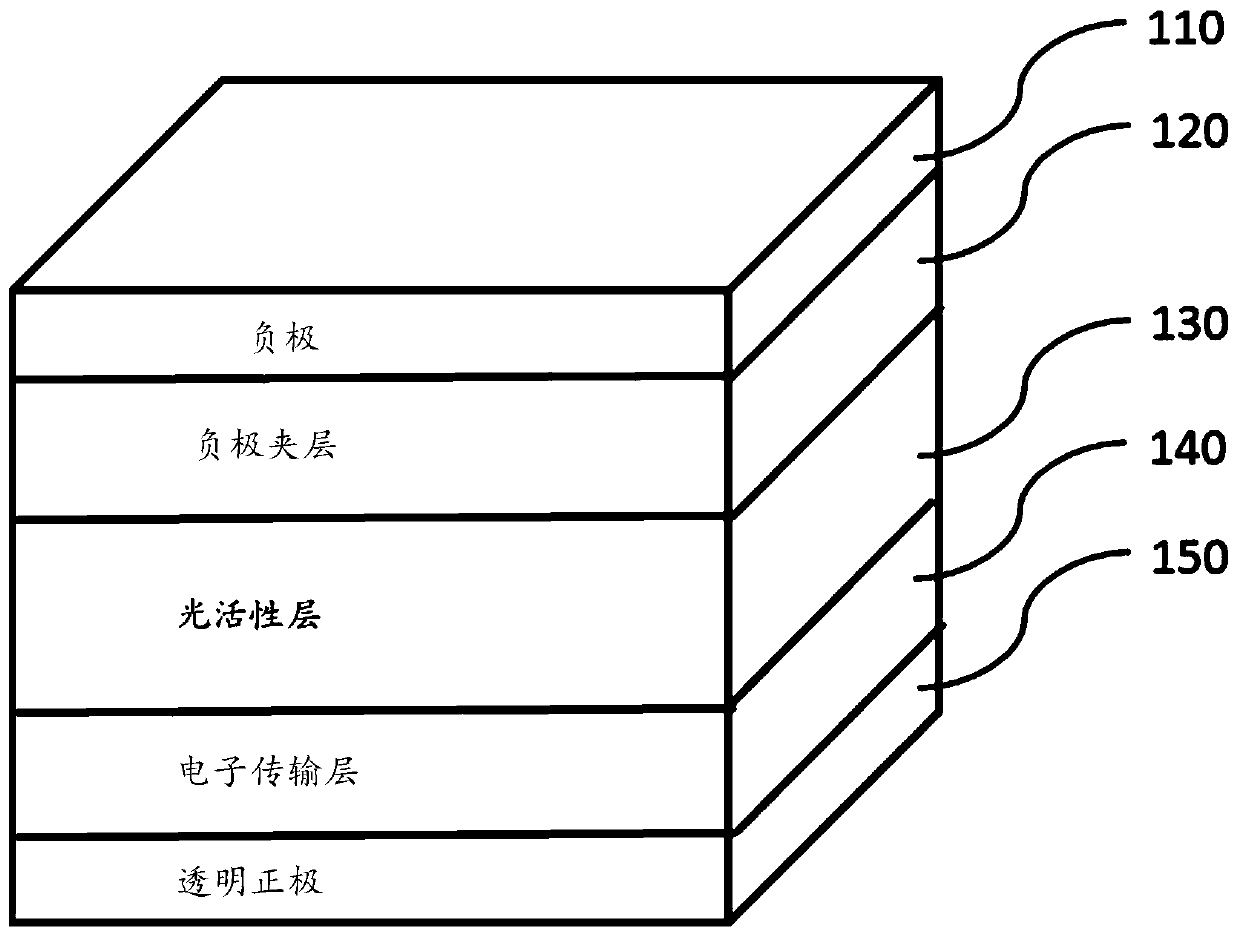

Thiophene-based fused aromatic systems

ActiveCN111418079AImprove uniformityImprove qualityOrganic chemistryFinal product manufactureSolar batteryPolymer chemistry

The invention relates to thiophene-based small molecule acceptors, their methods of preparation, and formulations thereof useful for preparing photoactive layers in organic solar cells (OSCs).

Owner:THE HONG KONG UNIV OF SCI & TECH

Method for making multicolour pattern on surface of violin-like musical instruments

InactiveCN101716864AColorfulThe appearance is visually rich and colorfulPattern printingViolinEngineering

The invention relates to a method for making a multicolour pattern on the surface of violin-like musical instruments, which is characterized by comprising the following steps: printing a film, activating the film, coloring the base material, washing with water, drying, spraying the finishing coat, redrying and the like. The invention solves the problem of undiversified color in the violin-like musical instruments, and has the advantages of good adhesive force and convenient and quick manufacture.

Owner:吴大旷

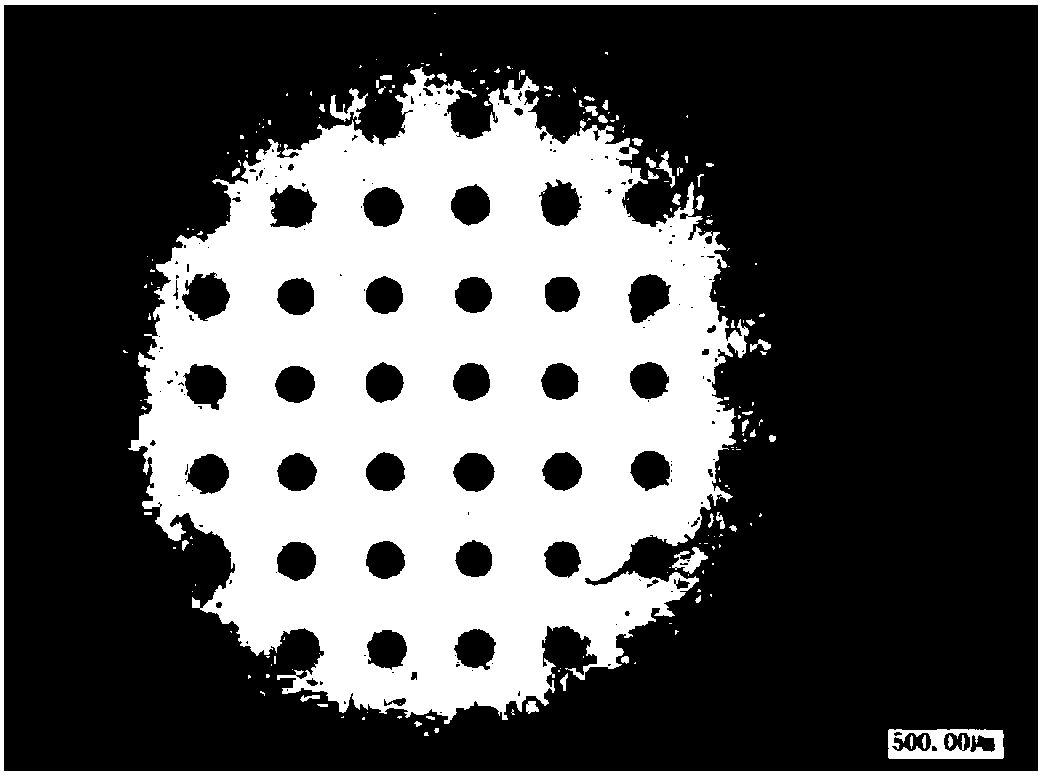

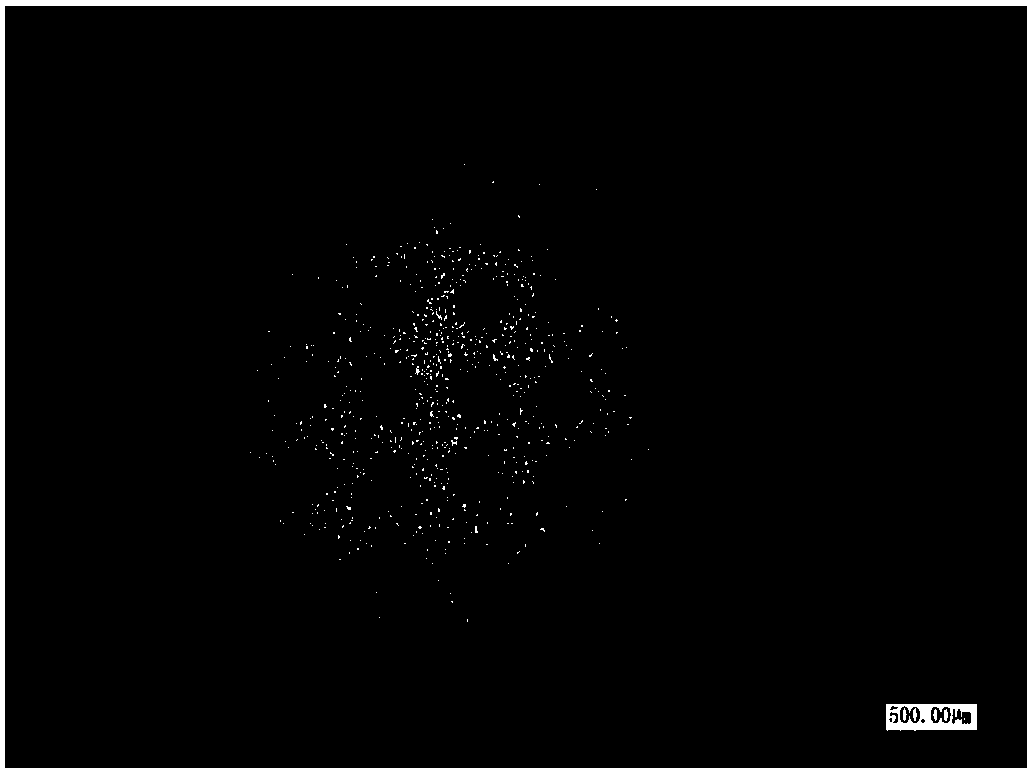

Fluorescent powder slurry materialfor plasma display and forming method on shadow mask

InactiveCN101159214AGood dispersionGood suspensionTube/lamp screens manufactureDischarge tube luminescnet screensOrganic solventMetallurgy

The invention relates to a fluorescent powder slurry for plasma display and the formation method on shadow mask, belonging to the technical field of flat panel TV set. The inventive slurry consists of fluorescent powder, organic resin, organic solvent and nanopowder, wherein the fluorescent powder accounts for 40-50 percent of the total weight, the organic resin accounts for 3-6 percent of the total weight, the organic solvent accounts for 45-55 percent of the total weight, and the nanopowder accounts for 0.5-3 percent of the total weight. The proper amount of nanopowder (0.5-3 percent) added into the fluorescent powder slurry can effectively improve the dispersion and the suspension properties of the fluorescent powder in the slurry and can well improve the thixotropy of the fluorescent powder slurry so as to ensure that the slurry viscosity decreases during printing to obtain adequate feeding amount and also ensure that the slurry can rapidly regain the high viscosity and settle at the periphery of small holes other than flowing out when the slurry is printed to the holes of the shadow mask. Meanwhile, the slurry can be oven-dried and sintered after the printing process such that the nanopowder is filled into the gap between particles of fluorescent powder, thereby well bonding the fluorescent powder particles and preventing powder loss resulting from insufficient bonding force of the fluorescent powder.

Owner:NANJING HUAXIAN HIGH TECH CO LTD

Manufacturing method for AgMeO electrical contact and integrated component thereof

ActiveCN104867620ANo wasteReduce volumeNon-conductive material with dispersed conductive materialCable/conductor manufactureEngineering3d printer

The invention relates to a manufacturing method for an AgMeO electrical contact and an integrated component thereof. Firstly coated silver-oxide composite powder is prepared and put into the powder cylinder of a 3D printer; and then a three-dimensional model of the AgMeO electrical contact and the integrated component thereof is established via a computer so that 3D printing formation of the AgMeO electrical contact and the integrated component thereof is completed. Direct and rapid formation of the AgMeO electrical contact and the integrated component thereof from raw material to the finished product is realized by 3D printing so that the raw material and production cost can be saved, zero inventory and zero time delivery can be realized, and thus the manufacturing method is a new method for preparing the AgMeO electrical contact and the integrated component thereof.

Owner:SHANGHAI HIWAVE COMPOSITE MATERIALS CO LTD

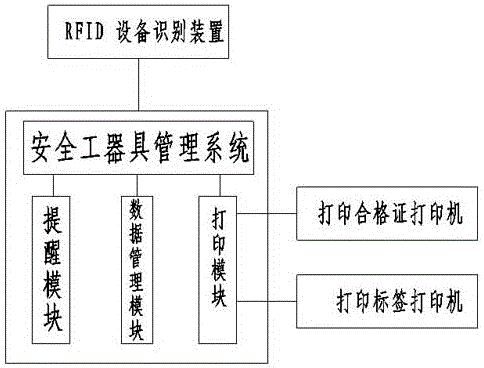

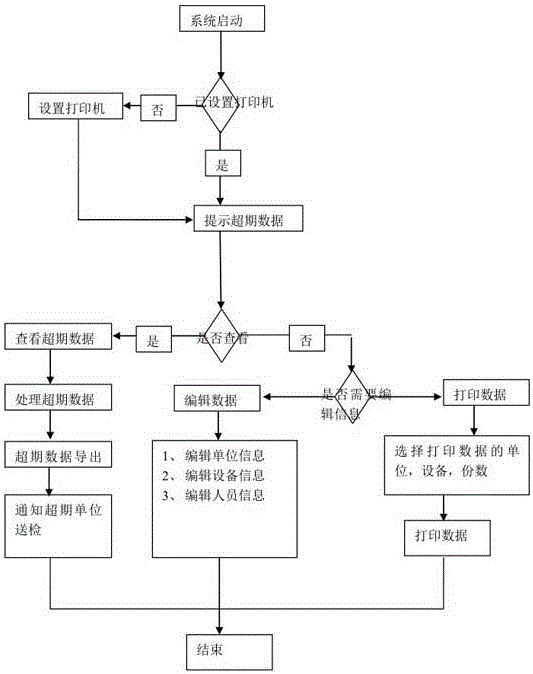

Electric power safety tool test management system

InactiveCN106127313ASolve printing problemsFast collection of inspection dataInstrumentsData managementTest management

The invention discloses an electric power safety tool test management system. The electric power safety tool test management system comprises a printing module, a data management module and a prompting module, wherein the printing module is used for printing a certificate and a printing label for detected equipment after the detected equipment is detected to be qualified, the printing data is classified and stored in a database, and querying printing records and re-printing corresponding labels and certificates are convenient; the data management module comprises a user management module, an equipment management module and a unit management module, the user management module is used for managing printing workers, including adding, deleting or modifying belonging units, names and the registration information of the printing workers, the equipment management module is used for adding, deleting or modifying the safety tool information, the safety tool information comprises titles, the units, codes and the coding information of safety tools, the unit management module is used for adding, deleting or modifying the basic unit information, and the basic unit information comprises titles of units, codes and the coding information.

Owner:ZIYANG POWER SUPPLY COMPANY STATE GRID SICHUAN ELECTRIC POWER +1

Ag-MeC electric contact and integrated assembly manufacturing method

ActiveCN104889391AImprove conductivityNo wasteAdditive manufacturing apparatusIncreasing energy efficiencyElectricityCarbide

The invention relates to an Ag-MeC electric contact and an integrated assembly manufacturing method. First, overlaying film silver-carbide composite powder is prepared and added to a 3D printer powder cylinder; then 3D models of a silver-carbide electric contact and an integrated assembly of the same are built via a computer; and at last 3D printing is finished for the silver-carbide electric contact and the integrated assembly of the same. Quick and direct formation of the silver-carbide electric contact and the integrated assembly of the same from raw material to completed products can be achieved via 3D printing, so raw material and production cost can be reduced; storage and delivery time can be avoided; and a new method is provided for preparation of Ag-MeC electric contact and integrated assembly.

Owner:SHANGHAI HIWAVE COMPOSITE MATERIALS CO LTD

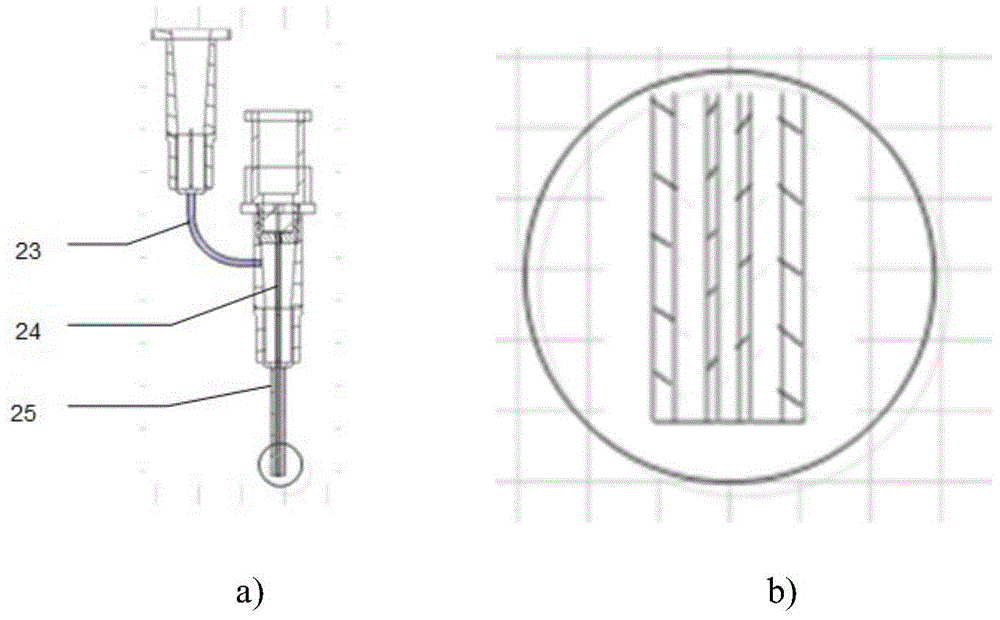

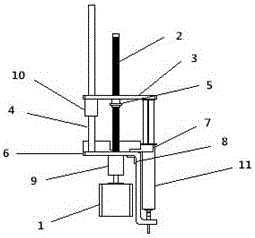

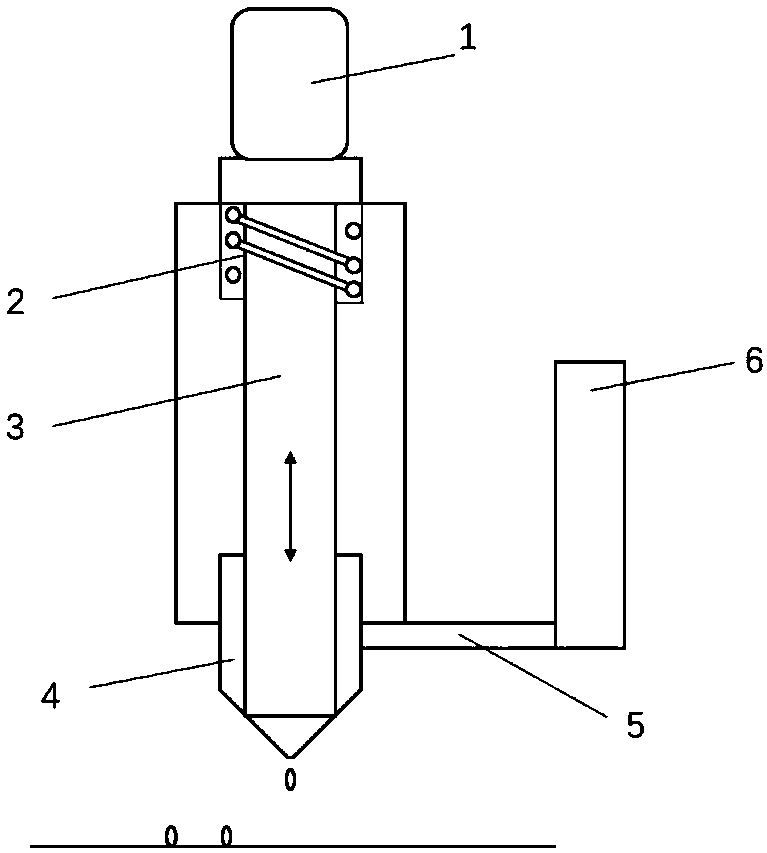

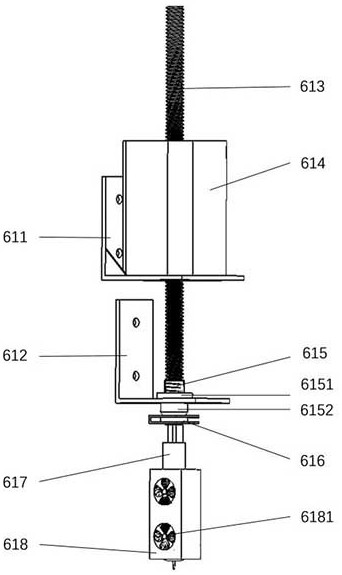

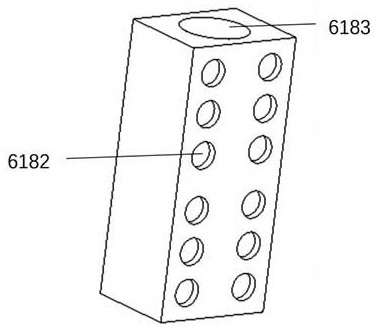

Normal-temperature 3D printing spray nozzle

InactiveCN106079450ASolve printing problemsEasy to disassembleAdditive manufacturing apparatusInterference fitCoupling

The invention relates to a normal-temperature 3D printing spray nozzle. The normal-temperature 3D printing spray nozzle comprises a stepping motor, a screw rod, an upper installation plate, a guide rod, a sleeve, a lower installation plate, a connecting plate, a coupler, a sliding bearing and an extruder needle cylinder. The stepping motor is connected with the screw rod through the coupler. The sleeve is fixed to the upper installation plate through a thread and is in threaded fit with the screw rod so that the screw rod can drive the upper installation plate to vertically move. The lower end of the guide rod is fixed to the lower installation plate. The sliding bearing is in interference fit with the upper installation plate. The guide rod penetrates the sliding bearing so that the upper installation plate can slide vertically along the guide rod. The extruder needle cylinder is fixed to the lower installation plate through the connecting plate. The top end of a piston rod of the extruder needle cylinder is fixed to the upper installation plate. The normal-temperature 3D printing spray nozzle is integrated on a desktop-level 3D printer, the problem about normal-temperature slurry 3D printing can be solved, demounting and mounting are convenient, and high strength is achieved; and in practical use, stress is more reasonable, and operation can be more convenient.

Owner:SHANGHAI UNIV

Three-dimensional printing method and three-dimensional printer

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

Magnesium alloy slurry and printing method thereof

InactiveCN108515175ASolve printing problemsImprove printing effectAdditive manufacturing apparatusTransportation and packagingSlurrySolvent

The invention discloses magnesium alloy slurry and a printing method thereof. The magnesium alloy slurry comprises, by weight percentage, 5-50 wt% of magnesium alloy particles, 10-40% of polylactic acid particles and the balance auxiliaries; the auxiliaries comprise a solvent, a consistency adjusting agent, an activating agent and a thixotropic agent; the magnesium alloy particles comprise an AZ31magnesium alloy, and the particle size is 25-38 microns; and the polylactic acid particles are polymer with the molecular weight being 10000-20000, the particle size being 0-10 microns and the decomposing temperature being 200-220 DEG C. According to the method, the prepared magnesium alloy slurry is injected into a material storing groove, pressurizing is performed, the slurry is made to uniformly enter an injecting valve body through a material conveying groove, the slurry is made to be fast sprayed out due to impacting of piezoelectric ceramics, and micro drops are formed. By adopting thetechnical scheme, due to printing and control on the magnesium alloy slurry, a new method is provided for 3D printing of magnesium alloy-polylactic acid composite materials.

Owner:SOUTHEAST UNIV

Printing method of PDF format electronic express sheet

The invention relates to the technical field of Web application and development, in particular to a printing method of a PDF format electronic express sheet. The method comprises the following steps:1, obtaining order data according to an order number; 2, packaging the order data into electronic express sheet PDF data; 3, combining a plurality of PDF electronic express sheet data; 4, setting a file stream output format as a PDF format; and 5, outputting and opening the file, and automatically connecting a printer for printing. The printing problem of PDF format electronic express sheet data is solved, and the method can be widely applied to WEB development and application.

Owner:ZHUHAI HENGQIN SHENGDA ZHAOYE TECH INVESTMENT CO LTD

Method for printing plastic film through offset printing press, finished product and product

InactiveCN108891142ARealize printingAvoid pollutionOther printing apparatusPrinting after-treatmentPlastic packagingRolling paper

The invention discloses a method for printing a plastic film through an offset printing press, a finished product and a product. Firstly, roll paper and a plastic film roll are fed onto an adhesive rolling machine or an adhesive spraying machine to complete adhering of the roll paper and the plastic film roll; then, flattening, airing and transverse cutting are performed to form to-be-printed paper with the plastic film on one face in a one-piece state; next, the to-be-printed paper is fed onto the offset printing press to complete printing of the face of the roll paper or the plastic film roll, so that finished product one-face film covering paper with one-face printing is obtained; finally, the finished product one-face film covering paper is used for manufacturing a needed environmentally-friendly packaging bag or packaging box. In this way, the plastic film or the paper covered with the plastic film is fed onto the offset printing press to be printed, the problem is solved that inthe prior art, gravure is solely adopted for a soft plastic film, and the soft plastic film can not be fed onto the offset printing press, and the method has the advantages that costs are low, environmental protection is realized, printing speed is high, efficiency is high, color rendition is good, and a life-like effect is realized; the mode of plastic packaging is enriched, the grade of packaging is increased, and the requirement for really sustainable, healthy and environmentally friendly development is met.

Owner:赵晓旭

AgMe electrical contact and manufacturing method of integrated assembly thereof

InactiveCN104907561ASolve printing problemsImprove conductivityAdditive manufacturing apparatusIncreasing energy efficiency3d printerRapid prototyping

The invention relates to an AgMe electrical contact and a manufacturing method of an integrated assembly thereof. The manufacturing method comprises the steps that film compound powder of silver and reinforced phase metal is prepared and contained in a three-dimensional printer powder cylinder, and then a three-dimensional model of the AgMe electrical contact and the integrated assembly thereof is built through a computer to complete three-dimensional printing forming of the AgMe electrical contact and the integrated assembly thereof. According to the AgMe electrical contact and the manufacturing method of the integrated assembly thereof, direct and quick forming of the AgMe electrical contact and the integrated assembly thereof from raw materials to finished products is achieved through three-dimensional printing, the raw materials and the production cost are saved, and meanwhile zero stock and zero-time handing over can be achieved; the method is a new method for preparing the AgMe electrical contact and the integrated assembly thereof.

Owner:SHANGHAI HIWAVE COMPOSITE MATERIALS CO LTD

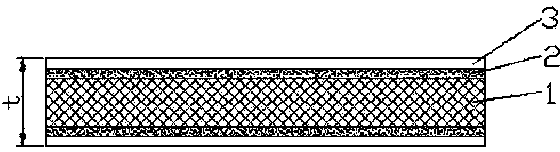

Thermal insulation can, thermal insulation can plate and manufacturing method of thermal insulation can plate

InactiveCN104191773ASolve environmental problemsSolve printing problemsSynthetic resin layered productsLaminationEcological environmentThermal insulation

The invention discloses a novel thermal insulation can, a thermal insulation can plate and a manufacturing method of the thermal insulation can plate. The method comprises the following steps: foaming a mixed material of 95 percent of polystyrene (PS) granules and 5 percent of polyethylene (PE) granules, molding the mixed material into plate cores output in a rolled material form, and curing the plate cores in the rolled material form; mounting two rolls of cured plate cores and two rolls of aluminized films onto a casting compound machine, and fusing the aluminized films and the plate cores together through heating extrusion of an equipment fusion mechanism, thereby forming a double-layer aluminized film thermal insulation can plate; and cooling the plate, cutting and setting, thereby obtaining the novel thermal insulation can plate finally. The thermal insulation plate is good in sealing property and thermal insulation property, protects the ecological environment, and is convenient to use and low in cost.

Owner:牛恪永

Additional composite function material for electrostatic developer

ActiveCN102636969APrevent sticking to photosensitive drumSolve printing problemsDevelopersElectricityComposite function

The invention discloses an additional composite function material for an electrostatic developer. The additional composite function material is prepared by raw materials including, by weight, from 50 to 70 parts of magnetic powder, from 8 to 15 parts of silicon oil, from 1 to 5 parts of zinc stearate and from 10 to 15 parts of fumed silica, and the materials are sequentially fed into a high-speed mixer to be mixed according to the proportions, so that the additional composite function material is obtained. The additional composite function material is used for the electrostatic photocopying technology, can be used with single-component silica, effectively prevents a tone agent from being adhered with a photosensitive drum during usage, and solves the problem of hollow printed or photocopied images and texts. In addition, the problem of image rippling due to over thick tone agent accumulated on a magnetic roller can be accessorily solved when the additional composite function material is used in a magnetic single-component system, and the quantity of electricity of the tone agent can also be regulated.

Owner:NANJING TESHINE IMAGING TECH

Novel printer for displaying printing media colors

InactiveCN108995389AStay parallelAchieve left and right movementTypewritersOther printing apparatusComputer engineeringAutomation

The invention discloses a novel printer for displaying printing media colors. The novel printer comprises a machine body, a first sliding block and a second sliding block, wherein the first sliding block is arranged above the machine body, the second sliding block is positioned above the first sliding block, a first cavity is formed in the machine body, an opening is formed in the left end wall ofthe first cavity, a second cavity with the right opening is formed in the left end wall of the first cavity, an arc-shaped groove which communicates up and down is formed in the top wall of the firstcavity, a third cavity extending leftwards is arranged in the bottom wall of the second cavity, and a fourth cavity is formed in the first sliding block. The novel printer is simple in structure andconvenient to operate, the horizontal movement of the printer and the angle adjustment of a printing assembly are driven by adopting the same power source, and the printing assembly can be locked in the switching process; and the printer is convenient to move, the automation is adjusted, the printing difficulty of the mural and the propaganda picture of the large wall surface is completely solved,the picture quality and the drawing efficiency are improved, the working procedures are matched with each other and are not affected, and the practical performance of the device is improved.

Owner:柴建华

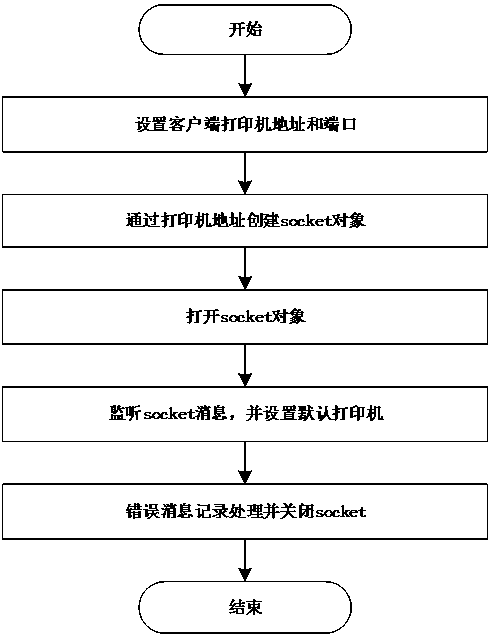

An online printing system and method for pdf electronic invoice format files

ActiveCN107450869BRealize online printingFast and efficient online printingDigital output to print unitsSoftware engineeringInvoice

The invention discloses an online printing system and method of a PDF (portable document format) electronic invoice format file. In the scheme, it is possible to print a PDF file online so that when using an electronic invoice business system, a customer may print PDF files efficiently online directly by the aid of the business system, manually downloading the PDF file to the locale and importing and printing the file via a PDF reader is not required, and directly opening the PDF file through a browser prior to printing single sheets through the printing function of the browser is not required either. By using the system and method of the invention, both the single sheet printing problem and the batch printing problem are solved, and time and labor are economized. In addition, it is possible to make calling across browser through a PDF printing service module and a PDF printing component module, and developing plugins for different browsers is not required.

Owner:国信电子票据平台信息服务有限公司

Double-sided identical unordered code printing treatment method

InactiveCN102632734ASolve the problem that can only be printed with digital printing machineSolve printing problemsPattern printingOther printing apparatusEngineeringPaper sheet

The invention relates to a double-sided identical unordered code printing treatment method, which comprises the following steps of: (1) printing image and text parts on the front face and the reverse face of a flat paper sheet through an ordinary offset press, and retaining code-spraying parts; (2) coding all unordered codes, and attaching an ordered code to the rear face of each unordered code on the same printing face or attaching the same ordered code to the rear faces of several unordered codes on the same printing face; (3) carrying out code spraying on the front face of the paper sheet processed in the step (1) according to the ordered codes in the step (2) by using a spray head; (4) carrying out code spraying on the reverse face of the paper sheet according to the ordered codes in the step (2) by using the spray head; and (5) cutting off ordered code parts after finishing spraying. Compared with the prior art, the double-sided identical unordered code printing treatment method has the advantages of simple processing steps, easiness in implementation, great reduction in production cost, and the like.

Owner:SHANGHAI ZIDAN PRINTING

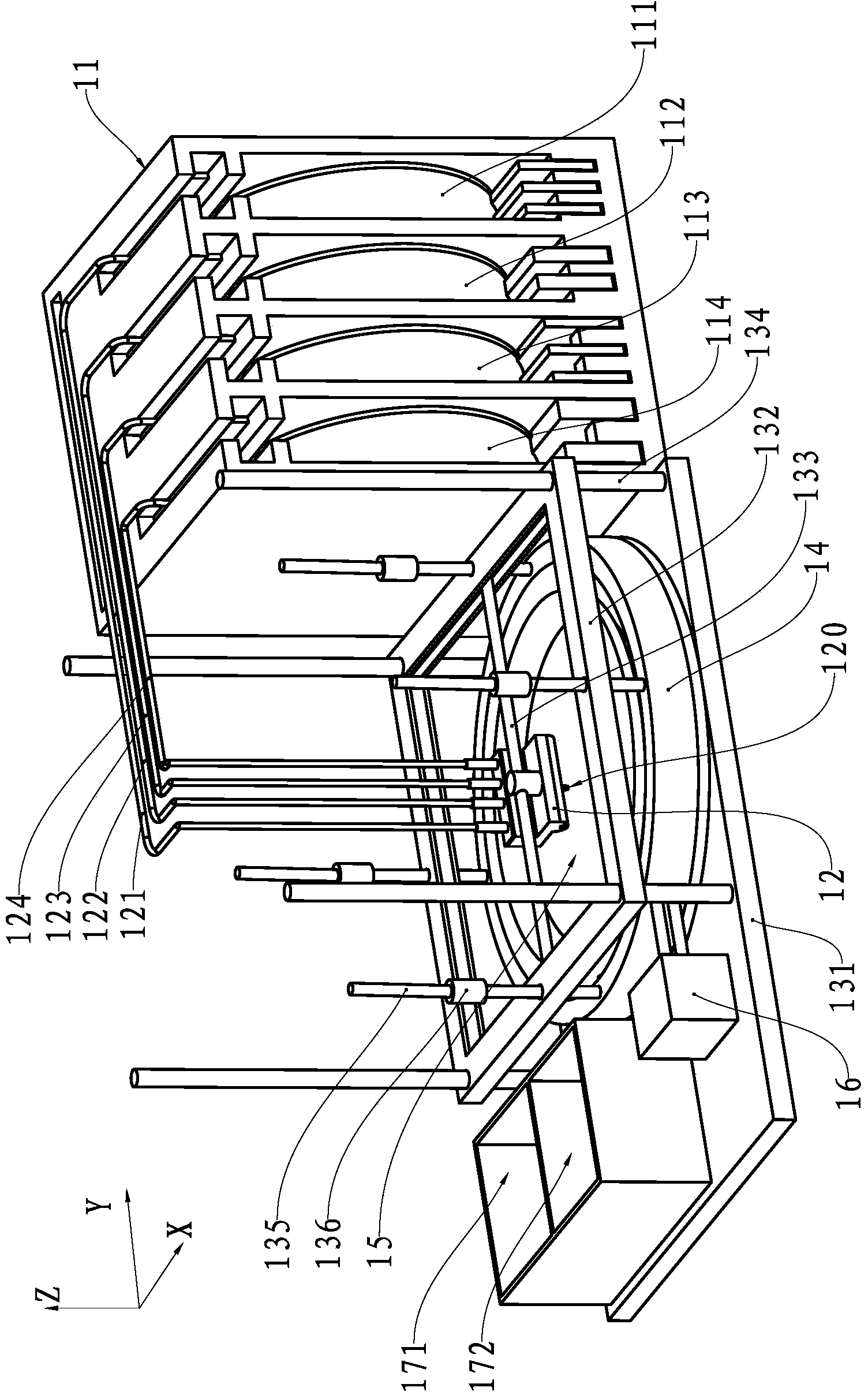

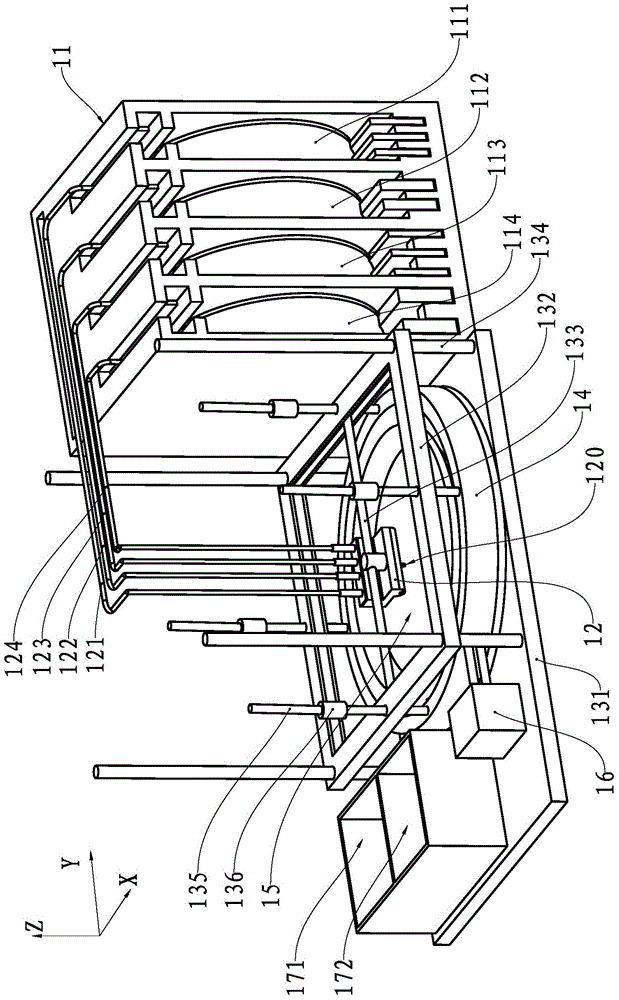

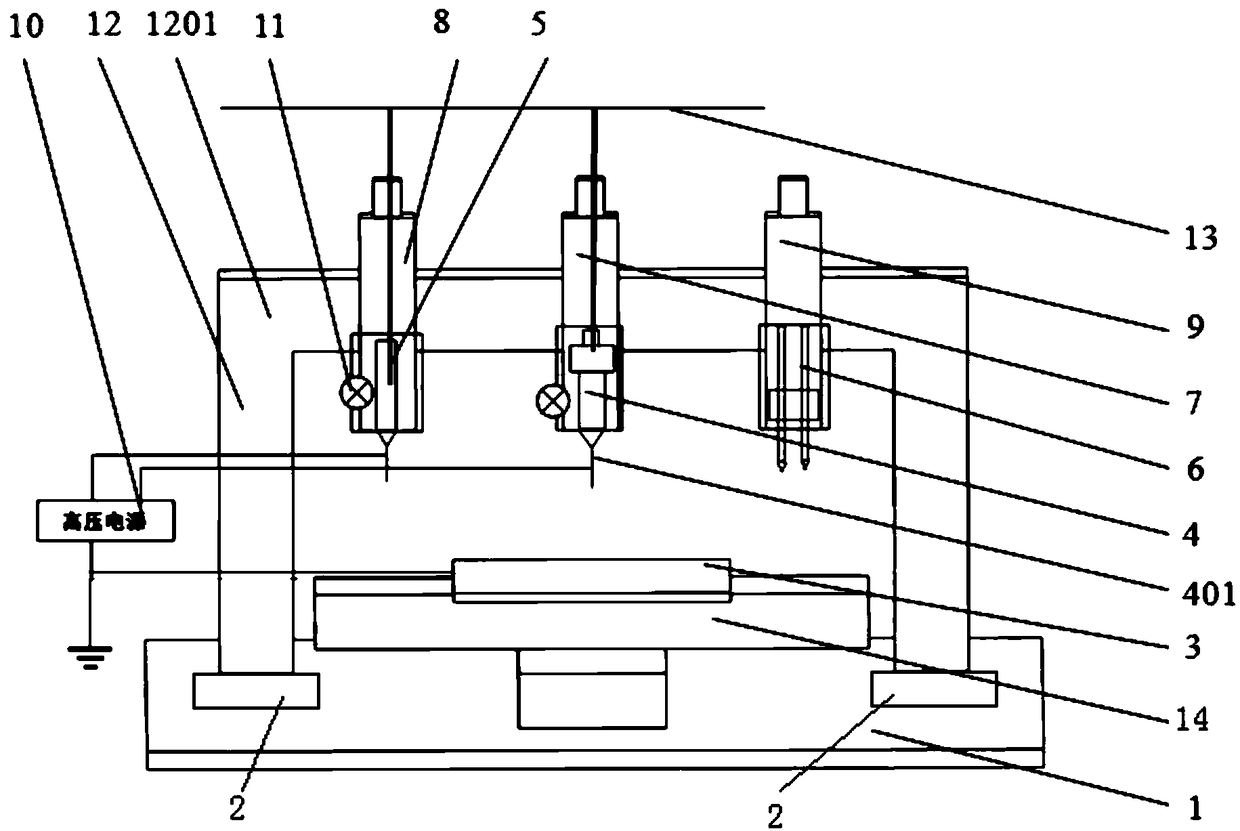

A kind of multi-material composite 3D printer and its working method and application

ActiveCN106273497BRealize integrated manufacturingSolve the problem of organic integrationAdditive manufacturing with liquids3D object support structuresMulti materialSpray nozzle

The invention discloses a multi-material composite 3D printer and a working method and application of the multi-material composite 3D printer. The multi-material composite 3D printer comprises a base which is provided with a working table and a rack, the working table is provided with a printing bed for supporting a printed object, the rack is at least fixedly provided with a first spray head, a second spray head and a third spray head, and the first spray head, the second spray head and the third spray head are all located above the printed object; the first spray head is a multi-material active mixing spray head, the second spray head comprises a micro injector material barrel and an electric conduction spray nozzle arranged at the lower portion of the micro injector material barrel, and the third spray head at least comprises two fusion deposition spray heads, wherein one fusion deposition spray head is used for printing structural materials, and the other fusion deposition spray head is used for printing supporting materials; and electric conduction spray nozzles of the first spray head and the second spray head are both connected with the positive pole of a power source, and the printing bed is connected with the negative pole of the power source. Multi-material and multi-scale complex structure integrated manufacturing is achieved, the structural materials and functional materials are integrally printed, and the technical bottleneck for limiting integrated manufacturing of materials, structures and devices is broken through.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

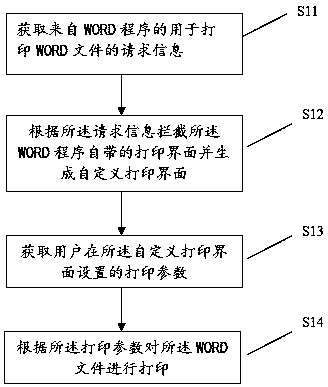

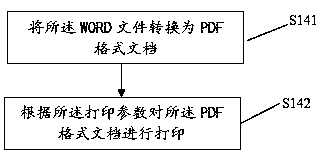

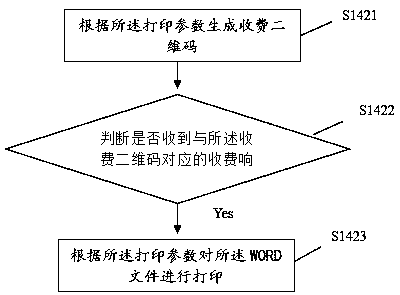

Single file rapid printing method, device and terminal equipment

ActiveCN110377249ALower operating thresholdReduce labor intensityPayment architectureApparatus for meter-controlled dispensingTerminal equipmentComputer terminal

The invention provides a single file rapid printing method, a single file rapid printing device and terminal equipment. The method comprises the steps of obtaining request information, from a WORD program, for printing a WORD file; intercepting a built-in printing interface of the WORD program according to the request information and generating a user-defined printing non-solidified option interface; acquiring printing parameters set by a user on the custom printing interface; and printing the WORD file according to the printing parameters. By intercepting the printing setting interface of theWORD program, the simplified custom printing plug-in interface is generated. The custom printing plug-in operation is simple and easy to understand. The interface is simple and clear. The operation threshold of an operator is reduced.

Owner:广东印萌科技有限公司

Three-dimensional manual curve surface screen printing machine

The invention relates to a three-dimensional manual curve surface screen printing machine which comprises a base plate, base plate supports and a space three-dimensional moving device. The base plate supports are disposed at four corners of the base plate. Lifting screws are disposed on the two base plate supports on the rear side. The space three-dimensional moving device is divided into an upper part and a lower part, the upper part is a liftable printing frame, and the lower part is a to-be-printed object three-dimensional moving mechanism. The lower mechanism is provided with a operation platform mounted on the base plate. Two slide rod station grooves are formed in the surface of the platform, four slidable longitudinal slide rods are mounted on the grooves, a transverses slide rod with a support bearing is mounted on each longitudinal slide rod, and the to-be-printed object is placed on the four support bearings. The upper printing frame is provided with an outer frame and a screen plate moving frame connected to the inside of the printing frame. A printing screen plate frame with a silk screen plate is connected into the screen plate moving frame. A scraper rack and a scraper are disposed on the screen plate moving frame. A balance iron square is disposed at the rear end of the outer frame. The printing machine is simple in structure, convenient to use, high in practicality and capable of printing cone frustums and cones with two ends of different diameters and irregular columns with handles.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

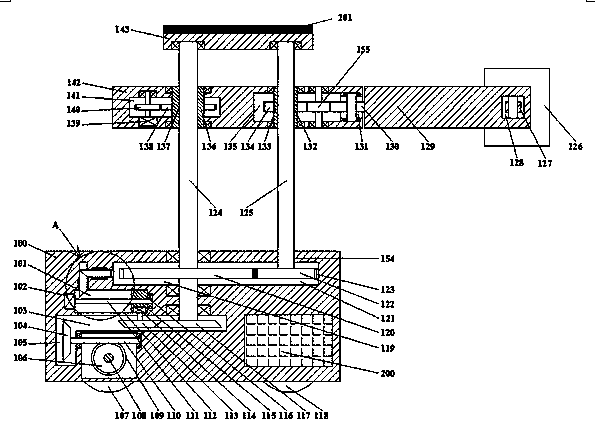

Extrusion molding-photocuring integrated three-dimensional printer and printing method thereof

PendingCN113334761AIncrease printing speedImprove mechanical propertiesManufacturing platforms/substratesManufacturing driving meansDrive motorEngineering

The invention discloses an extrusion molding-photocuring integrated three-dimensional printer and a printing method thereof. The extrusion molding-photocuring integrated three-dimensional printer comprises a rack, a photocuring molding trough module, a composite molding platform module, a non-interference switching device, a light processing device and an X-axis system driving motor, wherein the photocuring molding trough module is fixedly arranged on an axis movement mechanism; the composite molding platform module is fixedly arranged on a Z-axis movement mechanism; the non-interference switching device controls reverse movement of an extrusion molding platform and a photocuring molding platform by utilizing a gear engagement principle; the light processing device is positioned at the bottom end of the trough module, is fixedly arranged on the axis movement mechanism and is used for projecting a photocuring molded graph onto a composite deposition platform; and the X-axis system driving motor is fixed on an X-axis movement mechanism and drives an X-axis system motor lead screw to drive the composite deposition platform to turn over. According to the extrusion molding-photocuring integrated three-dimensional printer disclosed by the invention, a personalized customized high-precision three-dimensional structure is printed by a photocuring technology, and then a biological material is printed by an extrusion molding technology, so that high-precision personalized rapid printing of various materials is realized.

Owner:XINJIANG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com